service DATSUN B110 1973 Service Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 241 of 513

INSPECTION

Referring

to

the

wiring

diagram

check

the

wiring

harness

for

connection

with

electrical

equipment

and

connector

for

conned

ion

and

installation

When

checking

the

wiring

harness

note

the

following

matters

Connected

unit

should

not

be

loose

rusted

or

contaminated

2

Cable

insulator

cover

should

not

be

damaged

crack

ed

or

insulating

material

should

not

be

deteriorated

3

For

those

parts

which

are

grounded

through

the

installation

bolts

the

bolts

should

be

in

contact

with

the

body

completely

so

that

continuity

is

provided

in

between

the

body

and

bolts

4

Terminals

of

unit

through

which

current

flows

should

not

come

into

contact

with

other

metal

parts

5

No

erroneous

connection

should

be

present

DESCRIPTION

When

an

overcunent

exceeding

the

rated

amperage

flows

to

a

circuit

the

fuse

is

heated

and

melted

the

circuit

is

interrupted

and

thus

cables

and

electrical

equipment

are

protected

from

damaging

due

to

burning

or

damaging

is

limited

to

the

minimum

This

vehicle

is

equipped

with

six

fuses

and

one

fusible

link

The

fuses

are

located

in

the

fuse

box

and

used

to

protect

illumination

signal

and

other

systems

and

the

fusible

link

is

adopted

in

the

cable

between

the

battery

and

alternator

to

protect

the

charging

and

starting

circuits

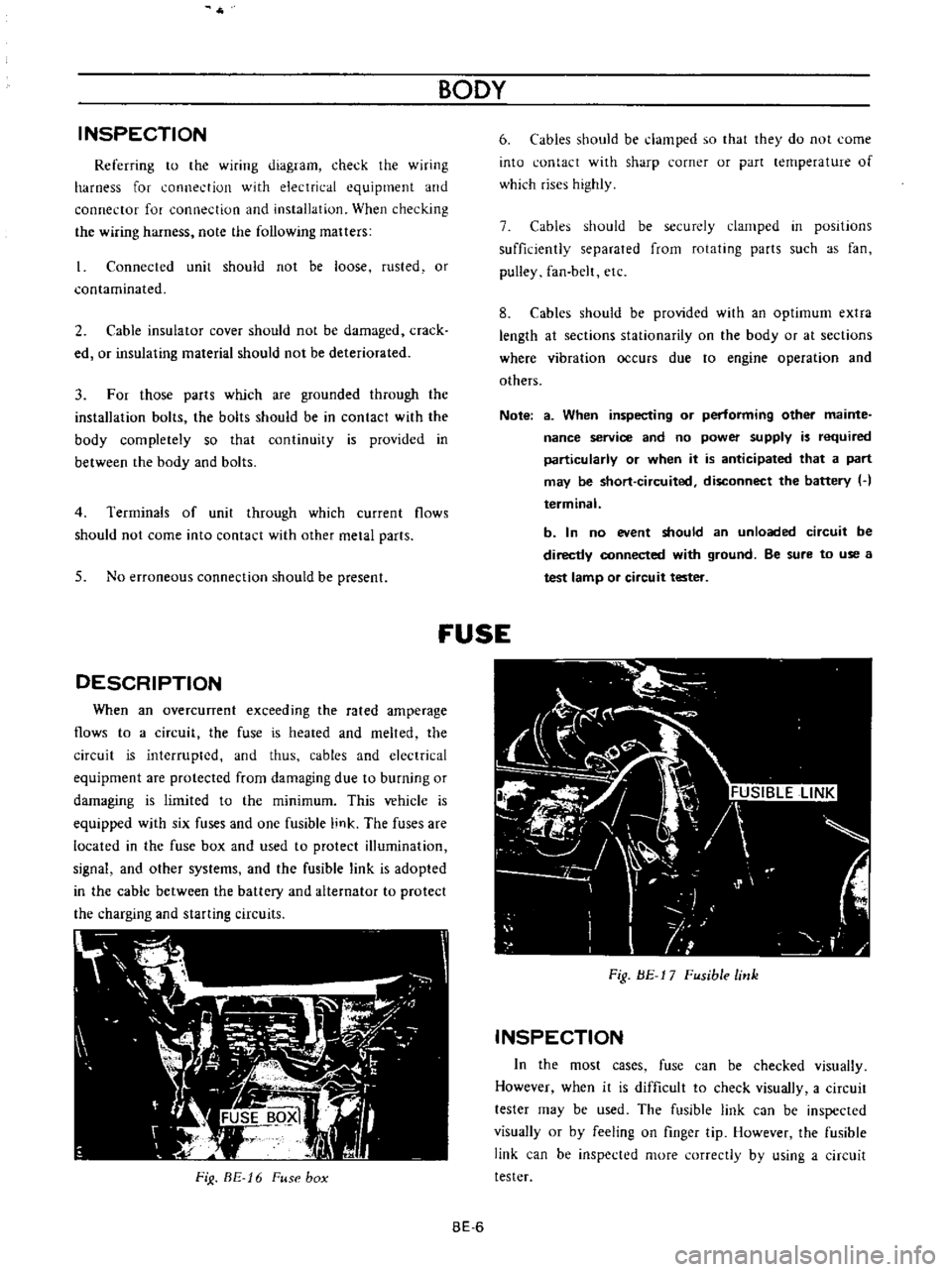

FiJ

BE

16

Fuse

box

BODY

6

Cables

should

be

damped

so

that

they

do

not

come

into

contact

with

sharp

corner

or

part

lernperature

of

which

rises

highly

7

Cables

should

be

securely

clamped

in

posItions

sufficiently

separated

from

rotating

parts

such

as

fan

pulley

fan

belt

etc

8

Cables

should

be

provided

with

an

optimum

extra

length

at

sections

stationarity

on

the

body

or

at

sections

where

vibration

occurs

due

to

engine

operation

and

others

Note

a

When

inspecting

or

performing

other

mainte

nance

service

and

no

power

supply

is

required

particularly

or

when

it

is

anticipated

that

a

part

may

be

short

circuited

disconnect

the

battery

H

terminal

b

In

no

event

should

an

unloaded

circuit

be

directly

connected

with

ground

Be

sure

to

use

a

test

lamp

or

circuit

tester

fUSE

Fig

BE

17

Fusible

link

INSPECTION

In

the

most

cases

fuse

