ECO mode DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 4 of 171

inteN

j

@IP

B

Index

ENGINE

COOLING

SYSTE

l

IGNITION

SYSTE

I

FUEL

SYSTBl

CLUTCH

GEARUOX

PROPELLER

SHAFT

Id

DIFFERENTIAL

REAR

AXLE

nd

REAR

SUSPENSION

FRONT

SUSPENSION

STEERING

BRAKING

SYSTEM

ELECTRICAL

EQUIP

JENT

WIRING

JAGRA

IS

TROUBLE

SHOOTING

TIGHTENING

TORQUES

SERIES

C

30

MODEL

SUPPLEMENT

AUTOSERVlCE

DATA

CHART

PART

NA

ES

nd

ALTERNATIVES

CONVERSION

TABLES

S

15

2S

33

43

51

62

7S

83

91

9S

lOB

liB

I2S

129

51

End

of

manuir

IntroductIon

OUf

intention

in

writing

this

Manual

is

to

provide

the

reader

with

all

the

data

and

in

formation

required

to

maintain

and

repair

the

vehicle

However

it

must

be

realised

that

special

equipment

and

skills

arc

required

in

some

caseS

to

carry

out

the

work

detailed

in

the

text

and

we

do

not

recommend

that

such

work

be

attempted

unless

the

reader

possesses

the

necessary

skill

and

equipment

It

would

be

better

to

have

an

AUTHQRISED

DEALER

to

carry

out

the

work

using

the

special

tools

and

equipment

available

to

his

trained

staff

He

will

also

be

in

possession

of

the

genuine

spare

parts

which

may

be

needed

for

replacement

The

information

in

the

Manual

has

been

checked

against

that

provided

by

the

vehicle

manufacturer

and

any

peculiarities

have

been

mentioned

if

they

depart

rom

usual

work

shop

practice

A

fault

finding

and

trouble

shooting

chart

has

been

inserted

at

the

end

of

the

Manual

to

enable

the

reader

to

pin

point

faults

and

so

save

time

As

it

is

impossible

to

include

every

malfunction

only

the

more

usual

ones

have

been

included

A

composite

conversion

table

has

also

been

included

at

the

end

of

the

manual

and

we

would

recommend

that

wherever

possible

for

greater

accuracy

the

metric

system

units

are

used

Brevity

and

simplicity

have

been

our

aim

in

compiling

this

Manual

relying

on

the

number

ous

illustrations

and

clear

text

to

inform

and

instruct

the

reader

At

the

request

of

the

many

users

of

our

Manuals

we

have

slanted

the

book

towards

repair

and

overhaul

rather

than

maintenance

Although

every

care

has

been

taken

to

ensure

that

the

information

and

data

are

correct

WE

CANNOT

ACCEPT

ANY

LIABILITY

FOR

INACCURACIES

OR

OMISSIONS

OR

FOR

DAMAGE

OR

MALFUNCTIONS

ARISING

FROM

THE

USE

OF

THIS

BOOK

NO

MATTER

HOW

CAUSED

I

3

Page 22 of 171

Wear

limit

Crank

pin

journal

diameter

Max

crankpin

taper

Max

crankpin

out

of

round

Thickness

of

main

bearing

shells

0

3

mm

0

012

in

49

961

49

975

mm

1

967

1

9675

in

0

03

mm

0

012

in

0

03

mm

0

012

in

1

827

1

835

mm

0

072

0

0722

in

Main

bearing

running

clearance

0

020

0

062

mm

0

0008

0

0024

in

Max

main

bearing

running

clearance

Crankshaft

bend

limit

Material

Type

Piston

diameters

Standard

I

st

oversize

2nd

oversize

3rd

oversize

4th

oversize

5th

oversize

Width

of

ring

grooves

Top

and

second

Oil

control

Piston

running

clearance

0

12

mm

0

0047

in

0

05

mm

0

002

in

PISTONS

Cast

aluminium

Slipper

skirt

82

99

83

04

mm

3

267

3

269

in

83

22

83

27

mm

3

276

3

278

in

83

47

83

52

mm

3

286

3

288

in

83

72

83

77

mm

3

296

3

298

in

83

97

84

02

mm

3

305

3

308

in

84

47

84

52

mm

3

326

3

328

in

2

0

mm

0

08

in

4

0

mm

0

16

in

0

025

0

045

mm

0

001

0

002

in

PISTON

PIN

Pin

diameter

20

995

21

000

mm

0

8266

0

8268

in

Pin

length

72

00

72

25

mm

2

8346

2

8445

in

Pin

running

clearance

in

piston

0

008

0

010

mm

0

0003

0

0004

in

Pin

interference

fit

in

small

end

bush

0

015

0

033

mm

0

0006

0

0013

in

Piston

ring

height

Top

and

second

Oil

control

Side

clearance

in

grooves

Top

PISTON

RINGS

2

0

mm

0

08

in

4

0

mm

0

16

in

0

040

0

073

mm

0

0016

0

0029

in

Second

Oil

control

Piston

ring

gaps

Top

Second

Oil

control

Material

Distortion

of

sealing

face

Max

distortion

Valve

seat

insert

material

Inlet

Exhaust

Fit

Drive

Chain

Chain

tensioner

0

030

0

063

mm

0

0012

0

0025

in

0

025

0

063

mm

0

001

0

0025

in

0

23

0

38

mm

0

0091

0

0150

in

0

15

0

30

mm

0

006

0

012

in

0

15

0

30

mm

0

006

0

012

in

CYLINDER

HEAD

Aluminium

alloy

0

03

mm

0

0012

in

0

1

mm

0

004

in

Aluminium

bronze

Special

cast

Hot

pressed

CAMSHAFT

DRIVE

From

crankshaft

double

roller

type

Spring

