service DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 109 of 513

FRONT

AXLE

FRONT

SUSPENSION

SERVICE

DATA

AND

SPECIFICATIONS

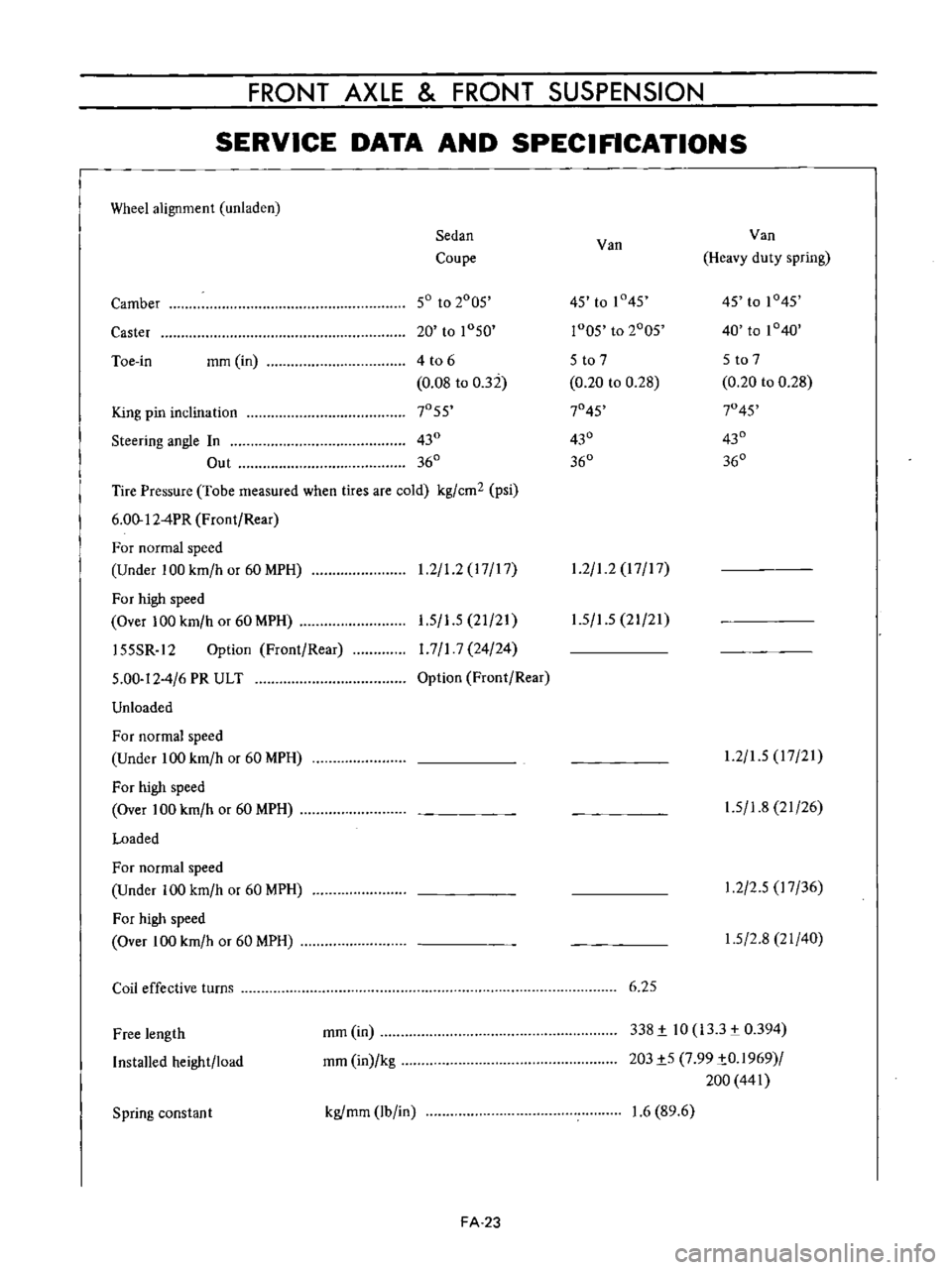

Wheel

alignment

unladen

Sedan

Van

Van

Coupe

Heavy

duty

spring

Camber

50

to

2005

45

to

1

45

45

to

1045

Caster

20

to

1050

r005

to

2005

40

to

1040

Toe

in

mm

in

4

t06

5

to

7

5

to

7

0

08

to

032

0

20

to

0

28

0

20

to

0

28

King

pin

inclination

7055

7045

7045

Steering

angle

In

430

430

430

Out

360

360

360

Tire

Pressure

Tobe

measured

when

tires

are

cold

kg

cm2

psi

6

00

12

4PR

Front

Rear

For

normal

speed

Under

100

km

h

or

60

MPH

1

2

1

2

17

17

1

2

1

2

17

17

For

high

speed

Over

100

km

h

or

60

MPH

155SR

12

Option

Front

Rear

5

00

12

4

6

PR

ULT

Unloaded

1

5

1

5

21

21

1

7

1

7

24

24

Option

Front

Rear

1

5

1

5

21

21

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

Loaded

1

2

1

5

17

21

1

5

1

8

21

26

For

normal

speed

Under

100

km

h

or

60

MPH

For

high

speed

Over

100

km

h

or

60

MPH

1

2

2

5

17

36

1

5

2

8

21

40

Coil

effective

turns

6

25

Free

length

Installed

height

load

mm

in

mm

in

kg

338

i

10

133

0394

203i5

7

99

iO

1969

200

441

Spring

constan

t

kgfmm

lb

in

1

6

89

6

FA

23

Page 114 of 513

CHASSIS

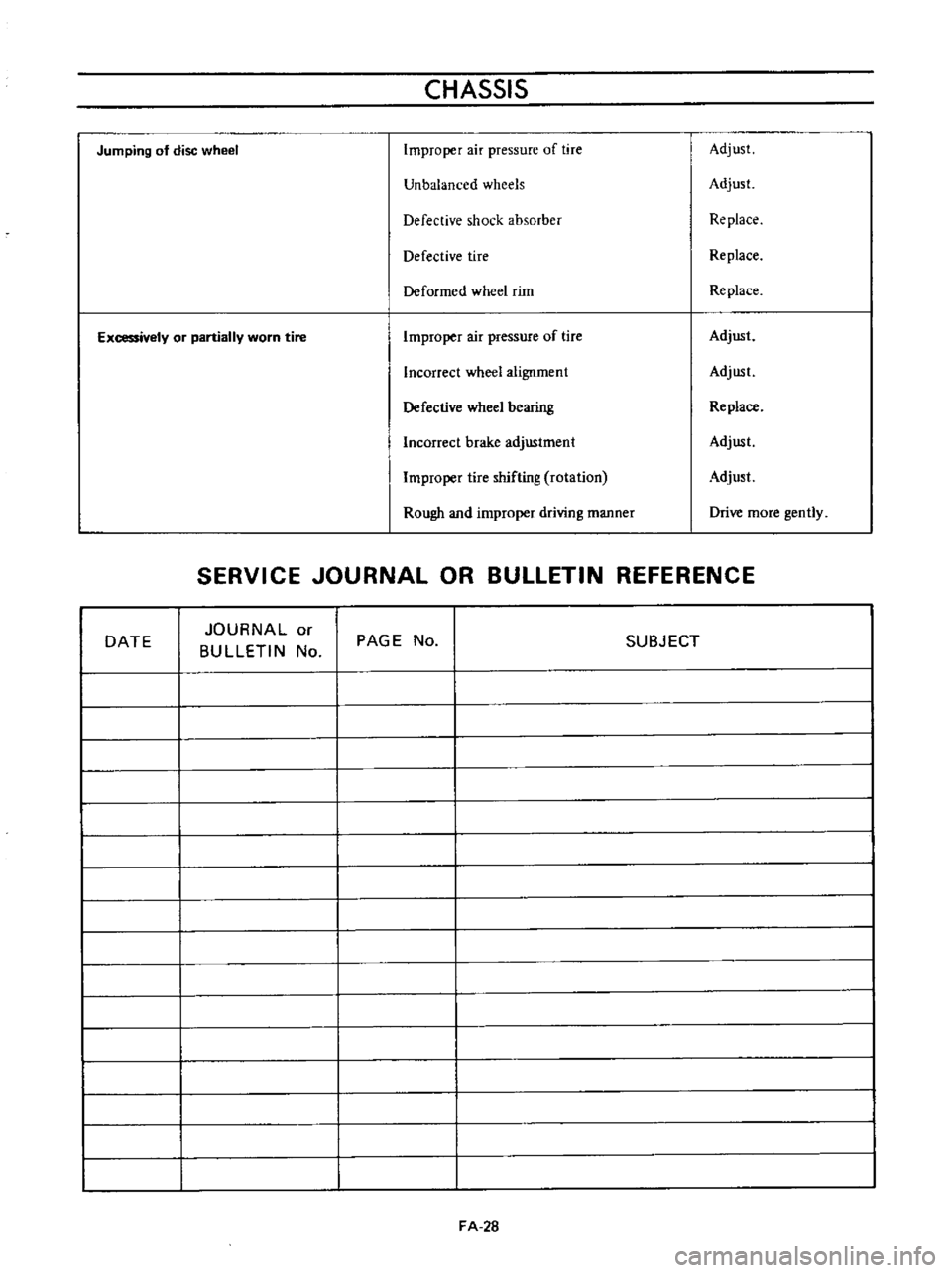

Jumping

of

disc

wheel

Improper

air

pressure

of

tire

Adjust

Unbalanced

wheels

