oil DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 339 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Drive

pinion

bearing

adjusting

washer

Thickness

mm

in

over

3

80

to

3

82

0

1496

to

O

lS04

over

3

82

to

3

84

O

lS04

to

0

ISI2

over

3

84

to

3

86

O

lSI2

to

0

IS20

over

3

86

to

3

88

O

lS20

to

O

IS28

over

3

88

to

3

90

O

lS28

to

0

IS3S

over

3

90

to

3

92

0

IS3S

to

O

IS43

over

3

92

to

3

94

0

IS43

to

O

lSS

I

over

3

94

to

3

96

O

lSSI

to

O

lS59

over

3

96

to

3

98

O

lSS9

to

0

IS67

over

3

98

to

4

00

O

lS67

to

O

lS7S

over

4

00

to

4

02

0

S7S

to

O

lS83

over

4

02

to

4

04

O

lS83

to

0

IS91

over

4

04

to

4

06

O

lS9I

to

0

IS98

over

4

06

to

4

08

O

lS98

to

0

1606

over

4

08

to

4

10

0

1606

to

0

1614

3

Check

and

adjust

tooth

contact

pattern

when

former

adjustment

of

bearing

preload

is

completed

Unless

anything

wrong

is

found

remove

drive

pinion

nut

and

companion

flange

and

press

n

oil

seal

into

gear

carrier

using

Oil

Seal

Fitting

Tool

KV38I02SS0

Apply

grease

cavity

be

tween

seal

lips

4

Again

install

companion

flange

and

washer

and

tighteh

nut

to

speci

fied

torque

14

0

to

17

0

kg

m

IO

to

123

ft

lb

S

Measure

preload

again

Preload

with

oil

seal

I

1

0

to

14

0

kg

cm

9

S

to

12

in

lb

At

companion

flange

bolt

hole

3

1

to

4

0

kg

6

8

to

8

81b

ADJUSTMENT

OF

SIDE

BEARING

SHIMS

I

If

hypoid

gear

set

carrier

dif

ferential

case

or

side

bearing

has

been

replaced

with

new

one

adjust

the

side

bearing

preload

with

adjusting

shim

The

required

thickness

of

adjusting

shim

can

be

calculated

by

the

follow

ing

formulas

T

A

C

D

H

xO

OI

O

l7S

E

T2

B

D

H

xO

OI

O

ISO

F

Where

T

1

Required

thickness

of

left

side

bearing

adjusting

shim

mm

T

2

Required

thickness

of

right

side

bearing

adjusting

shim

mm

A

Figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

B

Figure

marked

on

the

right

side

bearing

of

gear

carrier

C

0

Figure

marked

on

the

differ

entia

case

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

standard

width

20

00

mOl

mOl

If

bearing

width

is

19

89

the

differ

ence

will

be

as

follows

20

00

19

89

0

11

H

Figure

marked

on

the

ring

gear

See

Figures

PD

20

and

PD

2

I

Figures

for

A

B

C

0

and

H

are

dimensional

varia

tions

in

a

unit

of

1

100

mm

against

each

standard

meas

urement

f

@

a

rj

71

Markj

Mark

B

Mark

C

0

P0214

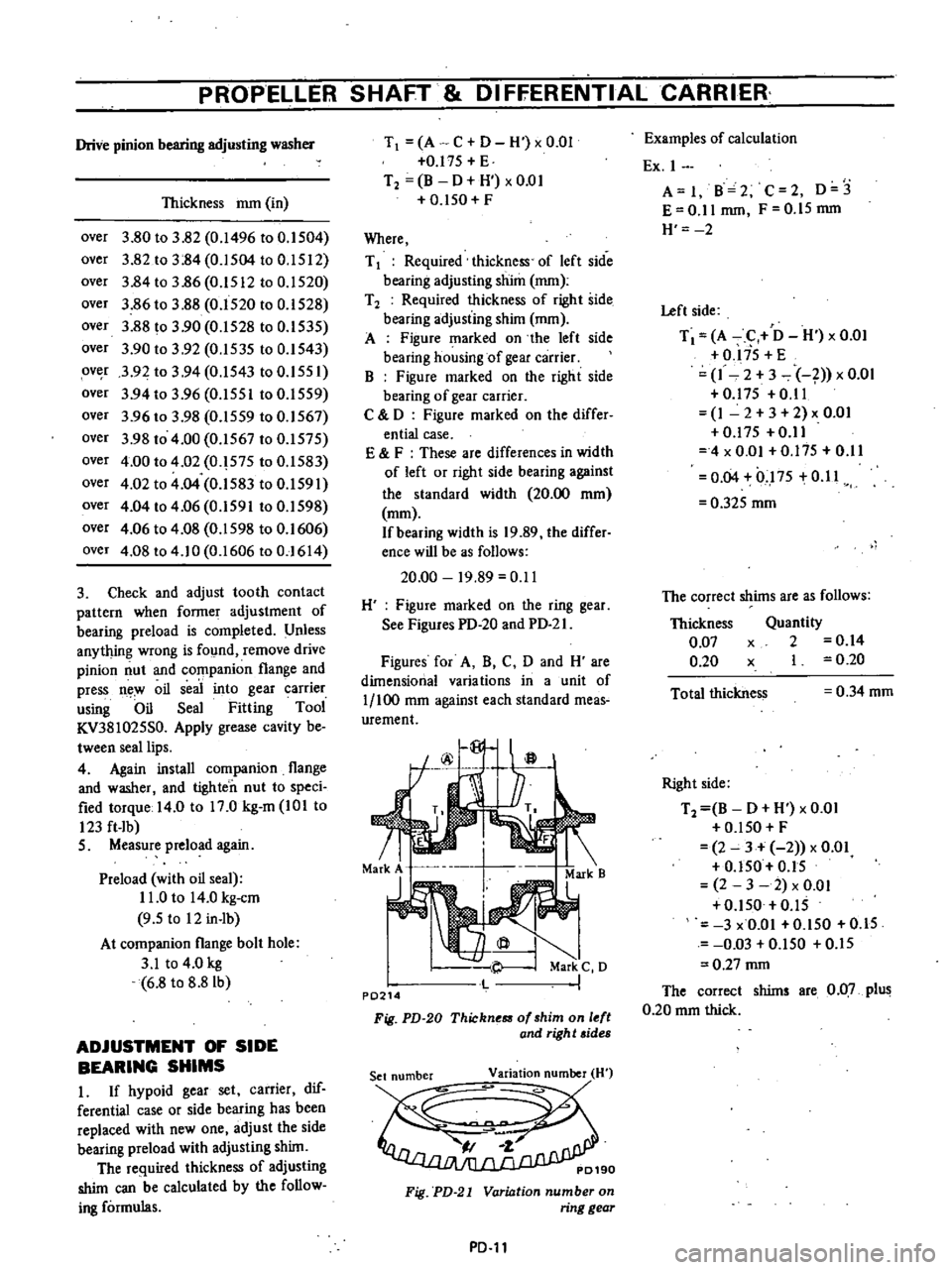

Fig

PD

20

Thickn

of

shim

on

l

ft

and

righ

t

sides

Fig

PD

21

Variation

number

on

ring

gear

PD

ll

Examples

of

calculation

Ex

I

A

I

B

2

C

2

0

3

E

0

11

mm

F

O

IS

mm

H

2

Left

side

T

A

C

0

H

x

0

01

O

liS

E

1

2

3

1

x

0

01

0

17S

0

11

1

2

3

2

x

O

O

O

l7S

0

11

4

x

0

01

0

175

0

11

0

04

0

1

7S

0

11

0

32S

mOl

The

correct

shims

are

as

follows

Thickness

0

07

0

20

Quantity

x

2

0

14

x

I

0

20

Total

thickness

0

34

mOl

Right

side

T2

B

0

H

x

0

01

O

lSO

F

2

3

2

x

0

01

O

ISO

0

15

2

3

2

x

0

01

O

ISO

0

15

3

x

O

OI

O

ISO

O

IS

0

03

O

lSO

O

lS

0

27

mm

The

correct

shims

are

0

07

plus

0

20

mm

thick

Page 340 of 537

PROPELLER

SHAFf

DIFFERENTIAL

CARR

IER

Ex

2

A

0

B

3

C

I

0

0

E

0

20

mOl

F

0

17

mOl

H

2

Left

side

T

I

A

C

D

H

x

om

0

17S

E

0

I

0

2

x

0

01

0

I7S

0

20

0

I

0

2

x

0

01

0

17S

0

20

3

Om

0

17S

0

20

0

03

0

17S

0

20

O

34S

mrn

The

correct

shinjs

are

O

OS

plus

0

10

plus

0

20

mrn

thick

Right

side

T2

B

D

H

xO

0l

O

ISO

F

3

0

2

x

om

O

ISO

0

17

3

0

2

x

om

0

150

0

17

S

x

0

01

0

ISO

0

I7

O

OS

0

1S0

0

17

0

37

mrn

The

correct

shims

are

0

07

plus

0

1

0

plus

0

20

mm

thick

Note

If

w1ues

signifying

A

