automatic transmission DATSUN B110 1973 Service Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 318 of 513

EMISSION

CONTROL

AND

TUNE

UP

Operation

manual

transmission

equipped

model

The

operation

of

the

solenoid

is

by

means

of

the

movement

of

the

speedometer

needle

When

vehicle

speed

falls

below

16

km

h

10

MPH

the

needle

movement

produces

a

signal

which

in

turn

is

amplified

to

actuate

the

solenoid

I

Vehicle

speed

Speed

Throttle

Throttle

switch

opener

opener

solenoid

Below

16

km

h

Not

10

MPH

ON

ON

actuated

Above

16

km

h

OFF

OFF

Actuated

10

MPH

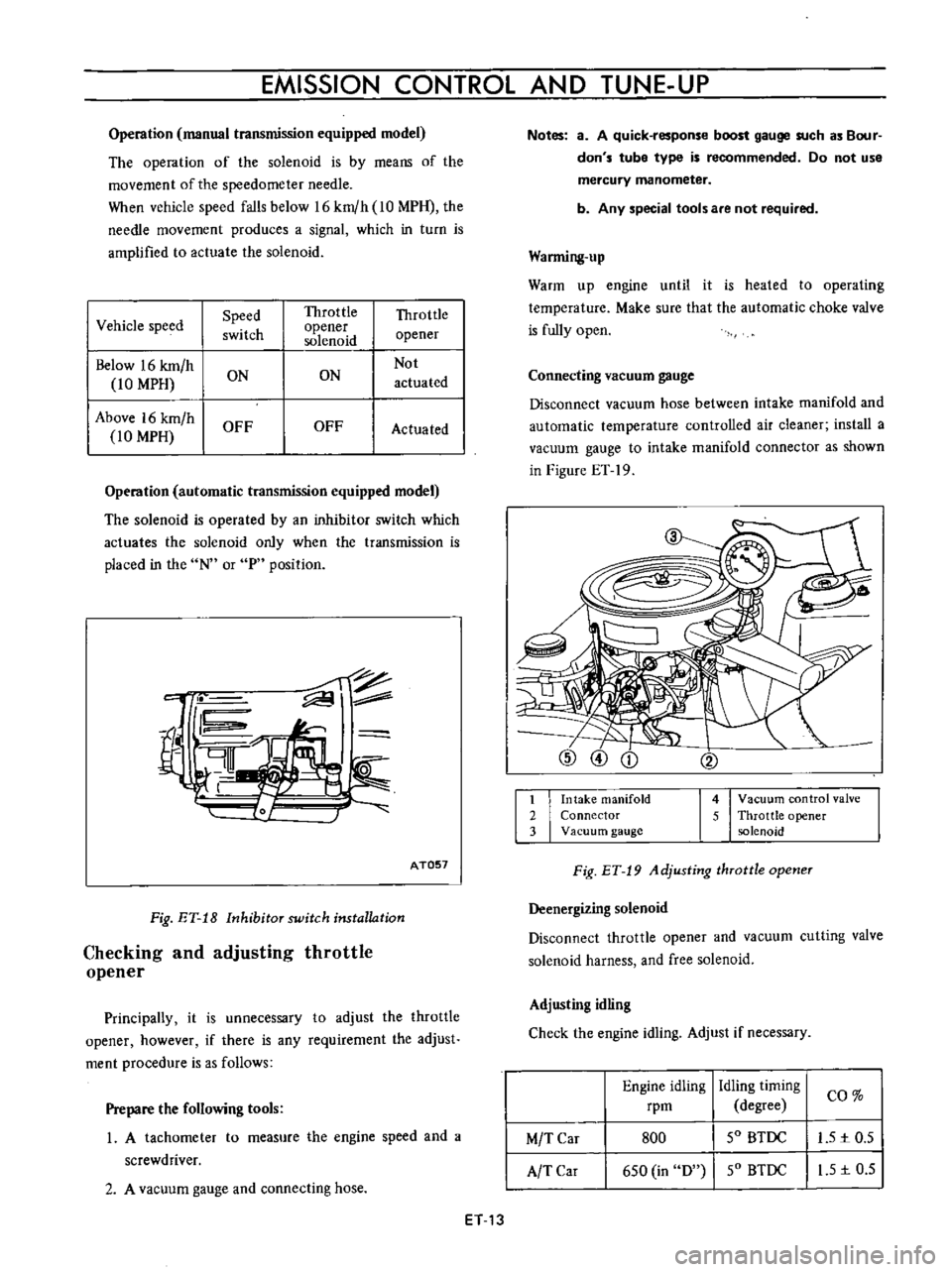

Operation

automatic

transmission

equipped

model

The

solenoid

is

operated

by

an

inhibitor

switch

which

actuates

the

solenoid

only

when

the

transmission

is

placed

in

the

N

or

P

position

c

fil

rn

AT057

Fig

ET

18

Inhibitor

switch

installation

Checking

and

adjusting

throttle

opener

Principally

it

is

unnecessary

to

adjust

the

throttle

opener

however

if

there

is

any

requirement

the

adjust

ment

procedure

is

as

follows

Prepare

the

following

tools

1

A

tachometer

to

measure

the

engine

speed

and

a

screwdriver

2

A

vacuum

gauge

and

connecting

hose

ET

13

Notes

a

A

quick

response

boost

gauge

such

as

Bour

don

s

tube

type

is

recommended

Do

not

use

mercury

manometer

b

Any

special

tools

are

not

required

Warming

up

Warm

up

engine

until

it

is

heated

to

operating

temperature

Make

sure

that

the

automatic

choke

valve

is

fully

open

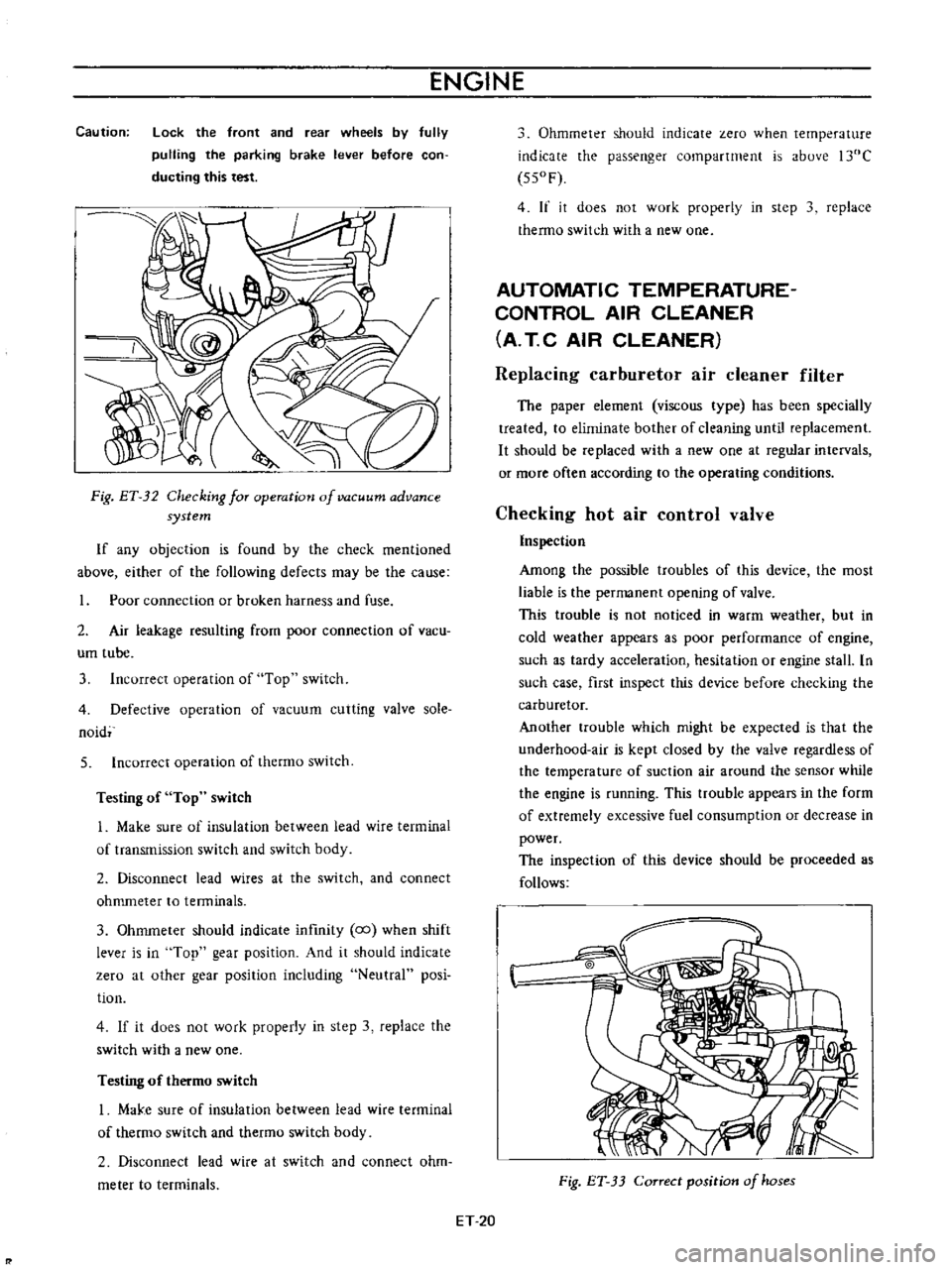

Connecting

vacuum

gauge

Disconnect

vacuum

hose

between

intake

manifold

and

automatic

temperature

controlled

air

cleaner

install

a

vacuum

gauge

to

intake

manifold

connector

as

shown

in

Figure

ET

19

1

Intake

manifold

2

Connector

3

Vacuum

gauge

4

Vacuum

control

valve

5

Throttle

opener

solenoid

Fig

ET

19

Adjusting

throttle

opener

Deenergizing

solenoid

Disconnect

throttle

opener

and

vacuum

cutting

valve

solenoid

harness

and

free

solenoid

Adjusting

idling

Check

the

