service DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 146 of 513

CHASSIS

2

Upon

completion

of

the

adjustment

release

the

hand

brake

lever

and

make

sure

that

the

rear

wheels

are

not

braked

Normal

stroke

78

5

mm

3

091

in

6

notches

Limited

stroke

136

0

mm

5

35

in

10

notches

The

term

Stroke

means

height

from

the

standard

position

220

mm

8

7

in

above

the

hand

brake

lever

fulcrum

Note

Readjust

hand

brake

stroke

when

it

reaches

the

limited

stroke

136

mm

5

35

inl

10

notches

Bleeding

hydraulic

system

Bleeding

the

hydraulic

brake

system

deserves

much

attention

as

it

is

an

essential

factor

for

regular

service

brake

operation

As

a

matter

of

fact

during

the

brake

service

air

is

likely

to

creep

into

the

circuit

with

the

result

that

the

fluid

action

is

altered

and

the

brake

pedal

becomes

spongy

at

the

travel

end

Bleeding

should

be

carried

out

at

first

with

the

masler

cylinder

then

from

the

longest

line

from

the

master

cylinder

and

then

finish

up

with

the

shortest

Note

Always

clear

away

any

dirt

around

master

cylinder

reservoir

cover

before

removing

cover

for

any

reason

Never

depress

pedal

while

brake

drums

are

removed

unless

bleeder

valve

is

open

Top

up

the

reservoir

master

cylinder

with

fluid

of

the

recommended

type

2

Thoroughly

wipe

the

bleeder

screw

and

from

any

mud