B

C

0

and

H

are

not

given

regard

them

as

zero

and

compute

Aft

assembly

check

to

see

that

preload

and

backlash

are

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

O

OS

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

adjusting

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST33230000

and

Adapter

ST33061000

3

Install

differential

case

assembly

into

gear

carrie

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tight

n

bolts

to

specified

torque

Tightening

torque

4

0

to

S

O

kg

m

29

to

36

fHb

S

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

small

remove

shims

from

left

side

and

add

them

to

right

side

To

reduce

backlash

remove

shims

from

right

side

and

add

them

to

left

side

Backlash

O

1S

to

0

20

mrn

0

00S9

to

0

0079

in

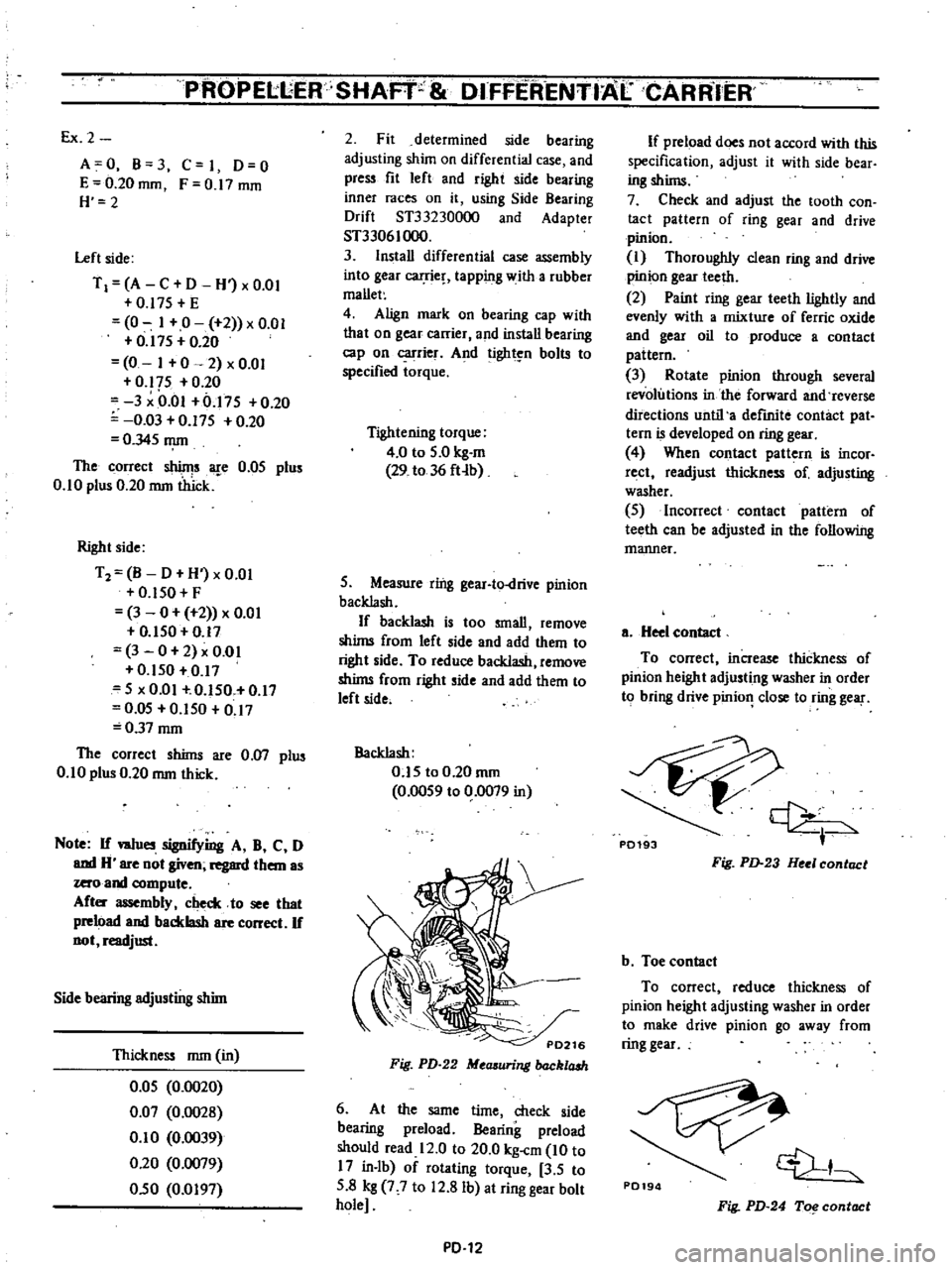

Fig

PD

22

Mccuuring

back1aah

6

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

read

12

0

to

20

0

kg

cm

10

to

17

in

lb

of

rotating

torque

3

S

to

S

8

kg

7

7

to

12

8

Ib

at

ring

gear

bolt

hole

PD

12

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bear

ing

shims

7

Check

and

adjust

the

tooth

con

tact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

ferric

oxide

and

gear

oil

to

produce

a

contact

pattern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

directions

until

a

defmite

contact

pat

tern

is

developed

on

ring

gear

4

When

contact

pattern

is

incor

rect

readjust

thickness

of

adjusting

washer

S

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

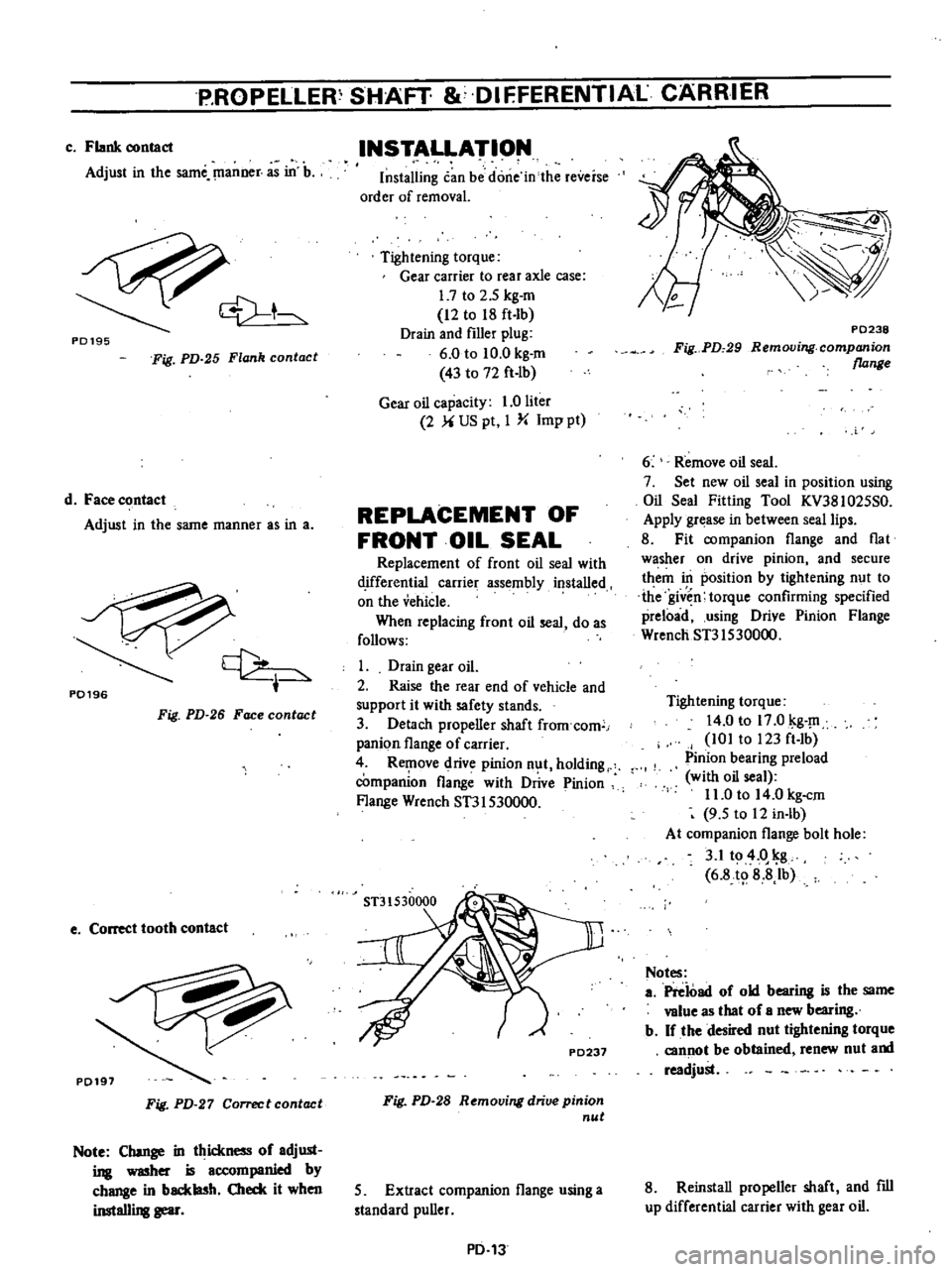

a

Heel

contact

To

correct

increase

thickness

of

pinion

height

adjusting

washer

in

order

to

bring

drive

pinio

close

to

ring

gear

P0193

Fig

PD

23

Hul

contact

b

Toe

contact

To

correct

reduce

thickness

of

pinion

height

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

P0194

1

Fig

PD

24

To

contact

Page 341 of 537

P

ROPELLER

