engine DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 438 of 513

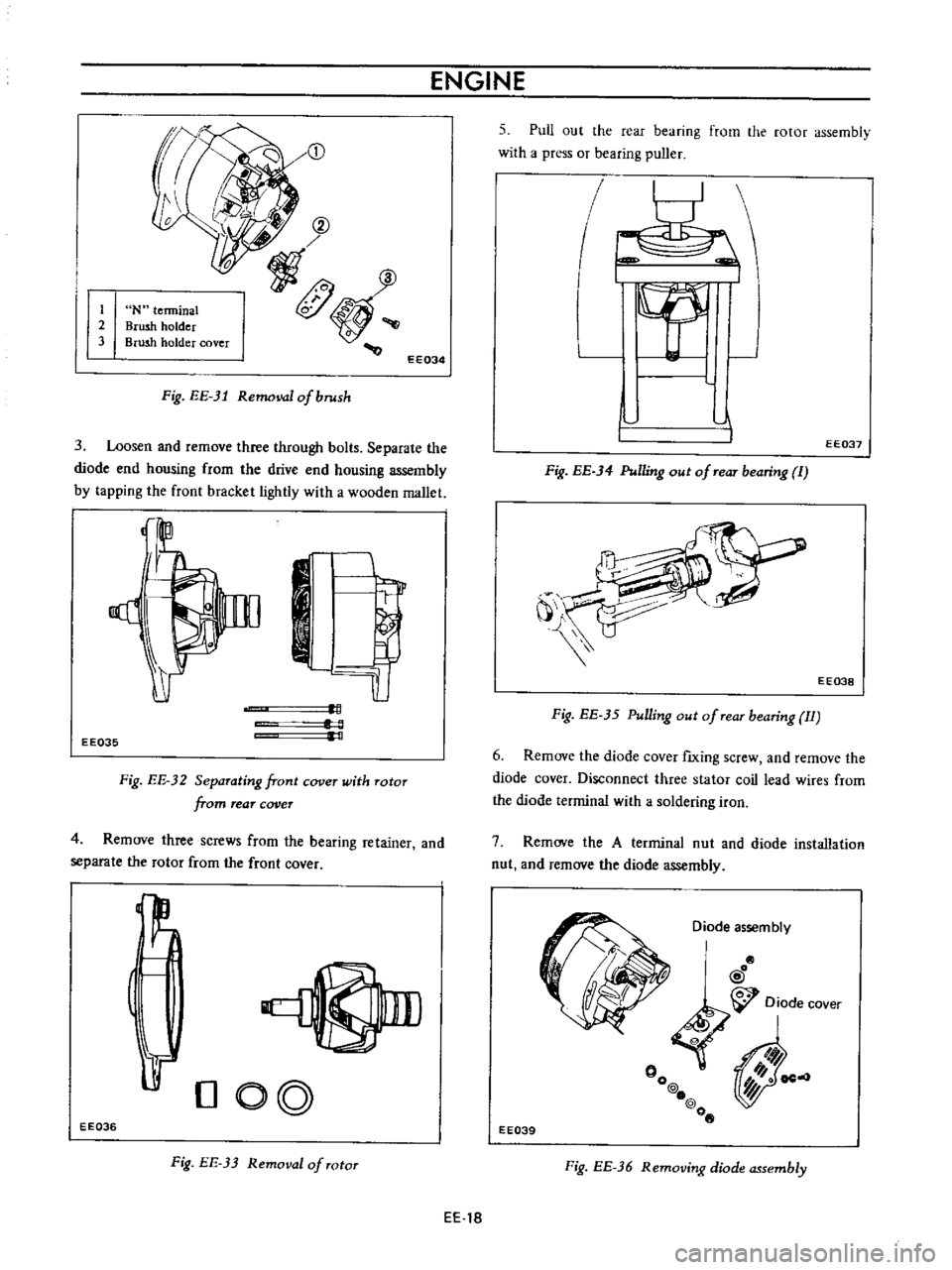

ENGINE

G

2

3

N

terminal

Brush

holder

Brush

holder

cover

@

f

fI

0

EE034

Fig

EE

31

Removal

of

brush

3

Loosen

and

remove

three

through

bolts

Separate

the

diode

end

housing

from

the

drive

end

housing

assembly

by

tapping

the

front

bracket

lightly

with

a

wooden

mallet

1

L

c

EE035

Fig

EE

32

Separating

front

cover

with

Totor

from

rear

cover

4

Remove

three

screws

from

the

bearing

retainer

and

separate

the

rotor

from

the

front

cover

L1

1

t

DO

L

EE036

Fig

EE

33

Removal

of

TOtOT

5

Pull

out

the

rear

bearing

from

the

rotor

assembly

with

a

press

or

bearing

puller

I

I

l

I

EE037

Fig

EE

34

Pulling

out

of

TeaT

bearing

I

j

EE038

Fig

EE

35

Pulling

out

of

Tear

bearing

II

6

Remove

the

diode

cover

fIxing

screw

and

remove

the

diode

cover

Disconnect

three

stator

coil

lead

wires

from

the

diode

terminal

with

a

soldering

iron

7

Remove

the

A

terminal

nut

and

diode

installation

nut

and

remove

the

diode

assembly

Diode

assembly

I

o

@

Diode

cover

rJ

0

00

@

Y

o@

o

EE039

Fig

EE

36

Removing

diode

assembly

EE

18

Page 439 of 513

ENGINE

ELECTRICAL

SYSTEM

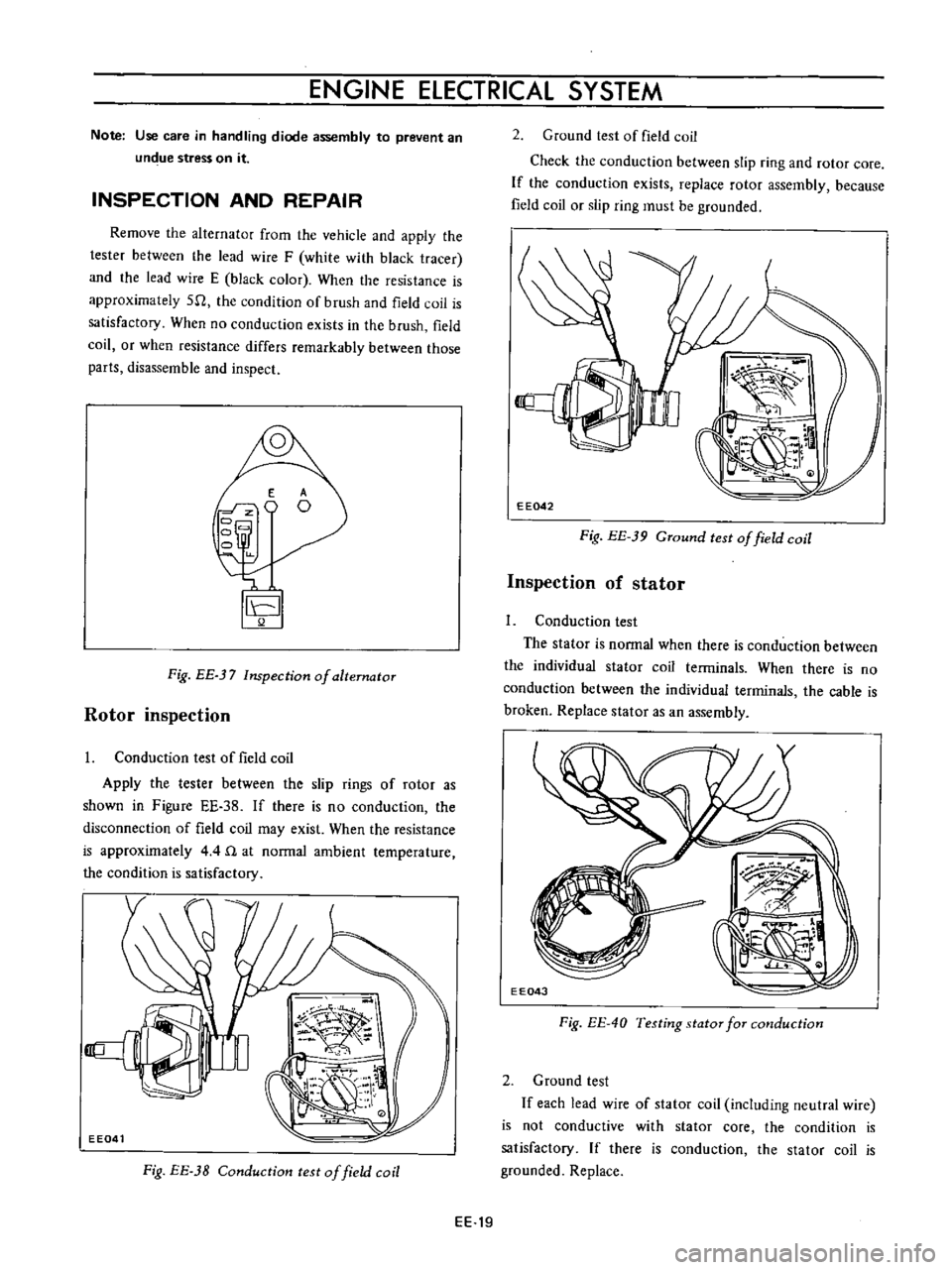

Note

Use

care

in

handling

diode

assembly

to

prevent

an

undue

stress

on

it

INSPECTION

AND

REPAIR

Remove

the

alternator

from

the

vehicle

and

apply

the

tester

between

the

lead

wire

F

white

with

black

tracer

and

the

lead

wire

E

black

color

When

the

resistance

is

approximately

511

the

condition

of

brush

and

field

coil

is

satisfactory

When

no

conduction

exists

in

the

brush

field

coil

or

when

resistance

differs

remarkably

between

those

parts

disassemble

and

inspect

E

o

Fig

BE

37

Inspection

of

alternator

Rotor

inspection

I

Conduction

test

of

field

coil

Apply

the

tester

between

the

slip

rings

of

rotor

as

shown

in

Figure

EE

38

If

there

is

no

conduction

the

disconnection

of

field

coil

may

exist

When

the

resistance

is

approximately

