oil change DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 229 of 537

Inspection

Note

To

clean

or

wash

all

parts

of

master

cylinder

operating

cylinder

and

piping

clean

brake

fluid

must

be

used

Never

use

minera10ils

llUch

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydrau

lic

system

I

Check

cylinder

and

piston

for

uneven

wear

or

damage

and

if

neces

sary

replace

2

If

the

clearance

between

cylinder

and

piston

is

more

than

0

15

mm

0

0059

in

replace

cylinder

3

Renew

piston

cup

when

dis

assembled

It

must

also

be

replaced

when

wear

or

deformation

due

to

fatigue

or

damage

is

found

4

Damaged

dust

cover

oil

reservoir

or

cap

should

be

replaced

Return

spring

and

valve

spring

must

also

be

replaced

when

they

are

broken

or

weak

5

Replace

clutch

hose

and

tube

if

any

abnormal

sign

of

damage

or

de

fro

ti

n

is

found

OPERATING

CYLINDER

Removal

and

installation

Removal

1

Detach

clutch

hose

from

operat

ing

cylinder

2

Remove

two

bolts

securing

op

erating

cylinder

to

clutch

housing

Installation

Install

in

the

reverse

order

of

re

moval

Observe

the

following

instructions

Bleed

air

thoroughly

from

clutch

hydraulic

system

2

Do

not

install

return

spring

or

clutch

will

not

be

disengaged

properly

Tightening

torque

Operating

cylinder

securing

bolt

2

5

to

3

5

kg

m

18

to

25

ft

lb

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ib

Clutch

hose

connector

1

7

to

2

0

kg

m

12

to

14

ft

b

CLUTCH

Disassembly

and

assembly

Disassembly

1

Remove

push

rod

with

dust

cover

2

Remove

piston

assembly

and

pis

ton

spring

3

Remove

bleeder

screw

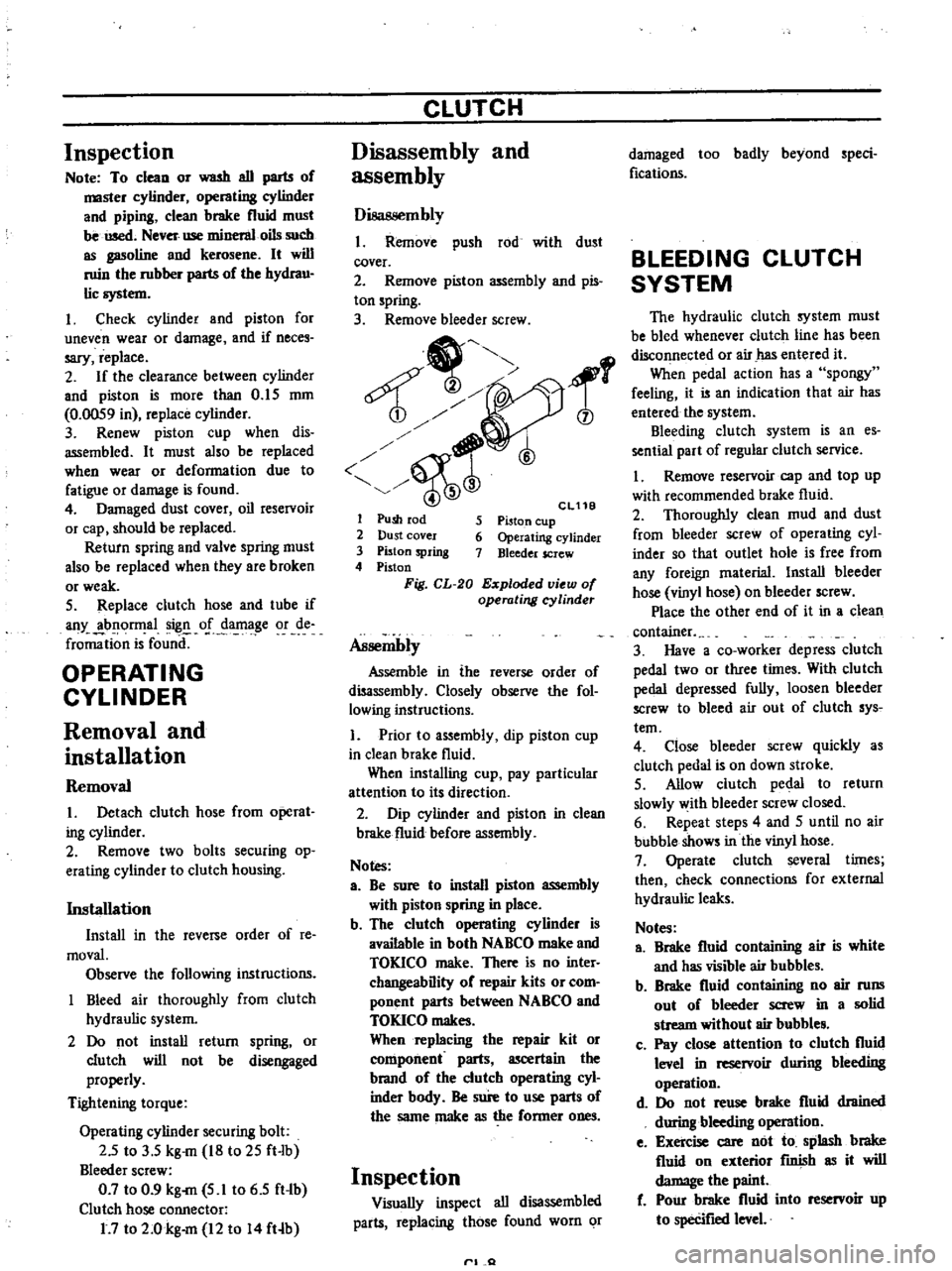

1

6

Cl11B

5

Piston

cup

6

Operating

cylinder

7

Bleeder

screw

1

Push

rod

2

Dust

cover

3

Piston

spring

4

Piston

Fig

CL

20

Exploded

view

of

operating

cyUnder

Assembly

Assemble

in

the

reverse

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

1

Prior

to

assembly

dip

piston

cup

in

clean

brake

fluid

When

installing

cup

pay

particular

attention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

Notes

a

Be

sure

to

install

piston

assembly

with

piston

spring

in

place

b

The

clutch

operating

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKICO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

