DATSUN 510 1968 Service Manual PDF

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

Page 61 of 252

56

CHAPTER

SIX

NOTE

Lubncate

the

cylinder

walls

with

new

engine

oil

prior

to

insertIOn

of

pistOns

Make

certain

that

the

ring

gaps

are

not

In

line

wIth

one

another

Place

the

gaps

180

degrees

from

each

other

and

not

posltloned

either

front

to

back

or

dIrectly

in

line

with

the

piston

pIns

CAUTION

Use

extreme

care

when

Inserting

pzs

tons

so

as

to

avoId

crankshaft

damage

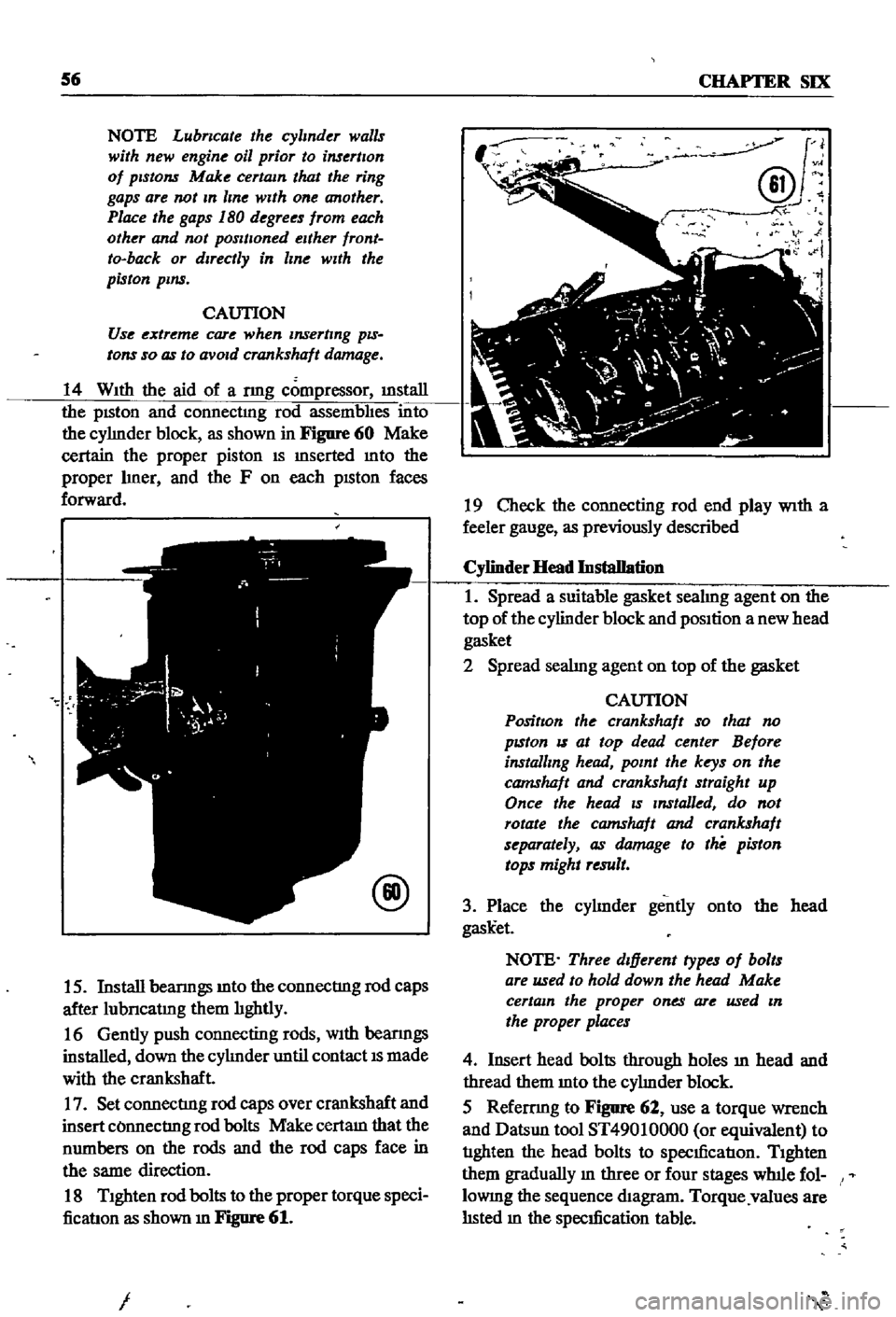

14

With

the

aid

of

a

nng

compressor

illStaIl

the

pISton

and

connectmg

rod

assembhes

into

the

cyhnder

block

as

shown

in

Figure

60

Make

certain

the

proper

piston

IS

mserted

mto

the

proper

hner

and

the

F

on

each

pISton

faces

forward

@

15

Install

beanngs

mto

the

connectIng

rod

caps

after

lubncatmg

them

hghtly

16

Gently

push

connecting

rods

With

beanngs

installed

down

the

cyhnder

until

contact

IS

made

with

the

crankshaft

17

Set

connectIng

rod

caps

over

crankshaft

and

insert

COnnectIng

rod

bolts

Make

certam

that

the

numbers

on

the

rods

and

the

rod

caps

face

in

the

same

direction

18

Tighten

rod

bolts

to

the

proper

torque

speci

ficatIon

as

shown

m

Figure

61

I

J

@v

N

i

19

Check

the

connecting

rod

end

play

With

a

feeler

gauge

as

previously

described

Cylinder

Head

Installation

1

Spread

a

suitable

gasket

seahng

agent

on

the

top

of

the

cylinder

block

and

position

a

new

head

gasket

2

Spread

seahng

agent

on

top

of

the

gasket

CAUTION

PositIon

the

crankshaft

so

that

no

pzston

IS

at

top

dead

center

Before

installing

head

point

the

keys

on

the

camshaft

and

crankshaft

straight

up

Once

the

head

zs

Installed

do

not

rotate

the

camshaft

and

crankshaft

separately

as

damage

to

the

piston

tops

might

result

3

Place

the

cyhnder

gently

onto

the

head

gask

et

NOTE

Three

dIfferent

types

of

bolts

are

used

to

hold

down

the

head

Make

certain

the

proper

ones

are

used

In

the

proper

places

4

Insert

head

bolts

through

holes

ill

head

and

thread

them

mto

the

cyhnder

block

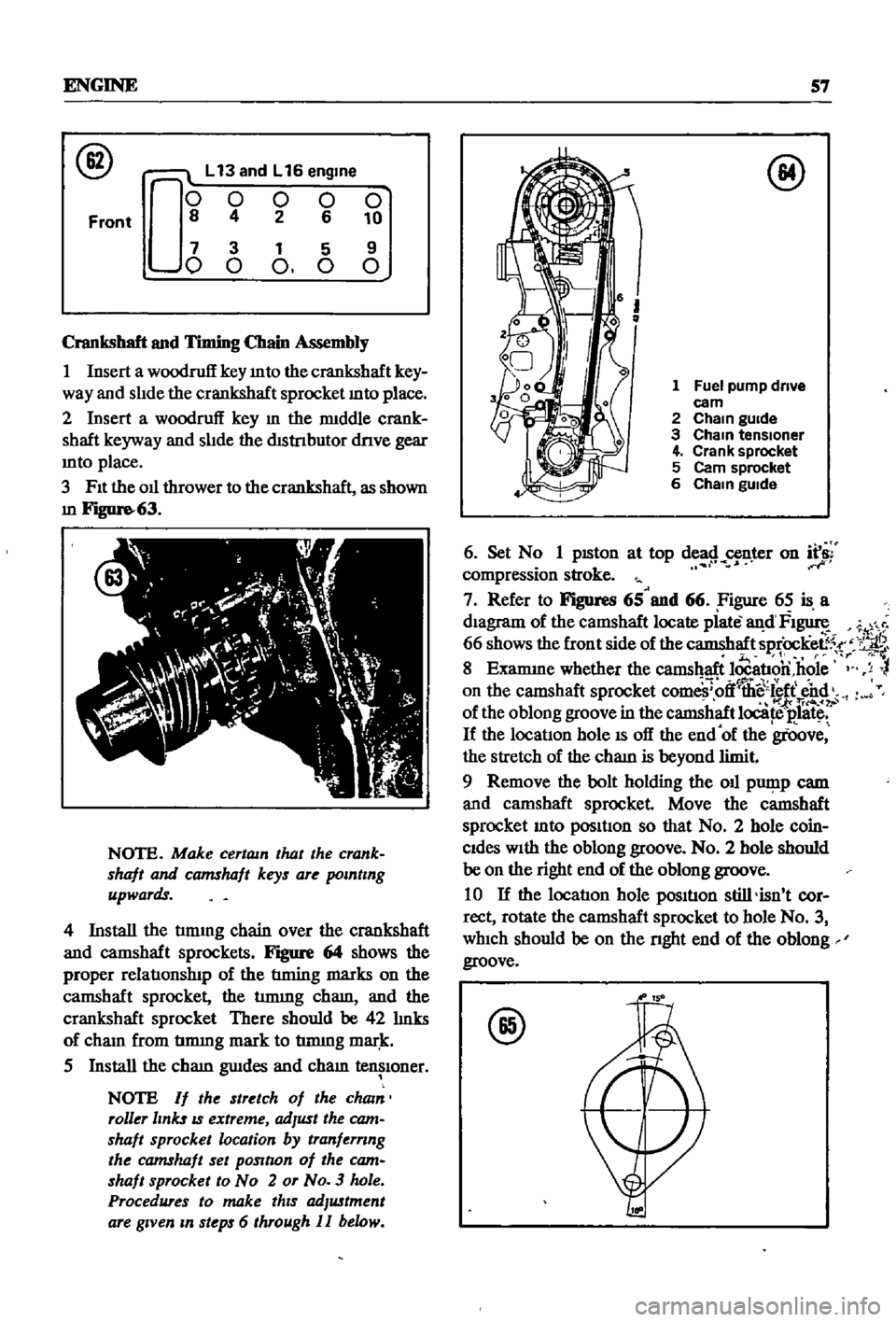

5

Refemng

to

Figure

62

use

a

torque

wrench

and

Datsun

tool

ST49010000

or

equivalent

to

tIghten

the

head

bolts

to

specIficatIon

Tighten

them

gradually

m

three

or

four

stages

wlnle

fol

lOWIng

the

sequence

diagram

Torque

values

are

hsted

m

the

specIfication

