engine DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 406 of 513

CD

r

Fuel

level

adjustment

@

@

It

I

Float

2

Float

seat

FUEL

SYSTEM

2

Adjust

bottom

float

position

so

that

clearance

h

between

the

float

seat

and

the

needle

valve

stem

is

1

3

to

1

7

mm

0

0512

to

0

0669

in

when

the

float

is

fully

raised

Bend

the

float

stopper

properly

as

required

l

lH

H

ld

up

@

h

Fast

idle

adjustment

Remove

the

bi

metal

cover

3

I

Float

stopper

4

Needle

valve

2

Place

the

fast

idle

arm

on

the

second

step

of

the

fast

idle

earn

Then

adjust

the

fast

idle

adjusting

screw

in

such

a

way

that

the

clearance

of

the

throttle

valve

shown

at

A

in

the

illustration

will

be

the

specifications

See

Figure

EF

26

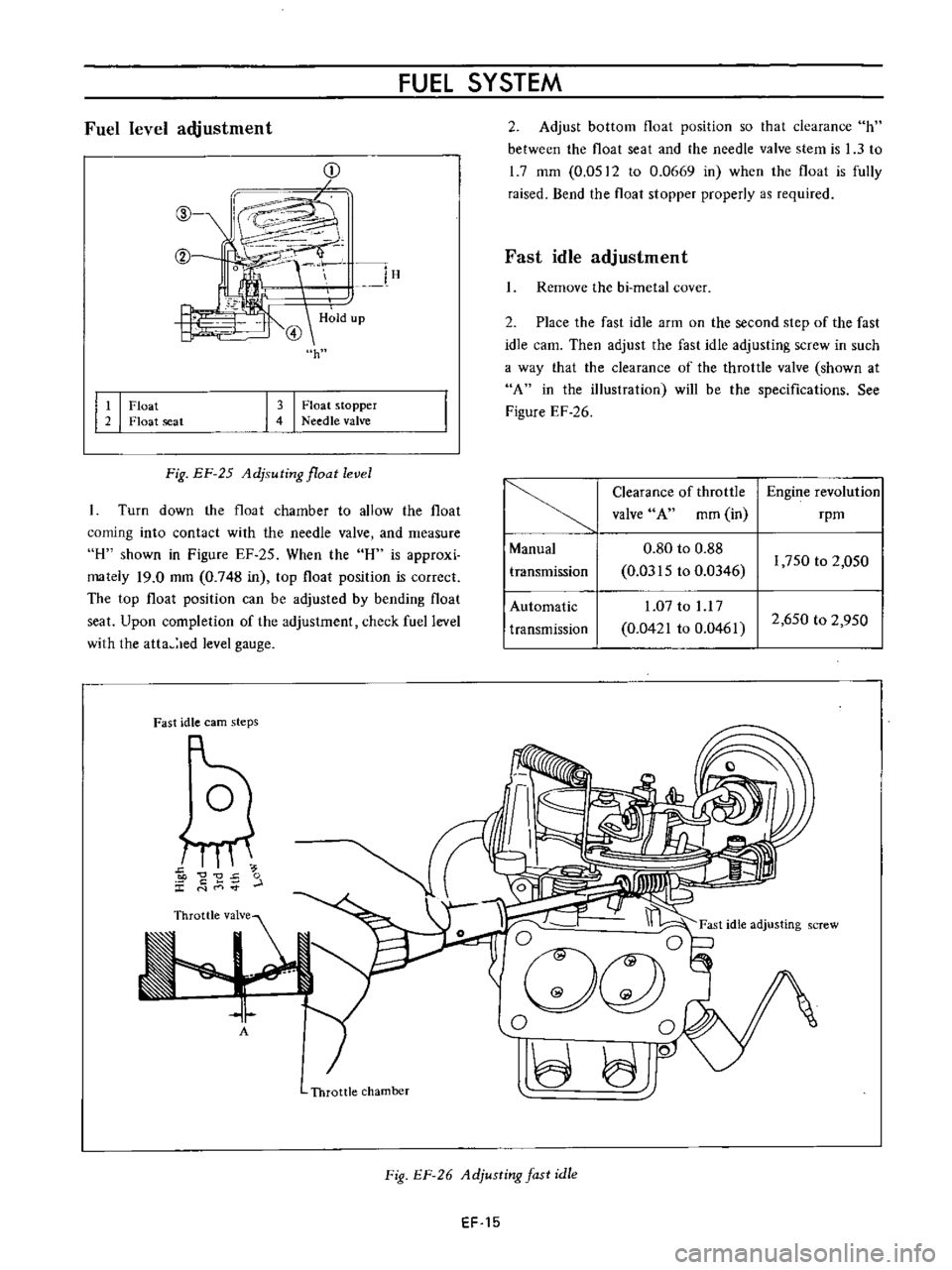

Fig

EF

25

Adjsuting

float

level

Turn

down

the

float

chamber

to

allow

the

float

coming

into

contact

with

the

needle

valve

and

measure

H

shown

in

Figure

EF

25

When

the

H

is

approxi

mately

19

0

mm

0

748

in

top

float

position

is

correct

The

top

float

position

can

be

adjusted

by

bending

float

seat

Upon

completion

of

the

adjustment

check

fuel

level

with

the

atta

led

level

gauge

Clearance

of

throttle

Engine

revolution

valve

A

mm

in

rpm

Manual

0

80

to

0

88

transmission

0

0315

to

0

0346

1

750

to

2

050

Automatic

1

07

to

l

l

7

transmission

0

0421

to

0

0461

2

650

to

2

950

Fast

idle

earn

steps

5

C

0

J

t

E

r

L

E

I

I

Ogc

l

0

0

JO

A

Throttle

chamber

Fig

EF

26

Adjusting

fast

idle

EF

15

Page 407 of 513

ENGINE

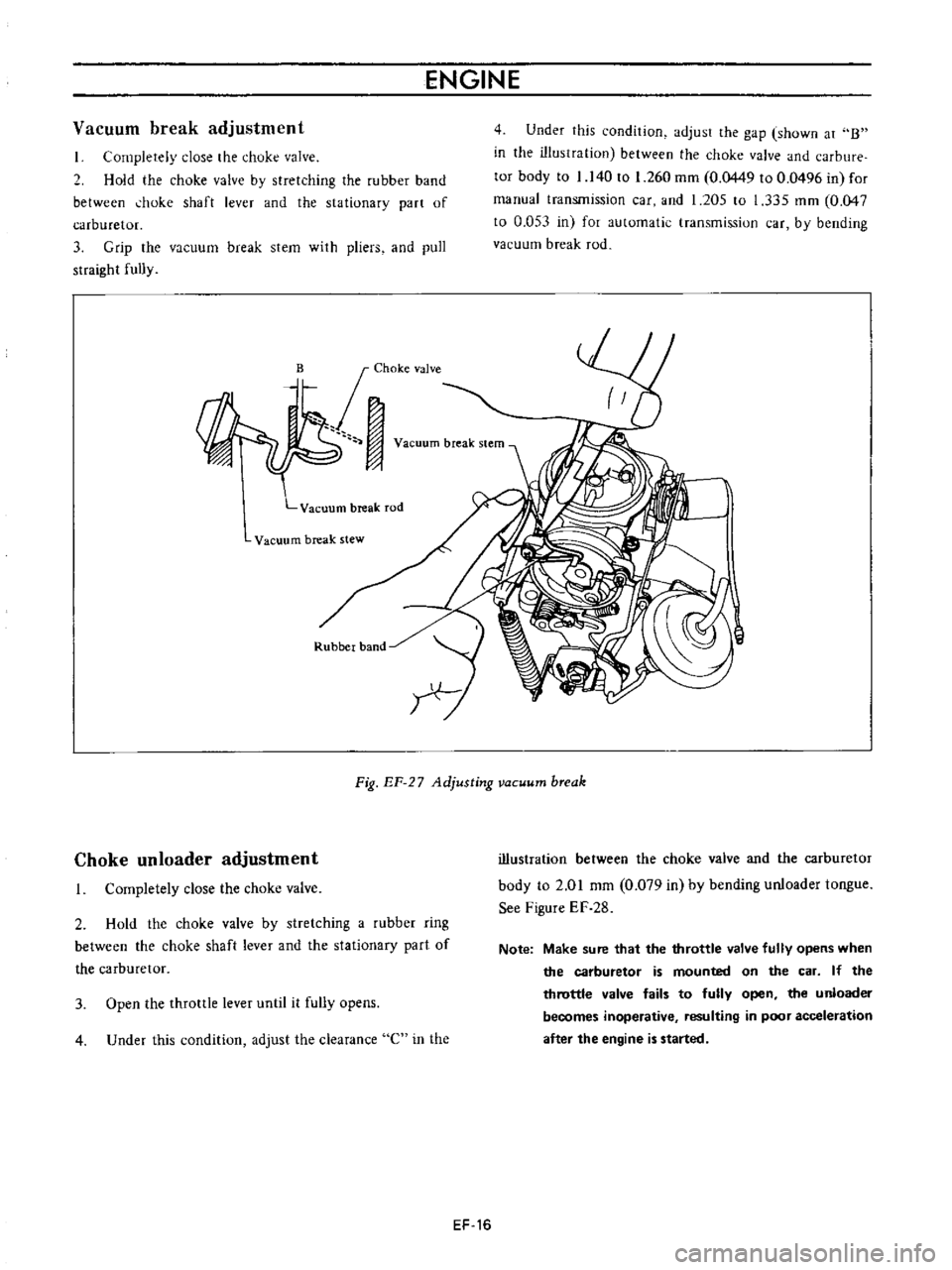

Vacuum

break

adjustment

I

Completely

close

the

chuke

valve

2

Hold

the

choke

valve

by

stretching

the

rubber

band

between

hoke

shaft

lever

and

the

sta

tionary

part

of

carburetor

3

Grip

the

vacuum

break

stem

with

pliers

and

pull

straight

fully

Vacuum

break

rod

Vacuum

break

stew

Rubber

band

4

Under

this

condition

adjust

the

gap

shown

at

B

in

the

illustration

between

the

choke

valve

and

carbure

tor

body

to

1

140

to

1

260