can

be

checked

visually

However

when

it

is

difficult

to

check

visually

a

circuit

tester

may

be

used

The

fusible

link

can

be

inspected

visually

or

by

feeling

on

finger

tip

However

the

fusible

link

can

be

inspected

more

correctly

by

using

a

circuit

tester

BE

6

Page 253 of 513

BODY

METERS

AND

GAUGES

CONTENTS

CLUSTER

LID

Oescri

ption

Removal

SPEEDOMETER

Replacement

FUEL

GAUGE

AND

TEMPERATURE

GAUGE

Description

Replacement

BE

1B

BE

18

BE

18

BE

19

BE

19

BE

19

BE

19

BE

20

CLUSTER

LID

Description

The

cluster

lid

holds

various

rneters

indicators

and

clock

located

around

the

speedorneter

Printed

circuit

board

is

used

at

the

back

of

the

meter

as

shown

in

Figure

BE

38

and

the

printed

circuit

board

is

connected

with

multiple

connectors

Thus

the

meters

Can

be

inspected

and

serviced

extremely

easily

Except

for

the

speed

ometer

all

rneters

are

operated

electrically

The

fuel

gauge

and

therrnometer

are

very

reliable

and

they

are

equipped

with

bimetal

devices

F

a

o

ill

I

1

a

a

Fig

BE

34

Combination

meters

Removal

Disconnect

the

battery

terminal

depressing

the

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