Adjust

Defective

shock

absorber

Replace

Defective

tire

Replace

Deformed

wheel

rim

Replace

Excessively

or

partially

worn

tire

Improper

air

pressure

of

tire

Adjust

Incorrect

wheel

alignment

Adjust

Defective

wheel

bearing

Replace

Incorrect

brake

adjustment

Adjust

Improper

tire

shifting

rotation

Adjust

Rough

and

improper

driving

manner

Drive

more

gently

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

FA

28

Page 115 of 513

DATSUN

1200

MODEL

B

1

10

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

RA

REAR

AXLE

REAR

SUSPENSION

REAR

AXLE

REAR

SUSPENSION

SERVICE

DATA

AND

SPECIFICATIONS

RA

1

RA

4

RA

7

Page 116 of 513

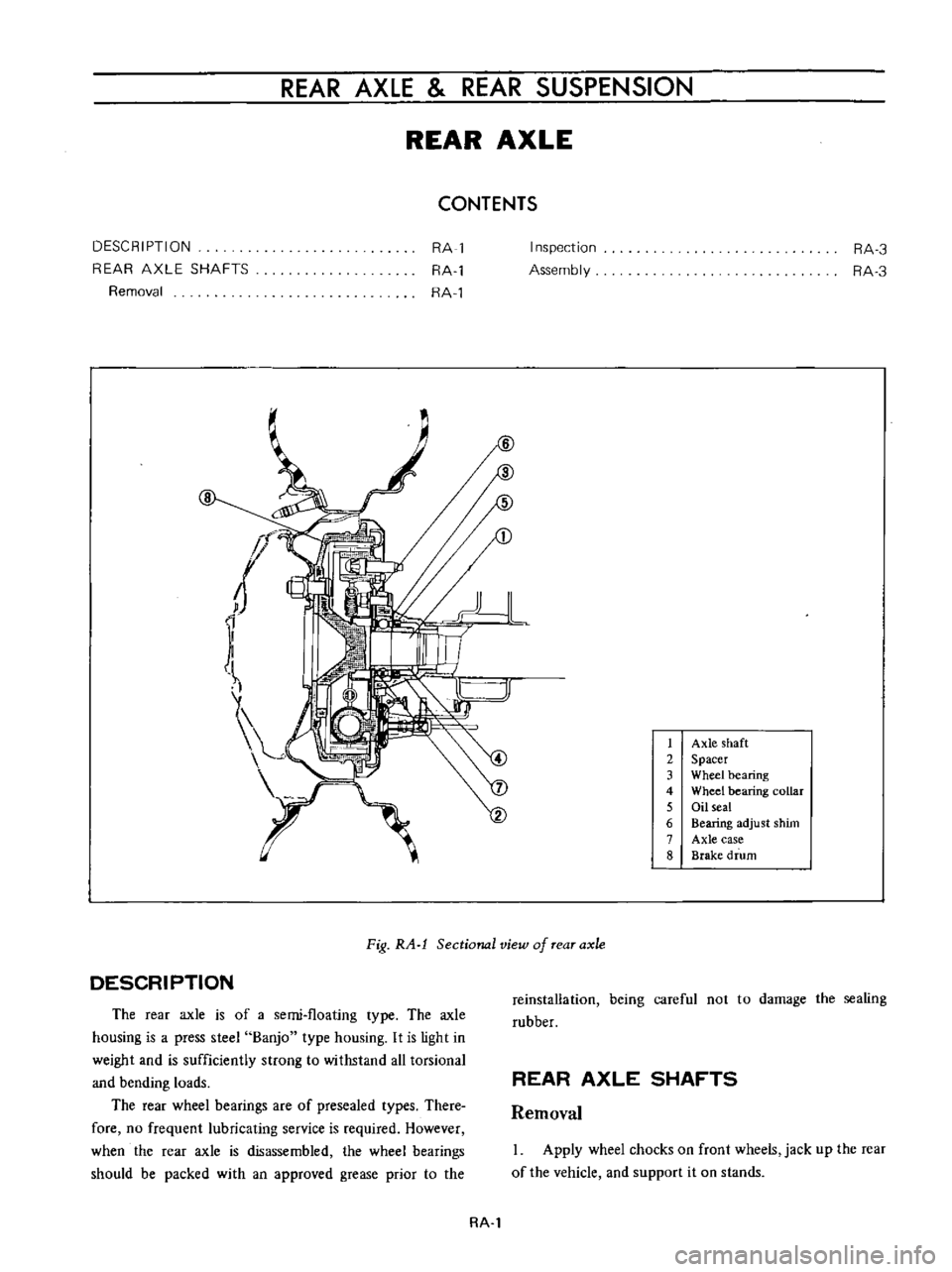

REAR

AXLE

REAR

SUSPENSION

REAR

AXLE

CONTENTS

DESCRIPTION

REAR

AXLE

SHAFTS

Removal

RA

1

RA

l

RA

l

8

Inspection

Assembly

RA

3

RA

3

1

Axle

shaft

2

Spacer

3

Wheel

bearing

4

Wheel

bearing

collar

5

Oil

seal

6

Bearing

adjust

shim

7

Axle

case

8

Brake

drum

DESCRIPTION

Fig

RA

l

Sectional

view

of

rear

axle

The

rear

axle

is

of

a

semi

floating

type

The

axle

housing

is

a

press

steel

Banjo

type

housing

It

is

light

in

weight

and

is

sufficiently

strong

to

withstand

all

torsional

and

bending

loads

The

rear

wheel

bearings

are

of

presea1ed

types

There

fore

no

frequent

lubricating

service

is

required

However

when

the

rear

axle

is

disassembled

the

wheel

bearings

should

be

packed

with