engine

idling

Adjust

if

necessary

Engine

idling

rpm

Idling

timing

I

CO

degree

SO

BTDC

I

L51c0

5

SO

BTDC

I

I

S

1c

0

5

M

T

Car

A

TCar

800

6S0

in

D

Page 325 of 513

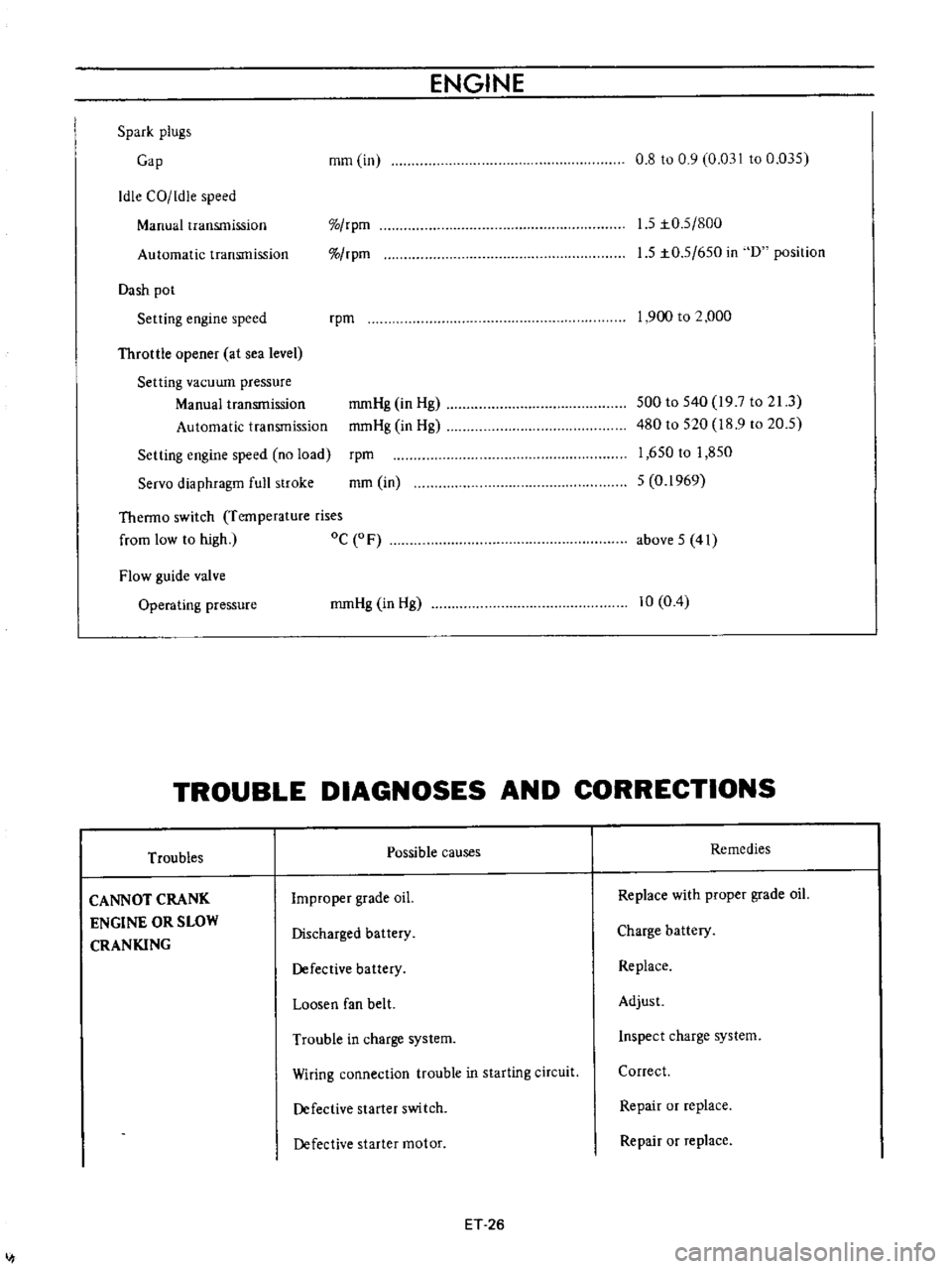

ENGINE

Caution

lock

the

front

and

rear

wheels

by

fully

pulling

the

parking

brake

lever

before

con

ducting

this

test

Fig

ET

32

Checking

for

operation

of

vacuum

advance

system

If

any

objection

is

found

by

the

check

mentioned

above

either

of

the

following

defects

may

be

the

cause

Poor

connection

or

broken

harness

and

fuse

2

Air

leakage

resulting

from

poor

connection

of

vacu

um

tube

3

Incorrect

operation

of

Top

switch

4

Defective

operation

of

vacuum

cutting

valve

sole

naid

5

Incorrect

operation

of

thermo

switch

Testing

of

Top

switch

1

Make

sure

of

insulation

between

lead

wire

terminal

of

transmission

switch

and

switch

body

2

Disconnect

lead

wires

at

the

switch

and

connect

ohmmeter

to

tenninals

3

Ohmmeter

should

indicate

infmity

co

when

shift

lever

is

in

Top

gear

position

And

it

should

indicate

zero

at

other

gear

position

including

Neutral

posi

tion

4

If

it

does

not

work

properly

in

step

3

replace

the

switch

with

a

new

one

Testing

of

thermo

switch

I

MaJ

e

sure

of

insulation

between

lead

wire

terminal

of

thermo

switch

and

thetmo

switch

body

2

Disconnect

lead

wire

at

switch

and

connect

ohm

meter

to

terminals

Ohmmeter

should

indicate

zero

when

temperature

indicate

the

passenger

compartment

is

above

l30C

550F

4

If

it

does

not

work

properly

in

step

3

replace

thermo

switch

with

a

new

one

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

A

T

C

AIR

CLEANER

Replacing

carburetor

air

cleaner

filter

The

paper

element

viscous

type

has

been

specially

treated

to

eliminate

bother

of

cleaning

until

replacement

It

should

be

replaced

with

a

new

one

at

regular

intervals

or

more

often

according

to

the

operating

conditions

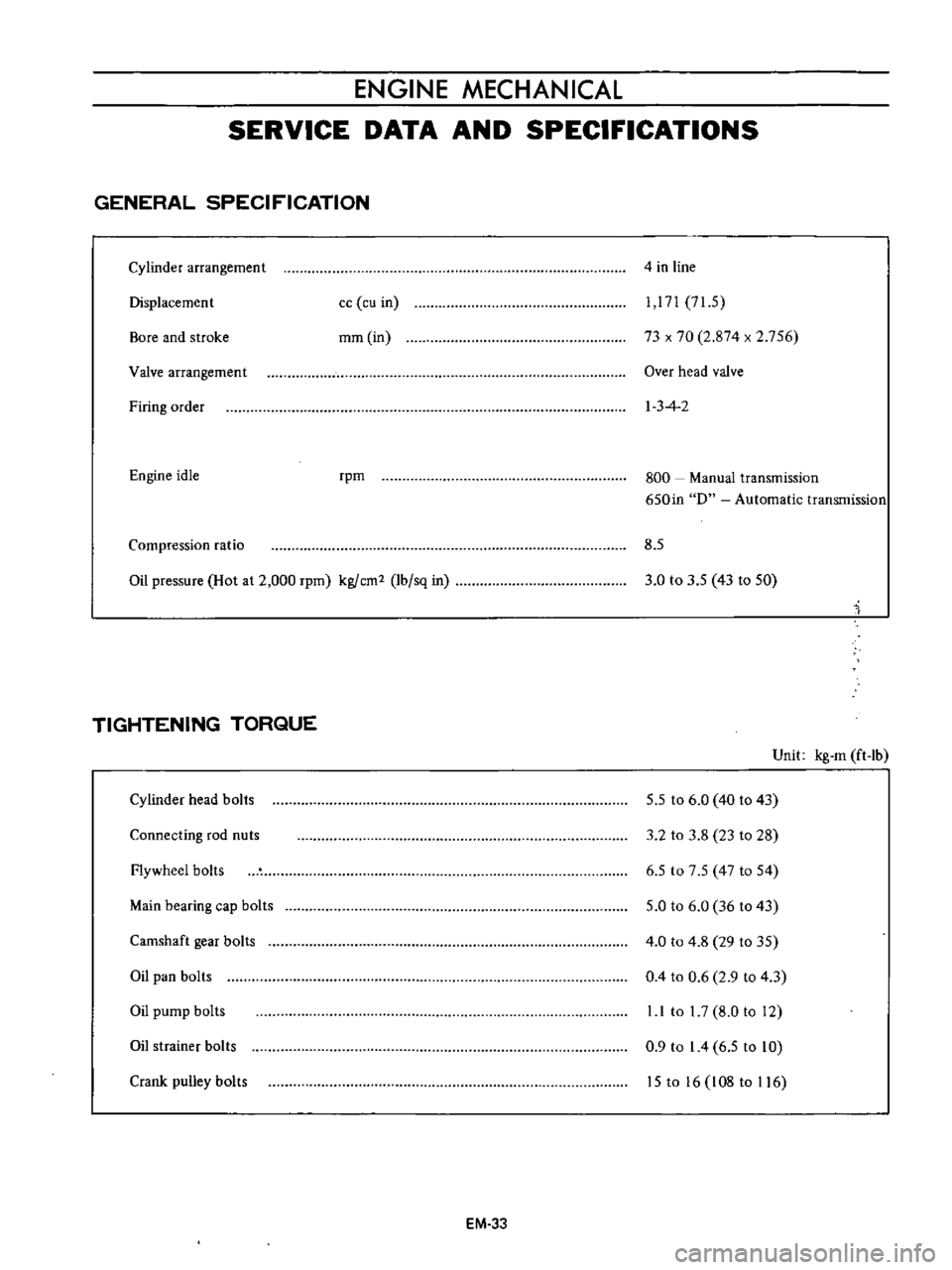

Checking

hot

air

control

