engine DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 428 of 513

ENGINE

EE022

Fig

EE

18

Ground

test

of

armature

5

Check

the

armature

for

short

circuit

by

placing

it

on

an

armature

tester

placing

a

hack

saw

blade

over

the

armature

core

and

by

rotating

the

armature

If

the

saw

blade

vibrates

armature

is

short

circuited

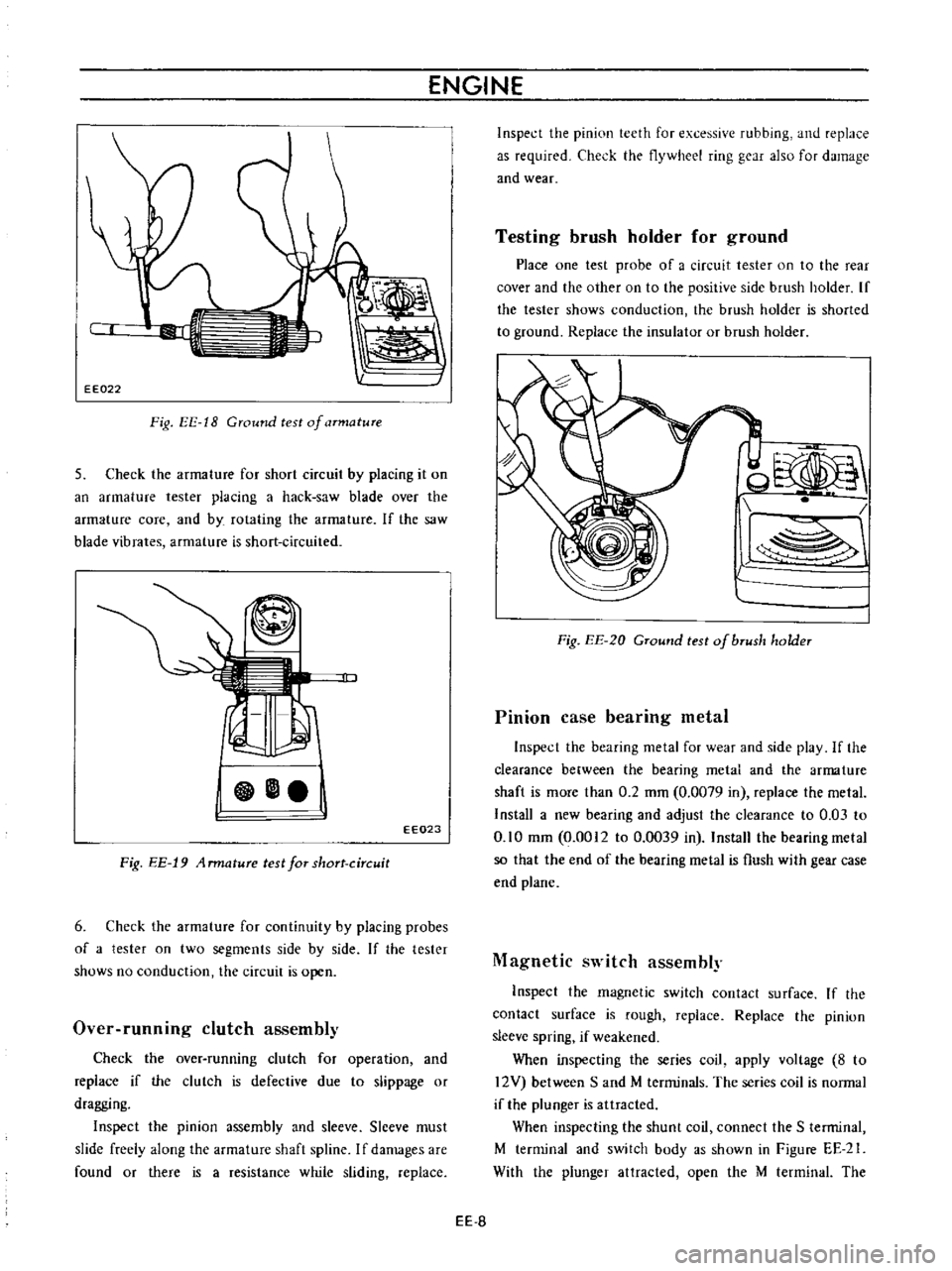

EE023

Fig

EE

19

4

rmature

test

for

short

circuit

6

Check

the

armature

for

continuity

by

placing

probes

of

a

tester

on

two

segments

side

by

side

If

the

tester

shows

no

conduction

the

circuit

is

open

Over

runnmg

clutch

assembly

Check

the

over

running

clutch

for

operation

and

replace

if

the

clutch

is

defective

due

to

slippage

or

dragging

Inspect

the

pinion

assembly

and

sleeve

Slceve

must

slide

freely

along

the

armature

shaft

spline

I

f

damages

are

found

or

there

is

a

resistance

while

sliding

replace

Inspect

the

pinion

teeth

for

excessive

rubbing

and

replace

as

required

Check

the

flywheel

ring

gear

also

for

damage

and

wear

Testing

brush

holder

for

ground

Place

one

test

probe

of

a

circuit

tester

on

to

the

rear

cover

and

the

other

on

to

the

positive

side

brush

holder

If

the

tester

shows

conduction

the

brush

holdcr

is

shorted

to

ground

Replace

the

insulator

or

brush

holder

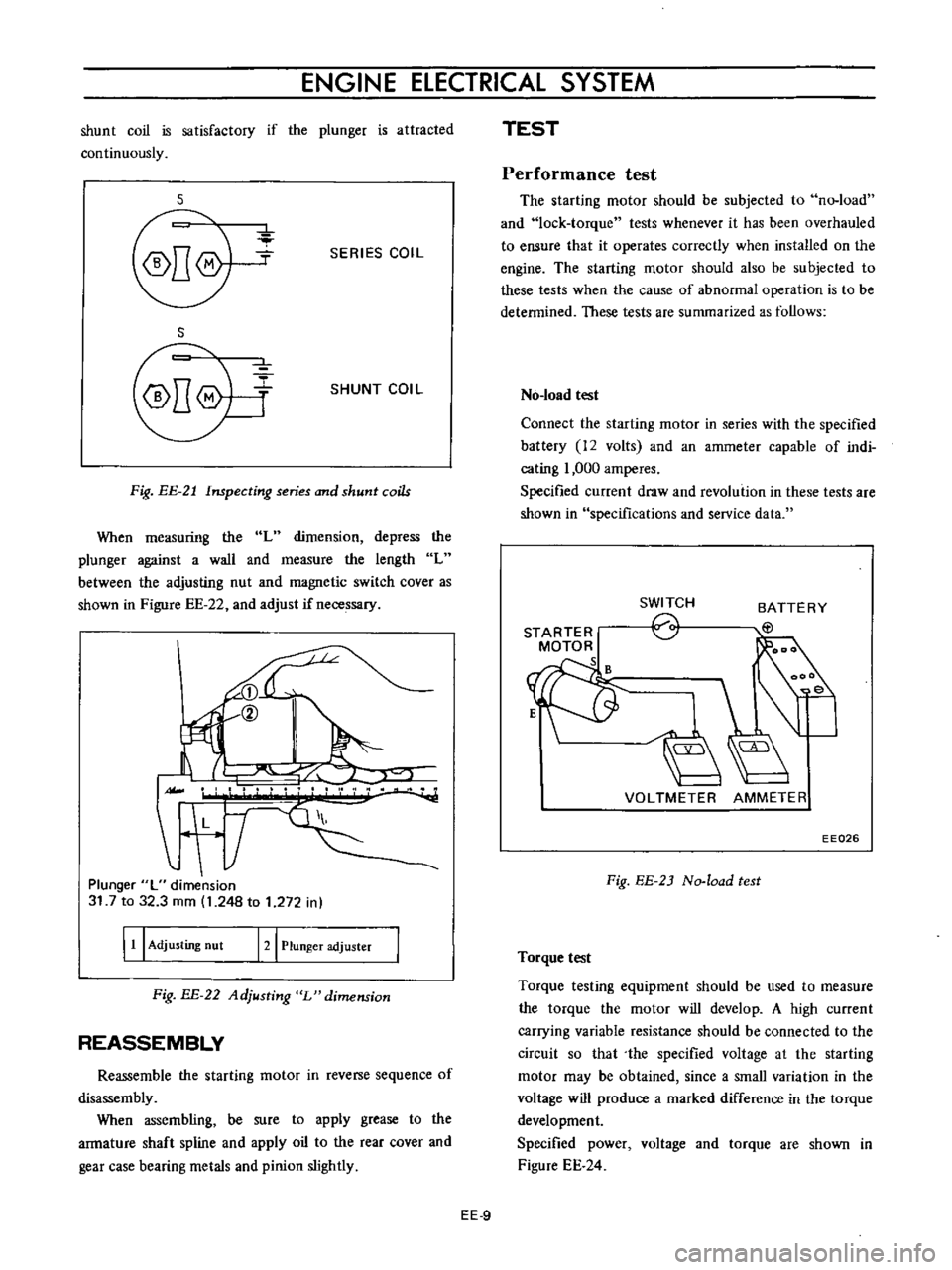

od

l

Fig

EE

20

GTound

test

of

bTush

holder

Pinion

case

bearing

metal

Inspect

the

bearing

metal

for

wear

and

sidc

play

If

the

clearance

between

the

bearing

metal

and

the

arma

ture

shaft

is

mOTe

than

0

2

mm

0

0079

in

replace

the

metal

Install

a

new

bearing

and

adjust

the

clearance

to

0

03

to

0

10

mm

0

0012

to

0

0039

in

Install

the

bearing

metal

so

that

the

end

of

the

bearing

metal

is

flush

with

gear

case

end

plane

Magnetic

switch

assembly

Inspect

the

magnetic

switch

contact

surface

If

the

contact

surface

is

rough

replace

Replace

the

pinion

sleeve

spring

if

weakened

When

inspecting

the

series

coil

apply

voltagc

8

to

12V

between

Sand

M

terminals

The

series

coil

is

normal

if

the

plunger

is

attracted

When

inspecting

the

shunt

coil

connect

the