mm

0

0449

to

0

0496

in

for

manual

transmission

car

and

1

205

to

1

335

mm

0

047

to

0

053

in

for

automatic

transmission

car

by

bending

vacuum

break

rod

I

Fig

EF

27

Adjusting

vacuum

break

Choke

un

loader

adjustment

I

Completely

close

the

choke

valve

2

Hold

the

choke

valve

by

stretching

a

rubber

ring

between

the

choke

shaft

lever

and

the

stationary

part

of

the

carburetor

3

Open

the

throttle

lever

until

it

fully

opens

4

Under

this

condition

adjust

the

clearance

C

in

the

illustration

between

the

choke

valve

and

the

carburetor

body

to

2

01

mm

0

079

in

by

bending

unloader

tongue

See

Figure

EF

28

Note

Make

sure

that

the

throttle

valve

fully

opens

when

the

carburetor

is

mounted

on

the

car

If

the

throttle

valve

fails

to

fully

open

the

unloader

becomes

inoperative

resulting

in

poor

acceleration

after

the

engine

is

started

EF

16

Page 409 of 513

ENGINE

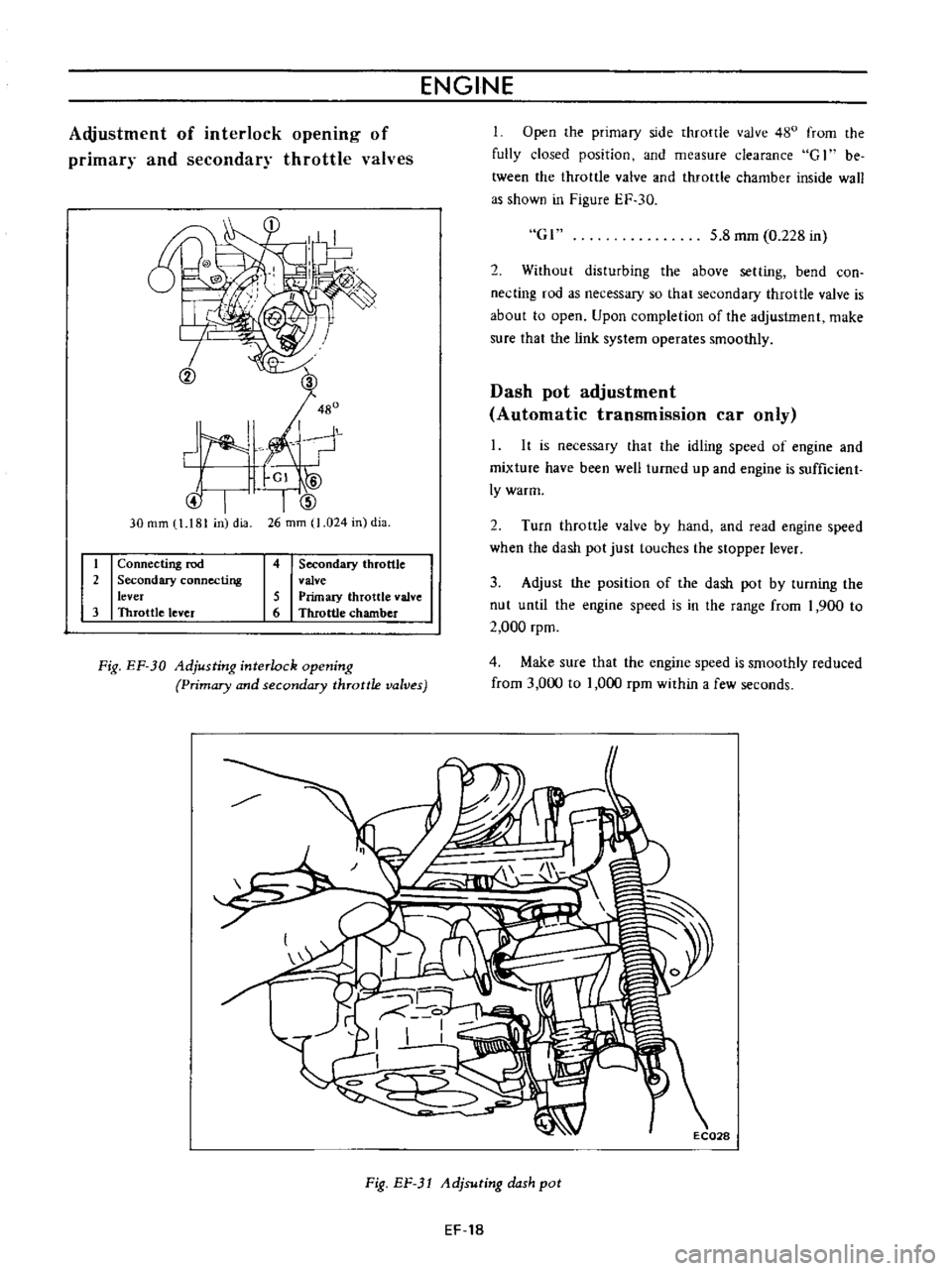

Adjustment

of

interlock

opening

of

primary

and

secondary

throttle

valves

Open

the

primary

side

throttle

valve

480

from

the

fully

closed

position

and

measure

clearance

G

1

be

tween

the

throttle

valve

and

throttle

chamber

inside

wall

as

shown

in

Figure

EF

30

@I

30

rom

1

181

in

dia

Gl

5

8

mm

0

228

in

I

V

2

Without

disturbing

the

above

setting

bend

con

necting

rod

as

necessary

so

that

secondary

throttle

valve

is

about

to

open

Upon

completion

of

the

adjustment

make

sure

that

the

link

system

operates

smoothly

2

Dash

pot

adjustment

Automatic

transmission

car

only

It

is

necessary

that

the

idling

speed

of

engine

and

mixture

have

been

weB

turned

up

and

engine

is

sufficient

Iywarm

2

Turn

throttle

valve

by

hand

and

read

engine

speed

when

the

dash

pot

just

touches

the

stopper

lever

1

Connecting

rod

2

Secondary

connecting

lever

3

Throttle

lever

4

Secondary

throttle

valve

5

Primuy

throttle

valve

6

Throttle

chamber

3

Adjust

the

position

of

the

dash

pot

by

turning

the

nut

until

the

engine

speed

is

in

the

range

from