valve

Inspection

Among

the

possible

troubles

of

this

device

the

most

liable

is

the

permanent

opening

of

valve

This

trouble

is

not

noticed

in

warm

weather

but

in

cold

weather

appears

as

poor

performance

of

engine

such

as

tardy

acceleration

hesitation

or

engine

stall

In

such

case

first

inspect

this

device

before

checking

the

carburetor

Another

trouble

which

might

be

expected

is

that

the

underhood

air

is

kept

closed

by

the

valve

regardless

of

the

temperature

of

suction

air

around

the

sensor

while

the

engine

is

running

This

ttOuble

appears

in

the

form

of

extremely

excessive

fuel

consumption

or

decrease

in

power

The

inspection

of

this

device

should

be

proceeded

as

follows

Fig

ET

33

Correct

position

of

hoses

ET

20

Page 331 of 513

ENGINE

Spark

plugs

Cap

mm

in

0

8

to

0

9

0

03110

0

035

Idle

CO

ldie

speed

Manual

transmission

rpm

rpm

1

5

to

5

800

1

5

to

5

650

in

D

position

Automatic

transmission

Dash

pot

Setting

engine

speed

rpm

1

900

to

2

000

Throttle

opener

at

sea

level

Setting

vacuwn

pressure

Manual

transmission

Automatic

transmission

Setting

engine

speed

no

load

Servo

diaphragm

full

stroke

rpm

mm

in

500

to

540

19

7

to

21

3

480

to

520

18

9

to

20

5

1

650

to

1

850

5

0

1969

mmHg

in

Hg

mmHg

in

Hg

Theono

switch

Temperature

rises

from

low

to

high

oC

0

F

above

5

41

Flow

guide

valve

Opera

ting

pressure

mmHg

in

Hg

10

0

4

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Troubles

Possible

causes

Remedies

CANNOT

CRANK

ENGINE

OR

SLOW

CRANKING

Improper

grade

oiL

Replace

with

proper

grade

oiL

Discharged

battery

Charge

battery

Defective

battery

Replace

Loosen

fan

belt

Adjust

Trouble

in

charge

system

Inspect

charge

system

Wiring

connection

trouble

in

starting

circuit

Correct

Defective

starter

switch

Repair

or

replace

Defective

starter

motor

Repair

or

replace

ET

26

I

Page 373 of 513

ENGINE

MECHANICAL

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATION

Cylinder

arrangement

4