SHAFT

DIFFERENTIAL

CARRIER

c

Flank

oontact

Adjust

in

the

same

manner

as

in

b

cV

t

PD195

Fig

PD

25

Flank

contact

d

Face

contact

Adjust

in

the

same

manner

as

in

a

P0196

t

Fig

PD

26

Face

contact

e

Correct

tooth

contact

Fig

PD

27

Correct

contact

Note

Change

in

thickness

of

adjWll

ing

washer

is

accompanied

by

change

in

backlash

Oled

it

when

instaIIi

gear

INSTALLATION

Installing

can

be

done

in

the

reverse

order

of

removal

Tightening

torque

Gear

carrier

to

rear

axle

case

1

7

to

2

5

kg

m

12

to

18

ft

lb

Drain

and

filler

plug

6

0

to

10

0

kg

m

43

to

72

ft

lb

Gear

oil

capacity

1

0

liter

2

US

pt

I

Y

Imp

pt

REPLACEMENT

OF

FRONT

OIL

SEAL

Replacement

of

front

oil

seal

with

d

ifferential

carrier

assembly

installed

on

the

vehicle

When

replacing

front

oil

seal

do

as

follows

1

Drain

gear

oil

2

Raise

the

rear

end

of

vehicle

and

support

it

with

safety

stands

3

Detach

propeller

shaft

from

com

panion

flange

of

carrier

4

R

1

ove

drive

pinion

n

t

holding

companion

flange

with

Drive

Pinion

Flange

Wrench

ST31S30000

P0238

Fig

PD

29

Removing

companion

flange

6

Remove

oil

seal

7

Set

new

oil

seal

in

position

using

Oil

Seal

Fitting

Tool

KV38102SS0

Apply

grease

in

between

seal

lips

8

Fit

companion

flange

and

flat

w

sher

on

drive

pinion

and

secure

them

in

position

by

tightening

nut

to

the

given

torque

confirming

specified

preload

using

Drive

Pinion

Flange

WrencliST31530000

Tightening

torque

14

0

to

17

0

kg

101

to

123

ft

Ib

Pinion

bearing

preload

with

oil

seal

11

0

to

14

0

kg

cm

9

5

to

12

in

lb

At

companion

flange

bolt

hole

3

1

to

4

o

g

6

8

8

8Ib

Notes

a

Preioad

of

old

bearing

is

the

same

value

as

that

of

a

new

bearing

b

If

the

desired

nut

tightening

torque

P0237

can

ot

be

obtained

renew

nut

and

readjust

Fig

PD

28

R

moving

drive

pinion