4

4

n

at

normal

ambient

temperature

the

condition

is

satisfactory

Fig

EE

3B

Conduction

test

of

field

coil

2

Ground

test

of

field

coil

Check

the

conduction

between

slip

ring

and

rotor

core

If

the

conduction

exists

replace

rotor

assembly

because

field

coil

or

slip

ring

must

be

grounded

EE042

Fig

EE

39

GTound

test

of

field

coil

Inspection

of

stator

1

Conduction

test

The

stator

is

normal

when

there

is

conduction

between

the

individual

stator

coil

terminals

When

there

is

no

conduction

between

the

individual

terminals

the

cable

is

broken

Replace

stator

as

an

assembly

EE043

Fig

EE

40

Testing

stator

for

cmlduction

2

Ground

test

If

each

lead

wire

of

stator

coil

including

neutral

wire

is

not

conductive

with

stator

core

the

condition

is

satisfactory

If

there

is

conduction

the

stator

coil

is

grounded

Replace

EE

19

Page 440 of 513

ENGINE

Stator

core

EE044

Fig

EE

41

Testing

stator

for

ground

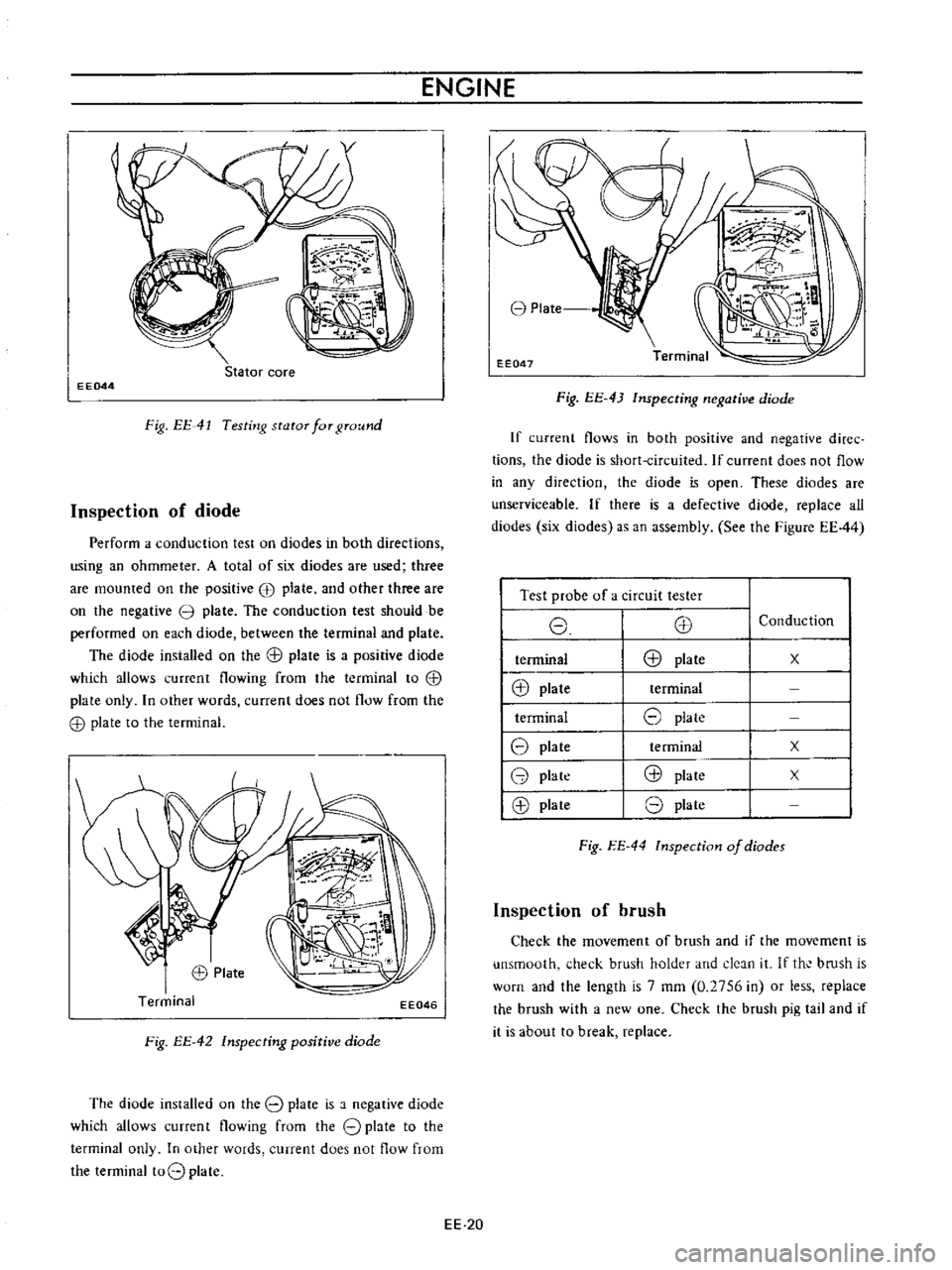

Inspection

of

diode

Perform

a

conduction

test

on

diodes

in

both

directions

using

an

ohmmeter

A

total

of

six

diodes

are

used

three

are

mounted

on

the

positive

EB

plate

and

other

three

are

on

the

negative

3

plate

The

conduction

test

should

be

performed

on

each

diode

between

the

terminal

and

plate

The

diode

installed

on

the

G

l

plate

is

a

positive

diode

which

allows

current

flowing

from

the

terminal

to

G

l

plate

only

In

other

words

current

does

not

flow

from

the

G

l

plate

to

the

terminal

EE046

Fig

EE

42

Inspecting

positive

diode

The

diode

installed

on

the

8

plate

is

a

negative

diode

which

allows

current

flowing

from

the

8

plate

to

the

terminal

only

In

other

words

current

does

not

flow

from

the

terminal

t08

plate

EE

20

8

Plate

EE047

Fig

EE

43

Inspecting

negative

diode

If

current

flows

in

both

positive

and

negative

diree

tions

the

diode

is

short

circuited

If

current

does

not

flow

in

any

direction

the

diode

is

open

These

diodes

are

unserviceable

If

there

is

a

defective