table

Page 62 of 252

ENGINE

57

@

L

13

and

L

16

engme

000000

8

4

2

6

10

7

3

1

5

9

o

0

0

0

0

Front

Crankshaft

and

Timing

Chain

Assembly

1

Insert

a

woodruff

key

mto

the

crankshaft

key

way

and

slide

the

crankshaft

sprocket

mto

place

2

Insert

a

woodruff

key

m

the

Illiddle

crank

shaft

keyway

and

slide

the

dIstnbutor

dnve

gear

mto

place

3

FIt

the

oil

thrower

to

the

crankshaft

as

shown

m

Figure

63

NOTE

Make

certam

that

the

crank

shaft

and

camshaft

keys

are

polntlng

upwards

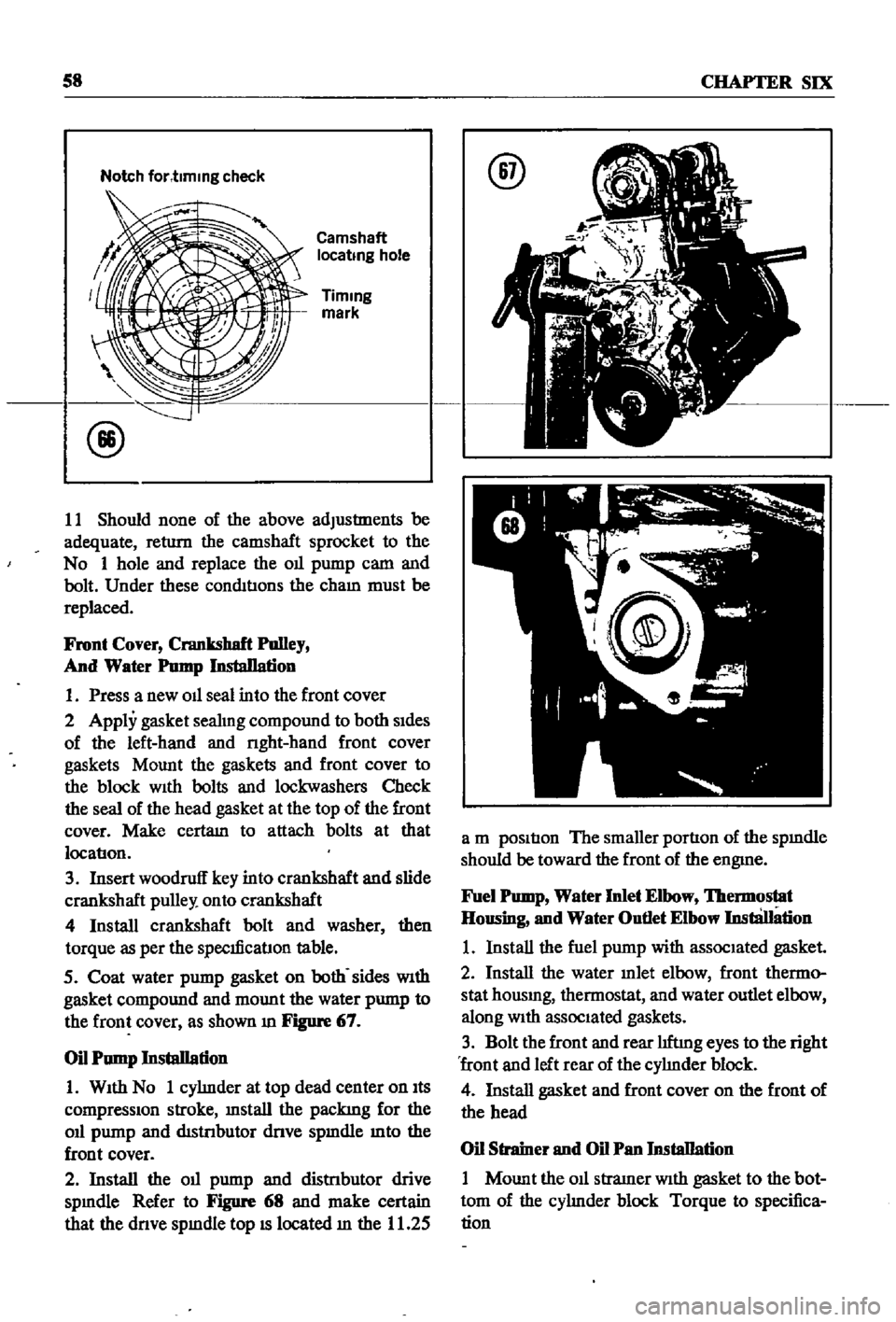

4

Install

the

tmung

chain

over

the

crankshaft

and

camshaft

sprockets

Figure

64

shows

the

proper

relatIonslnp

of

the

tIming

marks

on

the

camshaft

sprocket

the

tmung

cham

and

the

crankshaft

sprocket

There

should

be

42

hnks

of

cham

from

tmung

mark

to

tmung

mar

k

5

Install

the

cham

gwdes

and

cham

tensIoner

NOTE

If

the

stretch

of

the

cham

roller

links

IS

extreme

adJust

the

cam

shaft

sprocket

location

by

tranfernng

the

camshaft

set

pOSltlon

of

the

cam

shaft

sprocket

to

No

2

or

No

3

hole

Procedures

to

make

thIS

adJustment

are

gIVen

m

steps

6

through

II

below

@

1

Fuel

pump

drive

eam

2

Cham

gUide

3

Cham

tensloner

4

Crank

sprocket

5

Cam

sprocket

6

Cham

gUide

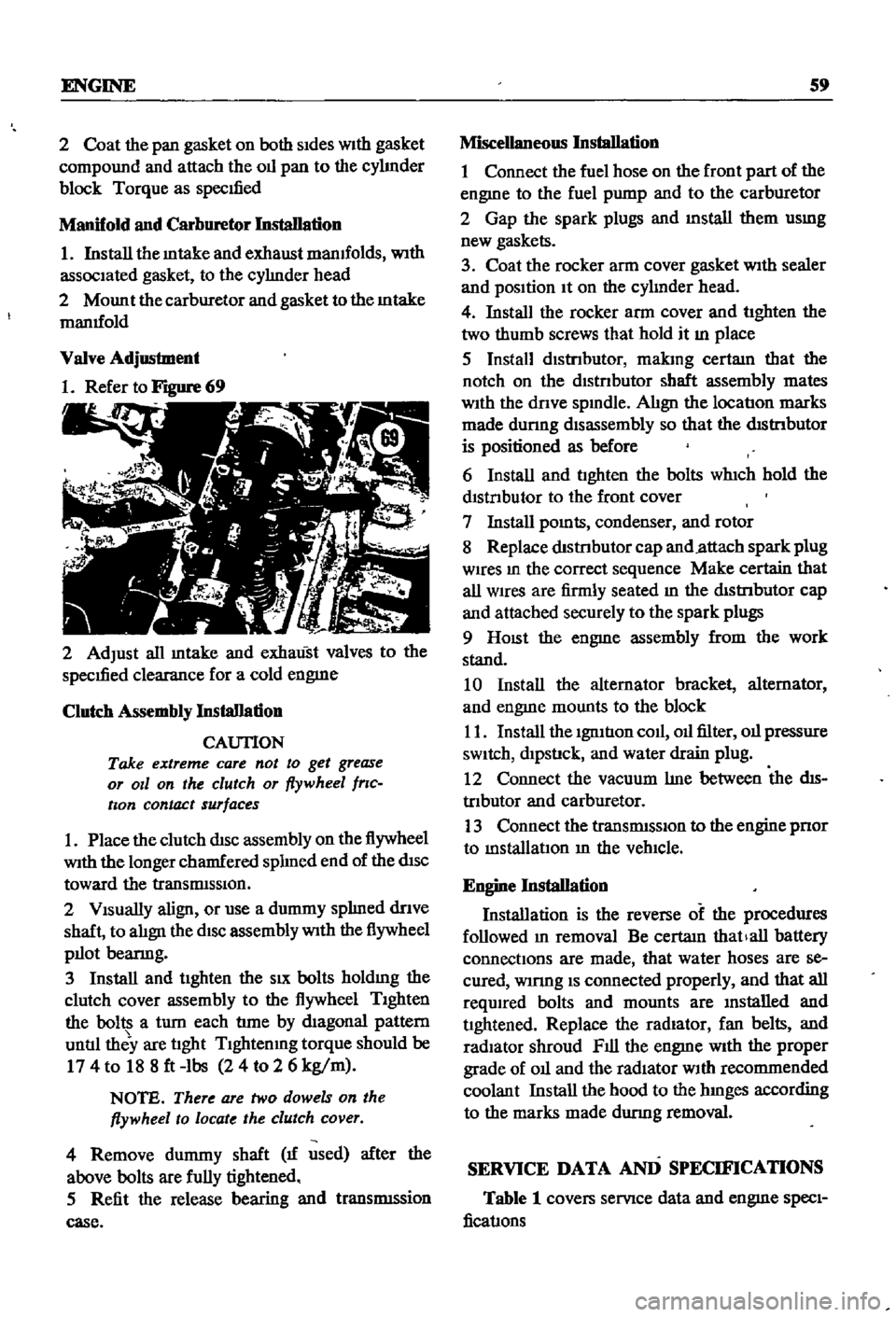

6

Set

N

1

pISton

at

top

de

8

n

r

on

f

compressIon

stroke

7

Refer

to

Figures

65

and

66

Figure

65

is

a

dIagram

of

the

camshaft

locate

piate

an

d

FI

1

66

shows

the

front

side

of

the

camshaft

sprOcKee5

r

11

r

If

8

Examme

whether

the

camshaft

locatIon

hole

y

on

the

camshaft

sprocket

com

ff

llii

sl

ff

end

foI

tri4o

of

the

oblong

groove

in

the

camshaft

locate

E

1litc

If

the

locatIon

hole

IS

off

the

end

of

the

groove

the

stretch

of

the

cham

is

beyond

limit

9

Remove

the

bolt

holding

the

oil

pwp

p

cam

and

camshaft

sprocket

Move

the

camshaft

sprocket

mto

posItIon

so

that

No

2

hole

coin

Cides

With

the

oblong

groove

No

2

hole

should

be

on

the

right

end

of

the

oblong

groove

10

If

the

locatIon

hole

posItIon

still

isn

t

cor

rect

rotate

the

camshaft

sprocket

to

hole

No

3

which

should

be

on

the

nght

end

of

the

oblong

groove

@

Page 63 of 252

58

CHAPTER

SIX

Notch

for

t1mmg

check

Camshaft

locatmg

hole

Timmg

mark

11

Should

none

of

the

above

adjustments

be

adequate

return

the

camshaft

sprocket

to

the

No

1

hole

