service DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 68 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

PROPELLER

SHAFT

AND

UNIVERSAL

JOINT

CONTENTS

DESC

R

I

PTI

ON

REMOVAL

DISASSEMBL

Y

INSPECTION

ASSEMBL

Y

PD

PD

2

PD

2

PD

2

PD

2

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

PD

3

PD

3

j

j

lI

ID

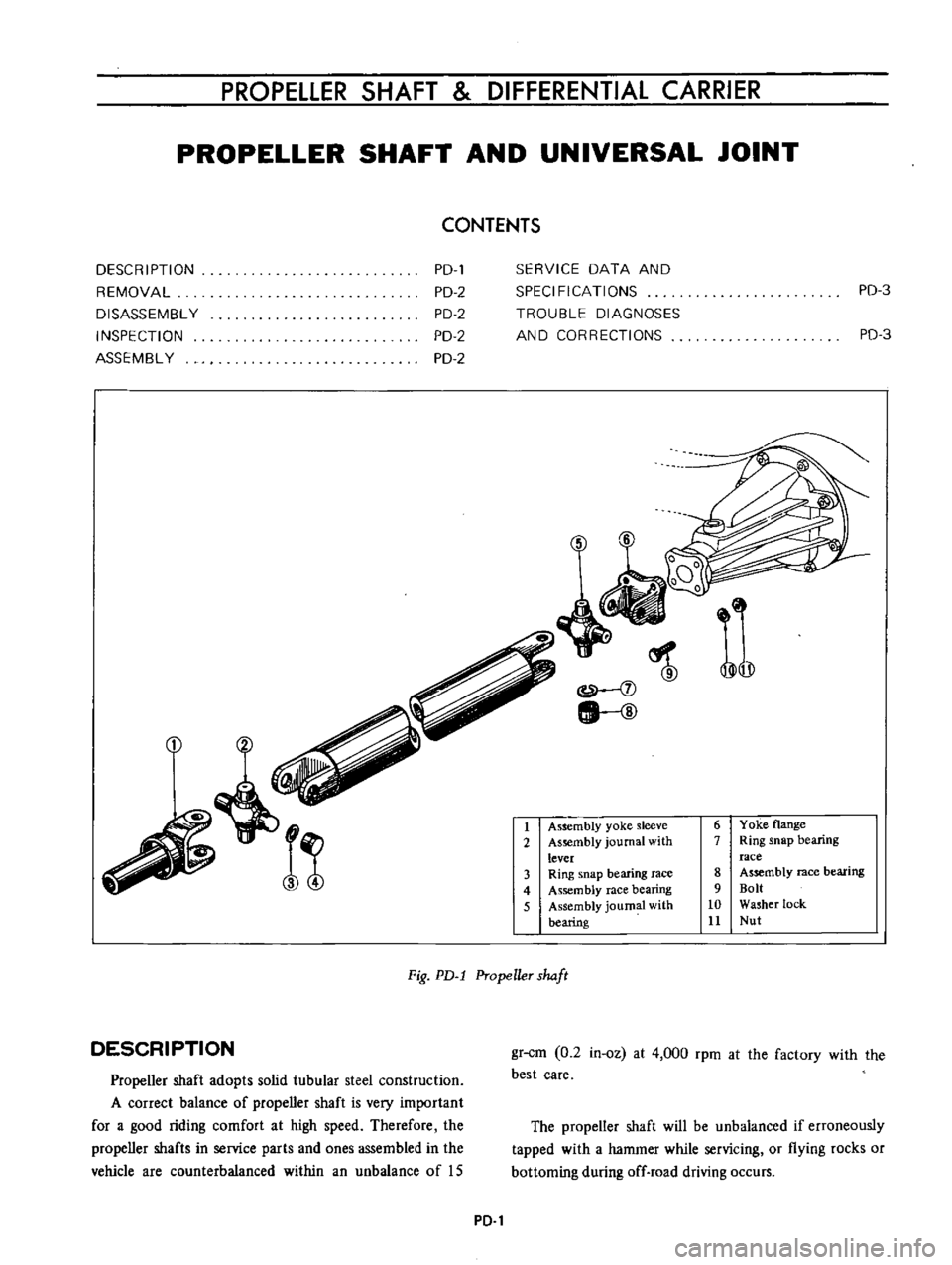

1

Assembly

yoke

sleeve

2

As

mbly

journal

with

lever

3

Ring

snap

bearing

race

4

Assembly

race

bearing

5

Assembly

journal

with

bearing

6

Yoke

flange

7

Ring

snap

bearing

race

8

Assembly

race

bearing

9

Bolt

10

Washer

lock

11

Nut

Fig

PD

l

Propeller

shaft

DESCRIPTION

Propeller

shaft

adopts

solid

tubular

steel

construction

A

correct

balance

of

propeller

shaft

is

very

important

for

a

good

riding

comfort

at

high

speed

Therefore

the

propeller

shafts

in

service

parts

and

ones

assembled

in

the

vehicle

are

counterbalanced

within

an

unbalance

of

IS

gr

cm

0

2

in

oz

at

4

000

rpm

at

the

factory

with

the

best

care

The

propeller

shaft

will

be

unbalanced

if

erroneously

tapped

with

a

hammer

while

servicing

or

flying

rocks

or

bottoming

during

off

road

driving

occurs

PD

1

Page 70 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Insert

the

journal

into

the

yoke

flange

Tap

the

journal

bearing

into

the

yoke

flange

using

a

brass

drift

smaller

than

the

hole

in

the

yoke

Tap

the

other

bearing

into

the

opposite

end

of

the

yoke

flange

until

the

bearing

is

in

line

with

the

snap

ring

grooves

With

a

pair

of

pliers

install

the

snap

rings

on

both

ends

of

the