operating

cyl

inder

bndy

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Inspection

Visually

inspect

all

disassembled

parts

replacing

those

found

worn

or

rl

Q

damaged

too

badly

beyond

speci

fications

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

es

sential

part

of

regular

clutch

service

I

Remove

reservoir

cap

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

rnaterial

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

clean

container

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clu

tch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tern

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

4

and

5

until

no

air

bubble

shows

in

the

vinyl

hose

7

Operate

clutch

several

times

then

check

connections

for

external

hydraulic

leaks

Notes

a

Brake

fluid

containing

air

is

white

and

has

visible

air

bubbles

b

Brake

fluid

containing

no

air

runs

out

of

bleeder

screw

in

a

solid

stream

without

air

bubble

c

Pay

close

attention

to

clutch

fluid

level

in

reservoir

during

bleeding

operation

d

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

e

Exercise

care

not

to

splash

brake

fluid

on

exterior

fInish

as

it

will

damage

the

paint

f

Pour

brake

fluid

into

reservoir

up

to

specifIed

level

Page 231 of 537

CLUTCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

and

testing

Clutch

slips

Corrective

action

Slipping

of

the

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Vehicle

will

not

respond

to

engine

speed

during

acceleration

2

Insufficient

vehicle

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

are

also

experienced

when

engine

problem

is

oc

urring

First

de

tennine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

until

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLlJfCH

proceed

as

follows

During

upgrade

travelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

at

the

same

time

rev

up

engine

If

clutch

is

slipping

vehicle

will

not

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

worn

excessively

Oil

or

grease

on

clutch

facing

W

r

d

clut

h

cov

r

pressure

plat

Replace

Replace

tpa

o

e

lace

Dragging

clutch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLlJfCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