diode

replace

all

diodes

six

diodes

as

an

assembly

See

the

Figure

EE44

I

Test

probe

of

a

circuit

tester

I

8

E8

I

terminal

E8

plate

I

@

plate

terminal

I

terminal

8

plate

18

plate

te

rminal

18

plate

@

plate

18

plate

8

plate

Conduction

x

x

x

Fig

EE

44

lnspection

of

diodes

Inspection

of

brush

Check

the

movement

of

brush

and

if

the

movement

is

unsmooth

check

brush

holder

and

deJn

it

If

th

bmsh

is

worn

and

the

length

is

7

mm

0

2756

in

or

less

replace

the

brush

with

a

new

one

Check

the

brush

pig

tail

and

if

it

is

about

to

break

replace

Page 441 of 513

ENGINE

ElECTRICAL

SYSTEM

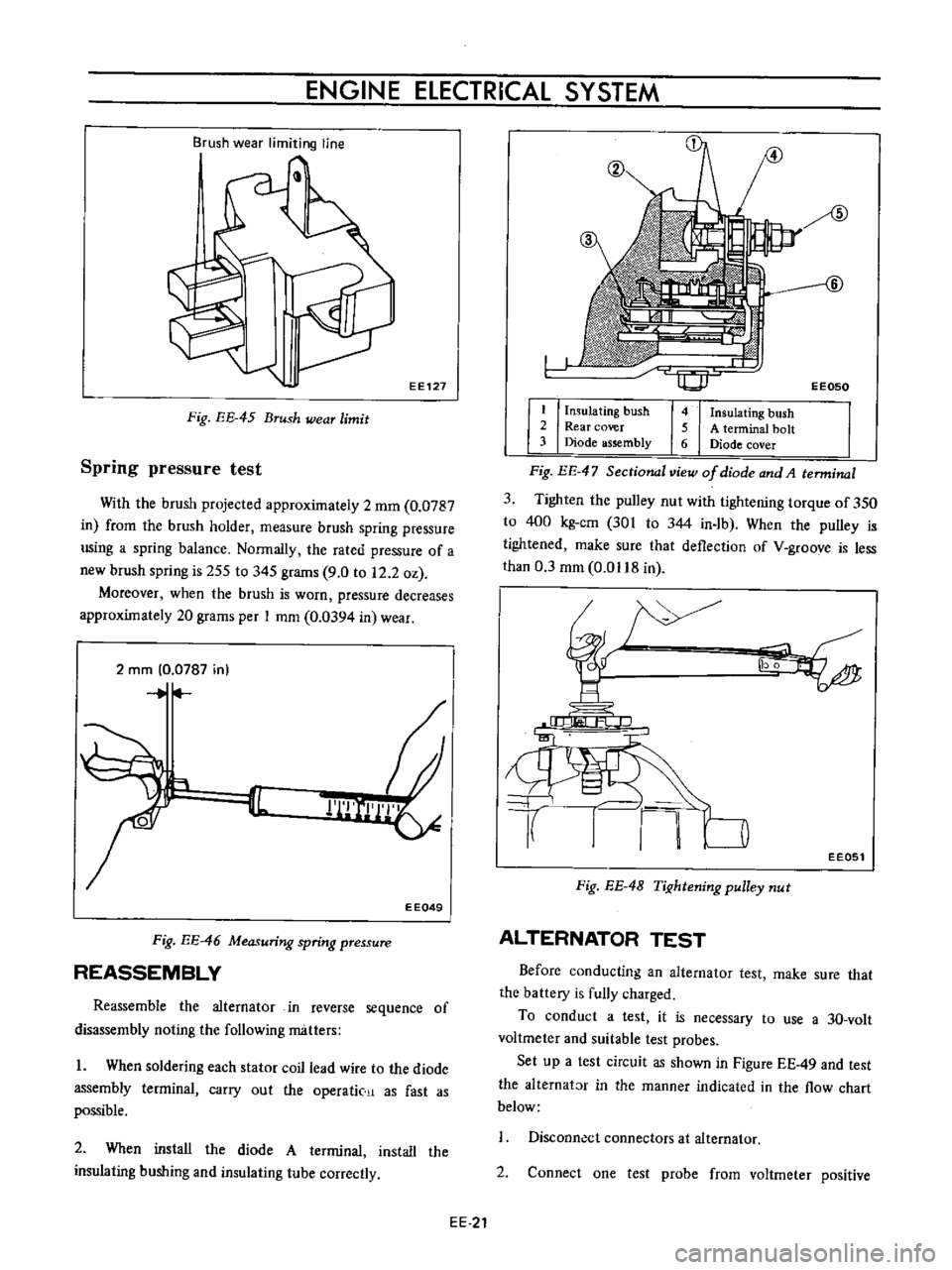

EE127

Fig

EE

45

Brush

wear

limit

Spring

pressure

test

With

the

brush

projected

approximately

2

mm

0

0787

in

from

the

brush

holder

measure

brush

spring

pressure

using

a

spring

balance

Normally

the

rated

pressure

of

a

new

brush

spring

is

255

to

345

grams

9

0

to

12

2

oz

Moreover

when

the

brush

is

worn

pressure

decreases

approximately

20

grams

per

I

mm

0

0394

in

wear

2

rnm

0

0787

in

r

II

EEQ49

Fig

EE

46

Measuring

spring

pressure

REASSEMBLY

Reassemble

the

alternator

in

reverse

sequence

of

disassembly

noting

the

following

matters

I

When

soldering

each

stator

coil

lead

wire

to

the

diode

assembly

terminal

carry

out

the

operatic

as

fast

as

possible

2

When

install

the

diode

A

terminal

install

the

insulating

bushing

and

insulating

tube

correctly

EE

21

EE050

I

Insulating

bush

2

Rear

cover

3

Diode

assembly

4

Insulating

bush

5

A

terminal

bolt

6

Diode

cover

Fig

EE

47

Sectional

view

of

diode

and

A

terminal

3

Tighten

the

pulley

nut

with

tightening

torque

of

350

to

400

kg

cm

301

to

344

in

Ib

When

the

pulley

is

tightened

make

sure

that

deflection

of

V

groove

is

less

than

0

3

mm

0

0118

in

EE051

Fig

EE

4B

TiJ

htening

pulley

nut

ALTERNATOR

TEST

Before

conducting

an

alternator

test

make

sure

that

the

battery

is

fully

charged

To

conduct

a

test

it

is

necessary

to

use

a

3D