in

line

Displacement

cc

cu

in

mm

in

1

171

71

5

73

x

70

2

874

x

2

756

Bore

and

stroke

Valve

arrangemen

t

Over

head

valve

Firing

order

I

3

4

2

Engine

idle

rpm

800

Manual

transmission

650in

D

Automatic

transmission

Compression

ratio

8

5

Oil

pressure

Hot

at

2

000

rpm

kgfcm2

Ibfsq

in

3

0

to

3

5

43

to

50

TIGHTENING

TORQUE

Unit

kg

m

ft

lb

Cylinder

head

bolts

Flywheel

bolts

5

5

to

6

0

40

to

43

3

2

to

3

8

23

to

28

6

5

to

7

5

47

to

54

5

0

to

6

0

36

to

43

4

0

to

4

8

29

to

35

0

4

to

0

6

2

9

to

4

3

l

l

to

I

7

8

0

to

12

0

9

to

I

4

6

5

to

10

15

to

16

108

to

116

Connecting

rod

nuts

Main

bearing

cap

bolts

Camshaft

gear

bolts

Oil

pan

bolts

Oil

pump

bolts

Oil

strainer

bolts

Crank

pulley

bolts

EM

33

Page 400 of 513

FUEl

SYSTEM

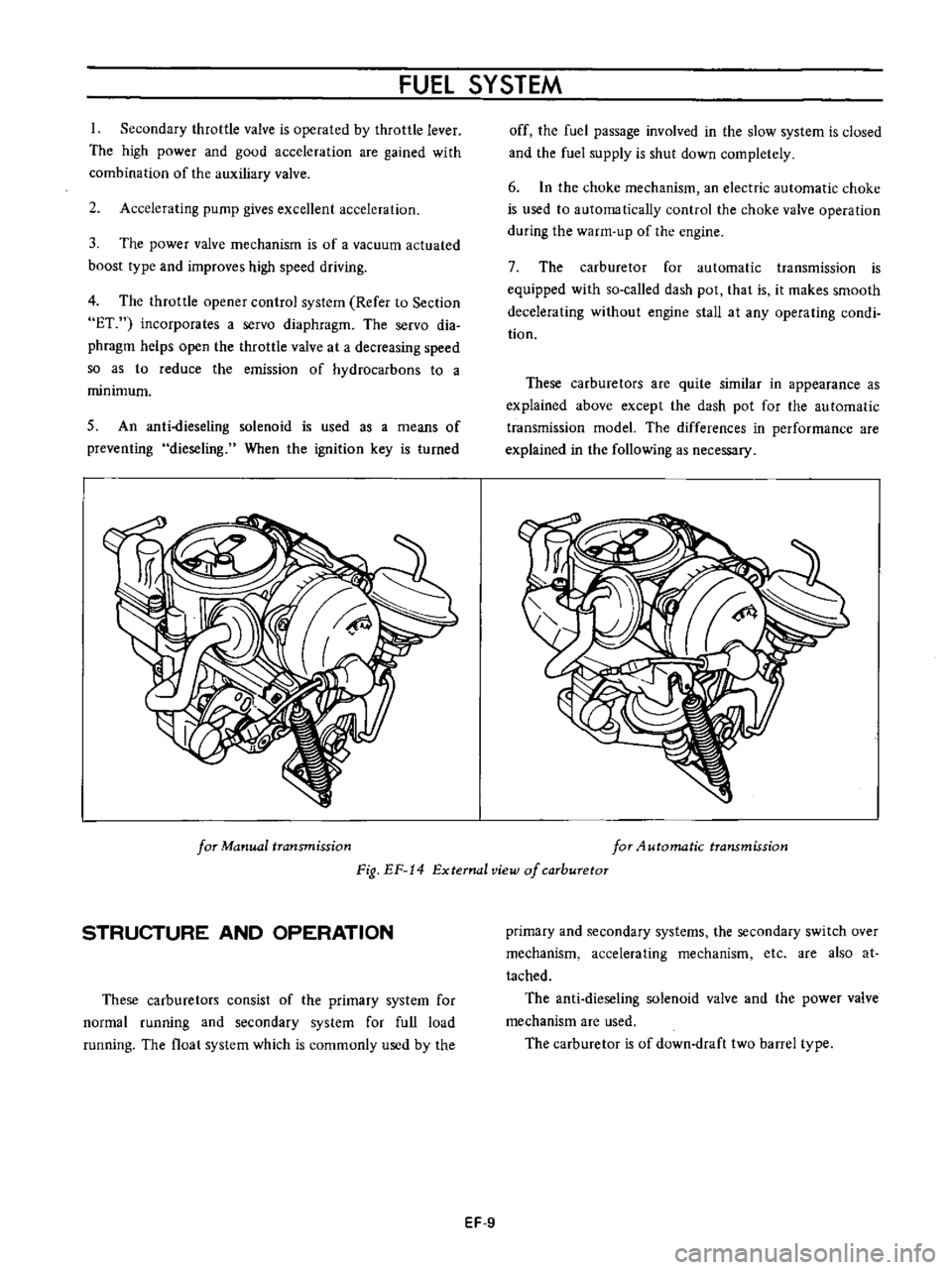

Secondary

throttle

valve

is

operated

by

throttle

lever

The

high

power

and

good

acceleration

are

gained

with

combination

of

the

auxiliary

valve

2

Accelerating

pump

gives

excellent

acceleration

3

The

power

valve

mechanism

is

of

a

vacuum

actuated

boost

type

and

improves

high

speed

driving

4

The

throttle

opener

control

system

Refer

to

Section

ET

incorporates

a

servo

diaphragm

The

servo

dia

phragm

helps

open

the

throttle

valve

at

a

decreasing

speed

so

as

to

reduce

the

emission

of

hydrocarbons

to

a

minimum

5

An

anti

dieseling

solenoid

is

used

as

a

means

of

preventing

dieseling

When

the

ignition

key

is

turned

off

the

fuel

passage

involved

in

the

slow

system

is

closed

and

the

fuel

supply

is

shut

down

completely

6

In

the

choke

mechanism

an

electric

automatic

choke

is

used

to

automatically

control

the

choke

valve

operation

during

the

warm

up

of

the

engine

7

The

carburetor

for

automatic

transmission

is

equipped

with

so

called

dash

pot

that

is

it

makes

smooth

decelerating

without

engine

stall

at

any

operating

condi

tion

These

carburetors

are

quite

similar

in

appearance

as

explained