and

oil

pressure

control

Engine

model

lWIN

CHOKE

CARBURE

ITOR

Outlet

diameter

Venturi

diameter

Main

jet

Main

air

bleed

Slow

running

jet

Power

jet

Float

level

Fuel

pressure

Weight

Altitude

setting

main

jet

1000

m

3300

ft

94

2000

m

6600

ft

92

3000

m

10

000

ft

89

4000

m

13

300

ft

87

5000

m

16

600

ft

85

PRIMARY

L13

SECONDARY

30mm

27x

12mm

150

90

180

26

mm

21

x

8

mm

96

80

43

40

23

I

mm

0

905

0

04

in

0

24

kg

sq

em

3

41b

sq

in

2

55

kg

5

61

lb

1

21

Page 34 of 171

Fuel

System

DESCRIPTION

FUEL

TANK

FUEL

PUMP

CARBURETTOR

IDLING

ADJUSTMENT

FAST

IDLE

OPENING

ADJUSTMENT

THROTTLE

VALVES

INTERLOCK

OPENING

DASHPOT

DESCRIPTION

The

diaphragm

type

fuel

pump

shown

in

Fig

D

1

feeds

fuel

from

the

tank

to

the

carburettor

in

a

regulated

supply

according

to

the

needs

of

the

engine

A

cartridge

type

fuel

strainer

prevents

any

dirt

from

reaching

the

pump

inlet

valve

The

carburettor

fitted

to

the

engine

is

either

a

down

draught

two

barrel

type

equipped

with

a

throttle

operated

acceleration

pump

and

power

valve

mechanism

See

Fig

D

2

or

a

twin

SU

carburettor

of

the

type

shown

in

Fig

D

3

In

the

two

barrel

type

carburettor

fuel

flows

from

the

passage

at

the

bottom

of

the

float

chamber

passes

through

the

primary

main

jet

and

mixes

with

air

introduced

through

the

main

air

bleed

screw

The

petrol

and

air

mixture

is

injected

into

the

venturi

through

the

main

nozzle

Each

time

the

accelerator

pedal

is

depressed

the

throttle

opens

and

the

accelerator

pump

forces

a

jet

of

petrol

into

the

air

stream

to

allow

the

engine

to

accelerate

smoothly

See

Fig

0

4

The

power

valve

mechanism

is

operated

automatically

according

to

the

demands

made

by

the

engine

Under

light

load

i

e

part

throttle

conditions

the

intake

manifold

depression

is

transmitted

below

the

throttle

valve

the

vacuum

pulls

a

piston

upwards

against

a

spring

and

leaves

the

power

valve

closed

allowing

additional

air

to

be

admitted

through

the

air

bleed

screw

and

thereby

weaken

the

petrol

and

air

mixture

When

the

vacuum

below

the

throttle

vaJve

is

lowered

during

full

load

conditions

the

piston

is

pushed

down

opening

the

power

valve

and

providing

additional

fuel

to

enrichen

the

mixture

The

model

HJ

L

38W6

SU

twin

carburettor

is

of

the

horizontal

variable

venturi

type

and

is

used

only

on

the

1600

and

1800

cc

engines

In

this

type

of

carburettor

a

constant

flow

of

intake

air

is

maintained

by

the

automatically

adjusted

venturi

opening

this

is

accomplished

by

the

suction

piston

sliding

in

accordance

with

changes

in

the

volume

of

intake

air

Referring

to

Fig

D

5

the

suction

chamber

is

mounted

above

the

venturi

The

suction

piston

slides

vertically

within

the

chamber

and

changes

the

venturi

opening

area

The

piston

is

operated

by

a

difference

between

the

upper

vacuum

pressure

which

is

applied

through

the

suction

poct

and

the

atmospheric

pressure

which

is

introduced

through

the

air

hole

from

the

air

cleaner

The

amount

by

which

the

throttle

is

opened

causes

the

suction

piston

to

rise

or

fall

under

the

intluence

of

the

engine

suction

The

pozzle

opening

therefore

changes

and

provides

an

optimum

air

fuel

mixture

at

all

engine

speeds

The

cartridge

type

fuel

strainer

utilizes

a

fibre

strainer

element

which

should

be

replaced

every

20

000

km

12

000

miles

Removal

of

the

fuel

strainer

is

a

simple

operation

but

as

it

cannot

be

drained

the

strainer

should

not

be

removed

when

CARBURETIOR

Removal

and

Overhaul

FLOAT

LEVEL

Adjustment

SU

TWIN

CARBURmORS

Adjustments

SU

TWIN

CARBURmORS

Dismantling

SU

TWIN

CARBURETTORS

Inspection

STARTING

INTERLOCK

VALVE

OPENING

HYDRAULIC

DAMPER

the

tank

is

full

unless

absolutely

necessary

A

viscous

paper

type

air

cleaner

element

is

fitted

which

does

not

require

cleaning

and

should

be

repl

ced

every

40

000

km

24

000

miles

The

air

cleaner

fitted

on

the

single

carburettor

is

equipped

with

an

idling

compensator

to

prevent

the

mixture

from

becoming

too

rich

at

high

idling

temperatures

Additional

fresh

air

is

introduced

into

the

inlet

manifold

by

the

action

of

a

bimettalic

strip

located

in

the

air

cleaner

When

the

temperature

under

the

bonnet

is

high

the

bimetal

is

heated