HAND

BRAKE

WARNING

LAMP

BULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Speedometer

Thermometer

and

fuel

meter

Oil

pressure

and

ignition

warning

lamps

BE

20

BE

21

BE

21

BE

22

BE

22

BE

23

BE

25

windshield

wiper

switch

lighting

switch

and

choke

lever

knobs

turn

them

counterclockwise

to

remove

Remove

the

escutcheon

2

Inserting

your

hand

into

back

of

the

cluster

lid

disconnect

the

cigarette

lighter

cable

and

turn

and

remove

the

cigarette

lighter

outer

case

3

Remove

the

radio

and

heater

control

knobs

4

Remove

the

shell

cover

from

the

steering

tube

loosen

the

screws

used

to

secure

the

meter

housing

to

the

instrument

panel

and

remove

the

cluster

lid

5

Pull

out

the

l2

pole

round

shape

connector

and

remove

the

speedometer

cable

union

nut

6

Remove

the

cluster

lid

from

the

instrument

panel

Fig

BE

35

Removing

clllSter

jd

BE

18

Page 256 of 513

BODY

ElECTRICAL

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

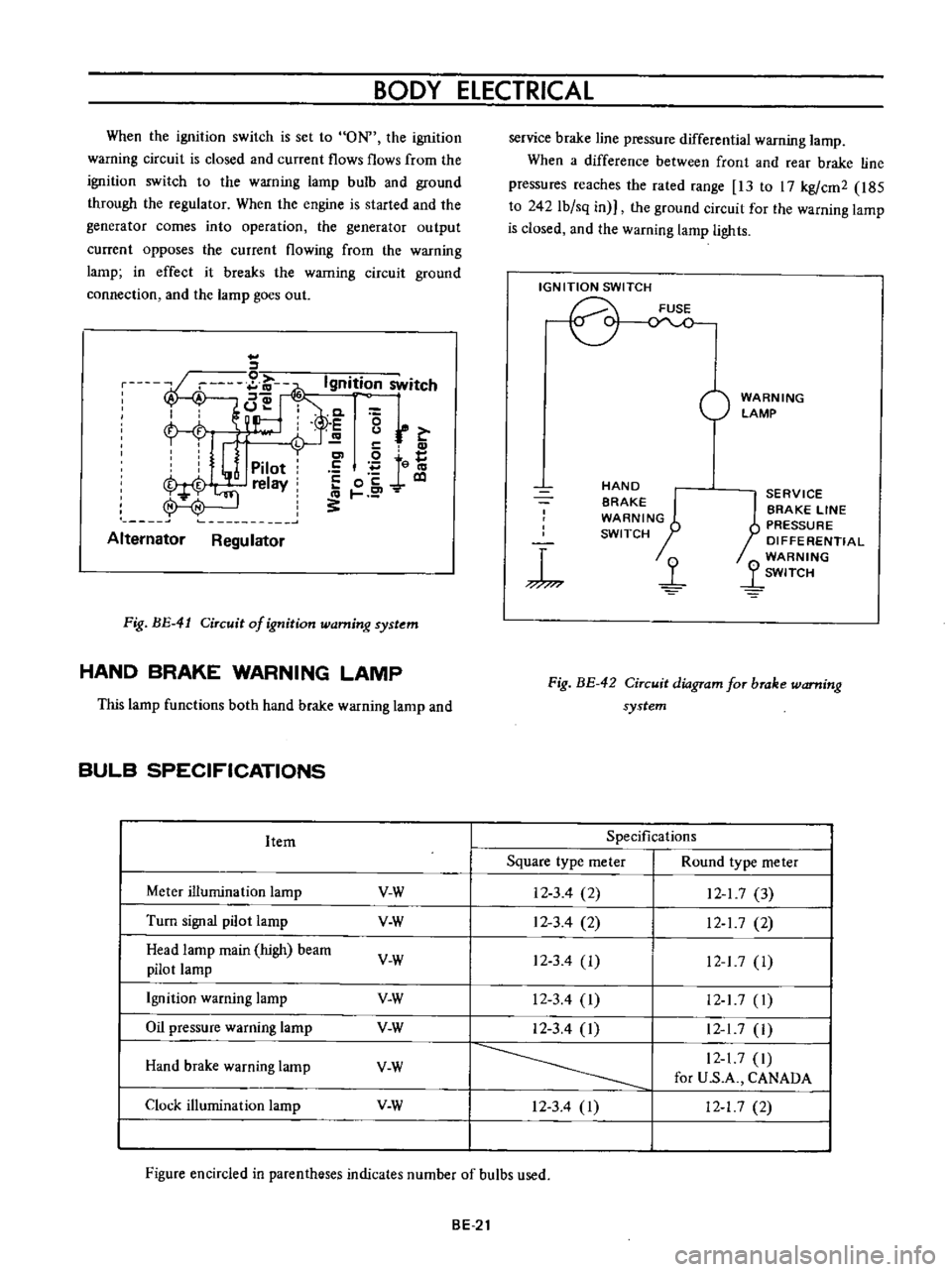

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21

Page 259 of 513

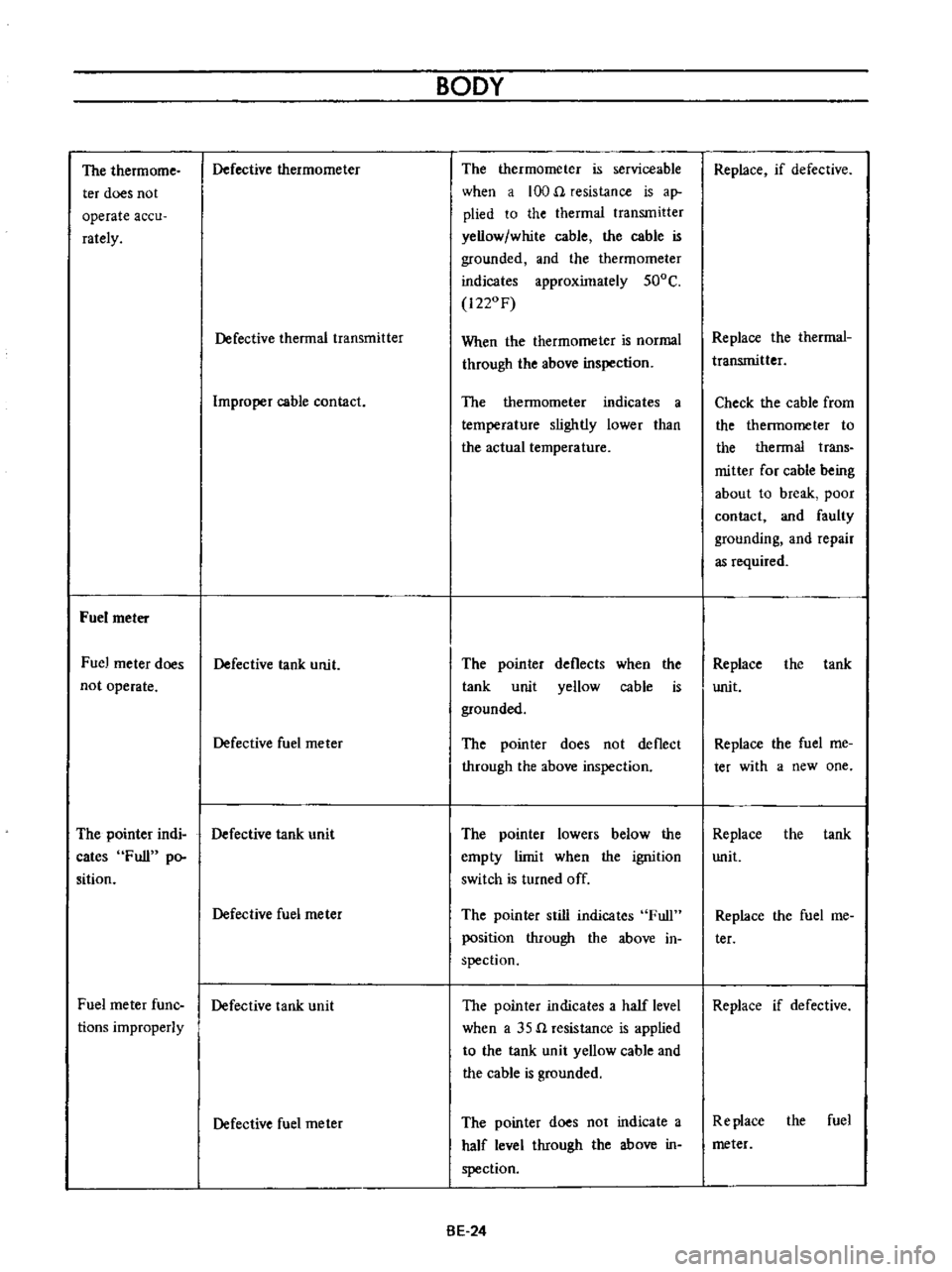

The

thermome

ter

does

not

operate

accu

rately