yoke

flange

Insert

the

flange

assembly

in

the

sleeve

yoke

Place

the

other

yoke

bearing

into

the

opposite

end

of

the

yoke

and

tap

this

bearing

into

the

yoke

until

the

bearing

is

in

line

with

the

snap

ring

grooves

Install

the

snap

rings

on

both

ends

of

the

yoke

When

all

parts

are

assembled

check

the

spider

and

surroundings

for

tightness

When

the

clearance

is

excessive

adjust

with

over

size

snap

rings

as

follows

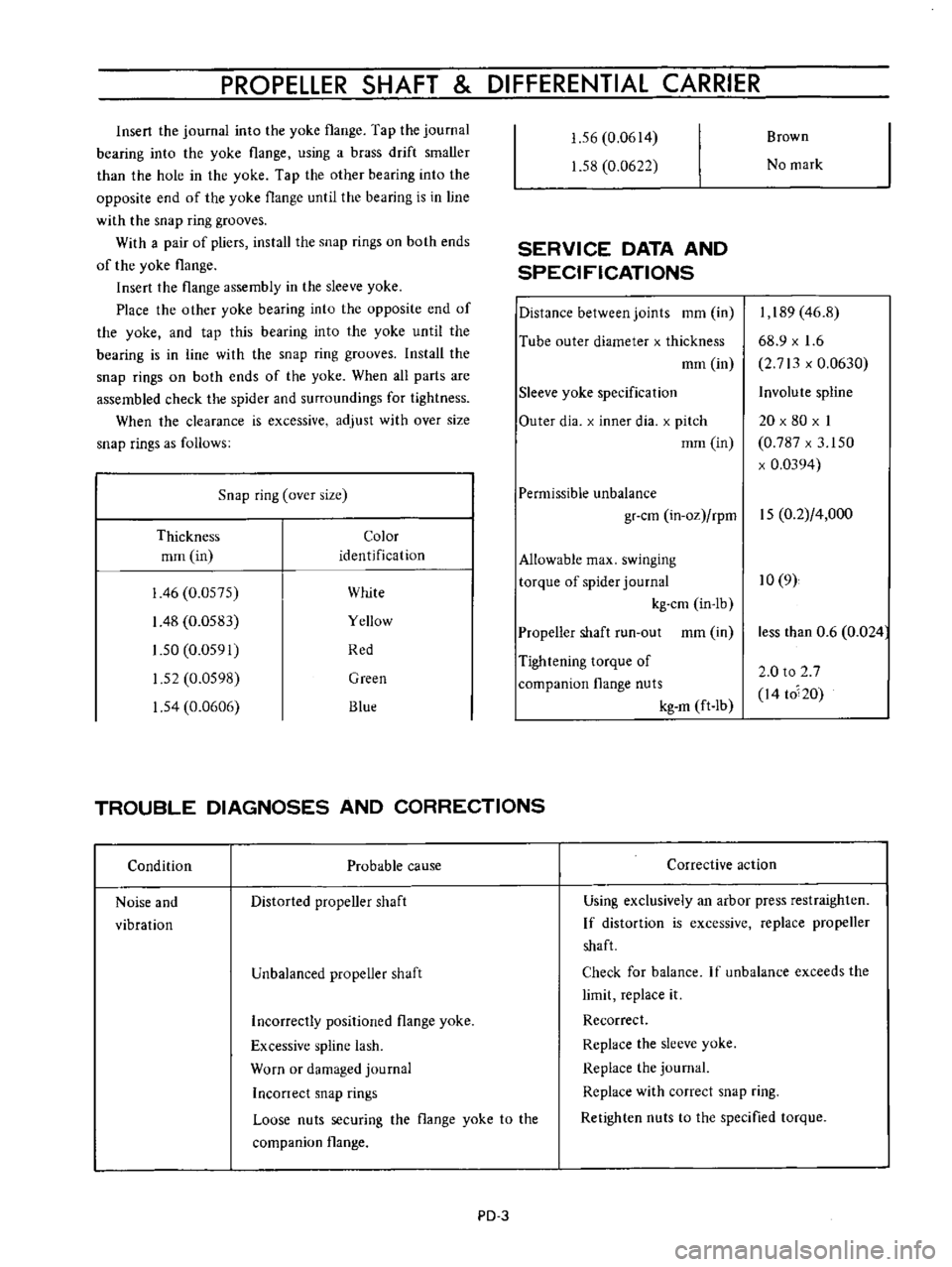

Snap

ring

over

size

Thickness

Color

mrn

in

identification

I

46

0

0575

White

I

48

0

0583

Yellow

1

50

0

0591

Red

1

52

0

0598

Green

1

54

0

0606

Blue

1

56

0

0614

1

58

0

0622

SERVICE

DATA

AND

SPECIFICATIONS

Distance

between

joints

mm

in

Tube

outer

diameter

x

thickness

mm

in

Sleeve

yoke

specification

Outer

dia

x

inner

dia

x

pitch

mm

in

Brown

No

mark

I

189

46

8

68

9

x

1

6

2

713

x

0

0630

Involute

spline

20

x

80

x

I

0

787

x

3

150

x

0

0394

Permissible

unbalance

gr

cm

in

oz

rpm

15

0

2

4

000

Allowable

max

swinging

torque

of

spider

journal

10

9

kg

cm

in

lb

Propeller

shaft

run

out

mm

in

Tightening

torque

of

companion

flange

nuts

kg

m

ft

Ib

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Noise

and

vibration

Distorted

propeller

shaft

Unbalanced

propeller

shaft

Corrective

action

less

than

0

6

0

024

2

0

to

2

7

I4

to

20

Using

exclusively

an

arbor

press

restraighten

If

distortion

is

excessive

replace

propeller

shaft

Check

for

balance

If

unbalance

exceeds

the

limit

replace

it

Recorrect

Replace

the

sleeve

yoke

Replace

