automatic transmission DATSUN B110 1973 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 279 of 513

SERVICE

EQUIPMENT

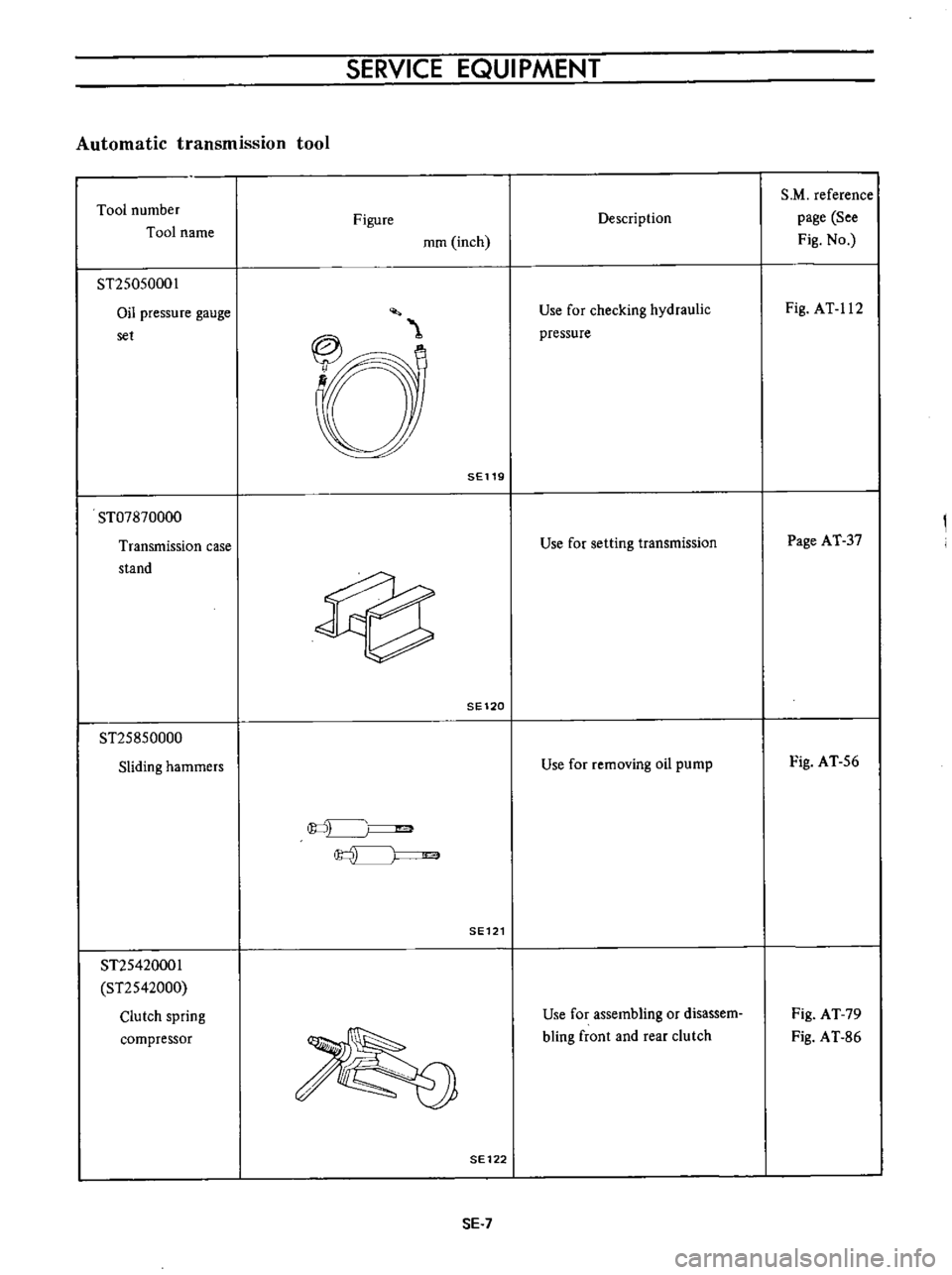

Automatic

transmission

tool

Tool

number

S

M

reference

Tool

name

Figure

Description

page

See

mm

inch

Fig

No

ST25050001

Oil

pressure

gauge

Use

for

checking

hydraulic

Fig

AT

112

set

Y

pressure

SE119

ST07870000

Transmission

case

Use

for

setting

transmission

Page

AT

37

stand

SE120

ST25850000

Sliding

hammers

Use

for

removing

oil

pump

Fig

AT

56

r

SE121

ST25420001

ST2542000

Clutch

spring

compressor

Use

for

assembling

or

disassem

bling

front

and

rear

clutch

Fig

AT

79

Fig

AT

86

SE122

sE

7

Page 297 of 513

GENERAL

INFORMATION

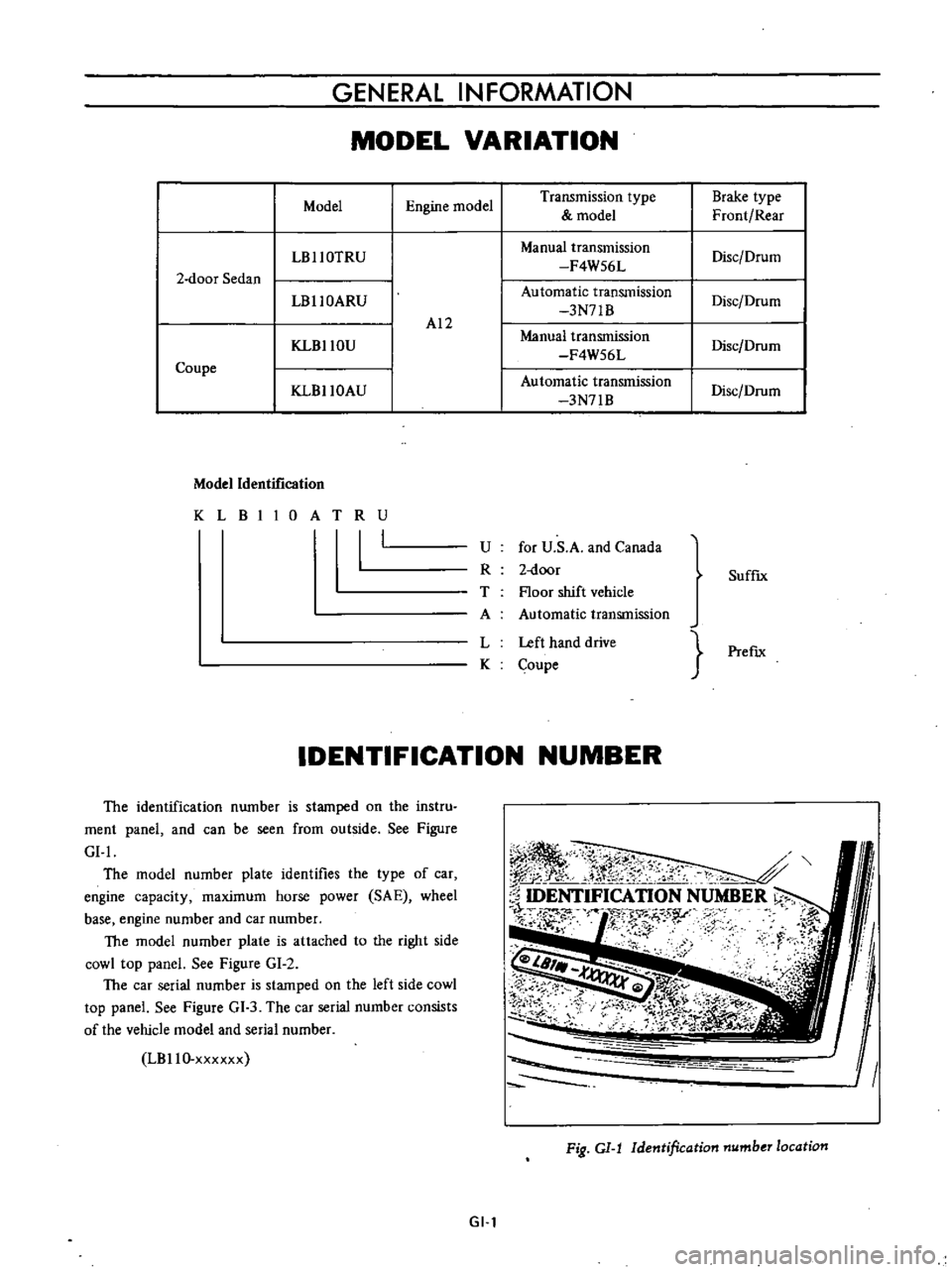

MODEL

VARIATION

Model

Engine

model

Transmission

type

Brake

type

model

Front

Rear

LBllOTRU

Manual

transmission

Disc

Drum

F4W56L

2

door

Sedan

LBllOARU

Automatic

transmission

Disc

Drum

3N71B

AI2

KLBllOU

Manual

transmission

Disc

Drum

F4W56L

Coupe

Automatic

transmission

KLBllOAU

3N71B

Disc

Drum

Model

Identification

KLBIIOATRU

I

U

for

U

S

A

and

Canada

R

2

door

T

Floor

shift

vehicle

A

Automatic

transmission

L

Left

hand

drive

K

Coupe

SuffIx

PrefIx

IDENTIFICATION

NUMBER

The

identification

number

is

stamped

on

the

instru

ment

panel

and

can

be

seen

from

outside

See

Figure

GI

I

The

model

number

plate

identifles

the

type

of

car

engine

capacity

maximum

horse

power

SA

E

wheel

base

engine

number

and

car

number

The

model

number

plate

is

attached

to

the

right

side

cowl

top

panel

See

Figure

GI

2

The

car

serial

number

is

stamped

on

the

left

side

cowl

top

panel

See

Figure

GI

3

The

car

serial

number

consists

of

the

vehicle

model

and

serial

number

LBllO

xxxxxx

I

ll

r

N

t

0

S

k

j

c

ftr

o

l

l

r

2

0

IDENTIFICATION

NUMBER

l

r

f

N

s

r

F

i

u

I

Fig

GI