nut

S

Extract

companion

flange

using

a

standard

puller

PD

13

8

Reinstall

propeller

shaft

and

fill

up

differential

carrier

with

gear

oil

Page 342 of 537

PROPELLER

SHAFT

DIFFERENTIAl

CARRIER

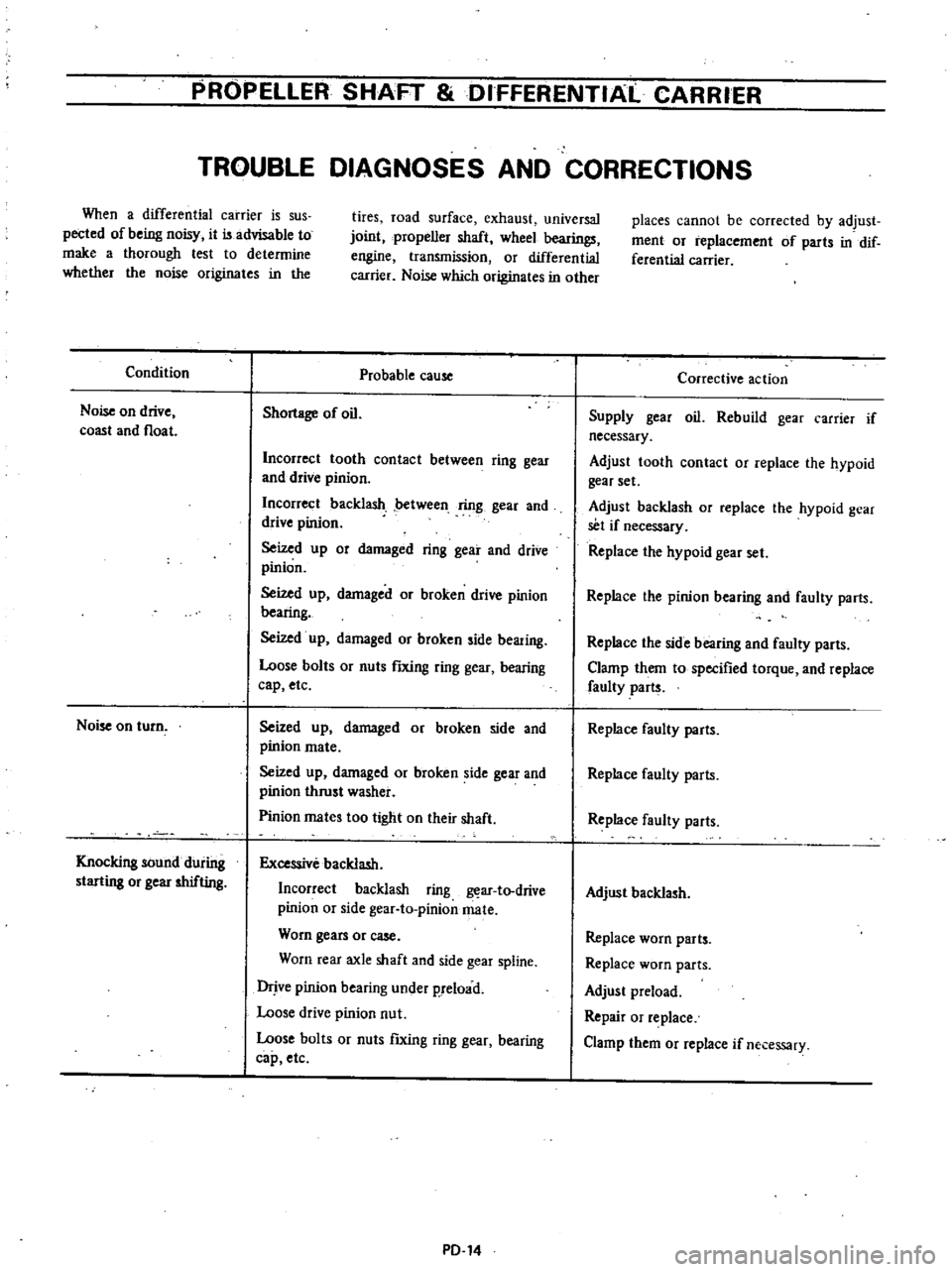

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

lest

to

determine

whether

the

noise

originates

in

the

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

other

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loose

bolts

or

nuts

fIXing

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

mate

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

mates

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

ar

to

drive

pinion

or

side

gear

to

pinionmate

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Drjve

pinion

bearing

under

p

reload

Loose

drive

pinion

nut

Loose

bolts

or

nuts

ftxing

ring

gear

bearing

cap

etc

PD

14

places

cannot

be

corrected

by

adjust

ment

or

replacement

of

parts

in

dif

ferential

carrier

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

faulty

parts

Replace

the

side

bearing

and

faulty

parts

Clamp

them

to

specified

torque

and

replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Page 343 of 537

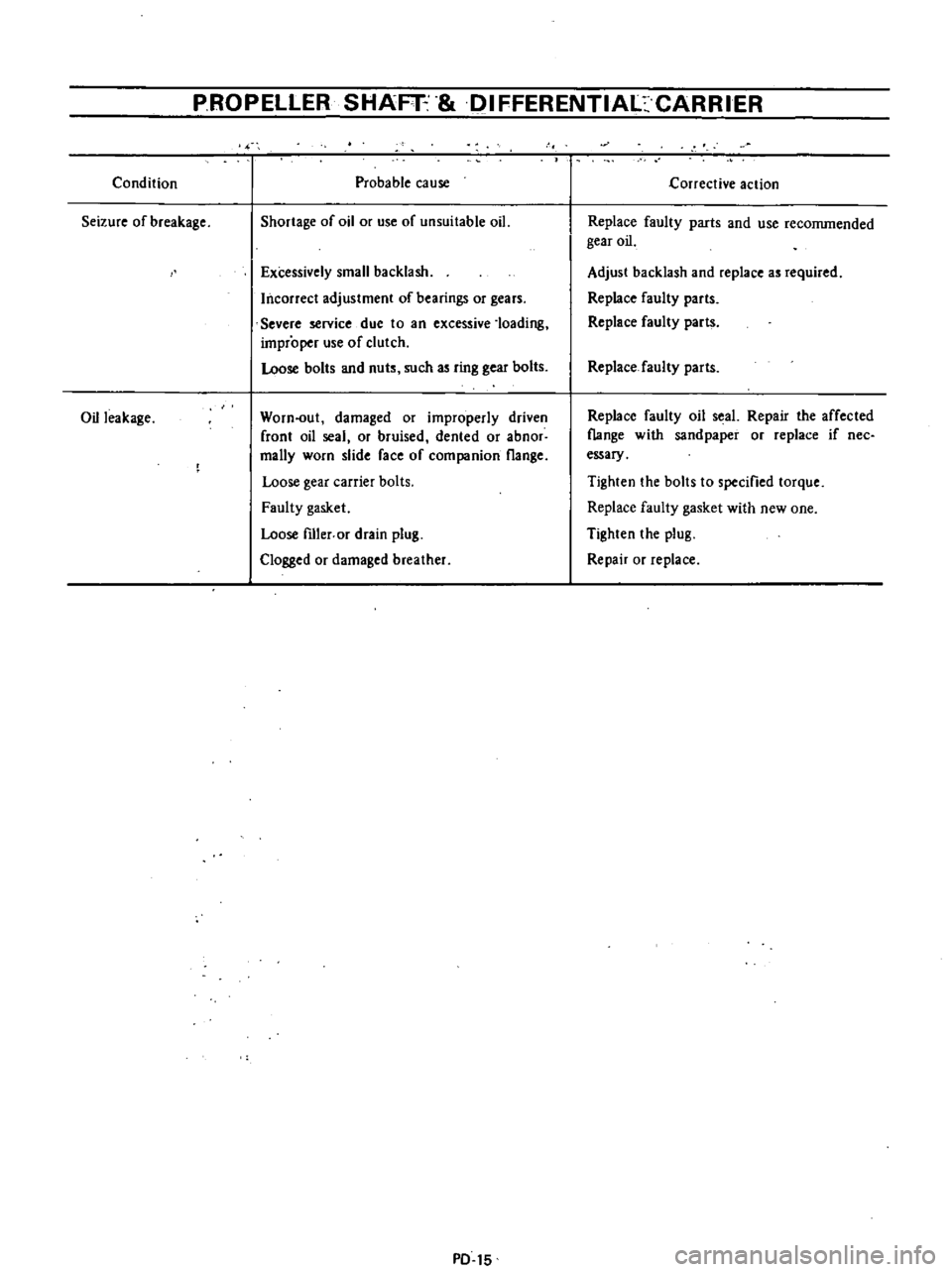

Condition

Seizure

of

breakage

Oil

leakage

PROPELLER

SHAFT

IFFERENTIAl

CARRIER

Probable

cause

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loose

bolts

and

nuts

such

as

ring

gear

bolts

Worn

out

damaged

or

improperly

driven

front

oil

seal

or

bruised

dented

or

abnor

mally

worn

slide

face

of

companion

flange

Loose

gear

carrier

bolts

Faulty

gasket

Loose

fIller

or

drain

plug

Clogged

or

damaged

breather

PD

15

1

j

Corrective

action

Replace

faulty

parts

and

use

reconunended

gear

oil

Adjust

backlash

and

replace

as

required

Replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Replace

faulty

oil

seal

Repair

the

affected

flange

with

sandpaper