the

journal

Replace

with

correct

snap

ring

Retighten

nuts

to

the

specified

torque

Incorrectly

positioned

flange

yoke

Excessive

spline

lash

Worn

or

damaged

journal

Inconect

snap

rings

Loose

nuts

securing

the

flange

yoke

to

the

companion

flange

PD

3

Page 71 of 513

CHASSIS

DIFFERENTIAL

CARRIER

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

ASSEMBLY

AND

ADJUSTMENT

Assembling

differential

gear

case

Setting

and

adjusting

drive

pinion

PD

4

PD

5

PD

5

PD

7

PD

8

PD

9

PD

10

Adjusting

drive

pinion

preload

Setting

and

adjusting

side

bearing

shims

INSTALLATION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SERVICE

DATA

AND

SPECIFICATIONS

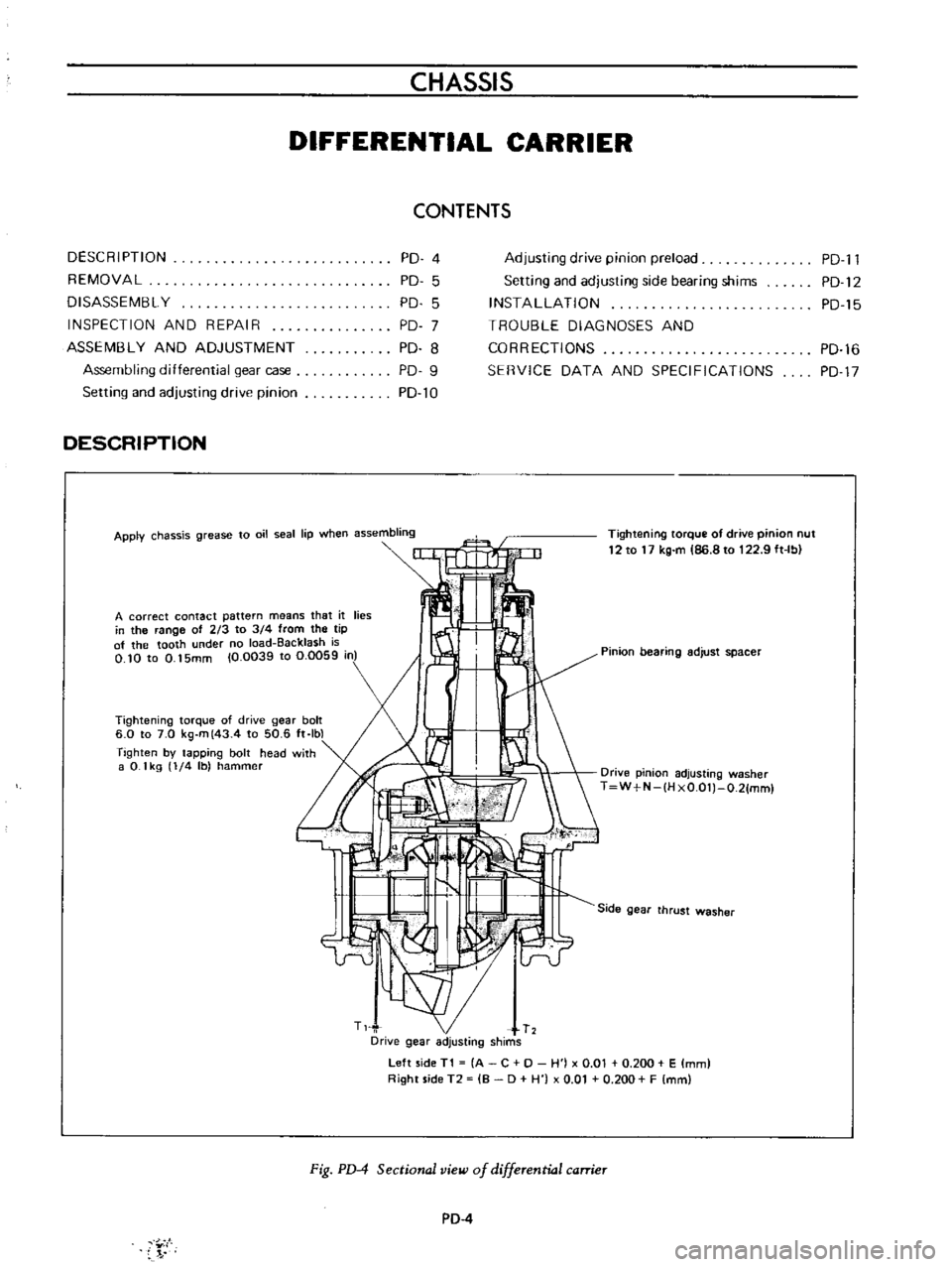

DESCRIPTION

Apply

chassis

grease

to

oil

seal

lip

when

assembling

Tightening

torque

of

drive

pinion

nut

12

to

17

kg

m

86

8

to

122

9

ft

Ib

A

correct

contact

pattern

means

that

it

lies

in

the

range

of

213

to

3

4

from

the

tip

of

the

tooth

under

no

load

Backlash

is

O

10

to

0

15mm

10

0039

to

0

0059

in

Pinion

bearing

adjust

spacer

Tightening

torque

of

drive

gear

bolt

6

0

to

7

0

kg

m

43

4

to

50

6

ft

Ibl

Tighten

by

tapping

bolt

head

with

a

0

1

kg

1

4

Ib

hammer

Drive

pinion

adjusting

washer

T

W

N

IH

xO

OlJ

O

21mml

Side

gear

thrust

washer

Left

side

T1

A

C

0

H

j

x

0

01

0

200

E

mm

Right

side

T2

B

0

H

0

01

0

200

F

mm

Fig

PD

4

Sectional

view

of

differential

carrier

PD

4

Y

I

PD

l1

PD

12

PD

15

PD

16

PD

17

Page 84 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

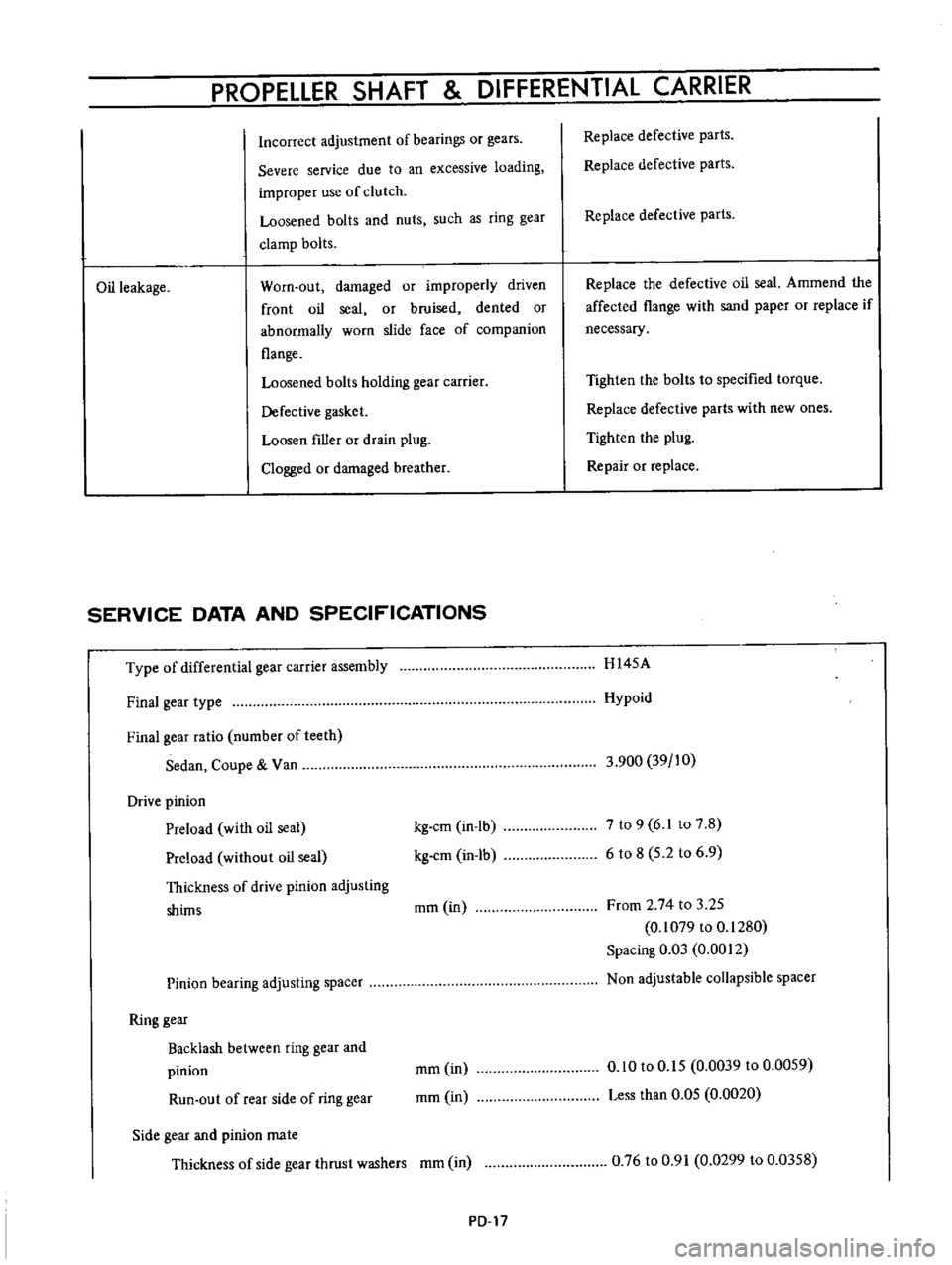