S

terminal

M

terminal

and

switch

body

as

shown

in

Figure

EE

21

With

the

plunger

attracted

open

the

M

terminal

The

EE

S

Page 429 of 513

ENGINE

ElECTRICAL

SYSTEM

shunt

coil

is

satisfactory

if

the

plunger

is

attracted

continuously

s

SERIES

COIL

S

SHUNT

COIL

Fig

EE

21

Inspecting

series

and

shunt

coils

When

measuring

the

L

dimension

depress

the

plunger

against

a

wall

and

measure

the

length

L

between

the

adjusting

nut

and

magnetic

switch

cover

as

shown

in

Figure

EE

22

and

adjust

if

necessary

II

L

T

Plunger

L

dimension

31

7

to

32

3

mm

1

248

to

1

272

in

I

11

I

Adjusting

nut

121

Plunger

adjuster

Fig

BE

22

Adjusting

L

dimension

REASSEMBLY

Reassemble

the

starting

motor

in

reverse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

the

armature

shaft

spline

and

apply

oil

to

the

rear

cover

and

gear

case

bearing

metals

and

pinion

slightly

TEST

Performance

test

The

starting

motor

should

be

subjected

to

no

load

and

lock

torque

tests

whenever

it

has

been

overhauled

to

ensure

that

it

operates

correctly

when

installed

on

the

engine

The

starting

motor

should

also

be

subjected

to

these

tests

when

the

cause

of

abnormal

operation

is

to

be

determined

These

tests

are

summarized

as

follows

No

load

test

Connect

the

starting

motor

in

series

with

the

specified

battery

12

volts

and

an

ammeter

capable

of

indi

cating

1

000

amperes

Specified

current

draw

and

revolution

in

these

tests

are

shown

in

specifications

and

service

data

STARTER

MOTOR

s

SWITCH

o

BATTERY

EtJ

VOLTMETER

AMMETER

EE026

Fig

EE

2J

No

load

test

Torque

test

Torque

testing

equipment

should

be

used

to

measure

the

torque

the

motor

will

develop

A

high

current

carrying

variable

resistance

should

be

connected

to

the

circuit

so

that

the

specified

voltage

at

the

starting

motor

may

be

obtained

since

a

small

variation

in

the

voltage

will

produce

a

marked

difference

in

the

torque

development

Specified

power

voltage

and

torque

are

shown

in

Figure

EE

24

EE

9

Page 430 of 513

ENGINE

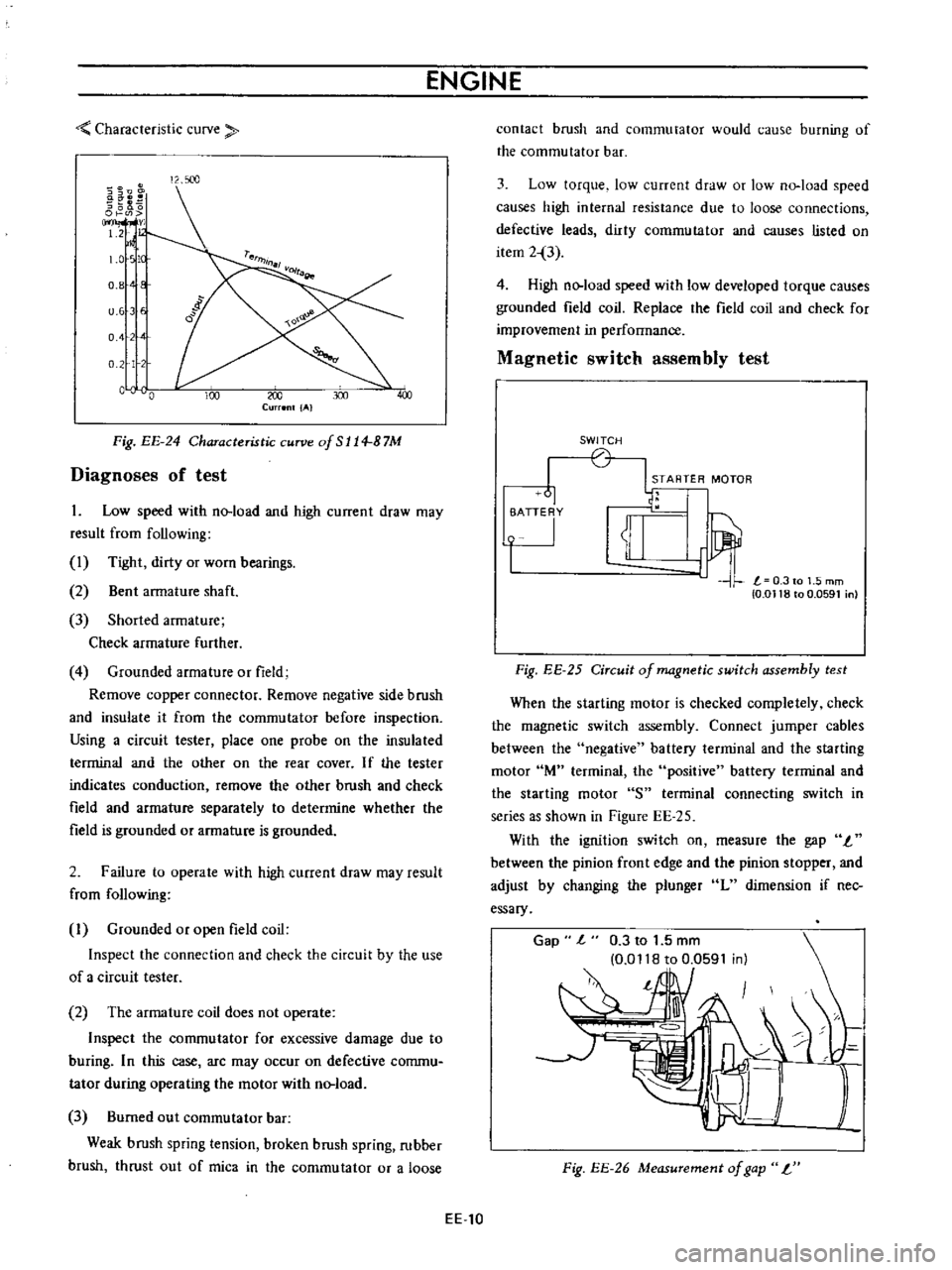

Characteristic

curve

i

8

s

l00

0

OJ

m

v

1

2

1

0

tc

0

8

E