an

approved

grease

prior

io

the

reinstallation

being

careful

not

to

damage

the

sealing

rubber

REAR

AXLE

SHAFTS

Removal

Apply

wheel

chocks

on

front

wheels

jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

RA

l

Page 120 of 513

REAR

AXLE

REAR

SUSPENSION

DESCRIPTION

Rear

suspension

consists

of

semi

elliptic

leaf

springs

telescopic

hydraulic

shock

absorbers

and

rubber

bumpers

The

rear

spring

center

pin

is

off

set

110

mm

4

33

in

toward

the

front

from

the

center

of

the

spring

This

is

done

to

reduce

spring

wind

up

and

to

decrease

the

arc

while

the

rear

wheel

swings

through

Thereby

minimizing

the

possibility

of

the

rear

suspension

effecting

vehicle

stability

Iso

clamp

devices

are

used

for

attaching

the

axle

housing

to

the

spring

The

leaf

springs

shock

absorbers

and

rear

axle

housing

are

mounted

on

rubber

bushings

at

each

end

to

minimize

noise

and

vibration

of

the

transmission

to

the

car

body

and

passenger

compartment

REAR

SPRING

Removal

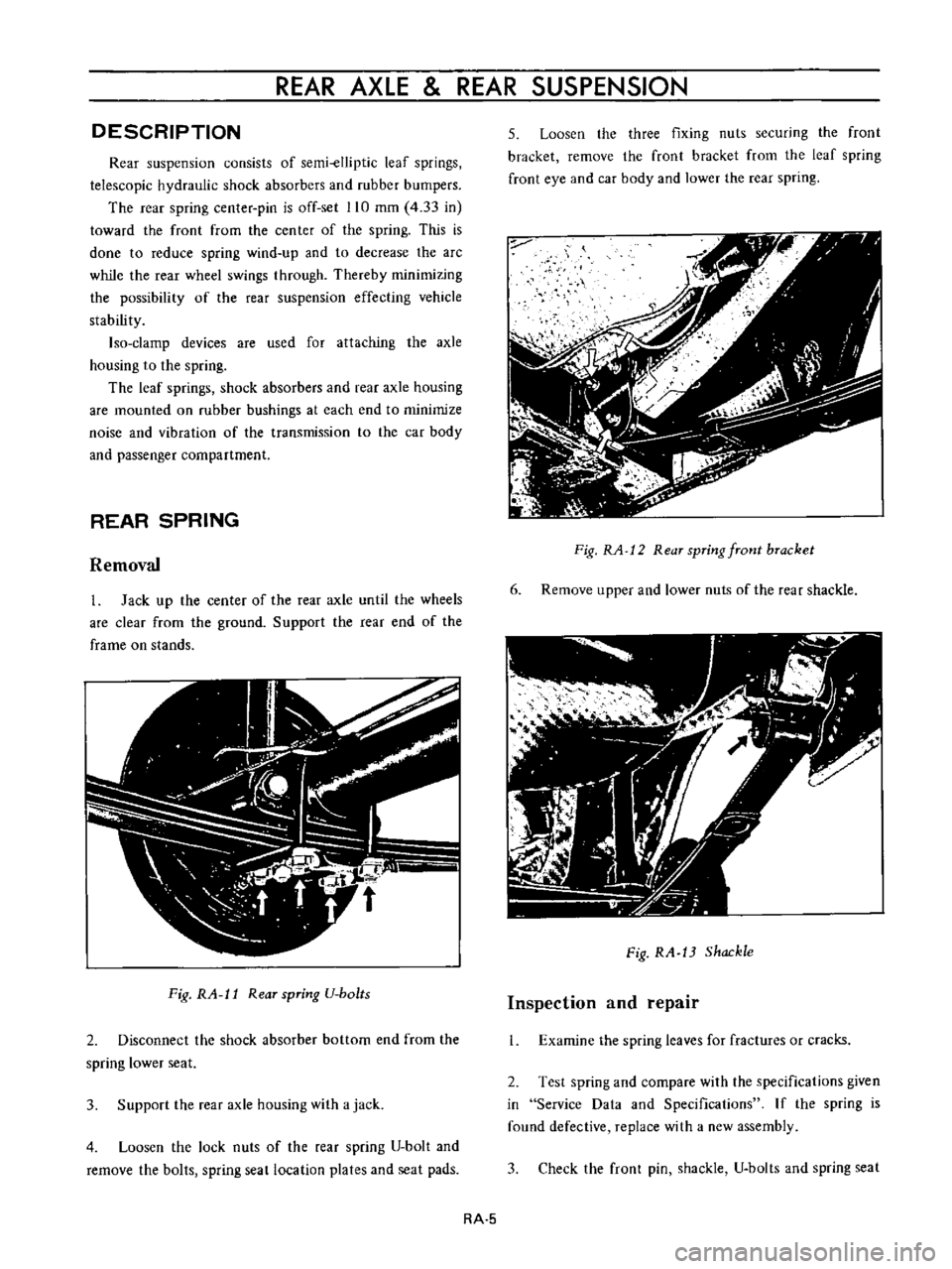

1

Jack

up

the

center

of

the

rear

axle

until

the

wheels

are

clear

from

the

ground

Support

the

rear

end

of

the

frame

on

stands

Fig

RA

l1

Rear

spring

U

bo

ts

2

Disconnect

the

shock

absorber

bottom

end

from

the

spring

lower

seat

3

Support

the

rear

axle

housing

with

a

jack

4

Loosen

the

lock

nuts

of

the

rear

spring

U

bolt

and

remove

the

bolts

