DATSUN 510 1968 Service Manual PDF

Manufacturer: DATSUN, Model Year: 1968, Model line: 510, Model: DATSUN 510 1968Pages: 252, PDF Size: 12.2 MB

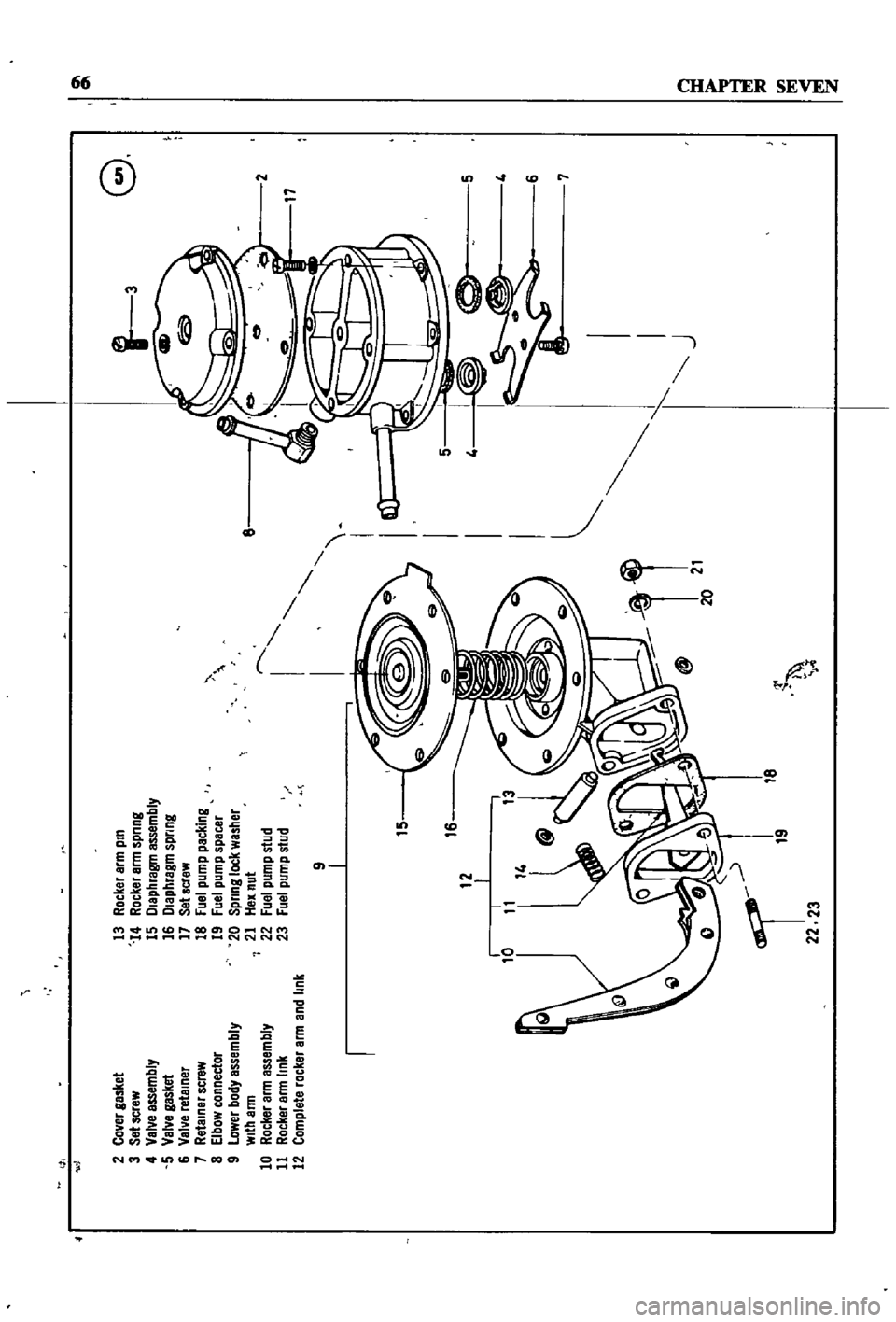

Page 71 of 252

01

01

G

1

3

2

Co

er

gasket

3

Set

screw

4

Val

e

assembly

5

Val

e

gasket

6

Val

e

retelner

7

Retainer

screw

8

Elbow

connector

9

lower

body

assembly

With

arm

10

Rocker

arm

assembly

11

Rocker

arm

link

12

Complete

rocker

arm

and

link

13

Rocker

arm

pin

14

Rocker

arm

spnng

15

Dlephragm

assembly

16

Diaphragm

spring

17

Sehcrew

18

Fuel

pump

pecking

19

Fuel

pump

spacer

20

Spnng

lock

washer

21

Hex

nut

22

Fuel

pump

stud

23

Fuel

pump

stud

2

17

r

I

I

I

I

I

I

I

I

I

J

9

I

I

15

I

0

5

I

16

1i

20

21

g

tI

i

I

lb

18

22

23

r

Page 72 of 252

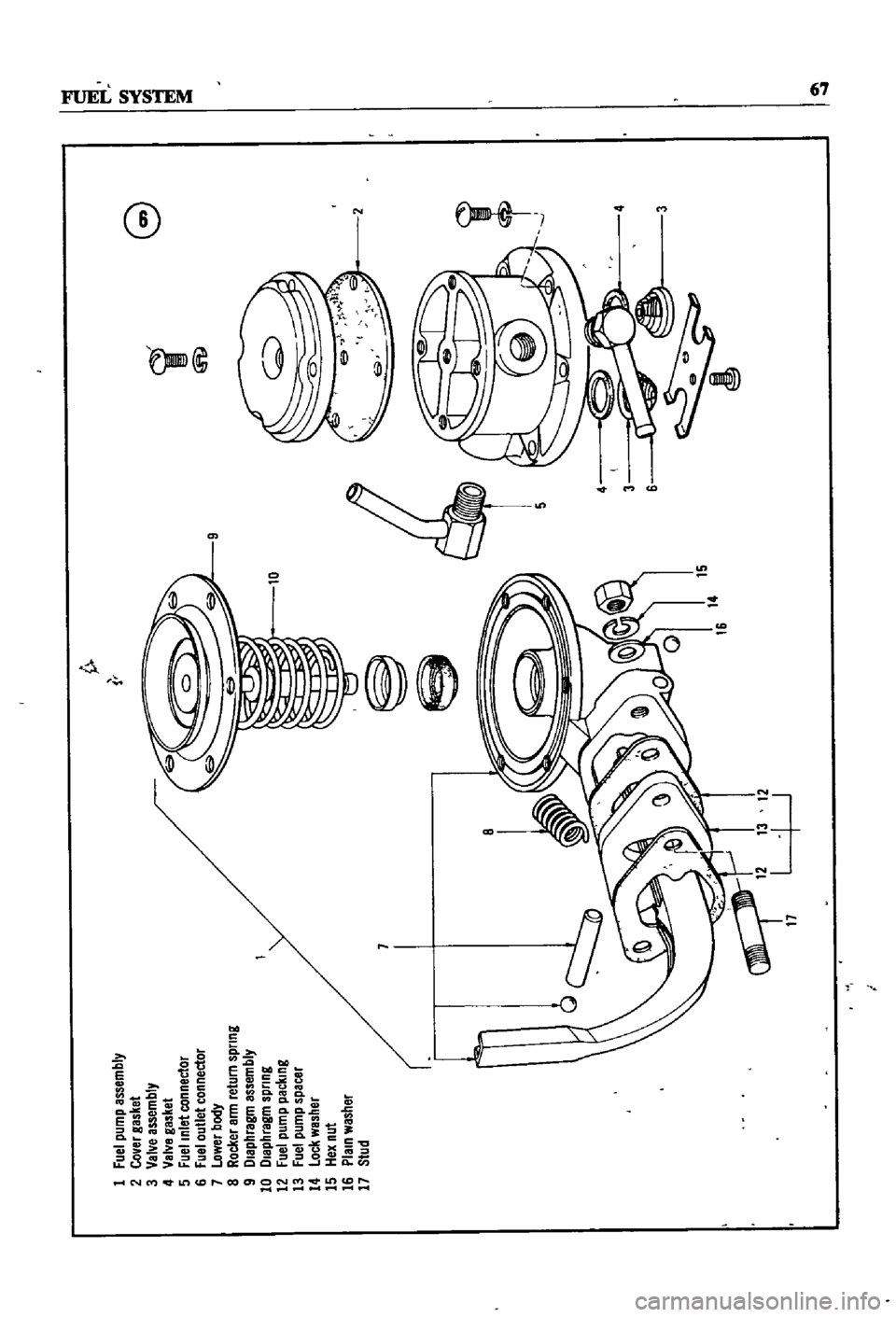

G

i

@

1

fuel

pump

assembly

2

CoVBr

gasket

3

VBNB

assemblY

4

VBNB

gBsl

et

5

Fuel

Inlet

connect01

6

fUBI

outlet

connector

7

OwerllodY

a

Rocker

Bll

Ireturn

spnng

9

l

IBP

1rBgm

BssemblY

10

l

IBphlBgm

sQnng

12

Fuel

QumQ

packIng

13

fuel

pump

spBcer

14

lOc

l

wBsl

er

15

lex

nut

16

PIBIn

was

1Br

17

Stud

Page 73 of 252

68

CHAPTER

SEVEN

Capacity

Test

Perform

the

capacity

test

only

when

the

statIc

pressiue

test

IS

withm

acceptable

lirmts

1

D

sconnect

the

fuellme

at

the

carburetor

2

Place

a

sUItable

container

at

the

end

of

the

fuellme

3

St

lrt

the

engm

and

run

at

OOO

rpm

4

The

fuel

pump

should

delIver

fuel

into

the

co

ntainer

at

a

rate

slightly

over

two

pints

per

minute

If

no

gasolme

or

only

a

lIttle

appears

the

fuel

lme

is

clogged

or

thefuel

pump

defectIve

Bef

removmg

the

fuel

pump

remove

the

gas

tank

filler

cap

dtsconnect

the

mlet

and

outlet

fuel

lmes

and

qlow

through

them

With

compressed

air

to

make

certam

they

are

clear

Reconnect

the

fuellmes

and

retest

the

flow

If

stIll

insufficient

the

fuel

p

mp

requires

servicmg

or

replacement

Fuel

Punip

Removal

and

Disassembly

1

Unscrew

the

two

mountIng

nuts

hOldmg

fuel

pump

to

the

cylmder

head

2

Disconnect

the

inlet

and

outlet

lines

3

Remove

the

fuel

pump

from

the

cylmder

head

4

Place

the

pump

on

a

work

bench

and

remove

the

screws

jommg

the

upper