u

6

E

o

4

0

2

L

c

0

00

J

300

Current

IAI

Fig

EE

24

Characteristic

curve

of

S

114

B

7M

Diagnoses

of

test

1

Low

speed

with

no

load

and

high

current

draw

may

result

from

following

1

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

3

Shorted

armature

Check

armature

further

4

Grounded

armature

or

field

Remove

copper

connector

Remove

negative

side

brush

and

insulate

it

from

the

commutator

before

inspection

Using

a

circuit

tester

place

one

probe

on

the

insulated

terminal

and

the

other

on

the

rear

cover

If

the

tester

indicates

conduction

remove

the

other

brush

and

check

field

and

armature

separately

to

determine

whether

the

field

is

grounded

or

armature

is

grounded

2

Failure

to

operate

with

high

current

draw

may

result

from

following

I

Grounded

or

open

field

coil

Inspect

the

connection

and

check

the

circuit

by

the

use

of

a

circuit

tester

2

The

armature

coil

does

not

operate

Inspect

the

commutator

for

excessive

damage

due

to

buring

In

this

case

arc

may

occur

on

defective

commu

tator

during

operating

the

motor

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

brush

spring

rubber

brush

thrust

out

of

mica

in

the

commutator

or

a

loose

EE

10

contact

brush

and

commutator

would

cause

burning

of

the

commutator

bar

3

Low

torque

low

current

draw

or

low

no

load

speed

causes

high

internal

resistance

due

to

loose

connections

defective

leads

dirty

commutator

and

causes

listed

on

item

2

3

4

High

no

load

speed

with

low

developed

torque

causes

grounded

field

coil

Replace

the

field

coil

and

check

for

improvement

in

performance

Magnetic

switch

assembly

test

SWITCH

STARTER

MOTOR

61

1u

i

T

0

0118

to

0

0591

n

Fig

EE

25

Circuit

of

magnetic

switch

assembly

test

When

the

starting

motor

is

checked

completely

check

the

magnetic

switch

assembly

Connect

jumper

cables

between

the

negative

battery

terminal

and

the

starting

motor

lM

terminal

the

positive

battery

terminal

and

the

starting

motor

S

terminal

connecting

switch

in

series

as

shown

in

Figure

EE

25

With

the

ignition

switch

on

measure

the

gap

I

between

the

pinion

front

edge

and