Fuel

meter

Fuel

meter

does

not

operate

Defective

thermometer

Defective

thermal

transmitter

Improper

cable

contact

Defective

tank

unit

Defective

fuel

meter

The

pointer

indi

Defective

tank

unit

cates

Full

po

sition

Fuel

meter

fune

tions

improperly

Defective

fuel

rneter

Defective

tank

unit

Defective

fuel

rneter

BODY

The

thermometer

is

serviceable

when

a

100

n

resistance

is

ap

plied

to

the

thermal

transmitter

yellow

white

cable

the

cable

is

grounded

and

the

thermorneter

indicates

approximately

500C

1220F

When

the

thermometer

is

normal

through

the

above

inspection

The

thermometer

indicates

a

temperature

slightly

lower

than

the

actual

temperature

The

poin

ter

tank

unit

grounded

deflects

yellow

when

the

cable

is

The

pointer

does

not

deflect

through

the

above

inspection

The

pointer

lowers

below

the

ernpty

limit

when

the

ignition

switch

is

turned

off

The

pointer

still

indicates

Full

position

through

the

above

in

spection

The

pointer

indicates

a

half

level

when

a

35

n

resistance

is

applied

to

the

tank

unit

yellow

cable

and

the

cable

is

grounded

The

pointer

does

not

indicate

a

half

level

through

the