or

replace

if

nee

essary

Tighten

the

bolts

to

specified

torque

Replace

faulty

gasket

with

new

one

Tighten

the

plug

Repair

or

replace

Page 344 of 537

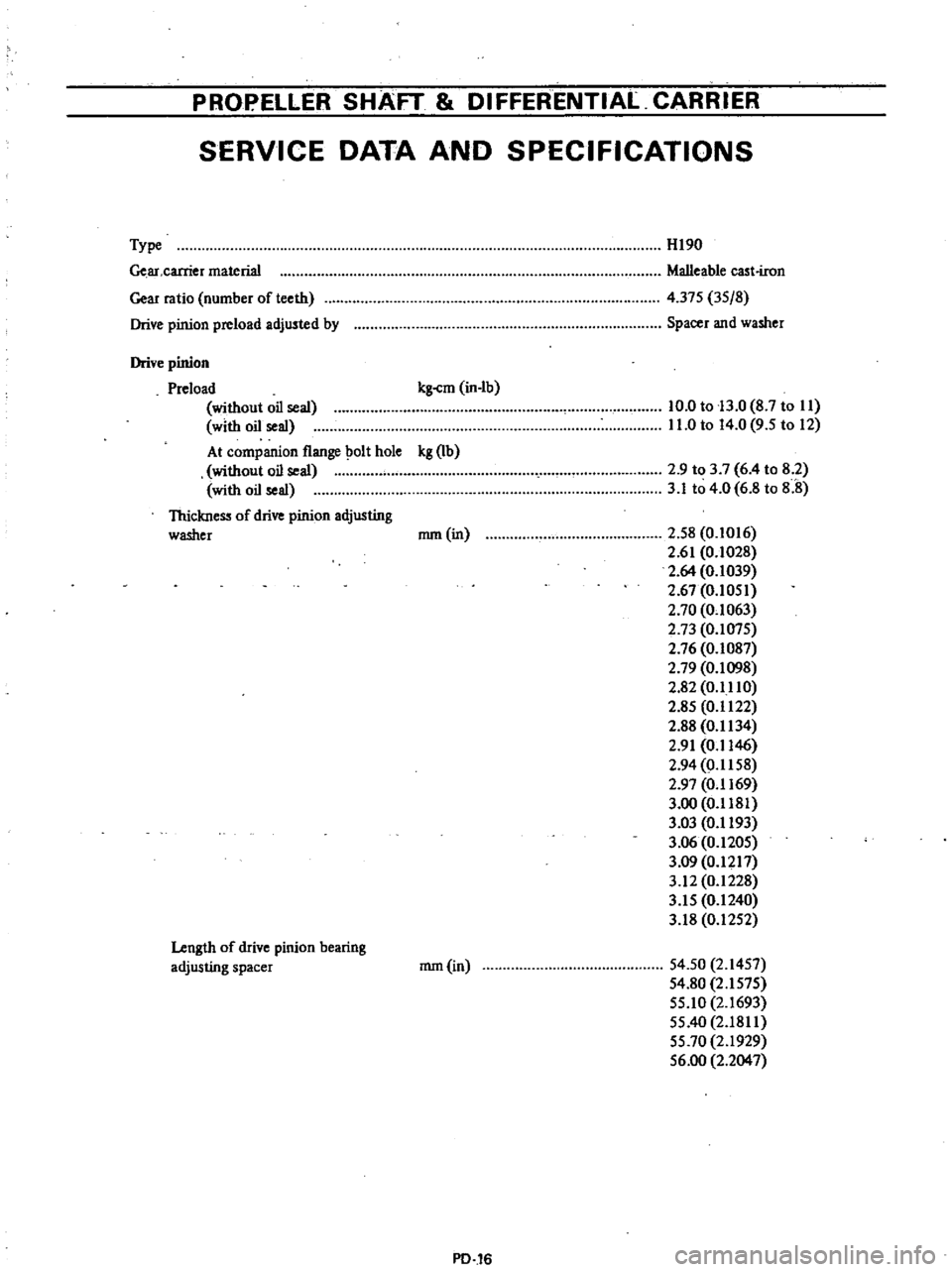

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

SERVICE

DATA

AND

SPECIFICATIONS

Type

Ge

ar

carrier

material

Gear

ratio

number

of

teeth

Drive

pinion

preload

adjusted

by

HI90

Malleable

cast

iron

4

375

3S

8

Spacer

and

washer

Drive

pinion

Preload

kg

cm

in

Ib

without

oil

seal

with

oil

seal

At

companion

flange

olt

hole

kg

Ib

without

oil

seal

with

oil

seal

Thickness

of

drive

pinion

adjusting

washer

nun

in

10

0

to

13

0

8

7

to

II

11

0

to

14

0

9

5

to

12

2

9

to

3

7

6

4

to

8

2

3

1

to

4

0

6

8

to

8

8

2

S8

0

1016

2

61

0

1028

2

64

0

1039

2

67

0

IOSI

2

70

0

1063

2

73

O

I07S

2

76

0

1087

2

79

0

1098

2

82

0

1110

2

8S

0

1122

2

88

0

1134

2

91

0

1146

2

94

0

1158

2

97

0

1169

3

00

0

1181

3

03

0

1193

3

06

0

120S

3

09

0

1217

3

12

0

1228

3

IS

0

1240

3

18

0

12S2

Length

of

drive

pinion

bearing

adjusting

spacer

nun

in

S4

50

2

14S7

54

80

2

IS7S

SS

IO

2

1693

SS

40

2

1811

SS

70

2

1929

S6

00

2

2047

PD

16

Page 345 of 537

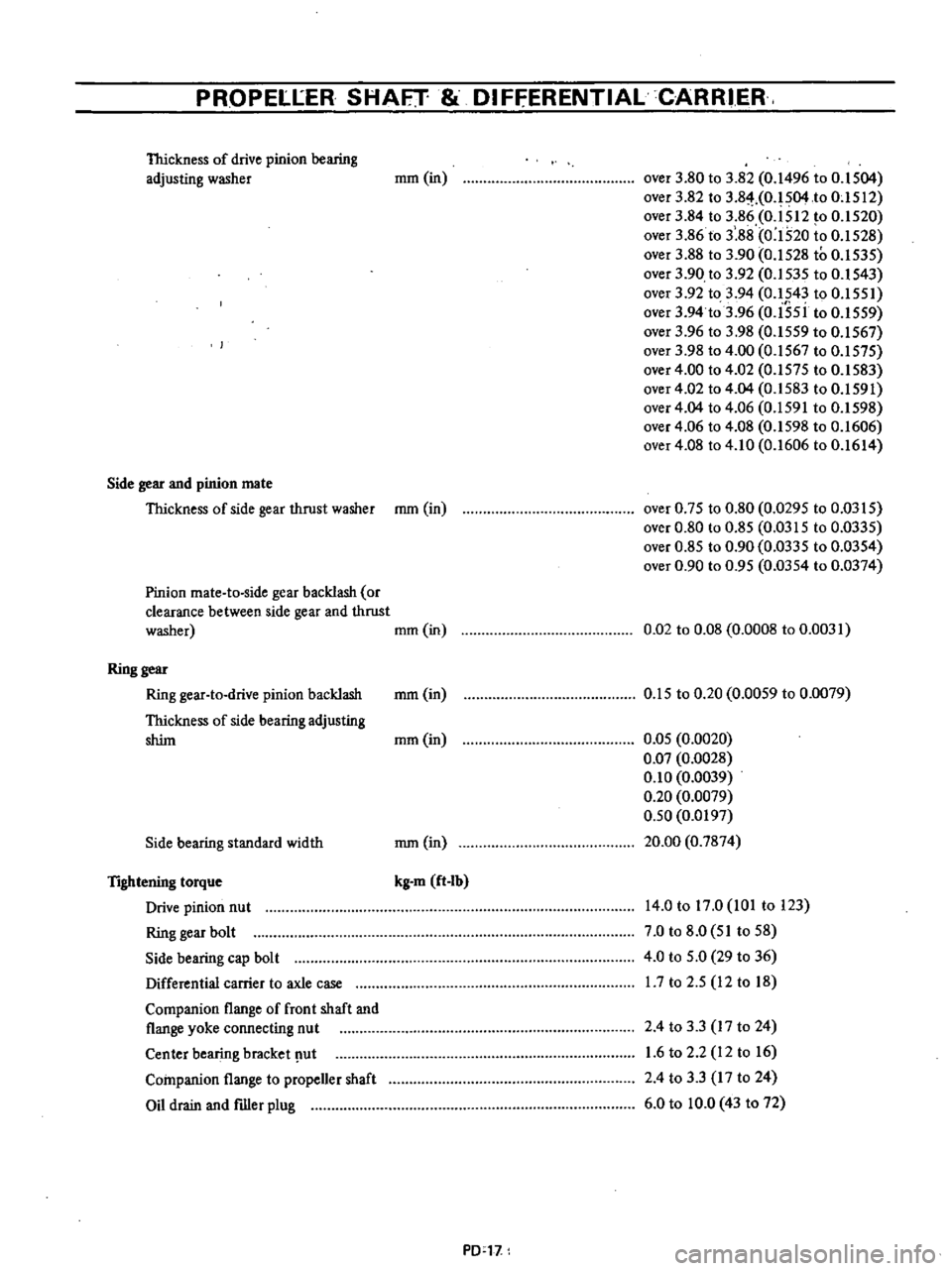

PROPELlER

SHAFT

DIFfERENTIALCARRI

ER

Thickness

of

drive

pinion

bearing

adjusting

washer

mm

in

over

3

80

to

3

82

0

1496

to

O

IS04

over

3

82

to

3

8

HO

IS04

to

OcISI2

over

3

84

to

3

86

0

ISI2

to

0

IS20

over

3

86

to

3

88

0

1520

to

0

IS28

over

3

88

to

3

90

0

IS28

to

0

IS3S

over

3

90

to

3

92

0

IS3S

to

0

1S43

over

3

92

to

3

94

0

1543

to

O

ISSI

over

3

94

to

3

96

0

I5si

to

0

ISS9

over

3

96

to

3

98

0

I5S9

to

0

IS67

over

3

98

to

4

00

0

1567

to

0

IS7S

over

4

00

to

4

02

0

157S

to

0

IS83

over

4

02

to

4

04

0

IS83

to

0

IS91

over

4

04

to

4

06

0

