engine oil DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 451 of 537

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

aim

use

adjusting

screw

on

side

of

head

lamp

Notes

Before

making

headlarnp

aiming

ad

justment

observe

the

foUowing

in

structions

Body

Electrical

System

a

Keep

aU

tires

inflated

to

correct

pressures

b

Place

vehicle

and

tester

on

the

same

flat

surface

c

See

that

there

is

no

load

in

vehicle

I

Gasoline

radiator

and

engine

oil

pan

filled

up

to

correct

levels

2

Without

passenger

When

performing

headlamp

aiming

adjustment

use

an

aiming

device

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

aimer

refer

to

respective

operation

manuals

supplied

with

the

unit

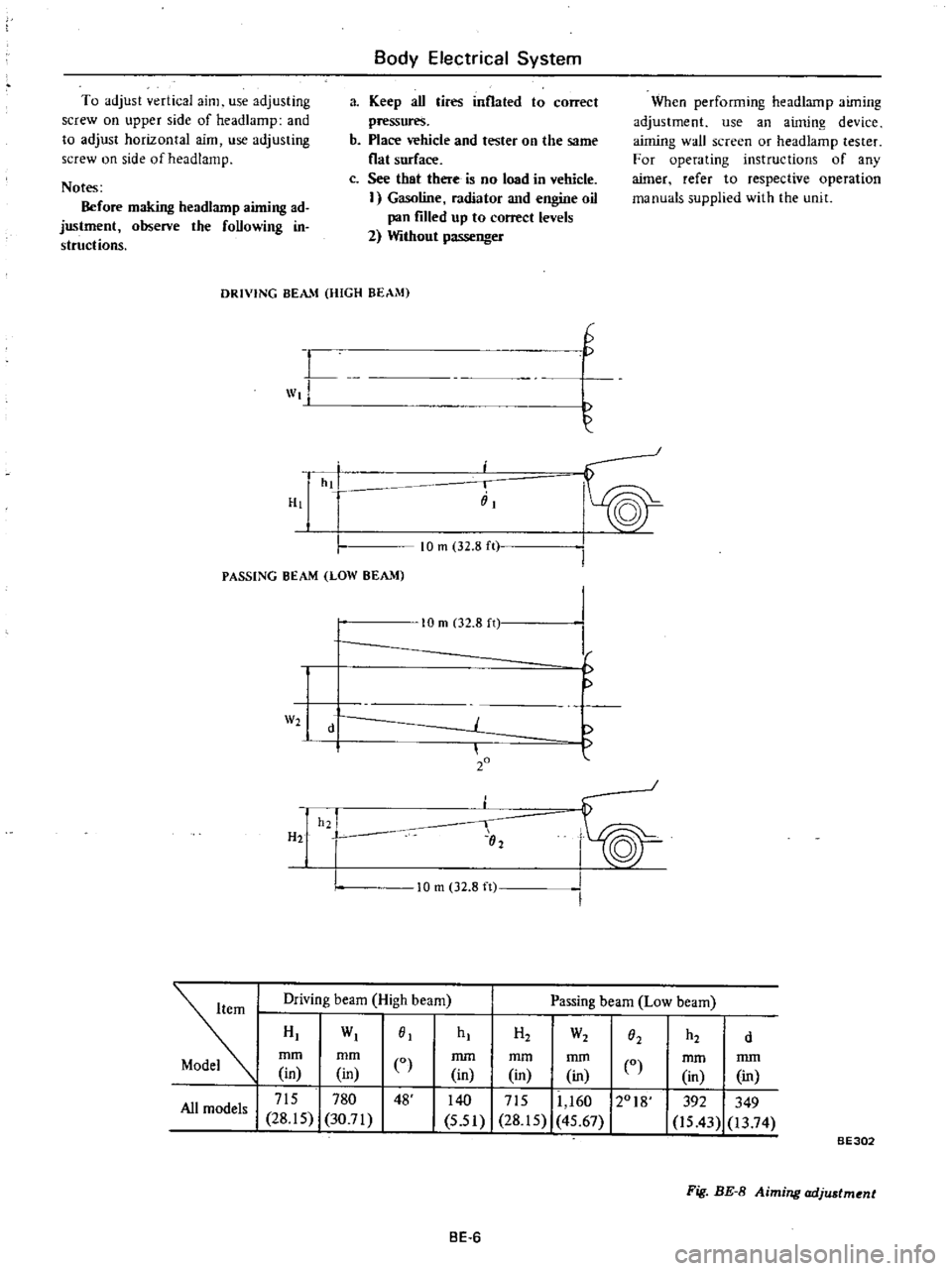

DRIVING

BEAM

HIGH

BEAM

L

wt

H

G

hi

i

iiI

PASSING

BEAM

LOW

BEAM

10

m

32

8

ft

W2

H2

10

m

02

8

n

d

20

h2

I

02

I

I

f

10

m

32

8

ft

Driving

beam

High

beam

Passing

beam

Low

beam

HI

WI

01

mm

mm

CO

in

in

I

715

780

48

All

models

28

15

30

71

hI

H2

W2

h2

O2

d

mm

mm

mm

in

in

in

0

140

I

715

11

160

12018

5

51

28

15

45

67

mm

mm

in

in

392

349

is

43

13

74

BE302

Fig

BE

8

Aiming

adjustment

BE

6

Page 461 of 537

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Working

through

meter

openings

of

cluster

lid

remove

three

screws

retaining

cluster

lid

to

instrument

panel

3

From

underneath

instrument

panel

remove

one

screw

retaining

me

ter

assembly

to

lower

panel

of

instru

ment

4

Withdraw

cluster

lid

slightly

For

ccess

to

switches

knobs

etc

follow

the

procedures

given

in

each

section

5

From

behind

combination

meter

disconnect

speedometer

cable

at

speedometer

head

and

multiple

con

nector

instrume

nt

wire

assembly

from

printed

circuit

6

On

vehicle

with

clock

disconnect

wires

at

each

connection

on

meter

printed

circuit

7

Remove

four

screws

retaining

me

ter

assembly

to

cluster

lid

8

Remov

combination

meter

as

sembly

9

When

installing

combination

me

ter

assembly

follow

the

reverse

se

quence

of

removal

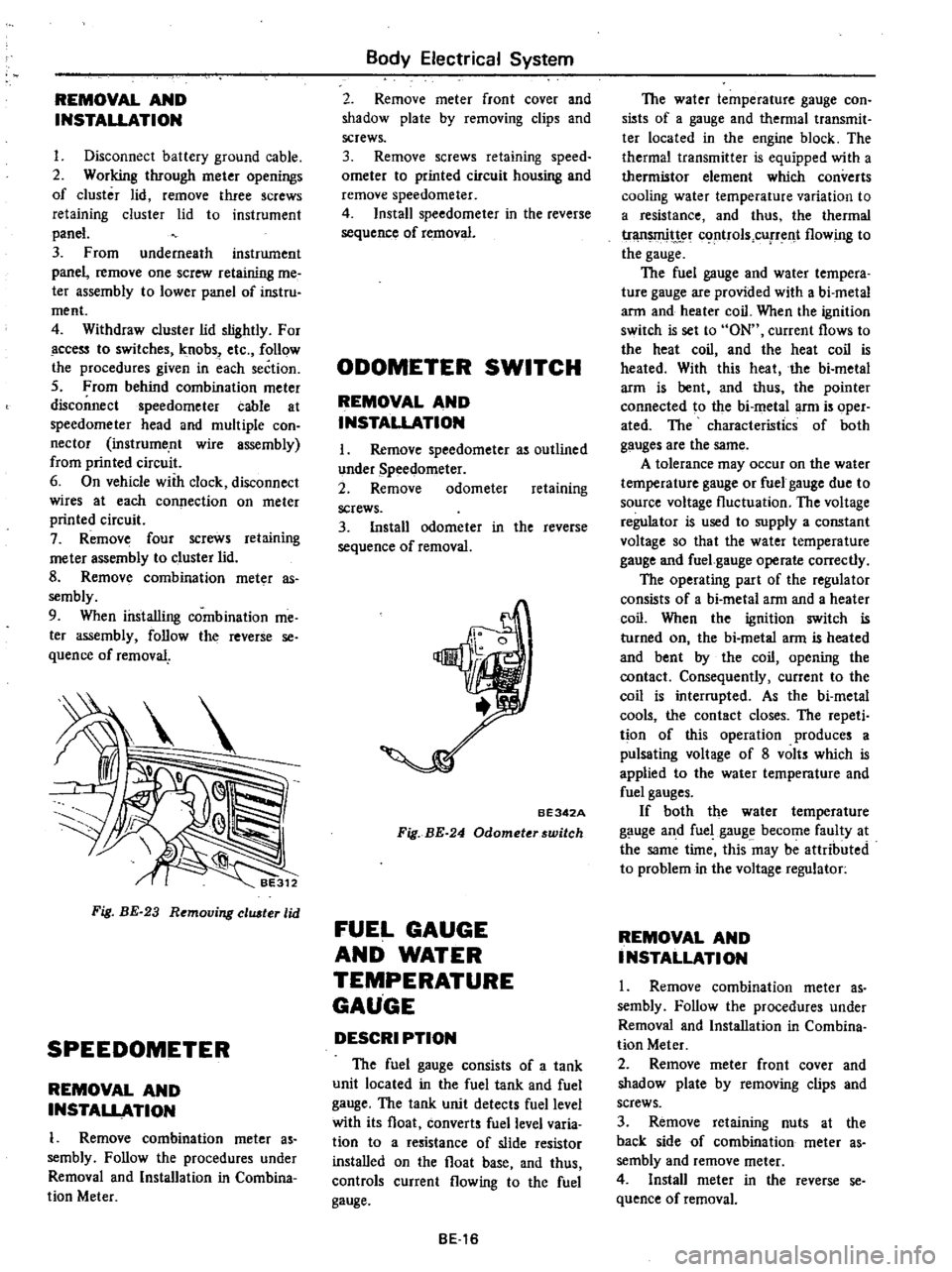

Fig

BE

23

Removing

eluster

lid

SPEEDOMETER

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

Body

Electrical

System

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

screws

retaining

speed

ometer

to

printed

circuit

housing

and