or

dust

present

so

that

the

outlet

hole

is

free

from

foreign

matter

3

Attach

a

vinyl

hose

to

the

wheel

cylinder

bleeder

screw

Dip

the

end

of

the

vinyl

hose

in

a

jar

con

taining

some

brake

fluid

BR

22

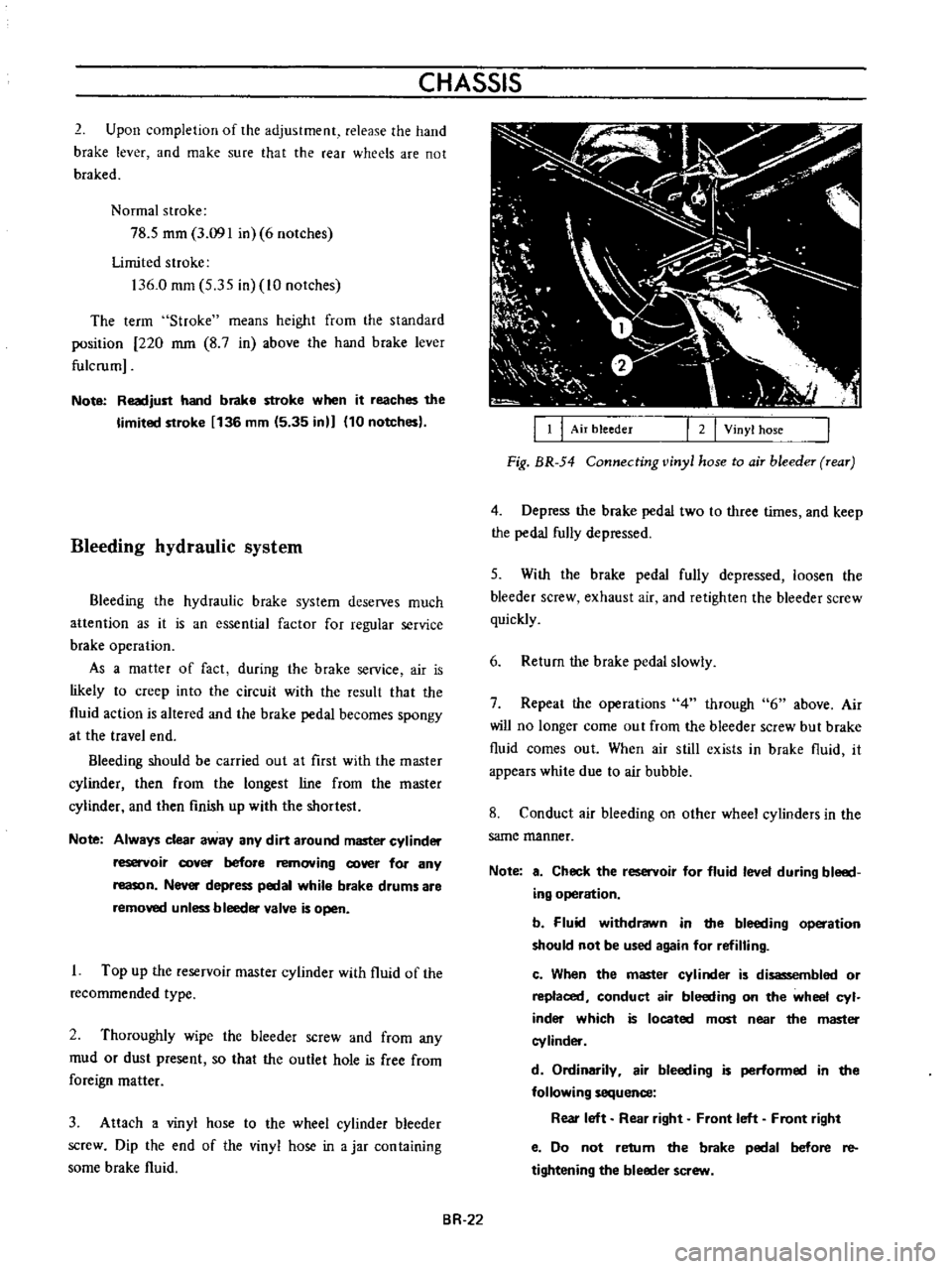

I

I

I

Air

bleeder

I

2

I

Vinyl

hose

Fig

BR

54

Connecting

vinyl

hose

to

air

bleeder

rear

4

Depress

the

brake

pedal

two

to

three

times

and

keep

the

pedal

fully

depressed

5

With

the

brake

pedal

fully

depressed

loosen

the

bleeder

screw

exhaust

air

and

retighten

the

bleeder

screw

quickly

6

Return

the

brake

pedal

slowly

7

Repeat

the

operations

4

through

6

above

Air

will

no

longer

come

out

from

the

bleeder

screw

but

brake

fluid

comes

out

When

air

still

exists

in

brake

fluid

it

appears

white

due

to

air

bubble

8

Conduct

air

bleeding

on

other

wheel

cylinders

in

the

same

manner

Note

a

Check

the

reservoir

for

fluid

level

during

bleed

ing

operation

b

Fluid

withdrawn

in

the

bleeding

operation

should

not

be

used

again

for

refilling

c

When

the

master

cylinder

is

disassembled

or

replaced

conduct

air

bleeding

on

the

wheel

cyl

inder

which

is

located

most

near

the

master

cylinder

d

Ordinarily

air

bleeding

is

performed

in

the

following

sequence

Rear

left

Rear

right

Front

left

Front

right

e

Do

not

retum

the

brake

pedal

before

re

tightening