above

in

spection

BE

24

Replace

if

defective

Replace

the

therrnal

transmitter

Check

the

cable

from

the

thermometer

to

the

thermal

trans

mitter

for

cable

being

about

to

break

poor

contact

and

faulty

grounding

and

repair

as

required

Replace

unit

the

tank

Replace

the

fuel

me

tee

with

a

new

one

Replace

the

tank

unit

Replace

the

fuel

me

ter

Replace

if

defective

Replace

the

fuel

meter

Page 271 of 513

BODY

I

Vibrating

noise

Loose

heater

support

Tighten

completely

Loose

fixing

screw

Retighten

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

n

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

BE

36

Page 272 of 513

DATSUN

1200

MODEL

B

110

SERIES

lNISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

SE

SERVICE

EQUIPMENT

AI2

ENGINE

SPECIAL

SERVICE

TOOL

SE

I

Page 273 of 513

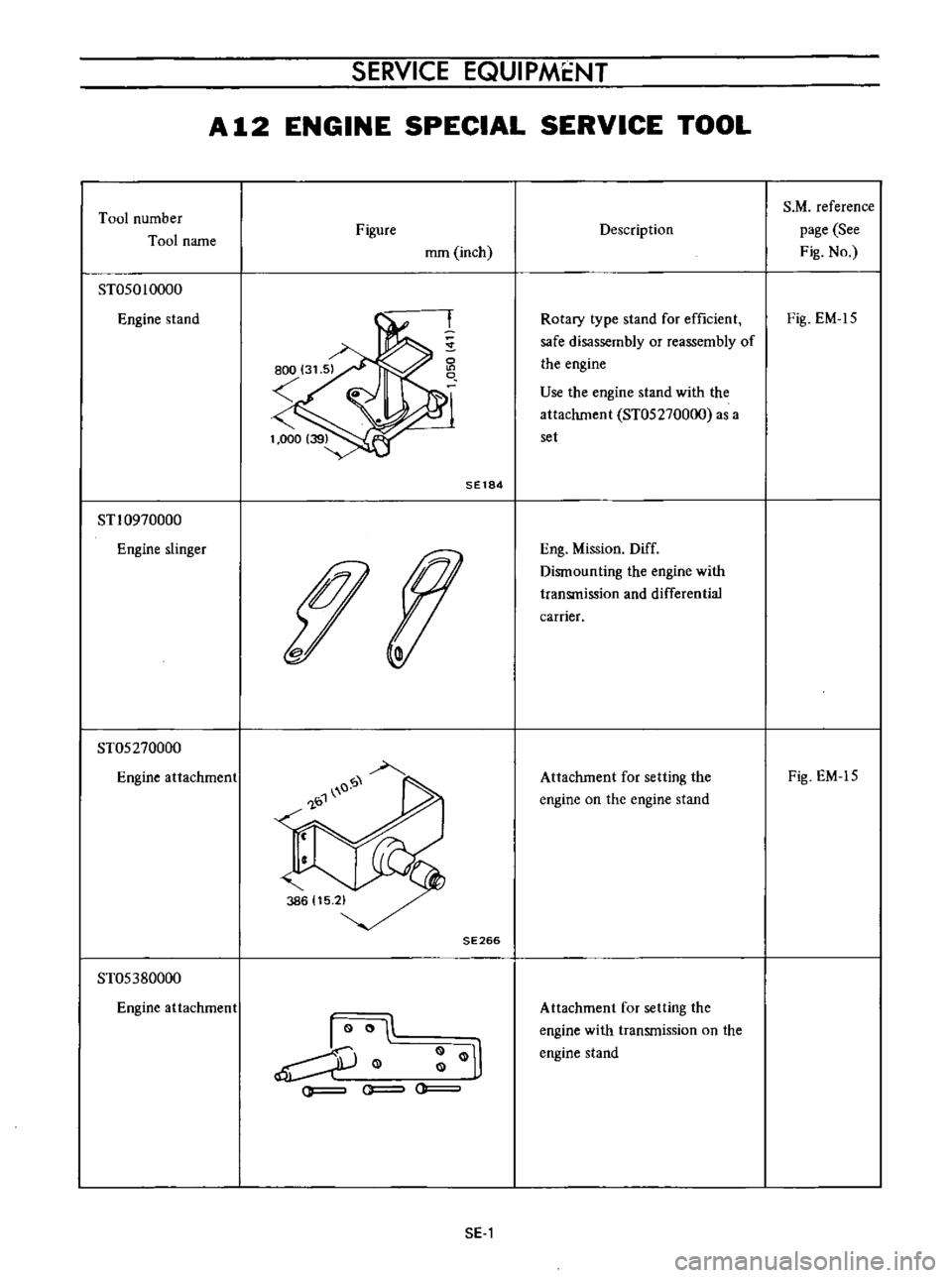

SERVICE

EQUIPMeNT

A12

ENGINE

SPECIAL

SERVICE

TOOL

Tool

number

Tool

name

ST050

10000

Engine

stand

STI

0970000

Engine

slinger

ST05270000

Engine

attachment

ST05380000

Engine

attachment

Figure

mm

inch

SE184

0

1

SE266

I

G

0

1

@

@

SE

1

Description

Rotary

type

stand

for

efficient

safe

disassembly

or