and

replace

the

Oll

pump

cam

and

bolt

Under

these

conditIons

the

cham

must

be

replaced

Front

Cover

Crankshaft

Polley

And

Water

Pomp

InstaDation

1

Press

a

new

Oll

seal

into

the

front

cover

2

Apply

gasket

seahng

compound

to

both

sides

of

the

left

hand

and

nght

hand

front

cover

gaskets

Mount

the

gaskets

and

front

cover

to

the

block

With

bolts

and

lockwashers

Check

the

seal

of

the

head

gasket

at

the

top

of

the

front

cover

Make

certam

to

attach

bolts

at

that

locatlon

3

Insert

woodruff

key

into

crankshaft

and

slide

crankshaft

pulley

onto

crankshaft

4

Install

crankshaft

bolt

and

washer

then

torque

as

per

the

speclficatlon

table

5

Coat

water

pump

gasket

on

both

sides

With

gasket

compound

and

mount

the

water

pump

to

the

front

cover

as

shown

m

Figure

67

Oil

Pump

Installation

1

With

No

1

cyhnder

at

top

dead

center

on

Its

compressIOn

stroke

mstall

the

packing

for

the

Oll

pump

and

distnbutor

dnve

spmdle

mto

the

front

cover

2

Install

the

Oll

pump

and

distnbutor

drive

spmdle

Refer

to

Figure

68

and

make

certain

that

the

dnve

spmdle

top

IS

located

m

the

11

25

@

a

m

position

The

smaller

portion

of

the

spmdle

should

be

toward

the

front

of

the

engme

Fuel

Pomp

Water

Inlet

Elbow

lbermostat

Housing

and

Water

Outlet

Elbow

InstliJIation

1

Install

the

fuel

pump

with

associated

gasket

2

Install

the

water

mlet

elbow

front

thermo

stat

housmg

thermostat

and

water

outlet

elbow

along

With

associated

gaskets

3

Bolt

the

front

and

rear

hftmg

eyes

to

the

right

front

and

left

rear

of

the

cyhnder

block

4

Install

gasket

and

front

cover

on

the

front

of

the

head

Oil

Strainer

and

Oil

Pan

Installation

1

Mount

the

011

stramer

With

gasket

to

the

bot

tom

of

the

cyhnder

block

Torque

to

specifica

tion

Page 64 of 252

ENGINE

59

2

Coat

the

pan

gasket

on

both

sides

With

gasket

compound

and

attach

the

oil

pan

to

the

cyhnder

block

Torque

as

specIfied

Manifold

and

Carburetor

Installation

1

Install

the

mtake

and

exhaust

manIfolds

WIth

associated

gasket

to

the

cylmder

head

2

Mount

the

carburetor

and

gasket

to

the

mtake

manIfold

2

Adjust

all

mtake

and

exhaust

valves

to

the

specIfied

clearance

for

a

cold

engme

Clutch

Assembly

Installation

CAUTION

Take

extreme

care

not

to

get

grease

or

011

on

the

clutch

or

flywheel

frlc

hon

contact

surfaces

1

Place

the