the

bleeder

screw

Page 147 of 513

BRAKE

SERVICE

DATA

AND

SPECIFICATIONS

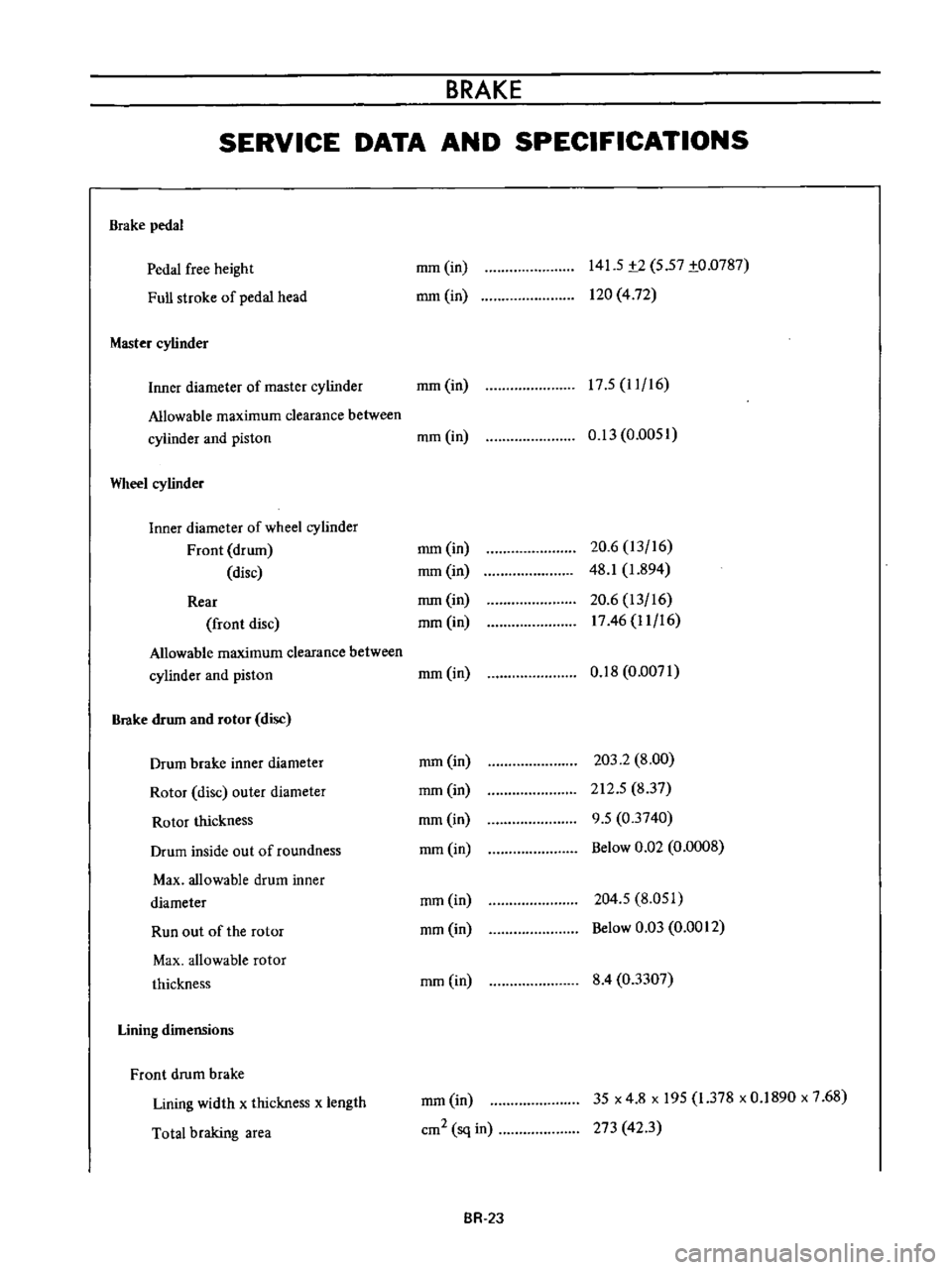

Brake

pedal

Pedal

free

height

Full

stroke

of

pedal

head

Master

cylinder

mm

in

mm

in

141

5

t2

5

57

to

0787

120

4

72

17

5

11

16

Inner

diameter

of

master

cylinder

mm

in

Allowable

maximum

clearance

between

cylinder

and

piston

mm

in

Wheel

cylinder

Inner

diameter

of

wheel

cylinder

Front

drum

disc

Rear

front

disc

Allowable

maximum

clearance

between

cylinder

and

piston

Brake

drum

and

rotor

disc

Drum

brake

inner

diameter

Rotor

disc

outer

diameter

Rotor

thickness

Drum

inside

out

of

roundness

Max

allowable

drum

inner

diameter

Run

out

of

the

rotor

Max

allowable

rotor

thickness

Lining

dimensions

Front

drum

brake

Lining

width

x

thickness

x

length

Total

braking

area

0

13

0

0051

mm

in

mm

in

mm

in

mm

in

20

6

13

16

48

1

1

894

20

6

13

16

1746

11

16

mm

in

0

18

0

0071

mm

in

mm

in

mm

in

mm

in

203

2

8

00

212

5

837

9

5

03740

Below

0

Q2

0

0008

mm

in

mm

in

204

5

8

051

Below

0

03

0

0012

mm

in

8

4

03307

mm

in

cm2

sq

in

35

x

4

8

x

195

1

378

x

0

1890

x

7

68

273

423

BR

2J

Page 149 of 513

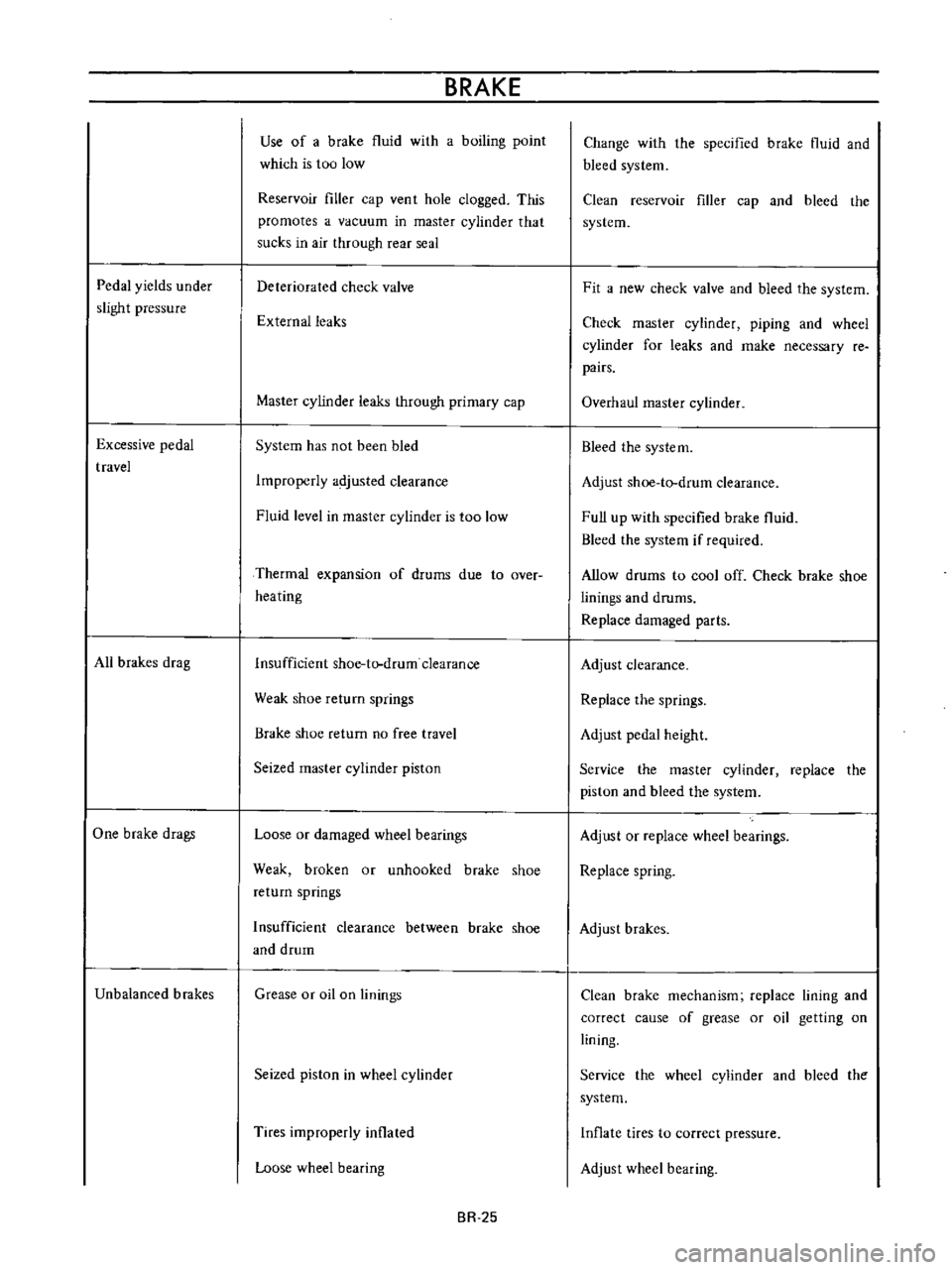

Pedal

yields

under

slight

pressure

Excessive

pedal

travel

All

brakes

drag

One

brake

drags

Unbalanced

brakes

BRAKE

Use

of

a

brake