remove

speedometer

4

Install

speedometer

in

the

reverse

sequence

of

removal

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

I

Remove

speedometer

as

outlined

under

Speedometer

2

Remove

odometer

retaining

screws

3

Install

odometer

in

the

reverse

sequence

of

removal

BE342A

Fig

BE

24

Odometerswitch

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRI

PTION

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

gauge

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

varia

tion

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

gauge

BE16

The

water

temperature

gauge

con

sists

of

a

gauge

and

thermal

transmit

ter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

tr

t

c

rtrols

cUfTent

flowing

to

the

gauge

The

fuel

gauge

and

water

tempera

ture

gauge

are

provided

with

a

bi

metal

arm

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bi

metal

arm

is

bent

and

thus

the

pointer

connected

to

the

bi

metal

arm

is

oper

ated

The

characteristics

of

both

gauges

are

the

same

A

tolerance

may

occur

on

the

water

temperature

gauge

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

water

temperature

gauge

and

fuel

gauge

operate

correctly

The

operating

part

of

the

regulator

consists

of

a

bi

metal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

bi

metal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bi

metal

cools

the

contact

closes

The

repeti

tion

of

this

operation

produces

a

pulsating

voltage

of

8

volts

which

is

applied

to

the

water

temperature

and

fuel

gauges

If

both

the

water

temperature

gauge

and

fuel

gauge

become

faulty

at

the

same

time

this

may

be

attributed

to

problem

in

the

voltage

regulator

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

retaining

nuts

at

the

back

side

of

combination

meter

as

sembly

and

remove

meter

4

Install

meter

in

the

reverse

se

quence

of

removal

Page 462 of 537

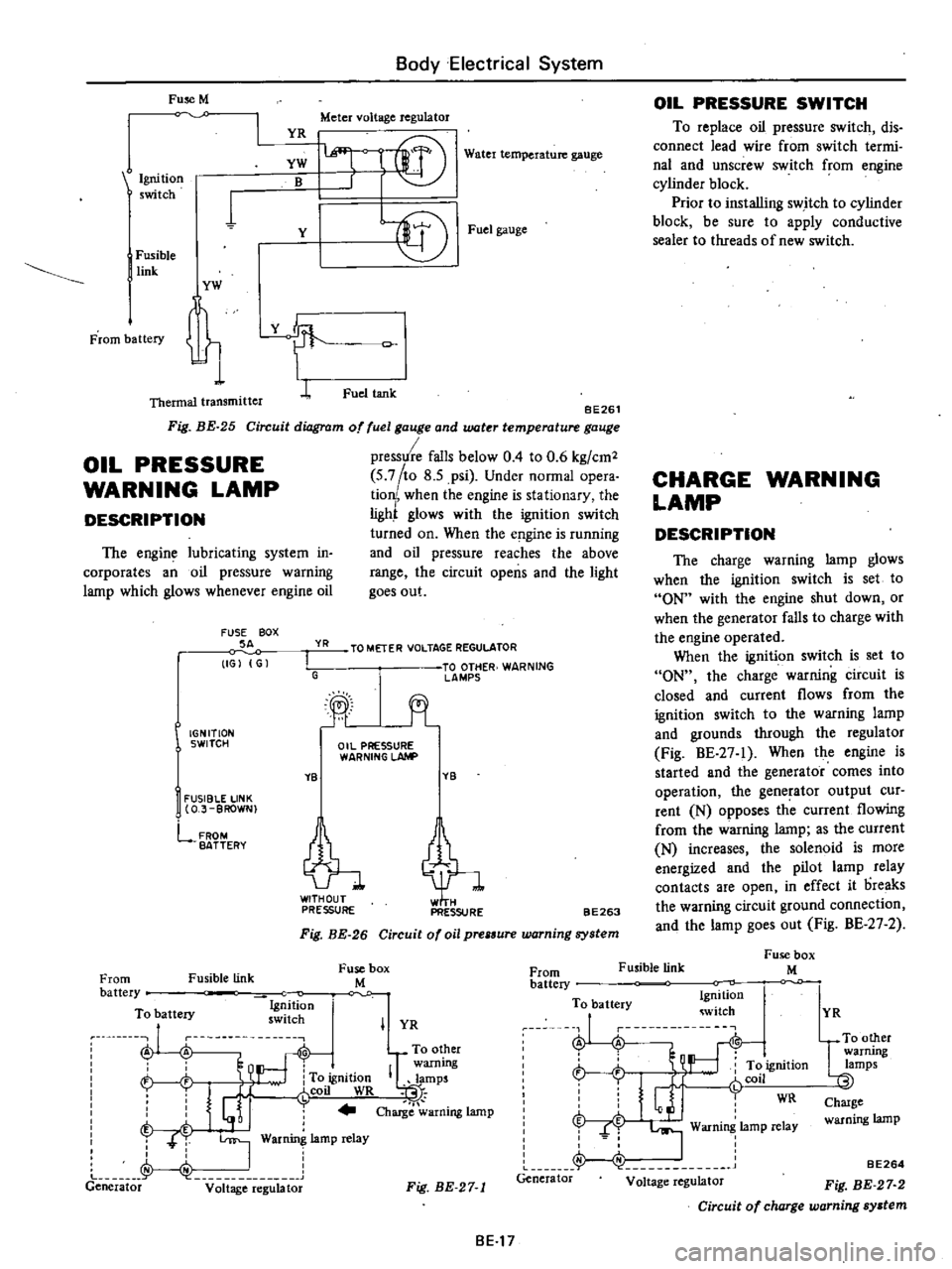

Fuse

M

Body

Electrical

System

YR

Meter

voltage

regulator

Water

temperature

gauge

BE261

Circuit

diagram

of

fuel

gauge

and

water

temperature

gauge

pressure

falls

below

0

4

to

0

6

kg

cm2

5

7

to

8

5

psi

Under

normal

opera

tion

when

the

engine

is

stationary

the

ligh

glows

with

the

ignition

switch

turned

on

When

the

e

gine

is

running

and

oil

pressure

reaches

the

above

range

the