J

Identification

number

location

GI

l

Page 300 of 513

GENERAL

INFORMATION

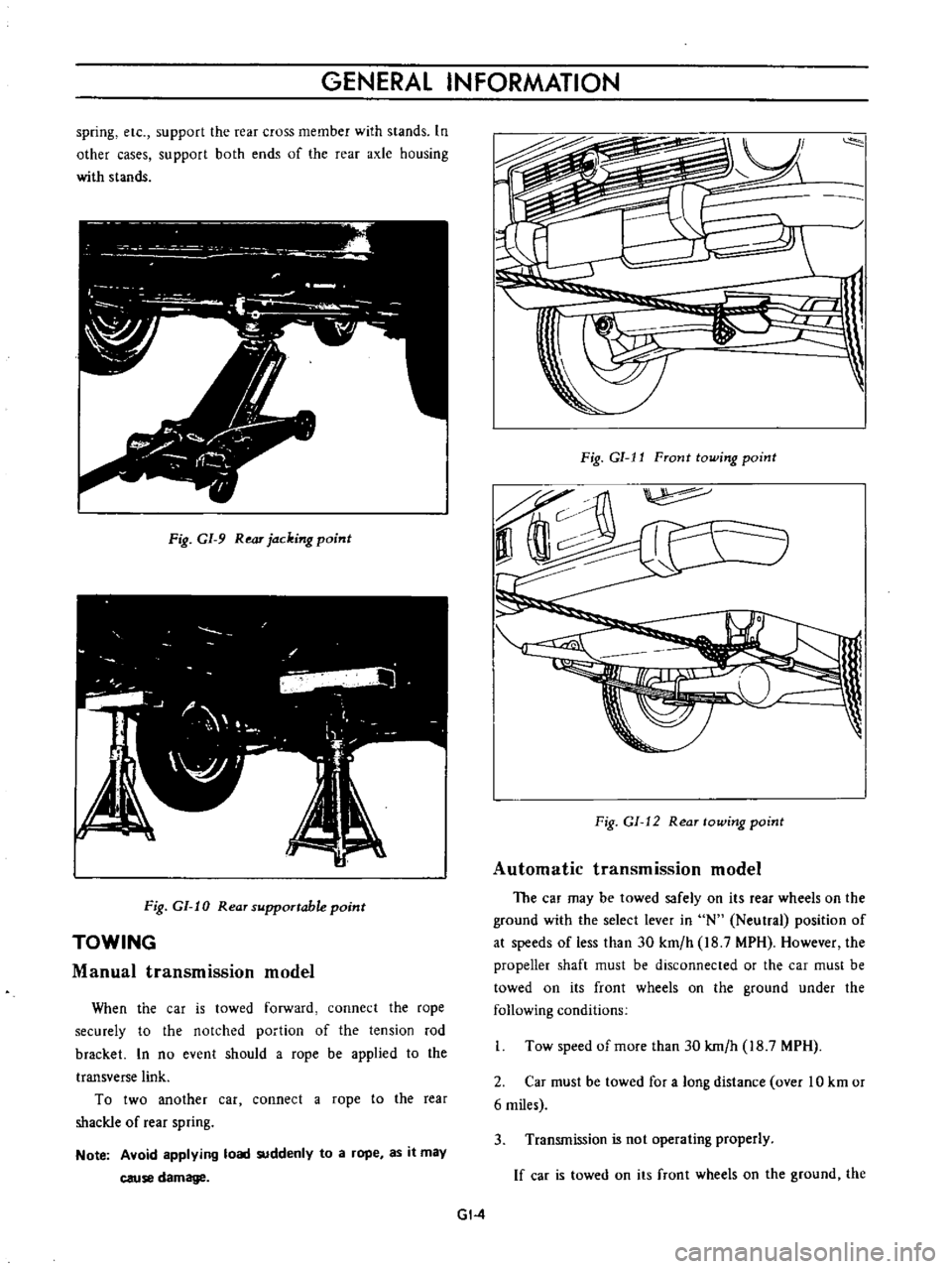

spring

etc

support

the

rear

cruss

member

with

stands

In

other

cases

support

both

ends

of

the

rear

axle

housing

with

stands

Fig

CI

9

Rear

jacking

point

Fig

C

J

0

Rear

supportable

point

TOWING

Manual

transmission

model

When

the

car

is

towed

forward

connect

the

rope

securely

to

the

notched

portion

of

the

tension

rod

bracket

In

no

event

should

a

rope

be

applied

to

the

transverse

link

To

two

another

car

connect

a

rope

to

the

rear

shackle

of

rear

spring

Note

Avoid

applying

load

suddenly

to

a

rope

as

it

may

cause

damage

Fig

GI

l1

Front

towing

point

Fig

GI

12

Rear

towing

point

Automatic

transmission

model

The

car

may

be

towed

safely

on

its

rear

wheels

on

the

ground

with

the

select

lever

in

N

Neutral

position

of

at

speeds

of

less

than

30

km

h

18

7

MPH

However

the

propeller

shaft

must

be

disconnected

or

the

car

must

be

towed

on

its

front

wheels

on

the

ground

under

the

following

conditions

Tow

speed

of

more

than

30

kro

h

18

7

MPH

2

Car

must

be

towed

for

a

long

distance

over

10

km

or

6

miles

3

Transmission

is

not

operating

properly

If

car

is

towed

on

its

front

wheels

on

the

ground

the

GI

4

Page 301 of 513

GENERAL

INFORMATION

steering

wheel

should

be

secured

to

maintain

a

straight

ahead

position

TIE

DOWN

The

front

tie

down

hook

is

used

the

both

front

end

of

tension

rod

Do

not

apply

the

hook

at

the

center

of

tension

rod

or

suspension

member

The

rear

tie

down

hook

is

used

the

both

front

shackle

of

rear

spring

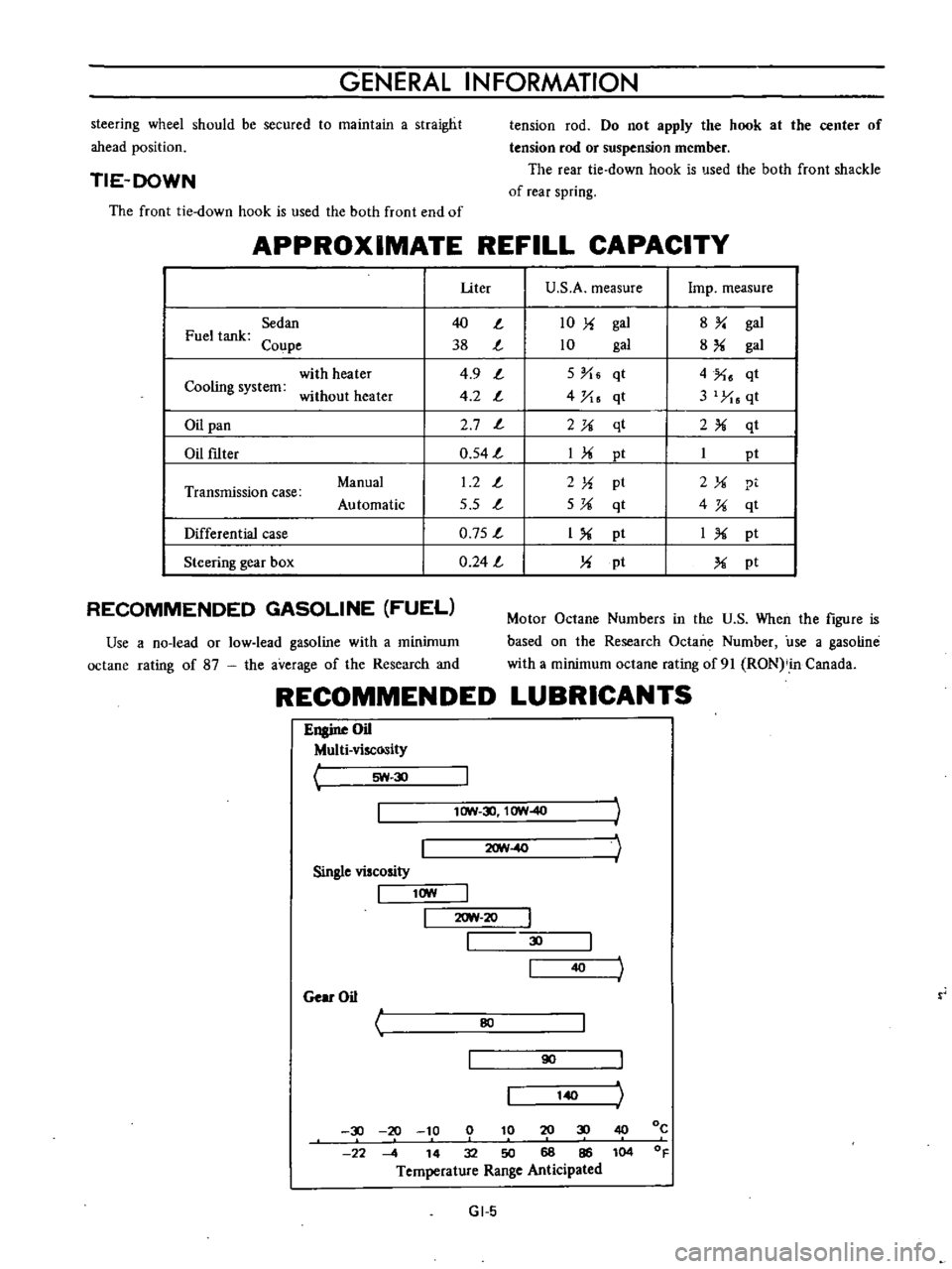

APPROXIMATE

REFILL

CAPACITY

Liter

U

S

A

measure

I

Imp

measure

Sedan

Fuel

tank

Coupe

with

heater

Cooling

system

without

heater

40

L

38

L

4

9

L

4

2

L

2

7

L

0