clutch

disc

assembly

on

the

flywheel

With

the

longer

chamfered

splmed

end

of

the

dISC

toward

the

transmISSion

2

Visually

align

or

use

a

dummy

splmed

dnve

shaft

to

ahgn

the

diSC

assembly

With

the

flywheel

pilot

beanng

3

Install

and

tighten

the

SIX

bolts

holdmg

the

clutch

cover

assembly

to

the

flywheel

Tighten

the

bolts

a

turn

each

tune

by

diagonal

pattern

until

they

are

tight

Tlghtenmg

torque

should

be

174

to

188ft

lbs

24

to

2

6

kg

m

NOTE

There

are

two

dowels

on

the

flywheel

to

locate

the

clutch

cover

4

Remove

dummy

shaft

If

used

after

the

above

bolts

are

fully

tightened

5

Refit

the

release

bearing

and

translI11Ssion

case

Miscellaneous

Installation

1

Connect

the

fuel

hose

on

the

front

part

of

the

engme

to

the

fuel

pump

and

to

the

carburetor

2

Gap

the

spark

plugs

and

mstall

them

usmg

new

gaskets

3

Coat

the

rocker

arm

cover

gasket

With

sealer

and

position

It

on

the

cylmder

head

4

Install

the

rocker

arm

cover

and

tighten

the

two

thumb

screws

that

hold

it

m

place

5

Install

distrIbutor

makmg

certam

that

the

notch

on

the

distributor

shaft

assembly

mates

With

the

drive

spmdle

Ahgn

the

location

marks

made

dunng

disassembly

so

that

the

distrIbutor

is

positioned

as

before

6

Install

and

tighten

the

bolts

which

hold

the

dIStributor

to

the

front

cover

7

Install

pomts

condenser

and

rotor

8

Replace

distrIbutor

cap

and

attach

spark

plug

Wires

m

the

correct

sequence

Make

certain

that

all

wires

are

firmly

seated

m

the

distrIbutor

cap

and

attached

securely

to

the

spark

plugs

9

HOISt

the

engme

assembly

from

the

work

stand

10

Install

the

alternator

bracket

alternator

and

engme

mounts

to

the

block

11

Install

the

IgnItIon

coil

oil

filter

oil

pressure

SWitch

dipstick

and

water

drain

plug

12

Connect

the

vacuum

Ime

between

the

dis

trIbutor

and

carburetor

13

Connect

the

transIDlSSlOn

to

the

engine

prior

to

mstallatIon

m

the

vehicle

Engine

Installation

Installation

is

the

reverse

of

the

procedures

followed

m

removal

Be

certaIn

thatlall

battery

connections

are

made

that

water

hoses

are

se

cured

wmng

IS

connected

properly

and

that

all

required

bolts

and

mounts

are

mstalled

and

tightened

Replace

the

radiator

fan

belts

and

radiator

shroud

Fill

the

engme

With

the

proper

grade

of

oil

and

the

radiator

With

recommended

coolant

Install

the

hood