and

lower

bodIes

5

Remove

the

cap

and

gasket

by

removing

the

cap

screws

6

Unscrew

the

elbow

and

connector

7

Remove

the

valve

retamer

by

unscrewmg

the

two

valve

retamer

screws

The

two

valves

are

then

easily

removed

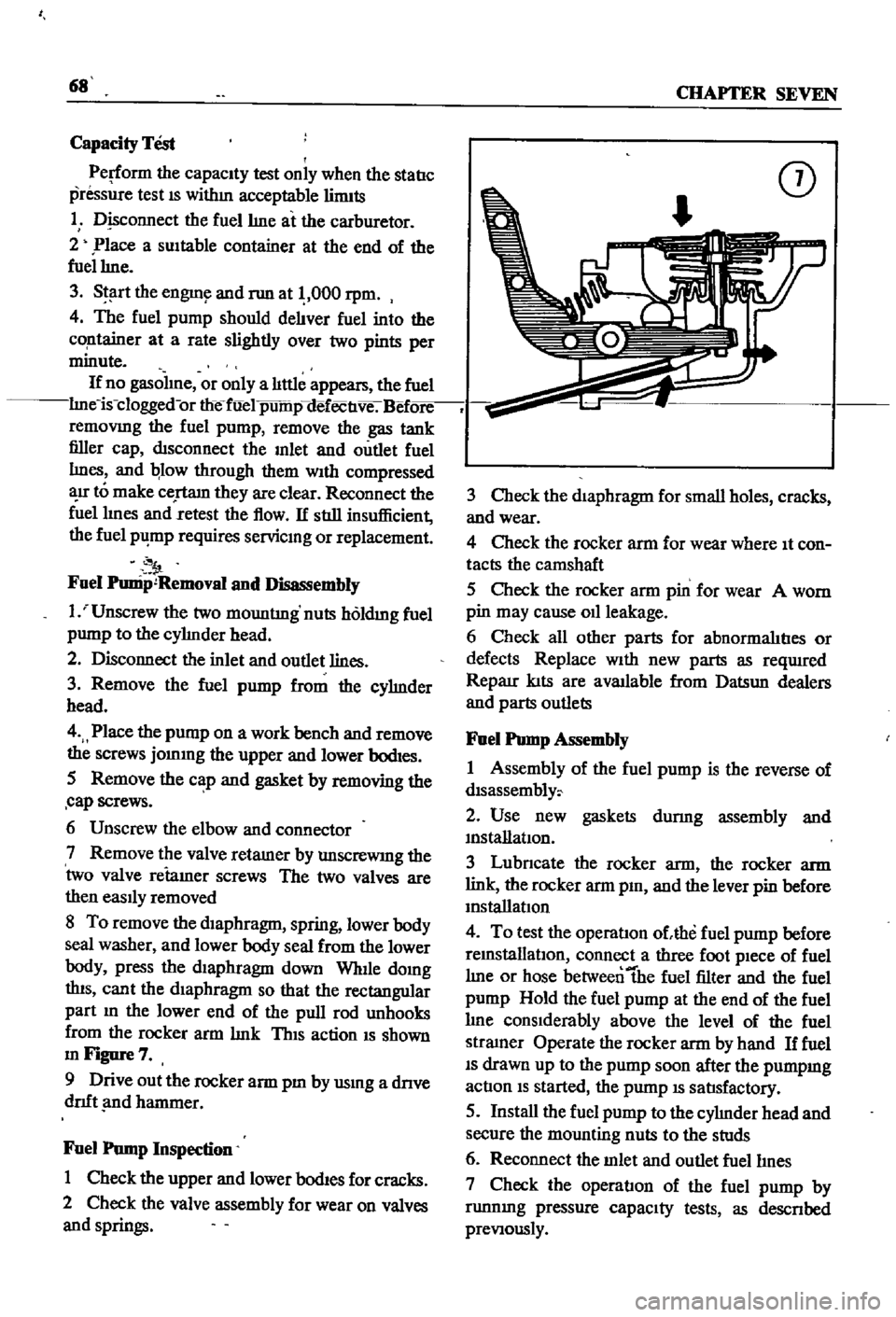

8

To

remove

the

dIaphragm

spring

lower

body

seal

washer

and

lower

body

seal

from

the

lower

body

press

the

diaphragm

down

Wh1le

domg

thIS

cant

the

dIaphragm

so

that

the

rectangular

part

m

the

lower

end

of

the

pull

rod

unhooks

from

the

rocker

arm

lmk

ThIS

action

IS

shown

mFigure7

9

Drive

out

the

rocker

arm

pm

by

usmg

a

dnve

dnft

nd

hammer

Fuel

Pump

Inspection

1

Check

the

upper

and

lower

bodIes

for

cracks

2

Check

the

valve

assembly

for

wear

on

valves

and

springs

CD

3

Check

the

diaphragm

for

small

holes

cracks

and

wear

4

Check

the

rocker

arm

for

wear

where

It

con

tacts

the

camshaft

5

Check

the

rocker

arm

pin

for

wear

A

worn

pin

may

cause

011

leakage

6

Check

all

other

parts

for

abnormalItIes

or

defects

Replace

With

new

parts

as

reqUlred

Reparr

kIts

are

available

from

Datsun

dealers

and

parts

outlets

Fuel

Pump

Assembly

1

Assembly

of

the

fuel

pump

is

the

reverse

of

dlsassembly

2

Use

new

gaskets

durmg

assembly

and

mstanatIon

3

Lubncate

the

rocker

arm

the

rocker

arm

link

the

rocker

arm

pm

and

the

lever

pin

before

mstallatIon

4

To

test

the

operatIon

ohhe

fuel

pump

before

remstallatlOn

connect

a

three

foot

pIece

of

fuel

lme

or

hose

betweentbe

fuel

filter

and

the

fuel

pump

Hold

the

fuel

pump

at

the

end

of

the

fuel

lme

conSIderably

above

the

level

of

the

fuel

stramer

Operate

the

rocker

arm

by

hand

If

fuel

IS

drawn

up

to

the

pump

soon

after

the

pumpmg

actIon

IS

started

the

pump

IS

satIsfactory

5

Install

the

fuel

pump

to

the

cylmder

head

and

secure

the

mounting

nuts

to

the

studs

6

Reconnect

the

mlet

and

outlet

fuellmes

7

Check

the

operatIon

of

the

fuel

pump

by

runnmg

pressure

capaCIty

tests

as

descnbed

preVIously

Page 74 of 252

FUEL

SYSTEM

69

CARBURETOR

The

carburetor

IS

an

Hltach1

Type

DAF328

Several

varIations

are

used

dependmg

on

the

model

year

type

of

transmissIOn

and

the

emIS

SIon