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loosened

bolts

and

nuts

such

as

ring

gear

clamp

bolts

Oil

leakage

Worn

out

damaged

or

improperly

driven

front

oil

seal

or

bruised

dented

or

abnormally

worn

slide

face

of

companion

flange

Loosened

bolts

holding

gear

carrier

Defective

gasket

Loosen

filler

or

drain

plug

Clogged

or

damaged

breather

SERVICE

DATA

AND

SPECIFICATIONS

Type

of

differential

gear

carrier

assembly

Final

gear

type

Final

gear

ratio

number

of

teeth

Sedan

Coupe

Van

Drive

pinion

Preload

with

oil

seal

Preload

without

oil

seal

Thickness

of

drive

pinion

adjusting

shims

kg

cm

in

lb

kg

cm

in

lb

mm

in

Pinion

bearing

adjusting

spacer

Ring

gear

Backlash

between

ring

gear

and

pinion

Run

out

of

rear

side

of

ring

gear

mm

in

mm

in

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washers

mm

in

PD

17

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

the

defective

oil

seal

Ammend

the

affected

flange

with

sand

paper

or

replace

if

necessary

Tighten

the

bolts

to

specified

torque

Replace

defective

parts

with

new

ones

Tighten

the

plug

Repair

or

replace

H145A

Hypoid

3

900

39

10

7

to

9

6

1

to

7

8

6

to

8

5

2

to

6

9

From

2

74

to

3

25

0

1079

to

0

1280

Spacing

0

Q3

0

0012

Non

adjustable

collapsible

spacer

0

10

to

0

15

0

0039

to

0

0059

Less

than

0

05

0

0020

0

76

to

0

91

0

0299

to

0

0358

Page 85 of 513

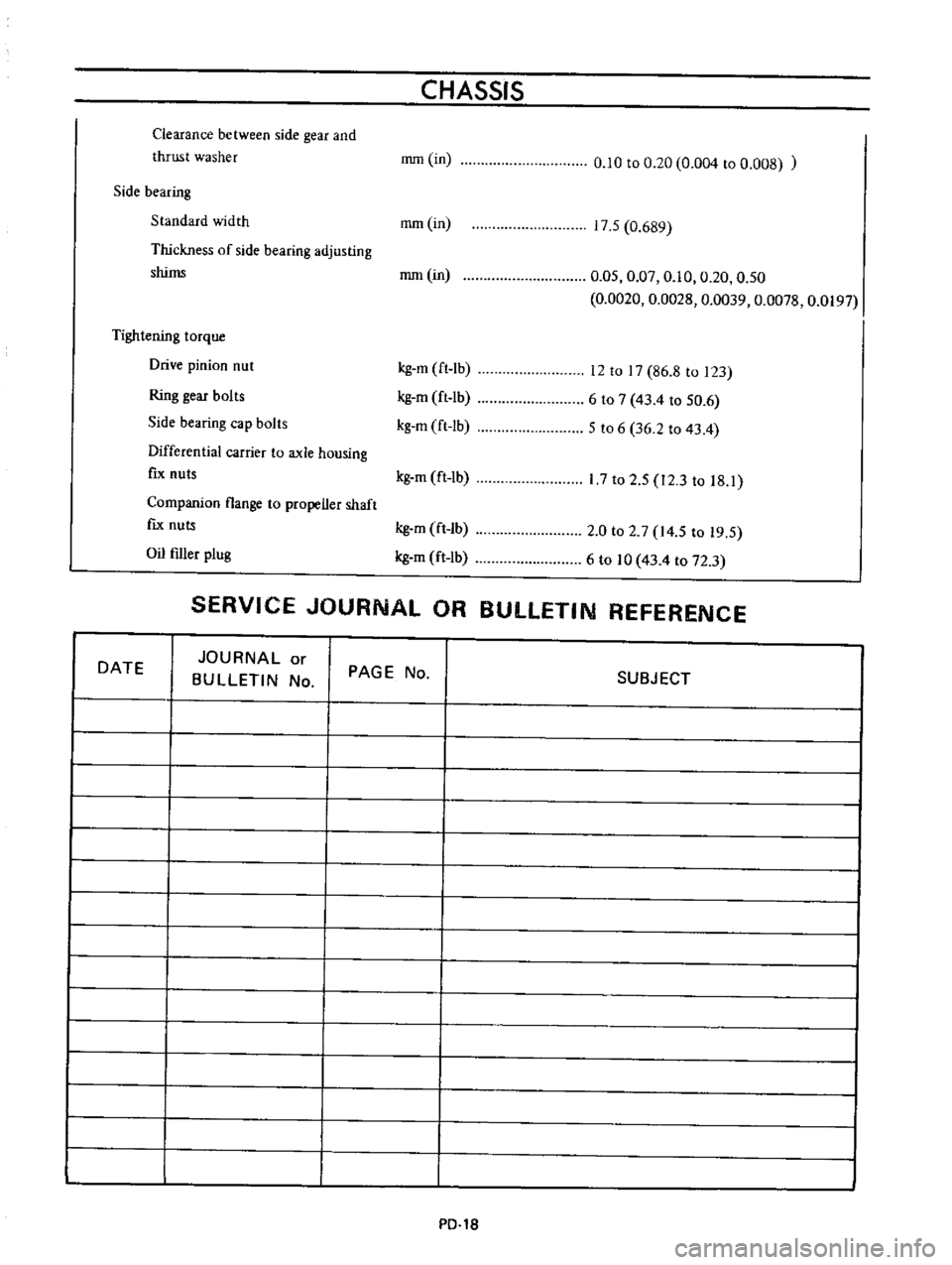

Clearance

between

side

gear

and

thrust

washer

CHASSIS

rrun

in

0

10

to

0

20

0

004

to

0

008

Side

bearing

Standard

width

rom

in