to

the

hInges

according

to

the

marks

made

dUrIng

removal

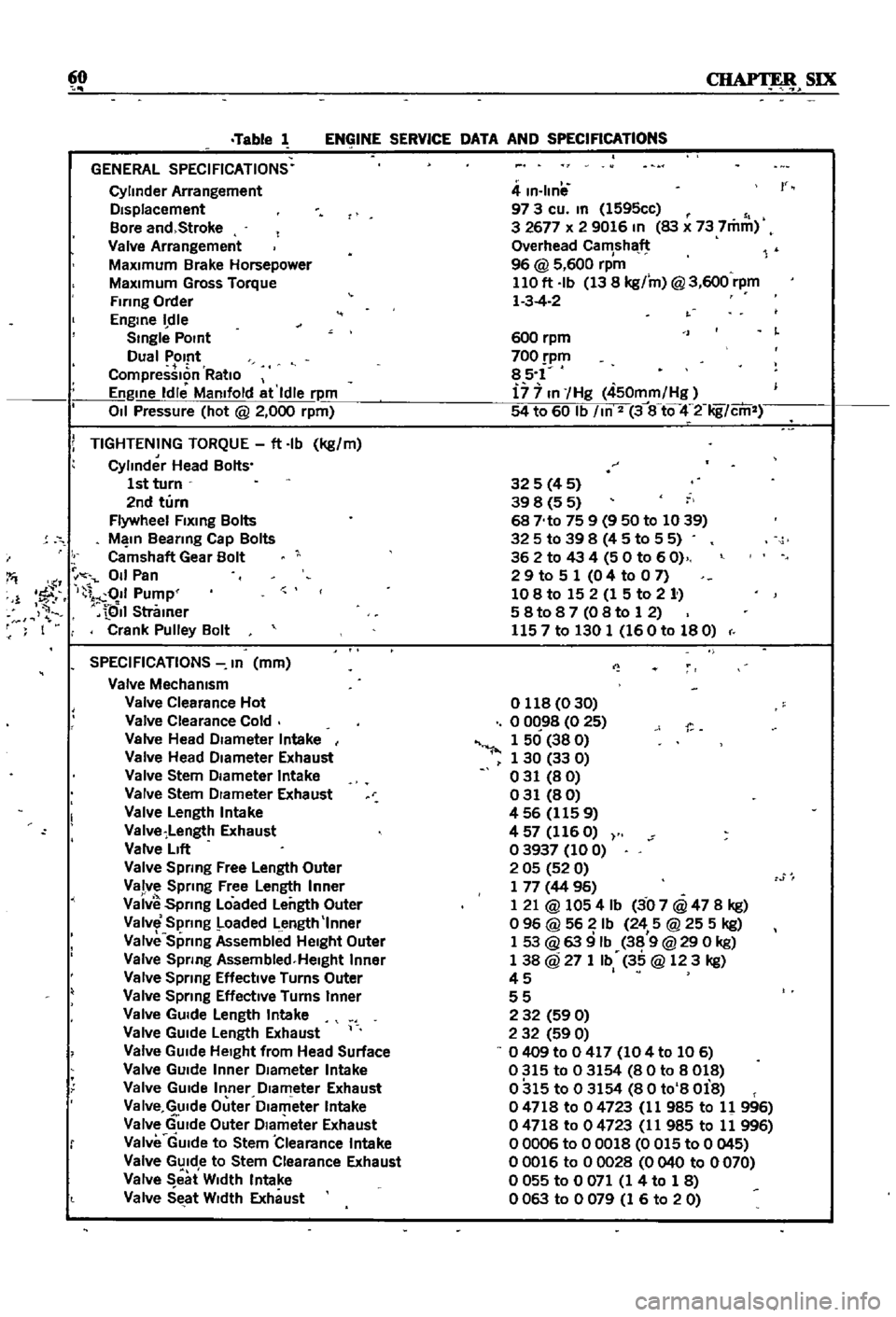

SERVICE

DATA

AND

SPECIFICATIONS

Table

1

covers

servIce

data

and

engme

Speci

fications

Page 65 of 252

60

SIX

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Cylinder

Arrangement

DIsplacement

Bore

and

Stroke

Valve

Arrangement

MaxImum

Brake

Horsepower

MaxImum

Gross

Torque

Firing

Order

Engme

dle

Smgle

POint

Dual

Pomt

CompressIon

RatIo

Engme

Idle

Mamfold

at

Idle

rpm

011

Pressure

hot

@

2

000

rpm

i

TIGHTENING

TORQUE

ft

Ib

kg

m

Cylinder

Head

Bolts

1st

turn

2nd

turn

Flywheel

Flxmg

Bolts

M

In

Beanng

Cap

Bolts

Camshaft

Gear

Bolt

I

011

Pan

1

1

fF

I

011

Pump

QII

Stramer

F

I

Crank

Pulley

Bolt

SPECIFICATIONS

In

mm

Valve

Mechamsm

Valve

Clearance

Hot

Valve

Clearance

Cold

Valve

Head

DIameter

Intake

Valve

Head

DIameter

Exhaust

Valve

Stem

DIameter

Intake

Valve

Stem

DIameter

Exhaust

Valve

Length

Intake

Valve

Length

Exhaust

Valve

LIft

Valve

Spring

Free

Length

Outer

Valve

Sprmg

Free

Length

Inner

Vaiv

Spnng

Loaded

Length

Outer

Valve

Spring

Loaded

Length

Inner

Valve

Sprmg

Assembllld

HeIght

Outer

Valve

Spnng

Assembled

Helght

Inner

Valve

Spnng

Effective

Turns

Outer

Valve

Sprmg

EffectIve

Turns

Inner

Valve

GUIde

Length

Intake

Valve

GUIde

Length

Exhaust

Valve

GUIde

HeIght

from

Head

Surface

Valve

GUIde

Inner

DIameter

Intake

Valve

GUIde

Inner

DIameter

Exhaust

Va

Ive

GUIde

Outer

Dlam

eter

Intake

Valve

GUIde

Outer

DIameter

Exhaust

Valve

GUIde

to

Stem

Clearance

Intake

Valve

GUIde

to

Stem

Clearance

Exhaust

Valve

eat

W

dth

Intake

Valve

SEtat

WIdth

Exhaust

4

m

Ilnil

97

3

cu

m

1595cc

3

2677

x

2

9016

In

83

x

73

7mm

Overhead

Camshaft

96

@

5

600

rpm

110

ft

Ib

13

8

kg

m

@

3

600

rpm

1

3

4

2

r

600

rpm

700

pm

85

1

i7

7

In

Hg

450mm

Hg

54

to

60

Ib

m

2

3

8

tQ

4

2

Iig

cm

325

4

5

39

8

5

5

68

No

75

9

9

50

to

1039

325

to

39

8

4

5

to

5

5

362

to

43

4

50

to

60

2

9

to

5

1

0

4

to

0

7

108

to

15

2

1

5

to

2

1

58t087

08to

12

1157

to

130

1

160

to

180

o

118

0

30

o

0C

98

0

25

1

50

38

0

1

30

33

0

031

80

031

80

456

1159

4

57

116

O

03937

100

2

05

52

0

1

77

44

96

1

21

@

1054

Ib

3

07

@

47

8

kg

o

96

@

56

Ib

24

5

@

25

5

kg

1

53

@

63

9

Ib

38

9

@

29

0

kg

1

38

@

27

1

Ib

35

@

123

kg

45

I

55

2

32

59

0

2

32

59

0

0409

to