by

the

hot

inlet

air

and

lifts

to

allow

the

valve

to

open

The

idling

compensator

valve

partially

opens

at

550

I310F

and

is

fully

open

at

650C

l490F

The

unit

cannot

be

dismantled

as

it

is

pre

sealed

and

correctly

adjusted

for

valve

timing

Fig

D

6

shows

the

layout

of

the

idling

compensator

piping

FUEL

TANK

Replacing

The

fuel

tank

can

be

removed

in

the

following

manner

Remove

the

rear

seat

and

back

rest

2

Take

out

the

board

behind

the

back

rest

3

Take

out

the

luggage

compartment

lining

board

and

disconnect

the

cable

to

the

petrol

gauge

unit

4

Disconnect

the

petrol

filler

tube

from

the

tank

5

Remove

the

tank

retaining

bolts

and

disconnect

the

rubber

fuel

outlet

and

return

hoses

Installation

is

a

reversal

of

the

removal

procedure

always

ensure

that

the

fuel

lines

arc

carefully

checked

for

signs

of

damage

before

replacing

the

tank

FUEL

PUMP

Testing

Pressure

and

capacity

tests

can

be

carried

out

with

the

pump

installed

in

the

following

manner

Static

pressure

test

Disconnect

the

fuel

line

at

the

carburettor

install

an

adaptor

tee

fitting

and

suitable

pressure

gauge

to

the

fuel

line

between

carburettor

and

fuel

pump

Start

the

engine

and

run

it

at

varying

speeds

The

reading

on

the

gauge

should

be

0

18

0

24

kg

sq

cm

2

6

34

Ib

sq

in

If

the

pressure

is

below

the

specified

figure

then

either

one

part

of

the

pump

has

worn

excessively

or

general

wear

has

occured

to

all

the

working

parts

The

faults

may

include

a

ruptured

diaphragm

worn

and

warped

valves

33

Page 43 of 171

Connect

the

fuel

line

from

the

float

chamber

to

the

nozzle

nipple

and

tighten

the

retaining

clip

Pull

out

the

choke

lever

and

place

the

connecting

plaie

betw

n

the

washer

and

sleeve

collar

Screw

the

plate

to

the

nozzle

head

and

check

that

the

collar

is

installed

in

the

hole

in

the

plate

by

mo

ing

the

choke

lever

as

necessary

Recheck

the

piston

to

make

sure

that

it

falls

freely

without

binding

SU

TWIN

CARBURETTOR

Centering

the

jet

Remove

the

damper

oil

cap

nut

and

gradually

raise

the

lifter

pin

4

in

Fig

D

17

Continue

to

raise

the

lifter

pin

until

the

head

of

the

pin

raises

the

piston

by

approximately

8

mm

0

31

in

When

the

lifter

pin

is

released

the

piston

should

drop

freely

and

strike

the

venturi

with

a

light

metallic

click

If

the

pi

ston

does

not

fall

freely

it

will

be

necessary

to

dismantle

the

carburettor

in

the

manner

previously

described

SU

TWIN

CARBURETTOR

FLOAT

LEVEL

Inspection

and

Adjustment

The

fuel

level

in

the

float

chamber

can

be

checked

using

the

special

gauge

ST

19200000

Remove

the

float

chamber

drain

plug

and

install

the

special

gauge

as

shown

in

Fig

D

20

Start

the

engine

and

allow

it

to

run

at

idling

speed

The

fuel

level

is

conect

if

it

is

indicated

on

the

glass

tu

be

at

a

distance

of

22

24

mm

0

866

0

945

in

below

the

top

of

the

float

chamber

The

level

of

the

fuel

can

be

corrected

if

necessary

by

adjusting

the

float

level

in

the

following

manner

Take

out

the

float

chamber

coveT

securing

screws

and

lift

off

the

cover

and

attached

float

lever

Hold

the

cover

so

that

the

float

lev

r

is

facing

upwards

Lift

the

float

lever

and

then

lower

it

until

the

float

lever

seat

just

contacts

the

valve

stem

The

dimension

uH

in

Fig

D

1

should

be

11

12

mm

0

43

0

47

in

and

can

be

corrected

by

bending

the

float

lever

at

the

point

indicated

SU

TWIN

CARBURETTOR

Starting

interlock

valve

opening

adjustment

To

adjust

the

starting

interlock

opening

the

connecting

rod

4

in

Fig

D

22

1

must

be

bent

using

a

suitable

pair

of

pliers

The

throttle

opening

can

be

increased

by

lengthening

the

connecting

rod

or

reduced

by

shortening

the

rod

The

throttle

opening

is

correctly

adjusted

when

the

clearance

8

between

the

throttle

valve

and

throttle

chamber

is

set

to

0

6

mm

0

023

in

with

the

choke

lever

half

completely

out

HYDRAULIC

DAMPER

The

damper

oil

should

be

checked

approximately

every

5000

km

3000

miles

To

check

the

oil

level

remove

the

oil

cap

nut

as

shown

in

Fig

D

23

and

check

the

level

of

oil

against

the

two

grooves

on

the

plunger

rod

Top

up

with

SAE

20

engine

oil

if

the

oil

level

is

below

the

lower

of

the

two

grooves