volt

voltmeter

and

suitable

test

probes

Set

up

a

test

circuit

as

shown

in

Figure

EE

49

and

test

the

alternator

in

the

manner

indicated

in

the

flow

chart

below

Disconn

ct

connectors

at

alternator

2

Connect

one

test

probe

from

voltmeter

positive

Page 442 of 513

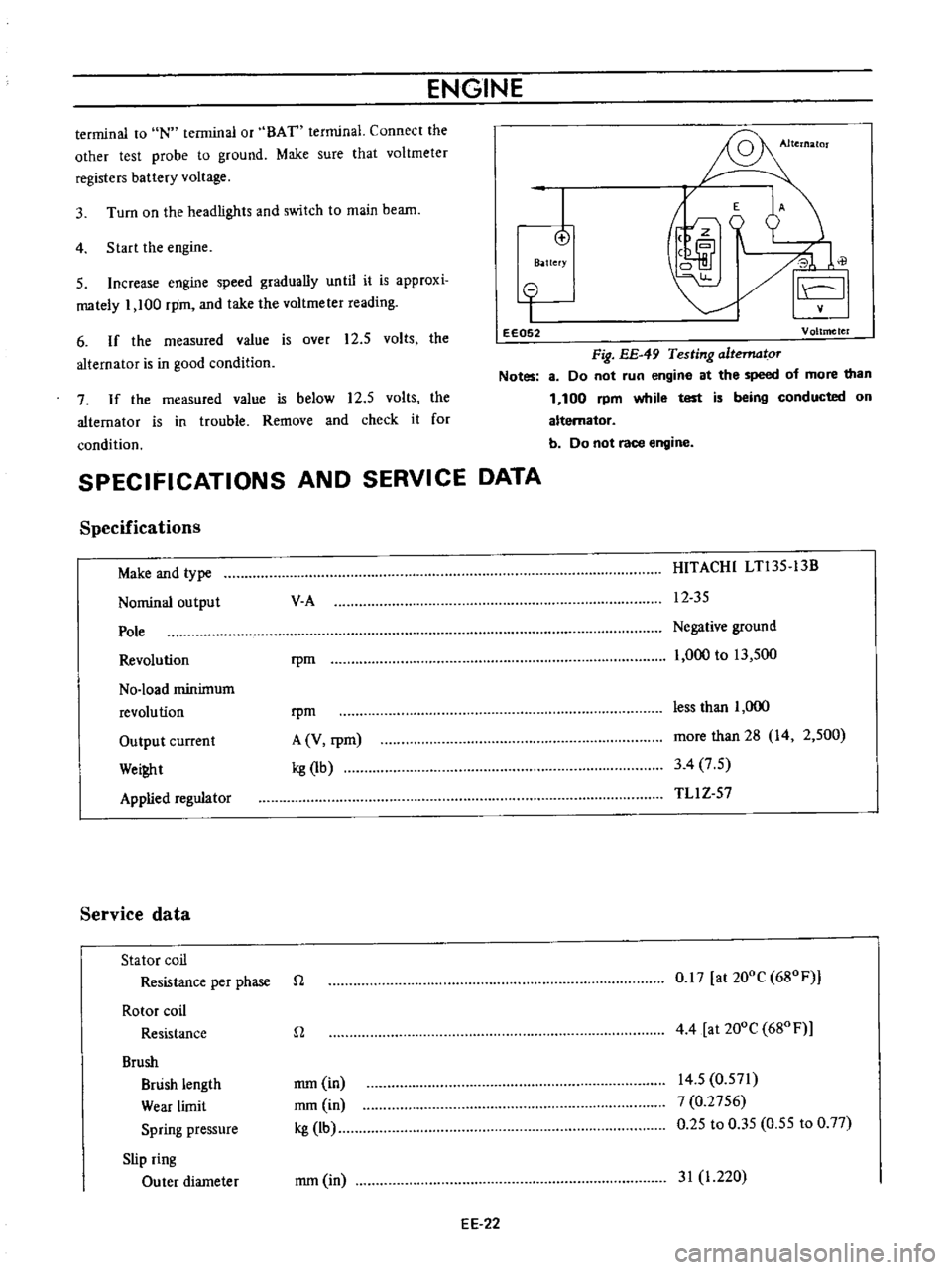

ENGINE

terminal

to

IN

terminal

or

BAT

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Start

the

engine

3

Turn

on

the

headlights

and

switch

to

main

beam

I

o

B

ttefY

E

A

J

0

il

I

5

Increase

engine

speed

gradually

until

it

is

approxi

mately

1

100

rpm

and

take

the

voltmeter

reading

6

If

the

measured

value

is

over

12

5

volts

the

alternator

is

in

good

condition

o

I

eE052

Voltmeter

Fig

EE

49

Testing

altematoT

Notes

8

Do

not

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

7

If

the

measured

value

is

below

12

5

volts

the

alternator

is

in

trouble

Remove

and

check

it

for

condition

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

Nominal

output

Pole

Revolution

No

load

minimum

revolution

Output

current

Wei

t

Applied

regulator

Service

data

Stator

coil

Resistance

per

phase

Rotor

coil

Resistance

Brush

Brush

length

Wear

limit

Spring

pressure

Slip

ring

Outer

diameter

V

A

HITACHI

LTl35

13B

12

35

rpm

Negative

ground

1

000

to

13

500

rpm

A

V

rpm

kg

1b

less

than

1

000

more

than

28

14

2

500

3

4

7

5

TLl

Z

57

n

0

17

at

200C

680F

n

4

4

at

200e

680

F

mm

in

mm

in

kg

lb

14

5

0

571

7

0

2756

0

25

to

0

35

0

55

to

0

77

mm

in

31

1

220

EE

22

Page 443 of 513

Charge

relay

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

ENGINE

ElECTRICAL

SYSTEM

Reduction

limit

Repair

limit

Repair

accuracy

mm

in

mm

in

mm

in

REGULATOR

CONTENTS

DESCRIPTiON

MEASUREMENT

OF

REGULATING

VOLTAGE

ADJUSTMENT

Voltage

regu

lator

EE

23

EE

24

EE

25

EE

25

DESCRIPTION

I

0

0394

0

3

0

0118

0

05

0

0197

EE

26

EE

26

EE

27

1

I

T

r

@

V

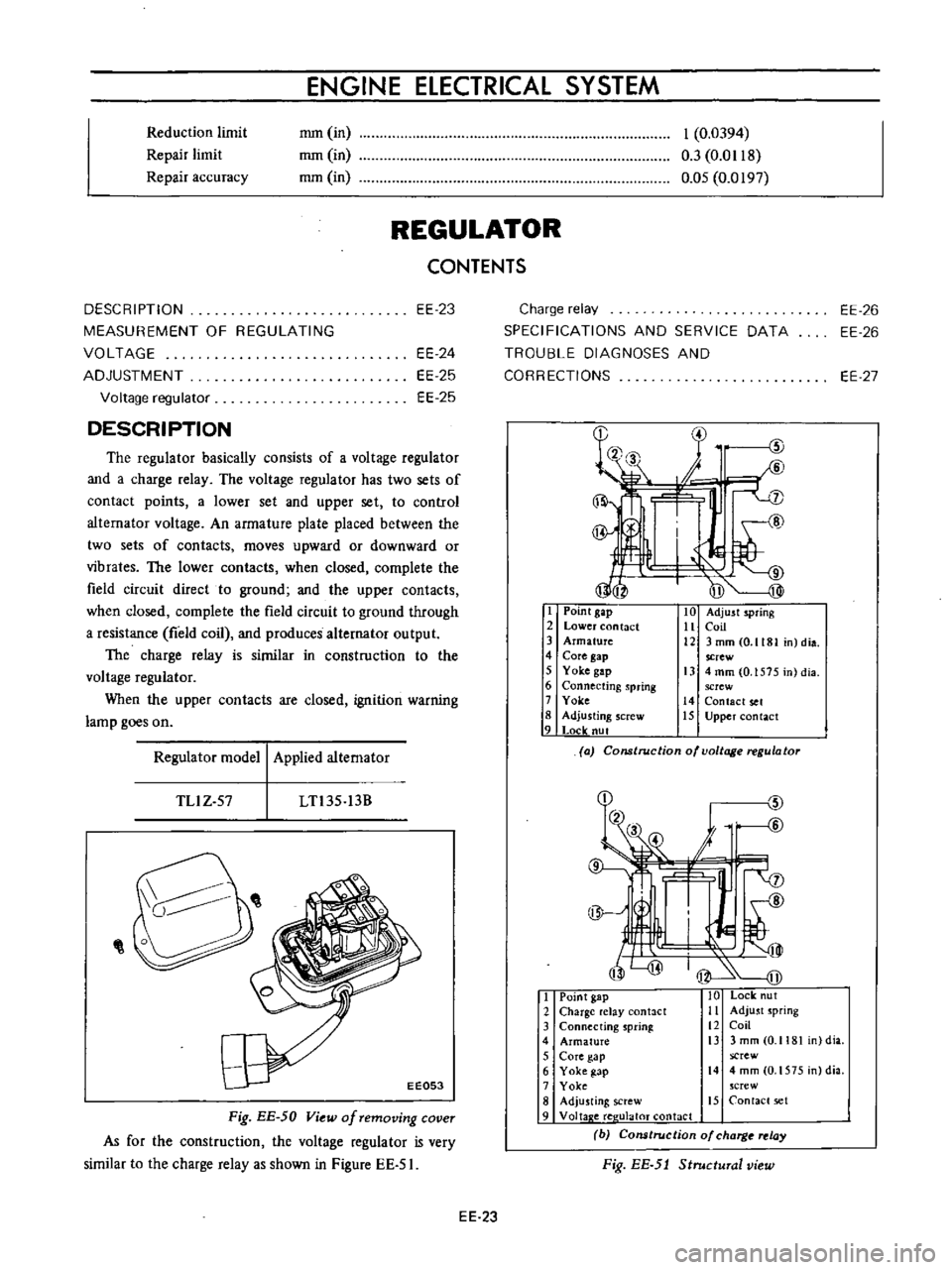

The

regulator

basically

consists

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