fluid

with

a

boiling

point

which

is

too

low

Reservoir

filler

cap

ven

t

hole

clogged

This

promotes

a

vacuum

in

master

cylinder

that

sucks

in

air

through

rear

seal

Deteriorated

check

valve

External

leaks

Master

cylinder

leaks

through

primary

cap

System

has

not

been

bled

Improperly

adjusted

clearance

Fluid

level

in

master

cylinder

is

too

low

Thermal

expansion

of

drums

due

to

over

heating

Insufficient

shoe

tlrdrum

clearance

Weak

shoe

return

springs

Brake

shoe

return

no

free

travel

Seized

master

cylinder

piston

Loose

or

damaged

wheel

bearings

Weak

broken

or

unhooked

brake

shoe

return

springs

Insufficient

clearance

between

brake

shoe

and

drum

Grease

or

oil

on

linings

Seized

piston

in

wheel

cylinder

Tires

improperly

inflated

Loose

wheel

bearing

BR

25

Change

with

the

specified

brake

fluid

and

bleed

system

Clean

reservoir

filler

cap

and

bleed

the

system

Fit

a

new

check

valve

and

bleed

the

system

Check

master

cylinder

piping

and

wheel

cylinder

for

leaks

and

make

necessary

re

pairs

Overhaul

master

cylinder

Bleed

the

system

Adjust

shoe

to

drum

clearance

Full

up

with

specified

brake

fluid

Bleed

the

system

if

required

Allow

drums

to

cool

off

Check

brake

shoe

linings

and

drums

Replace

damaged

parts

Adjust

clearance

Replace

the

springs

Adjust

pedal

height

Service

the

master

cylinder