the

pinion

stopper

and

adjust

by

changing

the

plunger

L

dimension

if

nec

essary

Gap

l

0

3

to

1

5

mm

0

0118

to

0

0591

in

l

Fig

EE

26

Measurement

of

gap

L

Page 431 of 513

ENGINE

ElECTRICAL

SYSTEM

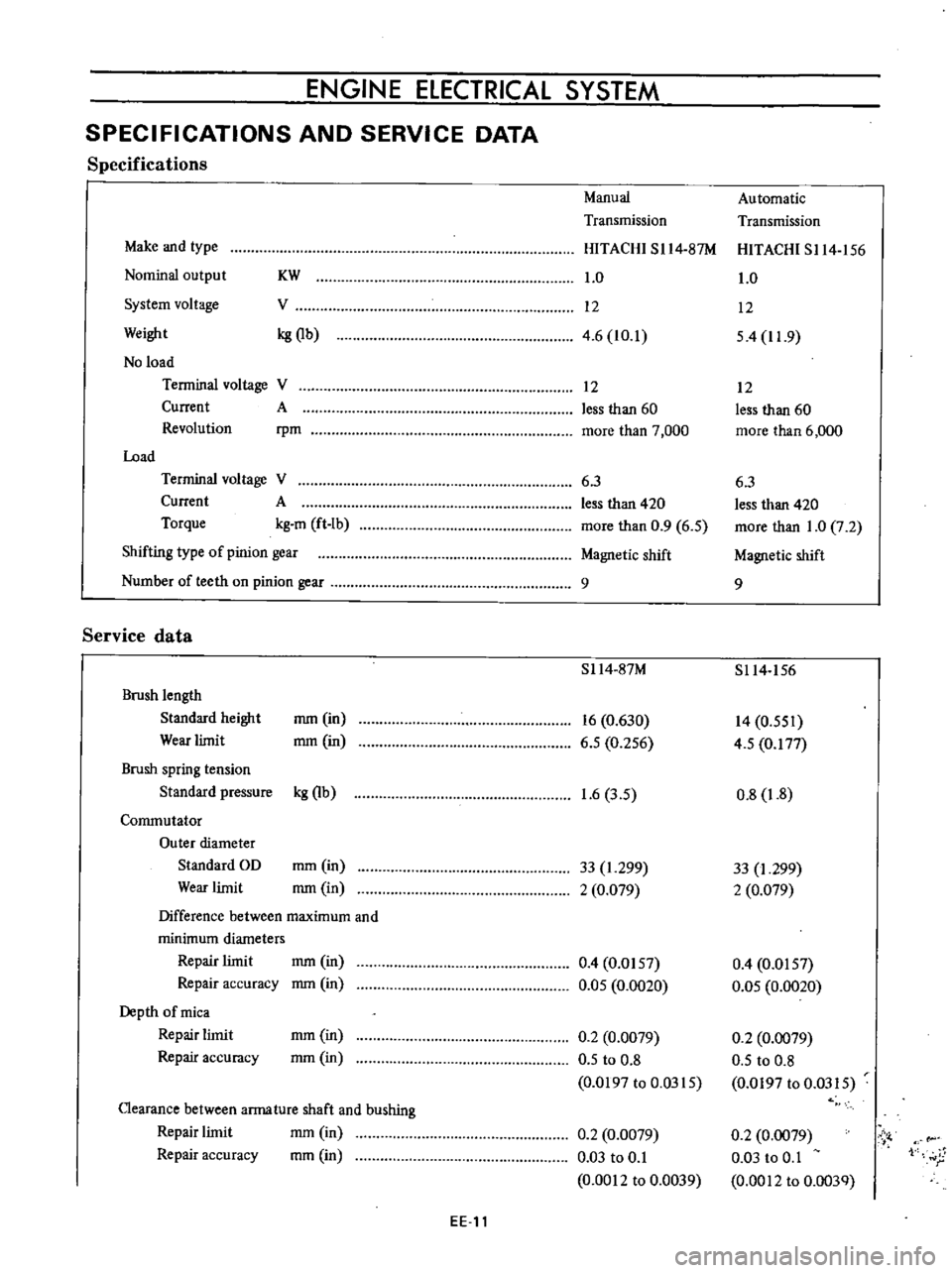

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Manual

Automatic

Transmission

Transmission

Make

and

type

HITACHI

SI14

87M

HITACHI

S114

156

Nominal

output

KW

1

0

1

0

System

voltage

V

12

12

Weight

kg

Qb

4

6

10

1

54

11

9

No

load

Terminal

voltage

V

12

12

Current

A

less

than

60

less

than

60

Revolution

rpm

more

than

7

000

more

than

6

000

Load

Terminal

voltage

V

6

3

6

3

Current

A

less

than

420

less

than

420

Torque

kg

m

ft

Ib

more

than

0

9

6

5

more

than

1

0

7

2

Shifting

type

of

pinion

gear

Magnetic

shift

Magnetic

shift

Number

of

teeth

on

pinion

gear

9

9

Service

data

S114

87M

S114

156

Brush

length

Standard

height

mm

in

16

0

630

14

0

551

Wear

limit

mm

in

6

5

0

256

4

5

0

177

Brush

spring

tension

Standard

pressure

kg

Qb

1

6

3

5

0

8

1

8

Commutator

Outer

diameter

Standard

OD

mm

in

33

1

299

33

I

299

Wear

limit

mm

in

2

0

079

2

0

079

Difference

between

maximum

and

minimum

diameters

Repair

limit

mm

in

0

4

0

0157

0

4

0

0157

Repair

accuracy

mm

in

0

05

0

0020

0

05

0

0020

Depth

of

mica

Repair

limit

mm

in

0

2

0

0079

0

2

0

0079

Repair

accuracy

mm

in

0

5

to

0

8

0

5

to

0

8

0

0197

to

0

0315

0

0197

to

0

0315

Clearance

between

arma

ture

shaft

and

bushing

mm

in

Repair

limit

0

2

0

0079

0

2

0

0079

Vi

Repair

accuracy

mm

in

0

03

to

0

1

0

03

to

0

1

1

r

0

0012

to

0

0039

0

0012

to

0

003Q

EE

11

Page 432 of 513

ENGINE

Arma

ture

shaft

Outer

diameter

Pinion

side

mm

in

12

950

to

12

968

0

5082

to

0

5105

11

450

to

II

468

0

4507

to

0

4515

0

1

0

0039

0

08

0

0031

Rear

end

mm

in

Wear

limit

Bend

limit

mm

in

mm

in

Gap

1

between

the

pinion

front

edge

and

the

pinion

stopper

mm

in

0

3

to

1

5

0

0118

to

0

0591

Magnetic

switch

Coil

resistance

Series

cuil

Q

Shunt

coil

n

Plunger

L

dimension

mm

in

0

3

at

20De

68UF

0

9

at

ooe

680F