Thickness

of

side

bearing

adjusting

shims

rom

in

Tightening

torque

Drive

pinion

nut

Ring

gear

bolts

Side

bearing

cap

bolts

Differential

carrier

to

axle

housing

fIx

nuts

Companion

flange

to

propeller

shaft

fIx

nuts

Oil

filler

plug

17

5

0

689

0

05

0

07

0

10

0

20

0

50

0

0020

0

0028

0

0039

0

0078

0

0197

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

12

to

17

86

8

to

123

6

to

7

43

4

to

50

6

5

to

6

36

2

to

43

4

kg

m

ft

1b

17

to

2

5

12

3

to

18

1

kg

m

ft

lb

kg

m

ft

lb

2

0

to

2

7

14

5

to

19

5

6

to

10

43

4

to

72

3

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

I

I

I

I

PAGE

No

SUBJECT

PO

1S

Page 86 of 513

DATSUN

1200

MODEL

B

110

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

FA

FRONT

AXLE

FRONT

SUSPENSION

all

FRONT

AXLE

AND

FRONT

SUSPENSION

ADJUSTMENT

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

FA

1

FA

21

FA

23

FA

25

Page 93 of 513

FRONT

AXLE

FRONT

SUSPENSION

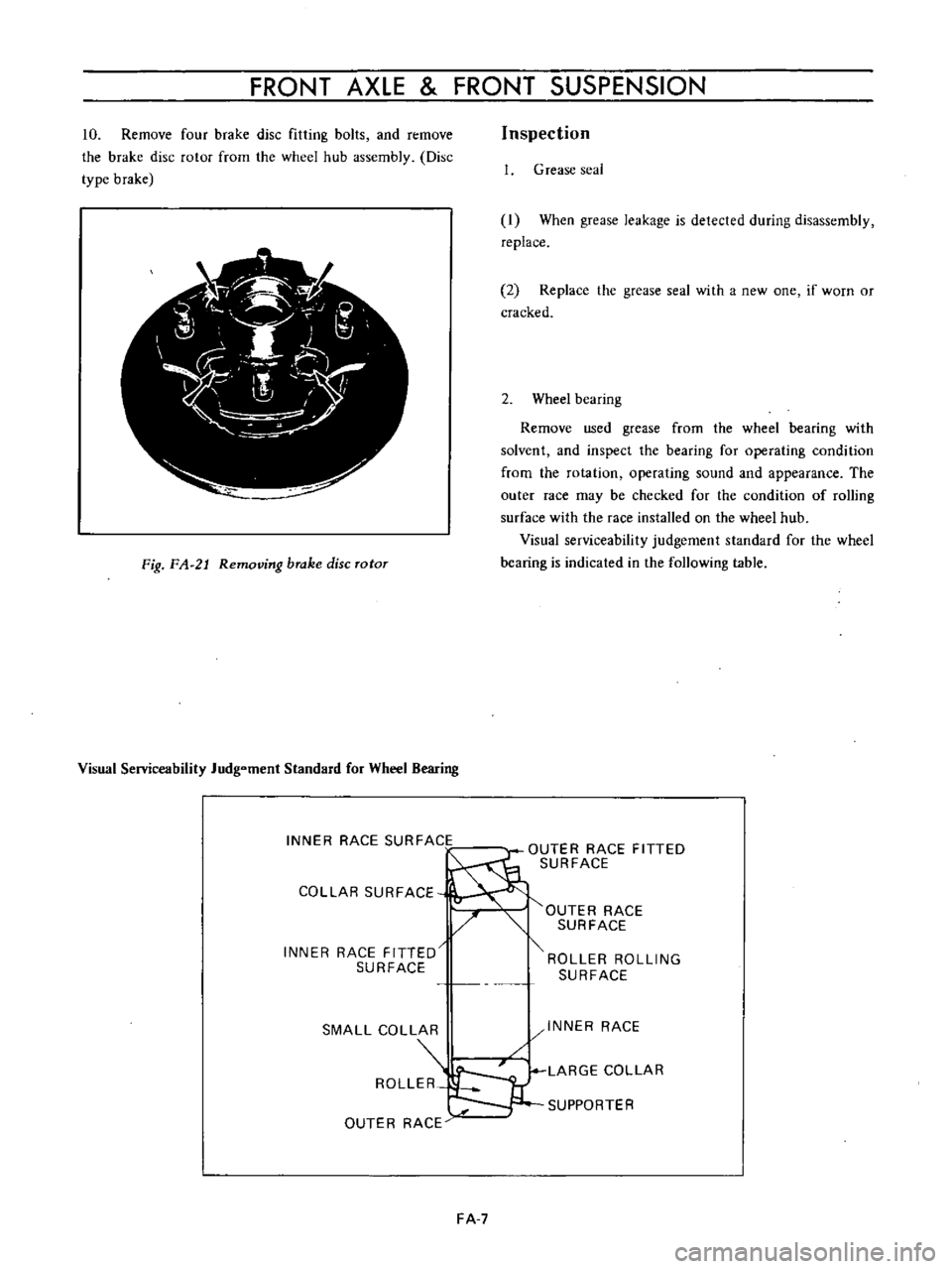

10

Remove

four

brake

disc

fitting

bolts

and

remove

the

brake

disc

rotor

from

the

wheel

hub

assembly

Disc

type

b

rake

Inspection

1

Grease

seal

I

ycQ

r

A

1

r

j

t

I

I

i

I

When

grease

leakage

is

delected

during

disassembly

replace

2

Replace

the

grease

seal

with

a

new

one

if

worn

or

cracked

Fig

FA

21

Removing

brake

disc

rotor

2

Wheel

bearing

Remove

used

grease

from

the

wheel

bearing

with

solvent

and

inspect

the

bearing

for

operating

condition

from

the

rotation

operating

sound

and

appearance

The

outer

race

may

be

checked

for

the

condition

of