IS91

to

0

IS98

over

4

06

to

4

08

0

1598

to

0

1606

over

4

08

to

4

10

0

1606

to

0

1614

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washer

mOl

in

over

0

7S

to

0

80

0

029S

to

0

03IS

over

0

80

to

0

8S

0

03IS

to

0

033S

over

0

8S

to

0

90

0

0335

to

0

03S4

over

0

90

to

0

9S

0

03S4

to

0

0374

Pinion

mate

to

side

gear

backlash

or

clearance

between

side

gear

and

thrust

washer

mOl

in

0

02

to

0

08

0

0008

to

0

0031

Ring

gear

Ring

gear

to

drive

pinion

backlash

mm

in

Thickness

of

side

bearing

adjusting

shim

mOl

in

O

1S

to

0

20

0

00S9

to

0

0079

Side

bearing

standard

width

mm

in

O

OS

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

20

00

0

7874

TIghtening

torque

Drive

pinion

nut

Ring

gear

bolt

Side

bearing

cap

bolt

Differential

carrier

to

axle

case

Companion

flange

of

front

shaft

and

flange

yoke

connecting

nut

Center

bearing

bracket

ut

Companion

flange

to

propeller

shaft

Oil

drain

and

filler

plug

kg

m

ft

Ib

14

0

to

17

0

101

to

123

7

0

to

8

0

SI

toS8

4

0

to

S

O

29

to

36

17

to

2

S

12

to

18

2

4

to

3

3

17

to

24

1

6

to

2

2

12

to

16

2

4

to

3

3

17

to

24

6

0

to

10

0

43

to

72

PD

l1

Page 346 of 537

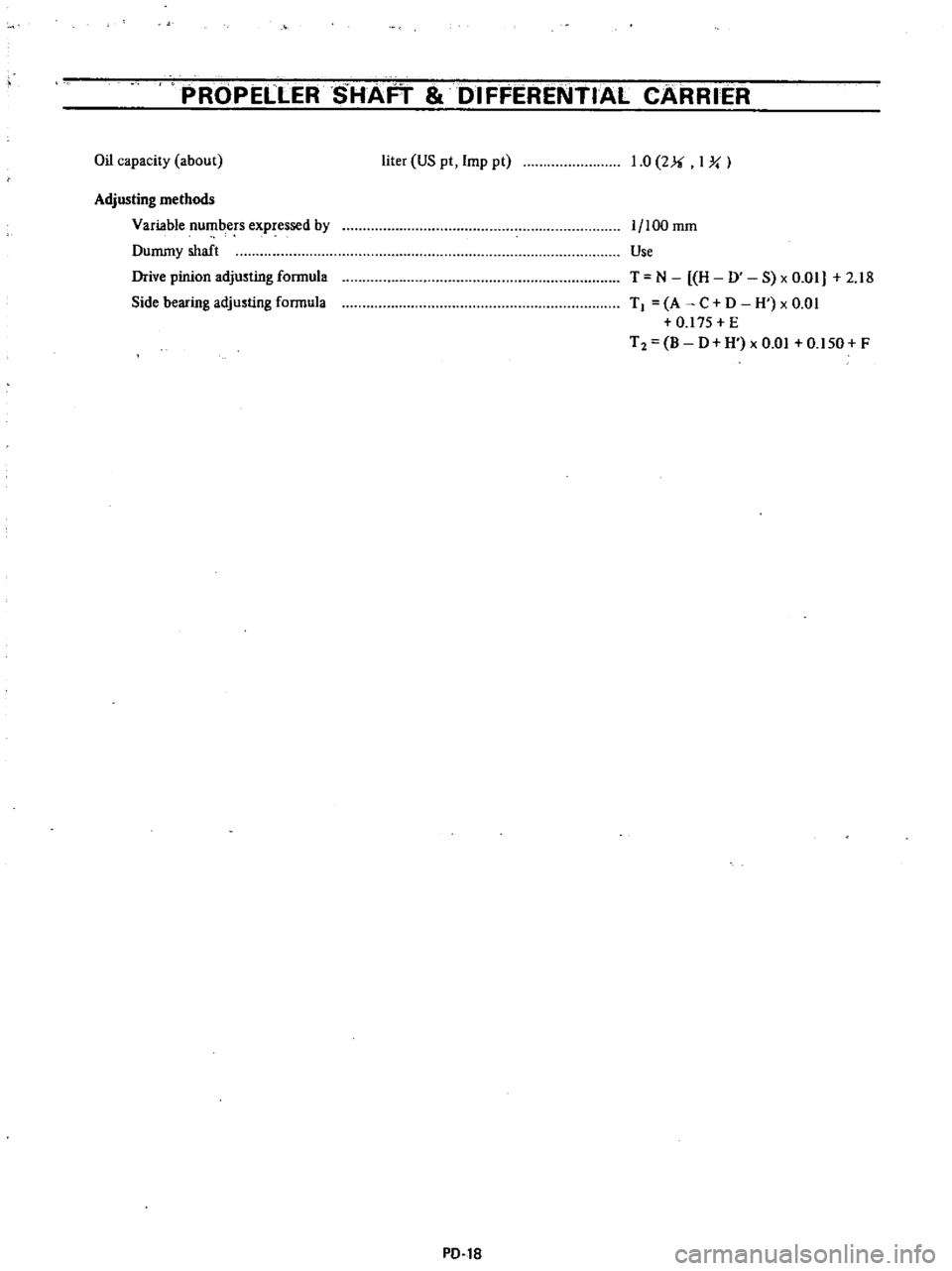

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Oil

capacity

about

liter

US

pt

Imp

pt

1

0

2Ji

I

Y

Adjusting

methods

Variable

numbers

expressed

by

Dummy

shaft

Drive

pinion

adjusting

fonnula

Side

bearing

adjusting

fonnula

1

100

mOl

Use

T

N

H

0

S

x

0

01

2

18

TI

A

C

D

H

xO

OI

0

17S

E

T2

B

0

H

x

0

01

0

150

F

PD

18

Page 348 of 537

PROPELEER

SHAFT

GIFFERENTIAl

CARRIER

No

Tool

number

tool

name

Description

Unit

nUll

in

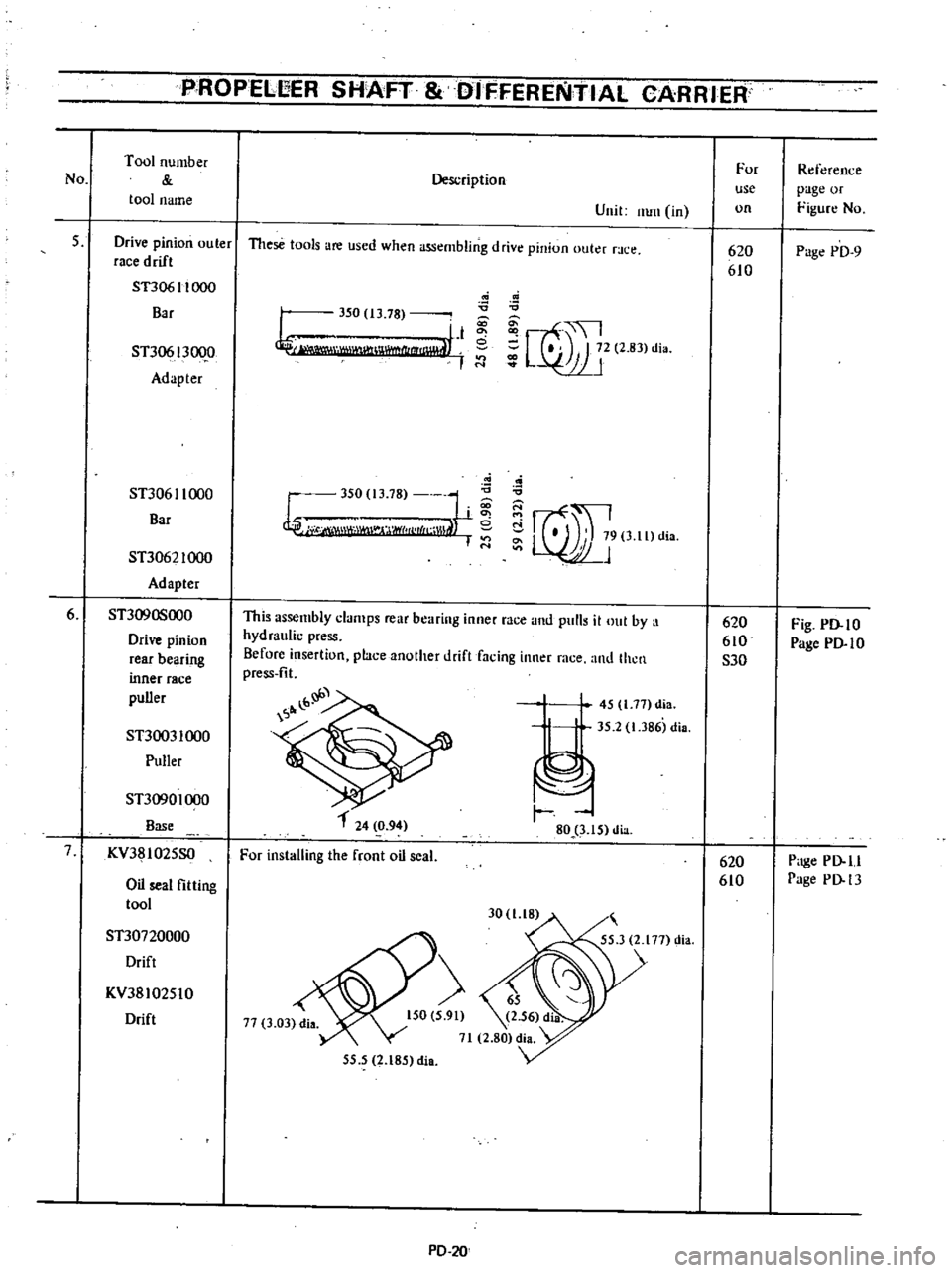

5

Drive

pinion

outer

These

tools

are

used

when

assembling

drive

pinion

outer

race

race

drift

ST30611000

Bar

ST306130qo