317t032

3

l

248

to

1

272

TROUBLE

DIAGNOSES

AND

CORRECTIONS

12

950

to

12

968

0

5082

to

0

5105

11

450

to

II

468

0

4507

to

0

4515

l

0

1

0

0039

0

08

0

0031

0

3

to

1

5

0

0118

to

0

0591

0

3

at

20De

680Fl

0

9

at

200e

680F

317

to

32

3

l

248

to

I

272

Troubles

Trouble

location

Causes

Remedies

Starting

motor

will

not

operate

No

magnetic

switch

Battery

Defective

battery

Replace

battery

operating

sound

Over

discharging

Measure

specific

gravity

of

e

Ie

ctrolyte

and

ch

lrge

or

replace

the

battery

Ignition

switch

Defective

contact

Correct

or

replace

ig

nition

switch

Wiring

Faulty

starting

motor

grounding

Correct

Faulty

battery

grounding

Correct

Broken

or

disconnected

cable

Correct

or

replace

EE

12

Page 433 of 513

Magnetic

switch

operating

sound

is

heard

The

starting

motor

rotates

Pinion

gear

does

not

intermesh

with

ring

gear

ENGINE

ELECTRICAL

SYSTEM

Starter

Magnetic

switch

Battery

Wiring

Starting

motor

Magnetic

switch

Ring

gear

Starting

motor

Broken

armature

or

field

coil

cable

Broken

brush

pig

tail

Defective

mica

Broken

or

shorted

series

coil

Faulty

plunger

sliding

Over

discharging

Faulty

terminal

contact

or

loose

connection

Faulty

B

or

M

terminal

connections

Shorted

armature

or

field

coil

Worn

brush

or

improper

spring

pressure

Contaminated

commutator

or

de

fective

mica

Faulty

brush

connection

Seized

metal

Armature

contacted

with

pole

core

Insufficient

plunger

L

dimension

Faulty

contact

Broken

or

shorted

shunt

coil

wire

Worn

teeth

Weakened

pinion

sleeve

spring

Worn

pinion

teeth

EE

13

Replace

Replace

Correct

or

replace

Replace

Repair

or

replace

Measure

specific

gravity

of

electrolyte

arid

charge

if

necessary

Clean

and

retighten

Retighten

Repair

or

replace

Repair

or

replace

Clean

or

repair

Repair

Replace

Repair

or

replace

Adjust

Replace

Replace

Replace

Replace

Replace

Page 434 of 513

Pinion

intermeshes

with

ring

gear

Starting

motor

rotates

and

pinion

intermeshes

with

ring

gear

but

ro

tation

is

too

slow

When

starting

switch

is

set

to

OFF

the

start

ing

motor

does

not

stop

Starting

motor

Battery

Wiring

Ignition

switch

Starting

motor