1

900

to

2

000

rpm

Fig

EF

30

Adjusting

interlock

opening

Primary

and

secondary

throttle

valves

4

Make

sure

that

the

engine

speed

is

smoothly

reduced

from

3

000

to

1

000

rpm

within

a

few

seconds

Fig

EF

1

Adjsuting

dash

pot

EF

18

Page 410 of 513

FUEl

SYSTEM

MA

JOR

SERVICE

OPERATIONS

A

completely

adjusted

and

serviced

carburetor

will

provide

the

engine

with

proper

mixture

at

all

speeds

Periodical

overhauling

which

cleans

all

components

and

passages

will

recover

the

originally

designed

performance

producing

the

engine

with

proper

gasoline

and

air

ratio

at

all

speeds

Passages

and

holes

of

the

carburetor

must

be

cleaned

carefully

Use

only

carburetor

solvent

and

com

pressed

air

to

clean

aU

passages

and

discharge

holes

Never

use

wire

or

other

pointed

tool

otherwise

accurately

calibrated

carburetor

will

be

affected

Removal

Remove

the

air

cleaner

2

Disconnect

the

fuel

line

vacuum

line

automatic

choke

harness

and

anti

dieseling

solenoid

harness

from

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

retaining

the

carbuTe

tor

to

the

manifold

if

necessary

5

Lift

the

carburetor

and

remove

from

the

manifold

6

Remove

and

discard

the

gasket

used

between

the

carburetor

and

manifold

Disassembly

The

main

jets

and

needle

valves

on

both

primary

and

secondary

sides

are

accessible

from

outside

of

the

carbure

tor

for

disassembly

2

Remove

throttle

return

spring

3

Remove

pump

lever

shaft

take

out

pump

lever

and

pump

connecting

rod

4

Remove

rubber

pipe

from

choke

piston

5

Loosen

off

bolts

securing

servo

diaphragm

in

posi

tion

take

out

diaphragm

6

Back

off

total

of

five

bolts

which

hold

choke

in

position

and

remove

rods

of

starter

system

take

out

choke

chamber

In

removing

chamber

exercise

care

to

avoid

damaging

float

EF

19

ilia

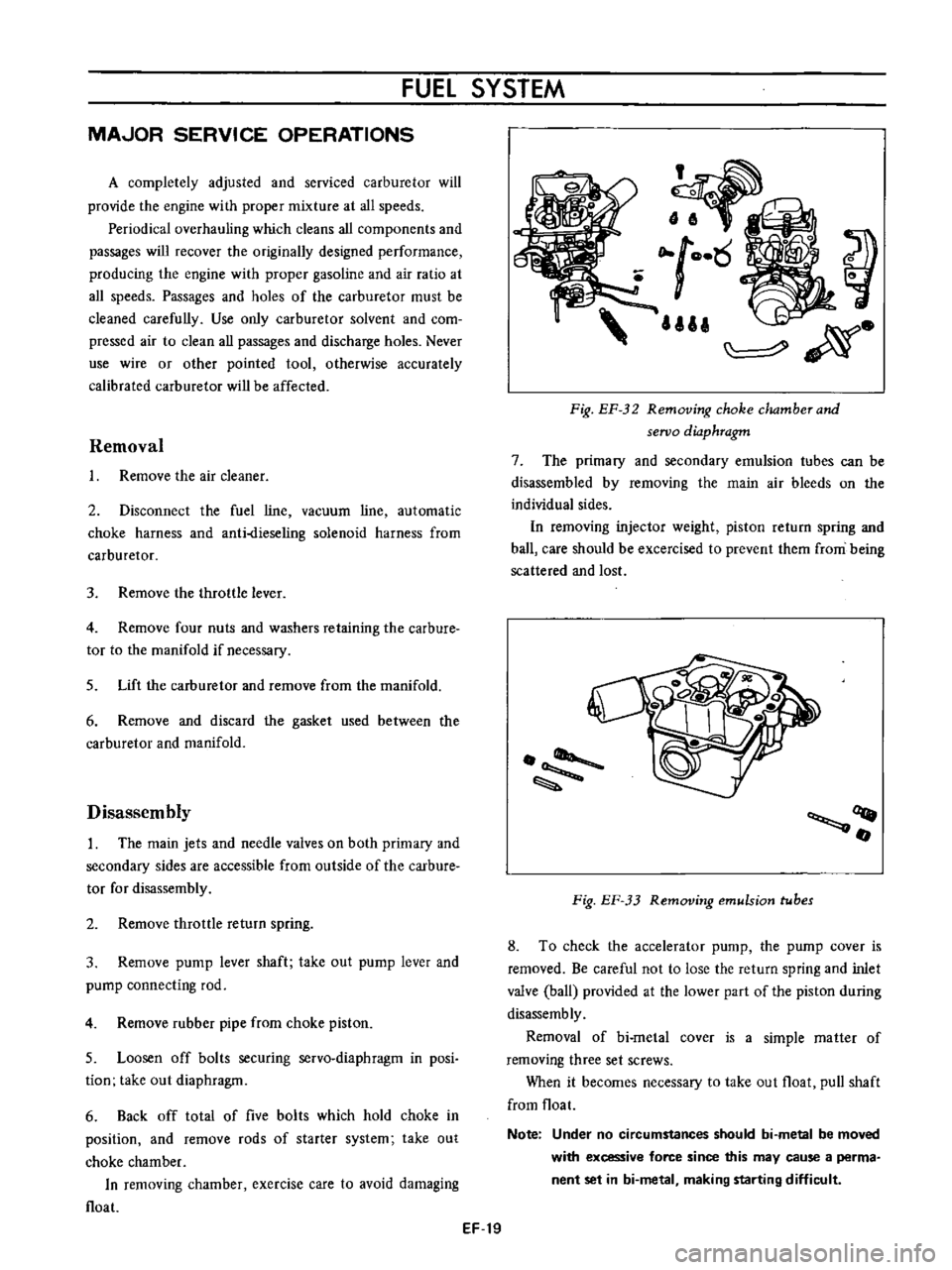

Fig

EF

32

Removing

choke

dwmherand

seroo

diaphragm

7

The

primary

and

secondary

emulsion

tubes

can

be

disassembled

by

removing

the

main

air

bleeds

on

the

individual