replace

the

piston

and

bleed

the

system

Adjust

or

replace

wheel

bearings

Replace

spring

Adjust

brakes

Clean

brake

mechanism

replace

lining

and

correct

cause

of

grease

or

oil

getting

on

lining

Service

the

wheel

cylinder

and

bleed

the

system

Inflate

tires

to

correct

pressure

Adjust

wheel

bearing

Page 150 of 513

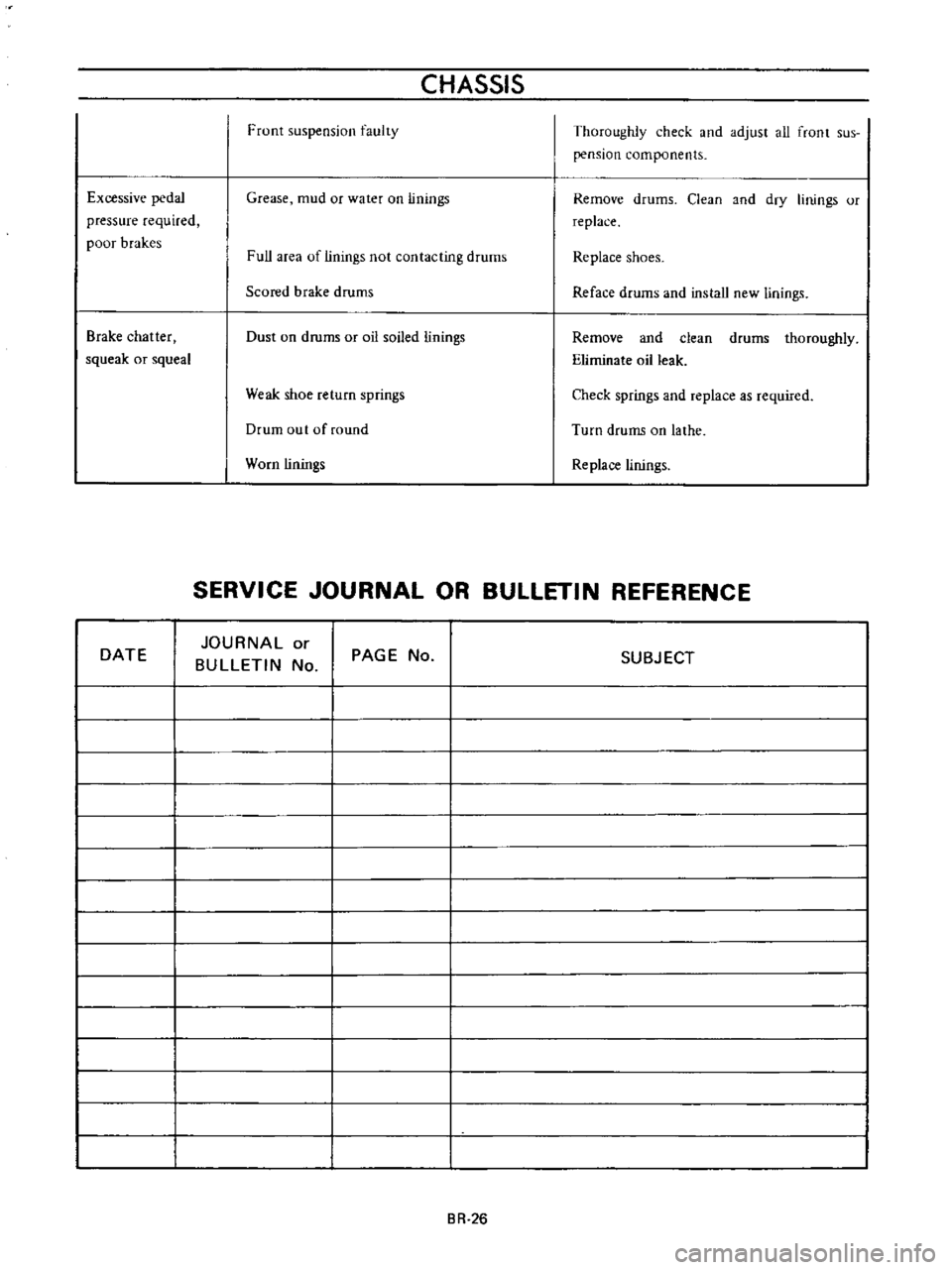

CHASSIS

Front

suspension

faulty

Thoroughly

check

and

adjust

all

front

sus

pension

components

Excessive

pedal

pressure

required

poor

brakes

Grease

mud

or

water

on

linings

Remove

drums

Clean

and

dry

linings

or

replace

Full

area

of

linings

not

contacting

drums

Replace

shoes

Scored

brake

drums

Reface

drums

and

install

new

linings

Brake

chatter

squeak

or

squeal

Dust

on

drums

or

oil

soiled

linings

Remove

and

clean

drums

thoroughly

Eliminate

oil

leak

Weak

shoe

return

springs

Check

springs

and

replace

as

required

Drum

out

of

round

Turn

drums

on

lathe

Worn

linings

Replace

linings

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

BR

26

Page 151 of 513

DATE

BRAKE

SERVICE

JOURNAL

OR

BUllETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

BR

27

Page 152 of 513

I

DATE

CHASSIS

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

BR

28

Page 154 of 513

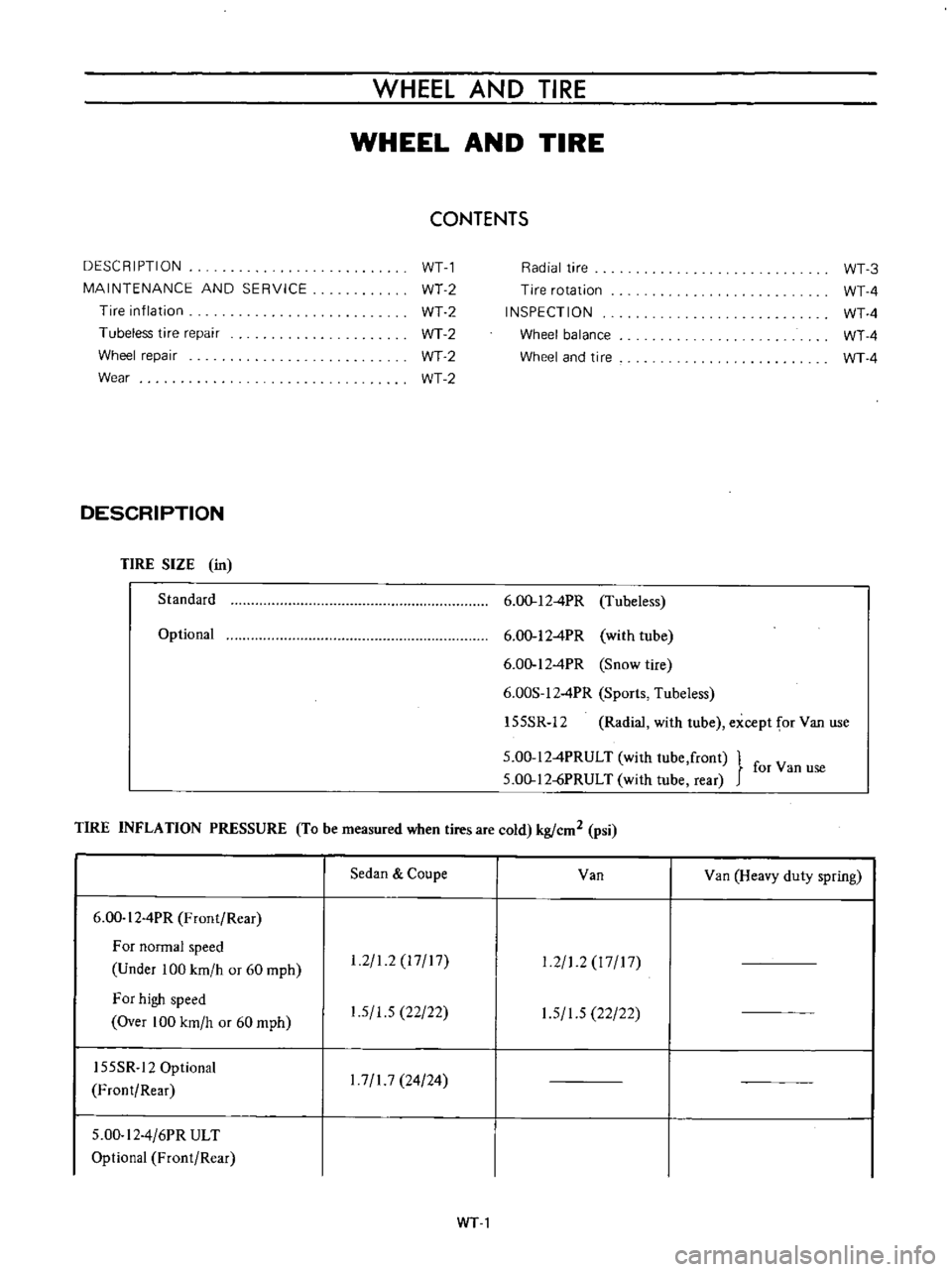

DESCRIPTION

MAINTENANCE

AND

SERVICE

Tire

inflation

Tubeless

tire

repair

Wheel