above

except

the

dash

pot

for

the

au

tomatic

transmission

model

The

differences

in

performance

are

explained

in

the

following

as

necessary

for

Manual

transmission

for

4utomatic

transmission

Fig

EF

14

External

view

of

carburetor

STRUCTURE

AND

OPERATION

These

carburetors

consist

of

the

primary

system

for

normal

running

and

secondary

system

for

full

load

running

The

float

system

which

is

commonly

used

by

the

primary

and

secondary

systems

the

secondary

switch

over

mechanism

accelerating

mechanism

etc

are

also

at

tached

The

anti

dieseling

solenoid

valve

and

the

power

valve

mechanism

are

used

The

carburetor

is

of

down

draft

two

barrel

type

EF

9

Page 405 of 513

ENGINE

AD

JUSTMENT

Idling

adjustment

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

N

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

50

800

rpm

5

Adjust

idle

adjusting

screw

so

that

ca

percentage

is

1

5

t

0

5

6

Repeat

the

adjustments

as

described

in

steps

3

and

5

above

so

that

ca

percentage

is

1

5

to

5

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

650

ca

percentage

with

lever

in

D

position

15

to

5

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

id

Ie

adjusting

screw

completely

to

avoid

damage

to

the

EF

14

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

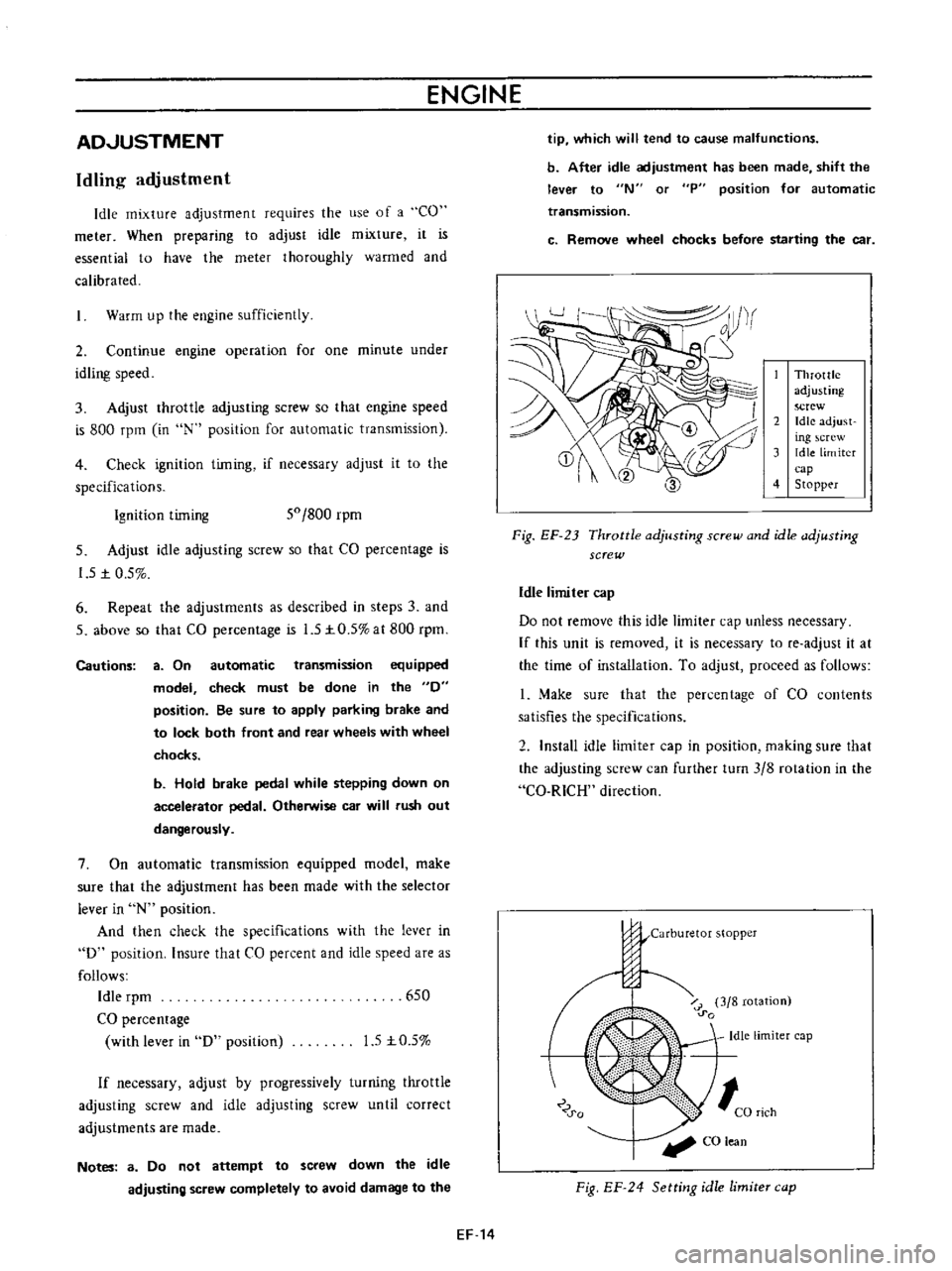

Throttle

adjusting

screw

2

Idle

adjust

ing

crew

3

Idle

limiter

cap

4

Stopp

r

Fig

EF

23

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

fe

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

Ca

RICH

direction

j

j

Carburetor

stopper

o

u

o

i

r

3

8

rotation

0

0

Idle

limiter

cap

0

0

CO

lean

Fig

EF

24

Setting

idle

limite

cap

Page 406 of 513

CD

r

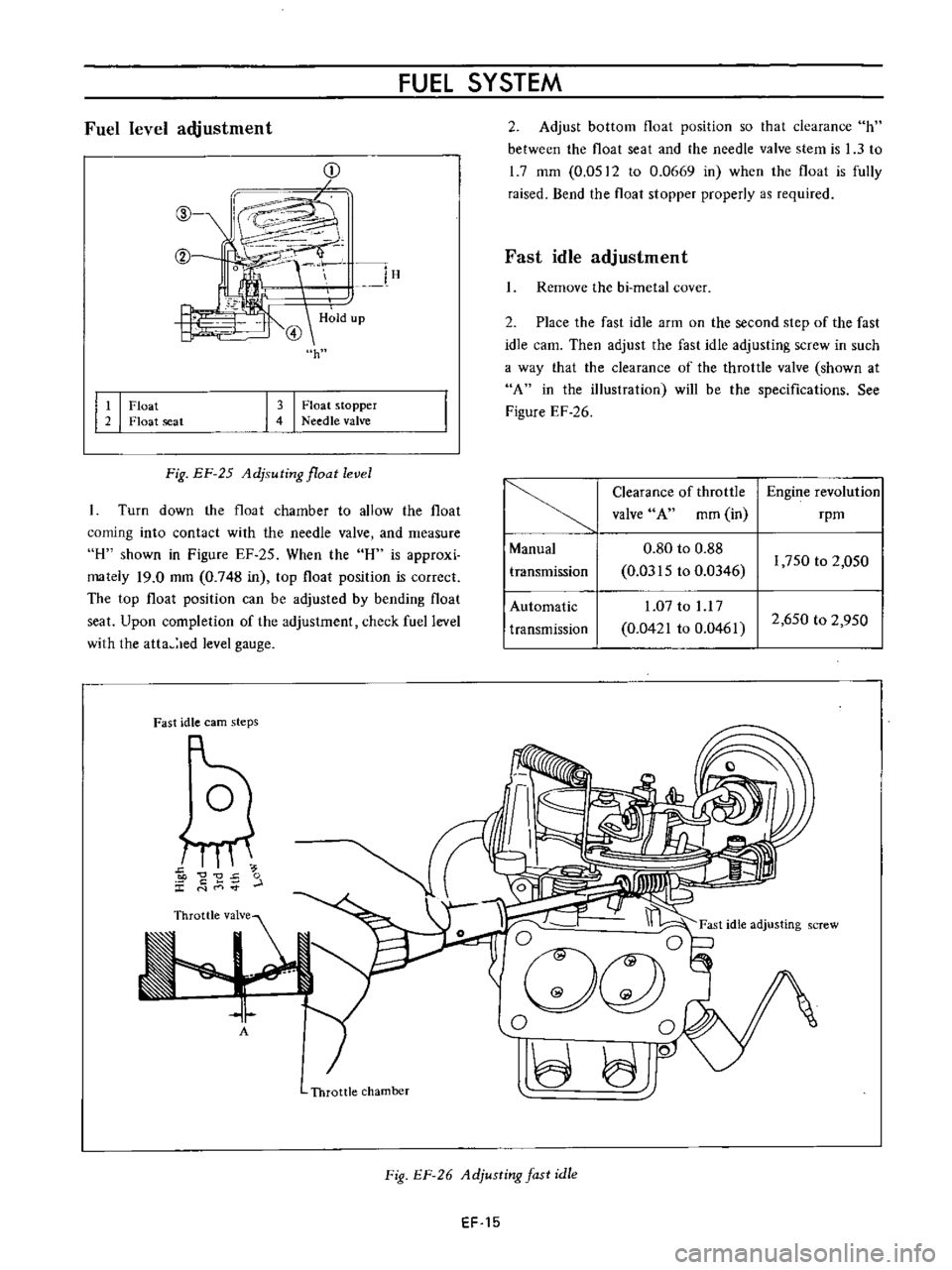

Fuel

level

adjustment

@

@

It

I

Float

2

Float

seat

FUEL

SYSTEM

2

Adjust

bottom

float

position

so

that

clearance

h

between

the

float

seat

and

the

needle

valve

stem

is

1

3

to

1

7

mm

0

0512

to

0

0669

in

when

the

float

is

fully

raised

Bend

