bulb DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 459 of 537

Body

Electrical

System

METERS

AND

GAUGES

COMBINATION

METER

COMBINATION

METER

CIRCUIT

DIAGRAM

REMOVAL

AND

INSTALLATION

SPEEDOMETER

REMOVAL

AND

INSTALLATION

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRIPTION

REMOVAL

AND

INSTALLATION

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

01

L

PRESSURE

SWITCH

COMBINATION

METER

COMBINATION

METER

CIRCUIT

DIAGRAM

@

BE6828

CONTENTS

BE

14

BE

14

BE

16

BE

16

BE

16

BE

16

8E

16

BE

16

BE

16

BE

16

8E

17

BE

17

BE

17

Turn

signal

indicator

lamp

L

H

OIL

0

BEAM

BE

14

Meter

illumination

lamps

M

T

only

9

9

Turn

sq

nal

indicator

lamp

lL

J

R

H

Tj

O

iJ

I

l

g

r

i

o

I

l8

J

CHARGE

WARNING

LAMP

DESCRIPTION

HAND

BRAKE

WARNING

LAMP

DESCRIPTION

HAND

BRAKE

SWITCH

METER

ILLUMINATION

INDICATOR

AND

WARNING

BULBS

REMOVAL

AND

INSTALLATION

8ULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPEEDOMETER

WATER

TEMPERATURE

AND

FUEL

GAUGES

OIL

PRESSURE

AND

CHARGE

WARNING

LAMPS

Voltage

regulator

TEMP

FUEL

CHG

0

BRK

C

I

Speedometer

2

Thermometer

3

Fuel

meter

4

Tachometer

Option

5

Cluster

lid

6

Speedometer

cable

7

Speed

switch

amplifier

Manual

transmission

only

BE

17

BE

17

BE

18

BE

18

8E

18

8E

18

BE

18

BE

18

BE

18

BE

18

BE

19

BE

20

Q

Speed

switch

BE856A

Fig

BE

21

Ci1

Cuit

diagram

of

combination

meter

Page 463 of 537

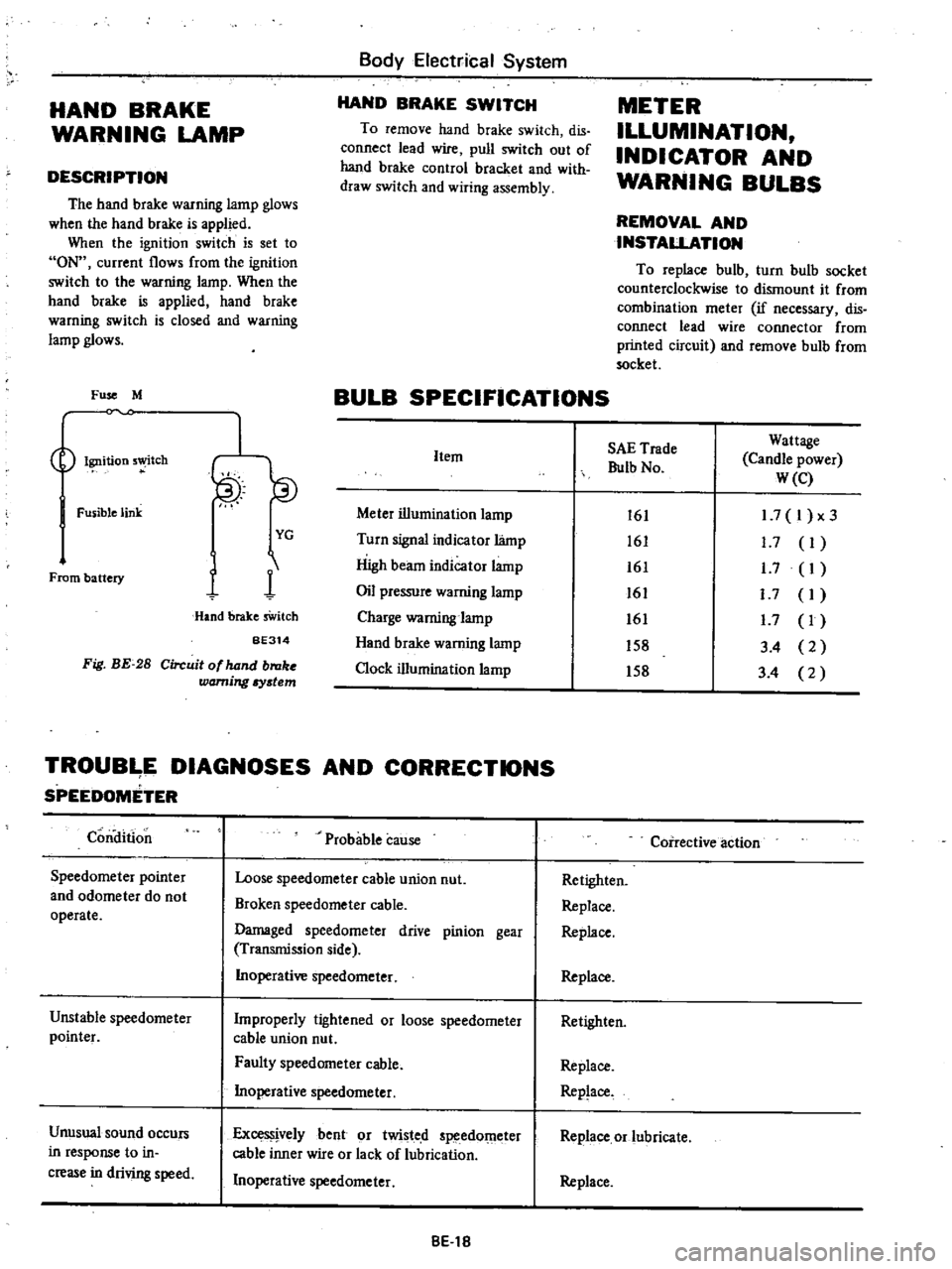

HAND

BRAKE

WARNING

LAMP

DESCRIPTION

The

hand

brake

warning

lamp

glows

when

the

hand

brake

is

applied

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

ignition

switch

to

the

warning

lamp

When

the

hand

brake

is

applied

hand

brake

warning

switch

is

closed

and

warning

lamp

glows

Fuse

M

Ignition

5

tch

Fusible

link

From

battery

I

YG

1

1

Hand

brake

sWitch

BE314

Fig

BE

28

Circuit

of

hand

broke

warning

Iystem

Body

Electrical

System

HAND

BRAKE

SWITCH

To

remove

hand

brake

switch

dis

connect

lead

wire

pull

switch

out

of

hand

brake

control

bracket

and

with

draw

switch

and

wiring

assembly

METER

ILLUMINATION

INDICATOR

AND

WARNING

BULBS

REMOVAL

AND

INSTALLATION

To

replace

bulb

turn

bulb

socket

counterclockwise

to

dismount

it

from

combination

meter

if

necessary

dis

connect

lead

wire

connector

from

printed

circuit

and

remove

bulb

from

socket

BULB

SPECIFICATIONS

Item

Meter

illumination

lamp

Turn

signal

indicator

lamp

High

beam

indicator

lamp

Oil

pressure

warning

lamp

Charge

warning

lamp

Hand

brake

warning

lamp

Clock

illumination