spring

seat

location

plates

and

seat

pads

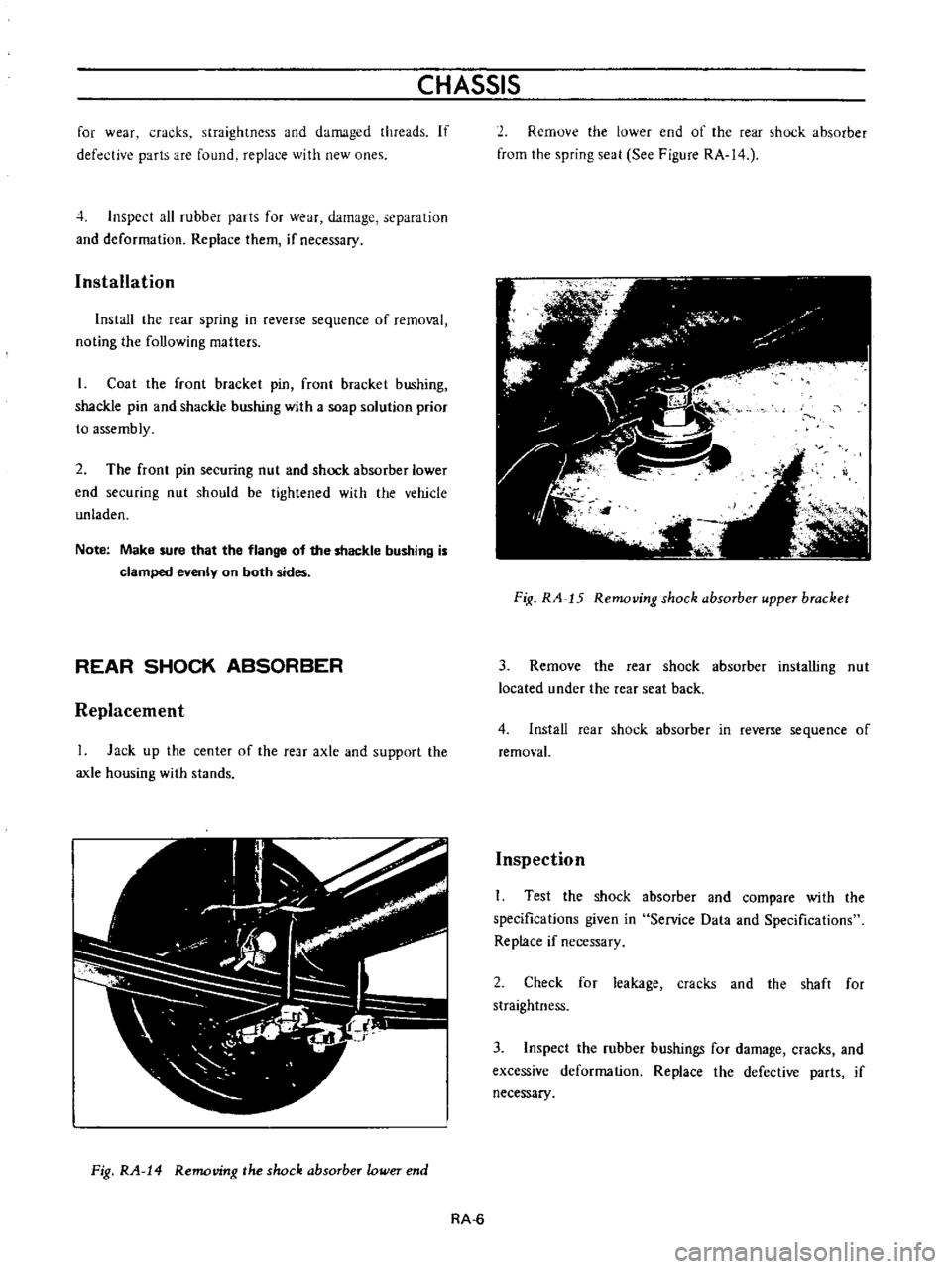

5

Loosen

the

three

fixing

nuts

securing

the

front

bracket

remove

the

front

bracket

from

the

leaf

spring

front

eye

and

car

body

and

lower

the

rear

spring

Fig

RA

12

Rear

spring

front

bracket

6

Remove

upper

and

lower

nuts

of

the

rear

shackle

Fig

RA

13

Shackle

Inspection

and

repair

1

Examine

the

spring

leaves

for

fractures

or

cracks

2

Test

spring

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

If

the

spring

is

found

defective

replace

with

a

new

assembly

3

Check

the

front

pin

shackle

U

bolts

and

spring

seat

RA

5

Page 121 of 513

CHASSIS

for

wear

cra

ks

straightness

and

damaged

thread

s

If

defective

parts

are

found

replace

with

new

ones

4

Inspect

all

rubber

pans

for

wear

damage

separation

and

deformation

Replace

them

if

necessary

Installation

Install

the

rear

spring

in

reverse

sequence

of

removal

noting

the

following

matters

Coat

the

front

bracket

pin

front

bracket

bushing

shackle

pin

and

shackle

bushing

with

a

soap

solution

prior

to

assembly

2

The

front

pin

securing

nut

and

shock

absorber

lower

end

securing

nut

should

be

tightened

with

the

vehicle

unladen

Note

Make

sure

that

the

flange

of

the

shackle

bushing

is

clamped

evenly

on

both

sides

REAR

SHOCK

ABSORBER

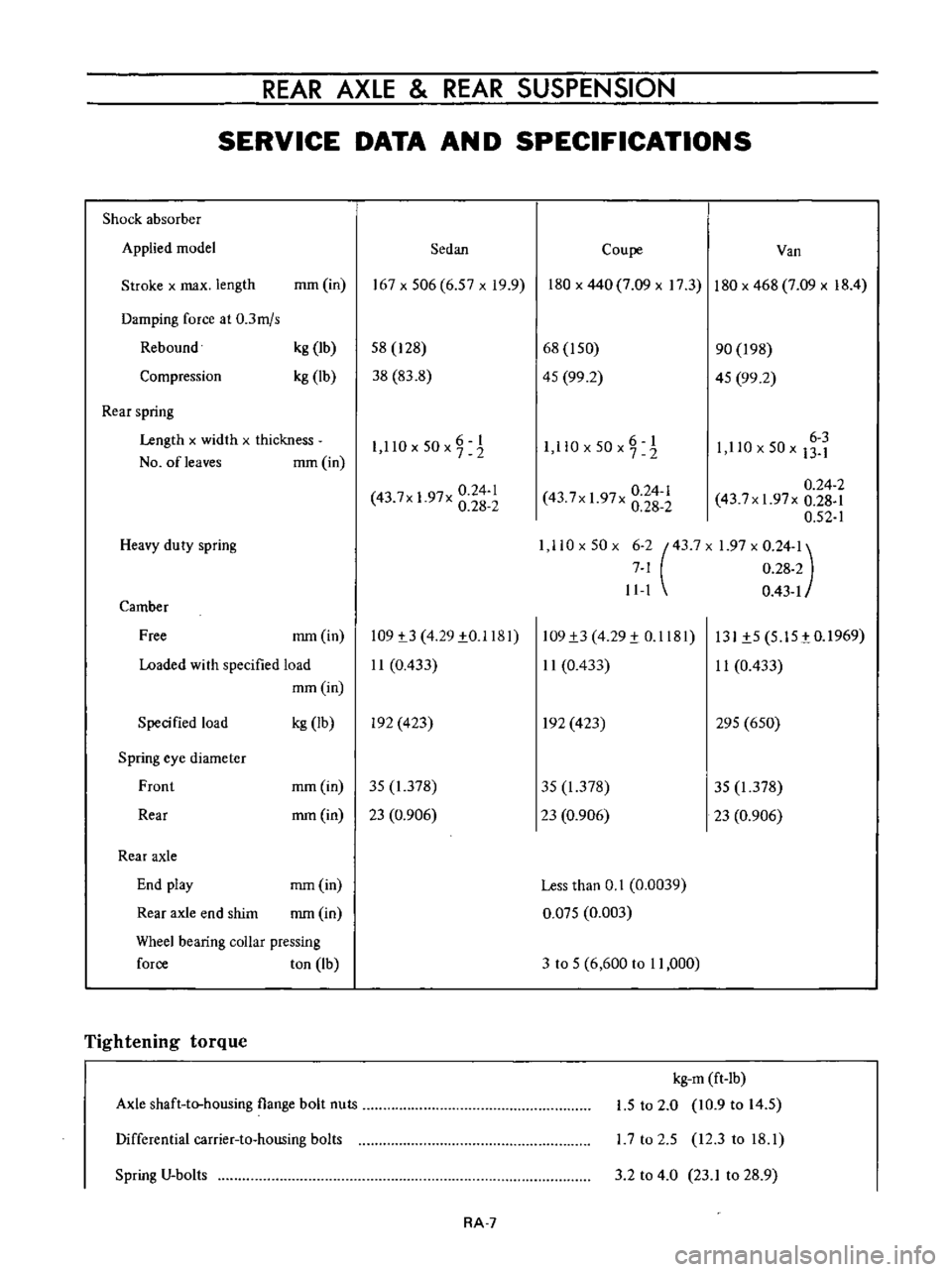

Replacement

lack

up

the

center