the

float

stopper

properly

as

required

l

lH

H

ld

up

@

h

Fast

idle

adjustment

Remove

the

bi

metal

cover

3

I

Float

stopper

4

Needle

valve

2

Place

the

fast

idle

arm

on

the

second

step

of

the

fast

idle

earn

Then

adjust

the

fast

idle

adjusting

screw

in

such

a

way

that

the

clearance

of

the

throttle

valve

shown

at

A

in

the

illustration

will

be

the

specifications

See

Figure

EF

26

Fig

EF

25

Adjsuting

float

level

Turn

down

the

float

chamber

to

allow

the

float

coming

into

contact

with

the

needle

valve

and

measure

H

shown

in

Figure

EF

25

When

the

H

is

approxi

mately

19

0

mm

0

748

in

top

float

position

is

correct

The

top

float

position

can

be

adjusted

by

bending

float

seat

Upon

completion

of

the

adjustment

check

fuel

level

with

the

atta

led

level

gauge

Clearance

of

throttle

Engine

revolution

valve

A

mm

in

rpm

Manual

0

80

to

0

88

transmission

0

0315

to

0

0346

1

750

to

2

050

Automatic

1

07

to

l

l

7

transmission

0

0421

to

0

0461

2

650

to

2

950

Fast

idle

earn

steps

5

C

0

J

t

E

r

L

E

I

I

Ogc

l

0

0

JO

A

Throttle

chamber

Fig

EF

26

Adjusting

fast

idle

EF

15

Page 407 of 513

ENGINE

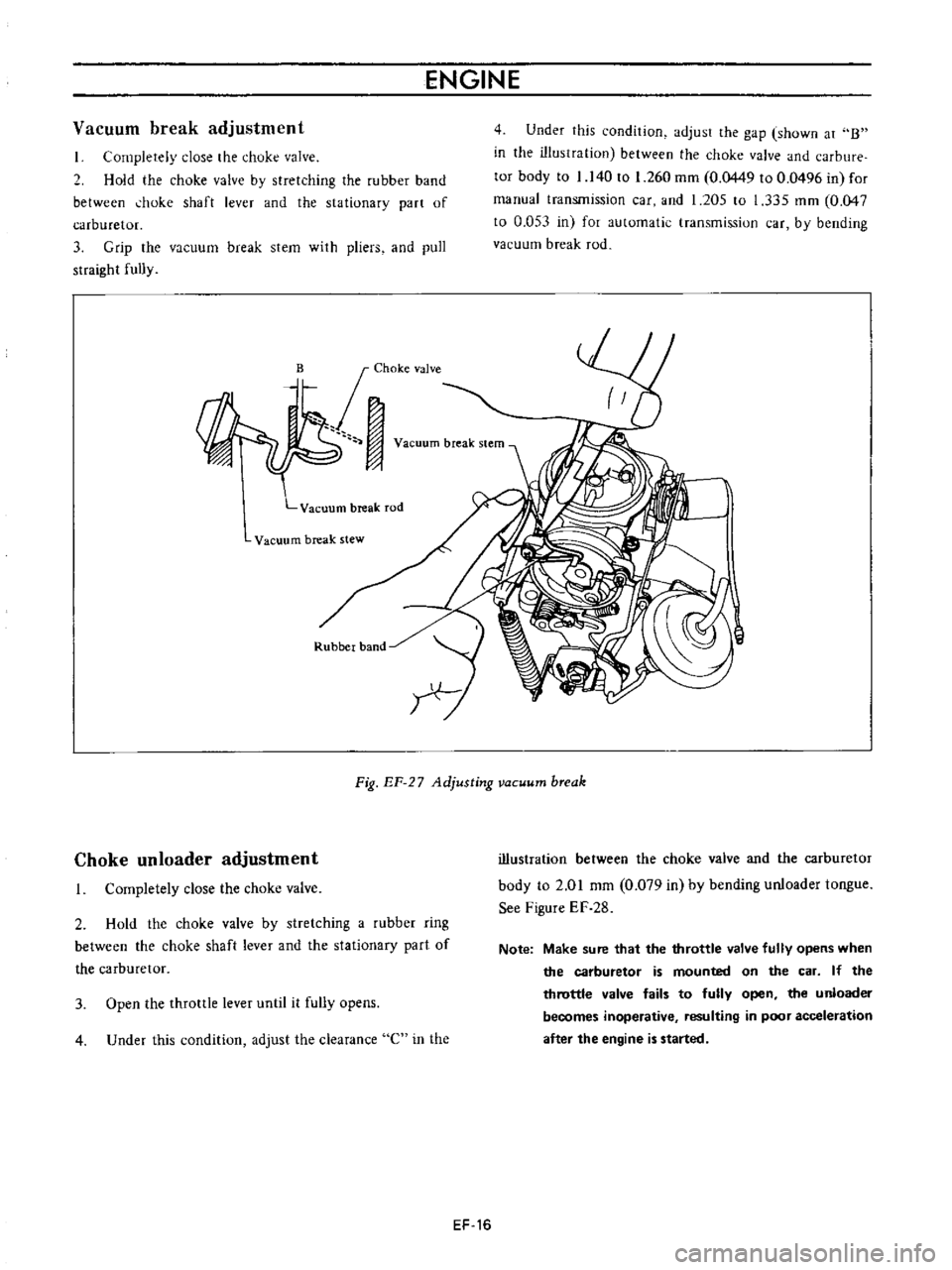

Vacuum

break

adjustment

I

Completely

close

the

chuke

valve

2

Hold

the

choke

valve

by

stretching

the

rubber

band

between

hoke

shaft

lever

and

the

sta

tionary

part

of

carburetor

3

Grip

the

vacuum

break

stem

with

pliers

and

pull

straight

fully

Vacuum

break

rod

Vacuum

break

stew

Rubber

band

4

Under

this

condition

adjust

the

gap

shown

at

B

in

the

illustration

between

the

choke

valve

and

carbure

tor

body

to

1

140

to

1

260

mm

0

0449

to

0

0496

in

for

manual

transmission

car

and

1

205

to

1

335

mm

0

047

to

0

053

in

for

automatic

transmission

car

by

bending

vacuum

break

rod

I

Fig

EF

27

Adjusting

vacuum

break

Choke

un

loader

adjustment

I

Completely

close

the

choke

valve

2

Hold

the

choke

valve

by

stretching

a

rubber

ring

between