Take

care

not

to

bend

the

plunger

rod

when

removing

and

replacing

the

oil

cap

nut

and

make

sure

that

the

nut

is

sufficiently

tightened

by

hand

TechnIcal

Data

Engine

Model

Ll4

I400cc

Primary

Secondary

28mm

32mm

21x7mrn

28xlOmm

96

165

60

60

I

Omm

220

100

1

6

Outlet

diameter

Venturi

diameter

Main

jet

Main

air

bleed

1

st

slow

air

bleed

2nd

slow

air

bleed

Economizer

Power

jet

Float

level

Fuel

pressure

Main

nozzle

55

22mm

0

24

kg

sq

cm

3

41b

sq

in

2

2mm

2

Smm

SU

Twin

Carburettors

Type

Bore

diameter

Piston

lift

Jet

needle

Nozzle

jet

diameter

Suction

spring

IUL

38

W6

38mm

1

4961

in

29mm

1417

in

M

76

2

34

mm

0

0921

in

No

23

Float

needle

valve

inner

diameter

Float

level

1

5mm

0

059

in

23mm

0

9055

in

42

Ll6

1600cc

Primary

Secondary

28mm

32mm

22x7mm

29xlOmm

102

165

60

60

1

0mm

180

100

1

6

Ll8

l80Occ

Primary

Secondary

30mm

34mm

23x14x7mm

30xlOmm

102

170

60

60

I

Omm

210

100

1

6

55

22mm

55

22m

2

3mm

2

5mm

2

3mm

2

8mm

Throttle

clearance

at

full

throttle

Position

at

full

throttle

0

6mm

0

0236

in

6

50

FUEL

PUMP

Type

Delivery

amount

Mechanical

1000cc

minute

at

1000

r

p

m

0

18

0

24

kg

sq

cm

2

5

3

41b

sq

in

from

eccentric

on

cam

shaft

Delivery

pressure

Drive

Page 51 of 171

other

end

of

the

tube

into

a

clean

container

partly

filled

with

brake

fluid

Top

up

the

master

cylinder

reservoir

with

recommended

fluid

and

open

the

bleed

screw

approximately

three

quarters

of

a

turn

Depress

the

clutch

pedal

slowly

and

hold

it

completely

down

re

tighten

the

bleed

screw

and

allow

the

pedal

to

return

slowly

Repeat

the

operation

until

the

fluid

emerging

from

the

tube

is

free

from

air

bubbles

It

should

be

noted

that

assistance

will

be

required

when

carrying

out

bleeding

operations

as

not

only

must

the

fluid

entering

the

glass

container

be

watched

but

also

the

clutch

pedal

has

to

be

operated

and

the

reservoir

topped

up

frequently

throughout

the

procedure

When

the

fluid

is

completely

free

from

air

bubbles

the

bleed

screw

should

be

retightened

on

a

down

stroke

of

the

pedal

Finally

remove

the

bleed

tube

and

replace

the

dust

cap

TechnIcal

Data

Outch

type

Pressure

spring

Free

length

Fitted

length

and

load

Side

distortion

Permissible

deterioration

of

spring

force

Outch

release

levers

Oearance

between

release

bearing

and

diaphragm

spring

release

levers

Height

between

diaphragm

spring

and

flywheel

Height

between

release

levers

and

flywheel

Outch

driven

plate

Outer

diameter

Inner

diameter

Thickness

of

facingS

Total

friction

area

TIrickness

of

clutch

plate

Free

Compressed

No

of

torsion

springs

Permissible

minimum

depth

of

rivet

heads

from

facing

surface

Permissible

run

out

of

clutch

facing

P

rmissible

free

play

of

splines

Outch

pedal

1400

and

1600cc

models

Pedal

height

in

the

rest

position

P

da1

free

stroke

P

da1

effort

Master

cylinder

Diameter

Maximum

clearance

between

piston

and

cylinder

Pressure

plate

Permissible

refacing

limit

Outch

pedal

180Occ

models

P

da1

height

Play

at

clevis

pin

Full

stroke

P

da1

effort

50

Diaphragm

spring

or

coil

spring

52

3mm

2

059

in

29

2mm

44

2kg

1

149

in

197

t

4

4

lb

5mm

per

IOOmm

0

2in

per

3

94

in

15

1

2

I

4mm

0

047

0

055

in

44

t

Imm

1

732

t

0

039

in

50

5

t

0

05mm

1

988

t

0

0197

in

200mm

7

87

in

130mm

5

12in

3

5mm

0

140in

362

sq

cm

56

11

sq

in

8

6

9

0mm

0

3386

o

3543in

7

65

7

95mm

0

3012

o

3130in

6

O

3mm

0

0118

in

0

5mm

0

0197

in

0

4mm

0

0157

in

182mm

7

17in

R

H

D

207mm

8

15in

L

H

D

25mm

0

984in

15kg

33

lb

15

87mm

0

625in

O

13mm

0

005lin

Imm

0

0394in

175mm

6

89in

1

5mm

0

04

0

20in

135mm

5

3lin

10

5kg

23Ib

Page 52 of 171

Gearbox

GEARBOX

Removal

GEARBOX

Dismantling

GEARBOX

Inspection

and

Overhaul

GEARBOX

Assembling

THREE

SPEED

GEARBOX

GEARCHANGE

CONTROL

Removal

and

Adjusting

AUTOMATIC

TRANSMISSION

Gearchange

control

linkage

DESCRIPTION

Three

types

of

transmission

are

available

for

the

Datsun

models

covered

by

this

manual

Either

a

three

speed

gearbox

a

four

speed

gearbox

or

three

speed

automatic

transmission

can

be

fitted

The

three

and

four

speed

gearboxes

are

equipped

with

nchromesh

on

all

forward

gears

with

the

three

speed

gearbox

operated

by

a

steering