lamp

SAE

Trade

Bulb

No

Wattage

Candle

power

W

e

161

161

161

161

161

158

158

1

7

I

x3

1

7

I

1

7

I

I

7

I

1

7

I

3

4

2

3

4

2

TROUB

E

DIAGNOSES

AND

CORRECTIONS

SPEEDOMETER

Condition

Speedometer

pointer

and

odometer

do

not

operate

Unstable

speedometer

pointer

Unusual

sound

occurs

in

response

to

in

crease

in

driving

speed

Probable

cause

Loose

speedometer

cable

union

nut

Broken

speedometer

cable

Damaged

speedometer

drive

pinion

gear

Transmission

side

Inoperative

speedometer

Improperly

tightened

or

loose

speedometer

cable

union

nut

Faulty

speedometer

cable

Inoperative

speedometer

ExceS

jvelybent

or

twisted

speedOmeter

cable

inner

wire

or

lack

of

lubrication

Inoperative

speedometer

8El8

Coirective

action

Retighten

Replace

Replace

Replace

Retighten

Replace

Replace

Replace

or

lubricate

Replace

Page 465 of 537

Condition

Fuel

gauge

Fuel

gauge

does

not

operate

Pointer

indicates

only

F

position

Body

Electrical

System

Probable

cause

Faulty

tank

unit

or

loose

unit

terminal

connection

pointer

indicates

a

half

level

when

a

35U

resistance

is

connected

between

tank

unit

yellow

wire

and

ground

Faulty

fuel

gauge

Poor

or

loose

cormection

Open

circuit

Faulty

tank

unit

pointer

lowers

below

E

mark

when

igni

tion

switch

Is

turned

off

Faulty

fuel

gauge

pointer

still

indicates

F

position

when

ignition

switch

is

turned

off

OIL

P

RESSURE

AND

CHARGE

WARNING

LAMPS

Condition

Oil

pressure

wamiug

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

while

engine

is

being

operated

OIarge

warning

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

when

engine

is

started

Probable

cause

Inoperative

oil

pressure

switch

or

loose

switch

terminal

connection

When

switch

yellow

black

wire

is

grounded

warning

lamp

lights

Burnt

bulb

or

loose

bulb

Open

circuit

Lack

of

engine

oil

Oil

pressure

too

low

Inoperative

oil

pressure

switch

Burnt

bulb

or

loose

bulb

Warning

lamp

does

not

light

when

voltage

regulator

white

red

wire

is

grounded

Open

circuit

Faulty

charging

system

BE

20

Corrective

action

Replace

tank

unit

or

correct

terminal

con

nection

Replace

fuel

gauge

Conect

connector

terminal

contact

Replace

tank

unit

Replace

fuel

gauge

Corrective

action

Replace

switch

OJ

correct

terminal

connee

tion

Replace

bulb

or

correct

bulb

socket

Check

oil

level

and

add

oil

as

required

Inspect

engine

oil

pressure

system

Replace

oil

pressure

switch

Replace

bulb

or

correct

bulb

socket

Inspect

charging

system