54

L

1

2

L

5

5

L

0

75

L

0

24

L

Oil

pan

Oilf1lter

Transmission

case

Manual

Automatic

Differential

case

Steering

gear

box

RECOMMENDED

GASOLINE

FUEL

Use

a

no

lead

or

low

lead

gasoline

with

a

minimum

octane

rating

of

87

the

average

of

the

Research

and

1O

gal

8Y

gal

10

gal

8

gal

5

v

qt

4

M

qt

4

Y

6

qt

3

Y

qt

2Ji

qt

2

qt

1

pt

I

pt

2

pt

2

pt

5Ji

qt

4

qt

1

pt

1

pt

pt

pi

Motor

Octane

Numbers

in

the

U

S

When

the

figure

is

based

on

the

Research

Octane

Number

use

a

gasoline

with

a

minimum

octane

rating

of

91

RON

in

Canada

RECOMMENDED

LUBRICANTS

GI

5

r

Page 302 of 513

GENERAL

INFORMATION

RECOMMENDED

LUBRICANT

SPECI

FICATIONS

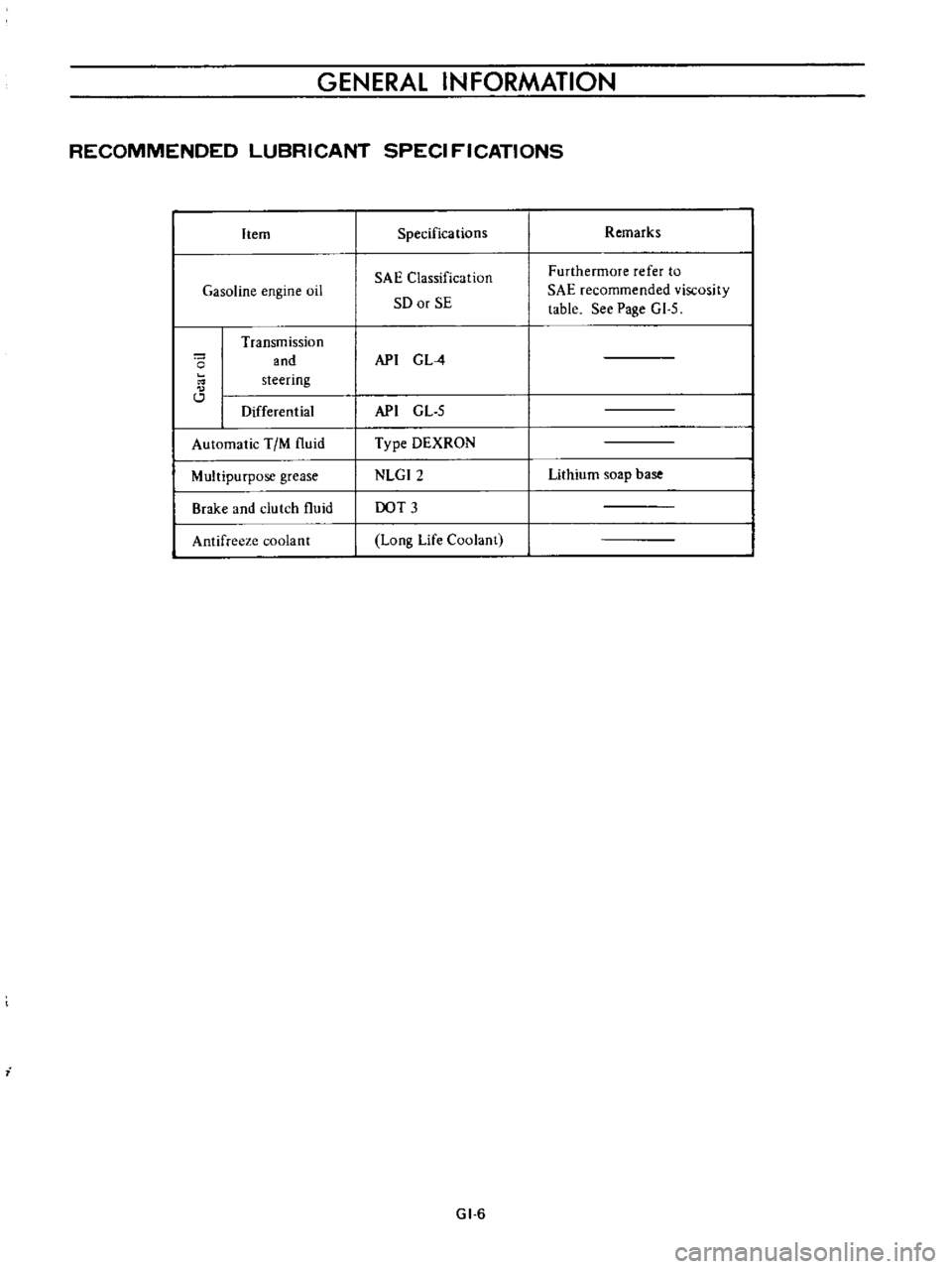

Item

Gasoline

engine

oil

o

Transmission

and

steering

Differential

Automatic

TIM

fluid

Multipurpose

grease

Brake

and

clutch

fluid

Antifreeze

coolant

i

Specifications

SAE

Classification

SO

or

SE

API

G

L

4

API

GL

5

Type

DEXRON

NLGI2

DOT

3

Long

Life

Coolant

GI

6

Remarks

Furthermore

refer

to

SAE

recommended

viscosity

table

See

Page

GI

5

Lithium

soap

base

Page 306 of 513

EMISSION

CONTROL

AND

TUNE

UP

EMISSION

CONTROL

SYSTEM

AN

D

ENGINE

TUNE

UP

CONTENTS

BASIC

MECHANICAL

SYSTEM

ET

Checking

and

adjusting

dash

pot

Adjusting

intake

and

exhaust

valve

automatic

transmission

model

only

ET

9

clearances

ET

1

Checking

carburetor

return

spring

ET

9

Checking

and

adjustin9

drive

belt

ET

2

Checking

choke

mechanism

choke

valve

Retightening

cylinder

head

bolts

manifold

and

linkagel

ET

9

nuts

and

carburetor

securing

nuts

ET

2

Checking

anti

dieseling

solenoid

ET

9

Checking

engine

oil

ET

2

Replacing

fuel

filter

ET

10

Replacing

oil

filter

ET

3

Checking

fuel

lines

hoses

pipings

Changing

engine

coolant

L

L

C

ET

3

connections

etc

ET10

Checking

cooling

system

hoses

and

THROTTLE

OPENER