of

the

rear

axle

and

support

the

axle

housing

with

stands

Fig

RA

14

Removing

the

shock

absorber

ower

end

2

Remove

the

lower

end

of

the

rear

shock

absorber

from

the

spring

seat

See

Figure

RA

14

FiK

RA

15

Removing

shock

absorber

upper

bracket

3

Remove

the

rear

shock

absorber

installing

nut

located

under

the

rear

seat

back

4

Install

rear

shock

absorber

in

reverse

sequence

of

removal

Inspection

Test

the

shock

absorber

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

Replace

if

necessary

2

Check

for

leakage

cracks

and

the

shafl

for

straightness

3

Inspect

the

rubber

bushings

for

damage

cracks

and

excessive

deformation

Replace

the

defective

parts

jf

necessary

RA

6

Page 122 of 513

REAR

AXLE

REAR

SUSPENSION

SERVICE

DATA

AN

D

SPECIFICATIONS

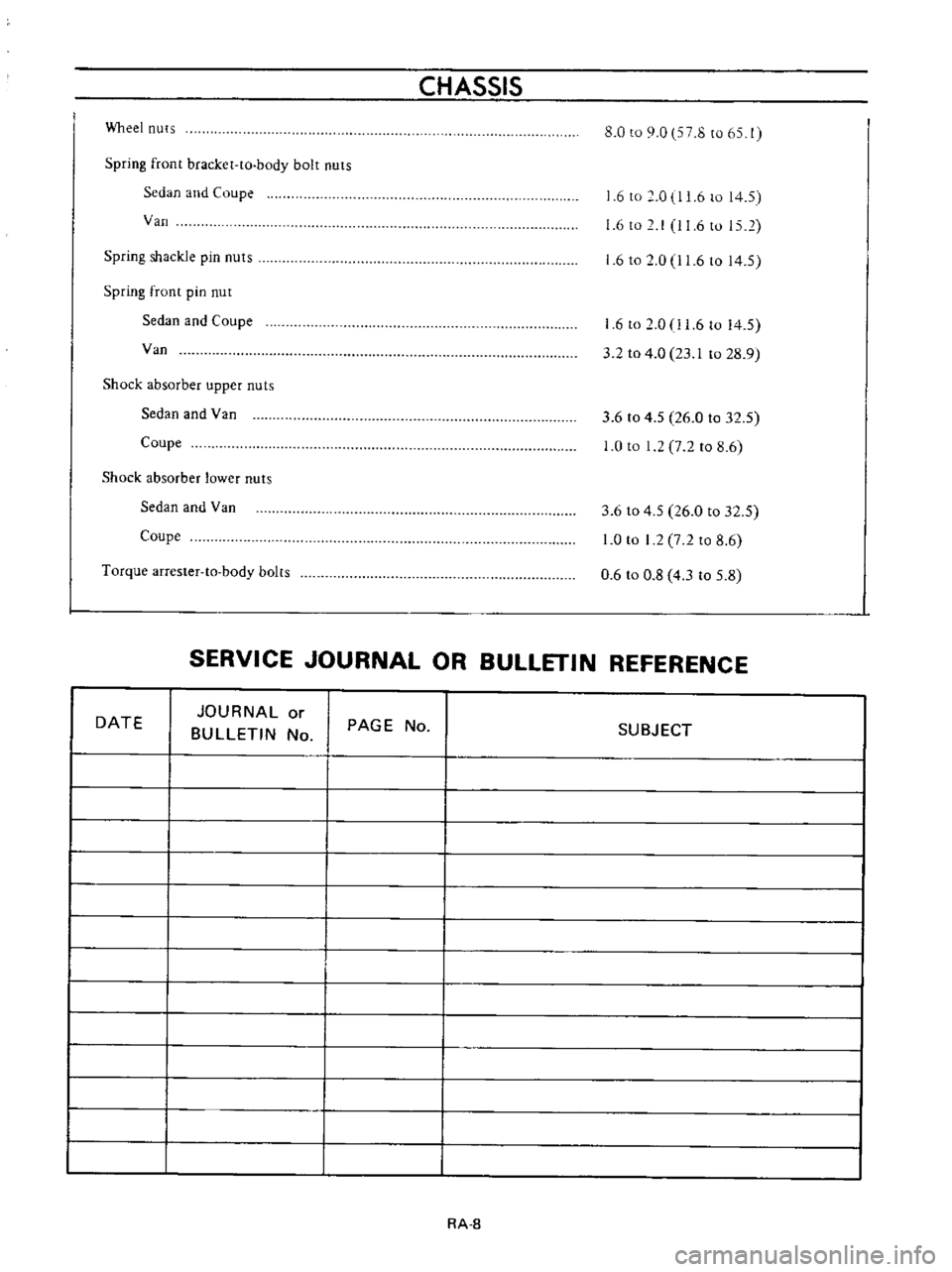

Shock

absorber

Applied

model

Sedan

Coupe

Van

Stroke

x

max

length

mm

in

167x506

6

57xI9

9

180

x

440

7

09

x

17

3

180

x

468

7

09

x

18

4

Damping

force

at

0

3mjs

Rebound

Compression

kg

Ib

kg

lb

58

128

38

83

8

68

I

50

45

99

2

90

198

45

99

2

Rear

spring

Length

x

widlh

x

thickness

NO

ofleaves

mm

in

6

I

1

llOx50x72

O

6

1

I

ll

x50x7

2

6

3

1

110

x

50

x

13

1

0

24

1

43

7x

1

97x

0

28

2

0

24

2

43

7xI

97x

0

28

1

0

52

1

1

110x50x

6

2

43

7X

1

97

x

0

24

1

7

1

0

28

2

11

1

0

43

1

0

24

1

43

7x

1

97x

0

28

2

Heavy