Page 466 of 537

Body

Electrical

System

ELECTRICAL

ACCESSORIES

CONTENTS

HORN

DESCRIPTION

REMOVAL

AND

INSTALLATION

IGNITION

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

WINDSHIELD

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

INSPECTION

RADIO

REMOVAL

AND

INSTALLATION

ADJUSTMENT

CLOCK

REMOVAL

I

NST

ALLA

TION

HEATER

DESCRIPTION

AIRFLOW

HEATER

UNIT

ASSEMBLY

BE

21

BE

21

BE

21

8E

n

BE

22

BE

22

BE

23

BE

23

BE

23

BE

25

BE

25

BE

25

BE

25

BE

25

BE

26

BE

26

BE

26

BE

28

BE

29

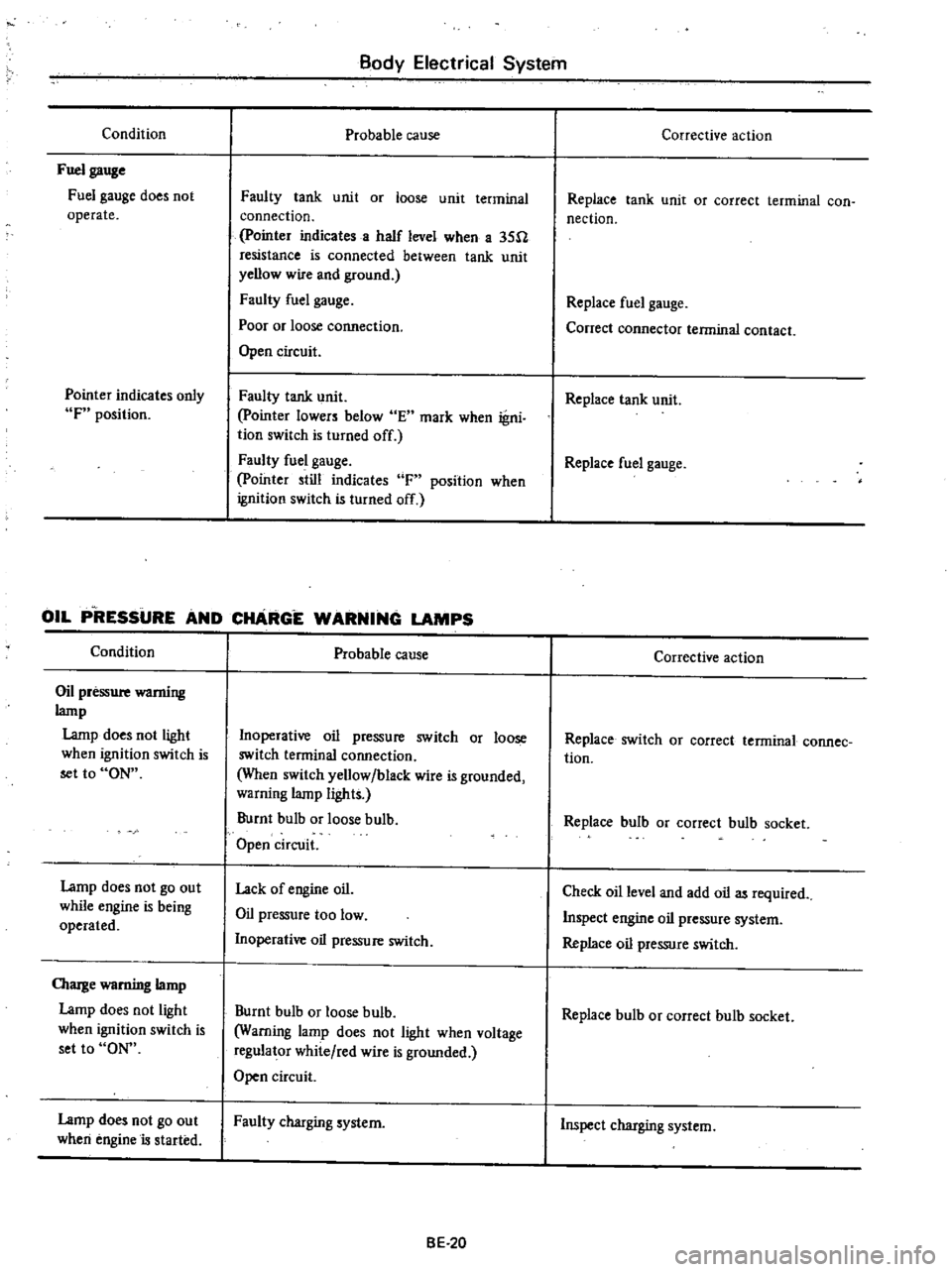

HORN

DESCRIPTION

The

horn

circuit

includes

a

horn

relay

Current

from

the

battery

flows

through

the

fusible

link

and

fuse

to

the

horn

relay

terminal

B

where

it

is

shunted

by

the

two

circuits

In

one

circuit

terminal

S

the

current

flow

is

supplied

through

the

solenoid

and

Fusible

link

Qi

att

Fu

H

I

HIBQ

t

J

JJI

L

J

Hornrelay

Qm

HEATER

CORE

FAN

MOTOR

CONTROL

ASSEMBLY

ADJUSTMENT

SPECIFICATIONS

TACHOMETER

REPLACEMENT

8UL8

REPLACEMENT

SEAT

8ELT

WARNING

SYSTEM

DESCRIPTION

REMOVAL

AND

INSTALLATION

WARNING

LAMP

BULB

REPLACEMENT

INSPECTION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

WINDSHIELD

WIPER

AND

WASHER

RADIO

Horn

button

BE859A

Fig

BE

29

Circuit

diagram

of

horn

sy

tem

horn

button

to

the

ground

In

the

other

circuit

terminal

H

the

current

flow

is

supplied

through

the

relay

contacts

and

horn

Horn

bracket

serves

as

a

grounding

When

the

horn

button

is

pressed

current

from

the

battery

energizes

the

solenoid

As

the

solenoid

is

energized

the

relay

contacts

are

closed

This

allows

the

current

to

flow

to

the

horn

BE

21

REMOVAL

AND

INSTALLATION

Horn

8E

29

BE

29

BE

29

8E

29

BE

30

BE

30

BE

30

8E

30

8E

31

BE

31

BE

31

8E

31

8E

31

BE

33

8E

33

8E

34

BE

35

I

Disconnect

battery

ground

cable

2

Disconnect

horn

wire

at

terminal

on

horn

body

3

Remove

horn

retaining

bolt

4

Install

horn

in

the

reverse

se

quence

of

removal

Horn

relay

The

horn

relay

is

installed

on

the

hoodIedge

on

the

right

side

of

the

engine

compartment

I

Disconnect

battery

ground

cable

2

Disconnect

horn

relay

wire

con

nector

at

terminals

on

horn

relay

3

Remove

retaining

screws

4

Install

horn

relay

in

the

reverse

sequence

of

removal

Page 475 of 537

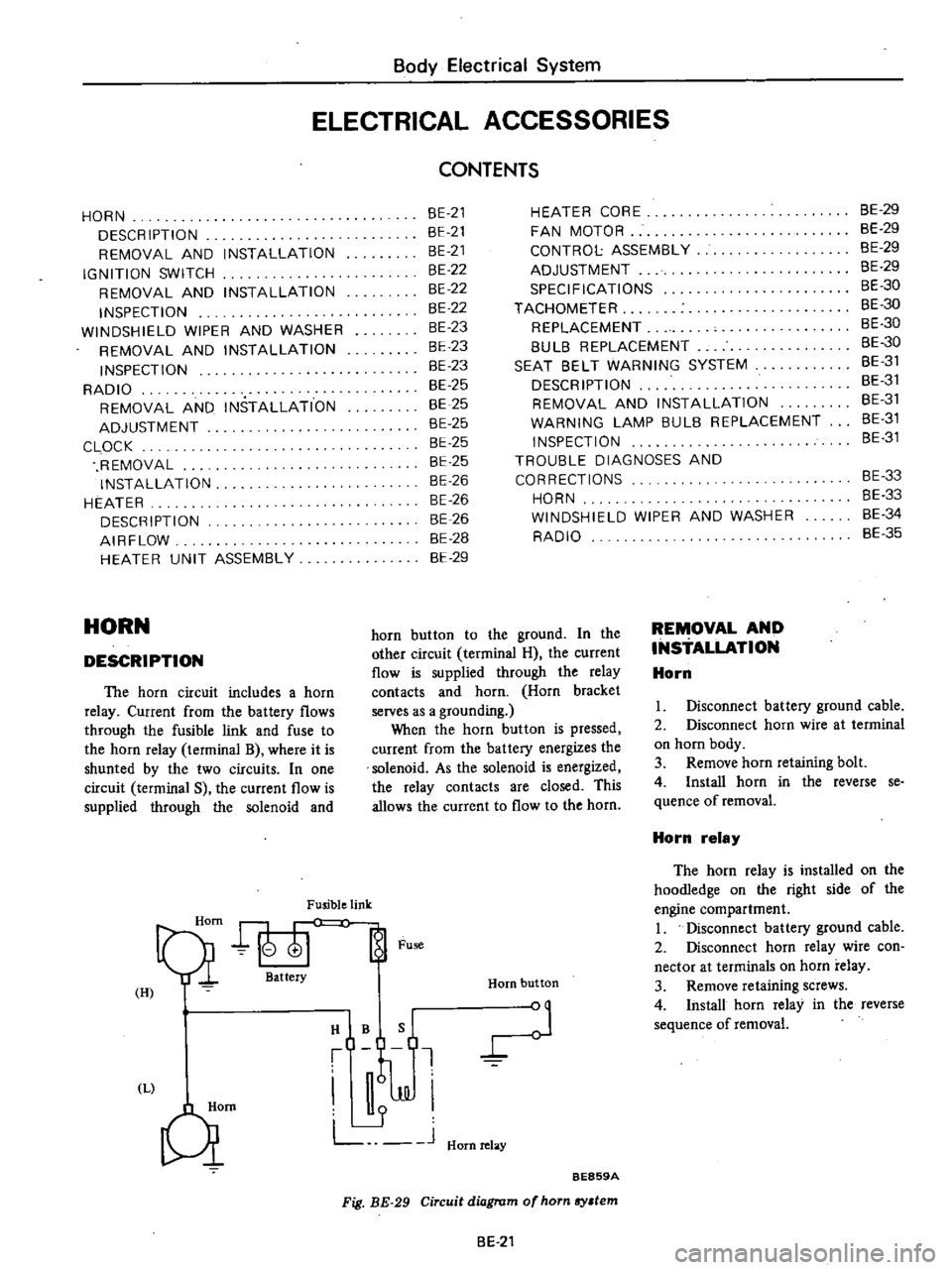

TEMP

lever

1

Move

TEMP

lever

to

the

OFF

position

2

Connect

control

cable

to

the

lever

of

water

ock

when

water

cock

lever

is

pulled

forward

fully

closed

3

Install

control

cable

on

