key DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 161 of 537

I

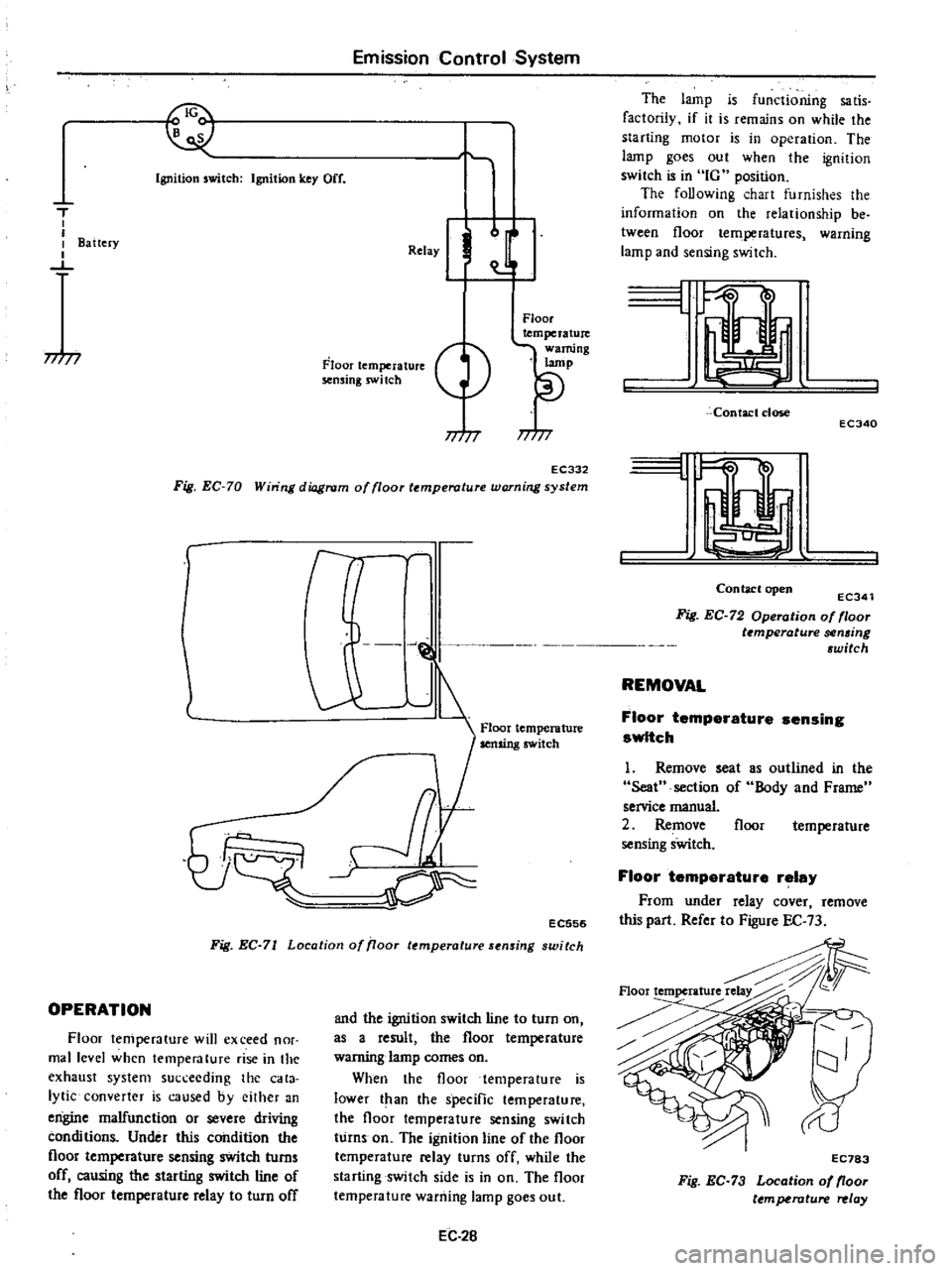

Emission

Control

System

Ignition

switch

Ignition

key

Off

T

I

I

I

Battery

I

J

77

77

Relay

J

Floor

temperature

sensing

swi

tch

Floor

temperature

warning

lamp

77

77

EC332

Fig

EC

70

Win

ng

diagram

of

floor

temperature

warning

system

r

l

J

@

1

Floor

temperature

Ij

cr

EC556

Fig

EC

71

Location

of

iJoor

temperature

sensing

switch

OPERATION

Floor

temperature

will

exceed

nor

mal

level

when

temperature

rise

in

the

exhaust

system

succeeding

the

cata

lytic

converter

is

caused

byeilher

an

engine

malfunction

or

severe

driving

conditions

Under

this

condition

the

floor

temperature

sensing

switch

turns

off

causing

the

starting

switch

line

of

the

floor

temperature

relay

to

turn

off

and

the

ignition

switch

line

to

turn

on

as

a

result

the

floor

temperature

warning

lamp

comes

on

When

the

floor

temperature

is

lower

t

an

the

specific

temperature

the

floor

temperature

sensing

switch

turns

on

The

ignition

line

of

the

floor

temperature

relay

turns

off

while

the

starting

switch

side

is

in

on

The

floor

temperature

warning

lamp

goes

out

EC

2B

The

lamp

is

functioning

sa

tis

factorily

if

it

is

remains

on

while

the

starting

motor

is

in

operation

The

lamp

goes

out

when

the

ignition

switch

is

in

IG

position

The

foUowing

chart

furnishes

the

information

on

the

relationship

be

tween

floor

temperatures

warning

lamp

and

sensing

switch

L

Contact

close

ECJ40

I

Contaclopen

ECJ41

Fig

EC

72

Operation

of

floor

t

mperature

sen6ing

6witch

REMOVAL

Floor

temperature

sensing

switch

1

Remove

seat

Seat

section

of

service

manual

2

Remove

sensing

sWitch

as

outlined

in

the

Body

and

Frame

floor

temperature

Floor

temperature

relay

From

under

relay

cover

remove

this

part

Refer

to

Figure

EC

73

Floortemperature

EC783

Fig

EC

73

Location

of

floor

ttmperature

relay

Page 173 of 537

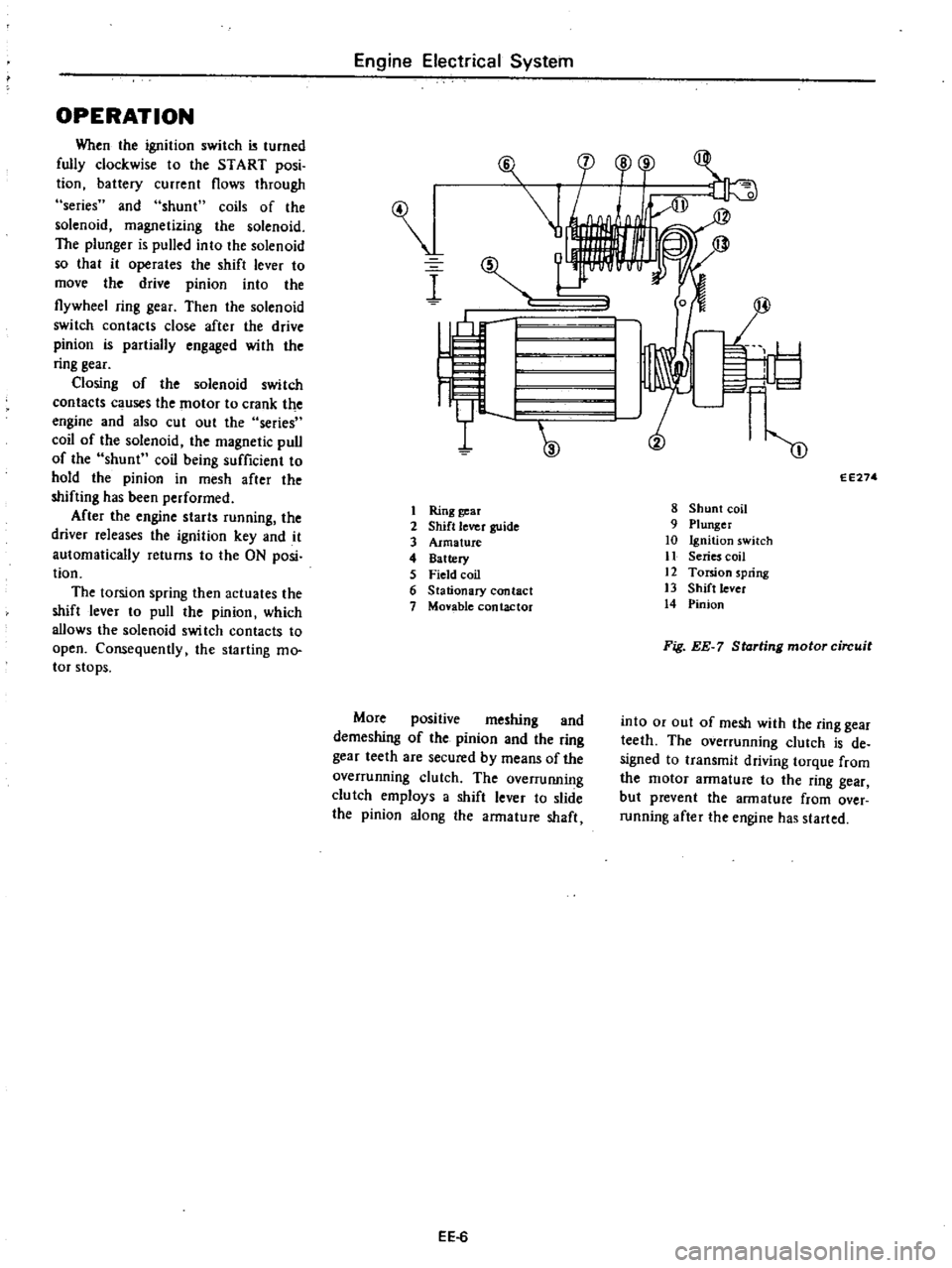

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 236 of 537

Manual

Transmission

4

SPEED

TRANSMISSION

TYPE

F4W71B

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

TRANSMISSION

CASE

DISASSEMBLY

D

ISASSEMBL

Y

OF

GEAR

ASSEMBLY

REAR

EXTENSION

DISASSEMBLY

ADAPTER

PLATE

DISASSEMBLY

INSPECTION

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

BEARING

GEARS

AND

SHAFTS

BAULK

RING

Oil

SEAL

ASSEMBL

Y

FRONT

COVER

ASSEMBLY

REAR

EXTENSION

ASSEMBLY

ADAPTER

PLATE

ASSEMBLY

GEAR

ASSEMBLY

TRANSMISSION

ASSEMBLY

INSTALLATION

MT

2

MT

4

MT

4

MT

4

MT

5

MT

B

MT

8

MT

8

MT

B

MT

8

MT

8

MT

9

MT

9

MT

9

MT

9

MT

9

MT

9

MT

9