column

gearchange

system

and

the

four

speed

gearbox

by

a

floor

mounted

gear

lever

Two

types

of

synchromesh

are

used

in

the

four

speed

gearboxes

Either

Borg

Warner

or

Servo

types

may

be

fitted

The

gearboxes

differ

only

in

the

synchromesh

devices

whereby

the

baulk

rings

synchronize

the

coupling

sleeve

with

the

main

shaft

gear

on

the

Warner

gearbox

This

action

is

accomplished

by

a

synchrcrring

on

the

servo

gearbox

THREE

SPEED

GEARBOX

Removal

I

Jack

up

the

vehicle

and

support

it

on

stands

2

Disconnect

the

hand

brake

cable

at

the

equalizer

bracket

Slacken

the

two

exhaust

pipe

centre

clamps

and

turn

the

centre

section

of

the

exhaust

assembly

to

the

left

as

shown

in

Fig

F

2

3

Disconnect

the

propeller

shaft

from

the

rear

axle

drive

flange

by

removing

the

four

securing

bolts

Seal

off

the

gearbox

extension

housing

to

prevent

the

loss

of

oil

and

withdraw

the

shaft

to

the

rear

4

Disconnect

the

speedometer

drive

cable

from

the

adaptor

in

the

gearbox

extension

housing

Fig

F3

S

Disconnect

the

lower

shift

rods

from

the

shift

levers

Fig

F

4

and

remove

the

cross

shaft

assembly

from

the

gearbox

casing

Remove

the

clutch

slave

cylinder

from

the

clutch

housing

Fig

F

5

6

Support

the

engine

with

ajack

positioned

underneath

the

oil

sump

making

sure

that

the

jack

does

not

foul

the

drain

plug

A

block

of

wood

should

be

placed

between

the

sump

and

jack

to

avoid

damaging

the

sump

7

Remove

the

bolts

securing

the

rear

engine

mounting

to

the

crossmember

Position

ajack

under

the

gearbox

and

remove

the

bolts

attaching

the

crossmember

to

the

body

Lower

the

jack

under

the

engine

so

that

the

engine

is

tilted

to

the

rear

Remove

the

starter

motor

and

the

bolts

securing

the

clutch

housing

to

the

engine

Lower

the

jack

slowly

and

withdraw

the

gearbox

towards

the

rear

of

the

vehicle

THREE

SPEED

GEARBOX

Dismantling

Drain

the

gearbox

oil

Remove

the

dust

cover

release

the

retainer

spring

and

remove

the

withdrawal

lever

complete

with

release

bearing

from

the

clutch

housing

See

section

CLUTCH

Remove

the

gearbox

bottom

cover

the

speedometer

drive

pinion

assembly

and

the

rear

extension

housing

Take

out

the

cross

shaft

retaining

rings

and

unscrew

the

nuts

securing

the

operating

lever

lock

pins

Use

a

hammer

and

punch

to

drive

out

the

pins

and

withdraw

both

cross

shafts

Fig

F

6

Remove

the

fr

mt

cover

and

withdraw

the

counter

shaft

Lift

out

the

countersbaft

gear

cluster

together

with

the

needle

roller

bearings

and

spacers

Fig

F

7

Remove

the

reverse

idler

gear

shaft

lock

bolt

and

remove

the

shaft

and

the

idler

gear

Fig

F

B

Drive

out

the

pins

securing

the

selector

forks

to

the

selector

rods

Unscrew

the

interlock

plug

and

remove

the

detent

ball

and

spring

Fig

F

9

Remove

the

first

reverse

speed

and

second

third

speed

selector

rods

and

lift

out

the

selector

forks

Withdraw

the

main

shaft

assembly

and

the

drive

shaft

assembly

from

the

gearbox

See

Fig

F

1O

and

F

11

To

dismantle

the

mainshaft

release

the

circlip

from

the

front

of

the

mainshaft

as

shown

in

Fig

F

12

and

remove

the

second

and

third

speed

synchronizer

hub

and

second

speed

gearwheel

Fig

F

13

Remove

the

circlip

securing

the

speedo

meter

drive

gear

and

withdraw

the

gear

together

with

the

ball

and

spacer

Fig

F

14

Remove

the

mainshaft

bearing

using

a

press

Hold

the

rnainshaft

reverse

gear

and

tap

the

shaft

on

a

piece

of

wood

to

release

the

reverse

gear

assembly

together

with

the

first

speed

gearwheel

GEARBOX

Inspection

and

Overhaul

Oean

all

parts

thoroughly

and

examine

the

gearbox

case

and

extension

housing

for

cracks

If

the

joint

faces

are

burred

or

pitted

it

may

be

necessary

to

replace

the

units

if

repair

cannot

be

carried

out

satisfactorily

Remove

any

adhesive

which

remains

on

the

faces

The

rear

extension

housing

bush

should

be

renewed

if

worn

unevenly

Clean

the

bearings

and

dry

with

compressed

air

taking

care

that

the

bearings

do

not

spin

Turn

the

ball

bearings

to

make

sure

that

they

run

smoothly

and

without

play

Replace

the

needle

bearings

if

worn

or

damaged

in

any

way

It

is

advisable

to

renew

the

needle

roller

bearings

after

they

have

been

installed

for

a

considerable

period

as