water

cock

bracket

with

cable

retaining

clip

SPECIFICATIONS

Item

FAN

MOTOR

Rated

power

consumption

Revolution

rpm

Fan

dia

mm

in

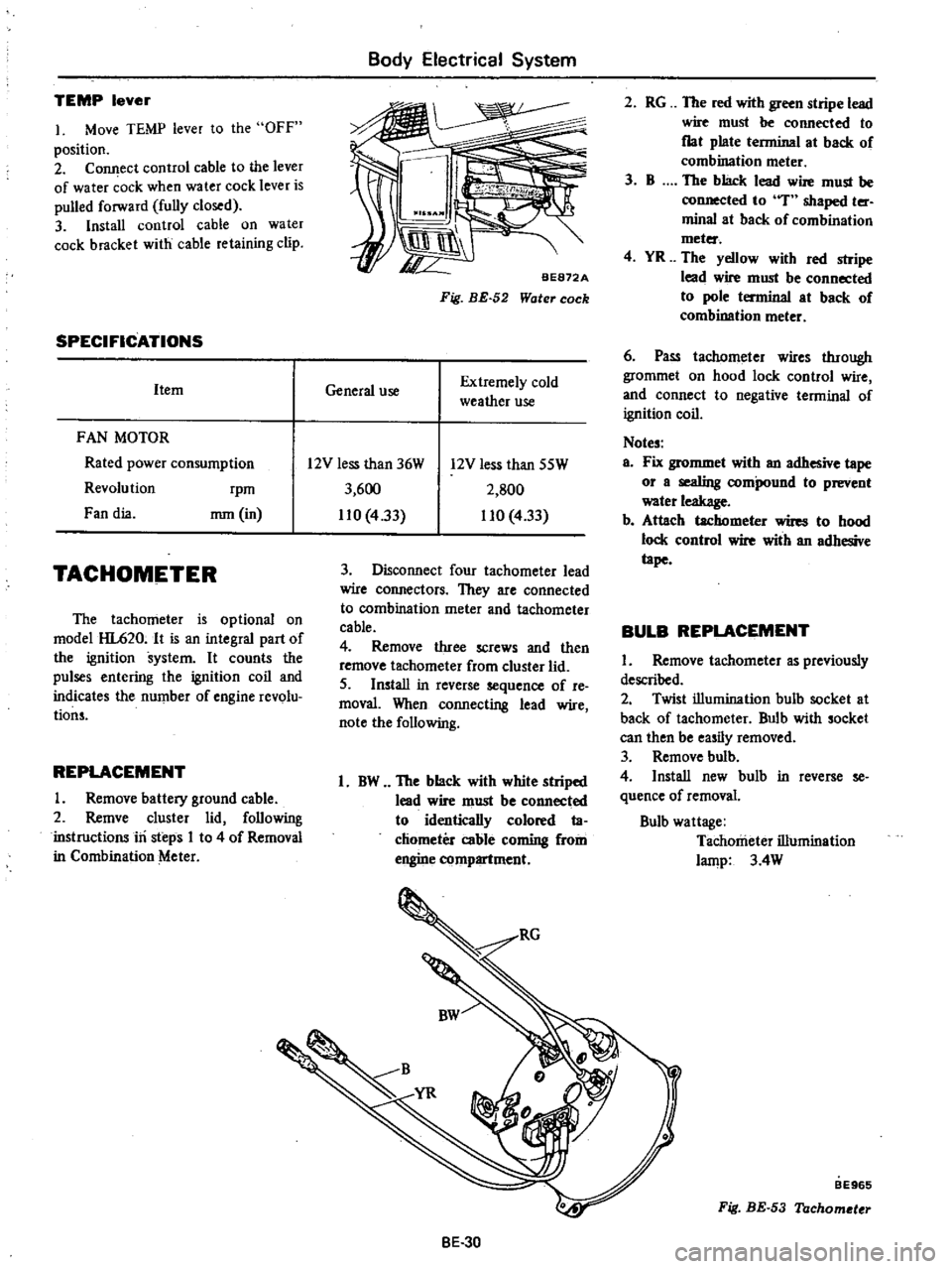

TACHOMETER

The

tachometer

is

optional

on

model

HL620

It

is

an

integral

part

of

the

ignition

system

It

counts

the

pulses

entering

the

ignition

coil

and

indicates

the

number

of

engine

revolu

tions

REPLACEMENT

I

Remove

battery

ground

cable

2

Remve

cluster

lid

following

instructions

iri

steps

I

to

4

of

Removal

in

Combination

Meter

Body

Electrical

System

BE872A

Fig

BE

52

Water

cock

General

use

Extremely

cold

weather

use

2

RG

The

red

with

green

stripe

lead

wire

must

be

connected

to

flat

plate

terminal

at

back

of

combination

meter

3

B

The

black

lead

wire

must

be

connected

to

T

shaped

ter

minal

at

back

of

combination

meter

4

YR

The

yellow

with

red

stripe

lead

wire

must

be

connected

to

pole

terminal

at

back

of

combination

meter

6

Pass

tachllmeter

wires

through

grommet

on

hood

lock

control

wire

and

connect

to

negative

terminal

of

ignition

coil

Notes

a

Fix

grommet

with

an

adhesive

tape

or

a

sealing

compound

to

prevent

water

leakage

b

Attach

tachometer

wires

to

hood

lock

control

wire

with

an

adhesive

tape

BULB

REPLACEMENT

I

Remove

tachometer

as

previously

described

2

Twist

illumination

bulh

socket

at

back

of

tachometer

Bulb

with

socket

can

then

be

easily

removed

3

Remove

bulb

4

Install

new

bulb

in

reverse

se

quence

of

removal

Bulb

wattage

Tachometer

illumination

lamp

3

4W

12V

less

than

36W

3

600

110

433

12V

less

than

SSW

2

SOO

110

4

33

3

Disconnect

four

tachometer

lead

wire

connectors

They

are

connected

to

combination

meter

and

tachometer

cable

4

Remove

three

screws

and

then

remove

tachometer

from

cluster

lid

5

Install

in

reverse

sequence

of

re

moval

When

connecting

lead

wire

note

the

following

1

BW

The

black

with

white

striped

lead

wire

must

be

connected

to

identically

colored

ta

chometer

cable

coming

from

engine

compartment

BE

30

BE965

Fig

BE

53

Tachometer

Page 476 of 537

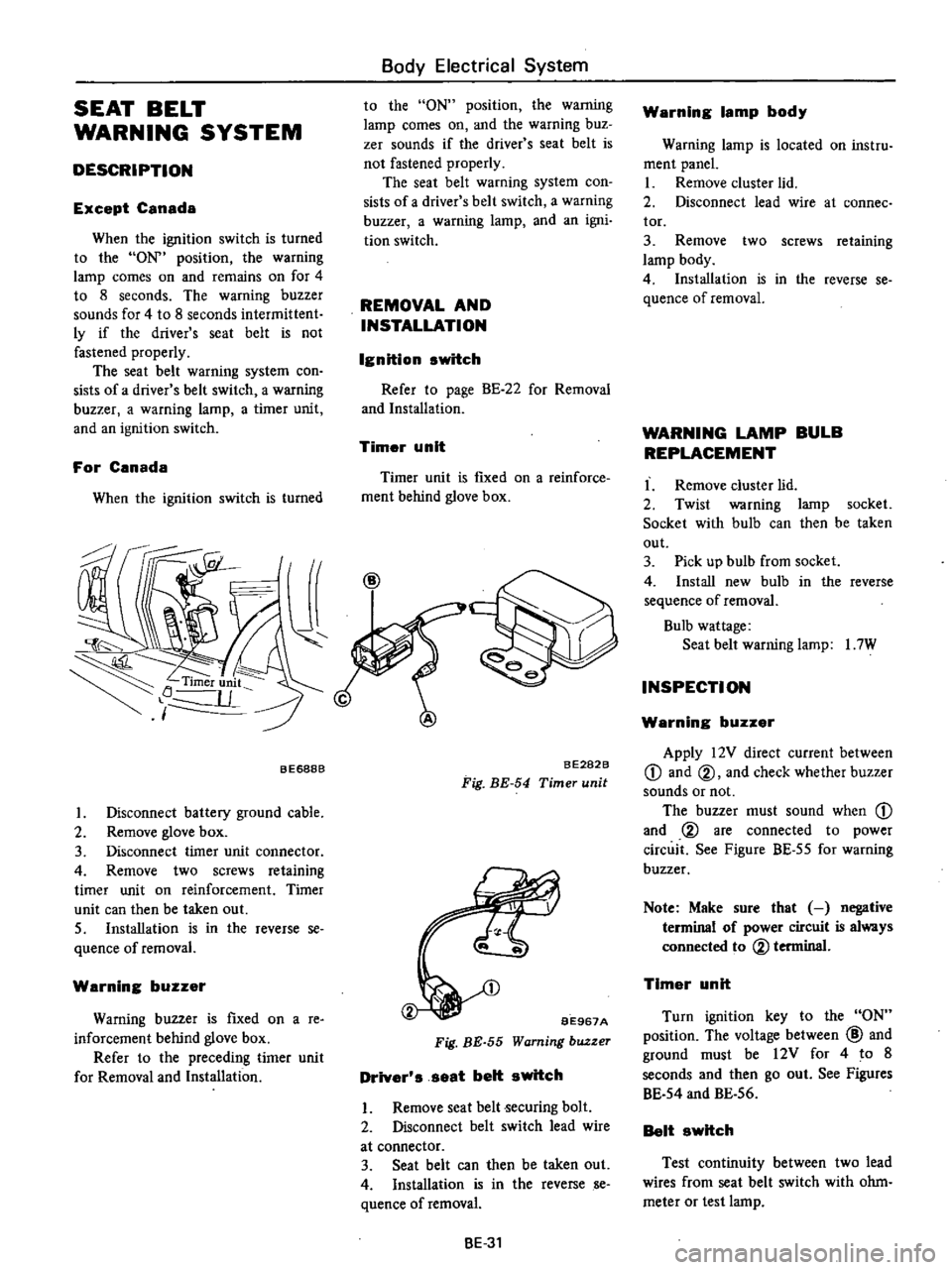

SEAT

BELT

WARNING

SYSTEM

DESCRIPTION

Except

Canada

When

the

ignition

switch

is

turned

to

the

ON

position

the

warning

lamp

comes

on

and

remains

on

for

4

to

8

seconds

The

warning

buzzer

sounds

for

4

to

8

seconds

intermittent

ly

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

a

timer

unit

and

an

ignition

switch

For

Canada

When

the

ignition

switch

is

turned