sides

In

removing

injector

weight

piston

return

spring

and

ball

care

should

be

excercised

to

prevent

them

from

being

scattered

and

lost

OQ

fI

Fig

EF

33

Removing

emulsion

tubes

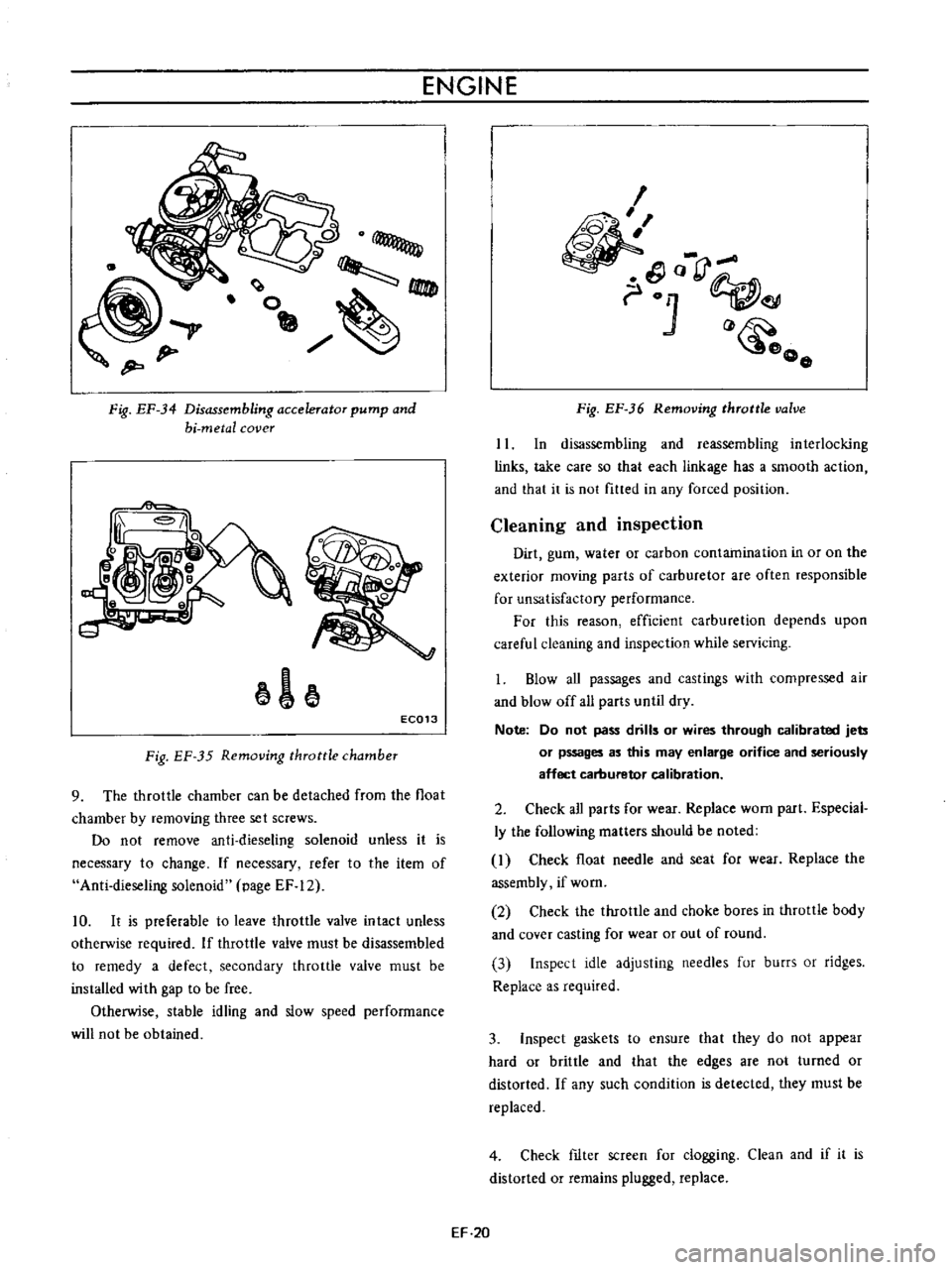

8

To

check

the

accelerator

pump

the

pump

cover

is

removed

Be

careful

not

to

lose

the

return

spring

and

inlet

valve

ball

provided

at

the

lower

part

of

the

piston

during

disassemb

ly

Removal

of

bi

metal

cover

is

a

simple

matter

of

removing

three

set

screws

When

it

becomes

necessary

to

take

out

float

pull

shaft

from

float

Note

Under

no

circumstances

should

bi

metal

be

moved

with

excessive

force

since

this

may

cause

a

perma

nent

set

in

bi

metal

making

starting

difficult

Page 411 of 513

ENGINE

Y

Q

0

Fig

EF

34

Disassembling

accelerator

pump

and

hi

metal

cover

1

EC013

Fig

EF

35

Removing

throttle

chamber

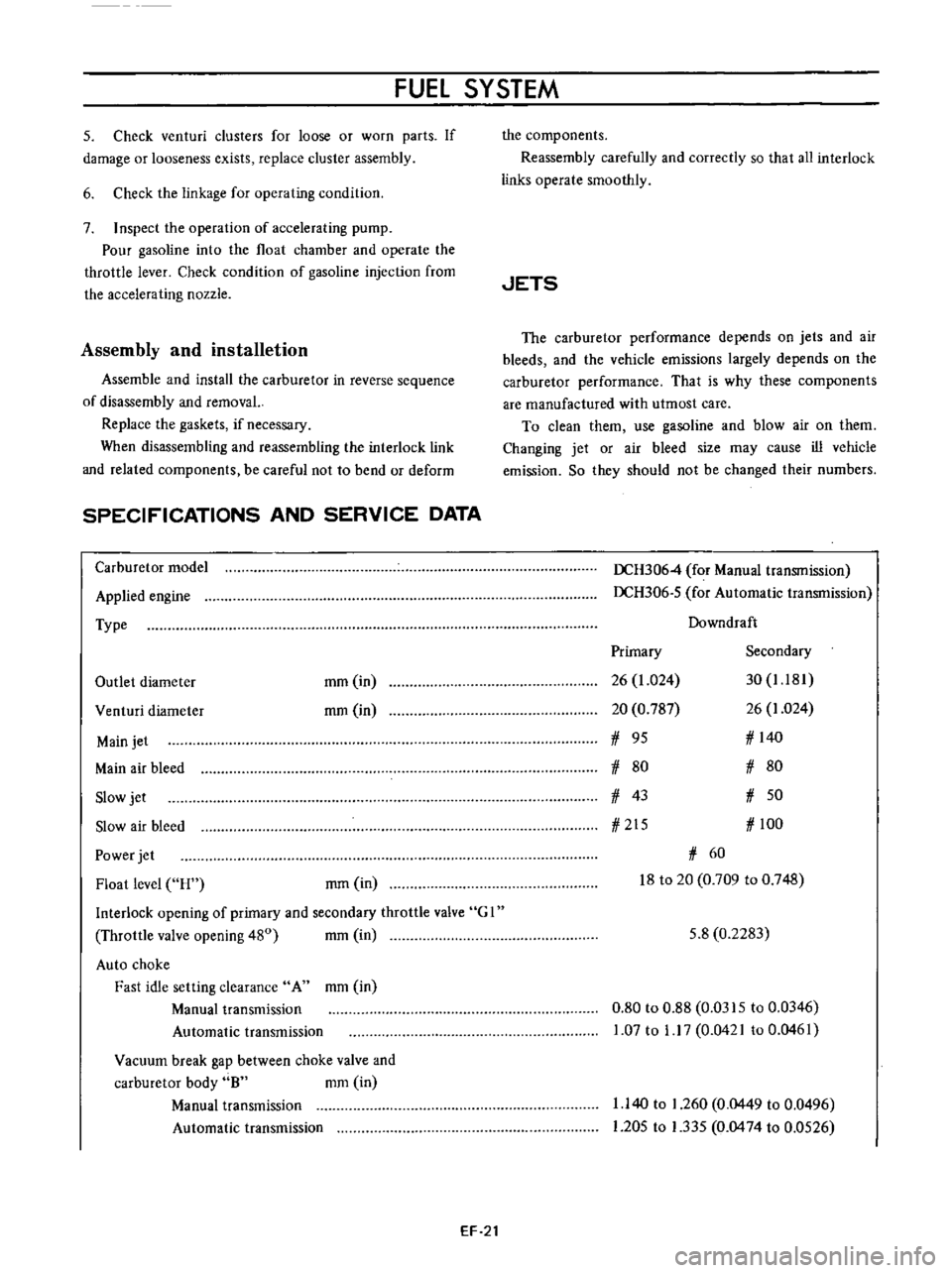

9

The

throttle

chamber

can

be

detached

from

the

float

chamber

by

removing

three

set

screws

Do

not

remove

anti

dieseling

solenoid

unless

it

is

necessary

to

change

If

necessary

refer

to

the

item

of

Anti

dieseling

solenoid

page

EF

12

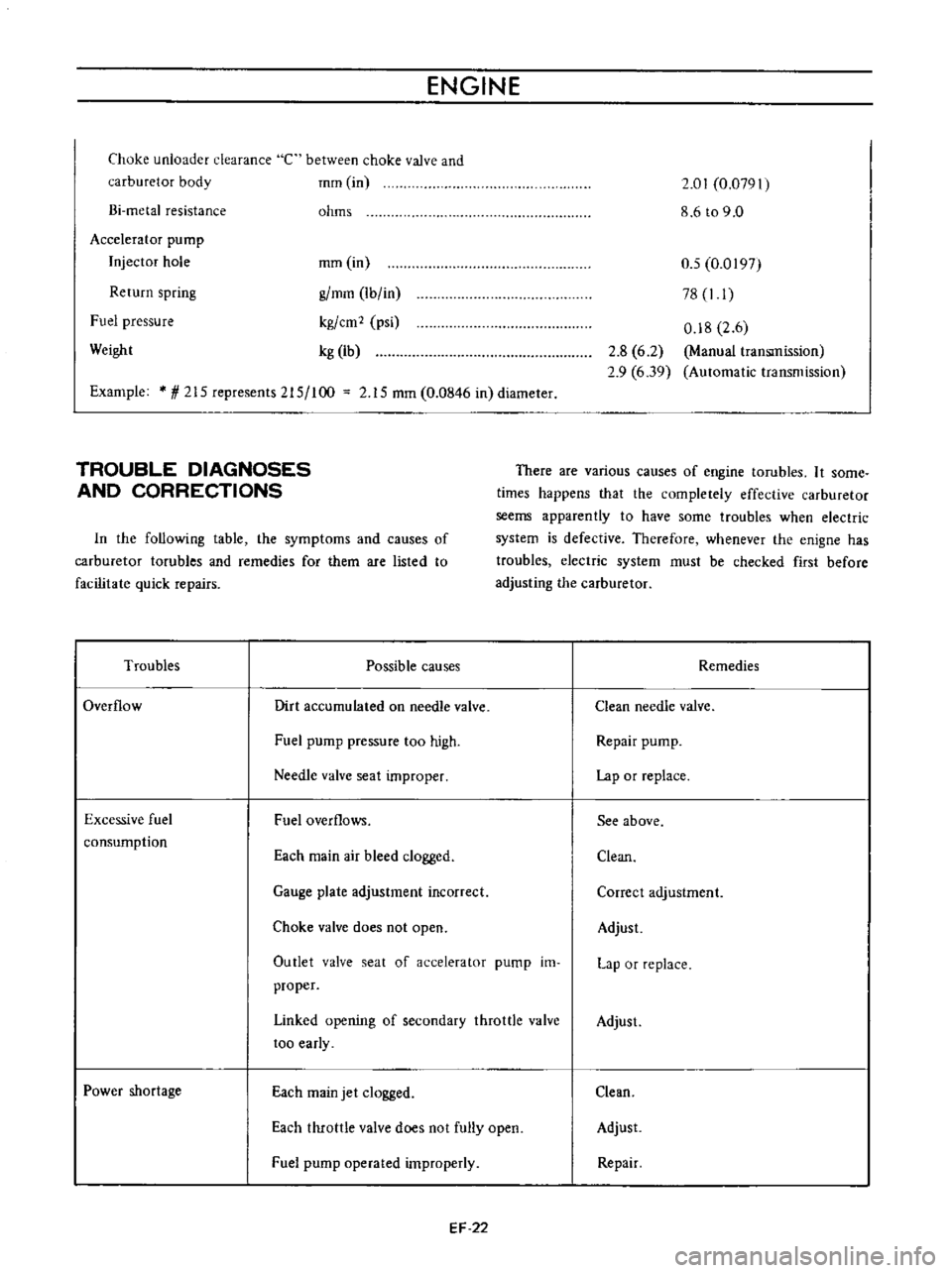

10

It

is

preferable

to

leave

throttle

valve

intact

unless

otherwise

required

If

throttle

valve

must

be

disassembled

to

remedy

a

defect

secondary

throttle

valve

must

be

installed

with

gap

to

be

free

Otherwise

stable

idling

and

slow

speed

performance

will

not

be

obtained

I

o

rJ

01

o

o

Fig

EF

36

Removing

throttle

valve

II

In

disassembling

and

reassembling

interlocking

links

take

care

so

that

each

linkage

has

a

smooth

action

and

that

it

is

not

fitted

in

any

forced

position

Cleaning

and

inspection

Dirt

gum

water

or

carbon

contamination

in

or

on

the

exterior

moving

parts

of

carburetor

are

often

responsible

for

unsatisfactory

performance

For

this

reason

efficient

carburetion

depends

upon

careful

cleaning

and

inspection

while

servicing

1

Blow

aU

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

pssages