repair

Wear

DESCRIPTION

TIRE

SIZE

in

Standard

Optional

WHEEL

AND

TIRE

WHEEL

AND

TIRE

CONTENTS

WTl

WT2

WT2

WT2

WT2

WT2

Radial

tire

Tire

rotation

INSPECTION

Wheel

balance

Wheel

and

tire

6

00

12

4PR

Tubeless

6

00

12

4PR

with

tube

6

00

12

4PR

Snow

tire

6

00S

12

4PR

Sports

Tubeless

155SR

12

Radial

with

tube

except

for

Van

use

5

00

12

4PRULT

with

lube

front

for

Van

use

5

00

12

jPRULT

with

tube

rear

TIRE

INFLATION

PRESSURE

To

be

measured

when

tires

are

cold

kg

cm2

psi

6

00

I

2

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

mph

For

high

speed

Over

100

km

h

or

60

mph

155SR

12

Optional

Front

Rear

5

00

I

2

4

6PR

ULT

Optional

Front

Rear

Sedan

Coupe

1

2

1

2

17

17

1

5

1

5

22

22

1

7

1

7

24

24

Van

Van

Heavy

duty

spring

1

2

1

2

I

7

17

1

5

1

5

22

22

WTl

WT

3

WT

4

WT

4

WT

4

WT

4

Page 155 of 513

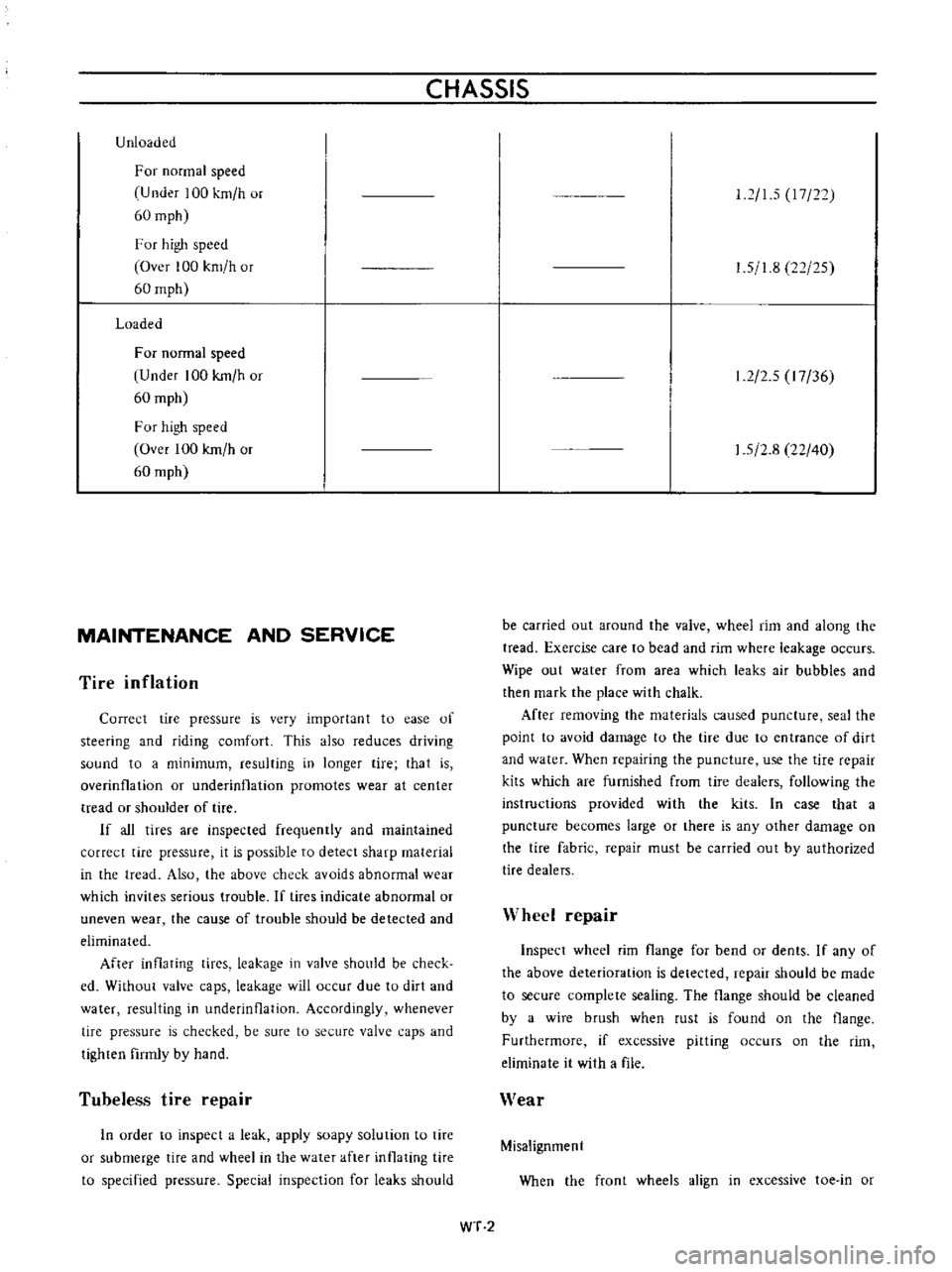

CHASSIS

Unloaded

For

normal

speed

U

nder

100

km

h

or

60

mph

F

or

high

speed

Over

100

km

h

or

60

mph

Loaded

For

normal

speed

Under

100

kmlh

or

60

mph

For

high

speed

Over

100

kmlh

or

60

mph

MAINTENANCE

AND

SERVICE

Tire

inflation

Correct

tire

pressure

is

very

importan

t

to

ease

of

steering

and

riding

comfort

This

also

reduces

driving

sound

to

a

minimum

resulting

in

longer

tire

that

is

overinfla

lion

or

underinflation