MT13

MT14

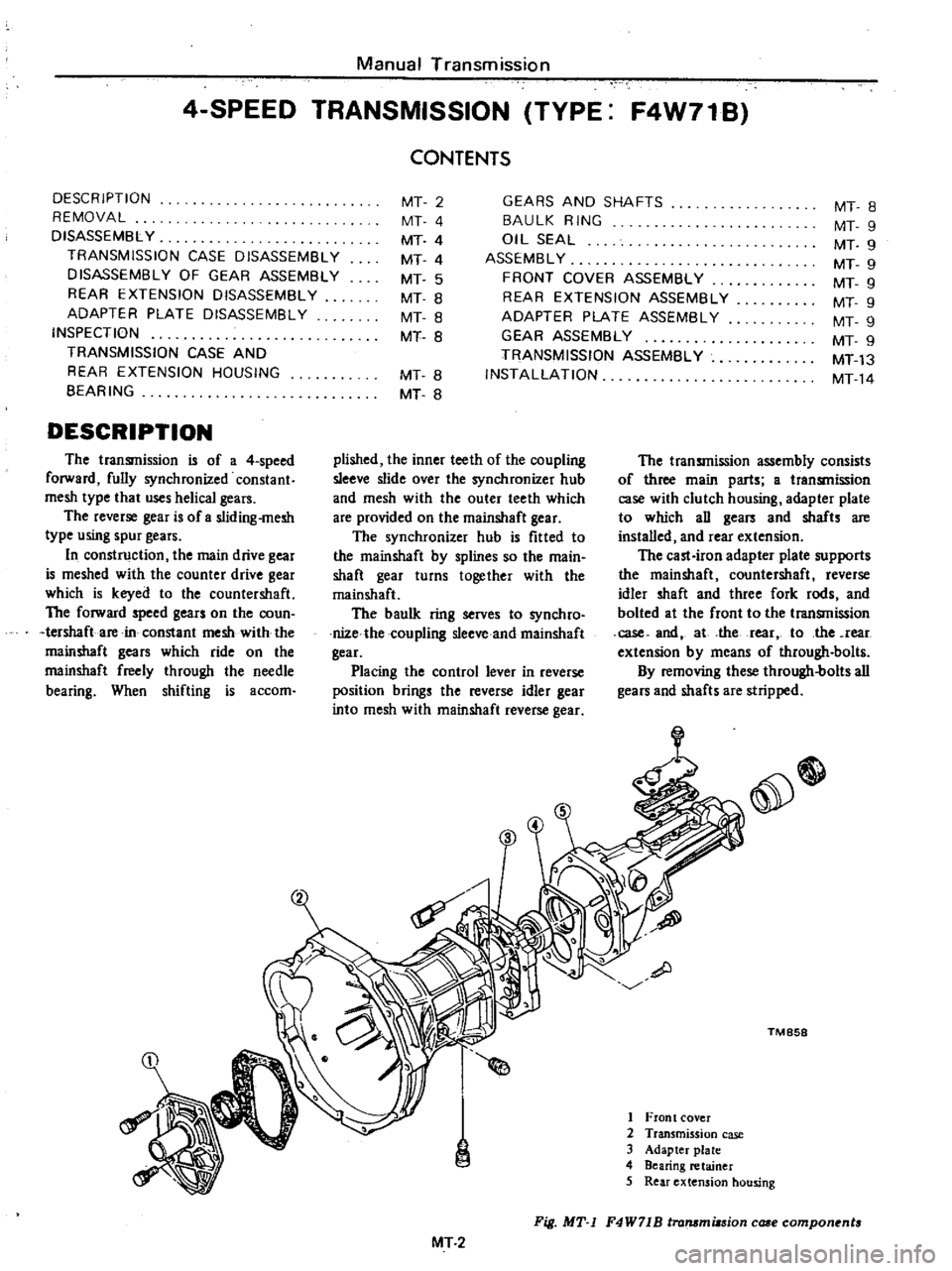

DESCRIPTION

pUshed

the

inner

teeth

of

the

coupling

sleeve

slide

over

the

synchronizer

hub

and

mesh

with

the

outer

teeth

which

are

provided

on

the

mainshaft

gear

The

synchronizer

hub

is

fitted

to

the

mainshaft

by

splines

so

the

main

shaft

gear

turns

together

with

the

mainshaft

The

baulk

ring

serves

to

synchro

nile

the

coupling

sleeve

and

mainshaft

gear

Placing

the

control

lever

in

reverse

position

brings

the

reverse

idler

gear

into

mesh

with

mainshaft

reverse

gear

The

transmission

is

of

a

4

speed

forward

fully

synchronized

constant

mesh

type

that

uses

helical

gears

The

reverse

gear

is

ofa

sliding

mesh

type

using

spur

gears

In

construction

the

main

drive

gear

is

meshed

with

the

counter

drive

gear

which

is

keyed

to

the

countershaft

The

forward

speed

gears

on

the

coun

tershaft

are

in

constant

mesh

with

the

mainshaft

gears

which

ride

on

the

mainshaft

freely

through

the

needle

bearing

When

shifting

is

accom

The

transmission

assembly

consists

of

three

main

parts

a

transmission

case

with

clutch

housing

adapter

plate

to

which

an

gears

and

shafts

are

installed

and

rear

extension

The

cast

iron

adapter

plate

supports

the

mainshaft

countershaft

reverse

idler

shaft

and

three

fork

rods

and

bolted

at

the

front

to

the

transmission

case

and

at

the

rear

to

the

rear

extension

by

means

of

through

bolts

By

removing

these

through

bolts

all

gears

and

shafts

are

stripped

e

TM

858

1

Front

cover

2

Transmission

case

3

Adapter

plate

4

Bearing

retainer

5

Rear

extension

hOUsing

Fig

MT

1

F4W71B

lrammiasion

case

compon

nt

MT

2

Page 241 of 537

Manual

Transmission

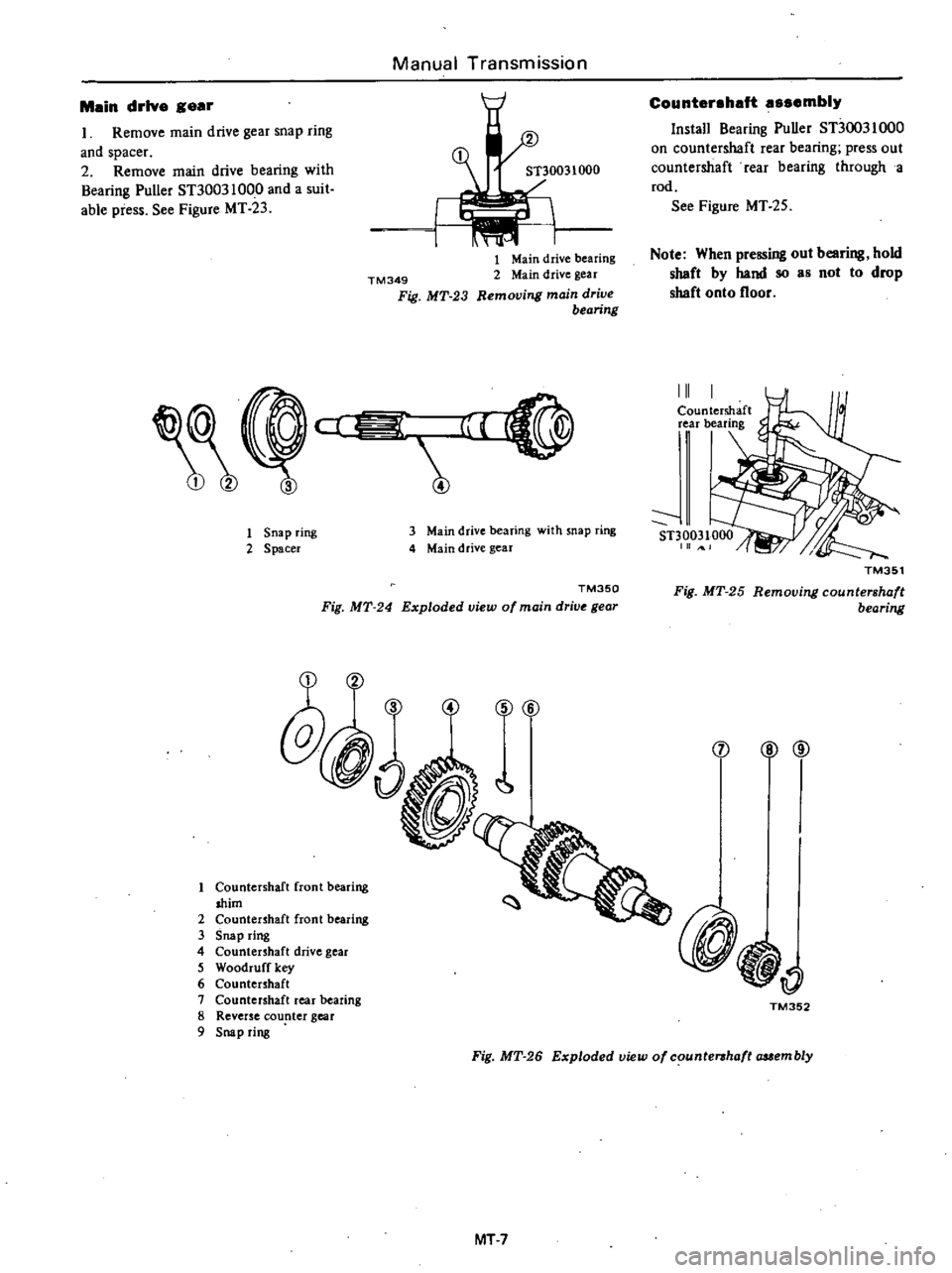

M

in

drlv

g

r

1

Remove

main

drive

gear

snap

ring

and

spacer

2

Remove

main

drive

bearing

with

Bearing

Puller

ST30031000

and

a

suit

able

piess

See

Figure

MT

23

TM349

Fig

MT

23

1

Main

drive

bearing

2

Main

drive

gear

Removing

main

drive

bearing

cl

iiiiiE

l

1

Snap

ring

2

Spacer

3

Main

drive

bearing

with

snap

ring

4

Main

drive

gear

TM350

Fig

MT

24

Exploded

view

of

main

drive

gear

e

q

1

f

1

Countershaft

front

bearing

shim

2

Countenhaft

front

bearing

3

Snap

ring

4

Countenhaft

drive

gear

5

Woodruff

key

6

Countenhaft

1

Countershaft

rear

bearing

8

Reverse

counter

gear

9

Snap

ring

Count

r

h

ft

mbl

Install

Bearing

Puller

STJOO31000

on

countershaft

rear

bearing

press

out

countershaft

rear

bearing

through

a

rod

See

Figure

MT

25

Note

When

pressing

out

bearing

hold

shaft

by

hand

so

as

not

to

drop

shaft

onto

floor

III

TM351

Fig

MT