CONTROL

SYSTEM

ET

10

connections

ET

4

Checking

and

adjusting

throttle

opener

ET

13

Checking

vacuum

fittings

hoses

and

TRANSMISSION

CONTROLLED

VACUUM

connections

ET

4

ADVANCE

SYSTEM

ET

17

Checking

engine

compression

ET

4

Checking

electrical

advance

control

system

ET

19

Checking

exhaust

manifold

heat

control

AUTOMATIC

TEMPERATURE

CONTROL

AIR

valve

ET

5

CLEANER

A

T

C

AIR

CLEANER

ET

20

IGNITION

AND

FUEL

SYSTEM

ET

5

Replacing

carburetor

air

cleaner

filter

ET

20

Checking

battery

ET

5

Checking

hot

air

control

valve

ET

20

Checking

and

adjusting

ignition

timing

ET

5

CRANKCASE

EMISSION

CONTROL

Checking

or

replacing

distributor

breaker

SYSTEM

ET

22

point

condenser

and

spark

plugs

ET

6

Checking

or

replacing

PCV

valve

ET

23

Checking

distributor

ignition

wiring

and

Checking

ventilation

hoses

ET

23

ignition

coil

ET

7

EVAPORATIVE

EMISSION

CONTROL

Checking

distributor

cap

and

rotor

ET

7

SYSTEM

ET

23

Adjusting

carburetor

id

Ie

rpm

and

Checking

engine

compartment

hose

mixture

ratio

ET

8

connections

and

fuel

vapor

control

valves

ET

23

Checking

fuel

tank

vacuum

relief

valve

operation

ET

24

BASIC

MECHANICAL

SYSTEM

1

Start

engine

and

run

it

until

it

is

heated

to

operating

temperature

or

at

least

more

than

800C

I760F

of

engine

oil

temperature

then

stop

engine

Adjusting

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

should

be

made

while

engine

is

stationary

To

adjust

proceed

as

follows

2

Rotate

crankshaft

to

bring

No

1

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

to

gain

access

to

valve

ET

1

Page 313 of 513

ENGINE

Adjusting

carburetor

idle

rpm

mixture

ratio

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

NO

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

SO

800

rpm

S

Adjust

idle

adjusting

screw

so

that

CO

percentage

is

1

5

t

O

S

6

Repeat

the

adjustments