circuit

opens

and

the

light

goes

out

Ignition

switch

YW

B

1

Y

I

Fusible

link

YW

t

Thermal

transmitter

L

Fig

BE

25

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

The

engine

lubricating

system

in

corporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

FUSE

BOX

SA

IGJ

G

YR

I

G

IGNITION

SWITCH

YB

I

FUSIBLE

LINK

O

J

BROWN

lffi

l

f

r@

Fuel

gauge

Fuel

tank

TO

METER

VOLTAGE

REGULATOR

TO

OTHER

WARNING

lAMPS

jt

Oil

PRESSURE

WARNING

LAhlP

YB

tl

PRESSURE

PRESSURE

FROM

BATTERY

BE263

Fig

BE

26

Circuit

of

oil

prelSure

warning

system

Fusible

link

Fuse

box

M

OIL

PRESSURE

SWITCH

To

replace

oil

pressure

switch

dis

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

from

engine

cylinder

block

Prior

to

installing

switch

to

cylinder

block

be

sure

to

apply

conductive

sealer

to

threads

of

new

switch

CHARGE

WARNING

LAMP

DESCRIPTION

The

charge

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

with

the

engine

shut

down

or

when

the

generator

falls

to

charge

with

the

engine

operated

When

the

ignition

switch

is

set

to

ON

the

charge

warning

circuit

is

closed

and

current

flows

from

the

ignition

switch

to

the

warning

lamp

and

grounds

through

the

regulator

Fig

BE

27

1

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

cur

rent

N

opposes

th

current

flowing

from

the

warning

lamp

as

the

current

N

increases

the

solenoid

is

more

energized

and

the

pilot

lamp

relay

contacts

are

open

in

effect

it

oreaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

Fig

BE

27

2

Fusible

link

Fuse

box

M

From

battery

To

battery

Ig

ition

ru

nu

swllch

A

A

To

other

warning

h

To

ignition

IQlamps

i

J

r

coil

WR

t

I

j

Charge

warning

lamp

T

T

I

War

lamp

relay

J

I

Generator

v

it

ge

e

g

bt

From

battery

To

battery

Ignition

witch

J

i

L

r

t

ft

ignition

r

Glj

fCOil

WR

f

I

Warning

lamp

relay

Generator

Voltage

regulator

I

YR

Fig

BE

27

1

BE17

YR

UTO

other

warrung

lamps

Charge

warning

lamp

BE264

Fig

BE

27

2

Circuit

of

charge

warning

system

Page 465 of 537

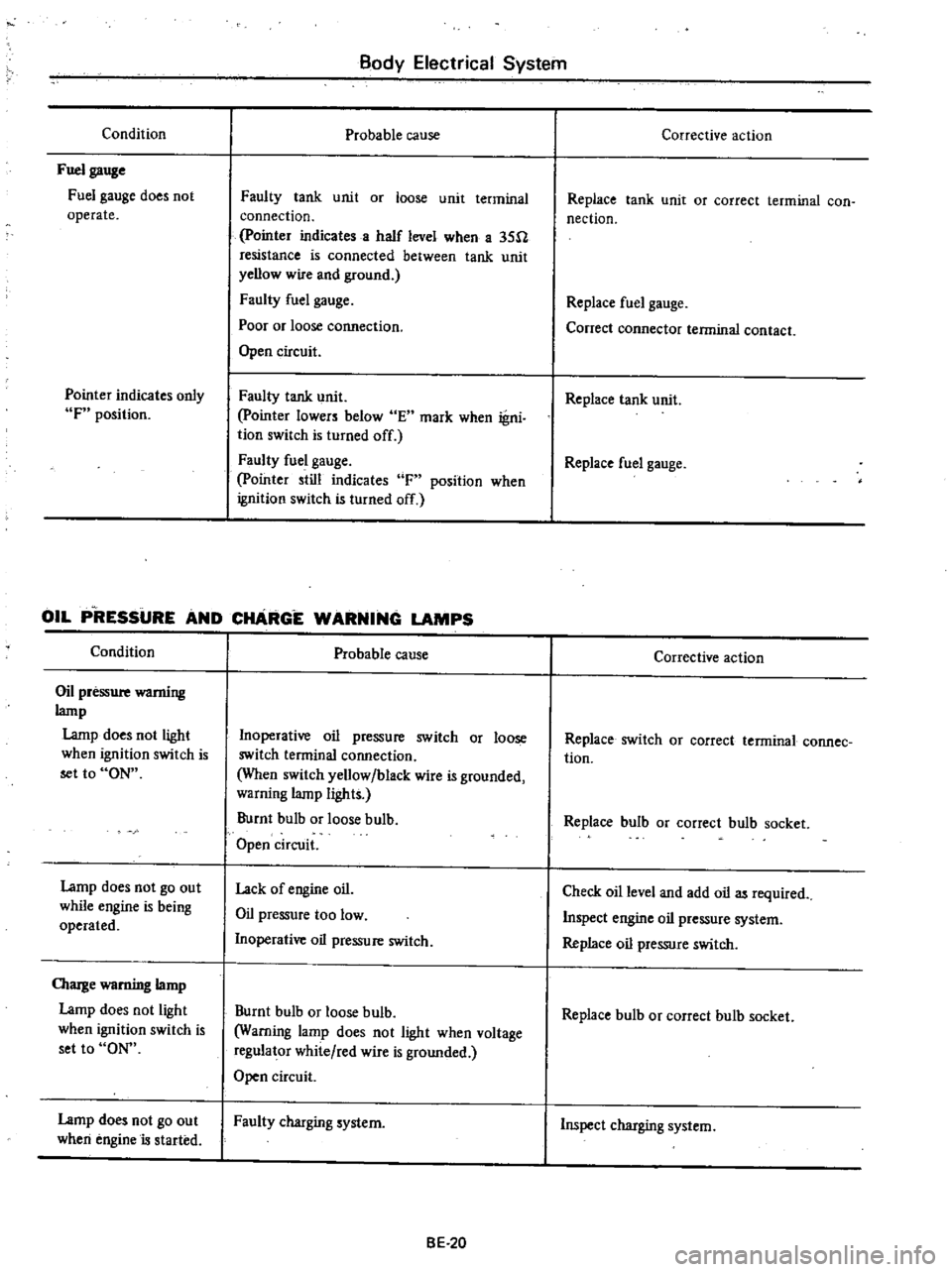

Condition

Fuel

gauge

Fuel

gauge

does

not

operate

Pointer

indicates

only

F

position

Body

Electrical

System

Probable

cause

Faulty

tank

unit

or

loose

unit

terminal

connection

pointer

indicates

a

half

level

when

a

35U