rolling

surface

with

the

race

installed

on

the

wheel

hub

Visual

serviceability

judgement

standard

for

the

wheel

bearing

is

indicated

in

the

following

table

Visual

Serviceability

Judg

ment

Standard

for

Wheel

Bearing

INNER

RACE

SURFACE

OUTER

RACE

FITTED

SURFACE

COLLAR

SURFACE

OUTER

RACE

SURFACE

INNER

RACE

FITTED

ROLLER

ROLLING

SURFACE

SURFACE

SMALL

COLLAR

INNER

RACE

LARGE

COLLAR

ROLLER

SUPPORTER

OUTER

RACE

FA

7

Page 94 of 513

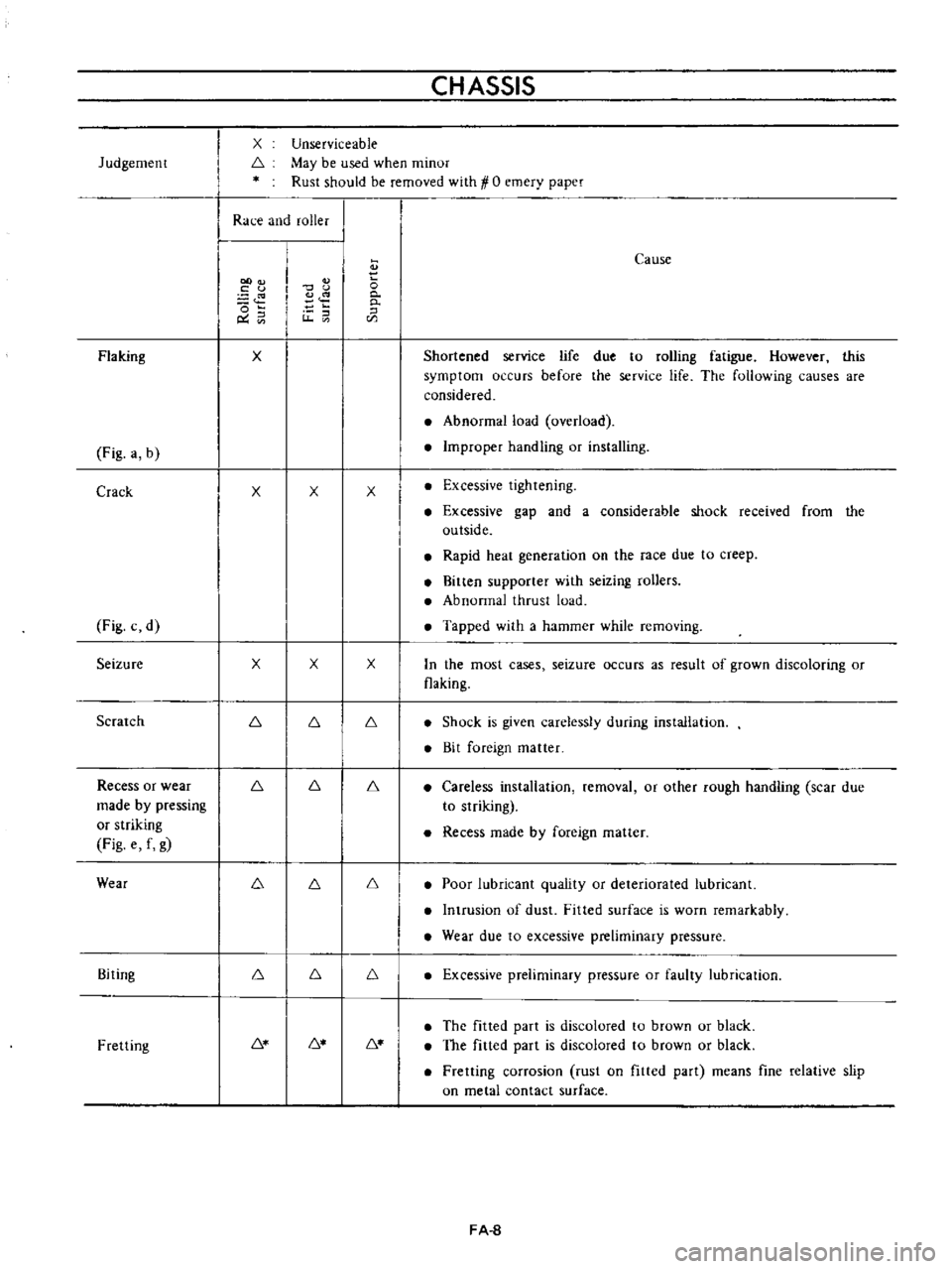

Judgemenr

Flaking

Fig

a

b

Crack

Fig

c

d

Seizure

Scratch

Recess

or

wear

made

by

pressing

or

striking

Fig

e

f

g

Wear

Biting

Fretting

CHASSIS

Unserviceable

May

be

used

when

minor

Rust

should

be

removed

with

1

0

emery

paper

X

6

Race

and

roller

oo

c

u

o

C

U

x

x

x

6

6

6

6

6

x

x

6

6

6

6

6

o

0

0

Cause

Shortened

service

life

due

to

rolling

fatigue

However

this

symptom

occurs

before

the

service

life

The

following

causes

are

considered

Abnormal

load

overload

Improper

handling

or

installing

x

Excessive

tighrening

Excessive

gap

and

a

considerable

shock

received

from

the

outside

Rapid

hear

generation

on

the

race

due

to

creep

Bitten

supporter

with

seizing

rollers

Abnormal

thrust

load

Tapped

with

a

hammer

while

removing

x

In

the

most

cases

seizure

occurs

as

result

of

grown

discoloring

or

flaking

6

Shock

is

given

carelessly

during

installation

Bit

foreign

matter

6

Careless

installation

removal

or

other

rough

handling

scar

due

to

striking

Recess

made

by

foreign

matter

6

Poor

lubricant

quality

or

deteriorated

lubricant

Intrusion