control

system

The

dIfferent

models

are

the

same

as

far

as

basiC

operation

IS

concerned

Therefore

the

followmg

dISCUSSIon

covers

a

typIcal

carburetor

The

automatIc

choke

IS

used

on

automatIc

transmISSIon

and

1972

models

only

All

other

chokes

are

manual

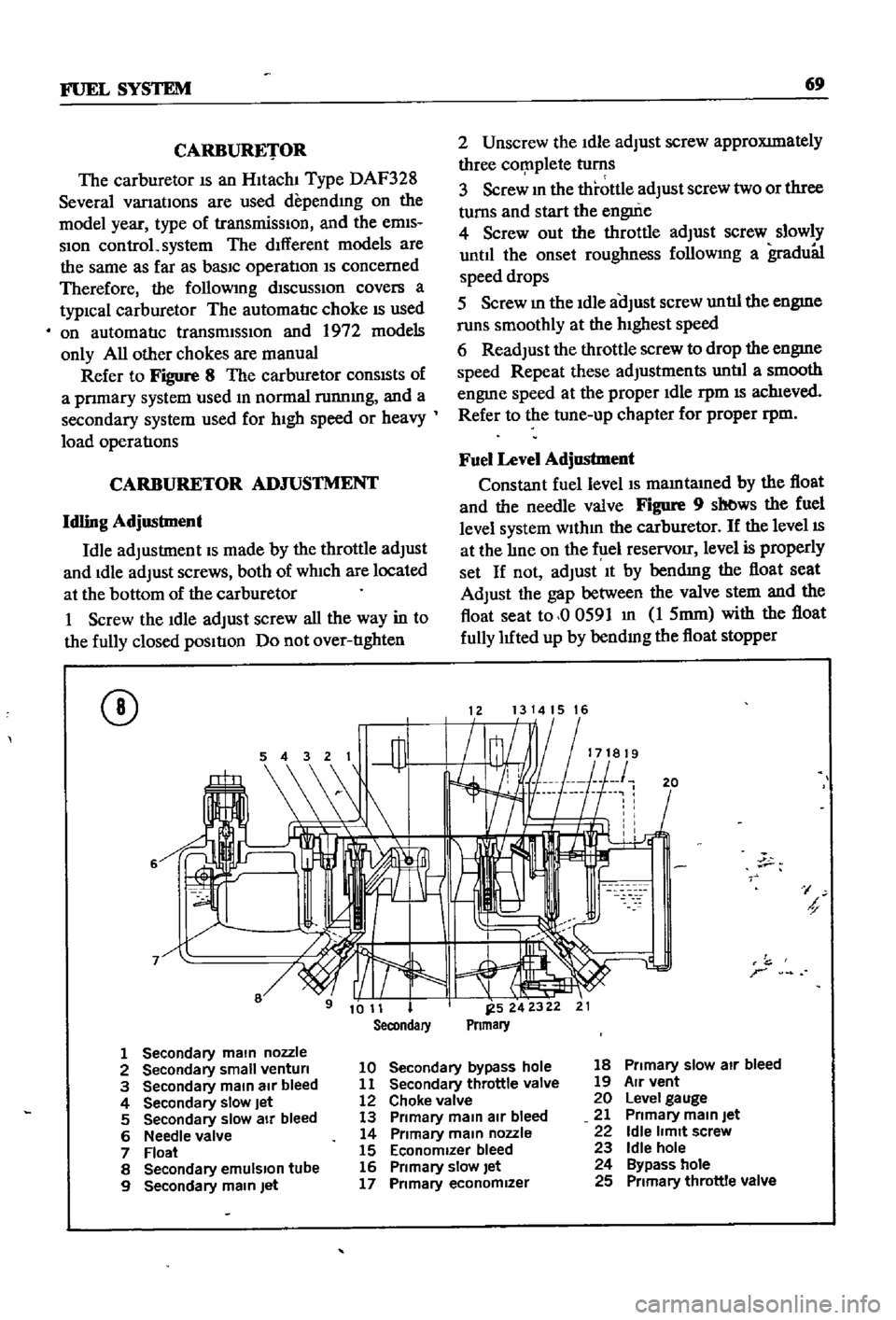

Refer

to

Figure

8

The

carburetor

conSIsts

of

a

pnmary

system

used

m

normal

runnmg

and

a

secondary

system

used

for

hIgh

speed

or

heavy

load

operatIons

CARBURETOR

ADJUSTMENT

Idling

Adjustment

Idle

adjustment

IS

made

by

the

throttle

adjust

and

Idle

adjust

screws

both

of

wh1ch

are

located

at

the

bottom

of

the

carburetor

1

Screw

the

Idle

adjust

screw

all

the

way

in

to

the

fully

closed

pOSItIon

Do

not

over

tIghten

CD

6

2

Unscrew

the

Idle

adjust

screw

approXImately

three

cor

nplete

turns

3

Screw

m

the

throttle

adjust

screw

two

or

three

turns

and

start

the

engui

e

4

Screw

out

the

throttle

adjust

screw

slowly

until

the

onset

roughness

followmg

a

gradu81

speed

drops

5

Screw

m

the

Idle

aOJust

screw

untIl

the

engme

runs

smoothly

at

the

hIghest

speed

6

Readjust

the

throttle

screw

to

drop

the

engme

speed

Repeat

these

adjustments

untIl

a

smooth

engme

speed

at

the

proper

Idle

rpm

IS

ach1eved

Refer

to

the

tune

up

chapter

for

proper

rpm

Fuel

Level

Adjustment

Constant

fuel

level

IS

mamtamed

by

the

float

and

the

needle

valve

Figure

9

sb

ws

the

fuel

level

system

wlthm

the

carburetor

If

the

level

IS

at

the

lIne

on

the

f

lel

reservOir

level

is

properly

set

If

not

adjust

It

by

bendmg

the

float

seat

Adjust

the

gap

between

the

valve

stem

and

the

float

seat

to

00591

m

1

5mm

with

the

float

fully

luted

up

by

bendmg

the

float

stopper

1213141516

20

I

h

r

1

Secondary

main

nozzle

2

Secondary

small

venturi

10

Secondary

bypass

hole

18

Primary

slow

air

bleed

3

Secondary

main

air

bleed

11

Secondary

throttle

valve

19

Air

vent

4

Secondary

slow

Jet

12

Choke

valve

20

Level

gauge

5

Secondary

slow

air

bleed

13

Primary

main

air

bleed

21

Primary

main

Jet

6

Needle

valve

14

Primary

main

nozzle

22

Idle

limit

screw

7

Float

15

Economizer

bleed

23

Idle

hole

8

Secondary

emulSion

tube

16

Primary