Ignition

switch

Magnetic

switch

Starting

motor

ENGINE

Faulty

pinion

sliding

Dropped

off

lever

pin

Excessive

plunger

L

dimension

Defective

over

running

clutch

Over

discharging

Improper

or

loose

terminal

contact

Improperly

tightened

connection

Rough

contact

surface

Shorted

armature

coil

or

field

coil

Worn

brush

or

insufficient

spring

pressure

Contaminated

commutator

or

im

proper

brush

contact

Defective

mica

Lack

of

metal

lubrication

Armature

contacted

with

pole

core

Faulty

returning

Seized

contact

Shorted

coil

Faulty

plunger

sliding

Pinion

does

not

disengage

from

the

ring

gear

smoothly

Pinion

spline

does

not

disengage

smoothly

Seized

pinion

metal

EE

14

Repair

Repair

Adjust

Replace

Charge

battery

Repair

and

retighten

Retighten

Repair

or

replace

Repair

or

replace

Repair

or

replace

Repair

Repair

Repair

or

replace

Repair

or

replace

Replace

Replace

Replace

Replace

Repair

or

replace

Repair

or

replace

Replace

Page 435 of 513

ENGINE

ElECTRICAL

SYSTEM

CHARGING

CIRCUIT

IGNITION

1

i

n

ITCH

r

B

i

i

vel

oU

ARMATURE

lip

J

l

t

lJ

FIEL

Df

e

I

I

3

2

I

u

P

5

0

IL

U

p

P

f

H

i

I

I

L

J

L

J

ALTERNATOR

VOL

TAGE

REGULATOR

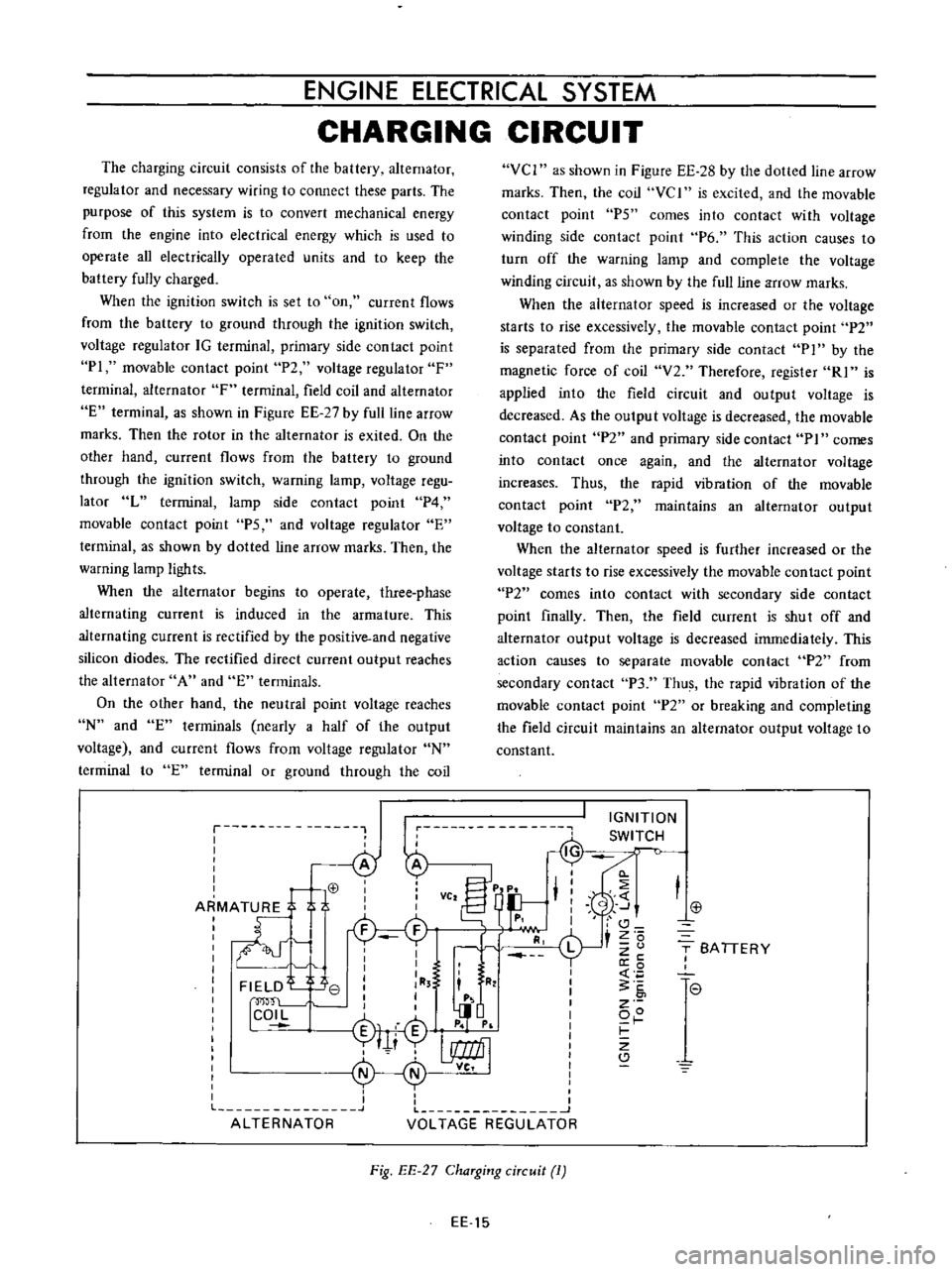

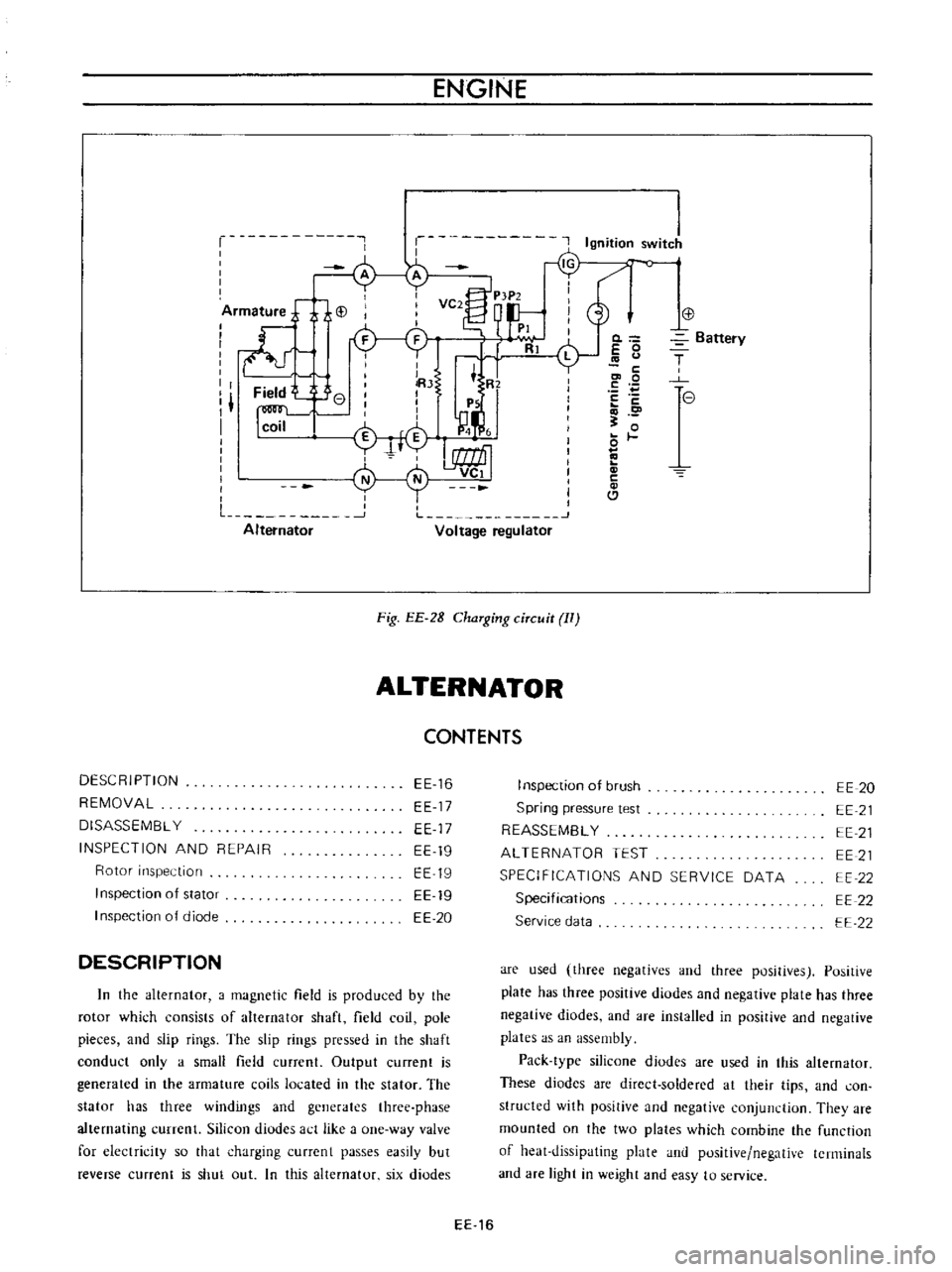

The

charging

circuit

consists

of

the

battery

alternator

regulator

and

necessary

wiring

to

connect

these

parts

The

purpose

of

this

system

is

to

convert

mechanical

energy

from

the

engine

into

electrical

energy

which

is

used

to

operate

all

electrically

operated

units

and

to

keep

the

battery

fully

charged

When

the

ignition

switch

is

set

to

on

current

flows

from

the

battery

to

ground

through

the

ignition

switch

voltage

regulator

IG

terminal

primary

side

contact

point

PI

movable

contact

point

P2

voltage

regulator

F

terminal

alternator

F

terminal

field

coil

and

alternator

E

terminal

as

shown

in

Figure

EE

27

by

full

line

arrow

marks

Then

the

rotor

in

the

alternator

is

exited

On

the

other

hand

current

flows

from

the

battery

to

ground

through

the

ignition

switch

warning

lamp

voltage

regu

lator

L

terminal

lamp

side

contact

point

P4

movable

contact

point