of

dust

Fitted

surface

is

worn

remarkably

Wear

due

to

excessive

preliminary

pressure

6

Excessive

preliminary

pressure

or

faulty

lubrication

6

The

fitted

part

is

discolored

to

brown

ur

black

The

fitted

part

is

discolored

to

brown

or

black

Fretting

corrosion

rust

on

fitted

part

means

fine

relative

slip

on

metal

contact

surface

FA

8

Page 95 of 513

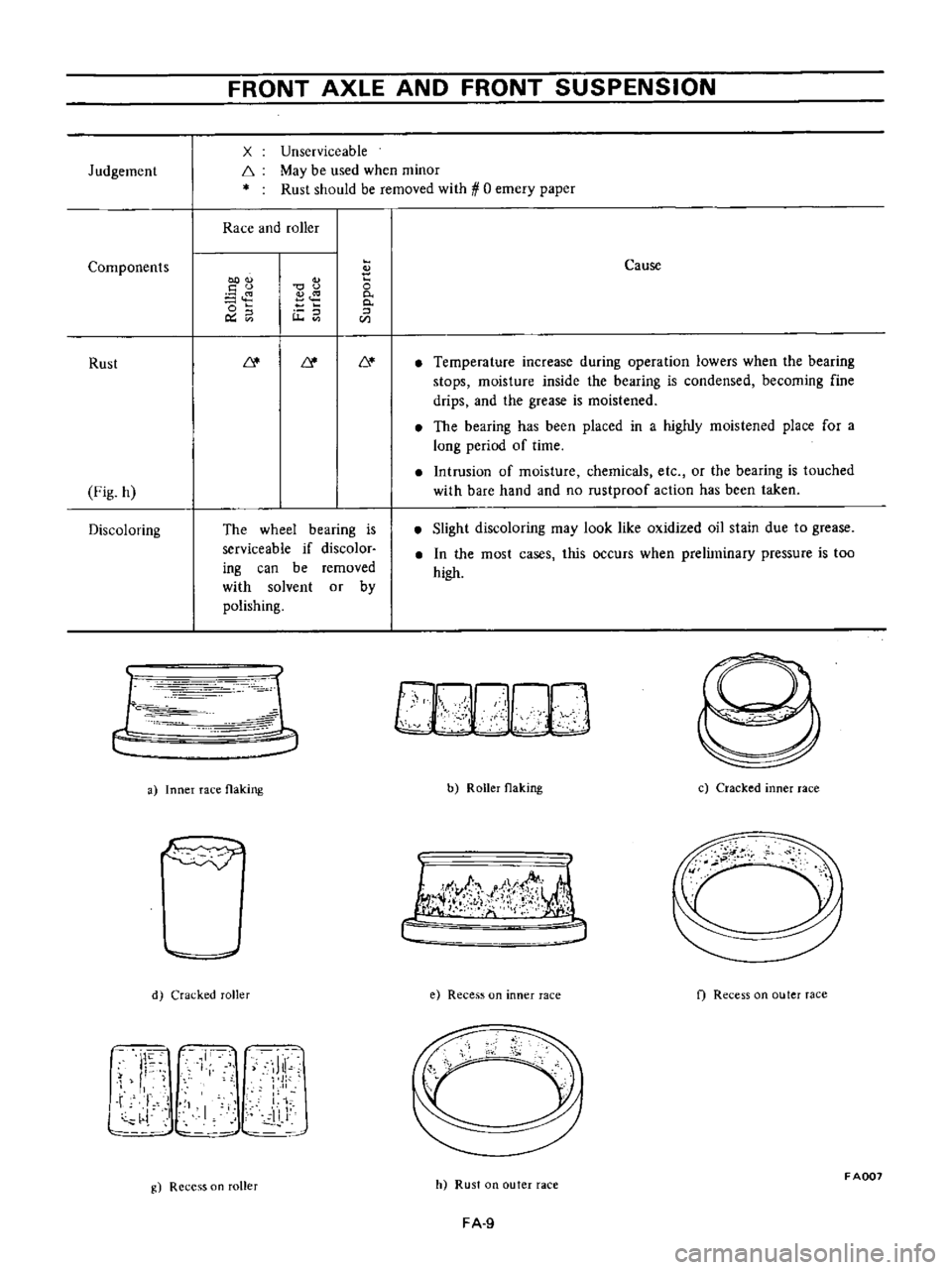

Judgement

Components

Rust

Fig

h

Discoloring

FRONT

AXLE

AND

FRONT

SUSPENSION

x

f

Unserviceable

May

be

used

when

minor

Rust

should

be

removed

with

0

emery

paper

Race

and

roller

00

u

o

o

Ou

u

The

wheel

bearing

is

serviceable

if

discolor

ing

can

be

removed

with

solvent

or

by

polishing

r

c

1

1

Ie

r

r

iJ

a

Inner

race

flaking

d

Cracked

roller

J

I

11

Ji

l

L

i

I

11

J

g

Recess

on

roller

o

0

0

CIl

Cause

Temperature

increase

during

operation

lowers

when

the

bearing

stops

moisture

inside

the

bearing

is

condensed

becoming

fine

drips

and

the

grease

is

moistened

The

bearing

has

been

placed

in

a

highly

moistened

place

for

a

long

period

of

time

Intrusion

of

moisture

chemicals

etc

or

the

bearing

is

touched

with

bare

hand

and

no

rustproof

action

has

been

taken

Slight

discoloring

may

look

like

oxidized

oil

stain

due

to

grease

In

the

most

cases

this

occurs

when

preliminary

pressure

is

too

high

b

Roller

flaking

c

Cracked

inner

race

I

lJ

f

t

j

e

Recess

on

inner

race

f

Recess

on

outer

race

cc

h

Rust

on

outer

race

FADD7

FA

9

Page 96 of 513

CHASSIS

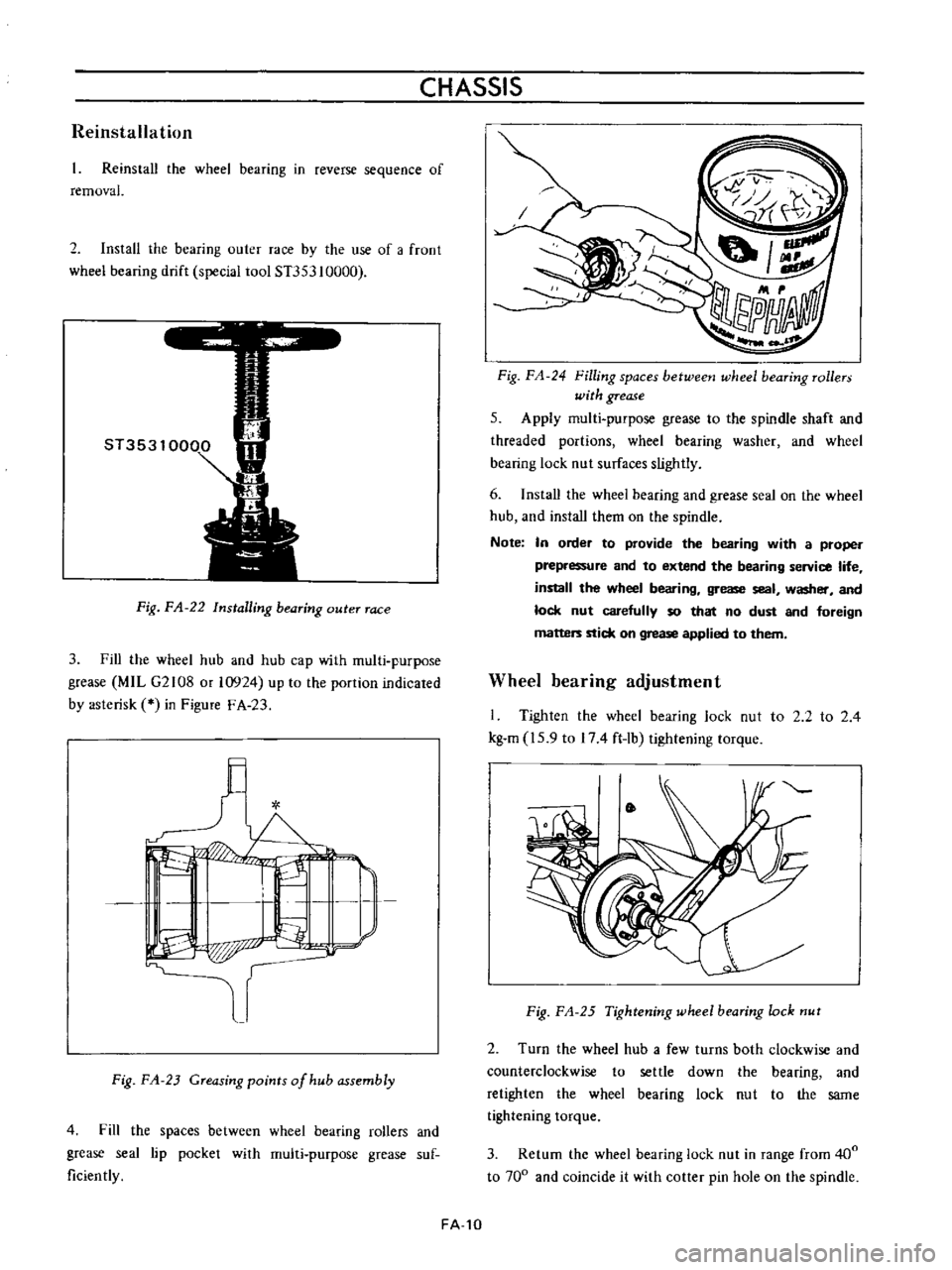

Reinstallation