slow

let

24

Bypass

hole

9

Secondary

main

Jet

17

Primary

economizer

25

Primary

throttle

valve

Page 75 of 252

70

CHAPTER

SEVEN

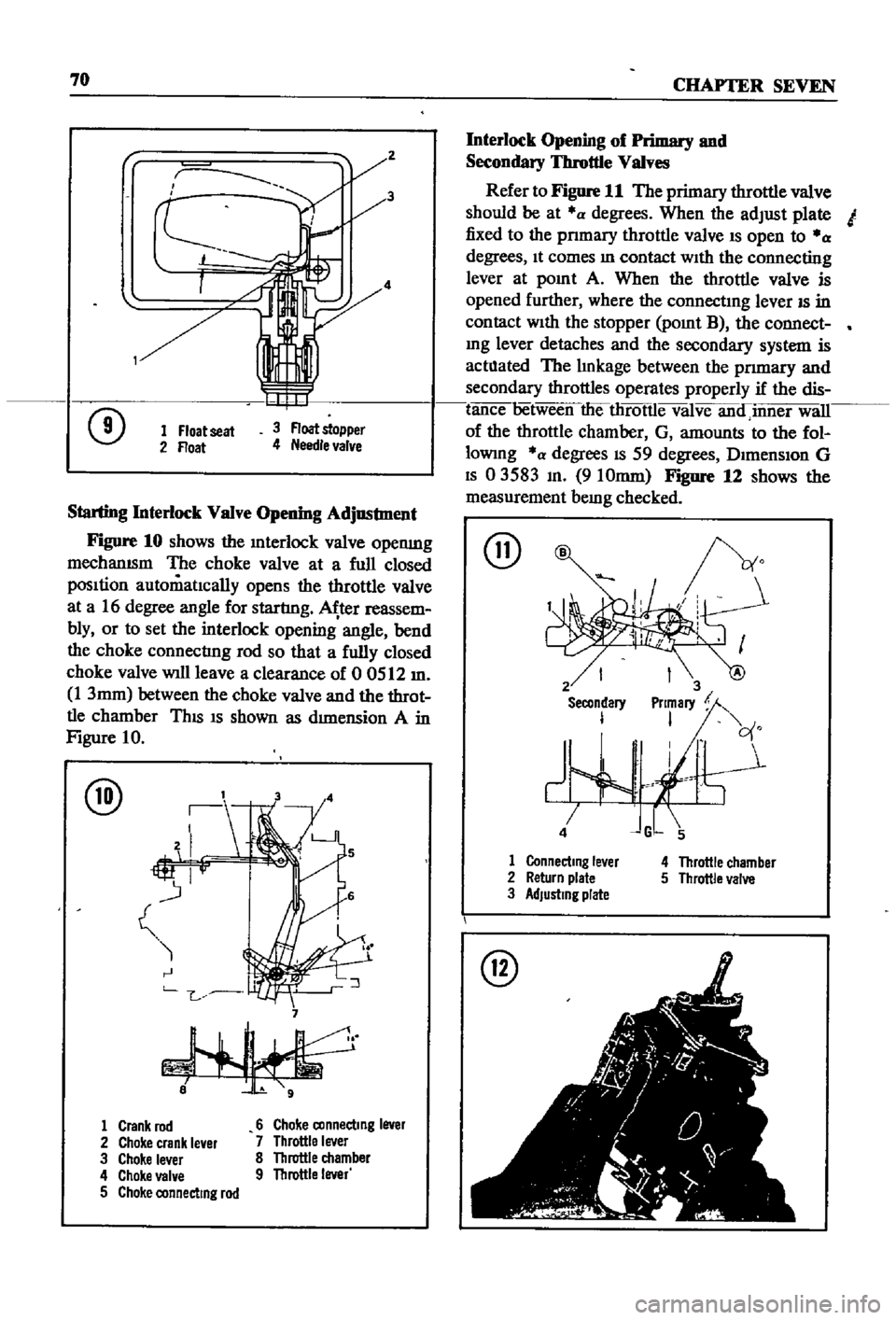

CD

1

Float

seat

2

Roat

3

Roat

stopper

4

Needle

valve

Starting

Interlock

Valve

Opening

Adjustment

Figure

10

shows

the

Interlock

valve

openmg

mechanISm

The

choke

valve

at

a

full

closed

pOSItion

automatIcally

opens

the

throttle

valve

at

a

16

degree

angle

for

startlng

ter

reassem

bly

or

to

set

the

interlock

opening

angle

bend

the

choke

connectlng

rod

so

that

a

fully

closed

choke

valve

will

leave

a

clearance

of

0

0512

m

1

3mm

between

the

choke

valve

and

the

throt

tle

chamber

ThIS

IS

shown

as

dImension

A

in

Figure

10

@

7

1

Crank

rod

6

Choke

connecting

lever

2

Choke

crank

le

er

7

Throttle

lever

3

Choke

lever

8

Throttle

chamber

4

Choke

VBI

e

9

Throttle

lever

5

Choke

connecting

rod

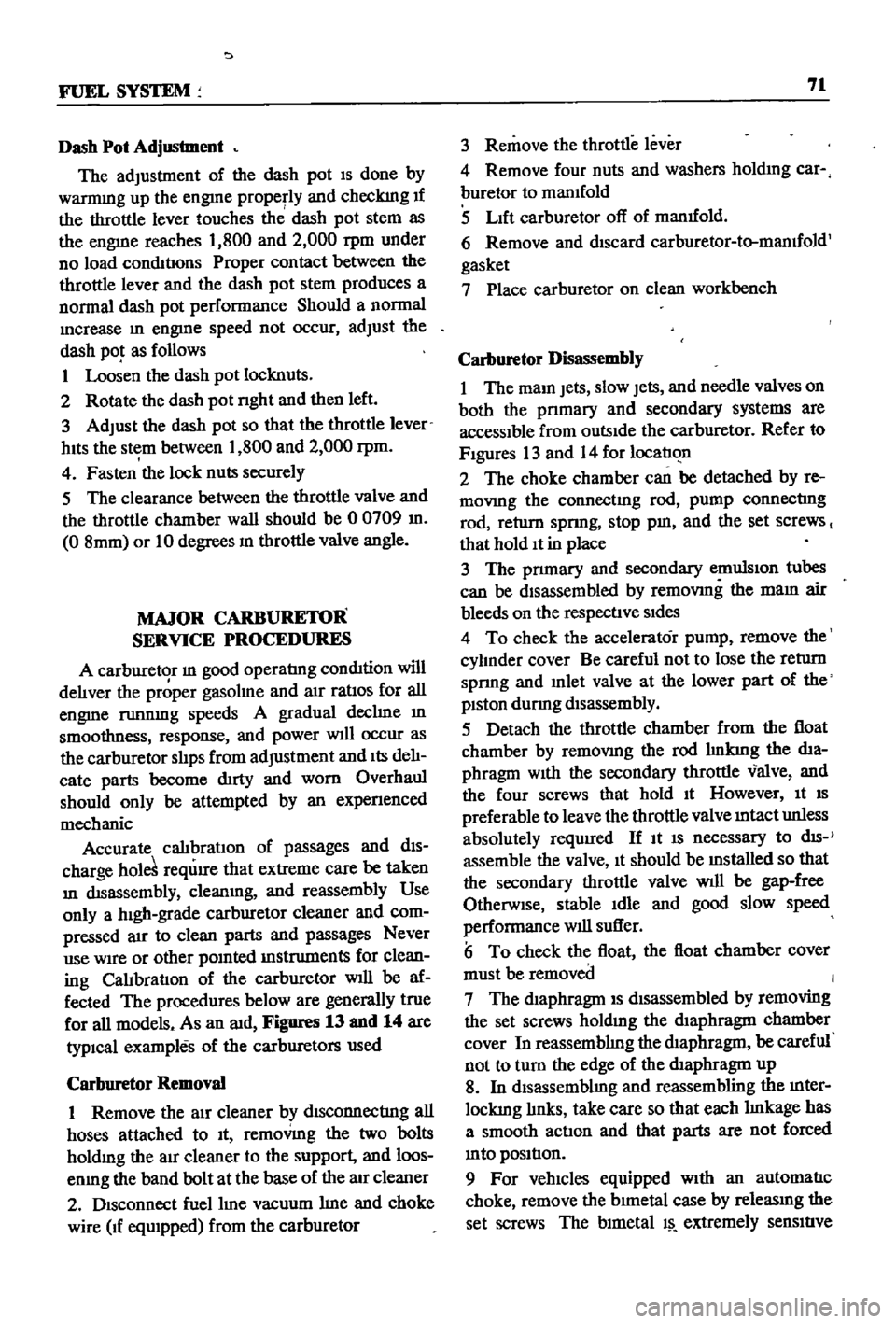

Interlock

Opening

of

Primary

and

Secondary

Throttle

Valves

Refer

to

Figure

11

The

primary

throttle

valve

should

be

at

a

degrees

When

the

adjust

plate

I

fixed

to

the

pnmary

throttle

valve

IS

open

to

a

degrees

It

comes

In

contact

WIth

the

connecting

lever

at

pOInt

A

When

the

throttle

valve

is

opened

further

where

the

connectIng

lever

IS

in

contact

With

the

stopper

POInt

B

the

connect

mg

lever

detaches

and

the

secondary

system

is

actllated

The

lInkage

between

the

pnmary

and

secondary

throttles

operates

properly

if

the

dis

tance

6etween

theilirotlle

valve

anainner

will

of

the

throttle

chamber

G

amounts

to

the

fol

lowmg

a

degrees

IS

59

degrees

DImenSIon

G

IS

03583

In

910mm

Figure

12

shows

the

measurement

bemg

checked

@

2

Secondary

I

1

Connecting

le

er

2

Return

plate

3

Adjusting

plate

4

Throttle

chamber

5

Throttle

valve

I

1

I

r

t

i

t

r

1

I

j

I

00

I

r

@

Page 76 of 252

FUEL

SYSTEM

71

Dash

Pot

Adjustment

The

adjustment

of

the

dash

pot

IS

done

by

warmmg

up

the

engme

properly

and

checkIng

If

the

throttle

lever

touches

th

dash

pot

stem

as

the

engine

reaches

1

800

and

2

000

rpm

under

no

load

conditIons

Proper

contact

between

the

throttle

lever

and

the

dash

pot

stem