as

described

in

steps

3

and

S

above

so

that

CO

percentage

is

I

i

t

O

S

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

CO

percentage

with

lever

in

D

position

6S0

I

S

t

O

S

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

idle

adjusting

screw

completely

to

avoid

damage

to

the

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

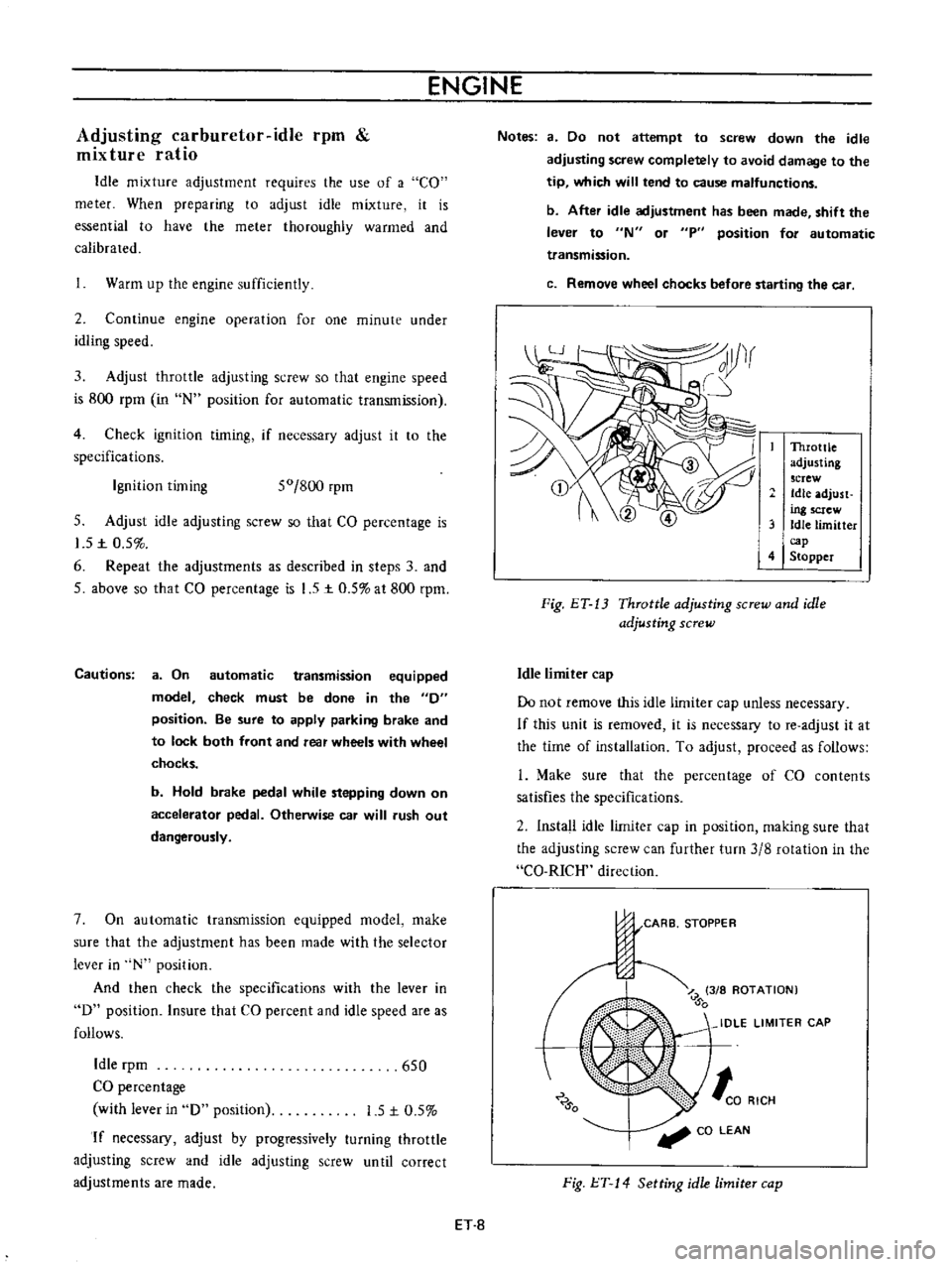

Throttle

adjusting

screw

Idle

adjust

ing

screw

3

Idle

limitter

cap

4

Stopper

Fig

ET

13

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

re

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

L

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

CO

RICH

direction

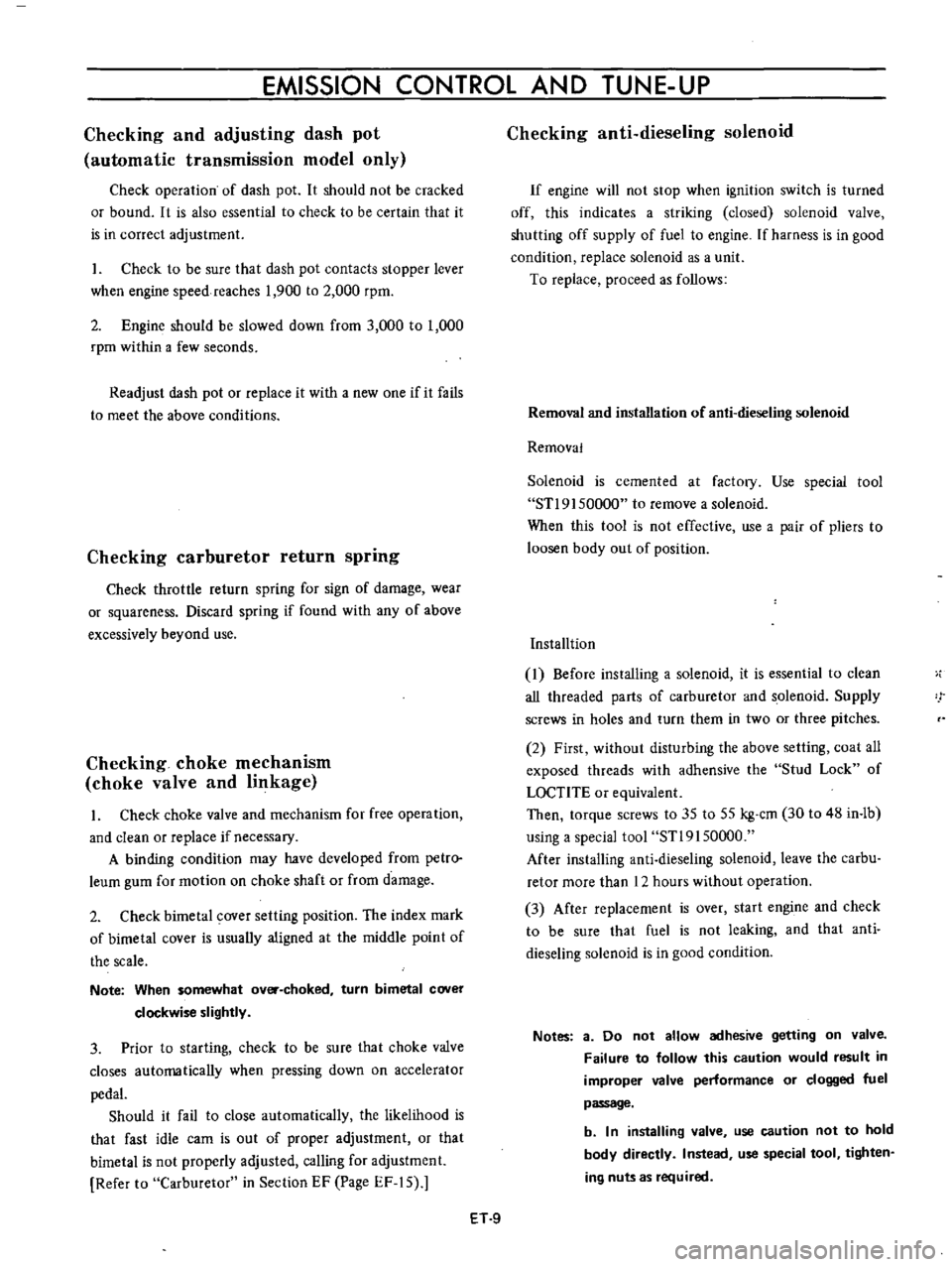

CARB

STOPPER

J

Z

3

8

ROTATION

0

IDLE

LIMITER

CAP

0

to

RICH

CO

LEAN

Fig

l

T

14

Setting

idle

limiter

cap

ET

8

Page 314 of 513

EMISSION

CONTROL

AND

TUNE

UP

Checking

and

adjusting

dash

pot

automatic

transmission

model

only

Check

operation

of

dash

pot

It

should

not

be

cracked

or

bound

It

is

also

essential

to

check

to

be

certain

that

it

is

in

correct

adjustment

L

Check

to

be

sure

that

dash

pot

contacts

stopper

lever

when

engine

speed

reaches

1

900

to

2

000

rpm

2

Engine

should

be

slowed

down

from

3

000

to

1

000

rpm

within

a

few

seconds

Readjust

dash

pot

or

replace

it

with

a

new

one

if

it

fails

to

meet

the

above

conditions

Checking

carburetor

return

spring

Check

throttle

return

spring

for

sign

of

damage

wear

or

squareness

Discard

spring

if

found

with

any

of

above

excessively

beyond

use

Checking

choke

mechanism

choke

valve

and

linkage

1

Check

choke

valve

and

mechanism

for

free

operation

and

clean

or

replace

if

necessary

A

binding

condition

may

have

developed

from

petro

leum

gum

for

motion

on

choke

shaft

or

from

damage

2

Check

bimetal

cover

setting

position

The

index

mark

of

