drain bolt DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 49 of 537

r

I

I

PRELIMINARY

CLEANING

AND

INSPECTION

DISASSEMBL

Y

PRELIMINARY

CLEANING

AND

INSt

ECTION

Before

disassembling

engine

note

the

following

I

Fuel

oil

or

water

may

leak

past

cylinder

head

and

block

Prior

to

disassembling

check

cylinder

head

1

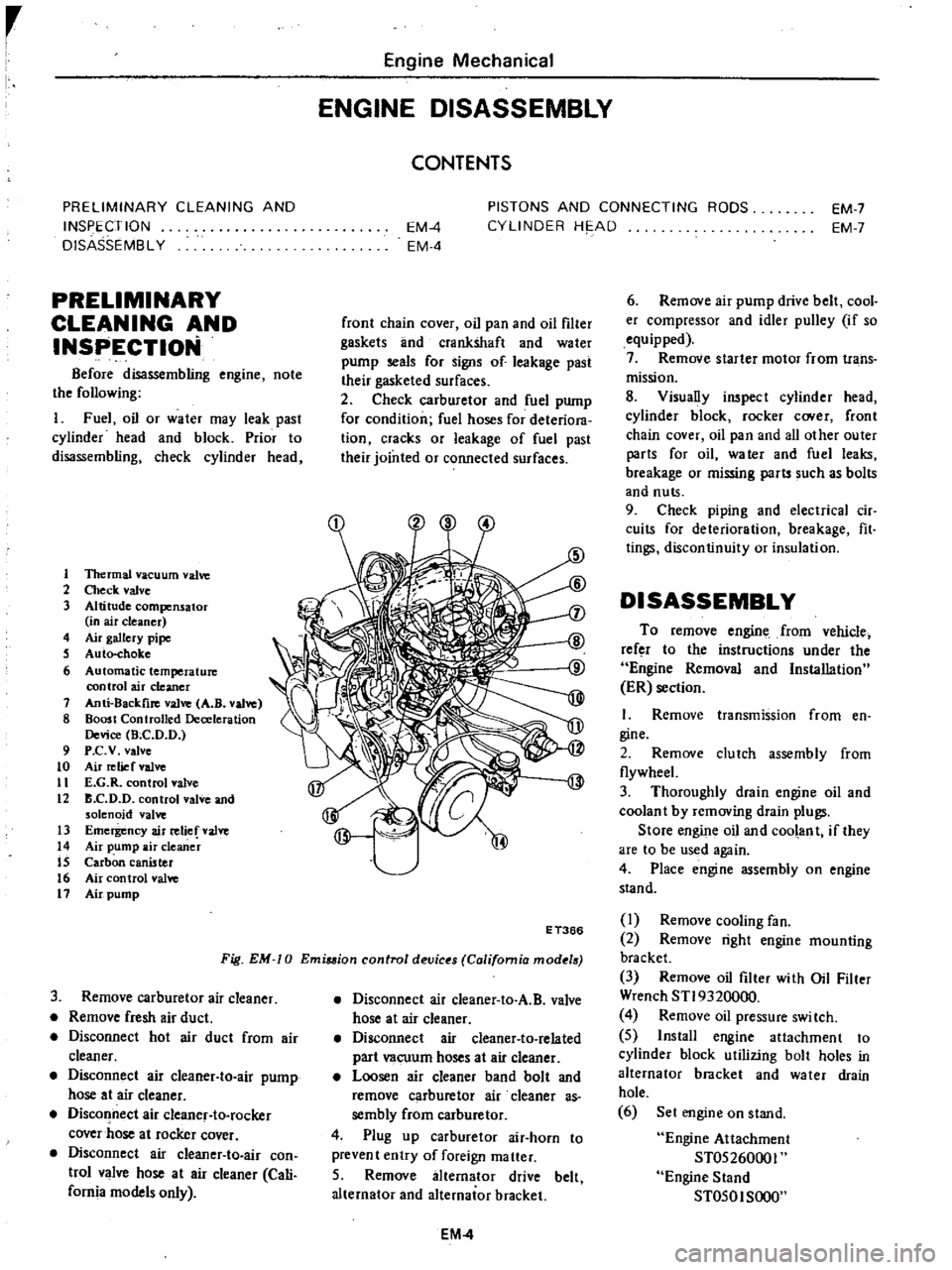

1ltermal

vacuum

valve

2

Check

valve

3

Altitude

compensator

in

air

cleaner

4

Air

gallery

pipe

S

Auto

choke

6

Automatic

temperature

control

air

cleaner

7

Anti

8ackfire

valve

A

B

valve

8

Boost

Controlled

Deceleration

Device

Bee

D

D

9

P

c

v

valve

to

Air

relief

valve

11

E

G

R

control

valve

12

B

C

D

D

control

valve

and

solenoid

valve

13

Emergency

air

relief

valve

14

Air

pump

air

cleaner

IS

Carbon

canister

16

Air

control

valve

11

Air

pump

Engine

Mechanical

ENGINE

DISASSEMBLY

CONTENTS

EM

4

EM

4

PISTONS

AND

CONNECTING

RODS

CYLINDER

HE

AD

EM

7

EM

7

front

chain

cover

oil

pan

and

oil

filter

gaskets

lInd

crankshaft

and

water

pump

seals

for

signs

of

leakage

past

their

gasketed

surfaces

2

Check

carburetor

and

fuel

pump

for

condition

fuel

hoses

for

deteriora

tion

cracks

or

leakage

of

fuel

past

their

jointed

or

connected

surfaces

Fig

EM

0

Emiuion

control

devic

s

California

mod

18

E

T366

3

Remove

carburetor

air

cleaner

Remove

fresh

air

duct

Disconnect

hot

air

duct

from

air

cleaner

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

Disconnect

air

cleanef

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cIeaner

to

air

con

trol

valve

hose

at

air

cleaner

Cali

fornia

models

only

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

Disconnect

air

cleaner

to

related

part

vacuum

hoses

at

air

cleaner

Loosen

air

cleaner

band

bolt

and

remove

carburetor

air

cleaner

as

sembly

from

carburetor

4

Plug

up

carburetor

air

horn

to

prevent

entry

of

foreign

matter

5

Remove

alternator

drive

belt

alternator

and

alternator

bracket

EM

4

6

Remove

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

if

so

equipped

7

Remove

starter

motor

from

trans

mission

8

Visually

inspect

cylinder

head

cylinder

block

rocker

C

Ner

front

chain

cover

oil

pan

and

all

other

outer

parts

for

oil

water

and

fuel

leaks

breakage

or

missing

parts

such

as

bolts

and

nuts

9

Check

piping

and

electrical

cir

cuits

for

deterioration

breakage

fit

tings

discontinuity

or

insulation

DISASSEMBLY

To

remove

engine

from

vehicle

refer

to

the

instructions

under

the

Engine

Removal

and

Installation

ER

section

I

Remove

transmission

from

en

gine

2

Remove

clutch

assembly

from

flywheeL

3

Thoroughly

drain

engine

oil

and

coolan

t

by

removing

drain

plugs

Store

engine

oil

and

coolant

if

they

are

to

be

used

again

4

Place

engine

assembly

on

engine

stand

I

Remove

cooling

fan

2

Remove

right

engine

mounting