promotes

wear

at

center

tread

or

shoulder

of

tire

If

all

tires

are

inspected

frequently

and

maintained

correct

tire

pressure

it

is

possible

to

detect

sharp

material

in

the

tread

Also

the

above

check

avoids

abnormal

wear

which

invites

serious

trouble

If

tires

indicate

abnormal

or

uneven

wear

the

cause

of

trouble

should

be

detected

and

eliminated

After

inflating

tices

leakage

in

valve

should

be

check

cd

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinOation

Accordingly

whenever

tire

pressure

is

checked

be

sure

to

secure

valve

caps

and

tighten

firmly

by

hand

Tubeless

tire

repair

In

urder

to

inspect

a

leak

apply

soapy

solution

to

tire

or

submerge

tire

and

wheel

in

the

water

after

inflating

tire

to

specified

pressure

Special

inspection

for

leaks

should

12

15

17

22

1

5

1

8

22

25

1

2

2

5

I

7

36

1

5

2

8

22

40

be

carried

out

around

the

valve

wheel

rim

and

along

the

tread

Exercise

care

to

bead

and

rim

where

leakage

occurs

Wipe

out

water

from

area

which

leaks

air

bubbles

and

then

mark

the

place

with

chalk

After

remuving

the

materials

caused

puncture

seal

the

point

to

avoid

damage

to

the

tire

due

to

entrance

of

dirt

and

water

When

repairing

the

puncture

use

the

tire

repair

kits

which

are

furnished

from

tire

dealers

following

the

instructions

provided

with

the