it

is

difficult

51

Page 64 of 171

Propeller

Shaft

and

DIfferentIaJ

DESCRIPTION

PROPELLER

SHAFT

DIFFERENTIAL

Removal

and

Dismantling

DIFFERENTIAL

Assembly

and

Adj

Jstment

DIFFERENTIAL

Installation

DIFFERENTIAL

Estate

car

and

van

TOOTH

CONTACT

PATTERN

Checking

DESCRIPTION

The

tubular

steel

propeller

shafts

are

shown

in

Fig

G

1

The

shaft

is

connected

to

the

drive

pinion

flange

by

a

yoke

flange

at

the

rear

and

to

the

transmission

output

shaft

by

a

splined

yoke

sleeve

at

the

front

The

Datsum

I800ce

station

wagon

and

van

has

a

three

section

shaft

in

contrast

to

the

two

piece

shaft

used

on

the

other

models

covered

by

this

manual

The

differential

carrier

houses

a

hypoid

bevel

gear

assembly

Although

this

manual

contains

dismantling

and

adjustment

procedures

for

the

differential

assembly

it

must

be

pointed

out

that

only

workshops

with

specialized

tools

and

equipment

will

be

able

to

carry

out

the

work

involved

PROPELLER

SHAFT

Removal

1

Release

the

hand

brake

jack

up

the

vehicle

at

the

fear

and

support

it

on

stands

2

Loosen

the

clamps

and

turn

the

pre

silencer

to

the

left

saloon

only

3

Remove

the

adjuster

nut

from

the

handbrake

cable

rear

adjuster

and

disconnect

the

left

hand

cable

Saloon

only

Remove

the

bolts

securing

the

centre

bearing

bracket

1800

cc

stati

n

wagon

4

Disconnect

the

fear

flange

from

the

rear

axle

flange

With

draw

the

propeller

shaft

to

the

rear

away

from

the

gear

box

mainshaft

Take

care

that

the

shaft

is

not

dropped

during

removal

or

the

balance

of

the

shaft

may

be

altered

5

Plug

the

gearbox

rear

extension

to

prevent

the

loss

of

oil

PROPELLER

SHAFT

Dismantling

and

Inspection

Oean

all

components

and

mark

them

before

dismantling

so

that

they

can

be

reassembled

in

their

original

positions

Correct

reassembly

is

most

important

otherwise

the

balance

of

the

shaft

may

be

affected

Remove

the

four

snap

rings

from

the

journal

assembly

and

withdraw

the

needle

bearing

cap

by

tapping

the

yoke

with

a

wooden

mallet

The

wear

on

the

spider

journal

diameter

must

not

exceed

0

15mm

0

006

in

the

standard

size

of

a

new

journal

is

14

7mm

0

579

in

Check

the

spider

seal

rings

and

replace

them

if

necessary

The

radial

backlash

of

the

sleeve

yoke

splines

to

gearbox

splines

should

not

exceed

0

5mm

0

002

in

Renew

the

sleeve

yoke

if

the

figures

are

in

excess

of

the

specified

value

E

Mount

the

shaft

between

the

centres

of

a

suitable

fixture

and

use

a

dial

gauge

to

check

that

the

run

out

of

the

shaft

does

not

exceed

0

6mm

0

024

in

at

the

centre

of

the

tubular

portion

The

shaft

can

only

be

straightened

with

a

hydraulic

press

it

is

advisable

however

to

renew

the

shaft

if

the

run

out

is

excessive

Check

that

the

dynamic

balance

of

the

shaft

does

not

exceed

15

grm

cm

0

208

oz

in

at

4000

r

p

m

PROPELLER

SHAFT

Assembly

and

11Istallation

r

Assembly

and

installation

is

a

reversal

of

the

removal

and

dismantling

procedures

not

the

following

points

Grease

the

needle

rollers

with

wheel

bearing

grease

before

placing

them

into

the

bearing

race

Lubricate

all

splines

with

gear

oil

Adjust

the

journal

radial

end

float

to

within

0

02mm

0

0008

in

using

a

suitable

snap

ring

Snap

rings

are

available

in

eight

thicknesses

from

2

00mm

0

079

in

to

2

14mm

0

084

in

and

are

colour

coded

as

detailed

in

Technical

Data

at

the

end

of

this

section

DIFFERENTIAL

Removal

Saloons

with

independent

rear

suspension

Remove

the

hand

brake

rear

cable

remove

the

propeller

shaft

and

drive

shafts

as

described

in

their

relevant

sections

2

Support

the

differential

with

ajack

and

remove

the

nuts

securing

the

differential

mounting

crossmemb

er

Fig

G

3

3

Remove

the

bolts

holding

the

differential

to

the

suspension

member

Withdraw

the

differential

and

jack

to

the

rear

4

Support

the

suspension

member

with

a

stand

to

prevent

the

mountings

from

becoming

twisted

or

damaged

DIFFERENTIAL

Dismantling

Before

dismantling

place

the

carrier

assembly

in

a

suitable

mounting

stand

or

special

stand

ST

06270001

and

carry

out

preliminary

checks

as

follows

Check

the

tooth

contact

pattern

of

the

crownwheel

and

pinion

by

applying

lead

oxide

to

three

or

four

teeth

of

the

crownwheel

Turn