0

417

104

to

106

0315

to

03154

80

to

8018

0315

to

03154

80

to

8

Oi8

04718

to

04723

11

985

to

11

996

04718

to

04723

11

985

to

11

996

00006

to

00018

0

015

to

0

045

00016

to

00028

0040

to

0070

o

055

to

0

071

1

4

to

1

8

0063

to

0079

1

6

to

20

Page 66 of 252

ENGINE

61

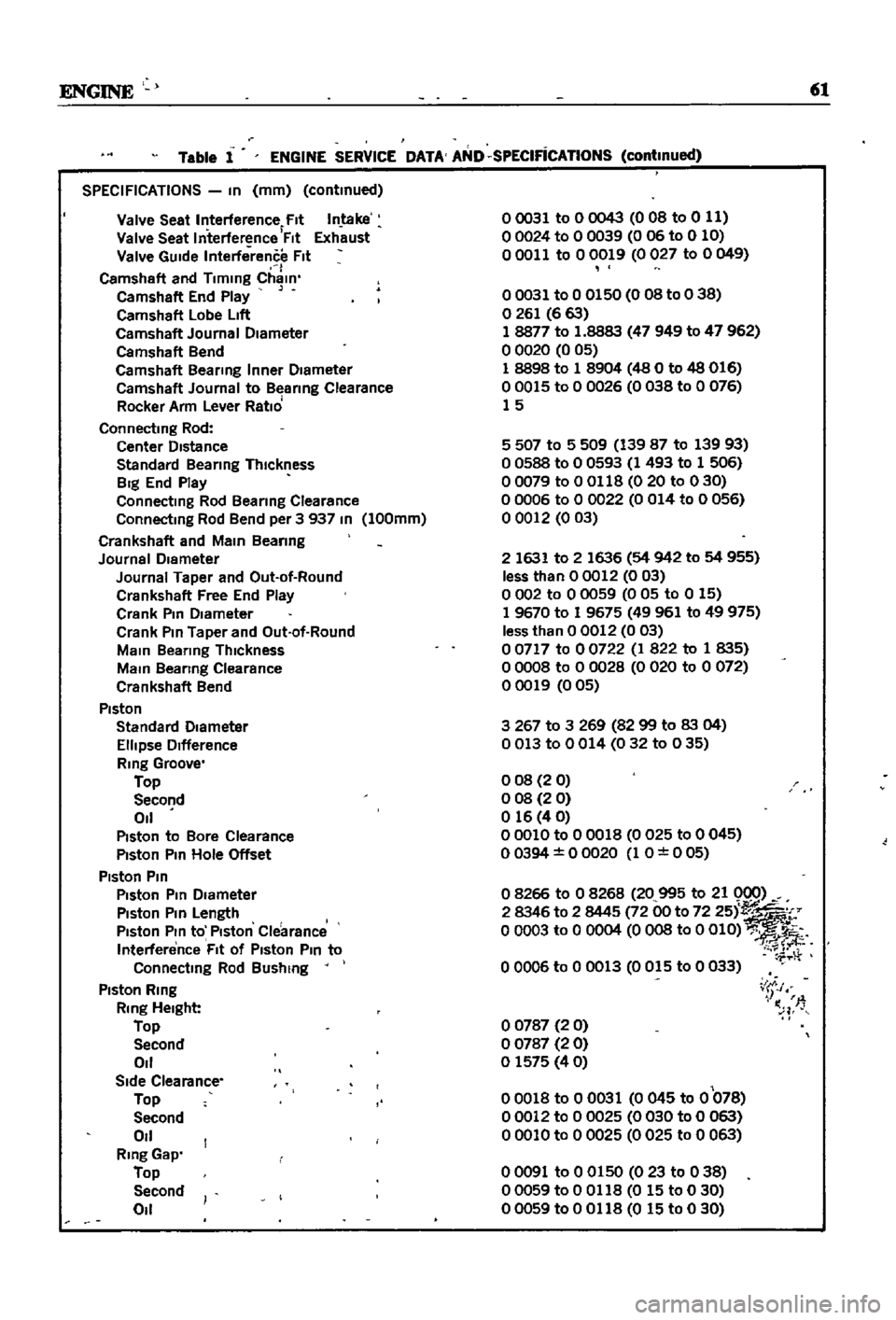

SPECIFICATIONS

In

mm

continued

Valve

Seat

Interference

Fit

Intake

Valve

Seat

Interference

Flt

Exh

ust

Valve

GUide

Interference

fit

I

Camshaft

and

Timing

Chain

Ca

mshaft

End

Play

Camshaft

Lobe

LIft

Camshaft

Journal

Diameter

Camshaft

Bend

Camshaft

Bearing

Inner

Diameter

Camshaft

Journal

to

B

arlng

Clearance

Rocker

Arm

Lever

Ratio

Connecting

Rod

Center

Distance

Standard

Bearing

Thickness

Big

End

Play

Connectmg

Rod

Beanng

Clearance

Connecting

Rod

Bend

per

3

937

In

100mm

Crankshaft

and

Main

Beanng

Journal

Diameter

Journal

Taper

and

Out

ot

Round

Crankshaft

Free

End

Play

Crank

Pin

Diameter

Crank

Pin

Taper

and

Out

ot

Round

Main

Bearing

Thickness

Main

Beanng

Clearance

Crankshaft

Bend

Piston

Standard

Diameter

Ellipse

Difference

Ring

Groove

Top

Second

011

Piston

to

Bore

Clearance

Piston

Pm

Hole

Offset

Piston

Pin

Piston

Pin

Diameter

Piston

Pin

Length

Piston

Pin

to

Piston

Clearance

Interference

Fit

ot

Piston

Pin

to

Connecting

Rod

Bushing

Piston

Ring

Ring

Height

Top

Second

011

Side

Clearance

Top

Second

011

Ring

Gap

Top

Second

011

Table

1

ENGINE

SERVICE

DATA

AND

SPECIFicATIONS

continued

00031

to

0

0043

0

OB

to

0

11

00024

to

0

0039

006

to

0

10

00011

to

00019

0027

to

0049

00031

to

0

0150

0

08

to

0

38

o

261

6

63

18877

to

1

8883

47

949

to

47

962

o

0020

0

05

1

8898

to

1

8904

48

0

to

48

016

00015

to

0

0026

0038

to

0

076

15

5

507

to

5

509

139

87

to

139

93

o

0588

to

0

0593

1

493

to

1

506

00079

to

0

0118

0

20

to

030

o

0006

to

0

0022

0

014

to

0

056

o

0012

003

2

1631

to

2

1636

54

942

to

54

955

less

than

00012

003

o

002

to

0

0059

0

05

to

0

15

1

9670

to

1

9675

49961

to

49

975

less

than

0

0012

0

03

o

0717

to

0

0722

1

822

to

1

835

o

0008

to

0

0028

0

020

to

0

072

00019

005

3267

to

3

269

8299

to

83

04

0013

to

0014

032

to

035

008

20

o

08

2

0

o

16

4

0

00010

to

0

0018

0

025

to

0

045

00394

0

0020

1

O

0

05

o

8266

to

0

8268

20

995

to

21

0

0

2

8346

to

2

8445

72

00

to

72