bracket

3

Remove

oil

filter

with

Oil

Filter

Wrench

STI9320000

4

Remove

oil

pressure

swi

tch

5

Install

engine

attachment

to

cylinder

block

utilizing

bolt

holes

in

alternator

bracket

and

water

drain

hole

6

Set

engine

on

stand

Engine

Attachment

ST05260001

Engine

Stand

ST050I

SOOO

Page 75 of 537

Engine

Mechanical

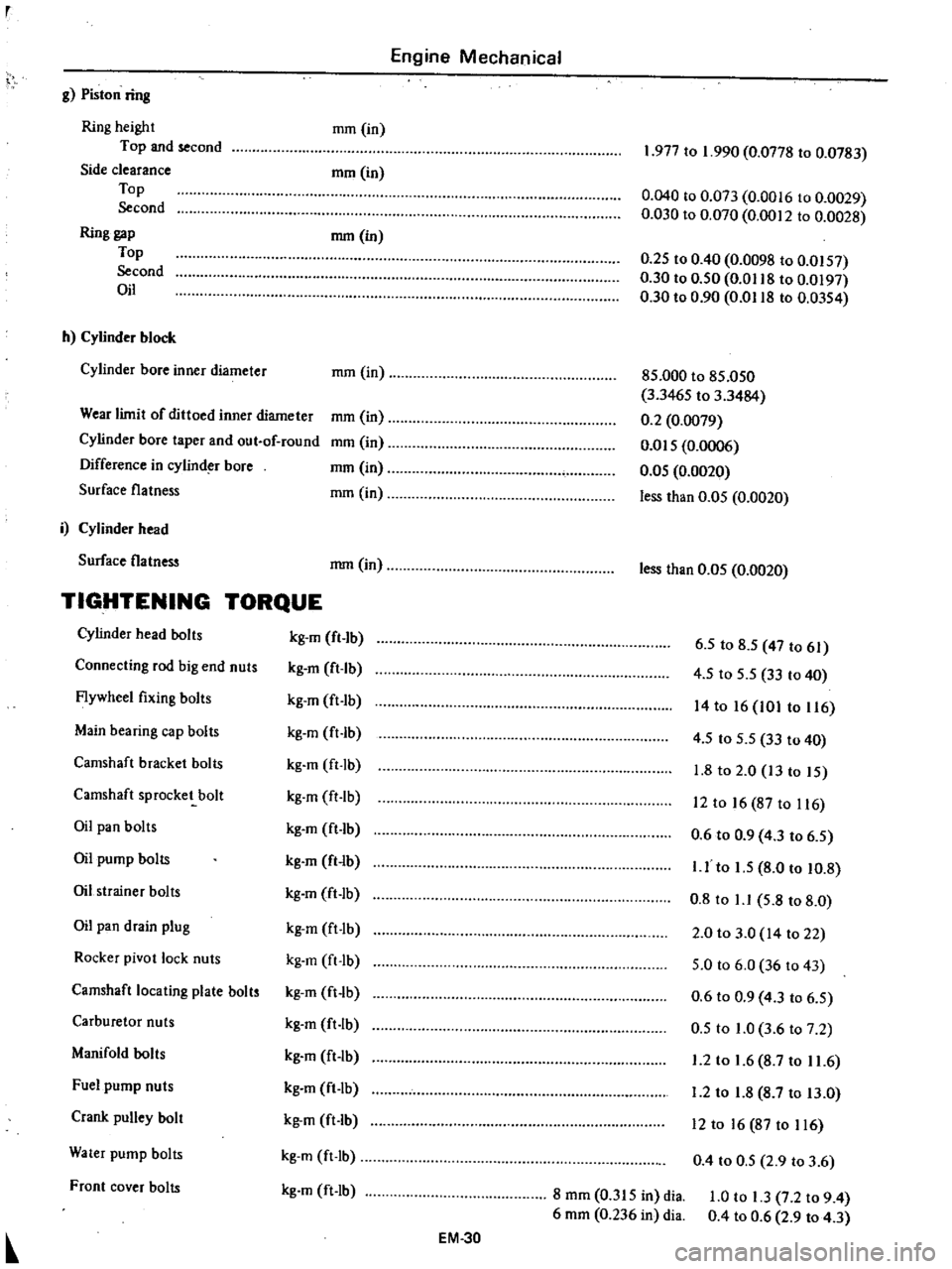

g

Piston

ring

Ring

height

Top

and

second

Side

clearance

Top

Second

Ring

gap

Top

Second

Oil

mm

in

mrn

in

mm

in

h

Cylinder

block

Cylinder

bore

inner

diameter

mm

in

Wear

limit

of

dittoed

inner

diameter

Cylinder

bore

taper

and

out

of

round

Difference

in

cylind

bore

Surface

flatness

mm

in

mm

in

mm

in

mm

in

i

Cylinder

head

Surface

flatness

mm

in

TIGHTENING

TORQUE

Cylinder

head

bolts

kg

m

fl

lb

Connecting

rod

big

end

nuts

kg

m

ft

Ib

Flywheel

fixing

bolts

kg

m

ft

Ib

Main

bearing

cap

bolts

kg

m

ft

lb

Camshaft

bracket

bolts

kg

m

ft

lb

Camshaft

sprocket

bolt

kg

m

ft

lb

Oil

pan

bolts

kg

m

ft

1b

Oil

pump

bolts

kg

m

ft

lb

Oil

strainer

bolts

kg

m

ft

lb

Oil

pan

drain

plug

kg

m

ft

lb

Rocker

pivot

lock

nuts

kg

m

ft

Ib

Camshaft

locating

plate

bolts

kg

m

ft

lb

Carburetor

nuts

kg

m

ft

lb

Manifold

bolts

kg

m

ft

lb

Fuel

pump

nuts

kg

m

ft

lb

Crank

pulley

bolt

kg

m

ft

lb

Water

pump

bolts

kg

m

ft

Ib

Front

cover

bolts

kg

m

ft

lb

EM

30

1

977

to

1

990

0

0778

to

0

0783

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

0

0012

to

0

0028

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0118

to

0

0197

0

30

to

0

90

0

0118

to

0

0354

85

000

to

85

050

3

3465

to

3

3484

0

2

0

0079

om

5

0

0006

0

05

0

0020

less

than

0

05

0

0020

less

than

0

05

0

0020

6

5

to

8

5

47

to

61

4

5

to

5

5

33

to

40

14

to

16

101

to

116

4

5

to

5

5

33

to

40

1

8

to

2

0

13

to

15

12

to

16

87

to

116

0

6

to

0

9

4

3

to

6

5

I

J

to

1

5

8

0

to

10

8

0

8

to

1

1

5

8

to

8

0

2

0

to

3

0

14

to

22

5

0

to

6

0

36

to

43

0

6

to

0

9

4

3

to

6

5

0

5

to

1

0

3

6

to

7

2

1

2

to

1

6

8

7

to

11

6

1

2

to

1

8

8

7

to

13

0

12

to

16

87

to

116

0

4

to

0

5

2

9

to

3

6

8

mm

0

315

in

dia

6

mm

0

236

in

dia

1

0

to

1

3

7

2

to

9

4

0

4

to

0

6

2

9

to

4

3

Page 85 of 537

ENGINE

LUBRICATION

SYSTEM

ENGINE

LUBRICATION

SYSTEM

CONTENTS

LUBRICATION

CIRCUIT

01

L

PUMP

Removal

Installation

Disassembly

and

assembly

EL

2

EL

2

EL

2

EL

2

EL

3

Inspection

OIL

PRESSURE

REGULATOR

VALVE

OIL

FILTER

RELIEF

VALVE

EL

3

EL

4

EL

4

EL

4

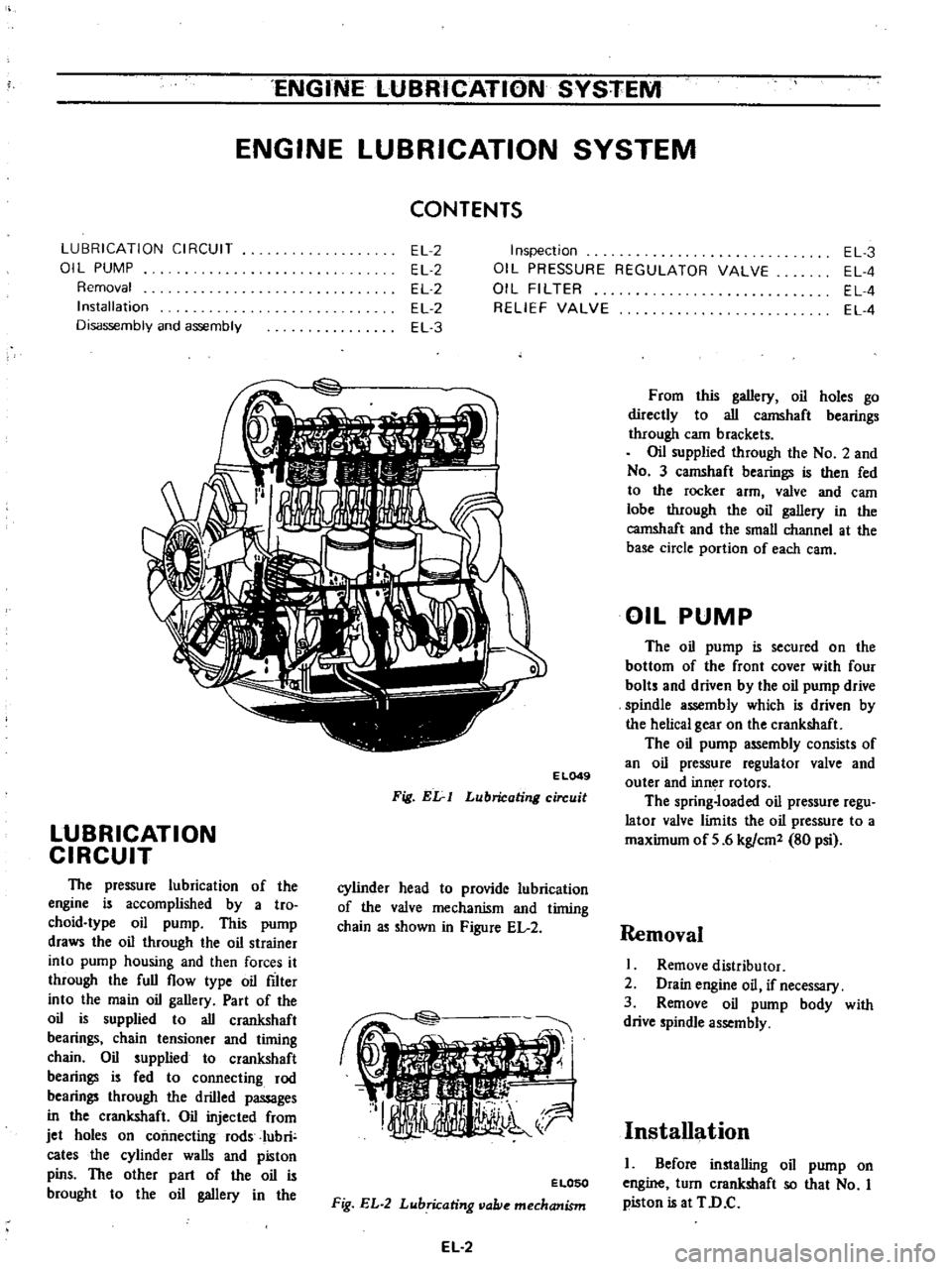

E

L049

Fig

Elr

I

Lubricating

circuit

LUBRICATION

CIRCUIT

The

pressure

lubrication

of

the

engine

is

accomplished

by

a

tro

choid

type

oil

pump

This

pump

draws

the

oil

through

the

oil

strainer

into

pump

housing

and

then

forces

it