points

a

lower

set

and

upper

set

to

control

altemator

voltage

An

armature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

vibrates

The

lower

contacts

when

closed

complete

the

field

circuit

direct

to

ground

and

the

upper

contacts

when

closed

complete

the

field

circuit

to

ground

through

a

resistance

field

coil

and

produces

alternator

output

The

charge

relay

is

similar

in

construction

to

the

voltage

regulator

When

the

upper

contacts

are

closed

ignition

warning

lamp

goes

on

I

Point

gap

2

Lower

contact

3

Armature

4

Core

gap

5

Yoke

gap

6

Connecting

spring

7

Yoke

8

Adjusting

screw

9

Locle

nut

10

Adjust

spring

11

Coil

12

3mmCO

1181

n

dia

screw

13

4

mm

0

1575

in

dia

screw

14

Contact

set

15

Upper

contact

Regulator

model

Applied

alternator

a

Construction

of

voltage

regulator

TLlZ

57

LTl35

13B

I

Point

gap

10

Lock

ut

2

Charge

elay

antact

Ii

Adjust

spring

3

Connecting

sprinl

12

Coil

4

Armature

i3

3

mm

0

1181

dia

5

Core

gap

screw

6

Yoke

gap

14

4mm

O

1575

n

dia

7

Yoke

crew

8

Adju

ting

screw

15

Contact

set

9

Voltap

e

ree

ulaloT

contact

b

Cons

rue

ion

of

charg

relay

Fig

EE

5J

Structural

view

Fig

EE

50

View

of

removing

cover

As

for

the

construction

the

voltage

regulator

is

very

similar

to

the

charge

relay

as

shown

in

Figure

EE

51

EE

23

Page 444 of 513

ENGINE

MEASUREMENT

OF

REGULATING

VOLTAGE

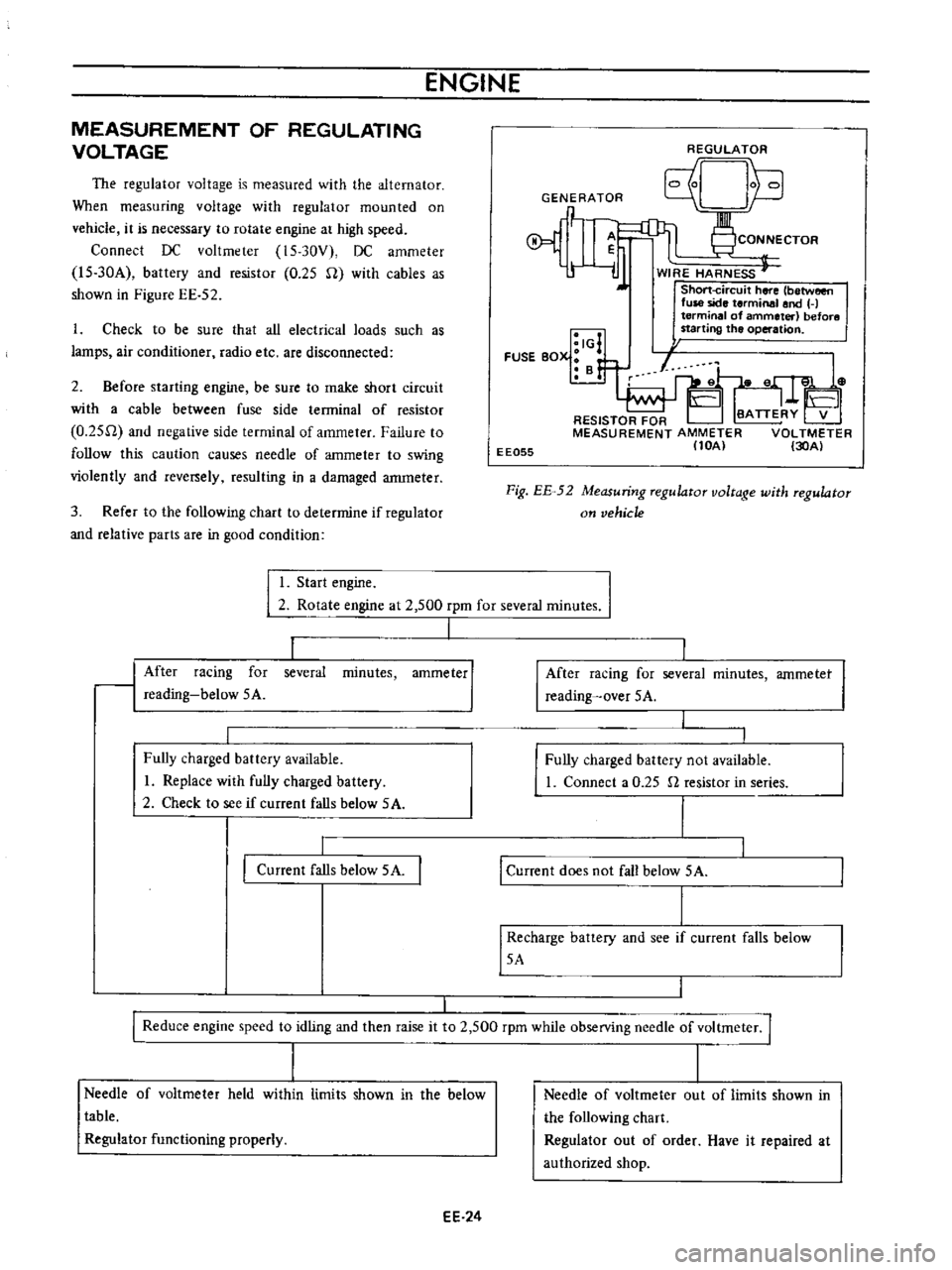

The

regulator

voltage

is

measured

with

the

alternator

When

measuring

voltage

with

regulator

mounted

on

vehicle

it

is

necessary

to

rotate

engine

at

high

speed

Connect

DC

voltmeter

15

30V

DC

ammeter

l5

30A

battery

and

resistor

0

25

U

with

cables

as

shown

in

Figure

EE

52

1

Check

to

be

sure

that

all

electrical

loads

such

as

lamps

air

conditioner

radio

etc

are

disconnected

2

Before

starting

engine

be

sure

to

make

short

circuit

with

a

cable

between

fuse

side

terminal

of

resistor

O

25U

and

negative

sIde

terminal

of

ammeter

Failure

to

follow

this

caution