reassembly

of

the

engine

Use

the

engine

stand

with

the

attachment

ST05270000

as

a

set

Eng

Mission

Difr

Dismounting

the

engine

with

transmission

and

differential

carrier

Attachment

for

setting

the

engine

on

the

engine

stand

Attachment

for

setting

the

engine

with

transmission

on

the

engine

stand

S

M

reference

page

See

Fig

No

Fig

EM

15

Fig

EM

15

Page 274 of 513

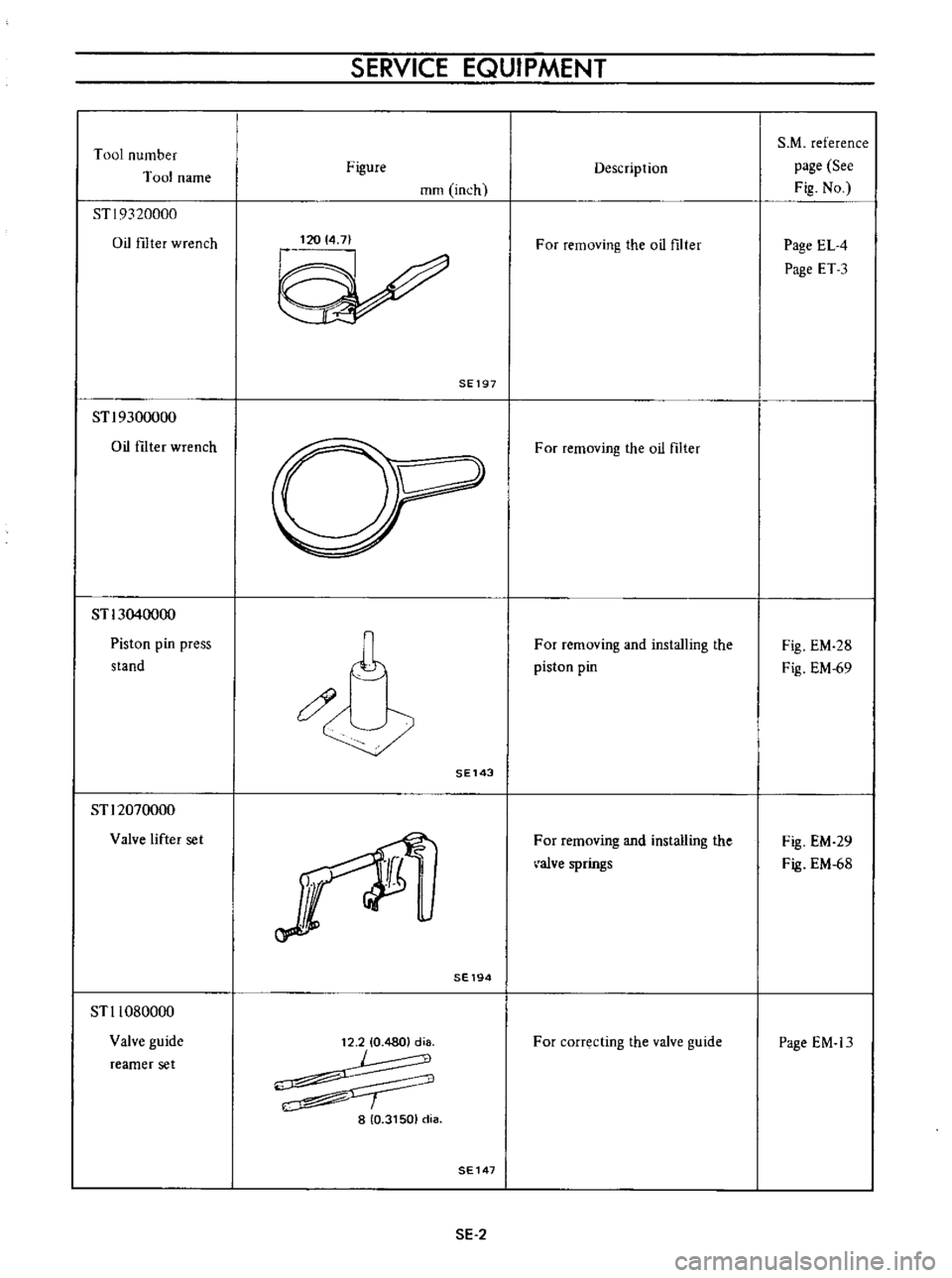

Tool

number

T

ooJ

name

ST

I

9320000

Oil

filter

wrench

STl9300000

Oil

ftIter

wrench

STl3040000

Piston

pin

press

stand

STl2070000

Valve

lifter

set

STl1080000

Valve

guide

reamer

set

SERVICE

EQUIPMENT

Figure

mm

inch

120

14

7

SE197

11

0

SE143

SE194

12

210

4801

d

8

L

8

10

31501

d

a

SE147

SE

2

Description

For

removing

the

oil

filter

For

removing

the

oil

filter

For

removing

and

installing

the

piston

pin

For

removing

and

installing

the

a1ve

springs

For

correcting

the

valve

guide

S

M

reference

page

See

Fig

No

Page

EL

4

Page

ET

3

Fig

EM

28

Fig

EM

69

Fig

EM

29

Fig

EM

68

Page

EM

13

Page 275 of 513

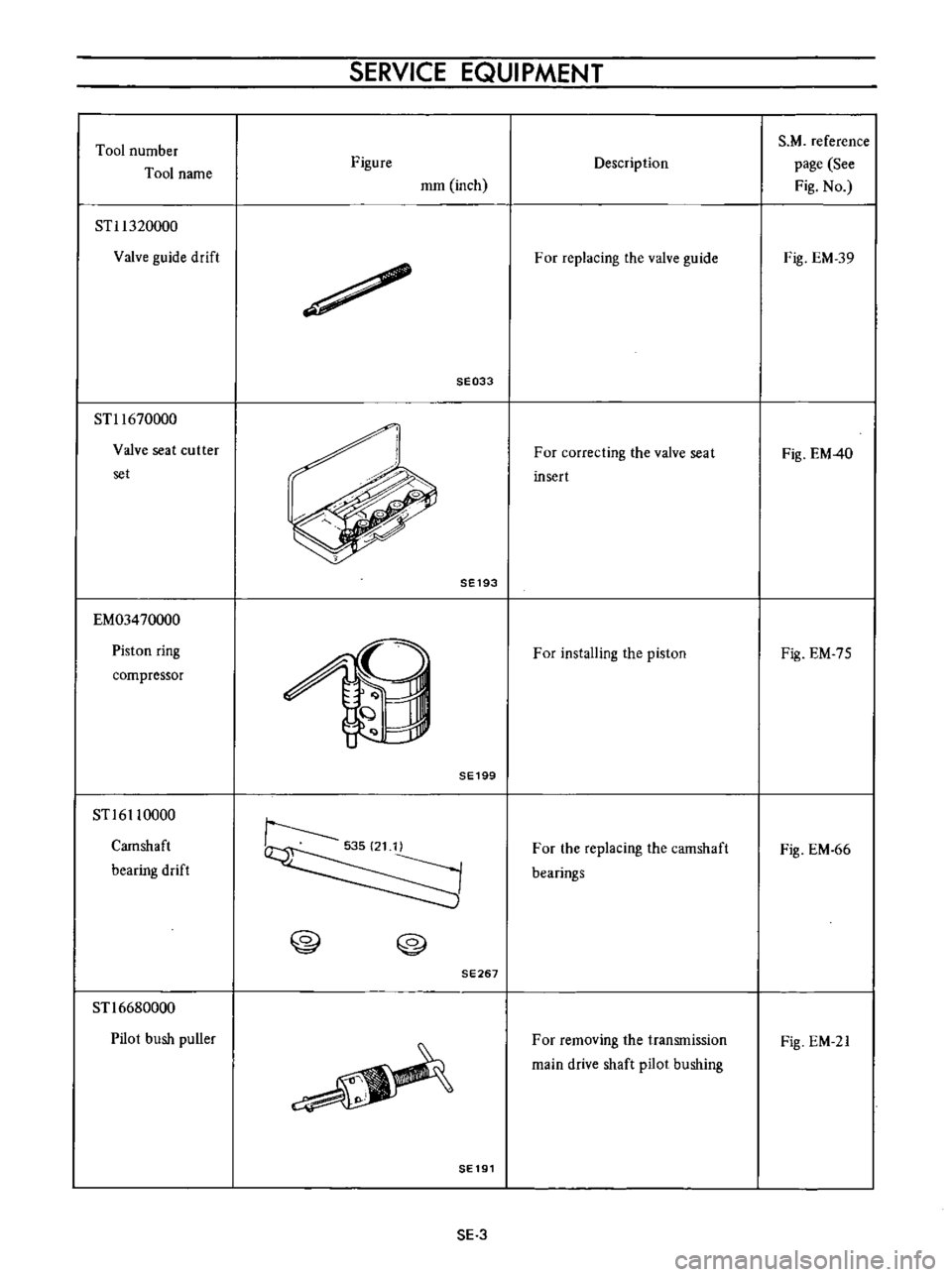

Tool

number

Tool

name

STlI320000

Valve

guide

drift

STlI670000

Valve