as

this

may

enlarge

orifice

and

seriously

affect

carburetor

calibration

2

Check

all

parts

for

wear

Replace

worn

part

Especial

ly

the

following

matters

should

be

noted

I

Check

float

needle

and

seat

for

wear

Replace

the

assembly

if

worn

2

Check

the

throttle

and

choke

bores

in

throttle

body

and

cover

casting

for

wear

or

out

of

round

3

Inspect

idle

adjusting

needles

fur

burrs

or

ridges

Replace

as

required

3

Inspect

gaskets

to

ensure

that

they

do

not

appear

hard

or

brittle

and

that

the

edges

are

not

turned

or

distorted

If

any

such

condition

is

detected

they

must

be

replaced

4

Check

fIlter

screen

for

clogging

Clean

and

if

it

is

distorted

or

remains

plugged

replace

EF

20

Page 412 of 513

FUEL

SYSTEM

5

Check

venturi

clusters

for

loose

or

worn

parts

If

damage

or

looseness

exists

replace

cluster

assembly

6

Check

the

linkage

for

operating

condition

7

Inspect

the

operation

of

accelerating

pump

Pour

gasoline

into

the

float

chamber

and

operate

the

throttle

lever

Check

condition

of

gasoline

injection

from

the

accelerating

nozzle

Assembly

and

instalIetion

Assemble

and

install

the

carburetor

in

reverse

sequence

of

disassembly

and

removal

Replace

the

gaskets

if

necessary

When

disassembling

and

reassembling

the

interlock

link

and

related

components

be

careful

not

to

bend

or

deform

SPECIFICATIONS

AND

SERVICE

DATA

Carburetor

model

Applied

engine

Type

Outlet

diameter

mm

in

rom

in

Venturi

diameter

Main

jet

Main

air

bleed

Slow

jet

Slow

air

bleed

Power

jet

Float

level

H

rom

in

Interlock

opening

of

primary

and

secondary

throttle

valve

G

I

Throttle

valve

opening

480

mm

in

Auto

choke

Fast

idle

setting

clearance

A

mm

in

Manual

transmission

Automatic

transmission

Vacuum

break

gap

between

choke

valve

and

carburetor

body

8

mm

in

Manual

transmission

Automatic

transmission

EF

21

the

components

Reassembly

carefully

and

correctly

so

that

all

interlock

links

operate

smoothly

JETS

The

carburetor

performance

depends

on

jets

and

air

bleeds