251

o

0003

to

0

0004

0

OOS

to

0

OlD

00006

to

0

0013

0015

to

0

033

o

0787

2

0

o

0787

2

0

o

1575

40

00018

to

00031

0

045

to

0

078

00012

to

0

0025

0030

to

0

063

00010

to

00025

0025

to

0

063

i

J

I

n

T

00091

to

0

0150

023

to

038

00059

to

0

0118

0

15

to

0

30

00059

to

0

0118

0

15

to

0

30

Page 67 of 252

CHAPTER

SEVEN

FUEL

SYSTEM

The

fuel

system

mcludes

the

fuel

tank

straIner

pump

carburetor

arr

cleaner

and

necessary

lines

Inspect

components

for

leaks

and

deterioratIOn

whenever

mamtenance

is

done

The

fuel

stramer

should

be

mspected

peri

odIcally

and

cleaned

AIR

CLEANER

The

au

filter

element

is

viscous

paper

and

does

not

require

cleanmg

Replace

It

every

24

000

mlles

or

more

frequently

under

harsh

condItIons

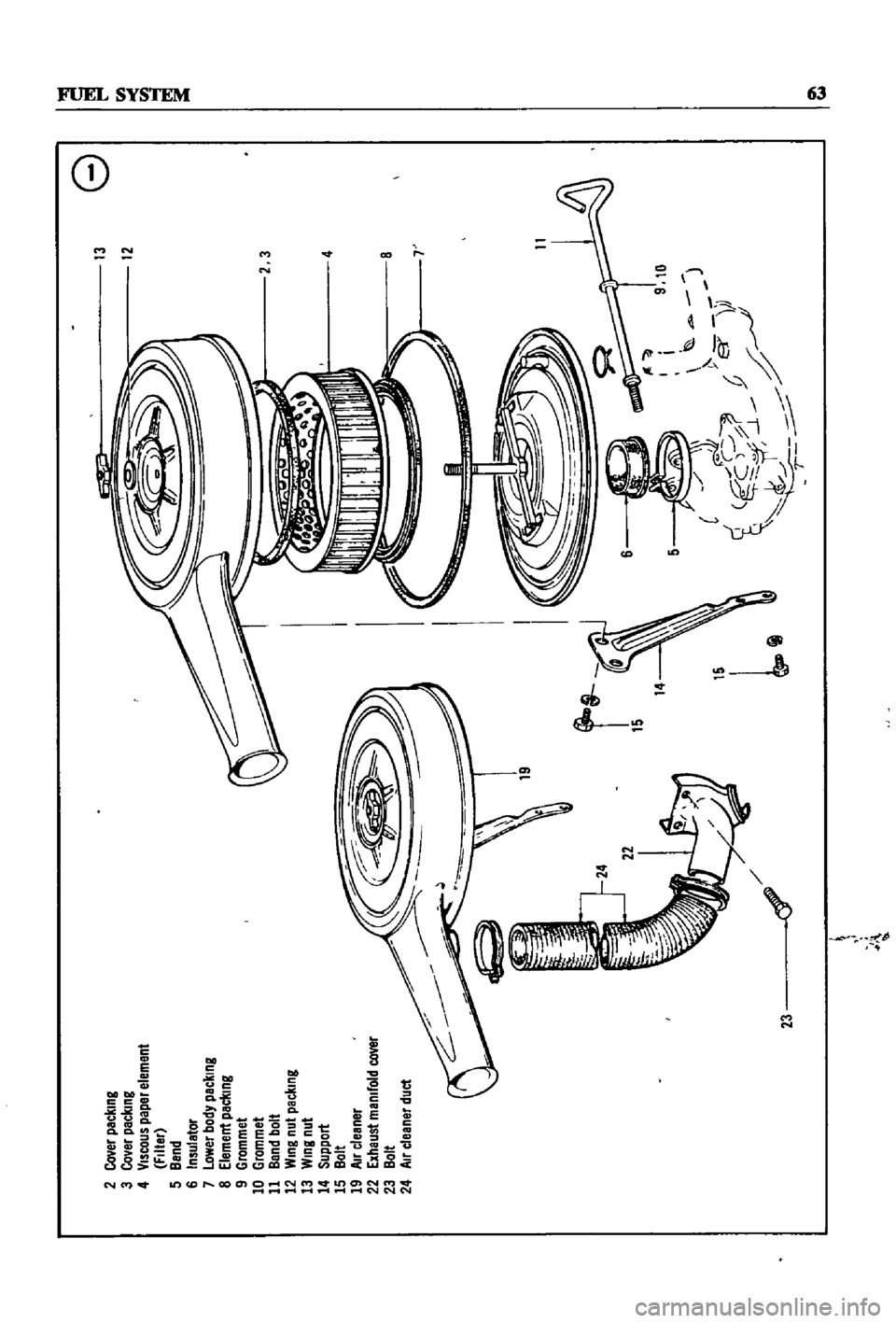

Several

mInor

differences

exist

between

vehicles

dependmg

on

the

type

of

emisSIOn

con

trol

device

used

Figure

1

shows

location

of

the

air

cleaner

on

the

engme

and

parts

compnsing

the

cleaner

system

on

model

years

through

1969

Figure

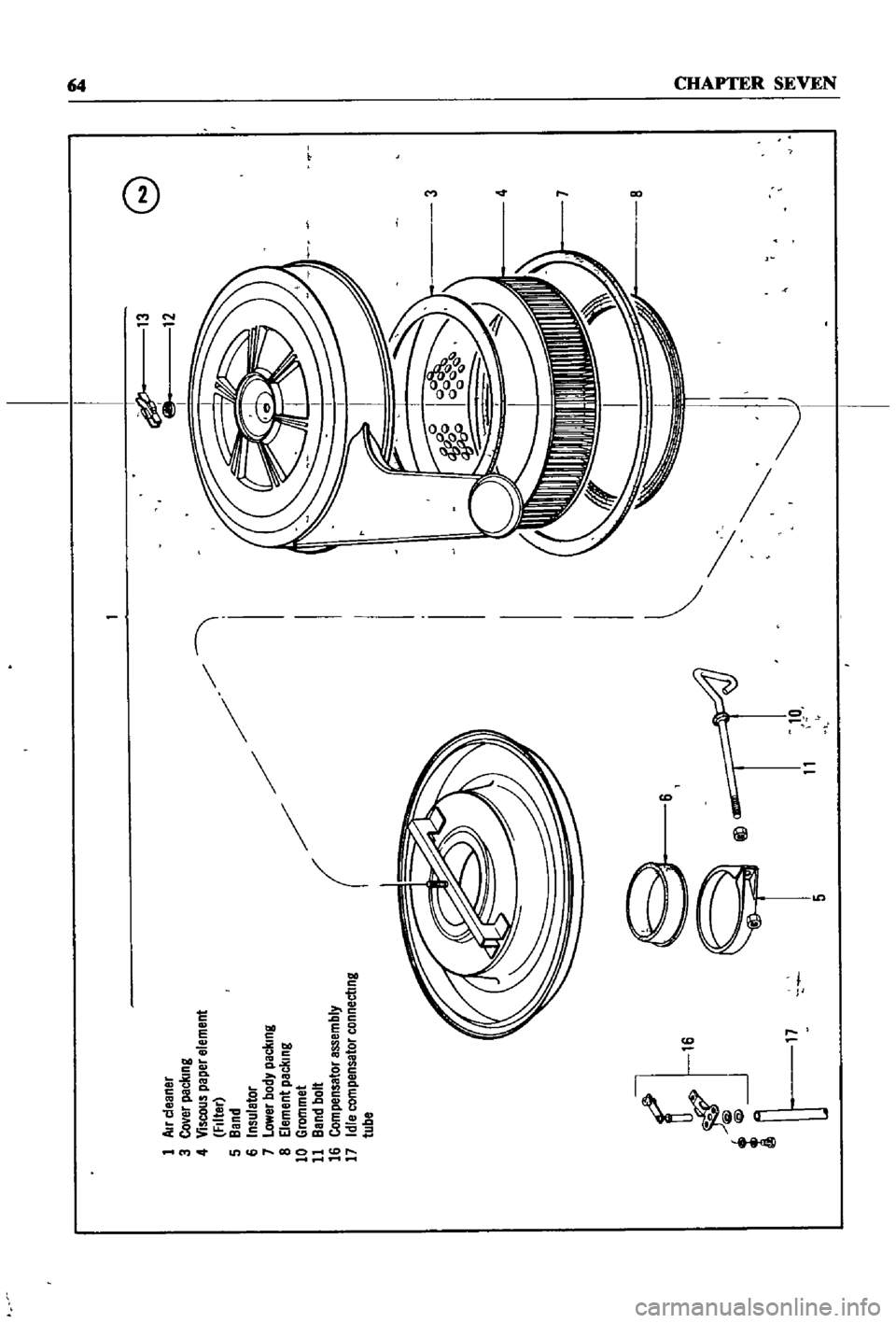

2

shows

the

changes

for

1970

and

later

Warm

air

is

supplIed

to

the

air

cleaner

from

the

exhaust

mamfold

to

prevent

carburetor

Icmg

AIR

CLEANER

REMOVAL

AND

REPLACEMENT

1

Unthread

the

WIng

nut

atop

the

cleaner

assembly

2

Remove

the

two

bolts

holdIng

the

air

cleaner

to

the

support

3

Disconnect

the

aIr

cleaner

duct

from

the

base

of

the

cleaner

intake

throat

4

LIft

off

the

aIr

cleaner

body

and

remove

the

aIr

filter

as

shown

m

Figure

3

To

remove

the

arr

cleaner

proceed

as

follows

1

Perform

steps

1

through

4

above

2

Unscrew

the

band

bolt

at

the

base

of

the

air

cleaner

3

DIsconnect

all

hoses

leadmg

to

the

air

cleaner

4

Pull

up

on

the

body

of

the

air

cleaner

and

remove

from

carburetor

5

Except

for

the

au

filter

element

thoroughly

clean

all

parts

6

Reverse

the

steps

above

for

reassembly

FUEL

STRAINER

The

fuel

stramer

IS

located

on

the

nght

hand

side

of

the

engme

compartment

Figure

4

shows

the

fuel

stratner

hoses

clamps

and

the

mount

Ing

clIp

that

holds

the

fuel

stramer

In

place

The

fuel

stramer

IS

of

the

cartrIdge

type

and

uses

a

fiber

mat

and

nylon

as

strainer

elements

The

fuel

stramer

should

be

mspected

frequently

for

foreIgn

material

and

replaced

at

least

every

24

000

rmles

1

DIsconnect

the

