height DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 5 of 171

t

r

Engine

type

Ovendi

cngth

1300

L

13

Overall

width

Oyerall

height

Turning

circle

din

metres

tfeet

Supen

eded

by

Track

font

rear

1400

c

c

car

Ground

dearance

Olin

Weight

dry

I

820

808

I

Fuel

tClflk

capacity

35

29

6

150

93

Fuel

consumption

aximum

peed

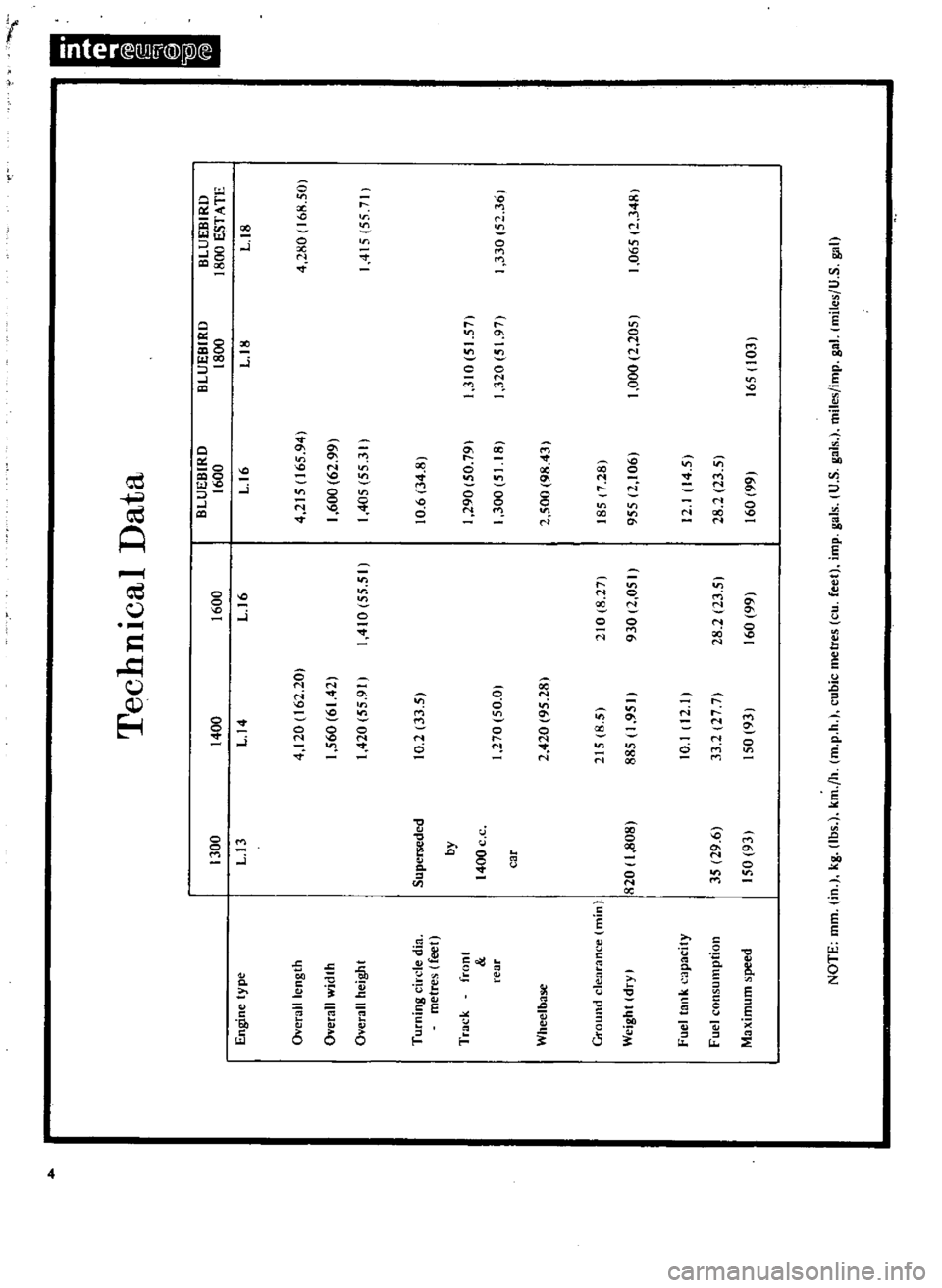

Technical

Data

BLUEBIRD

400

1600

1600

U4

U6

0

4

120

162

20

1

560

6142

410

55

51

420

55

91

10

2

33

5

270

50

0

2

420

95

281

215

8

5

885

1

950

210

8

27

930

2

050

10

1

12

33

2

27

7

50

931

28

2123

5

60

99

L

16

4

215

165

941

1

600

62

99

405

55

3

Ii

0

6

34

8

290

50

79

1

300

51

18

2

500

98

43

185

7

281

955

2

1061

12

14

5

28

2

23

5

60

991

BLUEBIRD

1800

L

18

3

0

5

57

320

5

971

000

2

2051

165

103

BLUEBIRD

1800

ESTATE

U8

4

280

168

501

4

5

557

330

52

361

1

065

2

348

Page 12 of 171

CYUNDER

HEAD

RECESS

DIAMETER

Standard

inoerts

Engine

L14

Ll6

and

Ll8

Inlet

41

000

41

016

1

6142

1

6148

in

45

000

45

016

mm

1

77l7

1

77231n

Engine

Ll4

Ll6

and

Ll8

Exhaust

37

000

37

016mm

1

4567

1

4573

in

37

000

37

016mm

l

4567

1

4573

in

CYLINDER

HEAD

RECESS

DIAMETER

Oversize

inserts

Engine

Ll4

Ll6andLl8

Inlet

41

500

41

516mm

l

6339

1

6345in

45

S00

45

516mm

I

7913

1

7920in

Engine

L14

Ll6andLl8

Exhaust

37

500

37

516mm

1

4764

14770in

37

500

37

516mm

1

4764

l4770in

Dimensions

for

the

standard

valve

inserts

are

shown

in

Fig

A

17

Heat

the

cylinder

head

to

a

temperature

of

ISO

20DOC

302

3920F

and

drive

in

the

inserts

making

sure

that

they

bed

down

correctly

The

inserts

should

be

caulked

at

more

than

four

positions

and

then

cuf

or

ground

to

the

specified

dimensions

shown

in

Fig

A

IS

Place

a

small

amount

of

fine

grinding

compound

on

the

seating

face

of

the

valve

and

insert

the

valve

into

the

valve

guide

Lap

the

valve

against

its

seat

by

rotating

it

backwards

and

forwards

approximately

half

a

revolution

in

each

direction

until

a

continous

seating

has

been

obtained

Remove

the

valve

and

clean

all

traces

of

the

grinding

compound

from

valve

and

seat

VALVE

SPRINGS

The

valve

springs

can

be

checked

for

squareness

using

a

steel

square

and

surface

plate

If

the

spring

is

out

of

square

by

more

than

1

6mm

0

063

in

it

must

be

replaced

Check

the

free

length

and

the

load

required

to

deflect

the

spring

to

its

assembled

height

Compare

the

figures

obtained

with

those

given

in

Technical

Data

and

replace

the

spring

if

the

specified

limits

are

exceeded

CAMSHAFT

AND

CAMSHAFT

BEARINGS

Checking

Measure

the

clearance

between

the

inner

diameter

of

the

camshaft

bearing

and

the

outer

diameter

of

the

camshaft

journal

If

the

wear

limit

for

the

bearing

clearance

exceeds

O

lmm

0

0039

in

it

will

be

necessary

to

replace

the

cylinder

block

assembly

See

Technical

Data

for

all

diameters

Check

the

camshaft

and

camshaft

journals

for

signs

of

wear

or

damage

ace

the

camshaft

in

V

Blocks

as

shown

in

Fig

A

19

and

position

the

dial

gauge

to

the

journal

The

run

out

of

the

cam

shaft

must

not

exceed

0

05

mm

0

0020in

It

should

be

noted

that

the

actual

run

out

will

be

half

the

the

value

indicated

on

the

dial

gauge

When

the

camshaft

is

turned

one

full

revolution

with

the

dial

gauge

positioned

against

the

second

and

third

journals

CYLINDER

BLOCK

Inspection

and

Overhaul

Ensure

that

the

cylinder

block

is

thoroughly

clean

and

check

it

for

cracks

and

flaws

Check

the

joint

face

of

the

block

for

distortion

using

a

straight

edge

and

feeler

gauge

as

shown

in

Fig

A

20

The

surface

must

be

reground

if

the

maximum

tolerance

of

O

lmm

0

0039

in

is

exceeded

Examine

the

cylinder

bores

for

out

of

round

or

taper

using

a

bore

gauge

as

shown

in

Fig

A

21

The

readings

must

be

taken

at

the

Top

middle

and

bottom

positions

indicated

in

Fig

A

22

The

standard

bore

diameters

are

83

000

83

050

rom

3

2677

3

3697

in

for

the

1400

and

1600cc

engines

and

85

000

85

050

mm

3

3465

3

3484

in

for

the

1800

cc

engine

with

a

wear

limit

of

0

2mm

0

0079

in

Out

of

round

and

taper

must

not

exceed

0

15mm

0

0006

in

If

the

bores

are

within

the

specified

limits

remove

the

carbon

ridge

at

the

top

of

the

cylinder

bores

wring

a

suitable

ridge

reamer

If

any

of

the

bores

are

in

excess

of

the

specified

limits

then

all

the

bores

must

be

rebored

at

the

same

time

Pistons

are

available

in

five

oversizes

See

Technical

Data

and

can

be

selected

in

accordance

with

the

amount

of

wear

of