the

choke

shaft

lever

and

the

stationary

part

of

the

carburetor

3

Open

the

throttle

lever

until

it

fully

opens

4

Under

this

condition

adjust

the

clearance

C

in

the

illustration

between

the

choke

valve

and

the

carburetor

body

to

2

01

mm

0

079

in

by

bending

unloader

tongue

See

Figure

EF

28

Note

Make

sure

that

the

throttle

valve

fully

opens

when

the

carburetor

is

mounted

on

the

car

If

the

throttle

valve

fails

to

fully

open

the

unloader

becomes

inoperative

resulting

in

poor

acceleration

after

the

engine

is

started

EF

16

Page 409 of 513

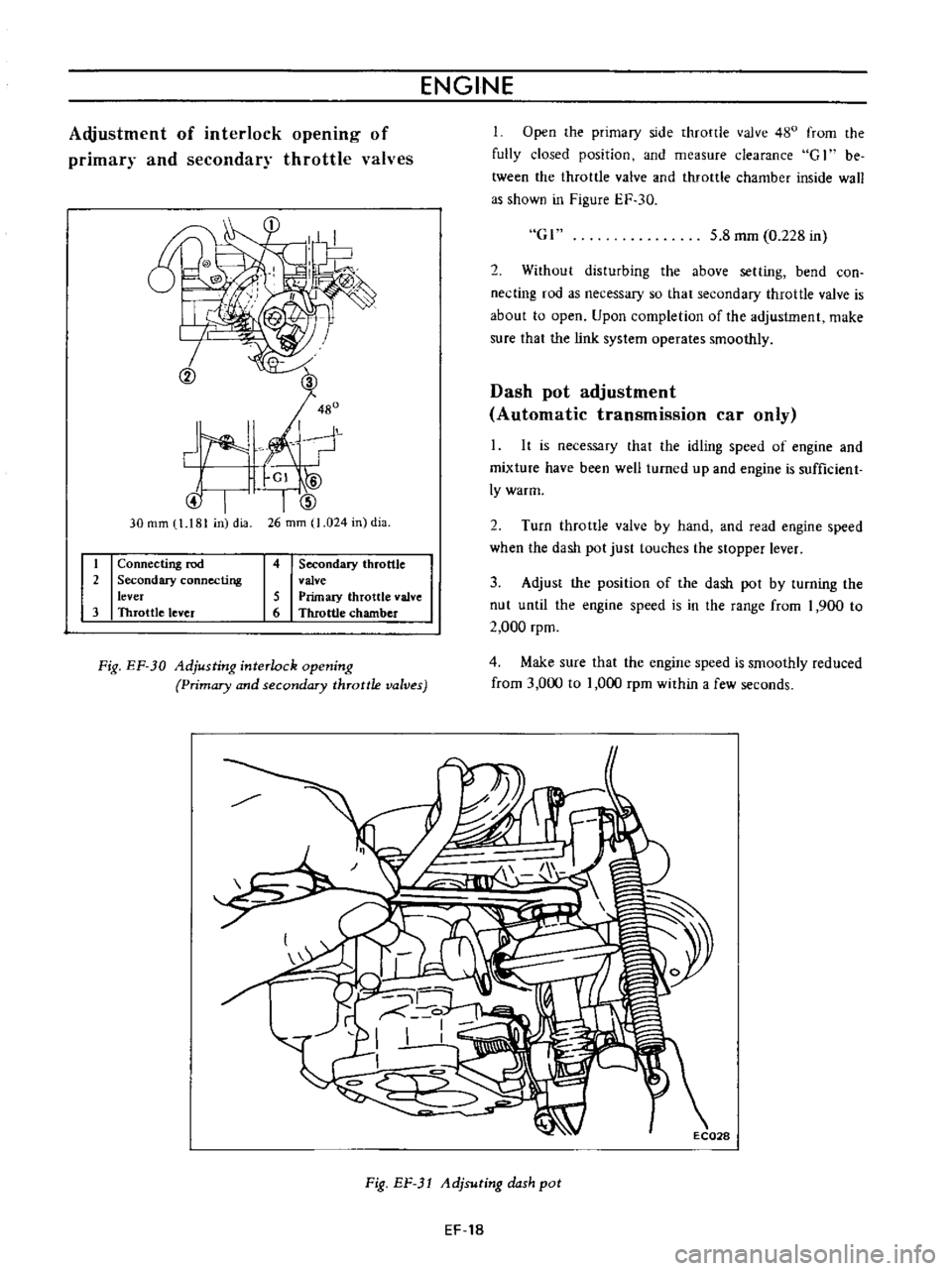

ENGINE

Adjustment

of

interlock

opening

of

primary

and

secondary

throttle

valves

Open

the

primary

side

throttle

valve

480

from

the

fully

closed

position

and

measure

clearance

G

1

be

tween

the

throttle

valve

and

throttle

chamber

inside

wall

as

shown

in

Figure

EF

30

@I

30

rom

1

181

in

dia

Gl

5

8

mm

0

228

in

I

V

2

Without

disturbing

the

above

setting

bend

con

necting

rod

as

necessary

so

that

secondary

throttle

valve

is

about

to

open

Upon

completion

of

the

adjustment

make

sure

that

the

link

system

operates

smoothly

2

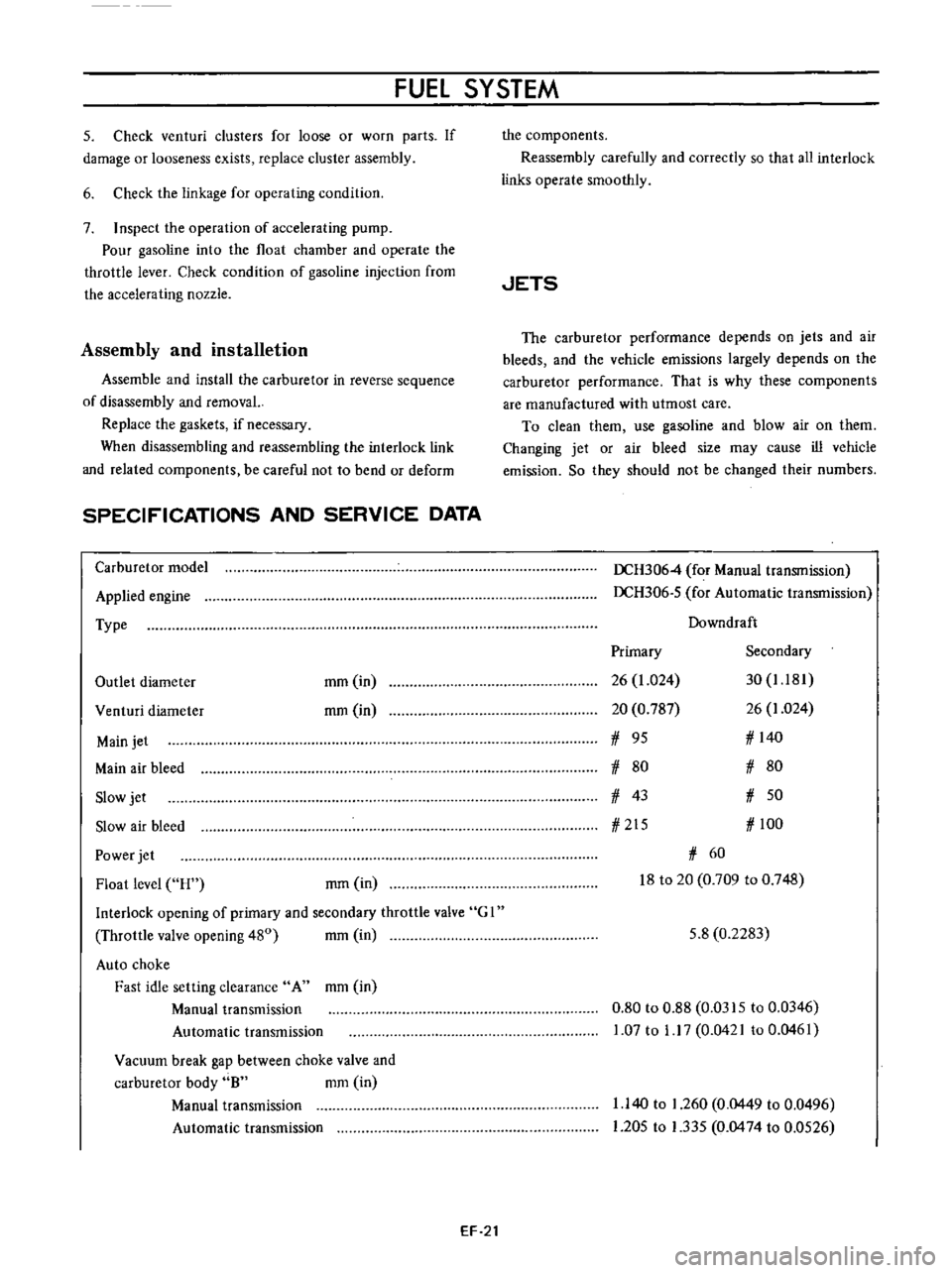

Dash

pot

adjustment

Automatic

transmission

car

only

It

is

necessary

that

the

idling

speed

of

engine

and

mixture

have

been

weB

turned

up

and

engine

is

sufficient

Iywarm

2

Turn

throttle

valve

by

hand

and

read

engine

speed

when

the

dash

pot

just

touches

the

stopper

lever

1

Connecting

rod

2

Secondary

connecting

lever

3

Throttle

lever

4

Secondary

throttle

valve

5

Primuy

throttle

valve

6

Throttle

chamber

3

Adjust

the

position

of

the

dash

pot

by

turning

the

nut

until

the

engine

speed

is

in

the

range

from

1

900

to

2

000

rpm

Fig

EF

30

Adjusting

interlock

opening

Primary

and

secondary

throttle

valves

4

Make

sure

that

the

engine

speed

is

smoothly

reduced

from

3

000

to

1

000

rpm

within

a

few

seconds

Fig

EF

1

Adjsuting

dash

pot

EF

18

Page 412 of 513