from

Neutral

into

Reverse

Clutch

drags

2

Stop

engine

and

shift

gear

Conduct

this

test

at

each

gear

position

3

Gears

are

smoothly

shifted

in

step

2

but

drag

when

shifting

to

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

side

depress

pedal

to

check

for

free

travel

a

If

pedal

can

be

depressed

further

check

clutch

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

travel

withdrawal

lever

play

etc

If

no

abnonnal

condition

exists

and

if

pedal

cannot

be

depressed

further

check

clutch

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

ad

justment

or

toe

tip

worn

Worn

or

improperly

installed

parts

CL10

Repair

or

replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

Page 247 of 537

Note

Prior

to

assembling

reverse

fork

rod

instaU

two

2

interlock

balls

into

adapter

piate

as

shown

in

Figure

MT

I6

6

Install

check

ball

and

check

ball

spring

Apply

sealant

to

check

ball

plug

and

install

it

in

place

Align

notch

in

reverse

fork

rod

with

check

ball

See

Figure

MT

52

TM369

Fig

MT

52

Installing

reverse

fork

rod

7

Torque

each

check

ball

plug

to

1

9

to

2

5

kg

m

14

to

18

ft

Ib

Note

BaD

plug

for

ht

2nd

fork

rod

is

longer

than

those

for

rev

shift

fork

rod

and

3rd

4th

fork

rod

8

Apply

gear

oil

to

all

sliding

sur

faces

and

check

to

see

that

shift

rods

operate

correctly

and

gears

are

engaged

smoothly

TRANSMISSION

ASSEMBLY

Tran

mis

lon

ea

mbly

1

Clean

mating

surfaces

of

adapter

plate

and

transmission

case

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

transmission

case

2

Slide

transmission

case

onto

adapter

plate

by

lightly

tapping

with

a

soft

hammer

until

case

bears

against

adapter

plate

Carefully

install

main

drive

bearing

and

countershaft

front

bearing

Make

certain

that

mainshaft

rotates

freely

3

Fit

main

drive

bearing

snap

ring

to

groove

in

main

drive

bearing

by

using

Expander

See

Figure

MT

53

Manual

Transmission

Fig

MT

53

Fitting

main

drive

bearing

snap

ring

R

ar

xt

nslon

ass

mbly

I

Clean

mating

surfaces

of

adapter

plate

and

fear

extension

Apply

sealant

to

mating

surfaces

of

adapter

plate

and

rear

extension

2

With