bimetal

cover

is

usually

aligned

at

the

middle

point

of

the

scale

Note

When

somewhat

over

choked

turn

bimetal

caver

clockwise

slightly

3

Prior

to

starting

check

to

be

sure

that

choke

valve

closes

automatically

when

pressing

down

on

accelerator

pedal

Should

it

fail

to

close

automatically

the

likelihood

is

that

fast

idle

cam

is

out

of

proper

adjustment

or

that

bimetal

is

not

properly

adjusted

calling

for

adjustment

Refer

to

Carburetor

in

Section

EF

Page

EF

15

Checking

anti

dieseling

solenoid

If

engine

will

not

stop

when

ignition

switch

is

turned

off

this

indicates

a

striking

closed

solenoid

valve

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solenoid

as

a

unit

To

replace

proceed

as

follows

Removal

and

installation

of

anti

dieseling

solenoid

Removal

Solenoid

is

cemented

at

factory

Use

special

tool

STl

91

50000

to

remove

a

solenoid

When

this

tool

is

not

effective

use

a

pair

of

pliers

to

loosen

body

out

of

position

lnstalltion

I

Before

installing

a

solenoid

it

is

essential

to

clean

all

threaded

parts

of

carburetor

and

solenoid

Supply

screws

in

holes

and

turn

them

in

two

or

three

pitches

2

First

without

disturbing

the

above

setting

coat

all

exposed

threads

with

adhensive

the

Stud

Lock

of

LOCTlTE

or

equivalent

Then

torque

screws

to

35

to

55

kg

cm

30

to

48

in

lb

using

a

special

tool

STl9150000

After

installing

anti

dieseling

solenoid

leave

the

carbu

retor

more

than

12

hours

without

operation

3

After

replacement

is

over

start

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

solenoid

is

in

good

condition

Notes

a

Do

not

allow

adhesive

getting

on

valve

Failure

to

follow

this

caution

would

result

in

improper

valve

performance

or

clogged

fuel

passage

b

I

n

installing

valve

use

caution

not

to

hold

body

directly

Instead

use

special

tool