causes

needle

of

ammeter

to

swing

violently

and

rever

ely

resulting

in

a

damaged

anuneter

3

Refer

to

the

following

chart

to

determine

if

regulator

and

relative

parts

are

in

good

condition

REGULATOR

Unh

GENERATOR

q

P

1

CONNECTOR

r

l

ij

WIRE

HARNESS

J

Short

circuit

here

between

fuse

side

terminal

and

H

terminal

of

ammeter

before

starting

the

operation

I

I

I

IG

FUSE

BOX

B

f

EE055

Fig

EE

52

Measuring

regulator

voltage

with

regulator

on

vehicle

I

Start

engine

I

2

Rotate

engine

at

2

500

rpm

for

several

minutes

I

1

minutes

ammeter

I

After

racing

for

reading

below

5A

several

Fully

charged

battery

available

I

Replace

with

fully

charged

battery

2

Check

to

see

if

current

falls

below

5A

Current

falls

below

5A

I

After

racing

for

several

reading

over

5A

minutes

ammetet

I

Fully

charged

battery

not

available

1

Connect

a

0

25

n

resistor

in

series

I

Current

does

not

fall

below

5A

I

Recharge

battery

and

see

if

current

falls

below

5A

I

I

Reduce

engine

speed

to

idling

and

then

raise

it

to

2

500

rpm

while

observing

needle

of

voltmeter

I

I

I

Needle

of

voltmeter

held

within

limits

shown

in

the

below

table

Regulator

functioning

properly

EE

24

Needle

of

voltmeter

out

of

limits

shown

in

the

following

chart

Regulator

out

of

order

Have

it

repaired

at

authorized

shop

Page 445 of 513

ENGINE

ElECTRICAL

SYSTEM

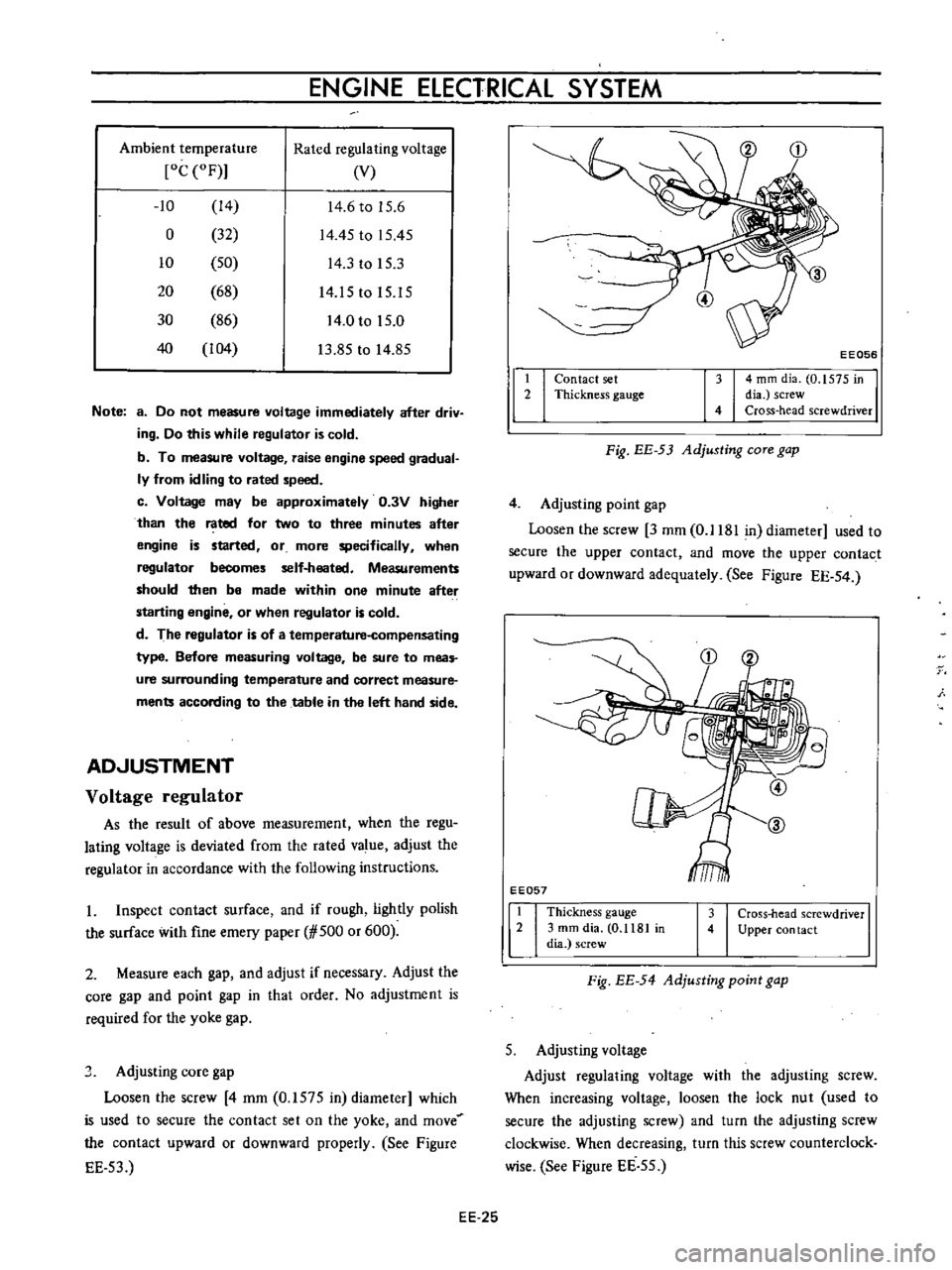

Ambient

temperature

Rated

regulating

voltage

roC

OF

V

10

14

14

6

to

15

6

0

32

14

45

to

15

45

10

50

14

3

to

15

3

20

68

14

15

to

15

15

30

86

14

0

to

15

0

40

104

13

85

to

14

85

Note

8

Do

not

measure

voltage

immediately

after

driv

ing

Do

this

while

regulator

is

cold

b

To

measure

voltage

raise

engine

speed

gradual

ly

from

idling

to

rated

speed

c

Voltage

may

be

approximately

O

3V

higher

than

the

rated

for

two

to

three

minutes

after

engine

is

started

or

more

specifically

when

regulator

becomes

self

heated

Measurements

should

then

be

made

within

one

minute