the

cylinder

When

the

oversize

of

the

pistons

has

been

decided

it

will

be

necessary

to

measure

the

piston

at

the

piston

skirt

Fig

A

23

and

add

to

this

dimension

the

specified

piston

to

cylinder

bore

clearance

to

determine

the

final

honed

measurement

of

the

cylinder

Machine

the

cylinder

bores

in

gradual

stages

taking

only

a

0

5mm

0

002

in

cut

each

time

The

bores

must

be

brought

to

the

final

size

by

honing

and

the

block

thoroughly

cleaned

to

remove

all

traces

of

metal

Measure

the

finished

bore

and

check

the

clearance

between

each

piston

and

its

cylinder

The

clearance

can

be

checked

as

shown

in

Fig

A

24

with

the

aid

of

a

feeler

gauge

and

spring

scale

The

standard

clearance

is

0

023

0

043

mm

0

0009

0

0017

in

NOTE

Cylinder

liners

can

be

fitted

if

the

cylinder

bores

are

worn

beyond

the

maximum

limit

The

liners

are

an

interference

fit

in

the

block

and

must

be

bored

to

the

correct

inner

diameter

after

fitting

Three

undersize

liners

are

available

in

the

following

sizes

11

Page 14 of 171

OUTER

DIAMETER

4

0mm

0

1575

in

Undersize

4

5mm

0

1772

in

Undersize

5

Omm

0

1969

in

Undersize

87

000

87

05mm

3

4252

3

4272

in

87

50

87

55mm

3

4449

3

4468

in

88

00

88

05mm

3

4646

3

4665

in

PISTONS

Checking

Check

each

piston

for

signs

of

seizure

and

wear

Renew

BIlY

piston

which

is

unsatisfactory

Remove

all

carbon

deposits

from

the

grooves

and

piston

rings

Measure

the

side

clearance

of

each

piston

ring

and

groove

with

a

feeler

gauge

as

shown

in

Fig

A

25

If

the

side

clearance

is

excessive

new

rings

should

be

fitted

The

clearance

required

for

new

pistons

a

piston

rings

can

be

found

in

Technical

Data

Check

the

piston

ring

gap

by

placing

the

ring

in

the

cylinder

bore

as

shown

in

Fig

A

26

The

ring

can

be

squared

in

the

bore

by

pushing

it

into

position

with

the

piston

Measure

the

ring

gaps

with

a

feeler

gauge

and

compare

the

dimensions

with

the

infor

mation

given

in

Technical

Data

NOTE

If

new

piston

rings

are

to

be

fitted

and

the

cylinder

has

not

been

rebafed

check

the

piston

ring

gap

with

the

ring

positioned

at

the

bottom

of

the

cylinder

This

being

the

position

with

the

least

amount

of

wear

O1eck

the

clearance

between

gudgeon

pin

and

piston

If

the

specified

limit

is

exceeded

it

will

be

necessary

to

replace

both

piston

and

pin

It

should

be

possible

to

press

the

gudgeon

pin

into

the

piston

by

hand

at

a

room

temperature

of

200C

680F

The

pin

should

be

a

tight

press

fit

in

the

connecting

rod

CONNECTING

RODS

O1ecking

Cleck

the

connecting

rods

for

bends

or

twists

using

a

guitable

connecting

rod

aligner

The

maximum

deviation

should

not

exceed

0

05

mm

0

0020

in

per

100

mm

3

94

in

length

of

rod

Straighten

or

replace

any

rod

which

does

not

comply

with

the

specified

limit

When

replacing

the

connecting

rod

it

is

essential

to

ensure

that

the

weight

difference

between

new

and

old

rods

is

within

5

gr

0

18

oz

for

the

1400

cc

engine

and

7

gr

0

25

oz

for

the

1600

and

1800

cc

engines

Install

the

connecting

rods

with

bearings

to

the

correspond

ing

crank

pins

and

measure

the

end

play

of

the

big

ends

s

e

Fig

A

27

The

end

play

should

be

between

0

2

0

3

mm

0

0079

0

0118

in

fthe

maximum

limit

of

0

6

mm

0

Ql18

in

is

exceeded

the

connecting

rod

must

be

replaced

CRANKSHAFT

Inspection

and

Overhaul

aean

the

crankshaft

thoroughly

before

checking

the

shaft

for

distortion

and

cracks

Measure

the

journals

and

crankpins

for

our

of

round

If

the

journals

and

pins

are

found

to

be

oval

or

if

the

wear

limit

exceeds

the

specified

fUnning

clearance

it

will

be

necessary

to

re

llrind

the

crankshaft

to

the

required

undersize

See

Technical

I

INNER

DIAMETER

82

45

82

60mm

3

24613

2520

in

82

4S

82

60mm

3

24613

2520

in

82

4S

82

60mm

3

24613

2520

in

Data

Place

the

crankshaft

in

V

blocks

as

shown

in

Fig

A

28

and

check

with

the

aid

of

a

dial

gauge

that

the

shaft

bending

limit

of

0

05

mm

0

002

in

is

not

exceeded

With

the

dial

gauge

positioned

against

the

centre

journal

the

crankshaft

should

be

rotated

by

one

turn

The

actual

bend

value

will

be

a

half

of

the

reading

obtained

on

the

gauge

If

the

specified

limit

is

exceeded

it

will

be

necessary

to

replace

the

crankshaft

Install

the

crankshaft

in

the

cylinder

block

and

check

the

crankshaft

end

float

which

should

be

be

J

Yieen

0

05

0

18

mm

0

0020

0

0071

in

Make

sure

that

the

main

drive

shaft

pilot

bushing

at

the

rear

of

the

crankshaft

is

not

worn