tighten

ing

nuts

as

required

ET

9

Page 315 of 513

ENGINE

Replacing

fuel

filter

Check

for

a

contamination

element

water

deposit

and

defection

Fig

ET

15

Fuel

strcrineT

All

engines

use

a

cartridge

type

strainer

If

it

is

found

to

be

defective

replace

as

an

assembly

Checking

fuel

lines

hoses

pipings

connections

etc

Check

fuel

lines

for

loose

connections

cracks

and

deterioration

Retighten

loose

connections

if

necessary

replace

any

damaged

or

defective

parts

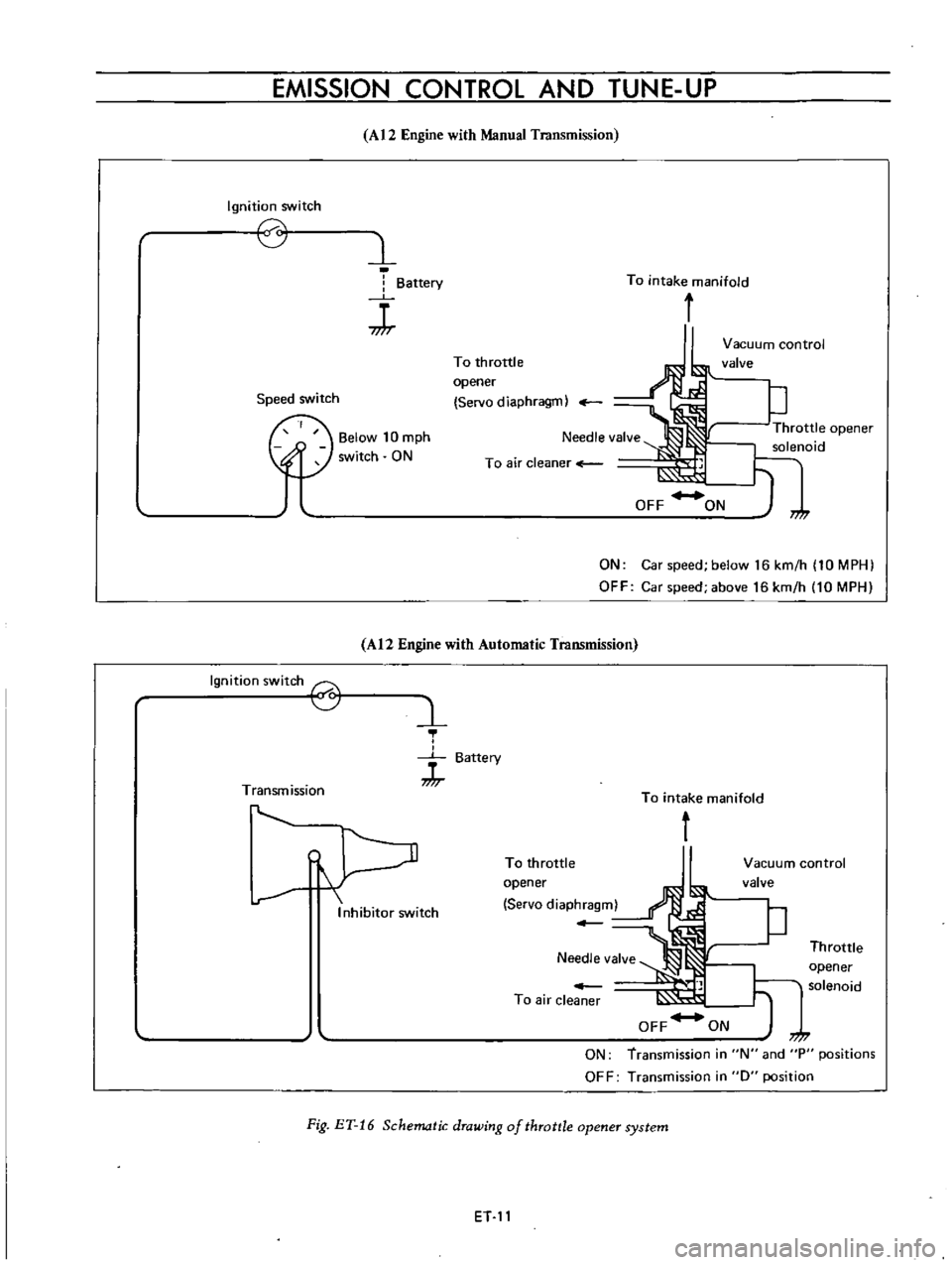

THROTTLE

OPENER

CONTROL

SYSTEM

The

function

of

the

throttle

opener

is

to

open

the

throttle

valve

of

carburetor

slightly

in

vehicle

decelera

tion

During

deceleration

manifold

vacuum

rises

and

a

quantity

of

mixture

in

the

enigne

is

not

sufficient

so

that

a

normal

combustion

can

not

continue

and

a

great

amount

of

unburned

HC

is

emitted

The

carburetor

equipped

with

the

throttle

opener

supplies

the

engine

with

an

adequate

charge

of

combustible

mixture

to

keep

proper

combustion

during

deceleration

resulting

in

re

markable

reduction

of

He

emission

The

operation

of

the

throttle

opener

is

as

follows

A

schematic

drawing

of

the

system

is

shown

in

Figure

ET

16

At

the

moment

when

the

manifold

vacuum

increases

as

occurs

upon

deceleration

the

control

valve

opens

to

transfer

the

manifold

vacuum

to

the

servo

diaphragm

chamber

and

the

throttle

valve

of

the

carburetor

opens

slightly

As

the

vehicle

speed

decreases

above

16

km

h

10

MPH

for

manual

transmission

only

the

manifold

vacuum

lowers

to

the

predetermined

value

The

vacuum

control

valve

begins

to

close

gradually

keeping

the

manifold

vacuum

at

the

predetermined

constant

value

As

a

result

both

low

HC

emission

and

normal

engine

brake

during

deceleration

are

obtained

The

altitude

corrector

is

provided

with

a

slight

preload