duty

spring

Camber

Free

mm

in

109

t3

4

29

1

0

1181

11

0

433

109

1

3

4

29

1

0

1181

11

0

433

131

1

5

5

15

tO

1969

11

0

433

Loaded

wi

th

specified

load

mm

in

Specified

load

kg

Ib

In

423

In

423

295

650

Spring

eye

diameter

Front

mm

in

35

1

378

35

1

378

35

1

378

Rear

mm

in

23

0

906

23

0

906

23

0

906

Rear

axle

End

play

mm

in

Less

than

0

1

0

0039

Rear

axle

end

shim

mm

in

0

Q75

0

003

Wheel

bearing

coUar

pressing

force

ton

Ib

3

to

5

6

600

to

11

000

Tightening

torque

Axle

shaft

to

housing

flange

bolt

nuts

kg

m

ft

lb

1

5

to

2

0

10

9

to

14

5

L7

to

2

5

12

3

to

18

1

Differential

carrier

to

housing

bolts

Spring

V

bolts

3

2

to

4

0

23

1

to

28

9

RA

7

Page 123 of 513

CHASSIS

Wheel

nuts

8

0

to

9

0

7

8

to

65

1

Spring

front

bracket

to

body

bolt

nuts

Sedan

and

Coupe

Van

6

to

0

1

6

to

14

5

6

to

I

11

6

to

15

2

Spring

shackle

pin

nuts

1

6

to

0

11

6

to

14

5

Spring

front

pin

nut

Sedan

and

Coupe

Van

6

to

2

0

1

6

to

14

5

3

2

to

4

0

23

1

to

28

9

Shock

absorber

upper

nuts

Sedan

and

Van

Coupe

3

6

to

4

5

26

0

to

32

5

0

to

1

7

2

to

8

6

Shock

absorber

lower

nuts

Sedan

and

Van

Coupe

3

6

to

4

5

26

0

to

32

5

0

to

I

2

7

2

to

8

6

0

6

to

0

8

4

3

to

5

8

Torque

arrester

to

body

bolts

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

RA

8