25

Removing

countershaft

bearing

@

@

j

i

TM352

Fig

MT

26

Exploded

view

of

counte

haft

auembly

MT

7

Page 244 of 537

Malnshaft

assembly

I

Assemble

2nd

gear

needle

bear

ing

2nd

gear

baulk

ring

1st

2nd

speed

synchronizer

assembly

st

gear

baulk

ring

I

st

gear

bush

needle

bear

ing

I

st

gear

steel

ball

and

thrust

washer

on

mainshaft

Before

installing

a

steel

ball

apply

grease

to

it

See

Figure

MT

36

TM358

Fig

MT

36

l

talling

thrust

washer

2

Set

Transmission

Press

Stand

KV311

00400

and

place

adapter

plate

assembly

on

it

See

Figure

MT

37

For

counterman

and

reverse

idler

shaft

For

main5haft

and

reverse

tdler

haft

V31100400

J

UJ

V

TM438

Holes

for

reverse

Idler

shaft

Fig

MT

37

Tromm

inion

PreS3

S

tond

3

Install

mainshaft

assembly

to

adapter

plate

assembly

Be

sure

to

place

bearing

squarely

against

shaft

and

press

it

into

place

on

shaft

gradu

ally

See

Figure

MT

38

KV31100400

TM439

Fig

MT

38

Installing

mai

haft

em

bly

Manual

Transmission

Countershaft

assembly

I

Place

new

woodruff

keys

in

grooves

in

countershaft

and

tap

them

lightly

until

they

are

seated

securely

Use

a

soft

hammer

to

avoid

dam

aging

keys

2

Place

adapter

plate

assembly

and

mainshaft

assembly

so

that

counter

shaft

rear

bearing

rests

on

Transmis

sion

Press

Stand

KV31100400

prop

erly

3

Install

countershaft

into

adapter

plate

by

pressing

it

See

Figure

MT

39

TM440

Fig

MT

39

l

talling

countersha

t

4

Position

3rd

gear

needle

bearing

fnaiiiSh

ifOfd

gear

baulk

ring

and

3rd

4th

synchronizer

assembly

on

the

front

of

mainshaft

S

Ins

iall

thrust

washer

on

mainshaft

and

e

ure

it

with

snap

ring

of

proper

thickness

that

will

fit

the

groove

in

mainshaft

See

Figure

MT

40

Available

snap

ring

No

Thickness

mm

in

I

2

3

1

4

0

055

1

5

0

059

1

6

0

063

TM441

Fig

MT

40

l

talling

snap

ring

MT

l0

Main

drive

gear

assembly

1

Using

Transmission

Adapter

ST23800000

press

main

drive

bearing

onto

the

shaft

of

main

drive

gear

Make

sure

that

snap

ring

groove

on

shaft

clears

bearing

2

Place

main

drive

bearing

spacer

on

main

drive

bearing

and

secure

main

drive

bearing

with

thicker

snap

ring

that

will

eliminate

end

play

See

Figure

MT

4l

Available

snap

ring

No

Thickness

mm

in

2

3

4

5

6

1

80

0

0709

1

87

0

0736

1

94

0

0764

2

01

0

0791

2

08

0

0819

2

15

0

0846

CD

I

TM364

Fig

MT

41

Installing

snap

ring

3

Position

baulk

ring

on

cone

sur

face

of

main

drive

gear

Apply

gear

oil

to

mainshaft

pilot

bearing

and

install

it

on

mainshaft

Assemble

main

drive

gear

assembly

on

the

front

end

of

mainshafl