after

starting

engine

or

when

regulator

is

cold

d

The

regulator

is

of

a

temperature

compensating

type

Before

measuring

voltage

be

sure

to

meas

ure

surrounding

temperature

and

correct

measure

ments

according

to

the

table

in

the

left

hand

side

ADJUSTMENT

Voltage

regulator

As

the

result

of

above

measurement

when

the

regu

lating

voltage

is

deviated

from

the

rated

value

adjust

the

regulator

in

accordance

with

the

following

instructions

I

Inspect

contact

surface

and

if

rough

lightly

polish

the

surface

with

fine

emery

paper

500

or

600

2

Measure

each

gap

and

adjust

if

necessary

Adjust

the

core

gap

and

point

gap

in

that

order

No

adjustment

is

required

for

the

yoke

gap

J

Adjusting

core

gap

Loosen

the

screw

4

mm

0

1575

in

diameter

which

is

used

to

secure

the

contact

set

on

the

yoke

and

move

the

contact

upward

or

downward

properly

See

Figure

EE

53

t

2

I

I

EE056

4

mm

dia

0

1575

in

dia

screw

Cross

head

screwdriver

Contact

set

Thickness

gauge

Fig

EE

53

Adjusting

COTe

gap

4

Adjusting

point

gap

Loosen

the

screw

3

mm

0

1181

in

diameter

used

to

secure

the

upper

contact

and

move

the

upper

contact

upward

or

downward

adequately

See

Figure

EE

54

EE057

1

Thickness

gauge

2

3

mm

dia

0

1181

in

dia

screw

3

Cross

head

screwdriver

4

Upper

con

tact

Fig

EE

54

Adjusting

point

gap

5

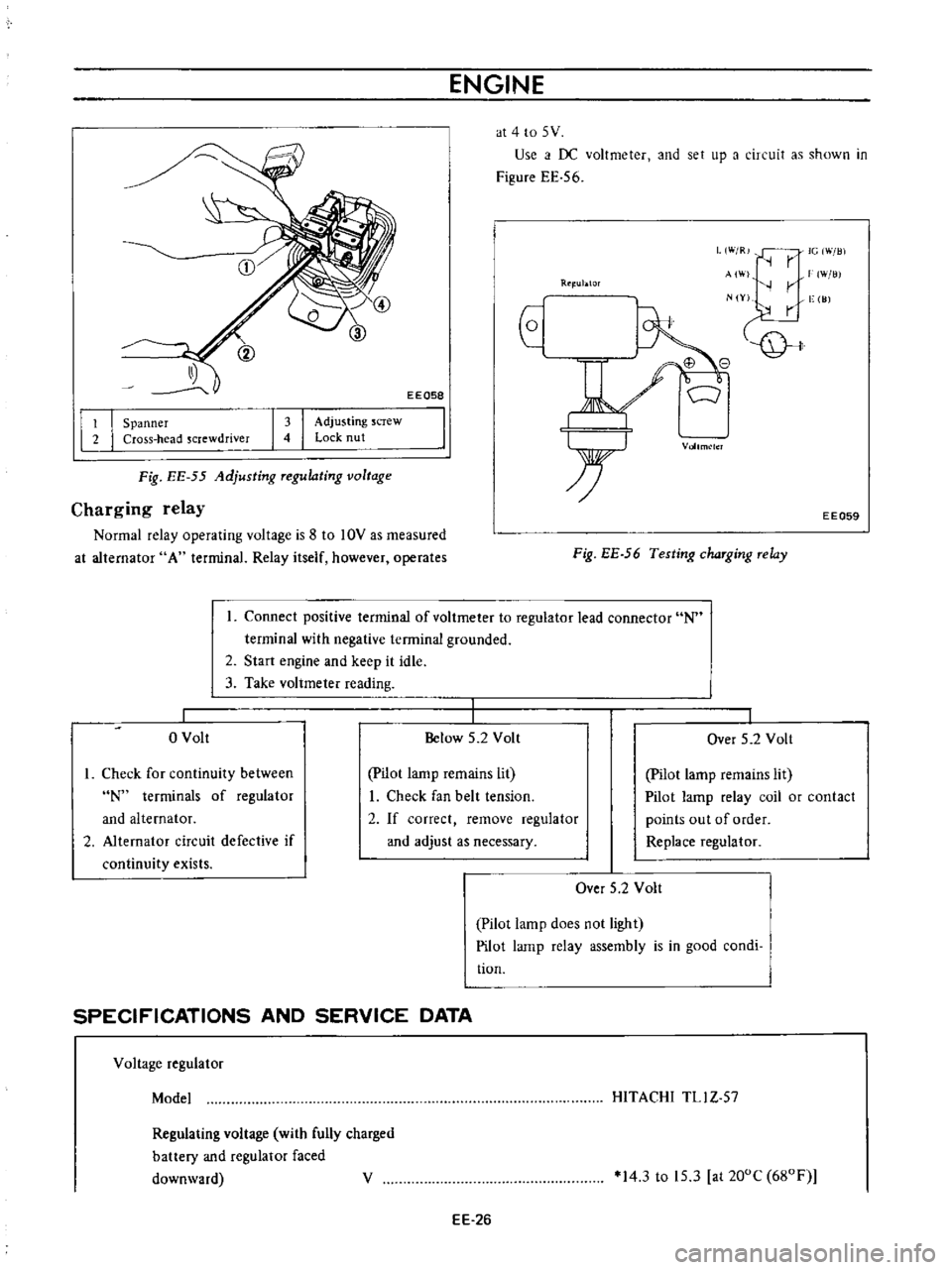

Adjusting

voltage

Adjust

regulating

voltage

with

the

adjusting

screw

When

increasing

voltage

loosen

the

lock

nut

used

to

secure

the

adjusting

screw

and

turn

the

adjusting

screw

clockwise

When

decreasing

turn

this

screw

counterclock

wise

See

Figure

EE

55

EE

25

Page 446 of 513

ENGINE

at

4

to

5

V

Use

i

f

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

56

EEQ58

L

W

R

IG

Will

r

AI

W

lli

r

N

Y

vge

I

JJ

Rtl

ublOr

I

I

Spanner

Cross

head

screwdriver

I

I

Adjusting

screw

Lock

nut

Vollm

lcl

Fig

EE

55

Adjusting

Tegulating

voltage

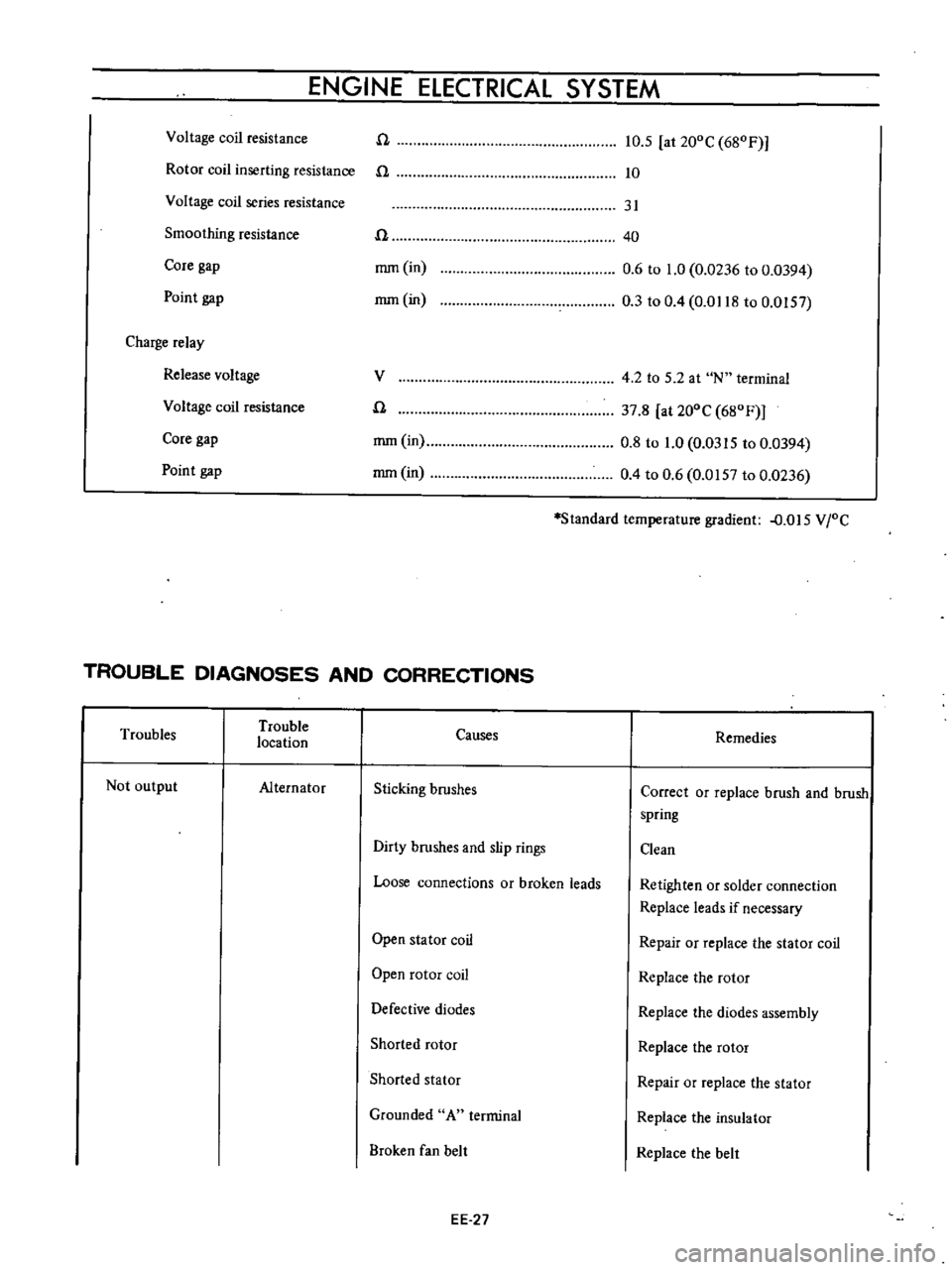

Charging

relay

Normal

relay