PS

and

voltage

regulator

E

terminal

as

shown

by

dotted

line

arrow

marks

Then

the

warning

lamp

ligh

ts

When

the

alternator

begins

to

operate

three

phase

alternating

current

is

induced

in

the

armature

This

alternating

current

is

rectified

by

the

positive

and

negative

silicon

diodes

The

rectified

direct

current

output

reaches

the

alternator

A

and

E

terminals

On

the

other

hand

the

neutral

point

voltage

reaches

N

and

E

terminals

nearly

a

half

of

the

output

voltage

and

current

flows

from

voltage

regulator

N

terminal

to

E

terminal

or

ground

through

the

coil

VCI

as

shown

in

Figure

EE

28

by

the

dolled

line

arrow

marks

Then

the

coil

vc

I

is

excited

and

the

movable

contact

point

P5

comes

into

contact

with

voltage

winding

side

contact

point

P6

This

action

causes

to

turn

off

the

warning

lamp

and

complete

the

voltage

winding

circuit

as

shown

by

the

ullline

arrow

marks

When

the

alternator

speed

is

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

is

separated

from

the

primary

side

contact

P

1

by

the

magnetic

force

of

coil

V2

Therefore

register

RI

is

applied

into

the

field

circuit

and

output

voltage

is

decreased

As

the

outpu

t

voltage

is

decreased

the

movable

contact

point

P2

and

primary

side

contact

PI

comes

into

contact

once

again

and

the

alternator

voltage

increases

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

maintains

an

alternator

output

voltage

to

constant

When

the

alternator

speed

is

further

increased

or

the

voltage

starts

to

rise

excessively

the

movable

contact

point

P2

comes

into

contact

with

secondary

side

contact

point

finally

Then

the

field

current

is

shut

off

and

alternator

output

voltage

is

decreased

immediately

This

action

causes

to

separate

movable

contact

P2

from

secondary

contact

P3

Thus

the

rapid

vibration

of

the

movable

contact

point

P2

or

breaking

and

completing

the

field

circuit

maintains

an

alternator

output

voltage

to

constant

j

T

SA

TIERY

I

l

e

7

Fig

EE

27

ChaTging

ciTcuit

1

EE

15

Page 436 of 513

ENGINE

r

Ignition

switJ

c

o

iArm

ture

j

i

i

VC2

P

tP2

d

I

I

I

PI

I

ll

Rl

L

I

I

lRJ