Body

Electrical

System

to

the

ON

position

the

warning

lamp

comes

on

and

the

warning

buz

zer

sounds

if

the

driver

s

seat

belt

is

not

fastened

properly

The

seat

belt

warning

system

con

sists

of

a

driver

s

belt

switch

a

warning

buzzer

a

warning

lamp

and

an

igni

tion

switch

REMOVAL

AND

INSTALLATION

Ignition

switch

Refer

to

page

BE

22

for

Removal

and

Installation

Timer

unit

Timer

unit

is

fIXed

on

a

reinforce

ment

behind

glove

box

BE688B

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Disconnect

timer

unit

connector

4

Remove

two

screws

retaining

timer

unit

on

reinforcement

Timer

unit

can

then

be

taken

out

S

Installation

is

in

the

reverse

se

quence

of

removal

Warning

buzzer

Warning

buzzer

is

fIxed

on

a

re

inforcement

behind

glove

box

Refer

to

the

preceding

timer

unit

for

Removal

and

Installation

BE282B

Fig

BE

54

Timer

unit

BE967A

Fig

BE

55

Warning

buzzer

Driver

s

seat

belt

switch

I

Remove

seat

belt

ecuring

bolt

2

Disconnect

belt

switch

lead

wire

at

connector

3

Seat

belt

can

then

be

taken

out

4

Installation

is

in

the

reverse

se

quence

ofremoval

BE

31

Warning

lamp

body

Warning

lamp

is

located

on

instru

ment

panel

I

Remove

cluster

lid

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

WARNING

LAMP

BULB

REPLACEMENT

I

Remove

cluster

lid

2

Twist

warning

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

4

Install

new

bulb

in

the

reverse

sequence

of

removal

Bulb

wattage

Seat

belt

warning

lamp

I

7W

INSPECTION

Warning

buzzer

Apply

12V

direct

current

between

CD

and

@

and

check

whether

buzzer

sounds

or

not

The

buzzer

must

sound

when

CD

and

@

are

connected

to

power

circuit

See

Figure

BE

55

for

warning

buzzer

Note

Make

sure

that

negative

terminal

of

power

circuit

is

always

connected

to

@

terminal

Timer

unit

Turn

ignition

key

to

the

ON

position

The

voltage

between

@

and

ground

must

be

12V

for

4

to

8

seconds

and

then

go

out

See

Figures

BE

54

and

BE

56

Belt

switch

Test

continuity

between

two

lead

wires

from

seat

belt

switch

with

ohm

meter

or

test

lamp

Page 488 of 537

Body

Electrical

System

EMISSION

WARNING

SYSTEM

California

models

CONTENTS

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehicle

floor

a

floor

temperature

relay

a

floor

temperature

warning

lamp

and

harnesses

When

the

floor

temperature

rises

to

an

abnormal

level

the

warning

lamp

will

come

on

to

call

the

attention

of

the

driver

i

f

FUSIBLE

LINK

P

BATTERY

IGNITION

SWITCH

BE