through

the

full

flow

type

oil

filter

into

the

main

oil

gallery

Part

of

the

oil

is

supplied

to

all

crankshaft

bearings

chain

tensioner

and

timing

chain

Oil

supplied

to

crankshaft

bearings

is

fed

to

connecting

rod

bearings

through

the

drilled

passages

in

the

crankshaft

Oil

injected

from

jet

holes

on

connecting

rods

Iubri

cates

the

cylinder

walls

and

piston

pins

The

other

part

of

the

oil

is

brought

to

the

oil

gallery

in

the

cylinder

head

to

provide

lubrication

of

the

valve

mechanism

and

timing

chain

as

shown

in

Figure

EL

2

ELOSO

Fig

EL

2

Lubricating

vallie

mechanism

EL

2

From

this

gallery

oil

holes

go

directly

to

all

camshaft

bearings

through

cam

brackets

Oil

supplied

through

the

No

2

and

No

3

camshaft

bearings

is

then

fed

to

the

rocker

arm

valve

and

eam

lobe

through

the

oil

gallery

in

the

camshaft

and

the

small

channel

at

the

base

circle

portion

of

each

earn

OIL

PUMP

The

oil

pump

is

secured

on

the

bottom

of

the

front

cover

with

four

bolts

and

driven

by

the

oil

pump

drive

spindle

assembly

which

is

driven

by

the

helical

gear

on

the

crankshaft

The

oil

pump

assembly

consists

of

an

oil

pressure

regulator

valve

and

outer

and

inn

r

rotors

The

spring

loaded

oil

pressure

regu

lator

valve

limits

the

oil

pressure

to

a

maximum

of

5

6

kg

em

80

psi

Removal

I

Remove

distributor

2

Drain

engine

oil

if

necessary

3

Remove

oil

pump

body

with

drive

spindle

assembly

Installation

I

Before

installing

oil

pump

on

engine

turn

crankshaft

so

that

No

I

piston

is

at

TD

C

Page 94 of 537

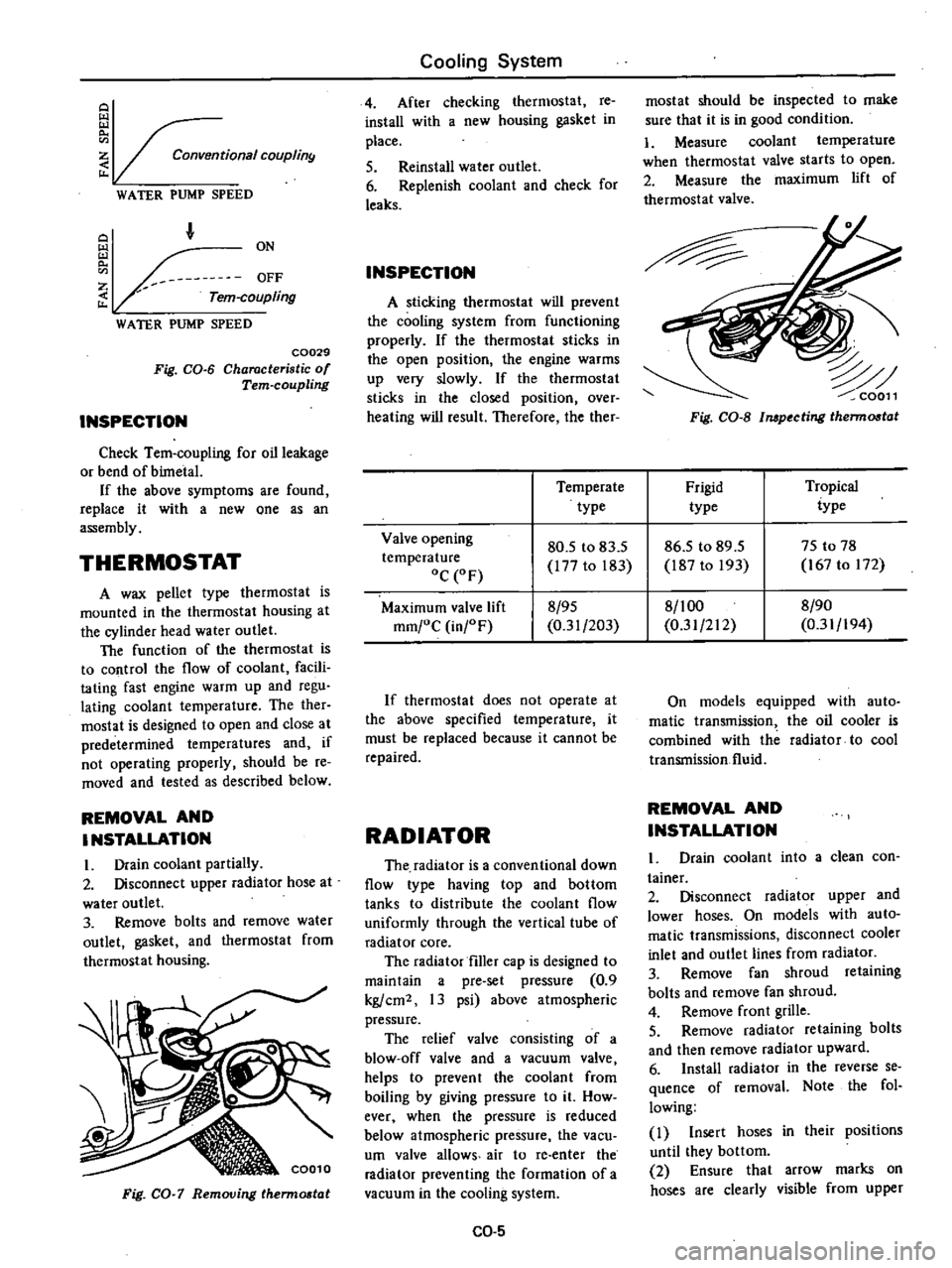

Conventional

COUplin9

WATER

PUMP

SPEED

F

Z

Tern

coupling

WATER

PUMP

SPEED

C0029

Fig

CO

6

Characteristic

of

Tern

coupling

INSPECTION

Check

Tem

coupling

for

oil

leakage

or

bend

of

bimetal

If

the

above

symptoms

are

found

replace

it

with

a

new

one

as

an

assembly

THERMOSTAT

A

wax

pellet

type

thermostat

is

mounted

in

the

thermostat

housing

at

the

cylinder

head

water

outlet

The

function

of

the

thermostat

is

to

control

the

flow

of

coolant

facili

tating

fast

engine

warm

up

and

regu

lating

coolant

temperature

The

ther

mostat

is

designed

to

open

and

close

at

predetermined

temperatures

and

if

not

operating

properly

should

be

re

moved

and

tested

as

described

below

REMOVAL

AND

INSTALLATION

I

Drain

coolant

partially

2

Disconnect

upper

radiator

hose

at

water

outlet

3

Remove

bolts

and

remove

water

outlet

gasket

and

thermostat

from

thermostat

housing

Fig

CO

7

Removing

therm06t

t

Cooling

System

4

After

checking

thermostat

re

install

with

a

new

housing

gasket

in

place

5

Reinstall

water

outlet

6

Replenish

coolant

and

check

for

leaks

INSPECTION

A

sticking

thermostat

will

prevent

the

cooling

system

from

functioning

properly

If

the

thermostat

sticks

in