or

damaged

in

any

way

Replace

the

bushing

if

necessary

using

the

special

puller

STl

66

1000

I

Thoroughly

clean

the

bushing

hole

before

installing

and

press

in

the

new

bushing

without

oiling

so

that

its

height

above

the

flange

end

is

4

5

5

0

mm

0

18

0

20

in

Main

bearing

clearance

The

main

bearing

clearances

can

be

checked

using

a

strip

of

plastigage

Set

the

main

bearings

on

the

caps

Cut

the

plasti

gage

to

the

width

of

the

bearing

and

place

it

along

the

crankpin

making

sure

that

it

is

clear

of

the

oil

hole

Install

the

bearing

caps

and

tighten

the

bearing

cap

bolts

to

a

torque

reading

of

4

5

5

5

kgm

33

40

Ib

ft

DO

NOT

turn

the

crankshaft

when

the

plastigage

is

inserted

Remove

the

main

bearing

cap

and

take

out

the

plastigage

which

should

be

measured

at

its

widest

po

t

with

the

scale

printed

in

the

plastigage

envelope

The

standard

clearance

is

0

020

0

062

mm

0

0008

0

0024

in

with

a

wear

limit

of

0

1

mm

0

0039

in

If

the

specified

limit

is

exceeded

an

undersize

bearing

must

be

used

and

the

crankshaft

journal

ground

accordingly

See

Technical

Data

Bearings

are

available

in

four

undersize

of

0

25

0

50

0

75

and

1

00

mm

0

0098

0

0197

0

0295

and

0

0394

in

Connecting

rod

bearing

clearance

The

connecting

rod

bearing

clearances

should

be

checked

in

a

similar

manner

to

the

main

bearing

clearances

The

standard

clearance

is

0

025

0

055

mm

0

0010

0

0022

in

with

a

wear

limit

of

0

1

mm

0

0039

in

Undersize

bearings

must

be

fitted

and

the

crankpins

reground

if

the

specified

wear

limit

is

ex

ceeded

See

Technical

Data

Bearings

are

available

in

six

under

sizes

of

0

6

0

12

0

25

0

50

0

75

and

1

00

mm

0

0236

0

0047

0

0098

0

0197

0

0295

and

0

0394

in

Fitting

the

crankshaft

bearings

Cb

eck

the

fit

of

the

bearing

shells

in

the

following

manner

Install

the

shells

on

the

main

bearing

caps

and

cylinder

block

bearing

recess

and

tighten

the

cap

bolts

to

the

specified

torque

13

Page 18 of 171

h

W

and

connecting

rod

assemblies

Use

a

piston

ring

compressor

to

install

the

pistons

through

the

top

of

the

cylbder

bore

Make

sure

that

the

pistons

and

rings

and

the

cylinder

bores

are

lubricated

with

clean

engine

oil

The

pistons

should

be

arranged

so

that

the

F

mark

faces

to

the

front

and

with

the

piston

ring

gaps

positioned

at

1800

to

each

other

Each

piston

must

be

refitted

into

its

original

bore

NOTE

Single

inlet

valve

springs

are

used

on

the

1400

cc

engine

double

valve

springs

are

used

on

the

1600cc

and

1800

cc

engines

Screw

the

valve

rocker

pivots

with

the

locknuts

into

the

pivot

bushing

Set

the

camshaft

locating

plate

and

install

the

camshaft

in

the

cylinder

head

with

the

groove

in

the

locating

plate

directed

to

the

front

of

the

engine

Install

the

camshaft

sprocket

and

tighten

it

together

with

the

fuel

pump

earn

to

a

torque

reading

of

12

16

kgm

86

116

IbJt

a

eck

that

the

camshaft

end

play

is

within

the

specified

limits

Install

the

rocker

arms

using

a

screwdriver

to

press

down

the

valve

springs

and

fit

the

valve

rocker

springs

Gean

the

joint

faces

of

the

cylinder

block

and

head

thoroughly

before

installing

the

cylinder

head

Turn

the

crank

shaft

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

and

make

sure

that

the

camshaft

sprocket

notch

and

the

oblong

groove

in

the

locating

plate

are

correctly

positioned

Care

should

be

taken

to

ensure

that

the

valves

are

clear

from

the

heads

of

the

pistons

The

crankshaft

and

camshaft

must

not

be

rotated

separately

or

the

valves

will

strike

the

heads

of

the

pistons

Temporarily

tighten

the

two

cylinder

head

bolts

1

and

2

in

Fig

A

37

to

a

torque

reading

of

2

kgm

14

5

lb

ft

Fit

the

crankshaft

sprocket

and

distributor

drive

gear

and

install

the

oil

thrower

Ensure

that

the

mating

marks

on

the

crankshaft

sprocket

face

towards

the

front

Install

the

timing

chain

making

sure

that

the

crankshaft

and

camshaft

keys

are

XJinting

upwards

The

marks

on

the

timing

chain

must

be

aligned

with

the

marks

on

the

right

hand

side

of

the

crankshaft

and

camshaft

sprockets

It

should

be

noted

that

three

location

holes

are

provided

in

the

camshaft

sprocket

See

Fig

A

38

The

camshaft

sprocket

being

set

to

the

No

2

location

hole

by

the

manufacturers

A

stretched

chain

will

however

affect

the

valve

timing

and

if

this

occurs

it

will

be

necessary

to

set

the

camshaft

to

the

No

3

location

hole

in

the

camshaft

sprocket

The

chain

can

be

checked

by

turning

the

engine