the

crownwheel

several

times

to

obtain

an

impression

of

the

tooth

contact

pattern

Check

the

backlash

between

the

teeth

of

the

crownwheel

and

pinion

using

a

dial

gauge

The

backlash

should

be

within

0

10

0

20mm

0

004

0

008

in

63

Page 70 of 171

The

standard

width

of

the

side

bearings

is

20

0mm

0

7874

this

width

must

be

measured

before

attempting

to

calculate

the

thickness

of

the

adjusting

shims

Use

a

dial

gauge

and

surface

plate

to

ohtain

the

measurement

Place

a

weight

of

approximately

2

5

kg

5

5

lb

on

the

bearing

to

obtain

steady

readings

Install

the

differential

cage

assembly

in

the

carrier

Fit

the

sckcted

shims

and

O

rings

into

both

differential

side

bearing

covers

and

install

the

covers

in

the

carrier

using

the

special

tool

ST

33720000

Fig

G

16

l

Make

sure

that

the

side

bearing

outer

races

are

not

damaged

by

the

roller

Measure

the

backlash

between

the

teeth

of

the

crown

wheel

and

drive

pinion

with

a

dial

gauge

as

shown

in

Fig

G

I

Sct

the

dial

gauge

to

0

10

f

O

mm

0

004

0

008

in

I

If

the

backlash

is

less

than

the

specifIed

value

move

he

left

side

adjusting

shim

to

the

right

side

and

vice

versa

if

the

backlash

exceeds

the

specified

figure

Check

that

the

run

out

at

the

rear

of

the

crownwheel

does

not

excecd

O

OSmm

0

002

in

for

the

1800ce

model

or

O

08mm

0

003

in

for

the

1400

Check

the

drive

pinion

turning

torque

Thc

turning

torque

should

be

higher

by

I

3

kg

em

compared

with

the

turning

torque

obtained

before

fitting

the

differential

cage

in

the

carrier

The

higher

value

can

be

provided

if

necessary

by

dmnging

the

jde

cover

shims

Note

howcver

that

any

decrease

or

increase

in

the

thickncss

of

shims

wjJl

alter

tht

budlush

between

the

teeth

of

the

crownwhee1

and

pinion

Check

the

tooth

contact

pat

tern

of

the

crown

wheel

and

pinion

as

described

under

the

appropriate

heading

DIFFERENTIAL

Installation

Secure

the

differential

carrier

on

the

rear

suspension

mem

ber

using

the

four

bolts

and

washers

Fit

the

differential

mounting

member

to

thc

mounting

holes

by

pushing

it

forwards

with

a

suitable

lever

Fig

G

18

Tighten

the

nuts

to

a

torque

reading

of

8

5

kgm

61

5

Ib

ft

Tighten

the

bolts

attaching

the

gear

carrier

to

the

suspension

member

to

a

torque

reading

of

6

7

kg

36

5Ilb

ft

t

The

rcmainder

of

the

installation

operations

are

a

reversal

of

thc

removal

procedure

Fill

the

differential

with

the

correct

quantity

of

recommended

oil

DIFFERENTIAL

CARRIER

Removal

and

Dismantling

Estate

car

alld

Vanl

To

remove

the

differential

carrier

disconnect

and

remove

rhe

propeller

shaft

as

previously

described

and

remove

the

two

rear

axle

shafts

as

described

in

the

section

REAR

AXLL

With

draw

the

nuts

securing

the

differential

and

remove

the

carrier

from

the

rear

axle

Mount

the

unit

on

the

special

attachment

as

shown

in

Fig

G

19

and

carry

out

a

preliminary

check

before

dismantling

Oleck

the

tooth

contact

of

the

crownwheel

and

pinion

by

applying

lead

oxide

to

three

or

four

teeth

of

the

crownwheel

Turn

the

crown

wheel

several

times

to

obtain

an

impression

of

the

tooth

contact

pattern

Check

the

backlash

between

the

teeth

of

the

crownwheel

and

pinion

with

a

dial

gauge

Hold

the

drive

pinion

with

one

hand

and

move

the

crown

wheel

backwards

and

forwards

to

check

that

the

backlash

is

Io

ithin

thL

speL

ified

limits

Shims

and

adjusting

washers

must

bL

altered

if

the

tooth

con

tact

pattern

and

backlash

is

incorre

L

the

neL

cssary

details

for

these

operations

can

be

found

towards

the

end

of

this

section

under

the

appropriate

he

Jdjn

s

Fil1JJly

mark

the

bearing

caps

with

a

hammer

and

punch

to

ensure

correct

t1ignment

on

re

assembly

Remove

the

bearing

caps

nd

withdraw

the

differ

ntial

cage

make

a

note

of

the

left

and

right

hand

positions

so

h

Jt

the

bearing

caps

and

outer

race

can

be

re

assembled

in

their

original

positions

Withdraw

the

side

beJrings

with

the

s

cjal

puller

as

shown

in

Fig

G

20

taking

care

not

to

catch

the

edge

of

the

bearing

inner

races

Place

the

assembly

in

a

vice

and

detach

the

crownwheel

by

slackening

the

retaining

bolts

in

a

diagonal

patter

Fig

G

lf

Drive

out

th

pinion

shaft

lock

pin