4

Press

counter

drive

gear

onto

countershaft

with

Counter

Gear

Drift

ST23860000

by

meshing

gears

and

secure

counter

drive

gear

with

thicker

snap

ring

See

Figures

MT

42

and

MT

43

Note

Be

sure

to

drive

in

counter

drive

gear

and

main

drive

gear

simultaneously

Page 313 of 537

In

these

cases

the

transmission

must

be

repaired

Notes

a

In

checking

oil

level

use

special

paper

cloth

to

handle

the

level

gauge

and

be

careful

not

to

let

the

scraps

of

paper

and

cloth

stick

to

the

gauge

b

Insert

the

gauge

fully

and

take

it

out

quickly

before

splashing

oil

adheres

to

the

gauge

Then

observe

the

level

c

Use

automatic

transmission

fluid

having

DEXRON

identifications

only

in

the

3N71B

automatic

trans

mission

d

Pay

attention

because

the

oil

to

be

used

differs

from

that

used

in

the

Nissan

Full

Automatic

TranSJTIis

sion

3N71A

Never

mix

the

oils

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

11

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Trarismission

and

rear

extension

Junction

of

transm

ss

ion

and

rear

extension

J

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

Refer

to

Figure

AT

il2

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

se

l

of

rear

extension

To

exactly

locate

the

place

of

oil

leaka

le

proceed

as

follows

Place

the

vehicle

in

a

pit

and

by

sampling

the

leaked

oil

determine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

r

d

wine

So

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Automatic

rransmission

Wipe

off

the

leaking

oil

and

dust

and

deiecl

the

spol

of

oil

eakage

l

se

nonflammable

organic

solve

t

s

ch

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperalure

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

spot

of

oil

lcakage

will

then

be

found

more

easily

Note

As

oil

leakage

from

the

breaih

er

does

not

take

place

except

when

running

at

high

speed

it

is

impos

sible

to

locate

this

leakage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLUTION

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

engine

does

not

operate

smoothly

and

if

too

high

a

strong

shock

or

creep

develops

when

changing

over

from

N

to

D

or

R

CHECKING

AND

ADJUSTING

KICK

DOWN

SWITCH

AND

DOWNSHIFT

SOLENOID

When

the

kickdown

operation

is

not

made

properly

or

the

speed

chang

ing

point

s

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

li

n

key

is

pqsitioned

a

t

the

I

st

stage

nd

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

should

be

closed

and

the

solenoid

should

click

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

instruments

See

Figure

ATl09

d

I

t

AT10S

Fig

AT

109

Downshift