fork

rods

in

their

neutral

positions

graduaUy

slide

rear

exten

sion

onto

adapter

plate

making

sure

that

speed

change

cross

lever

engages

with

fork

rod

brackets

correctly

3

Install

washers

and

through

bolts

and

torque

to

1

6

to

2

1

kg

m

12

to

15

ft

lb

Available

shim

Front

eov

r

s

mbly

I

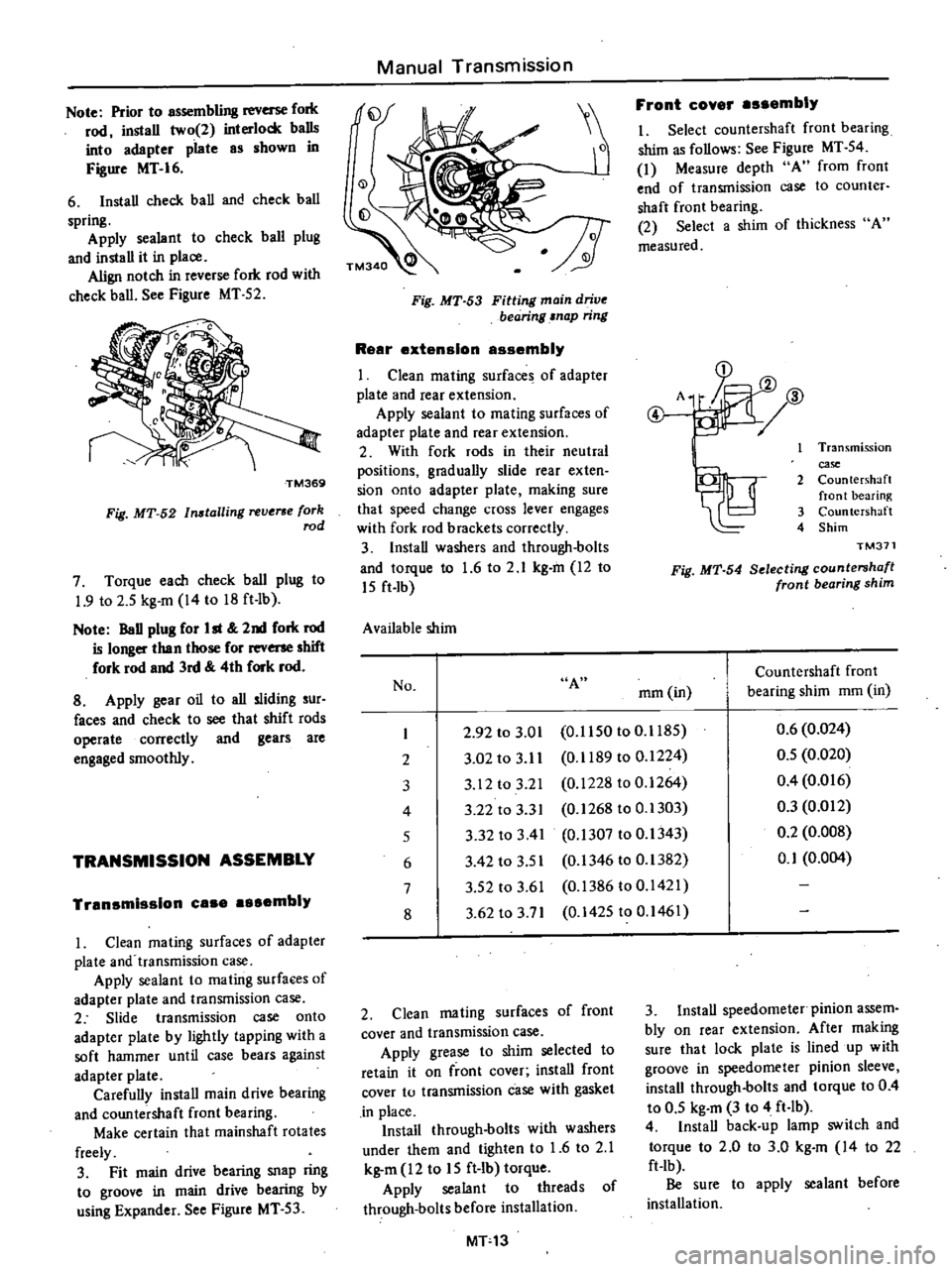

Select

countershaft

front

bearing

shim

as

follows

See

Figure

MT

54

1

Measure

depth

A

from

front

end

of

transmission

case

to

counter

shaft

front

bearing

2

Select

a

shim

of

thickness

A

measured

D

A

JJ

ID

@

2J1

I

Transmission

case

2

Countershaft

front

bearing

3

Countershaft

4

Shim

TM371

Fig

MT

54

Selecting

countershafl

front

bearing

shim

No

A

Countershaft

front

rnm

in

bearing

shim

mm

in

I

2

92

to

3

01

0

1150

to

0

1185

0

6

0

024

2

3

02

to

3

11

0

1189

to

0

1224

0

5

0

020

3

3

12

to

3

21

0

1228

to

0

1264

0

4

0

016

4

3

22

to

3

3

I

0

1268

to

0

1303

0

3

0

012

5

3

32

to

3

41

0

1307

to

0

1343

0

2

0

008

6

3

42

to

3

5

I

0

1346

to

0

1382

0

1

0

004

7

3

52

to

3

61

0

1386

to

0

1421

8

3

62

to

3

71

0

1425

to

0

1461

2

Clean

mating

surfaces

of

front

cover

and

transmission

case

Apply

grease

to

shim

selected

to

retain

it

on

front

cover

install

front

cover

to

transmission

case

with

gasket

in

place

Install

through

bolts

with

washers

under

them

and

tighten

to

1

6

to

2

1

kg

m

12

to

15

ft

lb

torque

Apply

sealant

to

threads

of

through

bolts

before

installation

MT13

3

Install

speedometer

pinion

assem

bly

on

rear

extension

After

making

Sure

that

lock

plate

is

lined

up

with

groove

in

speedometer

pinion

sleeve

install

through

bolts

and

torque

to

0

4

to

0

5

kg

m

3

to

4

ft

lb

4

Install

back

up

lamp

switch

and

torque

to

2

0

to

3

0

kg

m

14

to

22

ft

lb

Be

sure

to

apply

sealant

before

installation

Page 265 of 537

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

The

above

described

manual

shaft

is

further

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

tne

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rolor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