FUEL

SYSTEM

5

Check

venturi

clusters

for

loose

or

worn

parts

If

damage

or

looseness

exists

replace

cluster

assembly

6

Check

the

linkage

for

operating

condition

7

Inspect

the

operation

of

accelerating

pump

Pour

gasoline

into

the

float

chamber

and

operate

the

throttle

lever

Check

condition

of

gasoline

injection

from

the

accelerating

nozzle

Assembly

and

instalIetion

Assemble

and

install

the

carburetor

in

reverse

sequence

of

disassembly

and

removal

Replace

the

gaskets

if

necessary

When

disassembling

and

reassembling

the

interlock

link

and

related

components

be

careful

not

to

bend

or

deform

SPECIFICATIONS

AND

SERVICE

DATA

Carburetor

model

Applied

engine

Type

Outlet

diameter

mm

in

rom

in

Venturi

diameter

Main

jet

Main

air

bleed

Slow

jet

Slow

air

bleed

Power

jet

Float

level

H

rom

in

Interlock

opening

of

primary

and

secondary

throttle

valve

G

I

Throttle

valve

opening

480

mm

in

Auto

choke

Fast

idle

setting

clearance

A

mm

in

Manual

transmission

Automatic

transmission

Vacuum

break

gap

between

choke

valve

and

carburetor

body

8

mm

in

Manual

transmission

Automatic

transmission

EF

21

the

components

Reassembly

carefully

and

correctly

so

that

all

interlock

links

operate

smoothly

JETS

The

carburetor

performance

depends

on

jets

and

air

bleeds

and

the

vehicle

emissions

largely

depends

on

the

carburetor

performance

That

is

why

these

components

are

manufactured

with

utmost

care

To

clean

them

use

gasoline

and

blow

air

on

them

Changing

jet

or

air

bleed

size

may

cause

ill

vehicle

emission

So

they

should

not

be

changed

their

numbers

DCH3064

for

Manual

transmission

DCH306

5

for

Automatic

transmission

Downdraft

Primary

Secondary

26

1

024

30

1

181

20

0

787

26

1

024

1

95

1

140

1

80

1

80

1

43

1

50

1

215

1

100

1

60

18

to

20

0

709

to

0

748

5

8

0

2283

0

80

to

0

88

0

0315

to

0

0346

1

07

to

1

17

0

0421

to

0

0461

1

140

to

1

260

0

0449

to

0

0496

1

205

to

1

335

0

0474

to

0

0526