operating

voltage

is

8

to

10V

as

measured

at

alternator

A

terminal

Relay

itself

however

operates

EE059

Fig

EE

56

Testing

chaTging

Telay

Connect

positive

terminal

of

voltmeter

to

regulator

lead

connector

N

terminal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

Below

5

2

Volt

I

Over

5

2

Volt

I

Check

for

continuity

between

N

terminals

of

regulator

and

alternator

2

Alternator

circuit

defective

if

continuity

exists

pilot

lamp

remains

lit

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Pilot

lamp

remains

lit

Pilot

lamp

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volt

Pilot

lamp

does

not

light

Pilot

lamp

relay

assembly

is

in

good

condi

tion

SPECIFICATIONS

AND

SERVICE

DATA

Voltage

regulator

Model

HITACHI

TLl

Z

57

Regulating

voltage

with

fully

charged

battery

and

regulator

faced

downward

V

14

3

to

15

3

at

200C

680F

EE

26

Page 447 of 513

ENGINE

ELECTRICAL

SYSTEM

Rotor

coil

inserting

resistance

n

n

10

5

at

20DC

68DF

10

Voltage

coil

resistance

Core

gap

Point

gap

rnm

in

mm

in

31

40

0

6

to

1

0

0

0236

to

0

0394

0

3

to

0

4

0

0118

to

0

0157

Voltage

coil

series

resistance

Smoothing

resistance

n

Charge

relay

Release

voltage

Voltage

coil

resistance

V

4

2

to

5

2

at

N

terminal

n

37

8

at

20DC

68DF

mm

in

0

8

to

1

0

0

0315

to

0

0394

mm

in

0

4

to

0

6

0

0157

to

0

0236

Core

gap

Point

gap

Standard

temperature

gradient

D

015

VIDC

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Troubles

Trouble

location

Causes

Remedies

Not

output

Alternator

Sticking

brushes

Correct

or

replace

brush

and

brush

spring

Dirty

brushes

and

slip

rings

Clean

Loose

connections

or

broken

leads

Retighten

or

solder

connection

Replace

leads

if

necessary

Open

stator

coil

Repair

or

replace

the

stator

coil

Open

rotor

coil

Replace

the

rotor

Defective

diodes

Replace

the

diodes

assembly

Shorted

rotor

Replace

the

rotor

Shorted

stator

Repair

or

replace

the

stator

Grounded

A

terminal

Replace

the

insulator

Broken

fan

belt

Replace

the

belt

EE

27