t

R

I

Field

e

I

I

I

I

Ps

I

1

I

I

n

I

coil

M

4

i

f

I

L

1

J

Alternator

Voltage

regulator

Fig

EE

2B

ChaTging

ciTcuit

II

ALTERNATOR

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

Rotor

inspection

Inspection

of

stator

I

nspection

of

diode

EE

16

EE

17

EE

17

EE

19

EE

19

EE

19

EE

20

DESCRIPTION

In

the

alternator

a

magnetic

field

is

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

currenl

Silicon

diudes

act

like

a

one

way

valve

for

electricity

so

that

charging

currcnt

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

six

diodes

0

E

0

c

co

0

E

c

o

0

c

Cl

Battery

T

e

I

nspection

of

brush

Spring

pressure

test

REASSEMBL

Y

ALTERNATOR

TEST

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

EE

20

EE

21

EE

21

EE

21

EE

22

EE

22

EE

22

are

used

three

negatives

and

three

positives

Positive

plate

has

three

positive

diodes

and

negative

plate

has

three

negative

diodes

and

are

installed

in

positive

and

negative

plates

as

an

assembly

Pack

type

silicone

diodes

are

used

in

this

alternator

These

diodes

are

direct

soldered

at

their

tips

and

con

structed

with

positive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

EE

16

Page 437 of 513

ENGINE

ElECTRICAL

SYSTEM

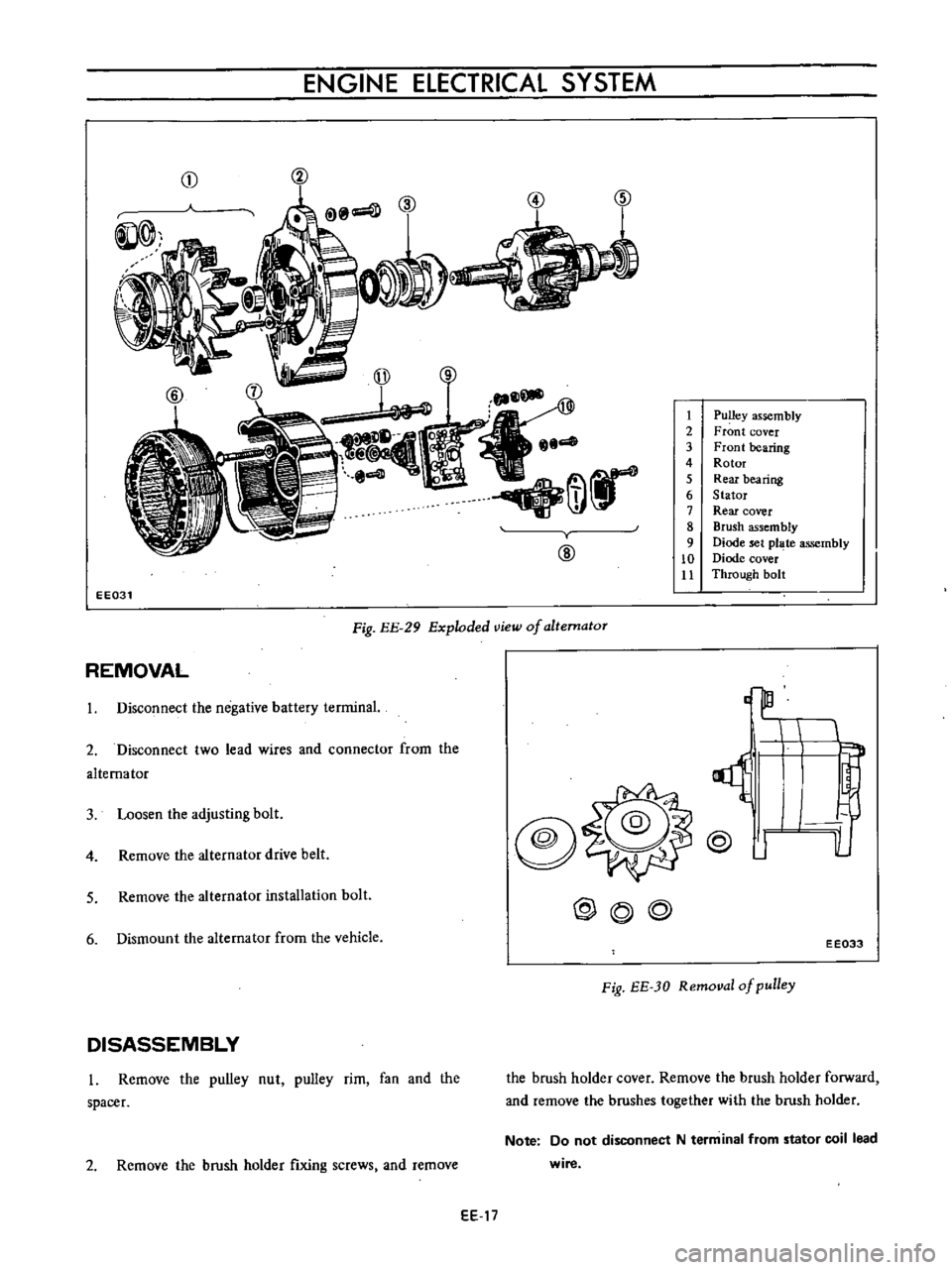

CD

@

@

@

y

@

1

Pulley

assembly

2

Front

cover

3

Front

bearing

4

Rotor

5

Rear

bearing

6

Stator

7

Rear

cover

8

Brush

assembly

9

Diode

set

pl

te

assembly

10

Diode

cover

Jl

Through

bolt

EE031

Fig

EE

29

Exploded

view

of

altematoT

REMOVAL

3

Loosen

the

adjusting

bolt

@

o

lL

1

Disconnect

the

negative

battery

terminal

2

Disconnect

two

lead

wires

and

connector

from

the

alternator

4

Remove

the

alternator

drive

belt

@

J

5

Remove

the

alternator

installation

bolt

@@@

6

Dismount

the

alternator

from

the

vehicle

EE033

Fig

EE

JO

Removal

of

pulley

DISASSEMBLY

l

Remove

the

pulley

nut

pulley

rim

fan

and

the

spacer

the

brush

holder

cover

Remove

the

brush

holder

forward

and

remove

the

brushes

together

with

the

brush

holder

2

Remove

the

brush

holder

fixing

screws

and

remove

Note

Do

not

disconnect

N

term

inal

from

stator

coil

lead

wire

EE

17