from

left

to

right

using

a

suitable

punch

or

special

tool

ST

23520000

Fig

C

22

With

draw

the

pinion

shaft

and

take

out

the

pinions

side

gears

and

thrust

washers

Store

the

gears

and

thrust

washers

so

that

they

can

be

assembled

in

their

original

positions

Check

the

initial

turning

torque

of

the

drive

pinion

with

the

preload

gauge

ST

3190000

and

measure

the

height

of

the

drive

pinion

with

the

special

gauge

ST

31941000

Compare

the

figures

obtained

with

those

givcn

in

Technical

Data

at

the

end

of

this

section

Hold

the

drive

pinion

with

the

speciaJ

wrench

ST

3

J

530000

as

shown

in

Fig

C

23

and

unscrew

the

drivc

pinion

nut

then

pull

out

the

drive

pjnion

flange

Tap

the

drive

pinion

assembly

to

the

rear

with

a

plastic

mallet

and

withdraw

it

together

with

the

rear

bearing

inner

race

bearing

spacer

and

adjusting

washer

Remove

and

discard

the

oil

seal

and

withdraw

thc

front

bearing

inner

race

Drive

out

the

outer

races

of

the

front

and

rear

bearings

with

a

suitable

drift

Fig

G

25

The

drive

pinion

rear

bearing

inncr

race

can

be

removed

with

the

special

tool

ST

300310000

as

shown

in

Fig

G

24

DIFFE

l

ENTlAL

Inspection

Clean

all

components

thoroughly

and

examine

for

signs

of

wear

or

damage

Check

the

teeth

of

the

crownwhcel

and

pinion

for

scoring

and

hipping

Ii

should

be

noted

that

the

crownwhecl

and

pinion

are

supplied

as

a

matched

set

and

if

either

part

is

damaged

the

complete

set

must

be

replaced

Examine

the

inner

faces

of

the

side

gears

and

seats

on

the

differential

case

Inspect

the

bearing

races

and

rollers

and

replace

them

if

necessary

Small

defects

on

the

faces

of

the

thrust

washers

can

be

corrected

using

emery

cloth

however

if

the

clearance

between

side

gear

and

thrust

washer

exceeds

0

1

O

2mm

0

0039

0

0079

in

it

ill

be

necessary

to

replace

the

washer

Various

sizes

of

washers

are

available

and

the

thicknesses

arc

detailed

under

the

heading

DIFFERENTIA

L

GEAR

CAGE

Assembling

69

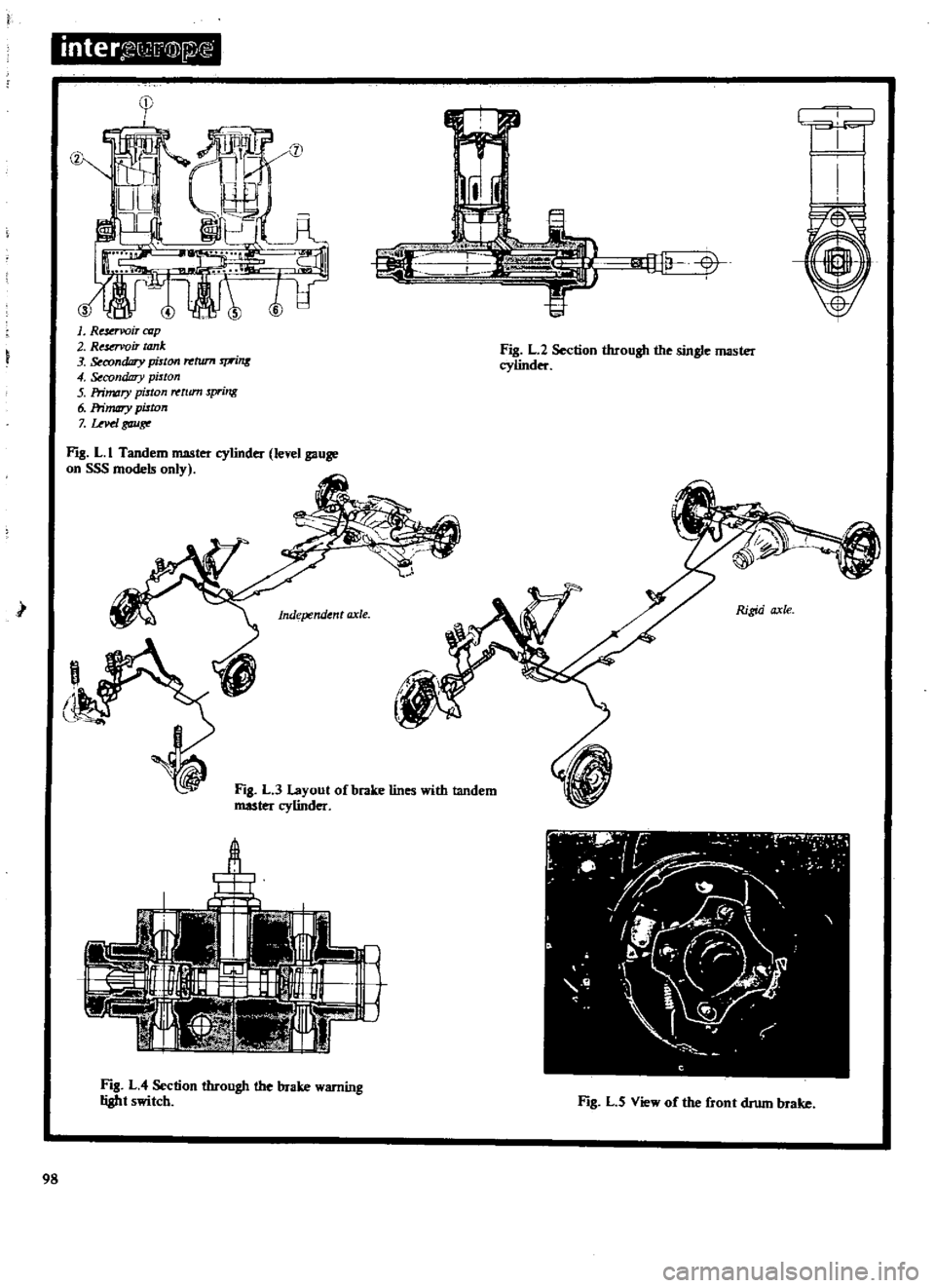

Page 99 of 171

inter

G

@lfi

r

OIl

ll

V

V

1

Re

rvoir

azp

2

Resovoir

tank

3

condDry

piston

rrtrun

rprins

4

Secondary

pitton

5

Primary

piston

tum

spring

6

Primary

piston

7

uvd

gau

Fl

L

I

Tandem

master

cylinder

level

gauge

on

SSS

models

only

Fig

L

2

Section

through

the

single

master

cylinder

I

Independent

axle

Rigid

axle

Fig

L

3

Layout

of

brake

lines

with

tandem

master

cylinder

A

Ji

I

I

f

tf

A1

r

Fig

L

4

Section

through

the

brake

warning

light

switch

Fl

L

5

View

of

the

front

drum

brake

98

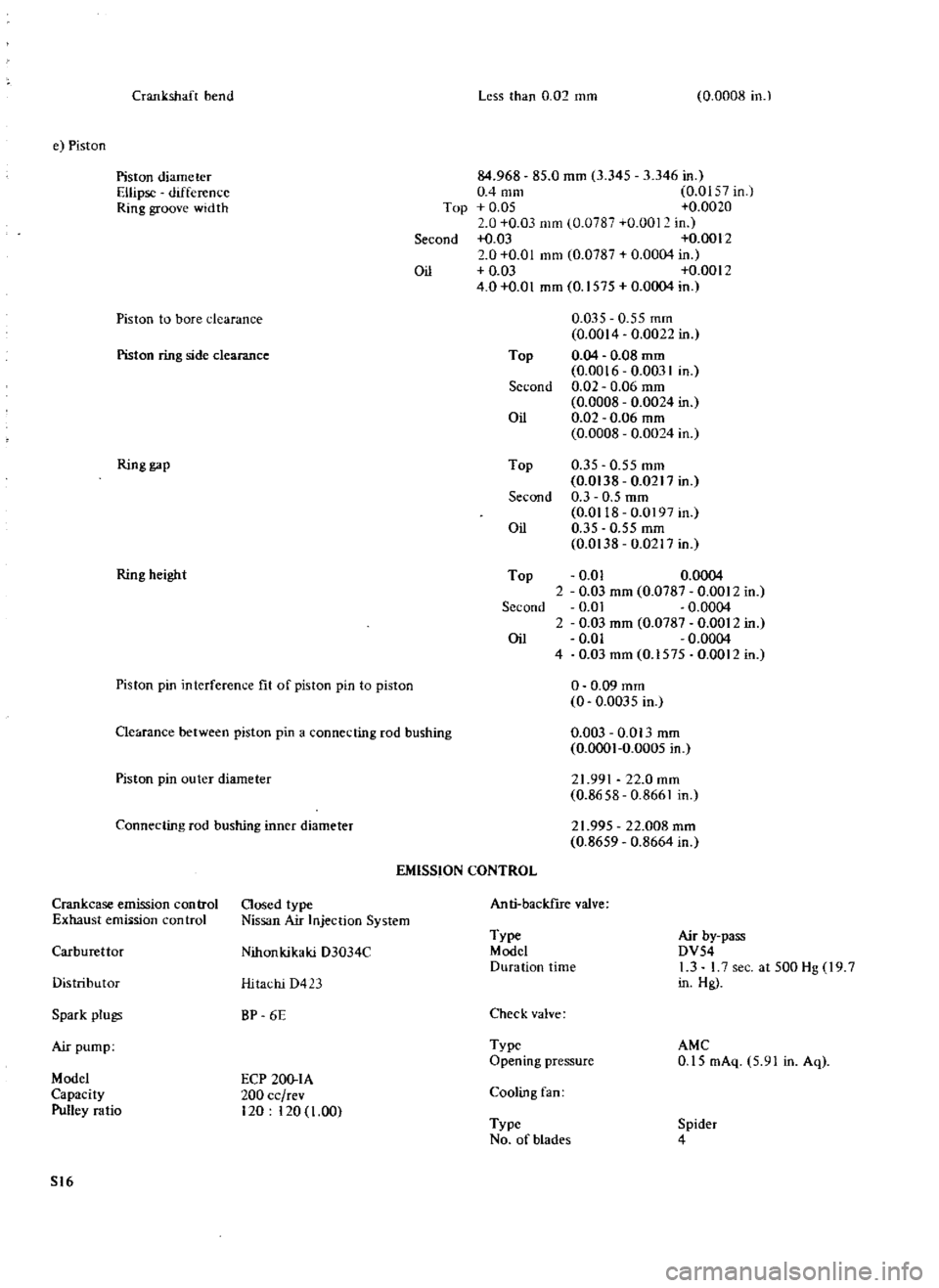

Page 147 of 171

Crank

shaf

bend

Less

than

0

02

mm

0

0008

in

e

Piston

Pis

on

diameter

Ellipse

difference

Ring

groove

wid

h

84

968

85

0

mm

3

345

3

346

in

0

4

mm

0

01

7

in

Top

0

05

0

0020

0

0

03

mm

0

0787

0

001

in

Second

I

03

0

0012

2

0

0

01

mm

0

0787

0

0004

in

Oil

0

03

0

0012

4

0

0

01

mm

0

1575

0

0004

in

Piston

ring

side

clearance

0

035

0

55

mm

0

0014

0

0022

in

Top

0

04

0

08

mID

0

0016

0

0031

in

Second

0

02

0

06

mm

0

0008

0

0024

in

Oil

0

02

0

06

mm

0

0008

0

0024

in

Piston

to

bore

clearance

Ring

gap

Top

0

35

0

55

mm

0

0138

0

0217

in

Second

0

3

0

5

mm

0

0118

0

0197

in

Oil

0

35

0

55

mm

0

0138

0

0217

in

Top

0

01

0

0004

2

0

03

mm

0

0787

0

0012

in

Second

0

01

0

0004

2

0

03

mm

0

0787

0

0012

in

Oil

0

Q1

0

0004

4

0

03mm

0

I575

0

0012in

Ring

height

Piston

pin

interferenl

c

fit

of

piston

pin

to

piston

o

0

09

mm

0

0

0035

in

0

003

0

013

mm

0

0001

0

0005

in

Clearance

between

piston

pin

a

connecting

rod

bushing

Piston

pin

outer

diameter

21

991

22

0

mm

0

8658

0

8661

in

Connecting

rod

bushing

inner

diameter

21

995

22

008

mm

0

8659

0

8664

in

EMISSION

CONTROL

Crankcase

emission

con

trol

Closed

type

Exhaust

emiision

control

Nissan

Air

Injec

ion

System

Anti

backIrre

valve

Carburettor

Nihonkikaki

D3034C

Type

Model

Duration

time

Air

by

pass

DV54

1

3

L7

sec

at

500

Hg

9

7

in

Hg

Distribu

or

Hitachi

D423

Spark

plugs

BP

6E

Check

valve

Air

pump

Type

Opening

pressure

AMC

0

15

mAq

5

91

in

Aq

Model

Capacity

Pulley

ratio

ECP

20Q

IA

200

cc

rev

120

120

1

00

Cooling

fan

Type

No

of

blades

Spider

4

S16