until

the

No

1

piston

is

at

T

D

C

on

its

compression

stroke

In

this

position

adjustment

will

be

required

if

the

location

notch

on

the

camshaft

sprocket

is

to

the

left

of

the

groove

on

the

camshaft

locating

plate

as

shown

in

the

illustration

The

correction

is

made

by

setting

the

camshaft

on

the

No

3

location

hole

in

the

camshaft

sprocket

the

No

3

notch

should

then

be

to

the

right

of

the

groove

and

the

valve

timing

will

have

to

be

set

using

the

No

3

timing

mark

Install

the

chain

guide

and

chain

tensioner

when

the

chain

is

located

correctly

There

should

be

no

protrusion

of

the

chain

tensioner

spindle

See

Fig

A

39

A

new

tensioner

must

be

fitted

if

the

spindle

protrudes

Press

a

new

oil

seal

into

the

timing

cover

and

fit

the

cover

into

position

using

a

new

gasket

Apply

sealing

compound

to

the

front

of

the

cylinder

block

and

to

the

gasket

and

to

the

top

of

the

timing

cover

Ensure

that

the

difference

in

height

between

the

top

of

the

timing

cover

and

the

upper

face

of

the

cylinder

block

does

not

exceed

0

15

mm

0

006

in

Two

sizes

of

timing

cover

bolts

are

used

the

size

M8

0

315

in

must

be

tightened

to

a

torque

reading

of

1

0

1

6

kgm

7

2

17

Ib

ft

and

the

size

M6

0

236

in

to

a

torque

reading

of

0

4

0

8

kgm

2

9

81b

ft

Install

the

crankshaft

pulley

and

water

pump

tighten

the

pulley

nut

to

a

torque

reading

of

12

16

kgm

86

8

115

7Ib

ft

then

set

the

No

1

piston

at

T

D

C

on

its

compression

stroke

Finally

tighten

the

cylinder

head

bolts

to

the

specified

torque

reading

in

accordance

with

the

tightening

sequence

shown

in

Fig

A

3

The

bolts

should

be

tightened

in

three

stages

as

follows

First

stage

Second

stage

Third

stage

4

kgm

28

9

lbJt

6

kgm

43

4

IbJ

t

6

5

85

kgm

47

0

61

5lb

ft

The

cylinder

head

bolts

should

be

retightened

if

necessary

after

the

engine

has

been

run

for

several

minutes

Install

the

oil

pump

and

distributor

drive

spindle

into

the

front

cover

as

described

under

Engine

Lubrication

System

r

rf

i

Install

the

fuel

pump

water

inlet

elbow

and

front

engine

slinger

Fit

the

oil

strainer

into

position

coat

the

oil

sump

gasket

with

sealing

compound

and

fit

the

gasket

and

oil

sump

to

the

cylinder

block

Tighten

the

oil

sump

bolts

in

a

diagonal

pattern

to

a

torque

reading

of

0

6

0

9

kgm

4

3

6

5

IbJt

Adjust

the

valve

clearances

to

the

specified

cold

engine

ftgures

following

the

procedures

described

under

the

appropriate

heading

Final

adjustments

will

be

carried

out

after

the

engine

has

been

assembled

completely

and

warmed

up

to

its

nonnal

temperature

Install

the

rear

engine

slinger

exhaust

manifold

and

inlet

manifold

Refit

the

distributor

and

carburettor

assemblies

as

described

in

their

relevant

sections

Install

the

fuel

pipes

and

vacuum

hose

making

sure

that

they

are

securely

cl

ped

Refit

the

thermostat

housing

thermostat

and

water

outlet

together

with

the

gasket

Bond

the

rocker

cover

gasket

to

the

rocker

cover

using

sealant

and

fit

the

rocker

cover

to

the

cylinder

head

Install

the

spark

plugs

and

connect

the

high

tension

leads

Fit

the

left

hand

engine

mounting

bracket

and

install

the

clutch

assembly

using

the

alignment

tool

ST20600000

to

fit

the

clutch

to

the

flywheel

as

described

in

the

section

ClUfCR

Lift

the

engine

away

from

the

mounting

stand

and

into

the

engine

compartment

Install

the

alternator

bracket

adjusting

bar

alternator

fan

pulley

fan

and

fan

belt

in

the

order

given

Check

the

tension

of

the

fan

belt

by

depressing

the

belt

at

a

point

midw

y

between

the

pulleys

The

tension

is

correct

if

the

belt

is

deflected

by

8

12

mm

0

3

0

4

in

under

thumb

pressure

Fit

the

right

hand

engine

mounting

bracket

the

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

Take

care

not

to

overtighten

the

oil

nIter

or

leakage

will

occur

Fill

the

engine

and

gearbox

to

the

correct

levels

with

recommended

lubricant

and

refill

the

cooling

system

Adjust

the

ignition

timing

and

carburettor

as

described

in

the

appro

priate

sections

17

Page 22 of 171

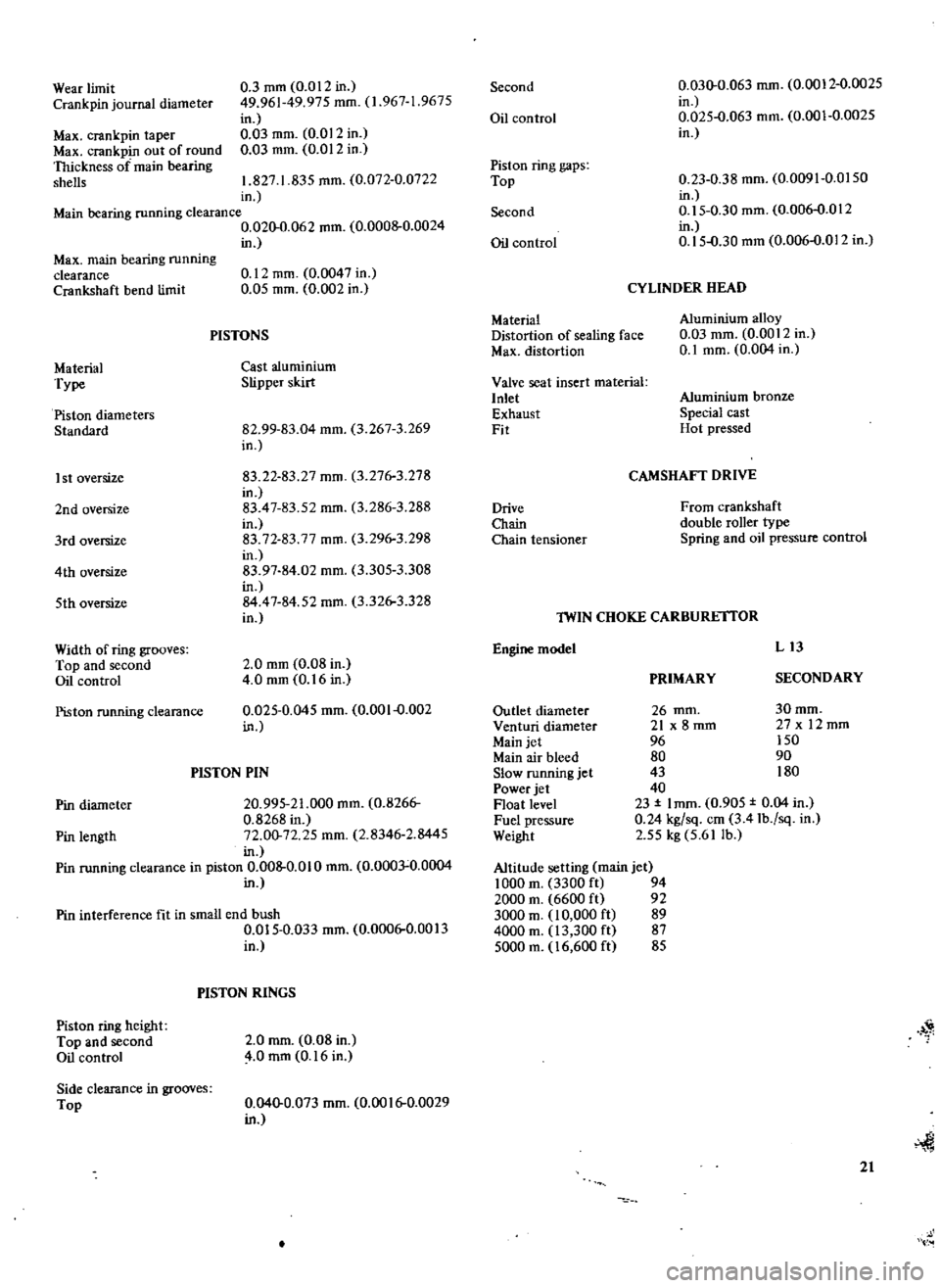

Wear

limit

Crank

pin

journal

diameter

Max

crankpin

taper

Max

crankpin

out

of

round

Thickness

of

main

bearing

shells

0

3

mm

0

012

in

49

961

49

975

mm

1

967

1

9675

in

0

03

mm

0

012

in

0

03

mm

0

012

in

1

827

1

835

mm

0

072

0

0722

in

Main

bearing

running

clearance

0

020

0

062

mm

0

0008

0

0024

in

Max

main

bearing

running

clearance

Crankshaft

bend

limit

Material

Type

Piston

diameters