seat

cutter

set

EM03470000

Piston

ring

compressor

STl6110000

Camshaft

bearing

drift

STl6680000

Pilot

bush

puller

SERVICE

EQUIPMENT

Figure

mm

inch

SE033

SE193

SE199

@

@

SE267

SE191

SE

3

Description

For

replacing

the

valve

guide

For

correcting

the

valve

seat

insert

For

installing

the

piston

For

the

replacing

the

camshaft

bearings

For

removing

the

transmission

main

drive

shaft

pilot

bushing

S

M

reference

page

See

Fig

No

Fig

EM

39

Fig

EM40

Fig

EM

75

Fig

EM

66

Fig

EM

21

Page 276 of 513

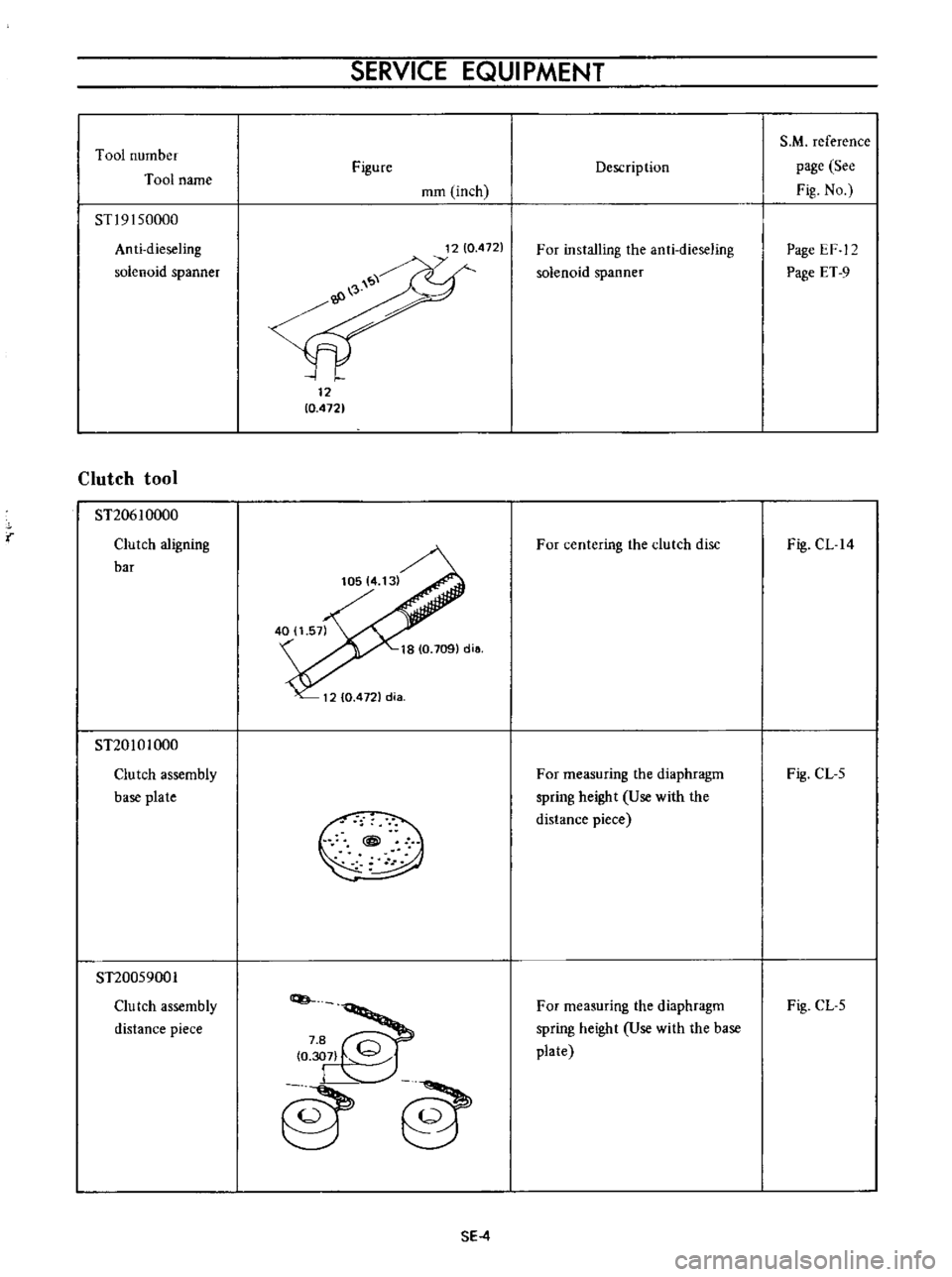

Tool

number

Tool

name

STl9

I

50000

Anti

dieseling

solenoid

spanner

Clutch

tool

ST20610000

Clutch

aligning

bar

ST20101000

Clutch

assembly

base

plate

ST20059001

Clu

tch

assembly

distance

piece

SERVICE

EQUI

PMENT

Figure

mm

inch

12

10

4721

0

o

8

C

307

l

j

@@

SE

4

Description

For

installing

the

anti

dieseling

solenoid

spanner

For

centering

the

clutch

disc

For

measuring

the

diaphragm

spring

height

Use

with

the

distance

piece

For

measuring

the

diaphragm

spring

height

Use

with

the

base

plate

S

M

reference

page

See

Fig

No

Page

EF

12

Page

ET

9

Fig

CL

14

Fig

CL

5

Fig

CL

5