inlet

and

outlet

hoses

from

the

fuel

stratner

Make

certatn

that

the

mlet

hose

bottom

IS

not

permItted

to

fall

below

the

level

of

the

fuel

tank

or

leakage

wIll

occur

Page 68 of 252

13

8

t

12

i

l

2

cover

packIng

3

Co

er

packIng

n

4

VISCOUS

paper

eleme

23

filter

5

Band

6

Insuletor

OWer

body

pecking

1

Element

pac

l

lng

liL

J

J

4

9

Grommet

10

Grommet

11

Band

bolt

lll

i

8

12

WIng

nut

packing

13

Wing

nut

AV

T

14

support

15

Ilolt

19

I

Il

cleaner

cover

22

ExhaUst

manIfold

23

Ilolt

24

I

Il

cleaner

duct

i

9

10

S

e

l

ci

r

C

t

f

J

14

IS

13

1

0

lot

Page 69 of 252

1

Air

cleaner

3

Co

er

paclung

4

Viscous

paper

element

FIlter

5

Band

6

Insuletor

7

Lower

body

packmg

8

Element

peclllng

10

Grommet

11

Band

bolt

16

Compensator

assembly

17

Idle

compensator

connectmg

tube

l

1

1

@

5

11

10

I

13

12

G

3

4

7

0

g

l

i

Page 70 of 252

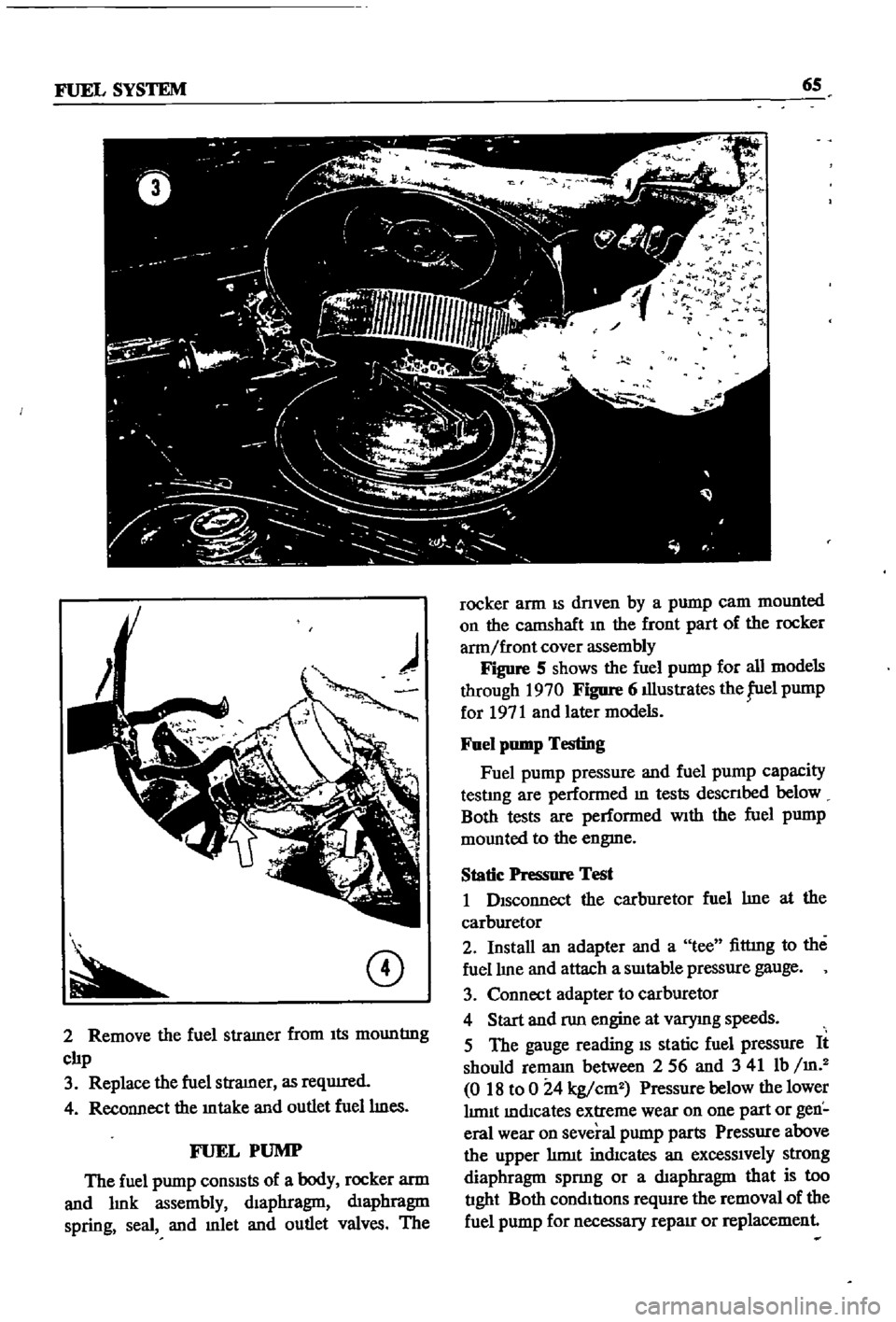

FUEL

SYSTEM

6S

CD

2

Remove

the

fuel

stramer

from

Its

mountlng

clIp

3

Replace

the

fuel

stramer

as

reqUIred

4

Reconnect

the

mtake

and

outlet

fuellmes

FUEL

PUMP

The

fuel

pump

conSISts

of

a

body

rocker

arm

and

lmk

assembly

dIaphragm

dIaphragm

spring

seal

and

mlet

and

outlet

valves

The

l

r

t

1

9

l

F

r

fl

rocker

arm

IS

dnven

by

a

pump

cam

mounted

on

the

catnShaft

In

the

front

part

of

the

rocker

arm

front

cover

assembly

Figure

S

shows

the

fuel

pump

for

all

models

through

1970

Figure

6

illustrates

the

fuel

pump

for

1971

and

later

models

Fuel

pump

Testing

Fuel

pump

pressure

and

fuel

pump

capacity

testlng

are

performed

m

tests

descnbed

below

Both

tests

are

performed

With

the

fuel

pump

mounted

to

the

engme

Static

Pressure

Test

1

DIsconnect

the

carburetor

fuel

lme

at

the

carburetor

2

Install

an

adapter

and

a

tee

fittmg

to

the

fuel

lIne

and

attach

a

SUItable

pressure

gauge

3

Connect

adapter

to

carburetor

4

Start

and

run

engine

at

varymg

speeds

5

The

gauge

reading

IS

static

fuel

pressure

It

should

remam

between

256

and

341

Ib

m

2

018

to

0

24

kg

cm2

Pressure

below

thelower

lImIt

mdlcates

extreme

wear

on

one

part

or

gen

eral

wear

on

several

pump

parts

Pressure

above

the

upper

hrmt

indIcates

an

excessIvely

strong

diaphragm

spnng

or

a

dIaphragm

that

is

too

tIght

Both

condItIons

require

the

removal

of

the

fuel

pump

for

necessary

repaIr

or

replacement