Standard

I

st

oversize

2nd

oversize

3rd

oversize

4th

oversize

5th

oversize

Width

of

ring

grooves

Top

and

second

Oil

control

Piston

running

clearance

0

12

mm

0

0047

in

0

05

mm

0

002

in

PISTONS

Cast

aluminium

Slipper

skirt

82

99

83

04

mm

3

267

3

269

in

83

22

83

27

mm

3

276

3

278

in

83

47

83

52

mm

3

286

3

288

in

83

72

83

77

mm

3

296

3

298

in

83

97

84

02

mm

3

305

3

308

in

84

47

84

52

mm

3

326

3

328

in

2

0

mm

0

08

in

4

0

mm

0

16

in

0

025

0

045

mm

0

001

0

002

in

PISTON

PIN

Pin

diameter

20

995

21

000

mm

0

8266

0

8268

in

Pin

length

72

00

72

25

mm

2

8346

2

8445

in

Pin

running

clearance

in

piston

0

008

0

010

mm

0

0003

0

0004

in

Pin

interference

fit

in

small

end

bush

0

015

0

033

mm

0

0006

0

0013

in

Piston

ring

height

Top

and

second

Oil

control

Side

clearance

in

grooves

Top

PISTON

RINGS

2

0

mm

0

08

in

4

0

mm

0

16

in

0

040

0

073

mm

0

0016

0

0029

in

Second

Oil

control

Piston

ring

gaps

Top

Second

Oil

control

Material

Distortion

of

sealing

face

Max

distortion

Valve

seat

insert

material

Inlet

Exhaust

Fit

Drive

Chain

Chain

tensioner

0

030

0

063

mm

0

0012

0

0025

in

0

025

0

063

mm

0

001

0

0025

in

0

23

0

38

mm

0

0091

0

0150

in

0

15

0

30

mm

0

006

0

012

in

0

15

0

30

mm

0

006

0

012

in

CYLINDER

HEAD

Aluminium

alloy

0

03

mm

0

0012

in

0

1

mm

0

004

in

Aluminium

bronze

Special

cast

Hot

pressed

CAMSHAFT

DRIVE

From

crankshaft

double

roller

type

Spring

and

oil

pressure

control

Engine

model

lWIN

CHOKE

CARBURE

ITOR

Outlet

diameter

Venturi

diameter

Main

jet

Main

air

bleed

Slow

running

jet

Power

jet

Float

level

Fuel

pressure

Weight

Altitude

setting

main

jet

1000

m

3300

ft

94

2000

m

6600

ft

92

3000

m

10

000

ft

89

4000

m

13

300

ft

87

5000

m

16

600

ft

85

PRIMARY

L13

SECONDARY

30mm

27x

12mm

150

90

180

26

mm

21

x

8

mm

96

80

43

40

23

I

mm

0

905

0

04

in

0

24

kg

sq

em

3

41b

sq

in

2

55

kg

5

61

lb

1

21

Page 23 of 171

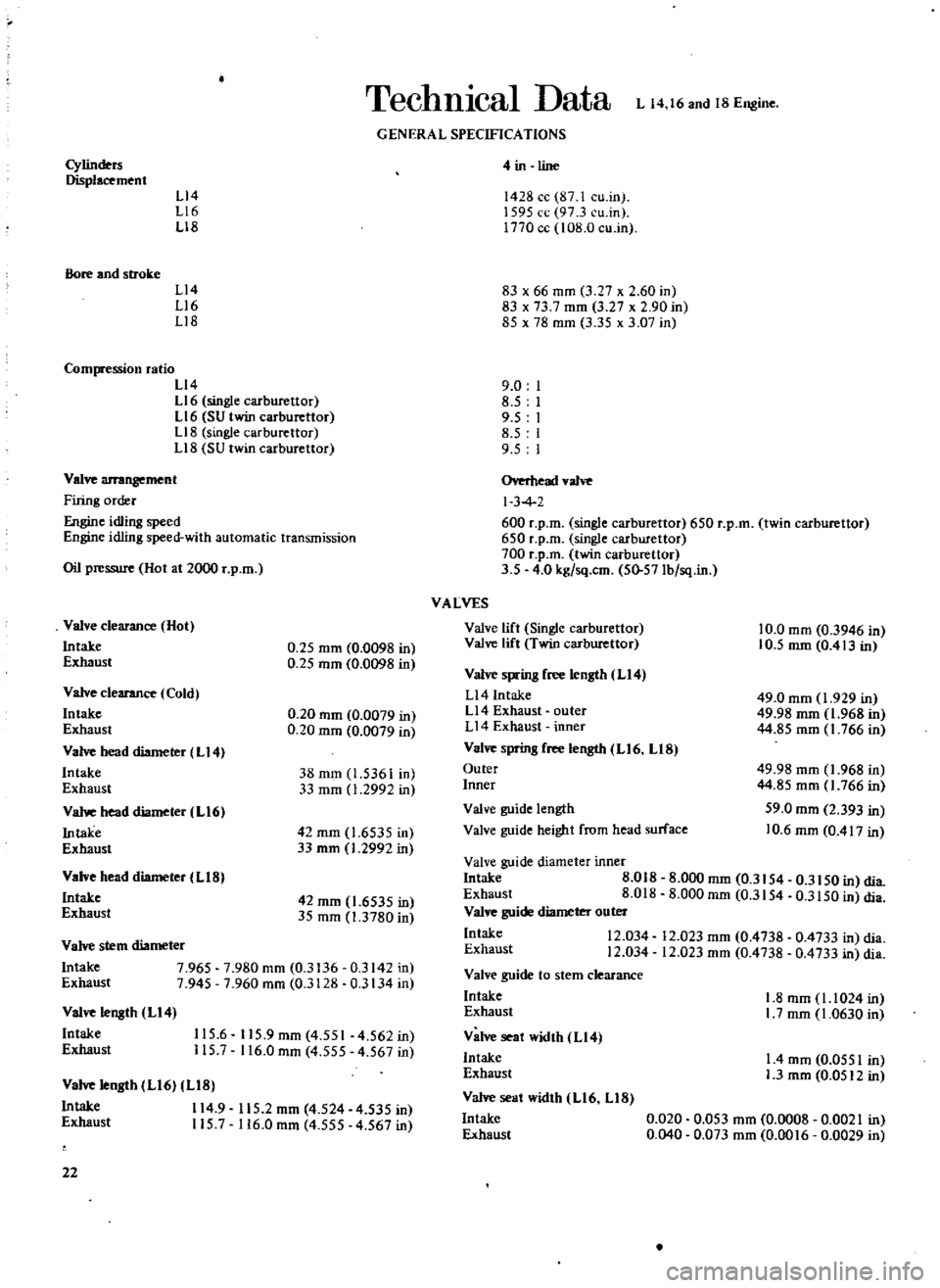

TechnIcal

Data

L

14

16

and

18

Engine

GENERAL

SPECIFICATIONS

Cylinders

Displacement

L14

L16

L18

Bore

and

stroke

L14

L16

Ll8

Compression

ratio

L14

L16

single

carburettor

L16

SU

twin

carburettor

L18

single

carburettor

Ll8

SU

twin

carburettor

Valve

arrangement

Firing

order

e

idling

speed

Engine

idling

speed

with

automatic

transmission

Oil

pressure

Hot

at

2000

r

p

m

Valve

clearance

Hot

Intake

Exhaust

0

25

mm

0

0098

in

0

25

mm

0

0098

in

Valve

clearance

Cold

Intake

Exhaust

Va

head

diameter

L14

Intake

Exhaust

Vahoe

head

diameter

L16

Intake

Exhaust

0

20

mm

0

0079

in

0

20

mm

0

0079

in

38

mm

1

5361

in

33

mm

1

2992

in

42

mm

1

6535

in

33

rom

1

2992

in

Valve

head

diameter

L18

Intake

Exhaust

42

mm

1

6535

in

35

mm

1

3780

in

Valve

stem

diameter

Intake

7

965

7

980

mm

0

3136

0

3142

in

Exhaust

7

945

7

960

mm

0

3128

0

3134

in

Valve

length

L14

Intake

Exhaust

115

6

115

9mm

4

551

4

562in

115

7

116

0

mm

4

555

4

567

in

Valve

length

L16

LIB

Intake

114

9

115

2

mm

4

524

4

535

in

Exhaust

115

7

116

0

mm

4

555

4

567

in

22

4

in

line

1428

cc

87

1

cu

in

1595

cc

97

3

cu

in

1770

cc

108

0

cu

in

83

x

66

mm

3

27

x

2

60

in

83

x

73

7

mm

3

27

x

2

90

in

85

x

7B

mm

3

35

x

3

07

in

9

0

8

5

9

5

8

5

9

5

Overhead

valve

I

3

4

600

r

p

m

single

carburettor

650

r

p

m

twin

carburettor

650

r

p

m

single

carburettor

700

r

p

m

twin

carburettor

3

5

4

0

kg

sq

cm

50

57Ib

sq

in

VALVES

Valve

lift

Single

carburettor

Valve

lift

Twin

carburettor

10

0

mm

0

3946

in

10

5

mm

0

413

in

Valve

spring

free

length

LI4

Ll4

Intake

Ll4

Exhaust

outer

L14

Exhaust

inner

Valve

sprin8

free

length

L16

LIB

Outer

Inner

49

0

mm

1

929

in

49

98

mm

1

968

in

44

85

mm

1

766

in

49

98

mm

1

968

in

44

85

mm

1

766

in

59

0

mm

2

393

in

10

6

mm

0

417

in

Valve

guide

length

Valve

guide

height

from

head

surface

Valve

guide

diameter

inner

Intake

8

018

Exhaust

8

018

Valve

guide

diameter

outer

Intake

12

034

Exhaust

12

034

Valve

guide

to

stem

clearance

Intake

Exhaust

Valve

seat

width

L14

Intake

Exhaust

Valve

seat

width

L16

LIB

Intake

Exhaust

8

000

mm

0

3154

0

3150

in

clia

8

000

mm

0

3154

0

3150

in

clia

12

023

mm

0

4738

0

4733

in

clia

12

023

mm

0

4738

0

4733

in

clia

1

8

mm

1

1024

in

I

7

mm

1

0630

in

I

4

mm

0

0551

in

1

3

mm

0

0512

in

0

020

0

053

mm

0

0008

0

0021

in

0

040

0

073

mm

0

0016

0

0029

in

Page 25 of 171

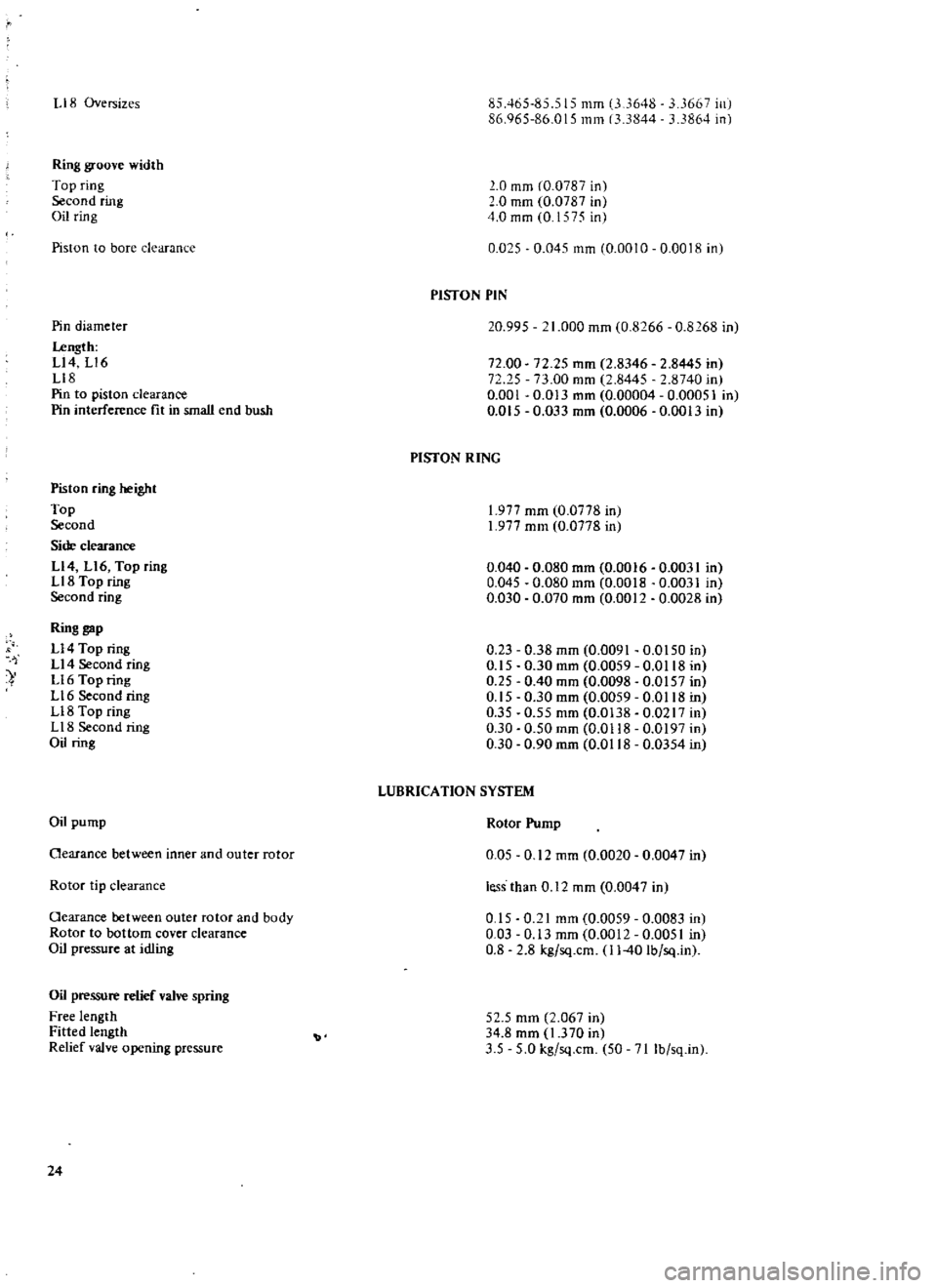

liB

Oversizes