and

the

vehicle

emissions

largely

depends

on

the

carburetor

performance

That

is

why

these

components

are

manufactured

with

utmost

care

To

clean

them

use

gasoline

and

blow

air

on

them

Changing

jet

or

air

bleed

size

may

cause

ill

vehicle

emission

So

they

should

not

be

changed

their

numbers

DCH3064

for

Manual

transmission

DCH306

5

for

Automatic

transmission

Downdraft

Primary

Secondary

26

1

024

30

1

181

20

0

787

26

1

024

1

95

1

140

1

80

1

80

1

43

1

50

1

215

1

100

1

60

18

to

20

0

709

to

0

748

5

8

0

2283

0

80

to

0

88

0

0315

to

0

0346

1

07

to

1

17

0

0421

to

0

0461

1

140

to

1

260

0

0449

to

0

0496

1

205

to

1

335

0

0474

to

0

0526

Page 413 of 513

ENGINE

Choke

unloader

clearance

carburetor

body

C

between

choke

valve

and

mm

in

Bi

metal

resistance

ohms

2

01

0

07911

8

6t09

0

Accelerator

pump

Injector

hole

Return

spring

Fuel

pressure

mm

in

g

mm

Ib

in

kg

cm

2

psi

kg

lb

0

5

0

0197

78

I

I

0

18

2

6

Manual

transmission

Automatic

transmission

Weight

2

8

6

2

2

9

6

39

Example

1

215

represents

215

100

2

15

mm

0

0846

in

diameter

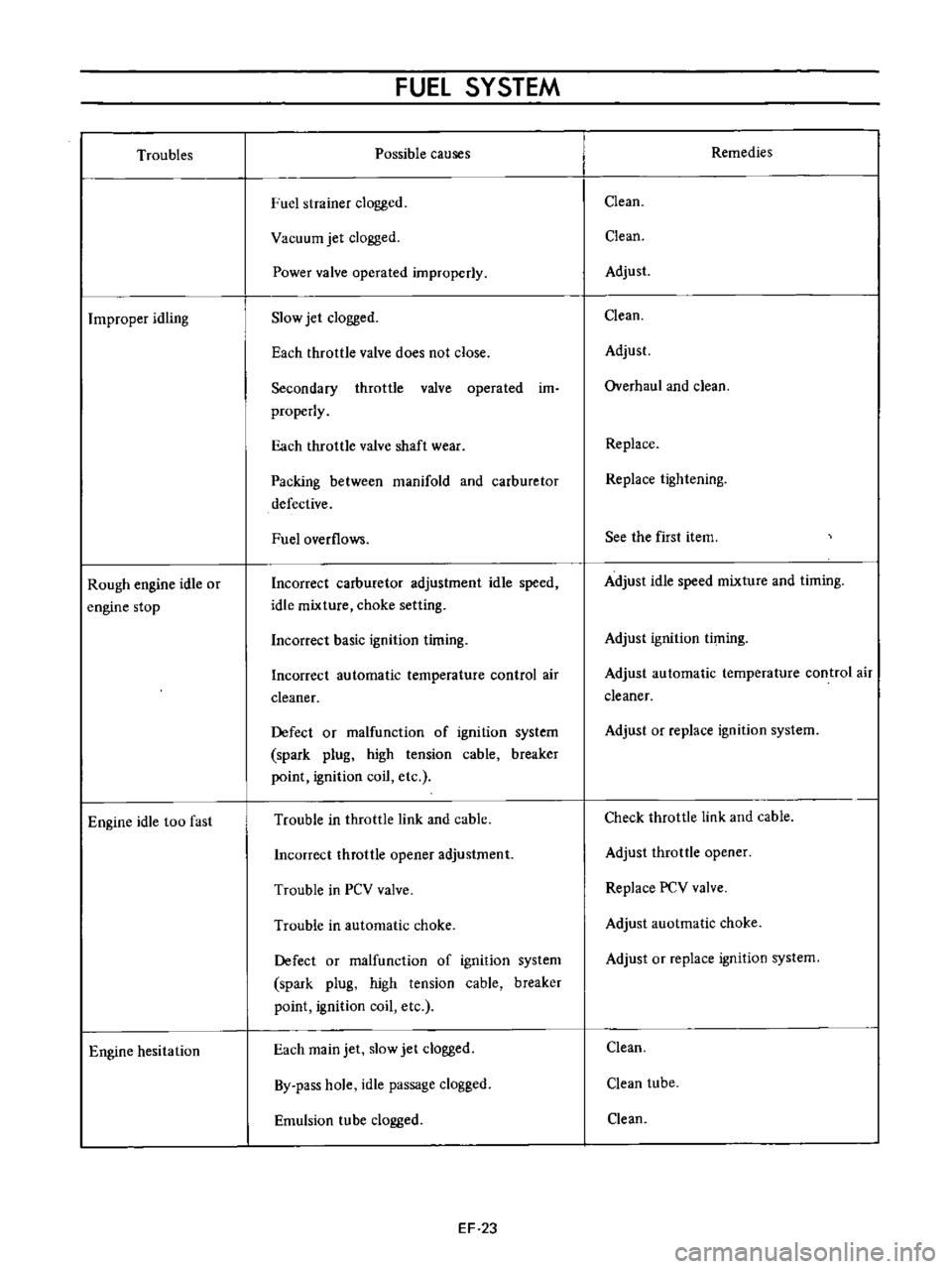

TROUBLE

DIAGNOSES

AND

CORRECTIONS

There

are

various

causes

of

engine

tarubles

It

some

times

happens

that

the

completely

effective

carburetor

seems

apparently

to

have

some

troubles

when

electric

system

is

defective

Therefore

whenever

the

enigne

has

troubles

electric

system

must

be

checked

first

before

adjusting

the

carburetor

In

the

following

table

the

symptoms

and

causes

of

carburetor

tarubles

and

remedies

for

them

are

listed

to

facilitate

quick

repairs

Troubles

Possible

causes

Remedies

Overflow

Dirt

accumulated

on

needle

valve

Clean

needle

valve

Fuel

pump

pressure

too

high

Repair

pump

Needle

valve

seat

improper

Lap

or

replace

Excessive

fuel

consumption

Fuel

overflows

See

above

Each

main

air

bleed

clogged

Clean

Gauge

plate

adjustment

incorrect

Correct

adjustment

Choke

valve

does

not

open

Adjust

Outlet

valve

seat

of

accelerator