produces

a

normal

dash

pot

performance

Should

a

normal

mcrease

m

engme

speed

not

occur

adjust

the

dash

pot

as

follows

1

Loosen

the

dash

pot

locknuts

2

Rotate

the

dash

pot

nght

and

then

left

3

Adjust

the

dash

pot

so

that

the

throttle

lever

hIts

the

stem

between

1

800

and

2

000

rpm

4

Fasten

the

lock

nuts

securely

5

The

clearance

between

the

throttle

valve

and

the

throttle

chamber

wall

should

be

0

0709

m

0

8mm

or

10

degrees

In

throttle

valve

angle

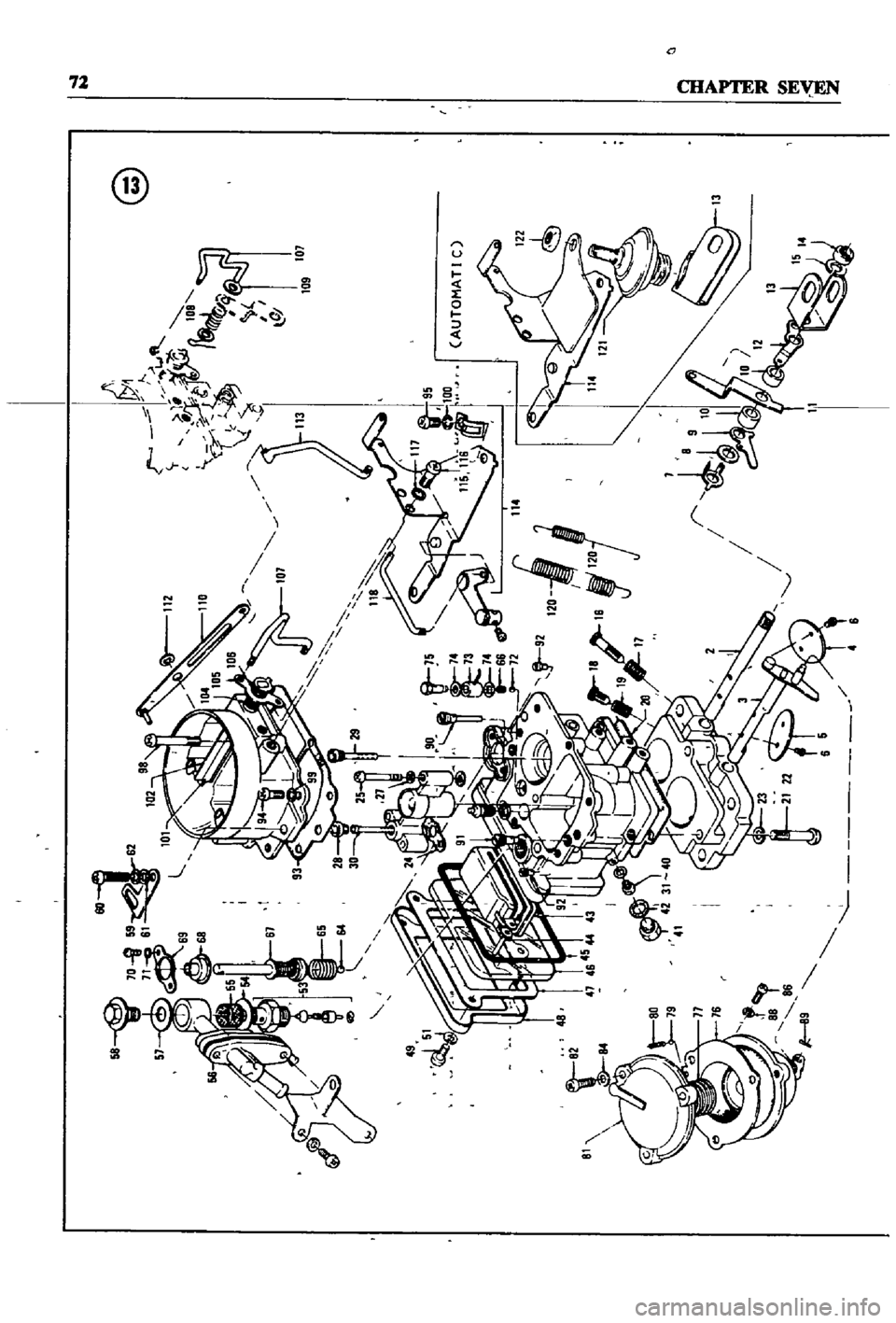

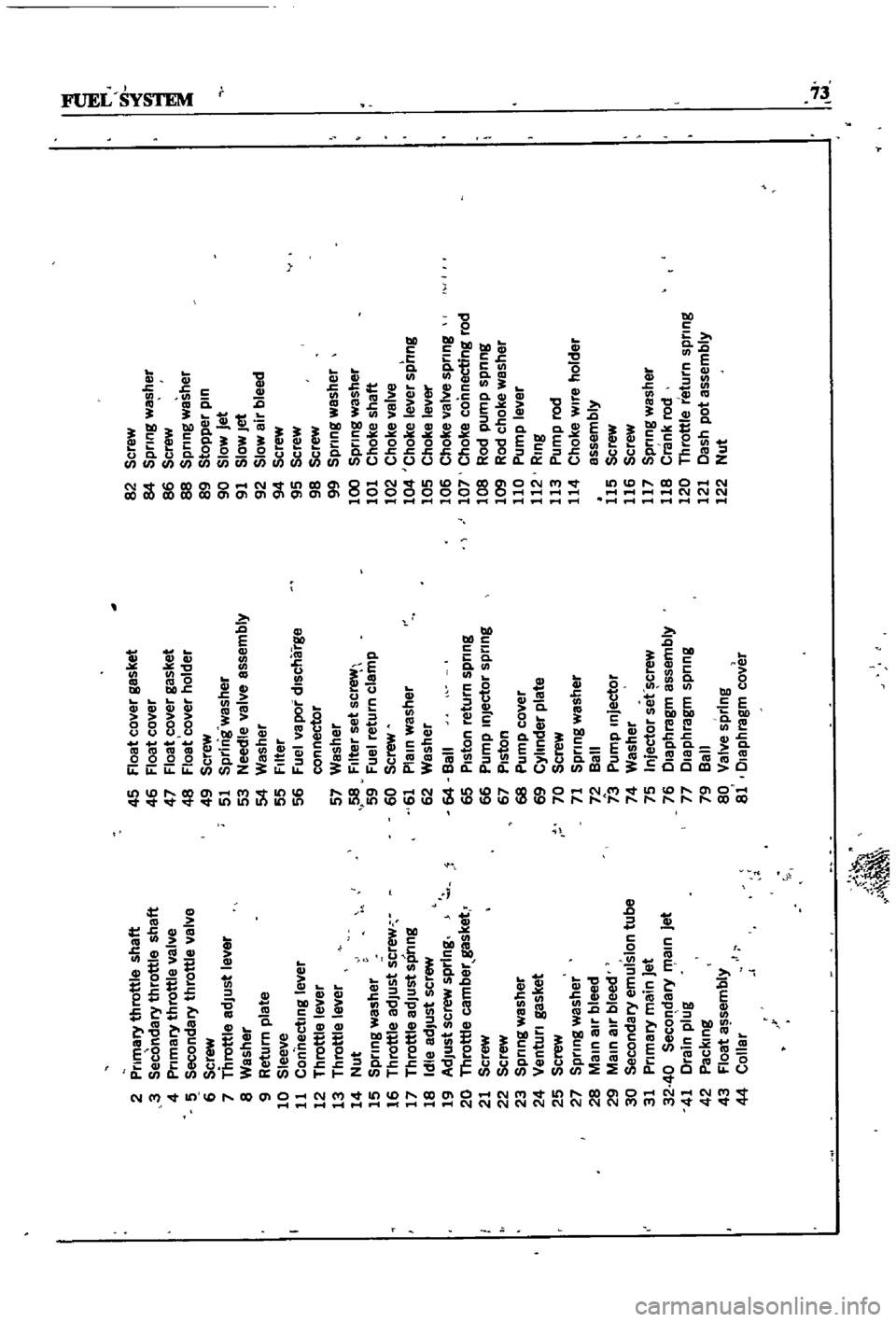

MAJOR

CARBURETOR

SERVICE

PROCEDURES

A

carburetor

m

good

operatIng

condition

will

delIver

the

pr

per

gasolme

and

aIr

ratIos

for

all

engme

runnmg

speeds

A

gradual

declme

In

smoothness

response

and

power

Will

occur

as

the

carburetor

slIps

from

adjustment

and

Its

delI

cate

parts

become

dirty

and

worn

Overhaul

should

only

be

attempted

by

an

expenenced

mechanic

Accurate

calIbratIon

of

passages

and

dIS

charge

hole

reqUIre

that

extreme

care

be

taken

In

dISassembly

cleanmg

and

reassembly

Use

only

a

hIgh

grade

carburetor

cleaner

and

com

pressed

arr

to

clean

parts

and

passages

Never

use

wire

or

other

pOInted

Instruments

for

clean

ing

CalIbratIon

of

the

carburetor

will

be

af

fected

The

procedures

below

are

generally

true

for

all

models

As

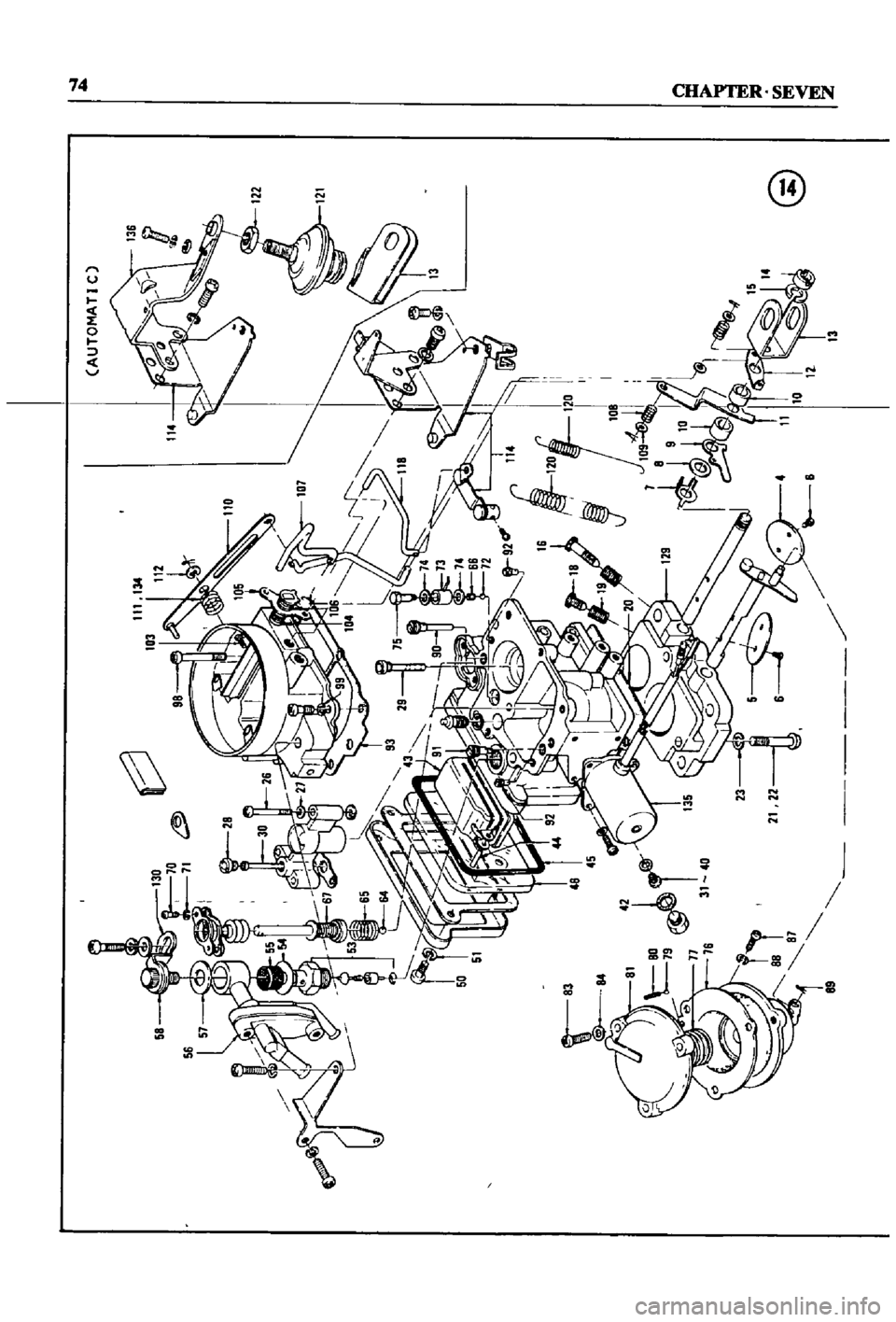

an

aId

Figures

13

and

14

are

typIcal

examples

of

the

carburetors

used

Carburetor

Removal

1

Remove

the

au

cleaner

by

dIsconnectIng

all

hoses

attached

to

It

remoVmg

the

two

bolts

holdmg

the

aIr

cleaner

to

the

support

and

loos

enmg

the

band

bolt

at

the

base

of

the

aIr

cleaner

2

DIsconnect

fuellme

vacuum

Ime

and

choke

wire

u

eqUIpped

from

the

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

holdmg

car

buretor

to

manIfold

5

Lift

carburetor

off

of

manuold

6

Remove

and

dIscard

carburetor

to

manuold

gasket

7

Place

carburetor

on

clean

workbench

Carburetor

Disassembly

1

The

maIn

Jets

slow

Jets

and

needle

valves

on

both

the

pnmary

and

secondary

systenIS

are

accessIble

from

outsIde

the

carburetor

Refer

to

FIgures

13

and

14

for

locatI

n

2

The

choke

chamber

can

be

detached

by

re