resistance

is

connected

between

tank

unit

yellow

wire

and

ground

Faulty

fuel

gauge

Poor

or

loose

cormection

Open

circuit

Faulty

tank

unit

pointer

lowers

below

E

mark

when

igni

tion

switch

Is

turned

off

Faulty

fuel

gauge

pointer

still

indicates

F

position

when

ignition

switch

is

turned

off

OIL

P

RESSURE

AND

CHARGE

WARNING

LAMPS

Condition

Oil

pressure

wamiug

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

while

engine

is

being

operated

OIarge

warning

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

when

engine

is

started

Probable

cause

Inoperative

oil

pressure

switch

or

loose

switch

terminal

connection

When

switch

yellow

black

wire

is

grounded

warning

lamp

lights

Burnt

bulb

or

loose

bulb

Open

circuit

Lack

of

engine

oil

Oil

pressure

too

low

Inoperative

oil

pressure

switch

Burnt

bulb

or

loose

bulb

Warning

lamp

does

not

light

when

voltage

regulator

white

red

wire

is

grounded

Open

circuit

Faulty

charging

system

BE

20

Corrective

action

Replace

tank

unit

or

correct

terminal

con

nection

Replace

fuel

gauge

Conect

connector

terminal

contact

Replace

tank

unit

Replace

fuel

gauge

Corrective

action

Replace

switch

OJ

correct

terminal

connee

tion

Replace

bulb

or

correct

bulb

socket

Check

oil

level

and

add

oil

as

required

Inspect

engine

oil

pressure

system

Replace

oil

pressure

switch

Replace

bulb

or

correct

bulb

socket

Inspect

charging

system

Page 475 of 537

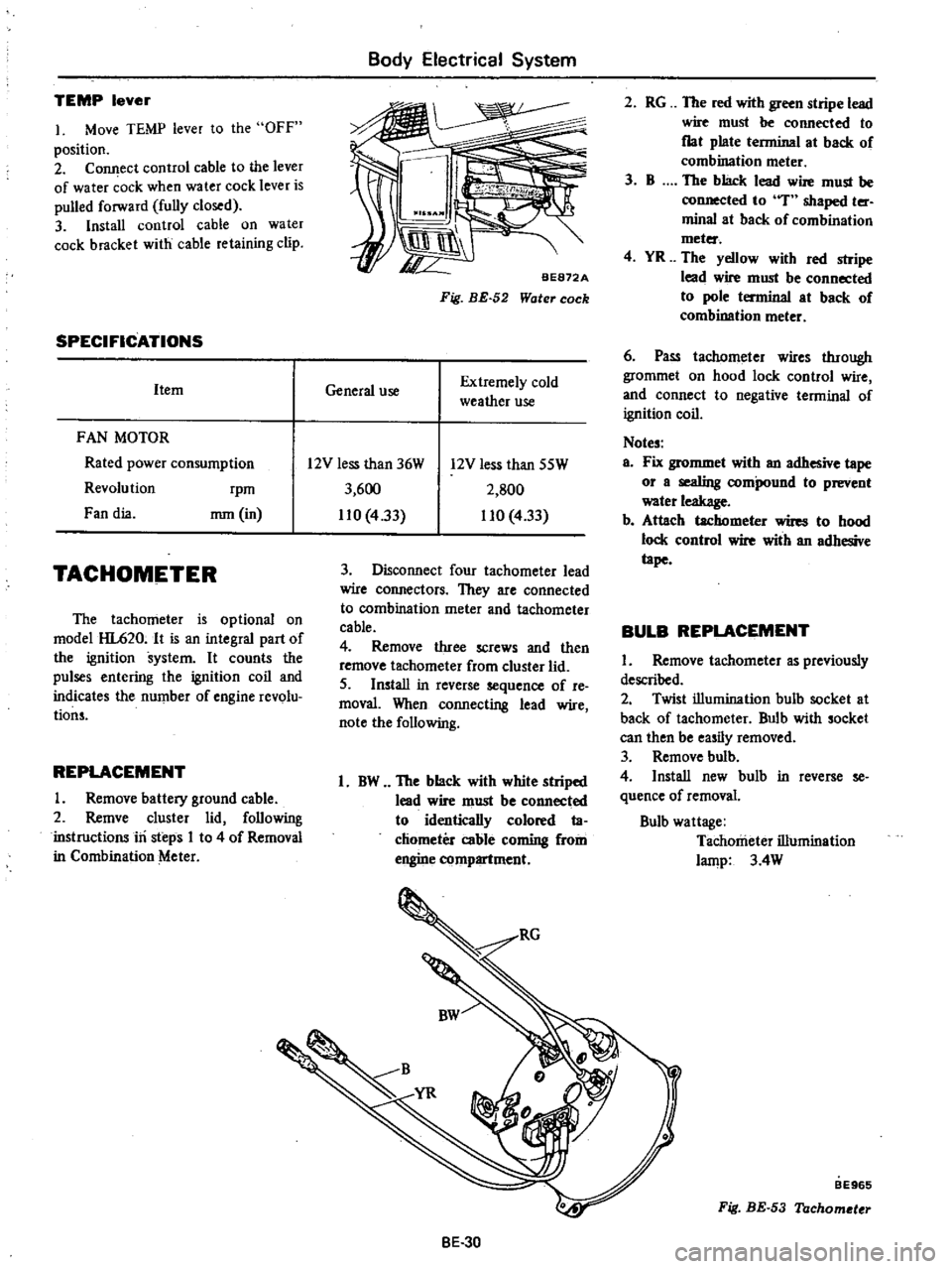

TEMP

lever

1

Move

TEMP

lever

to

the

OFF

position

2

Connect

control

cable

to

the

lever

of

water

ock

when

water

cock

lever

is

pulled

forward

fully

closed

3

Install

control

cable

on

water

cock

bracket

with

cable

retaining

clip

SPECIFICATIONS

Item

FAN

MOTOR

Rated

power

consumption

Revolution

rpm

Fan

dia

mm

in

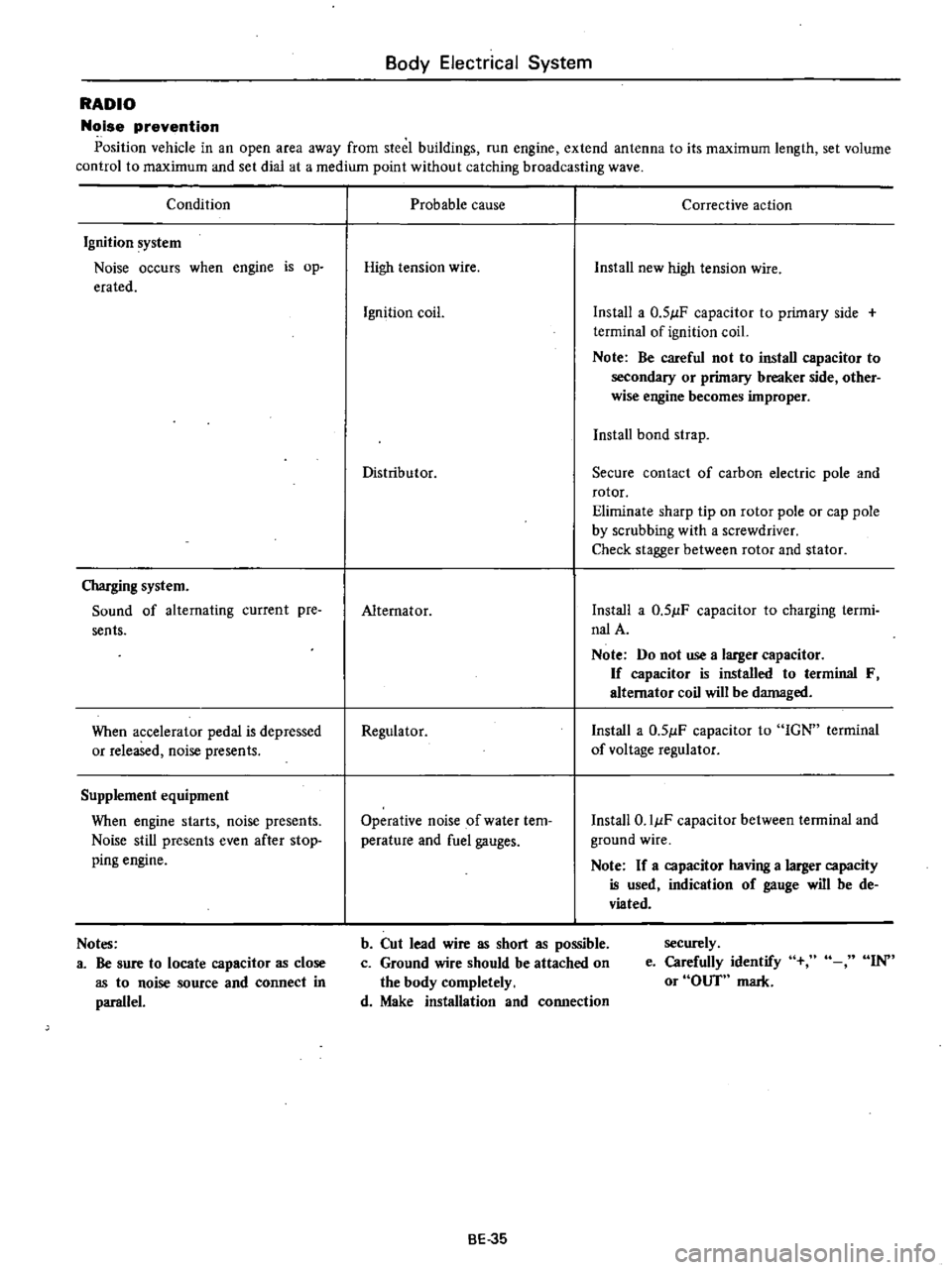

TACHOMETER

The

tachometer

is

optional

on

model

HL620

It

is

an

integral

part

of

the

ignition

system

It

counts

the

pulses

entering

the

ignition

coil

and

indicates

the

number

of

engine

revolu

tions

REPLACEMENT

I

Remove

battery

ground

cable

2

Remve

cluster

lid

following

instructions

iri

steps

I

to

4

of

Removal

in

Combination

Meter

Body

Electrical

System

BE872A

Fig

BE

52

Water

cock

General

use

Extremely

cold

weather

use

2

RG

The

red

with

green