solenoid

Note

Watch

for

oil

leakage

from

transmission

case

AT

4Q

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

is

equaUy

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Thereforc

great

care

should

be

exercised

because

incorrect

adjustment

will

rcsult

in

the

brcakdown

of

the

transmission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

as

far

as

P

to

I

range

wherc

clicks

will

be

felt

by

the

hand

This

is

the

detcnt

of

manual

valve

in

the

valve

body

and

indicates

th

correct

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accomplish

ed

by

refcrring

to

page

AT

35

for

Removal

and

Installa

tion

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operatio

l

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

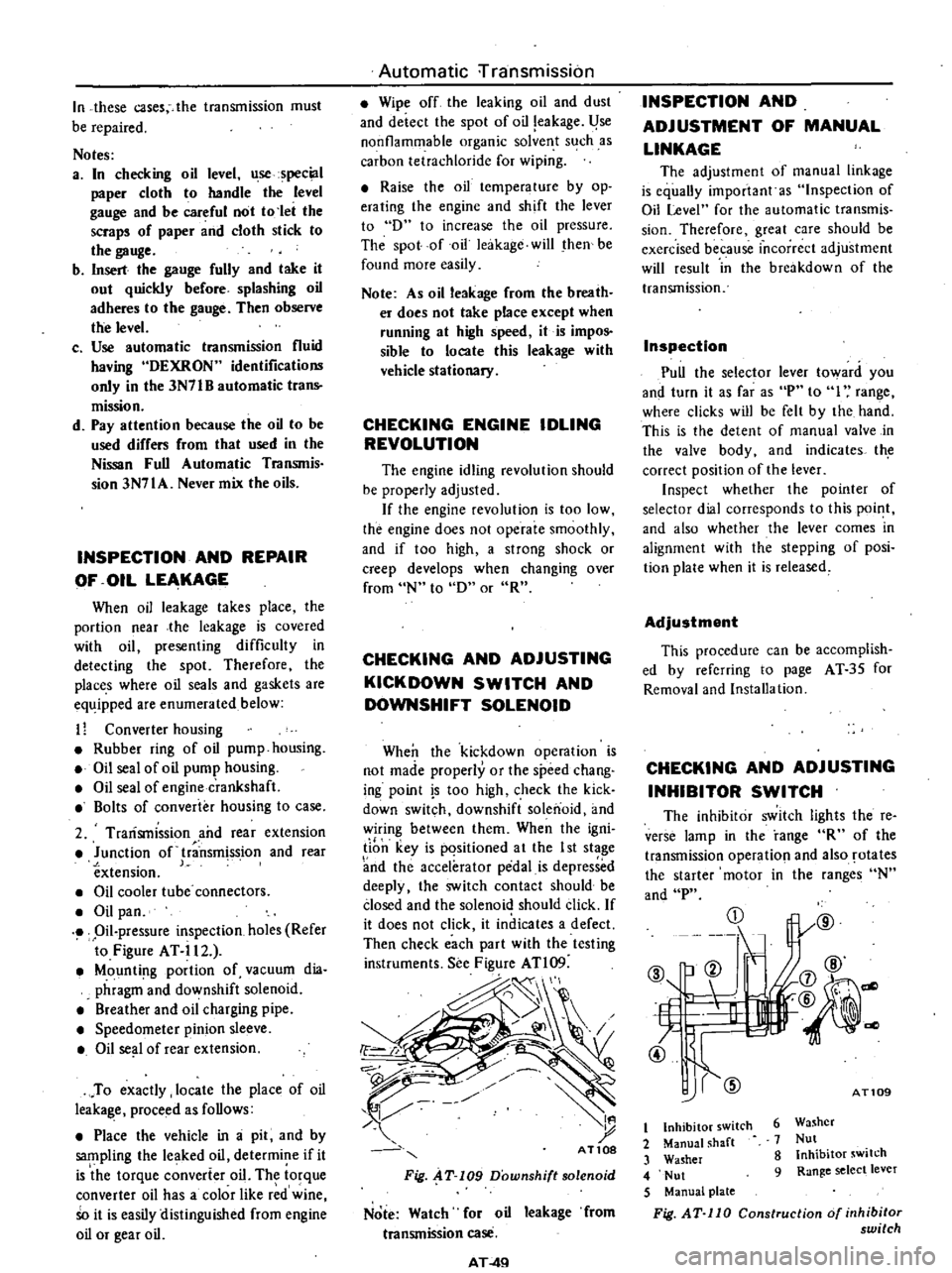

CD

@

b

ell

If

L

t

7

4l

@

1l

j7

@

@

@

dl

AT109

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

t

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

110

Construction

of

inhibitor

switch

Page 321 of 537

Automatic

Transmission

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

Order

Test

item

Checking

Oil

level

gauge

2

Downshift

solenoid

3

Manuallinkage

L

4

Inhibitor

switch

5

Engine

idling

rpm

6

Vacuum

pressure

of

vacuum

pipe

7

Operation

in

each

range

8

Creep

of

vehicle

Stall

test

I

Oil

pressure

before

tesling

1

2

Stall

test

3

Oil

pressure

after

testing

Road

test

Slow

acceleration

I

st

2nd

2nd

3rd

2

Quick

acceleration

lst

2nd

2nd

3rd

3

Kick

down

operation

3rd

2nd

or

2nd

1st

Procedure

Check

gauge

for

oil

level

and

leakage

before

and

after

each

test

Check

for

sound

of

operating

solenoid

when

depressing

accelerator

pedal

fully

with

ignition

key

ON

Check

by

shifting

into

P

lR

IN

D

2

and

I

ranges

with

selector

lever

Check

whether

starter

operates

in

N

and

p

ranges

only

and

whether

reverse

lamp

operates

in

R

range

only

Check

whelher

idling

rpm

meet

standard

Check

whether

vacuum

pressure

is

more

than

450

mmHg

in

idling

and

whether

it

decreases

with

increasing

rpm

Check

whether

transmission

engages

positively

by

shifting

N

0

N

2

N

l

I

and

N

R

range

while

idling

with

brake

applied

Check

whether

there

is

any

creep

in

D

2

R

ranges

and

Measure

line

pressures

in

D

2

I

and

R

range

while

idling

Measure

engine

rpm

and

line

pressure

in

D

2

I

and

R

ranges

during

full

throttle

operati

n

Notes

a

Temperature

of

torque

converter

oil

used

in

test

should

be

from

600

to

1000C

1400

to

2120F

i

e

sufficiently

warmed

up

but

not

overheated

b

To

cool

oil

between

each

stall

test

for

D

2

I

and

R

ranges

idle

engine

i

e

rpm

at

about

1

200