43

8E

43

WARNING

LAMP

TROUBLE

SHOOTING

GUIDE

BE

43

BE

44

The

warning

lamp

also

comes

on

during

operation

of

the

starter

motor

permitting

inspection

of

the

lamp

s

condition

The

lamp

goes

out

after

the

engine

starts

Refer

to

Section

EC

for

details

WARNING

LAMP

Bulb

replacement

I

Remove

cluster

lid

2

Twist

warni

ng

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

IGNITION

RELAY

I

I

4

Installation

is

in

the

reverse

se

quence

of

removaL

Bulb

wattage

Floor

temperature

warning

lamp

17W

Lamp

body

replacement

I

Remove

cluster

lld

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

FLOOR

I

l

I

SENSOR

RELAY

WARNING

I

LAMP

FLOOR

SENSOR

ON

FLOOR

TEMPERATURE

LOW

OFF

FLOOR

TEMPERATURE

HIGH

7

BE697B

Fig

BE

64

Circuit

diagram

of

floor

temperature

warning

system

BE

43

Page 489 of 537

Body

Electrical

System

TROUBLE

SHOOTING

GUIDE

Condition

Warning

lamp

does

not

light

in

START

posi

tion

of

ignition

switch

Probable

cause

Burnt

or

loose

bulb

Faulty

f1o

r

temperature

relay

Loose

connection

or

open

circuit

BE

44

Corrective

action

Replace

bulb

or

correct

bulb

socket

Conduct

continuity

test

and

repair

or

reo

place

Refer

to

Section

EC

Check

wiring

and

or

repair

if

necessary

Page 494 of 537

The

refrigerant

within

the

thermo

bulb

changes

in

pressure

through

the

super

heat

condition

of

vaporized

re

frigerant

gas

which

comes

out

of

the

evaporator

causing

the

deflection

of

the

diaphragm

The

lift

of

the

ball

valve

attached

to

the

diaphragm

is

changed

by

the

deflection

of

the

dia

phragm

thus

controlling

the

amount

of

refrigerant

passing

the

orifice

ELECTRICAL

CIRCUIT

DESCRIPTION

The

electrical

circuit

of

the

air

conditioner

consists

of

four

switches

two

relays

a

solenoid

valve

a

fan

motor

and

a

compressor

magnetic

clutch

Air

Conditioning

Diaphragm

Orifice

Valve

ball

AC729

4

Sensing

bulb

Fig

A

C

6

Expansion

value

The

following

wiring

diagram

pro

vides

a

complete

description

of

the

whole

circuit

When

the

ignition

switch

and

the

fan

switch

are

ON

the

main

relay

is

activated

causing

battery

power

to

flow

through

the

fan

motor

and

the

magnetic

clutch

The

magnetic

clutch

is

activated

by

the

thermo

switch

AC

5

000

l

1

Motor

2

Fan

3

Lower

case

4

Cooler

duct

5

Evaporator

6

Expansion

valve

7

Upper

case

8

Resistor

9

Main

relay

10

Thermo

switch

II

Cable

clamp

12

Cable

13

Harness

AC725

Fig

AC

7

Cooling

unit

pressure

switch

and

compressor

relay

The

blower

motor

fan