stripe

lead

wire

must

be

connected

to

flat

plate

terminal

at

back

of

combination

meter

3

B

The

black

lead

wire

must

be

connected

to

T

shaped

ter

minal

at

back

of

combination

meter

4

YR

The

yellow

with

red

stripe

lead

wire

must

be

connected

to

pole

terminal

at

back

of

combination

meter

6

Pass

tachllmeter

wires

through

grommet

on

hood

lock

control

wire

and

connect

to

negative

terminal

of

ignition

coil

Notes

a

Fix

grommet

with

an

adhesive

tape

or

a

sealing

compound

to

prevent

water

leakage

b

Attach

tachometer

wires

to

hood

lock

control

wire

with

an

adhesive

tape

BULB

REPLACEMENT

I

Remove

tachometer

as

previously

described

2

Twist

illumination

bulh

socket

at

back

of

tachometer

Bulb

with

socket

can

then

be

easily

removed

3

Remove

bulb

4

Install

new

bulb

in

reverse

se

quence

of

removal

Bulb

wattage

Tachometer

illumination

lamp

3

4W

12V

less

than

36W

3

600

110

433

12V

less

than

SSW

2

SOO

110

4

33

3

Disconnect

four

tachometer

lead

wire

connectors

They

are

connected

to

combination

meter

and

tachometer

cable

4

Remove

three

screws

and

then

remove

tachometer

from

cluster

lid

5

Install

in

reverse

sequence

of

re

moval

When

connecting

lead

wire

note

the

following

1

BW

The

black

with

white

striped

lead

wire

must

be

connected

to

identically

colored

ta

chometer

cable

coming

from

engine

compartment

BE

30

BE965

Fig

BE

53

Tachometer

Page 480 of 537

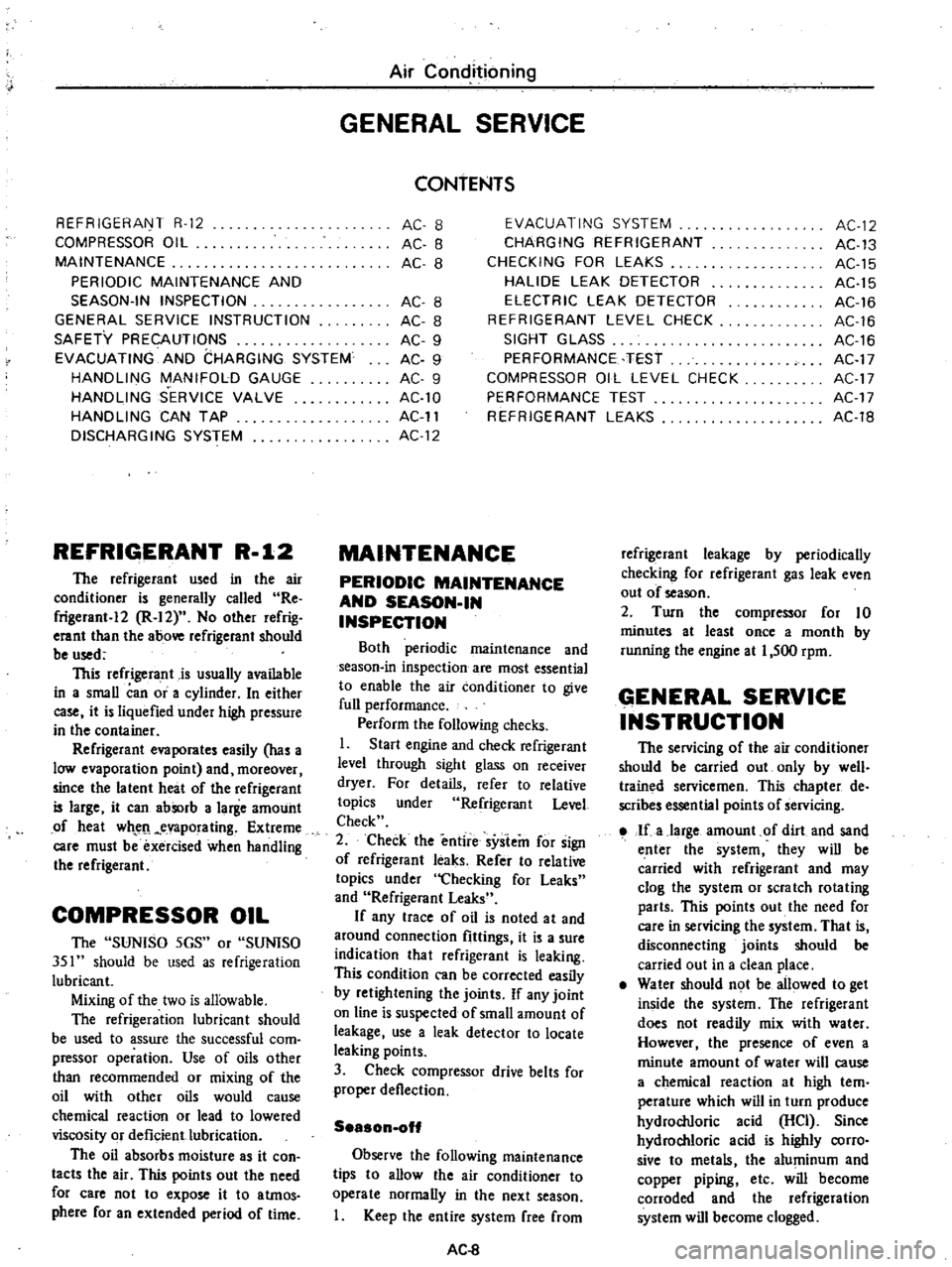

Body

Electrical

System

RADIO

Noise

prevention

Position

vehicle

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

medium

point

without

catching

broadcasting

wave

Condition

Ignition

system

Noise

occurs

when

engine

is

op

erated

Charging

system

Sound

of

alternating

current

pre

sents

When

accelerator

pedal

is

depressed

or

released

noise

presents

Supplement

equipment

When

engine

starts

noise

presents

Noise

still

presents

even

after

stop

ping

engine

Notes

a

Be

sure

to

locate

capacitor

as

close

as

to

noise

source

and

connect

in

parallel

Probable

cause

Corrective

action

High

tension

wire

Install

new

high

tension

wire

Ignition

coil

Install

a

0

51lF

capacitor

to

primary

side

terminal

of

ignition

coil

Note

Be

careful

not

to

install

capacitor

to

secondary

or

primary

breaker

side

other

wise

engine