Page 124 of 513

r

jWW

5

jJ

S

L

l

J

J

DATSUN

1200

MODEL

8110

SERIES

I

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BR

BRAKE

BRAKE

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

BR

1

BR

23

BR

24

GI

Page 126 of 513

CHASSIS

DESCRIPTION

The

Datsun

1200

series

new

models

adopt

a

hydraulic

brake

Dis

brake

or

two

leading

shoe

type

drum

brake

is

used

for

the

front

wheels

and

leading

trailing

shoe

type

drum

brake

is

used

for

the

rear

wheels

With

adoption

of

the

disc

brake

safety

at

high

speed

range

driving

is

further

improved

For

the

master

cylinder

either

single

type

or

tandem

type

is

used

There

are

two

types

of

tandem

type

master

cylinder

one

is

for

disc

brake

and

the

other

for

drum

brake

Under

the

standard

specifications

h0wever

the

tandem

type

master

cylinder

is

used

for

disc

brake

and

single

type

is

used

for

drum

brake

The

tandem

master

cylinder

provides

a

dual

brake

system

improving

safety

The

hand

brake

is

of

a

mechanical

type

which

brakes

the

rear

wheels

through

the

control

lever

and

steel

wire

The

control

lever

is

located

between

the

driver

and

assistant

seats

and

can

be

operated

easily

BRAKE

PEDAL

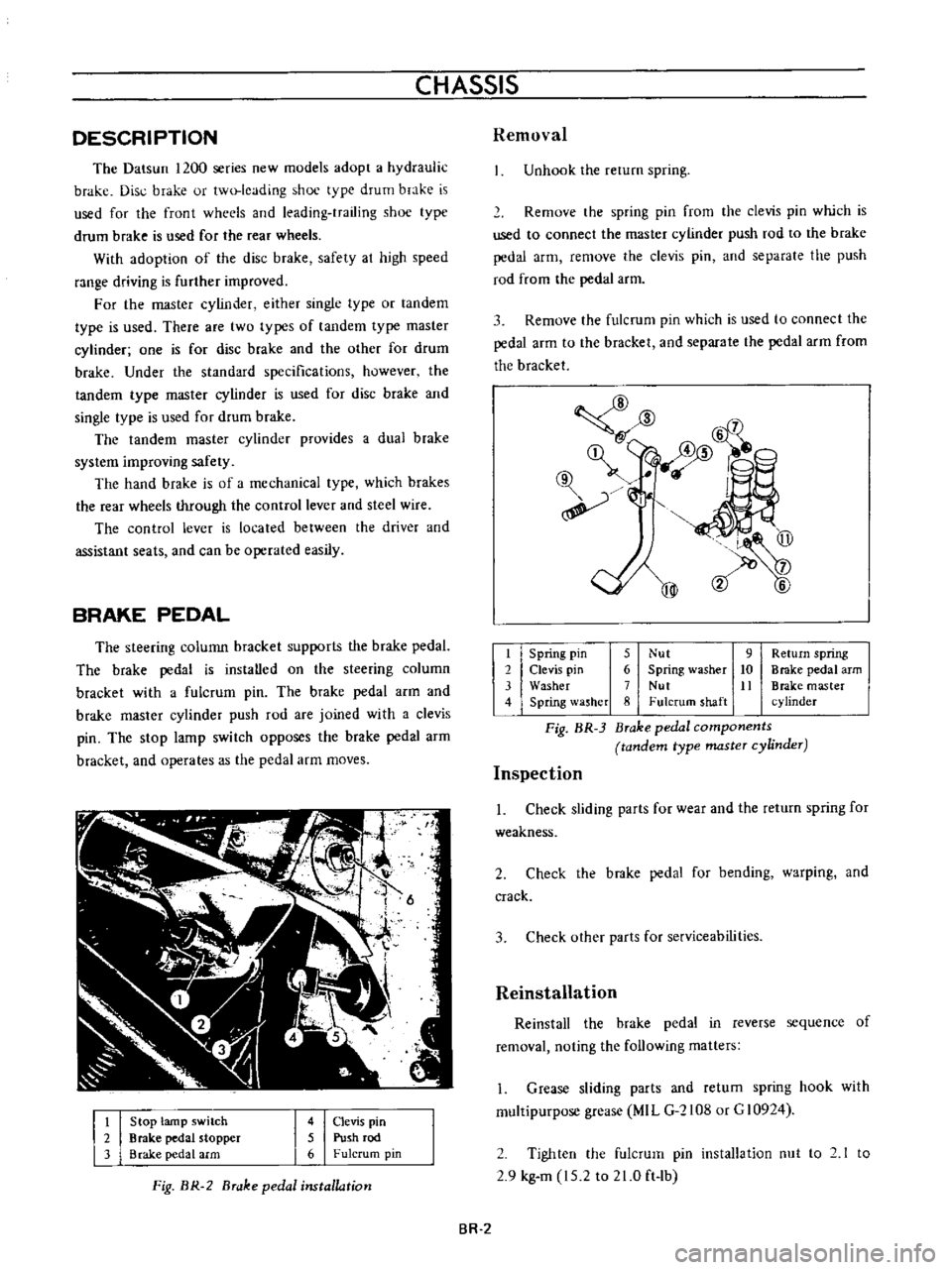

The

steering

colunm

bracket

supports

the

brake

pedaL

The

brake

pedal

is

instaUed

on

the

steering

column

bracket

with

a

fulcrum

pin

The

brake

pedal

arm

and

brake