pump

im

proper

Lap

or

replace

Linked

opening

of

secondary

throttle

valve

too

early

Adjust

Power

shortage

Each

main

jet

clogged

Clean

Each

throttle

valve

does

not

fully

open

Adjust

Fuel

pump

operated

improperly

Repair

EF

22

Page 414 of 513

Troubles

Improper

idling

Rough

engine

idle

or

engine

stop

Engine

idle

too

fast

Engine

hesitation

FUEl

SYSTEM

Possible

causes

ruel

strainer

clogged

Vacuum

jet

clogged

Power

valve

operated

improperly

Slow

jet

clogged

Each

throttle

valve

does

not

close

Secondary

throttle

valve

operated

im

properly

Each

throttle

valve

shaft

wear

Packing

between

manifold

and

carburetor

defective

Fuel

overflows

Incorrect

carburetor

adjustment

idle

speed

idle

mixture

choke

setting

Incorrect

basic

ignition

timing

Incorrect

automatic

temperature

control

air

cleaner

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Trouble

in

throttle

link

and

cable

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

Trouble

in

automatic

choke

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Each

main

jet

slow

jet

clogged

By

pass

hole

idle

passage

clogged

Emulsion

tube

clogged

EF

23

Remedies

Clean

Clean

Adjust

Clean

Adjust

Overhaul

and

clean

Replace

Replace

tightening

See

the

first

item

Adjust

idle

speed

mixture

and

timing

Adjust

ignition

timing

Adjust

automatic

temperature

control

air

cleaner

Adjust

or

replace

ignition

system

Check

throttle

link

and

cable

Adjust

throttle

opener

Replace

PCV

valve

Adjust

auotmatic

choke

Adjust

or

replace

ignition

system

Clean

Clean

tube

Clean

Page 415 of 513

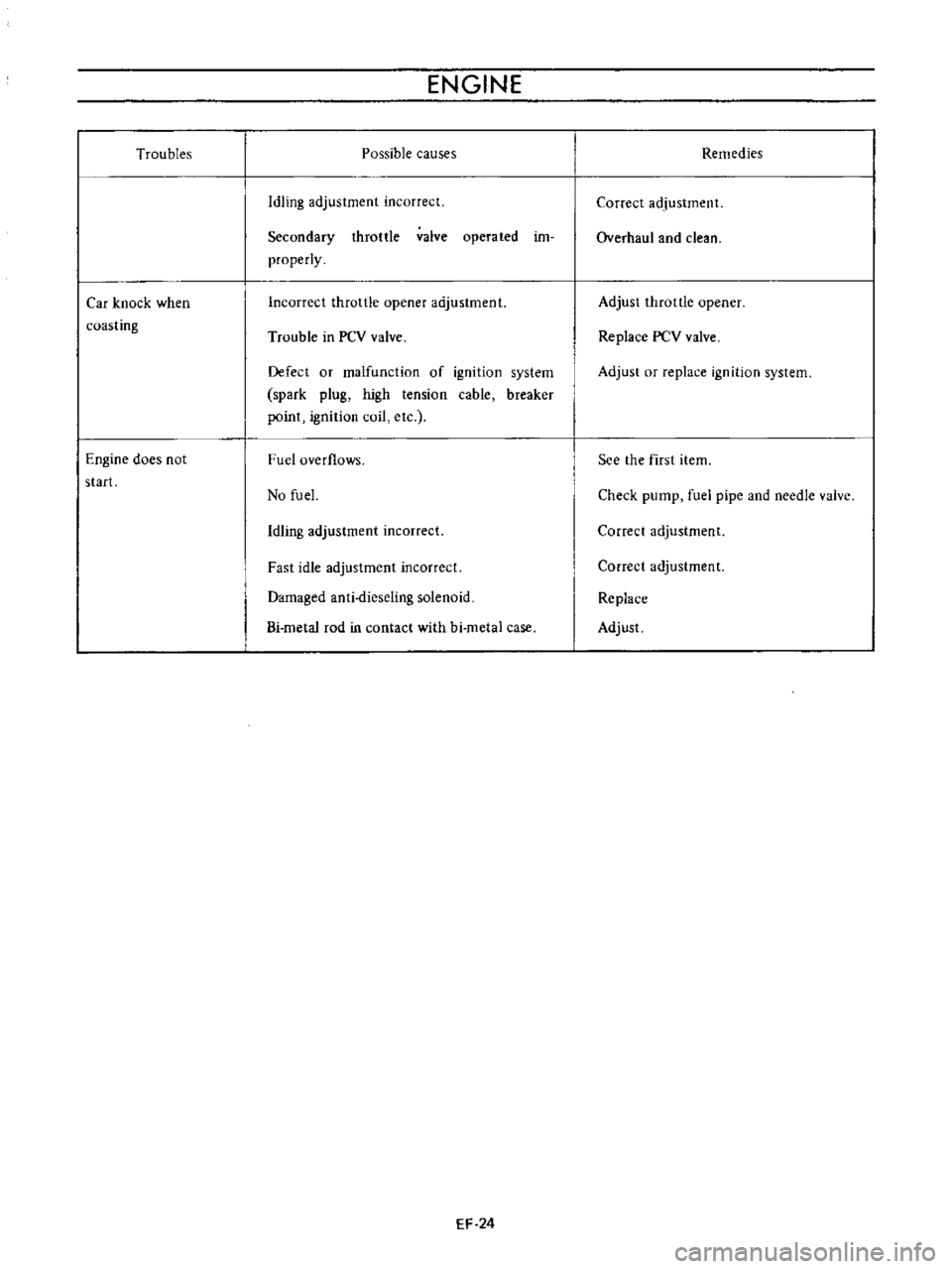

Troubles

Car

knock

when

coasting

Engine

does

not

start

ENGINE

Possible

causes

Idling

adjustment

incorrect

Secondary

throttle

valve

operated

im

properly

Incorrect

throttle

opener

adjustment

Trouble

in

PCV

valve

Defect

or

malfunction

of

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Fuel

overflows

No

fu

el

Idling

adjustment

incorrect

Fast

idle

adjustment

incorrect

Damaged

anti

dieseling

solenoid

Bi

metal

rod

in

contact

with