Ring

groove

width

Top

ring

Second

ring

Oil

ring

Piston

to

bore

clearanl

e

Pin

diameter

I

ength

Ll4

Ll6

Ll8

Pin

to

piston

clearance

Pin

interference

fit

in

small

end

bush

Piston

ring

height

Top

Second

Side

clearance

Ll4

Ll6

Top

ring

LI8

Top

ring

Second

ring

Ring

gap

U4

Top

ring

U4

Second

ring

Ll6

Top

ring

L

16

Second

ring

U8

Top

ring

U8

Second

ring

Oil

ring

Oil

pump

Oearance

between

inner

and

outer

rotor

Rotor

tip

clearance

Oearance

between

outer

rotor

and

body

Rotor

to

bottom

cover

clearance

Oil

pressure

at

idling

Oil

pressure

relief

valve

spring

Free

length

Fitted

length

Relief

valve

opening

pressure

24

85465485

515

mm

3

648

667

ill

86

065

86

015

mm

13

3844

33864

in

0

mm

CO

0787

in

0

mm

0

0787

in

4

0

mm

0

1

q

c

in

0

025

0

045

mm

0

0010

0

0018

in

PISTON

PIN

20

995

1

000

mm

0

8266

0

8168

in

72

00

72

25

0

001

0

Dl5

72

25

mm

2

8346

2

8445

in

73

00

mm

2

8445

2

8740

in

0

013

mm

0

00004

0

00051

in

0

033

mm

0

0006

0

0013

in

PISTON

RING

1

977

mm

0

0778

in

1

977

mm

0

0778

in

0

040

0

080

mm

0

0016

0

0031

in

0

045

0

080

mm

0

0018

0

0031

in

0

030

0

070

mm

0

0012

0

0028

in

0

23

0

38

mm

0

0091

0

0150

in

0

15

0

30

mm

0

0059

0

0118

in

0

25

0

40

mm

0

0098

0

0157

in

0

15

0

30

mm

0

0059

0

0118

in

0

35

0

55

mm

0

0138

0

0217

in

0

30

0

50mm

0

0118

0

0197

in

0

30

0

90

mm

0

0118

0

0354

in

LUBRICATION

SYSTEM

Rotor

Pump

0

05

0

12

mm

0

0020

0

0047

in

less

than

0

12

mm

0

0047

in

0

15

0

21

mm

0

0059

0

0083

in

0

03

0

13

mm

0

0012

0

0051

in

0

8

2

8

kg

sq

cm

11

40

Ib

sq

ln

52

5

mm

2

067

in

34

8

mm

1

370

in

3

5

5

0

kg

sq

cm

50

71

Ib

sq

ln

Page 28 of 171

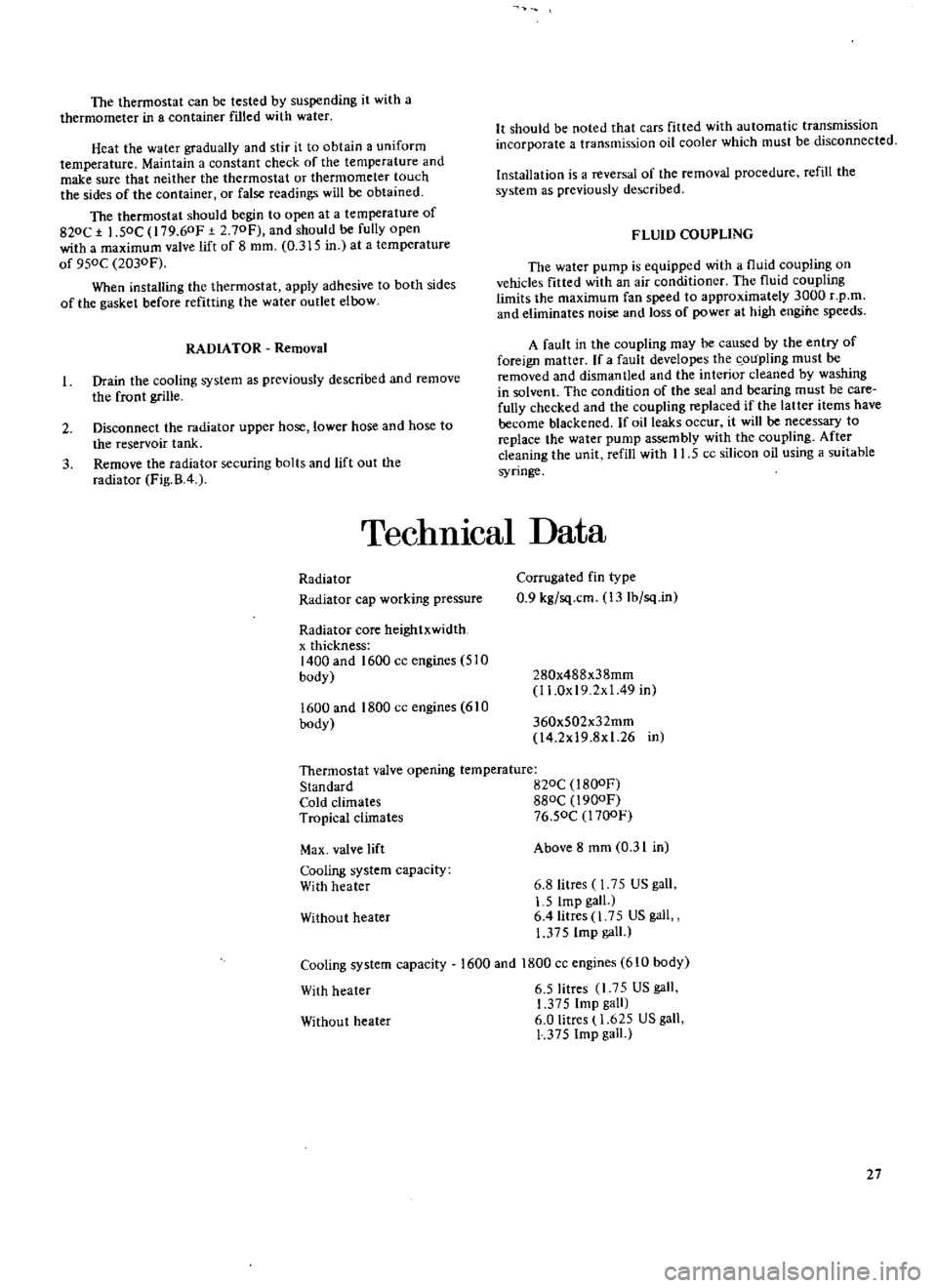

The

thermostat

can

be

tested

by

suspending

it

with

a

thermometer

in

a

container

ftlled

with

water

Heat

the

water

gradually

and

stir

it

to

obtain

a

uniform

temperature

Maintain

a

constant

check

of

the

temperature

and

make

sure

that

neither

the

thermostat

or

thermometer

touch

the

sides

of

the

container

or

false

readings

will

be

obtained

The

thermostat

should

begin

to

open

at

a

temperature

of

820C

1

50C

179

60F

2

70Fj

and

should

be

fully

open

with

a

maximum

valve

lift

of

8

mm

0

315

in

at

a

temperature

of

950C

2030F

When

installing

the

thermostat

apply

adhesive

to

both

sides

of

the

gasket

before

refitting

the

water

outlet

elbow

RADIATOR

Removal

Drain

the

cooling

system

as

previously

described

and

remove

the

front

grille

2

Disconnect

the

radiator

upper

hose

lower

hose

and

hose

to

the

reservoir

tank

3

Remove

the

radiator

securing

bolts

and

lift

out

the

radiator

Fig

B

4

It

should

be

noted

that

cars

fitted

with

automatic

transmission

incorporate

a

transmission

oil

cooler

which

must

be

disconnected

Installation

is

a

reversal

of

the

removal

procedure

refill

the

system

as

previously

described

FLUID

COUPLING

The

water

pump

is

equipped

with

a

fluid

coupling

on

vehicles

fitted

with

an

air

conditioner

The

fluid

coupling

Limits

the

maximum

fan

speed

to

approximately

3000

r

p

ro

and

eliminates

noise

and

loss

of

power

at

high

engine

speeds

A

fault

in

the

coupling

may

be

caused

by

the

entry

of

foreign

matter

If

a

fault

developes

the

oupling

must

be

removed

and

dismantled

and

the

interior

cleaned

by

washing

in

solvent

The

condition

of

the

seal

and

bearing

must

be

care

fully

checked

and

the

coupling

replaced

if

the

latter

items

have

become

blackened

If

oil

leaks

occur

it

will

be

necessary

to

replace

the

water

pump

assembly

with

the

coupling

After

cleaning

the

unit

refill

with

11

5

cc

silicon

oil

using

a

suitable

syringe

TechnIcal

Data

Radiator

Radiator

cap

working

pressure

Radiator

core

heightxwidth

x

thickness

1400

and

1600

cc

engines

510

body

1600

and

1800

cc

engines

610

body

Corrugated

fin

type

0

9

kg

sq

cm

13Ib

sq

in

280x488x38mm

I

LOx

19

2x

1

49

in

360x502x32mm

l4

2x19

8x1

26

in

Thermostat

valve

opening

temperature

Standard

B20C

l

BOOF

Cold

climates

880C

1900F

Tropical

climates

76

50C

l700F

Max

valve

lift

Cooling

system

capacity

With

heater

Without

heater

Cooling

system

capacity

With

heater

Above

8

mm

0

31

in

6

8litres

1

75

US

gall

1

5

Imp

gall

6

4litres

1

75

US

gall

1

375

Imp

gall

1600

and

1800

cc

engines

610

body

6

5litres

l

7

US

gall

1

375

Imp

gall

6

0

Iitres

1

625

US

gall

1

375

Imp

gall

Without

heater

27

Page 44 of 171

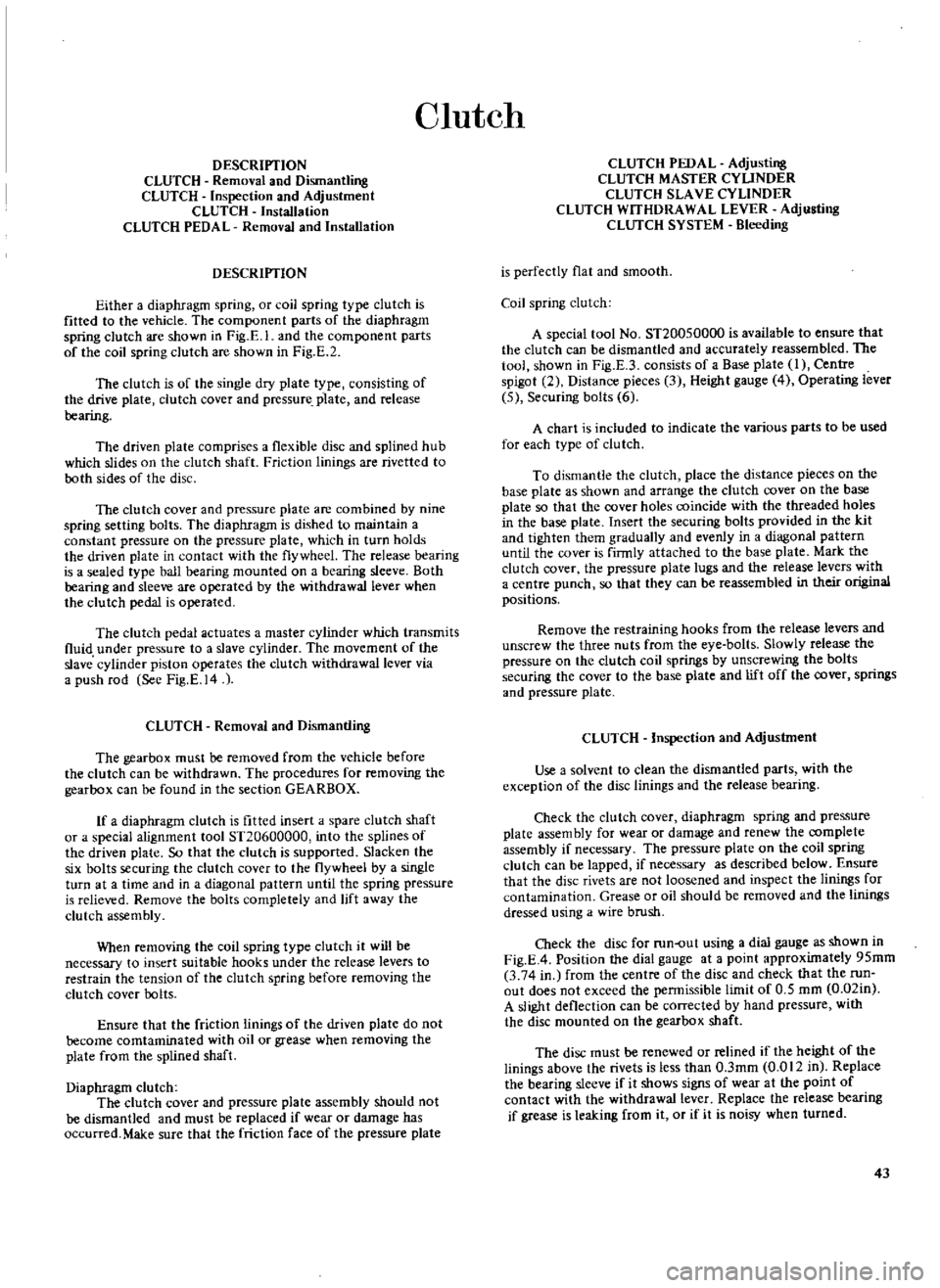

Clutch

DESCRIPTION

CLUTCH

Removal

and

Dismantling

CLUTCH