mOVIng

the

connectIng

rod

pump

connectIng

rod

return

sprmg

stop

pm

and

the

set

screws

I

that

hold

It

in

place

3

The

pnmary

and

secondary

emulSIon

tubes

can

be

disassembled

by

remOVIng

the

mam

air

bleeds

on

the

respectIve

SIdes

4

To

check

the

accelerator

pump

remove

the

cylInder

cover

Be

careful

not

to

lose

the

return

spnng

and

Inlet

valve

at

the

lower

part

of

the

pIston

durmg

dIsassembly

5

Detach

the

throttle

chamber

from

the

float

chamber

by

remOVIng

the

rod

lInkIng

the

dia

phragm

WIth

the

secondary

throttle

valve

and

the

four

screws

that

hold

It

However

It

IS

preferable

to

leave

the

throttle

valve

mtact

unless

absolutely

reqUired

If

It

IS

necessary

to

dlS

assemble

the

valve

It

should

be

Installed

so

that

the

secondary

throttle

valve

will

be

gap

free

OtherwIse

stable

Idle

and

good

slow

speed

performance

will

suffer

is

To

check

the

float

the

float

chamber

cover

must

be

removed

I

7

The

dIaphragm

IS

dIsassembled

by

removing

the

set

screws

holdmg

the

dIaphragm

chamber

cover

In

reassemblIng

the

diaphragm

be

careful

not

to

turn

the

edge

of

the

dIaphragm

up

8

In

dlsassemblmg

and

reassembling

the

mter

lockIng

lInks

take

care

so

that

each

lInkage

has

a

smooth

actIon

and

that

parts

are

not

forced

mto

pOSItIon

9

For

vehIcles

equipped

With

an

automatIc

choke

remove

the

brmetal

case

by

releasmg

the

set

screws

The

bimetal

1l

extremely

senSItIve

Page 77 of 252

a

C1

1AyTEll

Sy

VEN

@

t

i

o

j

J

1

I

cP

C

O

c

o

I

I

4

J

Page 78 of 252

j

2

Primary

throttle

shaft

45

Float

cover

gasket

82

Screw

I

f

l

3

Secondary

throttle

shaft

46

Float

cover

84

Spring

washer

4

Primary

throttle

valve

47

Float

cover

gasket

86

Screw

5

Secondary

throttle

valve

48

Float

cover

holder

88

Spring

washer

6

Screw

49

Screw

89

Stopper

pin

7

Throttle

adJust

lever

51

Sprln

g

washer

90

Slow

Jet

8

Washer

53

Needle

valve

assembly

91

Slow

Jet

9

Return

plate

54

Washer

92

Slow

air

bleed

10

Sleeve

55

Filter

94

Screw

11

Connecting

lever

56

Fuel

va

por

discharge

95

Screw

12

Throttle

lever

con

nectar

98

Screw

13

Throttle

lever

57

Washer

99

Spring

washer

14

Nut

58

Filter

set

sc

100