rpm

for

more

than

1

minute

in

P

range

Measurement

time

must

not

be

more

than

5

seconds

Same

as

item

I

Check

vehide

speeds

and

engine

cpm

in

shifting

up

Ist

2nd

range

and

2nd

Jo3rd

range

while

running

with

lever

in

D

range

and

engine

vacuum

pressure

of

about

200

I11I1lHg

Same

as

item

1

above

except

with

engine

vacuum

pressure

of

0

mmHg

i

e

in

position

just

before

kickdown

Check

whether

the

kickdown

operates

and

measure

the

time

delays

while

running

at

30

40

50

60

70

km

h

18

25

30

37

43

MPH

in

D3

range

AT

57

Page 391 of 537

REMOVAL

Referring

to

Figure

BR

29

remove

parts

in

numerical

order

enumerated

1

cD

2

BR17S

Fig

BR

29

Removal

method

of

Mcuter

Vae

DISASSEMBLY

When

disassembling

Master

Vac

ob

serve

the

following

instructions

a

Thoroughly

clean

mud

or

dust

from

Master

Vac

b

Extreme

care

should

be

taken

not

to

allow

dirt

dust

water

or

any

other

foreign

matter

into

any

com

ponent

parts

Be

sure

to

select

a

clean

place

before

disassembly

or

assembly

c

Mark

mating

joints

so

that

they

may

be

installed

exactly

in

their

original

positions

d

Keep

all

disassembled

parts

arranged

properly

so

that

they

may

readily

be

assembled

at

any

time

e

Clean

rubber

parts

and

synthetic

resin

parts

in

alcohol

f

Mter

all

disassembled

parts

are

cleaned

in

a

suitable

clean

solvent

place

on

a

clean

work

bench

Use

care

not

to

allow

dirt

and

dust

to

come

into

contact

with

these

parts

1

Install

spacer

on

rear

shell

spacer

temporarily

Place

Master

Vac

in

a

vise

Use

soft

jaws

2

Remove

clevis

and

lock

nut

De

tach

valve

body

guard

rW

ID

1

Clevis

2

Lock

nut

3

Valve

body

guard

BRD7S

Fig

BR

30

Removing

rear

hell

Brake

System

3

Identify

front

shell

and

rear

shell

clearly

so

that

they

may

be

reassem

bled

in

their

original

positions

from

which

they

were

withdrawn

Bolts

attached

on

dashboard

are

not

the

same

in

pitch

4

Using

Master

Vac

Wrench

ST08080000

remove

rear

shell

seal

assembly

and

disassemble

diaphragm

plate

assembly

front

shell

assembly

diaphragm

spring

and

push

rod

assem

bly

f

Q

BA076

Fig

BR

31

Removing

reor

shell

Rear

shell

seal

Pry

off

retainer

with

use

of

screw

driver

as

shown

and

detach

bearing

and

seal

Note

Do

not

disassemble

seal

assem

bly

unless

absolutely

necessary

Whenever

this

is

to

be

removed

use

care

not

to

damage

it

BRD7S

Fig

BR

32

Removing

retainer

Diaphragm

plate

Place

diaphragm

plate

assembly

on

a

clean

work

bench

Detach

dia

phragm

from

groove

in

plate

as

shown

BR

16

BA079

FlIf

BR

33

Separating

diaphragm

2

Using

a

screwdriver