the

open

position

the

engine

warms

up

very

slowly

If

the

thermostat

sticks

in

the

closed

position

over

heating

will

result

Therefore

the

ther

mostat

should

be

inspected

to

make

sure

that

it

is

in

good

condition

1

Measure

coolant

temperature

when

thermostat

valve

starts

to

open

2

Measure

the

maximum

lift

of

thermostat

valve

Fig

CO

S

Impecting

therm06t

t

Temperate

Frigid

Tropical

type

type

iype

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

177

to

183

187

to

193

167

to

172

oC

OF

Maximum

valve

lift

8

95

8

1

00

8

90

mm

oC

in

F

0

31

203

0

31

212

0

31

194

If

thermostat

does

not

operate

at

the

above

specified

temperature

it

must

be

replaced

because

it

cannot

be

repaired

RADIATOR

The

radiator

is

a

conventional

down

flow

type

having

top

and

bottom

tanks

to

distribute

the

coolant

flow

uniformly

through

the

vertical

tube

of

radiator

core

The

radiator

filler

cap

is

designed

to

maintain

a

pre

set

pressure

0

9

kg

cm2

13

psi

above

atmospheric

pressure

The

relief

valve

consisting

of

a

blow

off

valve

and

a

vacuum

valve

helps

to

prevent

the

coolant

from

boiling

by

giving

pressure

to

it

How

ever

when

the

pressure

is

reduced

below

atmospheric

pressure

the

vacu

um

valve

allows

air

to

re

enter

the

radiator

preventing

the

formation

of

a

vacuum

in

the

cooling

system

CO

5

On

models

equipped

with

auto

matic

transmission

the

oil

cooler

is

combined

with

the

radiator

to

cool

transmission

fluid

REMOVAL

AND

INSTALLATION

Drain

coolant

into

a

clean

con

tainer

2

Disconnect

radiator

upper

and

lower

hoses

On

models

with

auto

matic

transmissions

disconnect

cooler

inlet

and

outlet

lines

from

radiator

3

Remove

fan

shroud

retaining

bolts

and

remove

fan

shroud

4

Remove

front

grille

5

Remove

radiator

retaining

bolts

and

then

remove

radiator

upward

6

Install

radiator

in

the

reverse

se

quence

of

removal

Note

the

fol

lowing

I

Insert

hoses

in

their

positions

until

they

bottom

2

Ensure

that

arrow

marks

on

hoses

are

clearly

visible

from

upper

Page 96 of 537

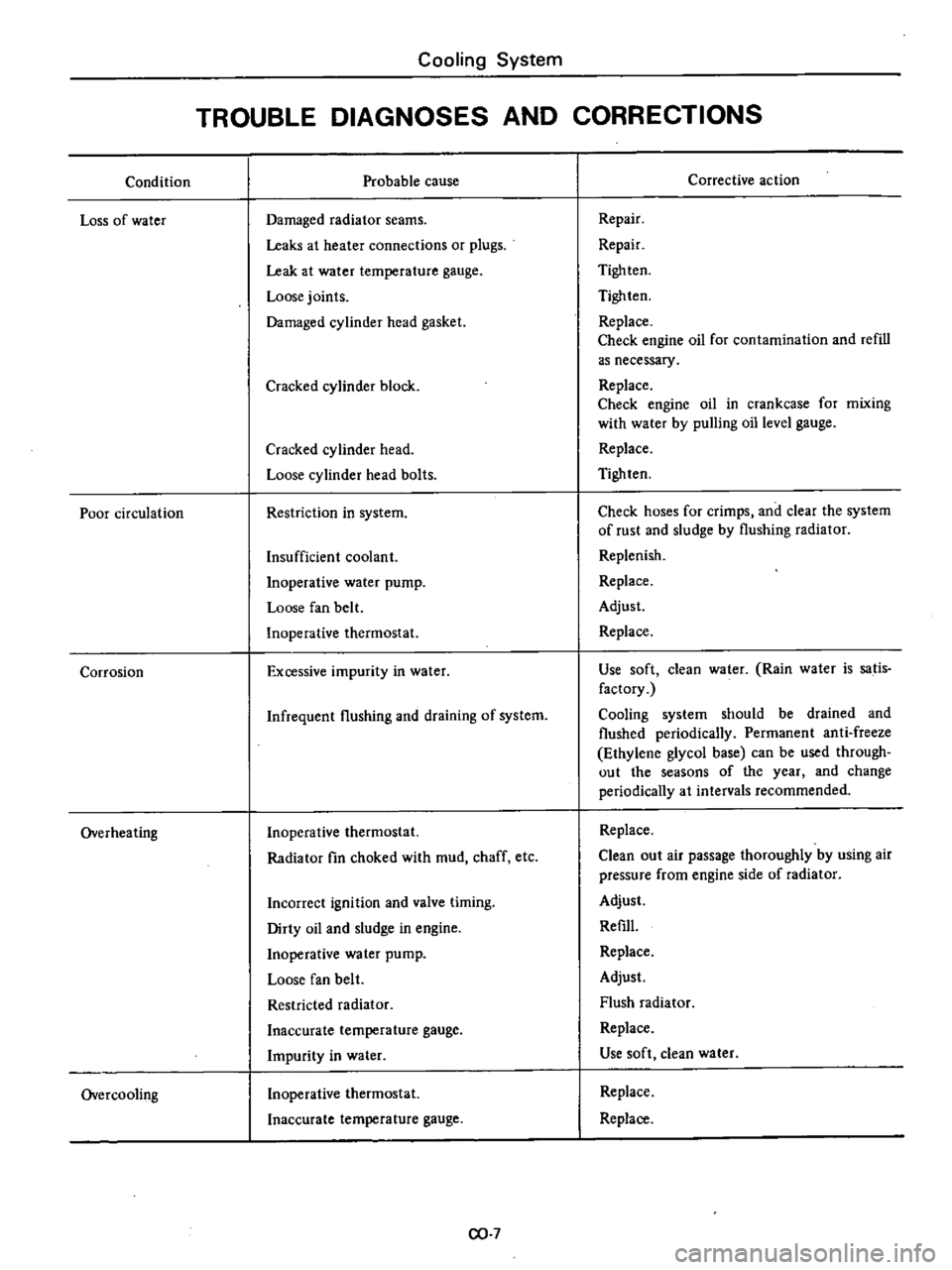

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace

Page 156 of 537

1

1

I

I

I

1

v

v

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L

0

I

Magnet

coil

Detector

drive

counter

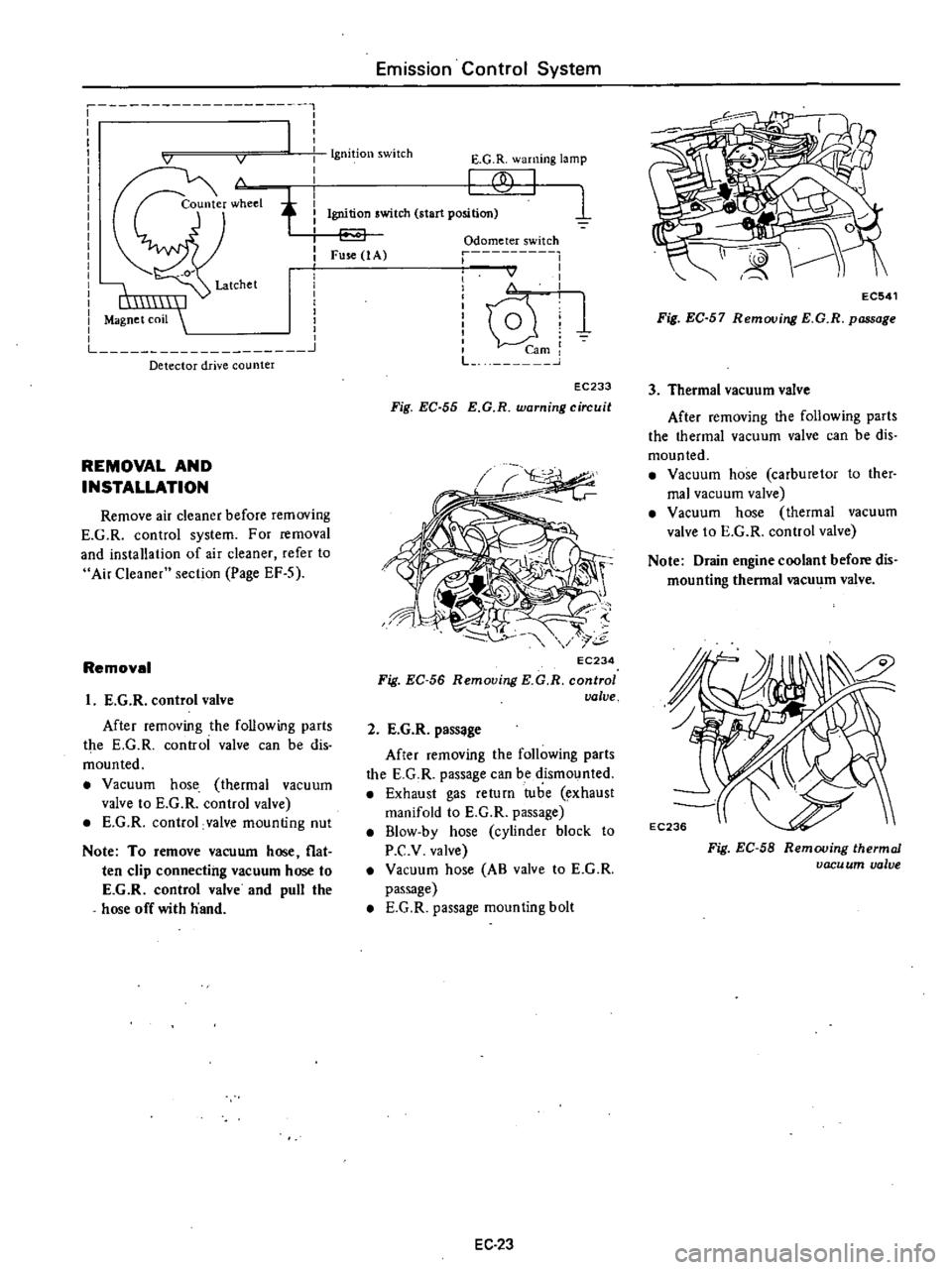

REMOVAL

AND

INSTALLATION

Remove

air

cleaner

before

removing

E

G

R

control

system

For

removal

and

installation

of

air

cleaner

refer

to

Air

Cleaner

section

Page

EF

S

Removal

I

E

G

R

control

valve

After

removing

the

following

parts

the

E

G

R

controi

valve

can

be

dis

mounted

Vacuum

hose

thermal

vacuum

valve

to

E

G

R

control

valve

E

G

R

control

valve

mounting

nut

Note

To

remove

vacuum

hose

flat

ten

clip

connecting

vacuum

hose

to

E

G

R

control

valve

and

pull

the

hose

off