Adapter

ST30611oo0

Bar

ST3062

1000

Adapter

6

ST309OS000

Drive

pinion

rear

bearing

inner

race

puller

ST3003Ioo0

Puller

ST30901000

Base

7

0

i

350

13

78

i

Wt

UWr

fl

I

fl

UU

ti

t

0

350

13

78

1

j

L

I

I

II

e

G

0

l

L

J2

2

83

dia

0

g

I

2l

7

9

3

11

dia

j

This

assembly

clamps

rear

bearing

inner

race

and

pulls

it

out

by

a

hydranlic

press

Before

insertion

place

another

drift

facing

inner

race

and

then

press

fit

lb

l

24

0

94

KV38102SSO

For

installing

the

front

oil

seal

Oil

seal

filling

tool

ST30720000

Drift

KV38102SIO

Drift

45

1

17

dia

35

2

1

386

dia

80g

5

dia

55

5

2

185

dia

PD

20

Fur

Reference

use

page

or

on

Figure

No

620

Page

PD

9

610

620

610

S30

620

610

Fig

PO

IO

Page

PD

IO

Page

PO

U

Page

PO

l3

Page 356 of 537

Components

Rust

Discoloring

Race

and

roller

u

u

e

2

2

0

3

0

t

c

6

6

6

Fig

h

The

wheel

bearing

is

serv

iceable

if

discoloring

can

be

removed

with

solvent

or

by

polishing

f

a

Inner

race

flaking

t

d

Cracked

roller

iT

t

j

t

11

1

1

t

t

I

l

1

t

F

1ll

JJ

J

t

I

1

ollf

oe

c

g

Recess

on

foDer

Front

Axle

Front

Suspension

Cause

Temperature

increased

during

operation

lowers

when

the

bearing

stops

moisture

inside

the

bearing

is

condensed

becoming

fine

drips

and

the

grease

is

moistened

The

bearing

has

been

placed

in

a

highly

moistened

place

for

a

long

period

of

time

Intrusion

of

moisture

chemicals

etc

or

the

bearing

is

touched

with

bare

hand

and

no

rustproof

action

has

been

taken

Slight

discoloring

may

become

like

oxidized

oil

stain

due

to

grease

In

the

most

cases

this

occurs

when

preliminary

pressure

is

too

high

I

I

I

1

v

i

n

dJ

b

RoUer

flaking

c

Cracked

inner

race

c

f

J

Jt

v

l

e

Recess

on

inner

race

f

Recess

on

outer

race

h

Rust

outer

race

F

A007

Fig

FA

12

Defective

conditions

of

bearing

FA

7