becomes

improper

Install

bond

strap

Distributor

Secure

contact

of

carbon

electric

pole

and

rotor

Eliminate

sharp

tip

on

rotor

pole

or

cap

pole

by

scrubbing

with

a

screwdriver

Check

stagger

between

rotor

and

stator

Alternator

Install

a

0

51lF

capacitor

to

charging

termi

nalA

Note

Do

not

use

a

larger

capacitor

If

capacitor

is

installed

to

terminal

F

alternator

coil

will

be

damaged

Regulator

Install

a

0

51lF

capacitor

to

IGN

terminal

of

voltage

regulator

Operative

noise

of

water

tem

perature

and

fuel

gauges

Install

O

IIlF

capacitor

between

terminal

and

ground

wire

Note

If

a

capacitor

having

a

larger

capacity

is

used

indication

of

gauge

will

be

de

viated

b

Cut

lead

wire

as

short

as

possible

c

Ground

wire

should

be

attached

on

the

body

completely

d

Make

installation

and

connection

securely

e

Carefully

identify

or

OUT

mark

IN

BE

35

Page 481 of 537

CD

m

Cl

@

D

@

I

j

1

To

instrument

harness

IS

To

battery

30

To

check

connector

2

To

full

transistor

amplifier

16

To

fusible

link

3t

To

headlamp

L

U

type

2

California

models

only

17

To

engine

harness

No

2

32

To

sido

marker

lamp

L

B

3

To

hood

switch

18

To

alternator

33

To

front

combination

lamp

L

H

4

To

engine

compartment

lamp

1

9

To

front

combination

lamp

R

n

34

To

horn

Low

ll

l

S

To

washer

motor

20

To

headlamp

R

H

type

2

3S

To

horn

High

l

l

0

6

To

auto

choke

heater

relay

1

To

side

marker

lamp

R

n

36

To

B

C

D

D

cut

olenoid

California

models

7

To

detector

dri

e

counter

22

To

headlamp

R

B

type

1

only

Non

Califunia

model

except

for

Canada

23

To

ground

37

To

block

tcrminal

distributor

California

8

To

ignition

relay

California

models

only

i4

To

thermal

transmitter

models

only

9

To

floor

sensor

relay

California

modeb

only

is

To

distributor

Non

California

models

only

38

To

ignition

coil

Non

California

models

only

n

10

To

inhibitor

relay

A

T

only

26

To

8

C

D

D

cut

solenoid

Non

California

39

To

condenser

t

II

To

head

lamp

relay

models

only

40

To

ignition

coil

and

resistor

@

12

To

horn

relay

27

To

fuel

cut

solenoid

California

models

only

OJ

v

m

13

To

voltage

regulator

28

To

auto

choke

heater

g

e

14

To

cooler

cable

29

To

headlamp

L

R

type

1

OJ

to

o

Q

m

r0

C

1