speed

is

con

trolled

by

the

fan

switch

and

resistor

The

solenoid

valve

is

also

activated

This

in

turn

causes

the

fast

idle

control

device

F

l

C

D

to

increase

engine

speed

when

the

vehicle

is

at

rest

with

the

engine

ON

Page 506 of 537

Notes

a

The

bubbles

seen

through

the

sight

glass

are

influenced

by

the

ambient

temperature

Since

the

bubbles

are

hard

to

show

up

in

comparatively

low

temperatures

below

200C

6S0

F

it

is

possible

that

a

slightly

larger

amount

of

refrigerant

would

be

filled

if

supplied

according

to

the

sight

glass

Be

sure

to

recheck

the

amount

when

it

exceeds

200C

680F

In

higher

temperature

the

bubbles

are

easy

to

show

up

b

When

the

screen

in

the

receiver

dryer

is

clogged

the

bubbles

will

appear

even

if

the

amount

of

refrig

erant

is

normal

In

this

case

the

outlet

side

pipe

of

the

receiver

dryer

becomes

considerably

cold

PERFORMANCE

TEST

Check

for

the

amount

of

refrigerant

in

the

system

can

be

made

by

meas

uring

pressure

on

discharge

side

The

correct

amount

of

refrigerant

is

in

the

system

if

pressure

on

the

discharge

side

is

within

the

specified

range

For

details

refer

to

Perform

ance

Test

described

later

Overcharging

will

show

up

in

higher

pressure

on

discharge

side

COMPRESSOR

OIL

LEVEL

CHECK

The

oil

used

to

lubricate

compres

sor

circulates

into

system

from

the

oil

sump

while

c9mpressor

is

operating

The

efore

to

correctly

measure

com

pressor

oil

the

amount

of

oil

flowing

to

system

must

be

considered

If

a

considerable

amount

of

leakage

of

refrigerant

gas

happens

the

leakage

of

compressor

oil

is

also

considered

There

will

be

no

compressor

oil

leak

age

from

a

completely

sealed

system

When

system

operates

under

satisfying

condition

the

compressor

oil

level

check

is

unnecessary

When

checking

the

level

of

com

pressor

oil

or

when

replacing

any

component

part

of

the

system

use

the

following

service

procedure

This

fa

cilitates

to

return

oil

to

compressor

I

Operate

compressor

at

engine

idling

speed

1

000

rpm

or

below

with

controls

set

for

maximum

cooling

Air

Conditionin

j

and

high

blower

speed

for

10

to

15

minutes

in

order

to

return

compressor

oil

to

compressor

2

Stop

the

engine

and

discharge

refrigerant

of

system

and

then

remove

compressor

from

the

vehicle

3

Remove

compressor

fIller

plug

Drain

compressor

oil

from

compres

sor

oil

sump

and

measure

the

amount

4

Compressor

oil

is

satisfactory

if

the

following