with

hand

Emission

Control

System

Ignition

switch

E

G

R

warning

lamp

f

1

Ignition

switch

start

position

Fuse

1

A

Odometer

switch

r

I

I

I

I

v

I

I

I

i

lQ

U

1

mi

L

J

EC233

Fig

EC

55

E

G

R

warning

circuit

EC234

Fig

EC

56

Removing

KG

R

control

valve

2

E

G

R

pass

ge

After

removing

the

following

parts

the

E

G

R

passage

can

be

dismounted

Exhaust

gas

return

tube

exhaust

manifold

to

E

G

R

passage

B1ow

by

hose

cylinder

block

to

P

C

v

valve

Vacuum

hose

AB

valve

to

E

G

R

passage

E

G

R

passage

mounting

bolt

EC

23

EC541

Fig

EC

57

Removing

E

G

R

passage

3

Thermal

vacuum

valve

After

removing

the

following

parts

the

thermal

vacuum

valve

can

be

dis

mounted

Vacuum

hose

carburetor

to

ther

mal

vacuum

valve

Vacuum

hose

thermal

vacuum

valve

to

E

G

R

control

valve

Note

Drain

engine

coolant

before

dis

mounting

thermal

vacu

m

valve

Fig

EC

58

Removing

thermal

vacu

um

valve

Page 219 of 537

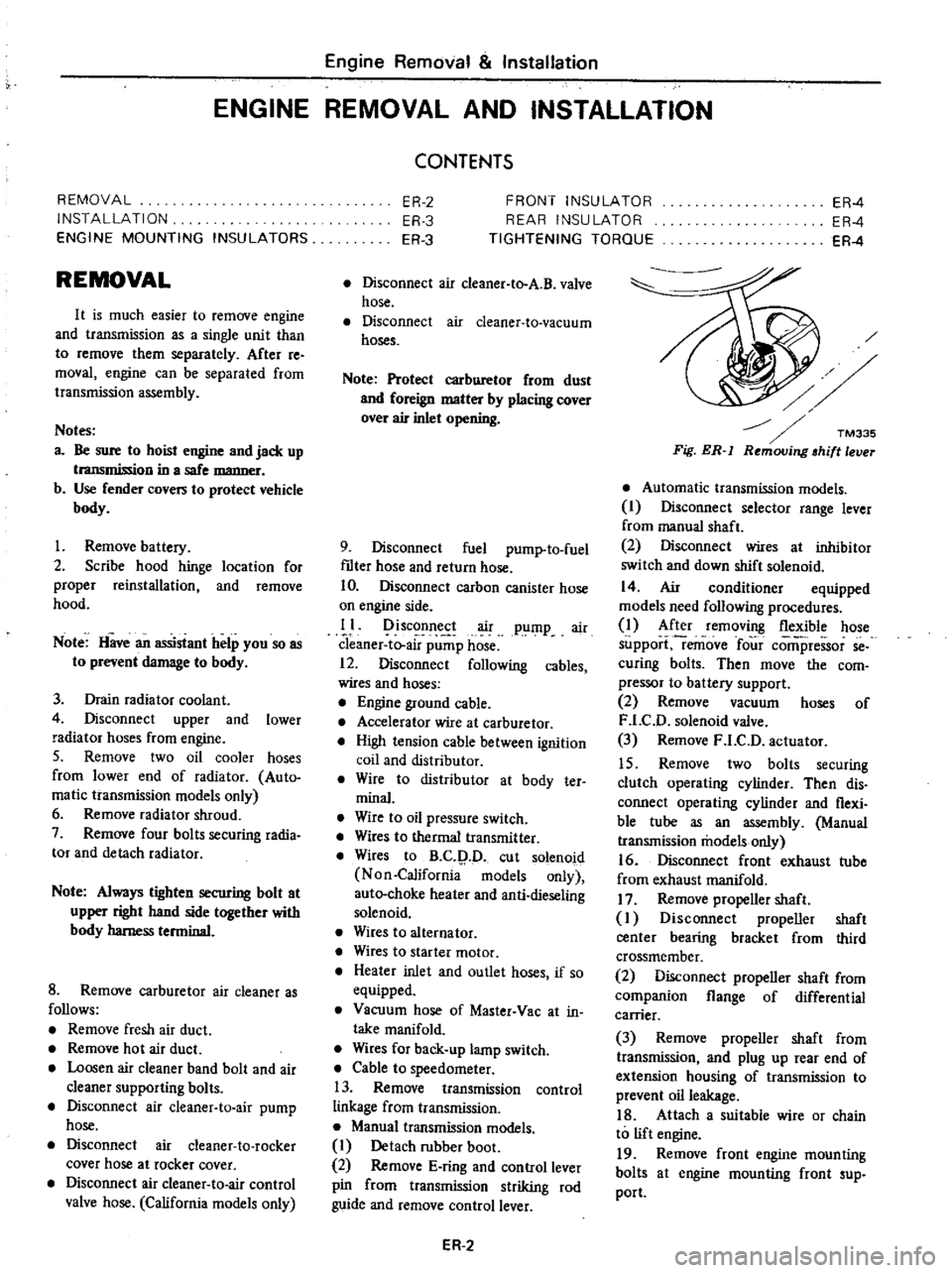

Engine

Removal

Installation

ENGINE

REMOVAL

AND

INSTAllATION

REMOVAL

INSTALLATION

ENGINE

MOUNTING

INSULATORS

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

them

separately

After

re

moval

engine

can

be

separated

from

transntission

assembly

Notes

a

Be

sure

to

hoist

engine

and

jack

up

transmission

in

a

safe

manner

b

Use

fender

cove

to

protect

vehicle

body

1

Remove

battery

2

Scribe

hood

hinge

location

for

proper

reinstallation

and

remove

hood

Note

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

3

Drain

radiator

coolant

4

Disconnect

upper

and

lower

radiator

hoses

from

engine

5

Remove

two

oil

cooler

hoses

from

lower

end

of

radiator

Auto

ma

tic

transmission

models

only

6

Remove

radiator

shroud

7

Remove

four

bolts

securing

radia

tor

and

detach

radiator

Note

Always

tighten

securing

bolt

at

upper

right

hand

side

together

with

body

harness

terminal

8

Remove

carburetor

air

cleaner

as

follows

Remove

fresh

air

duct

Remove

hot

air

duct

Loosen

air

cleaner

band

bolt

and

air

cleaner

supporting

bolts

Disconnect

air

cleaner

ta

air

pump

hose

Disconnect

air

cleaner

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cleaner

to

air

control

valve

hose

California

models

only

CONTENTS

ER

2

ER

3

ER

3

FRONT

INSULATOR

REAR

INSULATOR

TIGHTENING

TORQUE

ER

4

ER

4

ER

4

Disconnect

air

deaner

to

A

B

valve

hose

Disconnect

air

cleaner

ta

vacuum

hoses

Note

Protect

carburetor

from

dust

and

foreign

matter

by

placing

cover

over

air

inlet

opening

9

Disconnect

fuel

pump

to

fuel

fdter

hose

and

return

hose

10

Disconnect

carbon

canister

hose

on

engine

side

II

Disconnect

air

pump

air

C1eaner

to

al

p

p

hose

12

Disconnect

following

cables

wires

and

hoses

Engine

ground

cable

Accelerator

wire

at

carburetor

High

tension

cable

between

ignition

coil

and

distributor

Wire

to