i

Ql

CIl

Il

l

3

Page 484 of 537

m

W

D

to

l

l

0

c

l

l

s

Q

3

For

Automatic

Transmission

LB

B

For

Manual

Transmission

m

For

Automatic

Transmission

COLOR

CODE

B

Black

BI

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

BY

RB

RB

B

WB

RB

YB

2

RB

I

B

1

BW

r

BY

LB

For

Automatic

Transmission

to

o

c

m

r0

O

O

Dl

For

Manual

Transmission

@

CJ

lti

3

RB

fB

BY

YB

RB@RB

YB

BY

1

To

kickdown

solenoid

fOT

Automatic

Transmission

2

To

reverse

switch

for

Manual

Tranmission

3

To

inhibitor

switch

for

Automatic

Transmission

4

To

oil

pressure

switch

5

To

starter

motor

6

To

engine

room

harness

for

Manual

Transmission

7

To

engine

room

harness

for

Automatic

Transmission

Page 486 of 537

@

BG

B

LW

LW

B

L

AL

l

J

YA

CD

m

LW

4

ft

GL

LR

t4

B

t

R

LG

4D

It

GW

BW

GW

L

@

ii

b

l

l

l

lD

m

en

lD

A

A

G

Ri

G

L

Non

California

except

Canada

I

G

GR

13

L

R

j

M

T

only

GL

A

T

only

To

engine

compartment

harness

Non

california

except

Canada

G

r

wRfl

Lt

IIY

LIB

l

ll

RY

R

oIll

CD

o

c

m

o

O

II

fJl

1

3

Page 497 of 537

REFRIGERAi

H

R

12

COMPRESSOR

OIL

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

GENERAL

SERVICE

INSTRUCTION

SAFETY

PRECAUTIONS

EV

ACUA

TlNG

AND

CHARGING

SYSTEM

HANDLING

MANIFOLD

GAUGE

HANDLING

SERVICE

VALVE

HANDLING

CAN

TAP

DISCHARGING

SYSTEM

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

This

refrigerant

is

usually

available

in

a

small

can

or

a

cylinder

In

either

case

it

is

liquefied

under

high

pressure

in

the

container

Refrigerant

evaporates

easily

has

a

low

evaporation

point

and

moreover

since

the

latent

heat

of

the

refrigerant

is

large

it

can

abSorb

a

large

amount

of

heat

wh

err

e

vaporating

Extreme

care

must

be

exercised

when

handling

the

refrigerant

COMPRESSOR

OIL

The

SUNISO

5GS

or

SUNISO

351

should

be

used

as

refrigeration

lubricant

Mixing

of

the

two

is

allowable

The

refrigeration

lubricant

should

be

used

to

assure

the

successful

com

pressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrication

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

Air

Conditioning

GENERAL

SERVICE

CONTENTS

EVACUATING

SYSTEM

CHARGING

REFRIGERANT

CHECKING

FOR

LEAKS

HALIDE

LEAK

DETECTOR

ELECTRIC

LEAK

DETECTOR

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

PERFORMANCE