Spring

washer

15

Spring

washer

59

Fuel

return

clamp

101

Choke

shaft

16

Throttle

adJust

screw

60

Screw

102

Choke

valve

17

Throttle

adJUst

spring

61

Plain

washer

104

Choke

lever

spong

18

Idle

adJust

screw

62

Washer

105

Choke

lever

19

AdJust

screw

spring

64

Ball

106

Choke

valve

spring

20

Throttle

camber

gasket

65

Piston

return

spring

107

Choke

connecting

rod

21

Screw

66

Pump

inJector

spring

108

Rod

pump

spnng

22

Screw

67

Piston

109

Rod

choke

washer

23

Spring

washer

68

Pump

cover

110

Pump

lever

24

Venturi

gasket

69

Cylinder

plate

112

Ring

25

Screw

70

Screw

113

Pump

rod

27

Spring

washer

71

Spring

washer

114

Choke

wire

holder

28

Main

air

bleed

72

Ball

assembly

29

Main

aIr

bleed

73

Pump

Injector

115

Screw

30

Secondary

emulsion

tube

74

Washer

116

Screw

31

Primary

main

jet

75

Injector

set

crew

117

Spring

washer

32

40

Secondary

R

1aln

jet

76

Diaphragm

assembly

118

Crank

rod

41

Drain

plug

77

Diaphragm

spring

120

Throttle

return

spring

42

Packing

79

Ball

121

Dash

pot

assembly

43

Float

assembly

80

Valve

spring

122

Nut

44

Collar

81

Diaphragm

cover

I

I

4

6

Page 79 of 252

@

Page 80 of 252

FUEL

SYSTEM

75

s

E

u

m

c

DO

2

t

Eo

c

E

D

EEm

0

0

G

E

cac

cvu

cn

J

co

ucn

e

a

CVQ

CD

Q

c

E

C

u

0

J

oeQ

O

G

O

cQ

O

E

E

EE

g

0

E

E

Q

II

2

en

e

GJ

9

E

en

J

J

s

eJ

ctI

J

c

l

Joca

OmO

CZ

m

C

mO

NV

O

Nm

O

01

1

P

IC

lC

lC

lN

f

rr

r

tr

P

t

I

I

I

I

I

l

m

u

m

bOt

J

oCc

E

E

E

co

en

bel

3

J

ca

e

tt

tlu

3

j

31b031

31

c

G

Q

a

3

3

cuE

ca

0

0

0

0

O

Q

C

u

c3

0

I

q

COO

Ol

t

l

Q

O

ClOClOClOClOClOClOClOOlOlOlOlOl

2

DO

tlD

2

E

E

tl

cog

u

I

j

0

000

u

c

s

c

c

oooo

l

v

t

D

00000

tlD

tlD

3

f

c

0

CD

S

U

o

c

u

0

en

Q

en

Q

t

ee

o

B

c

e

cnbObO

ca

u

ca

ca

ga

C3

c

G

ccn2

ESft

EcnG

a

a

Joca

ca

J

ua

m

Jca

ca

u

ClO

ClO

CCClO

m

j

u

s

u

m

a

is

g

t

ii

E

l

1

b

en

1

t

t

iEc

c

m

cvCVQ

ccvcvCV

ca

E

co

C

C

E

caca

31

3l

m

ODO

00

3131

bel

bOcaca

caucca

UU

bO

CV

c3

cccoE

m

C

c

C

c

b

im

t

g

O

O

Z

d

M

ClOOlO

NNM

d

Ol

NM

d

NNNNNMMM

d

cvm

3

bO

u

5

cn

o

o

E

t

j

I

cn

c

z

lD

c

cn

tE