Inspection

and

Adjustment

CLUTCH

Installation

CLUTCH

PEDAL

Removal

and

Installation

DESCRIPTION

Either

a

diaphragm

spring

or

coil

spring

type

clutch

is

fitted

to

the

vehicle

The

component

parts

of

the

diaphragm

spring

clutch

are

shown

in

Fig

E

l

and

the

component

parts

of

the

coil

spring

clutch

are

shown

in

Fig

E

2

The

clutch

is

of

the

single

dry

plate

type

consisting

of

the

drive

plate

clutch

coveT

and

pressure

plate

and

release

bearing

The

driven

plate

comprises

a

flexible

disc

and

splined

hub

which

slides

on

the

clutch

shaft

Friction

linings

are

rivetted

to

both

sides

of

the

disc

The

clutch

cover

and

pressure

plate

are

combined

by

nine

spring

setting

bolts

The

diaphragm

is

dished

to

maintain

a

constant

pressure

on

the

pressure

plate

which

in

turn

holds

the

driven

plate

in

contact

with

the

flywheel

The

release

bearing

is

a

sealed

type

ball

bearing

mounted

on

a

bearing

sleeve

Both

bearing

and

sleeve

are

operated

by

the

withdrawalleveT

when

the

clutch

pedal

is

operated

The

clutch

pedal

actuates

a

master

cylinder

which

transmits

fluid

under

pressure

to

a

slave

cylinder

The

movement

of

the

slave

cylinder

piston

operates

the

clutch

withdrawal

lever

via

a

push

rod

See

Fig

E

14

CLUTCH

Removal

and

Dismantling

The

gearbox

must

be

removed

from

the

vehicle

before

the

clutch

can

be

withdrawn

The

procedures

for

removing

the

gearbox

can

be

found

in

the

section

GEARBOX

If

a

diaphragm

clutch

is

fitted

insert

a

spare

clutch

shaft

or

a

special

alignment

tool

ST20600000

into

the

splines

of

the

driven

plate

So

that

the

dutch

is

supported

Slacken

the

six

bolts

securing

the

clutch

cover

to

the

flywheel

by

a

single

turn

at

a

time

and

in

a

diagonal

pattern

until

the

spring

pressure

is

relieved

Remove

the

bolts

completely

and

lift

away

the

clutch

assembly

When

removing

the

coil

spring

type

clutch

it

will

be

necessary

to

insert

suitable

hooks

under

the

release

levers

to

restrain

the

tension

of

the

clutch

spring

before

removing

the

clutch

cover

lx

llts

Ensure

that

the

friction

linings

of

the

driven

plate

do

not

become

comtaminated

with

oil

or

grease

when

removing

the

plate

from

the

splined

shaft

Diaphragm

clutch

The

clutch

cover

and

pressure

plate

assembly

should

not

be

dismantled

and

must

be

replaced

if

wear

or

damage

has

occurred

Make

sure

that

the

friction

face

of

the

pressure

plate

CLUTCH

PEDAL

Adjusting

CLUTCH

MASTER

CYLINDER

CLUTCH

SLAVE

CYLINDER

CLUTCH

WITHDRAWAL

LEVER

Adjusting

CLUTCH

SYSTEM

Bleeding

is

perfectly

flat

and

smooth

Coil

spring

clutch

A

special

tool

No

ST200S0000

is

available

to

ensure

that

the

clutch

can

be

dismantled

and

accurately

reassembled

The

tool

shown

in

Fig

E

3

consists

of

a

Base

plate

I

Centre

spigot

2

Distance

pieces

3

Height

gauge

4

Operating

lever

5

Securing

bolts

6

A

chart

is

included

to

indicate

the

various

parts

to

be

used

for

each

type

of

clutch

To

dismantle

the

clutch

place

the

distance

pieces

on

the

base

plate

as

shown

and

arrange

the

clutch

cover

on

the

base

plate

so

that

the

cover

holes

coincide

with

the

threaded

holes

in

the

base

plate

Insert

the

securing

bolts

provided

in

the

kit

and

tighten

them

gradually

and

evenly

in

a

diagonal

pattern

until

the

cover

is

firmly

attached

to

the

base

plate

Mark

the

clutch

cover

the

pressure

plate

lugs

and

the

release

levers

with

a

centre

punch

so

that

they

can

be

reassembled

in

their

original

positions

Remove

the

restraining

hooks

from

the

release

levers

and

unscrew

the

three

nuts

from

the

eye

bolts

Slowly

release

the

pressure

on

the

clutch

coil

springs

by

unscrewing

the

bolts

securing

the

cover

to

the

base

plate

and

lift

off

the

cover

springs

and

pressure

plate

CLUTCH

Inspection

and

Adjustment

Use

a

solvent

to

clean

the

dismantled

parts

with

the

exception

of

the

disc

linings

and

the

release

bearing

Check

the

clutch

cover

diaphragm

spring

and

pressure

plate

assembly

for

wear

or

damage

and

renew

the

complete

assembly

if

necessary

The

pressure

plate

on

the

coil

spring

clutch

can

be

lapped

if

necessary

as

described

below

Ensure

that

the

disc

rivets

are

not

loosened

and

inspect

the

linings

for

contamination

Grease

or

oil

should

be

removed

and

the

linings

dressed

using

a

wire

brush

Check

the

disc

for

run

ut

using

a

dial

gauge

as

shown

in

Fig

E

4

Position

the

dial

gauge

at

a

point

approximately

9Smm

3

74

in

from

the

centre

of

the

disc

and

check

that

the

run

out

does

not

exceed

the

permissible

limit

of

0

5

mm

0

02in

A