CD

1

Manual

pia

te

2

Inhibitor

switch

ATOB7

Parking

rod

Manual

shaft

Fig

AT

4

Manual

linkage

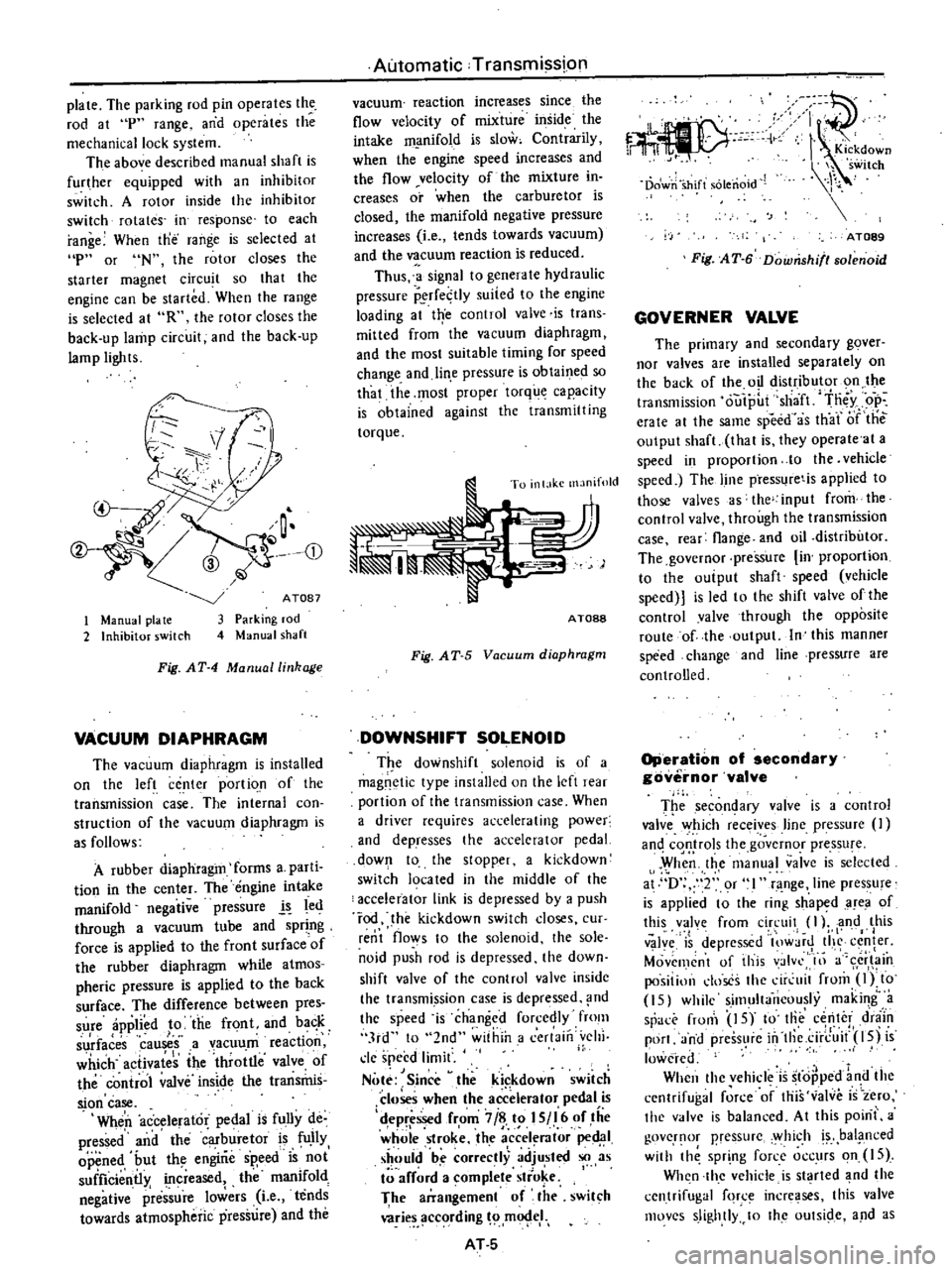

VACUUM

DIAPHRAGM

The

vacuum

diaphragm

is

installed

on

the

left

center

portio

n

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

parti

tion

in

the

center

The

engine

intake

manifold

negative

pressure

l

led

through

a

vacuum

tube

and

spring

force

is

applied

to

the

front

surfaceof

the

rubber

diaphragm

while

atmos

pheric

pressure

is

applied

to

the

back

surface

The

difference

between

pres

sure

applied

to

the

front

and

ba

K

I

surfaces

causes

a

vacuum

reactIOn

which

activates

the

throttle

valve

of

the

control

valve

inside

the

transrhis

sion

case

Wheri

accelerator

pedal

is

fully

de

pressed

and

the

buretor

is

fU

IIy

opened

but

th

engirie

sp

eed

is

not

suificientl

increased

the

manifold

negative

plre

sure

lowers

Le

tends

towards

atmospheric

pressure

and

the

Automatic

Transmission

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

m

mifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

in

creases

or

when

the

carburetor

is

closed

the

manifold

negative

pressure

increases

Le

tends

towards

vacuum

and

the

vacuum

reaction

is

reduced

Thus

a

signal

to

genera

Ie

hydraulic

pressure

P

rfe

tly

suited

to

the

engine

loading

at

trye

control

valve

is

trans

mitted

from

the

vacuum

diaphragm

and

the

most

suitable

timing

for

speed

change

and

lin

e

pressure

is

obtaine

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

To

inl

lkc

manifold

AT088

Fig

AT

5

Vacuum

diaphragm

DOWNSHIFT

SOLENOID

T

e

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

re

r

portion

of