c

C

bOQ

Q

cn

C

ca

L

CQ

c

mCQcnuu

CQ

C1

Q

eC1

C1

C1

cnC1

i

E

EE

E

E

E

E

8

f

e

cn

a

c

e

e

i

e

Q

e

w8

z

d

ClOOlO

NM

ClOOlO

N

1

11

1

I

1

1

l

l

l

l

l

l

lC

lC

lC

l

and

delIcate

Therefore

do

not

attempt

to

force

It

Improper

handlmg

WIll

cau

e

dIstortIOn

10

In

assemblIng

the

bImetal

place

the

ther

mostat

cover

gaSket

gently

In

place

and

mstall

the

thermostat

cover

after

makmg

sure

that

the

lever

on

which

the

bImetal

hangs

moves

smoothly

11

After

ughtenmg

completely

bend

and

ad

Just

the

bImetal

rod

so

that

the

upSIde

of

the

bImetal

case

IS

level

withm

0

02

m

O

5mm

of

the

slIt

on

the

bImetal

rod

Be

sure

the

bImetal

rod

operates

smoothly

12

Adjust

the

choke

valve

opening

to

00709

m

1

8mm

by

bendIng

the

connecting

rod

Carburetor

Cleaning

and

Inpection

Dirt

gum

water

or

carbon

contammation

of

cntIcal

parts

IS

often

responsIble

for

unsatlsfac

tory

carburetor

performance

Careful

cleanmg

and

InspectIon

IS

therefore

essential

1

After

disassembly

submerge

all

parts

In

a

specIal

carburetor

cleaner

Be

certam

to

follow

the

mmufacrurer

s

instructions

In

usmg

the

cleaner

2

After

cleanmg

blow

all

passages

and

cast

mgs

With

compressed

aIr

Make

certam

all

parts

are

completely

dry

3

Carefully

mspect

parts

for

SIgnS

of

wear

VISIble

wear

IS

suffiCIent

cause

to

replace

a

part

4

Pay

speCIal

attentIon

to

condItIon

of

the

float

seat

and

needle

the

throttle

and

choke

shaft

bores

In

the

throttle

body

and

cover

castIngs

and

to

the

Idle

adjustIng

needles

5

Inspect

all

gaskets

to

see

IT

they

are

hard

or

bnttle

or

IT

the

edges

are

tom

or

dIstorted

It

IS

sound

practIce

to

replace

them

whenever

the

carburetor

is

dIsassembled

6

Check

the

filter

screen

for

dIrt

or

lint

If

after

cleanmg

It

IS

not

completely

clean

replace

It

7

Check

all

lInkages

for

smooth

operatIon

Correct

as

reqUIred

8

Check

operation

of

the

acceleration

pump

by

puttIng

gas

m

the

float

chamber

and

operatIng

the

throttle

lever

by

hand

Fuel

should

be

pumped

from

the

acceleration

nozzle

IT

the

unIt

IS

satlsfactory

9

Carefully

InSpect

the

dIaphragm

for

holes

or

leaks

Replace

IT

defective

il