hi

metal

case

EF

24

Remedies

Correct

adjustment

Overhaul

and

clean

Adjust

throttle

opener

Replace

PCV

valve

Adjust

or

replace

ignition

system

See

the

first

item

Check

pump

fuel

pipe

and

needle

valve

Correct

adjustment

Correct

adjustment

Replace

Adjust

Page 416 of 513

FUEl

SYSTEM

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CONTENTS

OESCRI

PTION

Flow

guide

valve

MAINTENANCE

AND

TESTING

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

I

ins

EF

25

EF

26

EF

26

EF

26

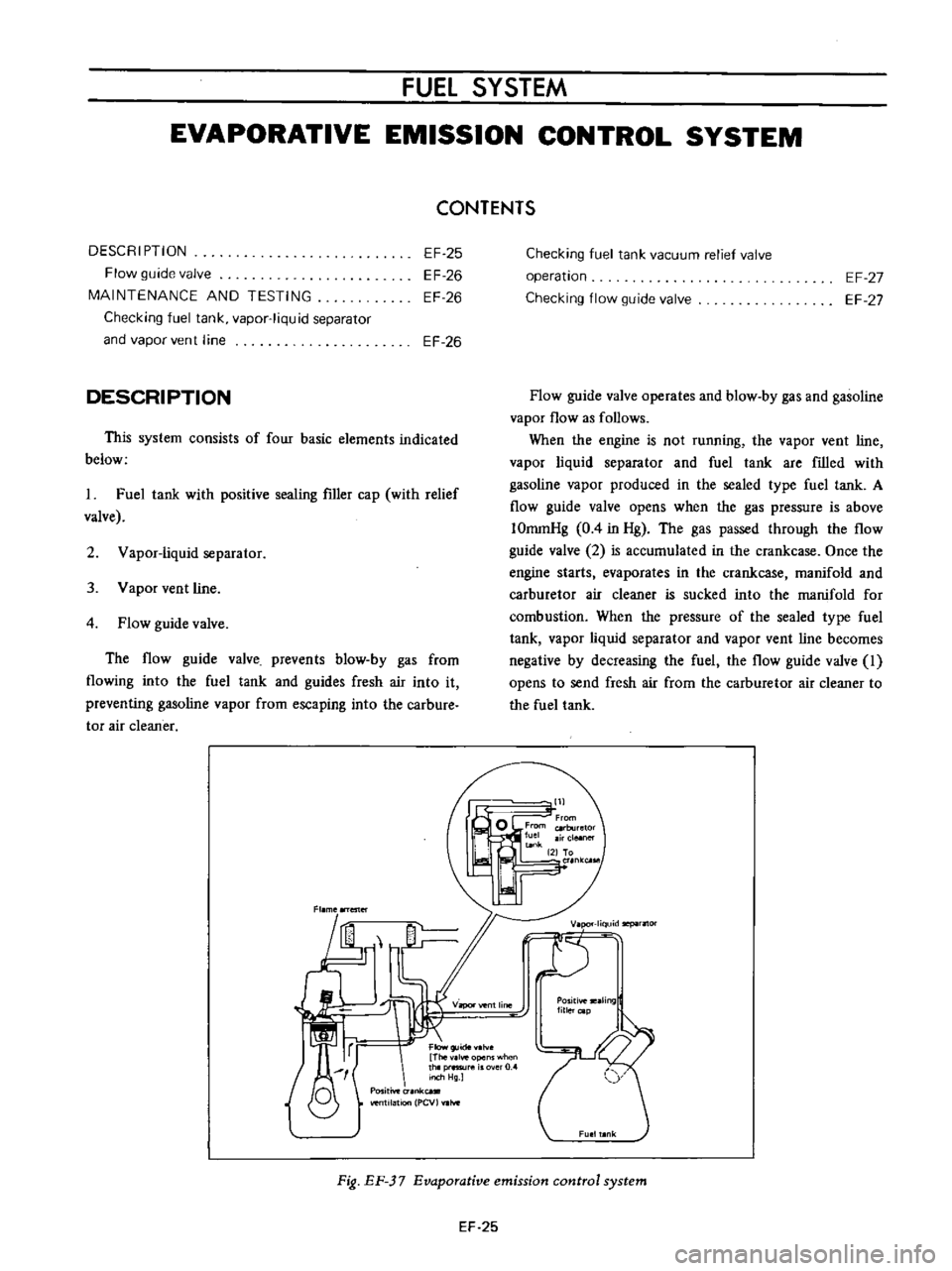

DESCRIPTION

This

system

consists

of

four

basic

elements

indicated

below

I

Fuel

tank

with

positive

sealing

filler

cap

with

relief

valve

2

Vapor

liquid

separator

3

Vapor

vent

line

4

Flow

guide

valve

The

flow

guide

valve

prevents

blow

by

gas

from

flowing

into

the

fuel

tank

and

guides

fresh

air

into

it

preventing

gasoline

vapor

from

escaping

into

the

carbure

tor

air

cleaner

Fl

me

ester

I

f

Flow

Thev

lve

opens

when

thlp

1l

rO

Inch

Hg

O

Positive

unk

venlI1atlon

PCV

hoe

Checking

fuel

tank

vacuum

relief

valve

operation

Checking

flow

guide

valve

EF

27

EF

27

Flow

guide

valve

operates

and

blow

by

gas

and

gasoline

vapor

flow

as

follows

When

the

engine

is

not

running

the

vapor

vent

line

vapor

liquid

separator

and

fuel

tank

are

filled

with

gasoline

vapor

produced

in

the

sealed

type

fuel

tank

A

flow

guide

valve

opens

when

the

gas

pressure

is

above

IOromHg

0

4

in

Hg

The

gas

passed

through

the

flow

guide

valve

2

is

accumulated

in

the

crankcase

Once

the

engine

starts

evaporates

in

the

crankcase

manifold

and

carburetor

air

cleaner

is

sucked

into

the

manifold

for

combustion

When

the

pressure

of

the

sealed

type

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

becomes

negative

by

decreasing

the

fuel

the

flow

guide

valve

I

opens

to

send

fresh

air

from

the

carburetor

air

cleaner

to

the

fuel

tank

lill

K

riquidllepilrflOr

T

VilPOl

vent

line

Positiveteilling

lillercap

Fig

EF

37

Evaporative

emission

control

system

EF

25