the

transmission

case

When

a

driver

requires

accelerating

power

and

dePresses

the

accelerator

pedal

down

to

the

stopper

a

kickdown

switch

19ca

ted

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

he

kickdown

switch

doses

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valvc

insidc

the

transmi

ssion

case

is

depressed

nd

the

speed

is

changed

forcedly

fmm

3rd

to

2nd

within

a

cerlaill

vehi

cle

speed

limit

Note

Since

theki

kdown

switch

closes

when

the

accelerator

pedal

is

d

epr

ssed

from

7

i

t

I

S

I

6

of

tiie

whole

stroke

the

a

ccel

rator

ped

1

should

be

correctly

adjusted

so

as

arf

rd

a

omplete

stro

e

I

The

arrangement

of

the

swit

h

wries

ccording

m

eI

AT

S

c

C

r

11

I

Kickdown

h

switch

Dowri

shift

solenoid

AT089

Fig

AT

6

Downshifl80lenoid

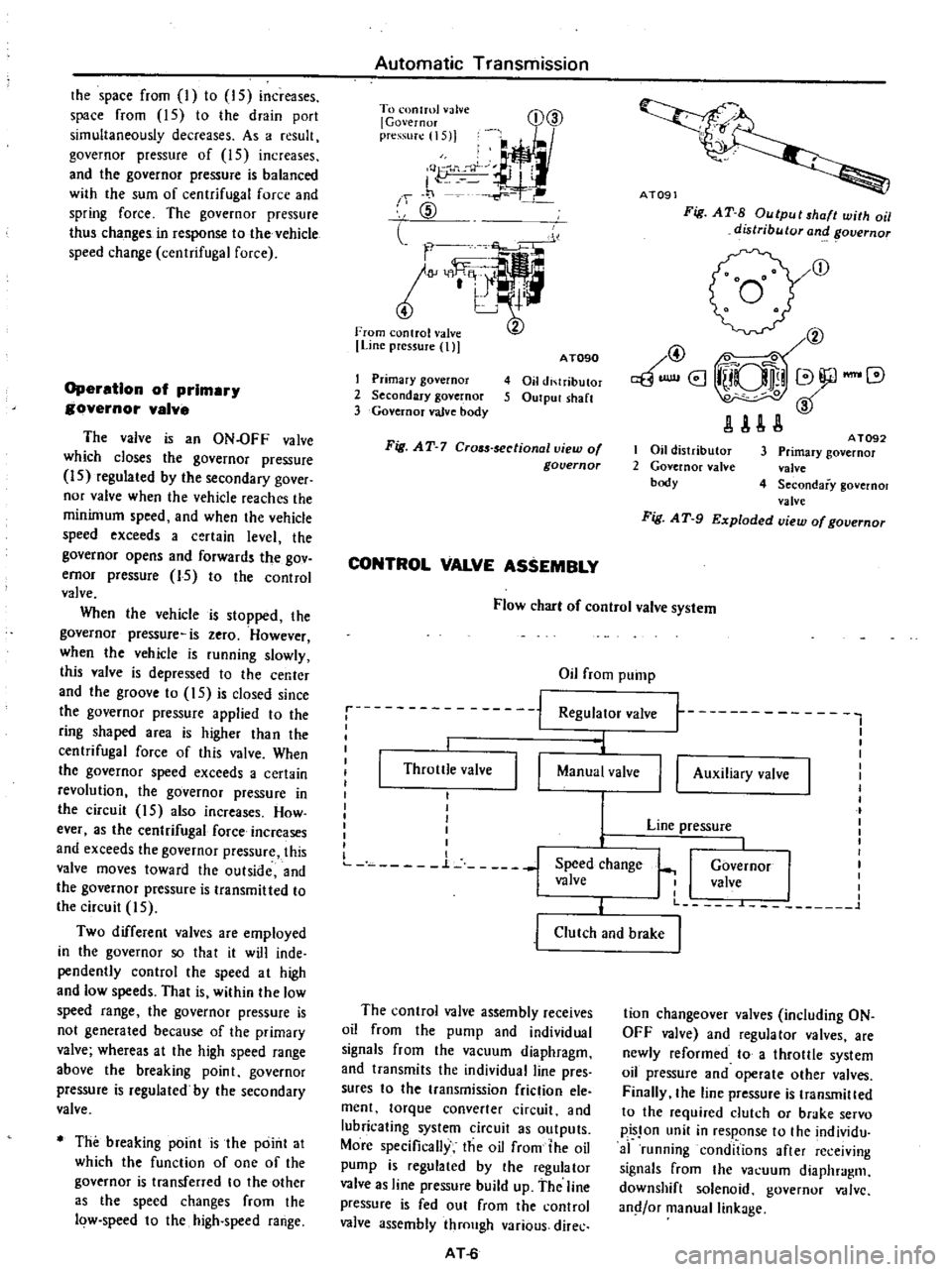

GOVERNER

VALVE

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

transmission

outp

t

sha

ft

tn

y

op

erate

al

the

same

speed

as

th

ar

iJf

tile

output

shaft

thai

is

they

operate

at

a

speed

in

proportion

10

the

vehicle

speed

The

line

press

retis

applied

to

those

valves

s

the

input

from

the

control

valve

through

the

transmission

case

rear

flange

and

oil

distributor

The

governor

pressure

in

proportion

to

the

ouiput

shaft

speed

vehicle

speed

is

led

to

the

shift

valve

ofthe

control

valve

through

the

opposite

route

of

the

output

In

this

manner

speed

change

and

line

pressure

are

controlled

Operation

of

secondary

governor

valve

T

e

secon

ary

valve

is

a

contro

valve

Y

hich

receives

line

pressure

an

cqQ

rols

the

governor

pressu

e

When

the

manual

valve

is

selected

at

D

2

or