distributor

at

body

ter

minal

Wire

to

oil

pressure

switch

Wires

to

thermal

transmitter

Wires

to

B

C

p

D

cut

solenoid

Non

California

models

only

auto

choke

heater

and

anti

dieseling

solenoid

Wires

to

alternator

Wires

to

starter

motor

Heater

inlet

and

outlet

hoses

if

so

equipped

Vacuum

hose

of

Master

Vac

at

in

taJce

manifold

Wires

for

back

up

lamp

switch

Cable

to

speedometer

13

Remove

transmission

control

linkage

from

transmission

Manual

transmission

models

I

Detach

rubber

boot

2

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

ER

2

Fig

ER

l

Automatic

transmission

models

I

Disconnect

selector

range

lever

from

manual

shaft

2

Disconnect

wires

at

inhibitor

switch

and

down

shift

solenoid

14

Air

conditioner

equipped

models

need

following

procedures

1

After

removing

flexible

hose

support

remove

four

comi

ressor

se

curing

bolts

Then

move

the

com

pressor

to

battery

support

2

Remove

vacuum

hoses

of

F

LC

D

solenoid

valve

3

Remove

F

LC

D

actuator

15

Remove

two

bolts

securing

clutch

operating

cylinder

Then

dis

connect

operating

cylinder

and

flexi

ble

tube

as

an

assembly

Manual

transmission

models

only

16

Disconnect

front

exhaust

tube

from

exhaust

manifold

17

Remove

propeller

shaft

I

Disconnect

propeller

shaft

center

bearing

bracket

from

third

crossmember

2

Disconnect

propeller

shaft

from

companion

flange

of

differential

carrier

3

Remove

propeller

shaft

from

transmission

and

plug

up

rear

end

of

extension

housing

of

transmission

to

prevent

oil

leakage

18

Attach

a

suitable

wire

or

chain

to

lift

engine

19

Remove

front

engine

mounting

bolts

at

engine

mounting

front

sup

port

Page 228 of 537

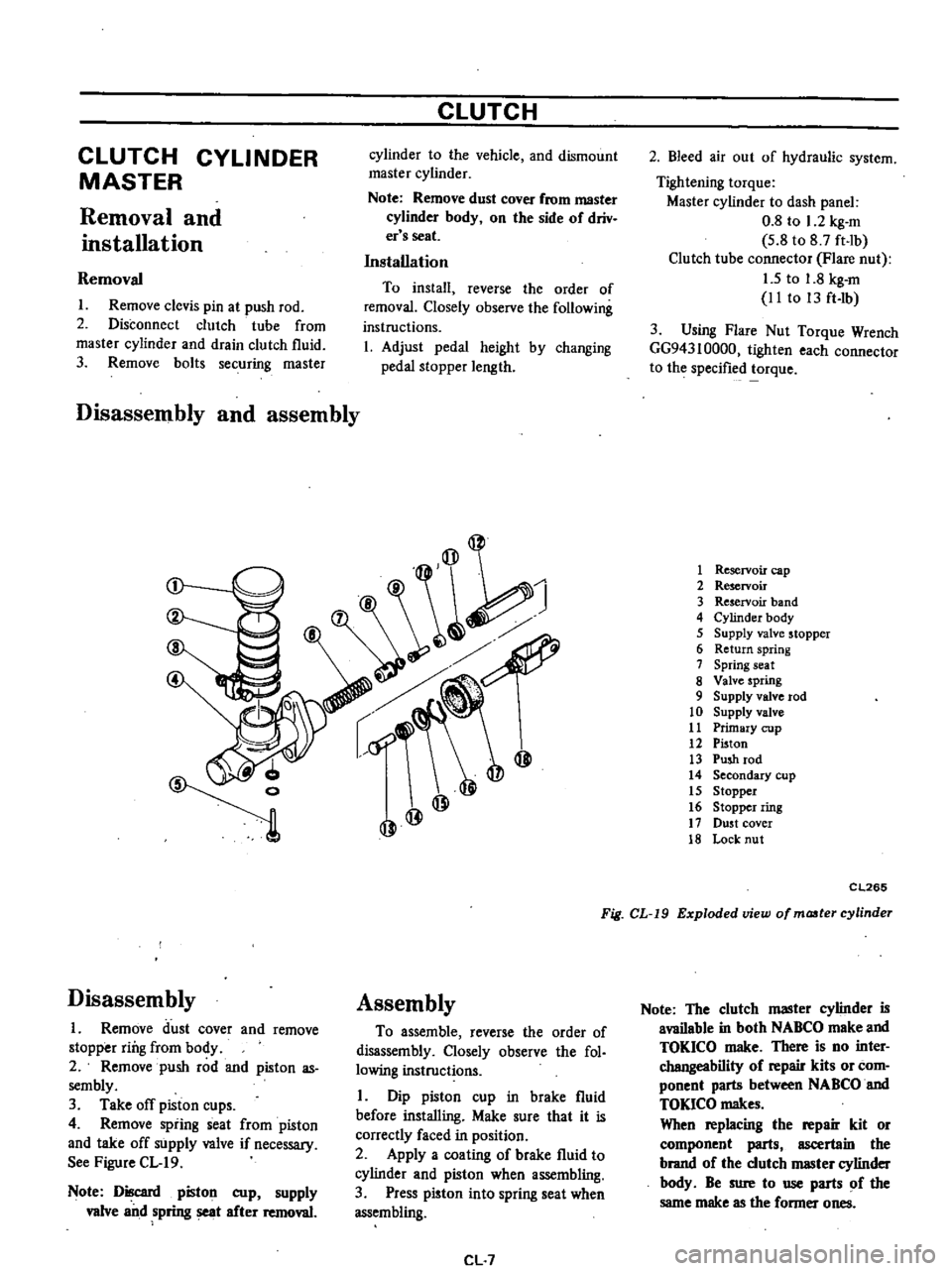

CLUTCH

CYLINDER

MASTER

Removal

and

installation

Removal

I

Remove

clcvis

pin

at

push

rod

2

Disconnect

clutch

tube

from

master

cylinder

and

drain

clutch

fluid

3

Remove

bolts

securing

master

Disassembly

and

assembly

CLUTCH

cylinder

to

the

vehicle

and

dismount

master

cylinder

Note

Remove

dust

cover

from

master

cylinder

body

on

the

side

of

driv

er

s

seat

Installation

To

install

reverse

the

order

of

removal

Closely

observe

the

following

instructions

1

Adjust

pedal

height

by

changing

pedal

stopper

length

Disassembly

1

Remove

dust

cover

and

remove

stopper

ring

from

body

2

Remove

push

rod

and

piston

as

sembly

3

Take

off

piston

cups

4

Remove

spiing

seat

from

piston

and

take

off

supply

valve

if

necessary

See

Figure

CL

19

Note

Discard

piston

cup

supply

valve

and

spring

seat

after

removal

Assembly

To

assemble

reverse

the

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

3

Press

piston

into

spring

seat

when

assembling

CL

7

2

Bleed

air

out

of

hydraulic

system

Tightening

torque

Master

cylinder

to

dash

panel

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

Clutch

tube