slight

deflection

can

be

corrected

by

hand

pressure

with

the

disc

mounted

on

the

gearbox

shaft

The

disc

must

be

renewed

or

relined

if

the

height

of

the

linings

above

the

rivets

is

less

than

0

3mm

0

012

in

Replace

the

bearing

sleeve

if

it

shows

signs

of

wear

at

the

point

of

contact

with

the

withdrawal

lever

Replace

the

release

bearing

if

grease

is

leaking

from

it

or

if

it

is

noisy

when

turned

43

Page 46 of 171

The

coil

spring

clutch

pressure

plate

can

be

lapped

with

a

surface

grinder

to

remove

dents

or

scratches

only

the

minimum

amount

of

metal

should

be

removed

to

restore

the

surface

Check

the

plate

for

distortion

by

placing

it

on

a

surface

plate

with

the

friction

face

towards

the

surface

plate

Press

the

pressure

plate

down

and

insert

a

feeler

gauge

of

1

0mm

0

0039

in

between

the

pressure

plate

and

surface

plate

If

it

is

possible

to

insert

the

feeler

gauge

then

the

pressure

plate

must

be

repaired

or

replaced

The

plate

can

be

skimmed

but

the

maximum

amount

of

metal

that

can

be

removed

is

1

0mm

0

0039in

CLUTCH

SPRING

Diaphragm

clutch

With

the

diaphragm

spring

assembled

to

the

pressure

plate

inspect

the

spring

height

and

load

in

the

following

manner

Place

distance

pieces

of

7

8

mm

0

307

in

on

the

base

plate

as

shown

in

Fig

E

3

and

bolt

down

the

clutch

cover

using

the

special

bolts

provided

with

the

kit

Meas

Jre

the

height

B

in

Fig

E

5

at

a

diameter

of

44mm

1

732

in

The

release

fingers

should

not

exceed

a

height

of

43

45

mm

1

693

1

772

in

from

the

base

plate

Replace

the

spring

if

the

height

is

in

excess

of

the

figures

quoted

Press

the

dutch

down

as

shown

in

Fig

E

6

to

a

depth

of

7

8mm

0

307

in

or

until

the

clutch

driven

plate

upper

surface

lines

up

with

the

clutch

cover

mounting

face

If

the

load

applied

is

less

than

350

kg

770

lbs

it

will

be

necessary

to

renew

the

diaphragm

spring

Do

not

press

the

clutch

disc

down

by

more

than

9mm

0

35

in

or

the

diaphragm

spring

may

be

broken

CLUTCH

SPRINGS

Coil

spring

clutch

The

clutch

springs

must

be

replaced

as

a

set

if

any

of

the

springs

are

found

to

be

defective

Specifications

for

the

springs

are

given

in

Technical

Data

at

the

end

of

this

section

Generally

a

spring

may

be

considered

faulty

if

when

assembled

the

load

is

reduced

by

more

than

15

or

if

the

free

length

has

altered

by

more

than

1

5mm

0

0590

in

or

if

the

deflection

B

to

A

in

Fig

E

7

exceeds

5mm

per

100mm

0

2

in

per

3

94

in

Release

Bearing

The

release

bearing

should

be

renewed

if

excessively

worn

or

if

roughness

can

be

felt

when

the

bearing

is

turned

by

hand

The

bearing

should

also

be

renewed

if

the

grease

has

leaked

away

or

if

the

clearance

between

the

clutch

cover

and

inner

diameter

of

the

sleeve

is

more

than

0

5

mm

0

0197

in

The

bearing

can

be

removed

using

a

conventional

puller

as

shown

in

Fig

E

8

Two

types

of

release

bearings

are

available

and

care

must

be

taken

when

fitting

onto

the

bearing

sleeve

The

release

bearing

should

be

pressed

into

place

on

the

diaphragm

spring

type

of

clutch

with

a

force

of

400

kg

880

lbs

applied

at

the

outer

race

as

shown

in

Fig

E

9

On

the

coil

spring

clutch

the

same

force

must

be

applied

at

the

inner

race

as

shown

in

Fig

E

IO

It

should

be

possible

to

turn

the

bearing

freely

and

smoothly

when

it

is

pressed

into

place

CLUTCH

Assembly

Coil

spring

type

Press

the

pin

into

the

eyebolt

and

through

the

lug

on

the

pressure

plate

Place

the

three

distance

pieces

on

the

surface

of

the

base

plate

of

the

special

tool

ST20050000

and

position

the

pressure

plate

pressure

springs

and

retainers

on

the

plate

Set

the

retracting

springs

on

the

cover

and

insert

the

release

levers

through

the

spring

Place

the

clutch

cover

over

the

pressure

plate

and

springs

making

sure

that

the

retracting

springs

do

not

become

dislodged

or

distorted

Compress

the

pressure

springs

by

screwing

the

special

set

bolts

into

the

holes

in

the

cover

Tighten

the

bolts

gradually

in

a

diagonal

pattern

to

avoid

distorting

the

cover

Place

the

release

levers

on

the

eye

bolts

and

screw

OR

the

securing

nuts

Place

retaining

hooks

under

the

release

levers

and

remove

the

clutch

assembly

from

the

base

plate

slackening

the

set

bolts

in

a

diagonal

pattern

COIL

SPRING

CLUTCH

Adjusting

Screw

the

centre

pillar

into

the

base

plate

and

place

the

high

finger

over

the

pillar

The

height

of

the

release

levers

must

be

adjusted

by

turning

the

eye

bolt

nuts

until