Reinstall

the

wheel

bearing

in

reverse

sequence

of

removal

2

Install

the

bearing

outer

race

by

the

use

of

a

froot

wheel

bearing

drift

special

tool

ST353

10000

Fig

FA

22

Installing

bearing

outer

race

3

Fill

the

wheel

hub

and

hub

cap

with

multi

purpose

grease

MIL

G2108

or

10924

up

to

the

portion

indicated

by

asterisk

in

Figure

F

A

23

l

I

L

I

I

P

p

r

Fig

FA

23

Greasing

points

of

hub

assembly

4

Fill

the

spaces

between

wheel

bearing

rollers

and

grease

seal

lip

pocket

with

multi

purpose

grease

suf

ficiently

FA

10

Fig

FA

24

Filling

spaces

betweetJ

wheel

bearing

rollers

with

grease

5

Apply

multi

purpose

grease

to

the

spindle

shaft

and

threaded

portions

wheel

bearing

washer

and

wheel

bearing

lock

nut

surfaces

slightly

6

Install

the

wheei

bearing

and

grease

seal

on

the

wheel

hub

and

install

them

on

the

spindle

Note

In

order

to

provide

the

bearing

with

a

proper

prepressure

and

to

extend

the

bearing

service

life

install

the

wheel

bearing

grease

seal

washer

and

lock

nut

carefully

so

that

no

dust

and

foreign

matters

stick

on

grease

applied

to

them

Wheel

bearing

adjustment

I

Tighten

the

wheel

bearing

lock

nut

to

2

2

to

2

4

kg

m

15

9

to

174

ft

lb

tightening

torque

Fig

FA

25

Tightening

wheel

bearing

lock

nut

2

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

to

settle

down

the

bearing

and

retighten

the

wheel

bearing

lock

nut

to

the

same

tightening

torque

3

Return

the

wheel

bearing

lock

nut

in

range

from

400

to

700

and

coincide

it

with

cotter

pin

hole

on

the

spindle