l

range

line

pressure

is

applied

t

the

ri

g

sh

aped

area

of

this

valve

from

circuit

I

l

and

this

I

v

Jy

is

depressed

lOW

jr

tI

c

fer

Movemcnt

of

this

valvl

III

a

cr

in

positillll

doses

the

dr

uit

from

Olto

15

while

simultaneously

making

a

sr

rronl

IS

to

Iii

center

d

niin

port

and

press

re

in

tllc

ci

rJ

it

l5j

is

lowered

When

thc

vehicle

is

stopped

1

d

the

cenlrifugal

force

of

this

valve

is

zero

the

v

lve

is

balanced

At

this

poini

a

govcr

lOr

pressurc

y

hich

bal

i1

nced

with

th

spr

ng

force

occurs

on

IS

Wh

n

thc

vehicle

is

st

rted

nd

the

centrifugal

fqr

incre

ses

this

valve

movcs

slightly

10

Ihc

oUlSide

and

as

Page 266 of 537

the

space

from

I

to

IS

increases

space

from

15

to

the

drain

port

simultaneously

decreases

As

a

resull

governor

pressure

of

15

increases

and

the

governor

pressure

is

balanced

with

the

sum

of

centrifugal

force

and

spring

force

The

governor

pressure

thus

changes

in

response

to

the

vehicle

speed

change

centrifugal

force

Operation

of

prlmar

governor

valve

The

valve

is

an

ON

OFF

valve

which

closes

the

governor

pressure

IS

regulated

by

the

secondary

gover

nor

valve

when

the

vehicle

reaches

the

minimum

speed

and

when

the

vehicle

speed

exceeds

a

certain

level

the

governor

opens

and

forwards

the

gov

ernor

pressure

15

to

the

control

valve

When

the

vehicle

is

stopped

the

governor

pressure

is

zero

However

when

the

vehicle

is

running

slowly

this

valve

is

depressed

to

Ihe

center

and

the

groove

to

15

is

closed

since

the

governor

pressure

applied

to

the

ring

shaped

area

is

higher

than

the

centrifugal

force

of