TEST

COMPRESSOR

OIL

LEVEL

CHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

AC

8

AC

8

AC

8

AC

8

AC

8

AC

9

AC

9

AC

9

AC10

AC

11

AC

12

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

Both

periodic

maintenance

and

season

in

inspection

are

most

essential

to

enable

the

air

conditioner

to

give

full

performance

Perform

the

following

checks

Start

engine

and

check

refrigerant

level

through

sight

glass

on

receiver

dryer

For

details

refer

to

relative

topics

under

Refrigerant

Level

Check

2

Check

the

entire

sysiein

for

sign

of

refrigerant

leaks

Refer

to

relative

topics

under

Checking

for

Leaks

and

Refrigerant

Leaks

If

any

trace

of

oil

is

noted

at

and

around

connection

fittings

it

is

a

sure

indication

that

refrigerant

is

leaking

This

condition

can

be

corrected

easily

by

retightening

the

joints

If

any

joint

on

line

is

suspected

of

small

amount

of

leakage

use

a

leak

detector

to

locate

leaking

points

3

Check

compressor

drive

belts

for

proper

deflection

Season

off

Observe

the

following

maintenance

tips

to

allow

the

air

conditioner

to

operate

normally

in

the

next

season

I

Keep

the

entire

system

free

from

AC

8

AC12

AC

13

AC15

AC15

AC16

AC

16

AC16

AC

17

AC17

AC

17

AC18

refrigerant

leakage

by

periodically

checking

for

refrigerant

gas

leak

even

out

of

season

2

Turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

c

ENERAL

SERVICE

INSTRUCTION

The

servicing

of

the

air

conditioner

should

be

carried

out

only

by

well

trained

servicemen

This

chapter

de

scribes

essential

points

of

servicing

Jf

a

Jarge

amount

of

dirt

and

sand

enter

the

system

they

will

be

carried

with

refrigerant

and

may

clog

the

system

or

scratch

rotating

parts

This

points

out

the

need

for

care

in

servicing

the

system

That

is

disconnecting

joints

should

be

carried

out

in

a

dean

place

Water

should

not

be

allowed

to

get

inside

the

system

The

refrigerant

does

not

readily

mix

with

water

However

the

presence

of

even

a

minute

amount

of

water

will

cause

a

chemical

reaction

at

high

tem

perature

which

will

in

turn

produce

hydrochloric

acid

HCl

Since

hydrochloric

acid

is

highly

corro

sive

to

metals

the

aluminum

and

copper

piping

etc

will

become

corroded

and

the

refrigeration

system

will

become

clogged