connector

Flare

nut

1

5

to

1

8

kg

m

II

to

13

ft

lb

3

Using

Flare

Nut

Torque

Wrench

GG94310000

tighten

each

connector

to

the

specified

torque

1

Reservoir

cap

2

Reservoir

3

Reservoir

band

4

Cylinder

body

5

Supply

valve

stopper

6

Return

spring

7

Spring

seat

8

Valve

spring

9

Supply

valve

rod

10

Supply

valve

11

Primary

cup

12

Piston

13

Push

rod

14

Secondary

cup

15

Stopper

16

Stopper

ring

17

DU5t

cover

18

Lock

nut

CL265

Fig

CL

19

Exploded

view

of

maater

cylinder

Note

The

clutch

master

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

IIIBSter

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Page 229 of 537

Inspection

Note

To

clean

or

wash

all

parts

of

master

cylinder

operating

cylinder

and

piping

clean

brake

fluid

must

be

used

Never

use

minera10ils

llUch

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydrau

lic

system

I

Check

cylinder

and

piston

for

uneven

wear

or

damage

and

if

neces

sary

replace

2

If

the

clearance

between

cylinder

and

piston

is

more

than

0

15

mm

0

0059

in

replace

cylinder

3

Renew

piston

cup

when

dis

assembled

It

must

also

be

replaced

when

wear

or

deformation

due

to

fatigue

or

damage

is

found

4

Damaged

dust

cover

oil

reservoir

or

cap

should

be

replaced

Return

spring

and

valve

spring

must

also

be

replaced

when

they

are

broken

or

weak

5

Replace

clutch

hose

and

tube

if

any

abnormal

sign

of

damage

or

de

fro

ti

n

is

found

OPERATING

CYLINDER

Removal

and

installation

Removal

1

Detach

clutch

hose

from

operat

ing

cylinder

2

Remove

two

bolts

securing

op

erating

cylinder

to

clutch

housing

Installation

Install

in

the

reverse

order

of

re

moval

Observe

the

following

instructions

Bleed

air

thoroughly

from

clutch

hydraulic

system

2

Do

not

install

return

spring

or

clutch

will

not

be

disengaged

properly

Tightening

torque

Operating

cylinder

securing

bolt

2

5

to

3

5

kg

m

18

to

25

ft

lb

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ib

Clutch

hose

connector

1

7

to

2

0

kg

m

12

to

14

ft

b

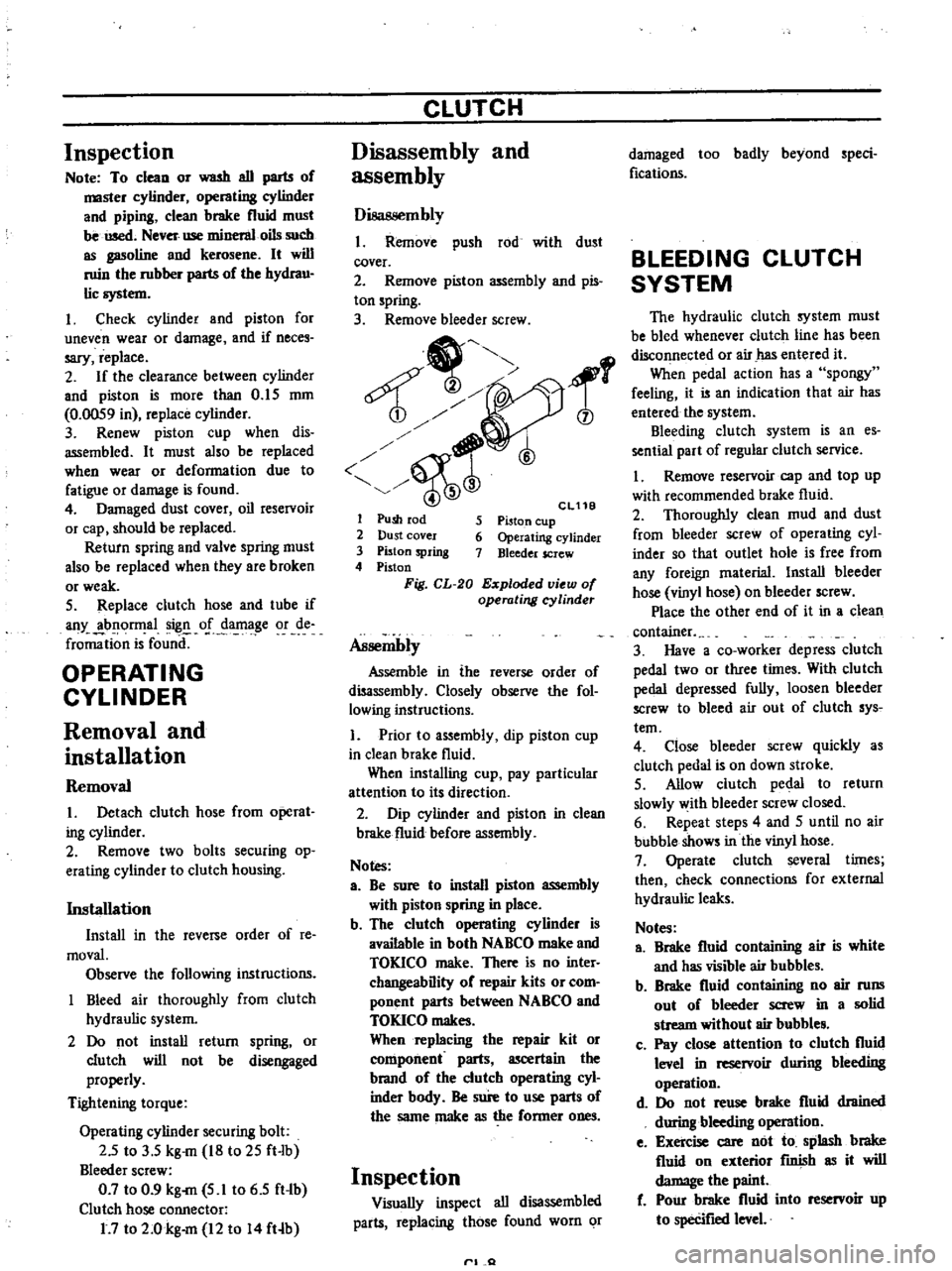

CLUTCH

Disassembly

and

assembly

Disassembly

1

Remove

push

rod

with

dust

cover

2

Remove

piston

assembly

and

pis

ton

spring

3

Remove

bleeder

screw

1

6

Cl11B

5

Piston

cup

6

Operating

cylinder

7

Bleeder

screw

1

Push

rod

2

Dust

cover

3

Piston

spring

4

Piston

Fig

CL

20

Exploded

view

of

operating

cyUnder

Assembly

Assemble

in

the

reverse

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

1

Prior

to

assembly

dip

piston

cup

in

clean

brake

fluid

When

installing

cup

pay

particular

attention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

Notes

a

Be

sure

to

install

piston

assembly

with

piston

spring

in

place

b

The

clutch

operating

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKICO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