to

compensate

the

variation

of

the

atmospheric

pressure

Vacuum

control

solenoid

The

purpose

of

this

control

is

to

return

the

speed

of

engine

to

the

prescribed

idling

positively

To

be

accurate

the

control

prevents

the

throttle

opener

from

taking

normal

operation

when

vehicle

speed

is

below

16

km

h

IO

MPH

for

manual

transmission

equipped

model

or

when

transmission

is

placed

in

N

or

P

position

for

automatic

transmission

equipped

model

Current

flows

through

the

solenoid

when

vehicle

speed

falls

below

16

km

h

10

MPH

on

manual

transmission

equipped

model

or

when

the

transmission

is

placed

in

N

or

P

position

on

automatic

transmission

equipped

model

As

this

takes

place

the

needle

valve

is

lifted

off

its

seat

directing

air

from

the

air

chamber

to

the

servo

diaphragm

This

releases

the

operation

of

the

throttle

opener

When

vehicle

speed

goes

over

16

km

h

IO

MPH

or

when

transmission

is

placed

in

a

position

other

than

N

or

P

position

the

solenoid

is

deenergized

allowing

the

throttle

opener

to

take

normal

action

to

reduce

He

emission

to

a

minimum

ET

10

Page 316 of 513

EMISSION

CONTROL

AND

TUNE

UP

Ignition

switch

0

Speed

switch

Ignition

switch

6

Transmission

A12

Engine

with

Manual

Transmission

l

Battery

J

Below

10

mph

switch

ON

To

throttle

opener

Servo

diaphragm

Needle

valve

To

air

cleaner

To

intake

manifold

f

Vacuum

control

valve

p

Throttle

opener

noid

ON

Car

speed

below

16

km

h

10

MPH

OFF

Car

speed

above

16

km

h

10

MPH

A12

Engine

with

Automatic

Transmission

Inhibitor

switch

1

J

Battery

To

intake

manifold

t

ET

11

OFF

ON

Fig

BY

16

Schematic

drawing

of

throttle

opener

system

To

throttle

opener

Servo

diaphragm

Vacuum

control

valve

P

Throttle

t

opener

solenoid

7

7

ON

transmission

in

N

and

P

positions

OFF

Transmission

in

0

position