amount

of

oil

remains

in

the

compressor

Residual

oil

S5

to

128

gr

3

to

4

oz

5

Check

the

cleanliness

of

the

oil

If

the

oil

contains

chips

or

other

foreign

material

clean

oil

5ump

with

new

oil

6

Discard

the

used

oil

and

fili

with

the

same

amount

of

new

oil

Add

oil

if

found

less

than

above

amount

Fig

AC

27

Filler

plug

If

compressor

is

inoperative

due

to

faulty

compressor

or

heavy

loss

of

refrigerant

remove

compressor

and

repair

as

necessary

Then

pour

oil

up

to

correct

level

and

install

on

engine

After

above

steps

have

been

complet

ed

recheck

oil

level

drain

oil

to

correct

level

if

level

is

excessively

high

PERFORMANCE

TEST

The

cooling

performance

of

the

air

conditioner

changes

considerably

with

changes

in

surrounding

conditions

Testing

must

be

performed

using

the

correct

method

This

test

is

used

to

judge

whether

system

is

operating

cor

rectly

and

can

also

be

used

as

a

guide

in

checking

for

problems

I

Park

the

vehicle

indoors

or

in

the

shade

AC

17

2

Open

all

the

windows

of

the

vehicle

fully

However

close

the

doors

3

Open

the

hood

4

Connect

manifold

gauge

to

high

and

low

side

service

valves

of

the

system

Refer

to

Handling

Manifold

Ga

uge

5

Set

fan

control

lever

to

maxi

mum

6

Set

temperature

control

lever

to

max

cool

position

7

Start

the

engine

and

hold

engine

speed

at

1

500

rpm

S

After

the

air

conditioner

has

been

operated

for

about

10

minutes

measure

system

pressures

at

high

pres

sure

discharge

side

and

low

pressure

suction

side

9

Measure

the

temperature

of

dis

charge

air

at

outlet

grille

10

Measure

the

temperature

of

capin

11

Measure

ambient

temperature

and

humidity

one

meter

3

3

ft

away

from

condenser

front

Be

careful

not

to

expose

dry

buib

and

wet

bulb

to

direct

sunlight

12

Check

for

any

abnormalities

by

comparing

the

test

results

with

stand

ard

pressure

in

Performance

Chart

Notes

a

The

pressure

will

change

in

the

followi

g

manner

with

changes

in

conditions

When

blower

speed

is

low

dis

charge

pressure

will

drop

When

the

relative

humidity

of

in

take

air

is

low

discharge

pressure

will

drop

b

The

temperature

will

change

in

the

following

manner

with

changes

in

conditions

When

the

ambient

air

temperature

is

low

the

outlet

air

temperature

will

become

low

If

the

test

reveals

that

there

is

any

abnormality

in

system

pressure

isolate

the

cause

and

repair

by

reference

to

the

Trouble

Diagnoses

and

Cor

rections