as

shown

evenly

pry

air

silencer

retainer

until

it

is

detached

from

diaphragm

plate

as

sembly

Note

Never

use

a

hammer

to

remove

this

retainer

since

this

win

be

the

sure

y

of

damaging

it

BA322

Fig

BR

34

Removing

air

silencer

retainer

3

Pull

out

valve

plunger

stop

key

and

withdraw

silencer

and

plunger

assembly

Note

To

remove

valve

plunger

stop

key

properly

proceed

as

follows

With

key

hole

facing

down

lightly

push

valve

operating

rod

simulta

neously

while

applying

vibration

to

it

BA180

Fig

BR

35

Pulling

out

top

key

Page 392 of 537

BA1Bl

Fig

BR

36

Remouing

ualue

operating

rod

assembly

4

Withdraw

reaction

disc

BA286

Fig

BR

37

Remouing

reaction

disc

Front

shell

seal

I

Detach

flange

from

front

shell

assembly

BR287

g

Fig

BR

38

Removing

lange

2

Withdraw

front

seal

assembly

INSPECTION

I

Check

poppet

assembly

for

condi

tion

If

it

shows

evidence

of

wear

or

damage

replace

it

and

valve

operating

rod

assembly

2

Check

other

component

parts

for

condition

If

any

part

shows

evidence

of

wear

or

damage

replace

it

with

a

new

one

Brake

System

ASSEMBLY

AND

ADJUSTMENT

Assemble

in

the

reverse

sequence

of

disassembly

Rear

shell

seal

1

Apply

a

coating

of

Master

Vac

grease

to

the

sealing

surface

and

lip

of

seal

and

install

that

seal

in

rear

shell

with

the

use

of

Master

Vac

Oil

Seal

Retainer

Drift

ST08060000

Fig

BR

39

Installing

oil

seal

Note

Referring

to

Figure

BR

40

in

stall

seal

in

place

by

properly

aligning

the

pawl

of

special

tool

with

seal

hole

Adjustment

is

cor

rect

when

specified

length

at

A

is

obtained

Length

A

6

7

to

7

Omm

0

264

to

0

276

in

BA1S5

Fig

BR

40

Length

at

A

Diaphragm

plate

I

Apply

a

thin

coating

of

grease

to

the

sliding

contact

portion

on

the

periphery

of

plunger

assembly

BR

17

1

SR1S6

Fig

BR

41

Requiring

grease

place

2

Install

plunger

assembly

and

silencer

in

diaphragm

plate

and

lightly

push

plunger

stop

key

in

place

Note

Diaphragm

plate

is

made

of

bakelite

Exercise

care

in

instaJJing

plunger

assembly

not

to

damage

diaphragm

plate

BROB3

Fig

BR

42

Inserting

stop

key

3

Before

installing

diaphragm

into

position

apply

a

thin

coating

of

mica

power

to

it

except

outer

diameter

and

seating

portion

with

which

shell

comes

into

contact

4

Before

installing

reaction

disc

in

place

on

diaphragm

plate

apply

a

thin

coating

of

Master

Vac

grease

Front

shell

seal

Before

installing

front

shell

seal

as

sembly

apply

a

coating

of

Master

Vac

grease

to

the

inner

wall

of

seal

and

front

sheU

with

which

seal

comes

into

contact

Final

sssembly

Apply