kits

In

case

that

a

puncture

becomes

large

or

there

is

any

other

damage

on

the

tire

fabric

repair

must

be

carried

out

by

authorized

tire

dealers

Wheel

repair

Inspect

wheel

rim

flange

for

bend

or

dents

If

any

of

the

above

deterioration

is

detected

repair

should

be

made

to

secure

complete

sealing

The

flange

should

be

cleaned

by

a

wire

brush

when

rust

is

found

on

the

flange

Furthermore

if

excessive

pitting

occurs

on

the

rim

eliminate

it

with

a

file

Wear

Misalignment

When

the

front

wheels

align

in

excessive

toe

in

or

WT

2

Page 159 of 513

Tire

squeals

DATE

CHASSIS

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

start

and

improper

speeding

due

to

rapid

acceleration

or

improper

brake

appli

cation

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

Realign

Repair

correctly

or

replace

if

necessary

or

reinstall

correctly

Reduce

speed

Follow

correct

and

proper

driving

manner

Measure

and

adjust

correctly

Realign

correctly

Repair

or

replace

if

necessary

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

WT

6

SUBJECT

Page 160 of 513

DATSUN

1200

MODEL

8110

SERIES

l

NISSAN

I

NI55AN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

ST

STEERING

DESCRIPTION

ST

1

STEERING

ST

1

COllAPSIBLE

STEERING

ST

7

STEERING

LINKAGE

ST

13

SERVICE

DATA

AND

ST

17

SPECI

FICATlONS

TROUBLE

DIAGNOSES

AND

ST

18

CORRECTIONS