operating

cyl

inder

bndy

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Inspection

Visually

inspect

all

disassembled

parts

replacing

those

found

worn

or

rl

Q

damaged

too

badly

beyond

speci

fications

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

es

sential

part

of

regular

clutch

service

I

Remove

reservoir

cap

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

rnaterial

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

clean

container

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clu

tch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tern

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

4

and

5

until

no

air

bubble

shows

in

the

vinyl

hose

7

Operate

clutch

several

times

then

check

connections

for

external

hydraulic

leaks

Notes

a

Brake

fluid

containing

air

is

white

and

has

visible

air

bubbles

b

Brake

fluid

containing

no

air

runs

out

of

bleeder

screw

in

a

solid

stream

without

air

bubble

c

Pay

close

attention

to

clutch

fluid

level

in

reservoir

during

bleeding

operation

d

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

e

Exercise

care

not

to

splash

brake

fluid

on

exterior

fInish

as

it

will

damage

the

paint

f

Pour

brake

fluid

into

reservoir

up

to

specifIed

level

Page 238 of 537

REMOVAL

In

dismounting

transmission

from

the

vehicle

proceed

as

follows

I

Disconnect

battery

ground

cable

from

terminal

2

Place

transmission

control

lever

in

neutIal

position

3

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

See

Figure

MT

4

TM335

Fig

MT

4

Remouing

controllelJ

r

4

Jack

up

the

vehicle

and

support

its

weight

on

safety

stands

Use

a

hydraulic

hoist

or

open

pit

if

avail

able

Confirm

that

safety

is

insured

5

Disconnect

exhaust

front

tube

6

Disconnect

wires

from

reverse

lamp

switch

See

Figure

MT

5

7

Disconnect

speedometer

cable

from

rear

extension

housing

See

Figure

MT

5

8

Remove

clutch

operating

cylinder

from

transmission

case

See

Figure

MT5

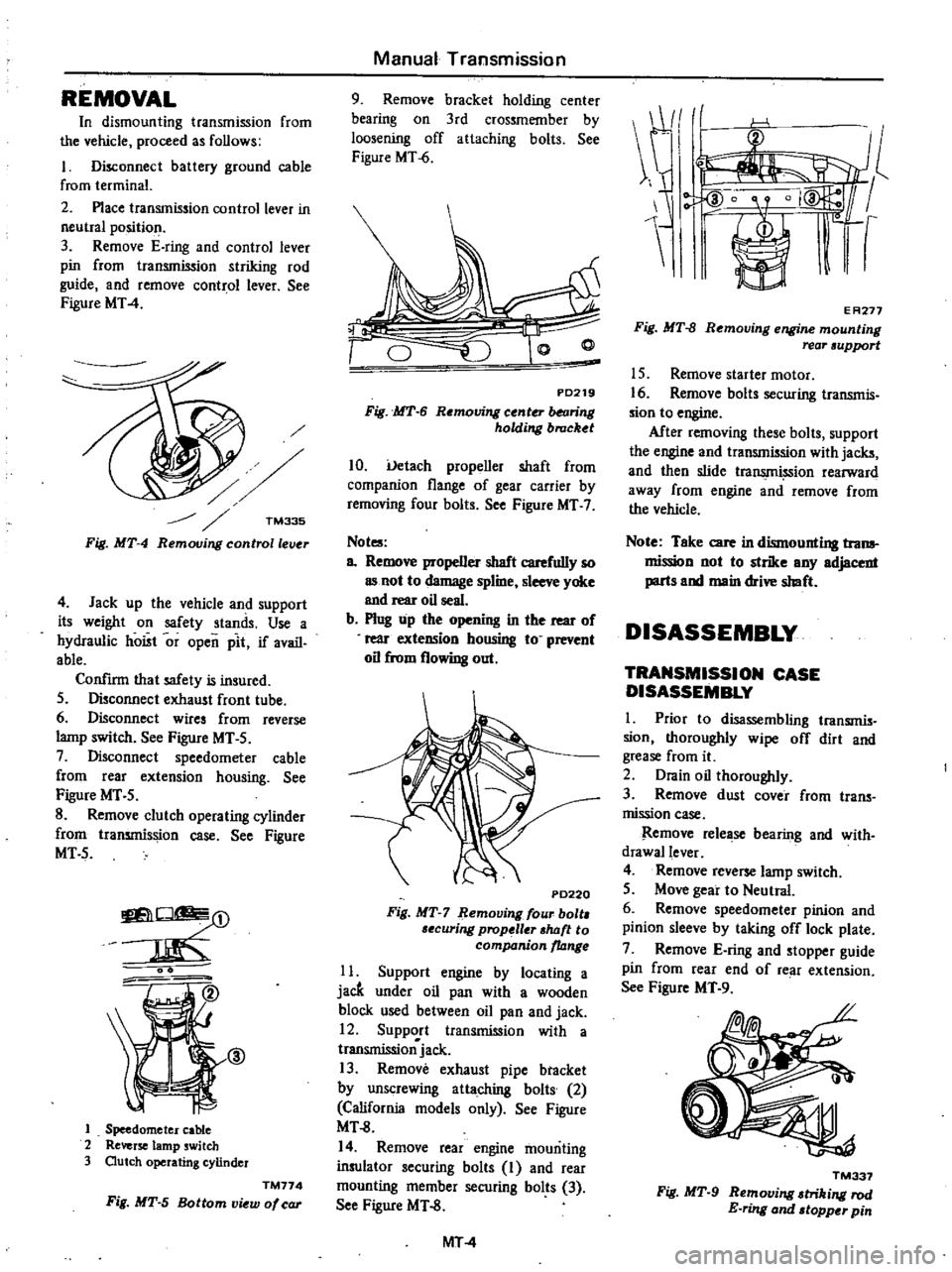

O

m

J

@

1

Speedometer

cable

2

Reverse

lamp

switch

3

Outch

operating

cylinder

TM774

Fig

MT

5

Bottom

view

of

car

Manual

Transmission

9

Remove

bracket

holding

center

bearing

on

3rd

crossmember

by

loosening

off

attaching

bolts

See

Figure

MT

6

PD219

Fig

MT

6

Removing

center

balring

holding

brucket

10

Uetach

propeller

shaft

from

companion

flange

of

gear

carrier

by

removing

four

bolts

See

Figure

MT

7

Not

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

exteDSion

housing

to

prevent

oil

from

flowing

out

P0220

Fig

MT

7

Remouing

four

bolt

6ecuring

prop

ller

shtJft

to

companion

ltJnge

11

Support

engine

by

locating

a

jacft

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

12

Support

transmission

with

a

transmissionjack

13

Remove

exhaust

pipe

btacket

by

unscrewing

attaching

bolts

2

California

models

only

See

Figure

MT

8

14

Remove

rear

engine

mounting

insulator

securing

bolts

I

and

rear

mounting

member

securing

bolts

3

See

Figure

MT

8

MT

4

E

A277

Fig

MT

8

Removing

engine

mounting

rear

support

15

Remove

starter

motor

16

Remove

bolt

securing

transmis

sion

to

engine

After

removing

these

bolts

support

the

engine

and

transmission

with

jacks

and

then

slide

tra

ion

rearward

away

from

engine

and

remove

from

the

vehicle

Note

Take

care

in

dismounting

trona

mission

not

to

strike

any

adjacent

parts

and

main

drive

shaft

DISASSEMBLY

TRANSMISSION

CASE

DISASSEMBLY

I

Prior

to

disassembling

transmis

sion

thoroughly

wipe

off

dirt

and

grease

from

it

2

Drain

oil

thoroughly

3

Remove

dust

cover

from

trans

mission

case

Remove

release

bearing

and

with

drawallever

4

Remove

reverse

lamp

switch

5

Move

gear

to

Neutral

6

Remove

speedometer

pinion

and

pinion

sleeve

by

taking

off

lock

plate

7

Remove

E

ring

and

stopper

guide

pin

from

rear

end

of

re

ll

extension

See

Figure

MT

9

TM337

Fig

MT

9

Removing

triking

rod

E

ring

and

topper

pin