thin

coating

of

Master

Vac

grease

to

the

outer

edges

of

diaphragm

with

which

rear

and

front

shells

come

into

contact

before

instaIling

dia

phragm

in

position

2

Before

installing

push

rod

assem

bly

in

place

apply

a

coating

of

Master

Vac

grease

to

the

sliding

con

tact

surface

of

diaphragm

plate

Page 439 of 537

REMOVAL

AND

INSTALLATION

I

Open

door

2

Remove

inside

door

handle

es

cutcheon

3

Remove

pull

handle

4

Remove

arm

rest

5

Remove

regulator

handle

6

Remove

door

finish

7

Peel

off

water

seal

screen

8

Raise

door

glass

to

full

up

posi

tion

9

Remove

inside

door

lock

knob

10

Remove

rear

lower

sash

attach

iog

bolts

11

Disconnect

remote

control

rod

from

key

cylinder

and

outside

door

handle

12

Remove

three

door

lock

assem

bly

attaching

screws

13

Remove

two

inside

door

handle

attaching

screws

14

Together

with

inside

door

handle

take

out

door

lock

as

an

assembly

through

large

access

hole

in

door

panel

15

Remove

two

outside

door

handle

attaching

nuts

Outside

door

handle

can

then

be

taken

out

16

Remove

lock

plate

from

key

cylinder

and

detach

key

cylinder

17

To

install

door

lock

assembly

outside

and

inside

door

handles

and

key

cylinder

reverse

removal

pro

cedure

18

Lubricate

door

lock

with

grease

which

meets

the

requirements

of

MIL

G

I0924B

or

equivalent

as

listed

below

ALVANIA

GREASE

RA

SHELL

BEACON

325

ESSO

MOBILE

GREASE

22

MOBIL

Body

Frame

ADJUSTMENT

OutsIde

door

handle

Adjustment

of

play

in

outside

door

handle

is

controlled

by

play

adjust

ment

of

nylon

nut

on

threaded

end

of

outside

door

handle

rod

Correct

play

is

1

0

mm

0

039

in

or

below

as

measured

between

nylon

nut

and

locking

plate

Inside

door

handle

Elongated

hole

in

inside

door

handle

provides

for

play

adjustment

of

inside

door

handle

Correct

play

is

1

0

mm

0

039

ill

or

below

as

measured

at

control

rod

A

L

A

I

1

rB

I

B

REMOVAL

AND

INSTAUATION

I

Open

door

2

Free

weatherstrip

from

door

sash

clamp

BF

15

DOOR

LOCK

STRIKER

Adjustment

of

door

lock

striker

should

be

made

after

door

hinge

has

been

adjusted

correctly

Elongated

holes

three

provide

for

up

and

down

or

fore

and

aft

adjust

ment

to

establish

proper

engagement

between

door

lock

striker

and

door

lock

latch

WEATHERSTRIP

DESCRIPTION

The

weatherstrip

is

retained

by

clamp

to

the

door

sash

and

by

19

clips

to

the

door

panel

No

adhesive

is

used

to

retain

the

weatherstrip

to

door

Section

A

A

j

Section

B

B

BF645

Fig

BF

34

Door

weatheratrip

3

Pry

off

clips

from

door

panel

remove

weatherstrip

4

To

instaH

reverse

removal

pro

cedure