master

cylinder

push

rod

are

joined

with

a

clevis

pin

The

stop

lamp

switch

opposes

the

brake

pedal

arm

bracket

and

operates

as

the

pedal

arm

moves

t

2

3

Stop

lamp

switch

Brake

pedal

stopper

Brake

pedal

arm

4

Clevis

pin

5

Push

rod

6

Fulcrum

pin

Fig

BR

2

Brake

pedal

installation

Removal

Unhook

the

rerum

spring

Remove

the

spring

pin

from

the

clevis

pin

which

is

used

to

connect

the

master

cylinder

push

rod

to

the

brake

pedal

arm

remove

the

clevis

pin

and

separate

the

push

rod

from

the

pedal

arm

3

Remove

the

fulcrum

pin

which

is

used

to

connect

the

pedal

arm

to

the

bracket

and

separate

the

pedal

arm

from

the

bracket

@

mm

l6

qf

@

@

t

Spring

pin

5

Nut

9

Return

spring

2

Clevis

pin

6

Spring

washer

10

Brake

pedal

arm

3

Washer

7

Nut

It

Brake

master

4

Spring

lasher

8

Fulcrum

shaft

cylinder

Fig

BR

3

Brake

pedal

components

tandem

type

master

cylinder

Inspection

1

Check

sliding

parts

for

wear

and

the

return

spring

for

weakness

2

Check

the

brake

pedal

for

bending

warping

and

crack

3

Check

other

parts

for

serviceabilities

Reinstallation

Reinstall

the

brake

pedal

in

reverse

sequence

of

removal

noting

the

following

matters

1

Grease

sliding

parts

and

retum

spring

hook

with

multipurpose

grease

MIL

G

2108

or

G

10924

2

Tighten

the

fulcrum

pin

installation

nut

to

2

1

to

2

9

kg

m

15

2

to

21

0

ft

lb

BR

2