this

valve

When

the

governor

speed

exceeds

a

certain

revolution

the

governor

pressure

in

the

circuit

15

also

increases

How

ever

as

the

centrifugal

force

increases

and

exceeds

the

governor

pressure

this

valve

moves

toward

the

outside

and

the

governor

pressure

is

transmitted

to

the

circuil

5

Two

different

valves

are

employed

in

the

governor

so

that

it

will

inde

pendently

control

the

speed

at

high

and

low

speeds

That

is

within

the

low

speed

range

the

governor

pressure

is

not

generated

because

of

the

primary

valve

whereas

at

the

high

speed

range

above

the

breaking

point

governor

pressure

is

regulated

by

the

secondary

valve

The

breaking

point

is

the

point

at

which

the

function

of

one

of

the

governor

is

transferred

to

the

other

as

the

speed

changes

from

the

low

speed

to

the

high

speed

range

Automatic

Transmission

To

onlml

valve

l

Governor

pre

S1I

1I5

j

I

Q

J

J

f

1

1

CID

l

l

m

Line

pressure

t

D@

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

AT090

4

Oil

di

lributor

5

Output

sh

lft

Fig

AT

7

Cr05s

sectionallliew

of

governor

CONTROL

VALVE

ASSEMBLY

Ai09

Fig

AT

S

Output

shaft

with

oil

distributor

and

overnor

r

@

@

0

aBUlllI8

iUQlli

V

JlAU

I

Oil

distributor

2

Governor

nlve

body

A

T092

3

Primary

governor

valve

4

Secondary

governol

valve

Fig

A

T

9

Exploded

view

of

governor

Flow

cbar

of

control

valve

system

Oil

from

pump

Regulator

valve

1

I

i

j

Throttle

valve

I

I

l

Manual

valve

I

I

I

I

I

I

I

L

n

L

j

Speed

change

valve

I

I

t

t

I

I

I

I

I

I

Governor

I

I

valve

I

I

I

L

L

1

II

Auxiliary

valve

Line

pressure

j

Clutch

and

brake

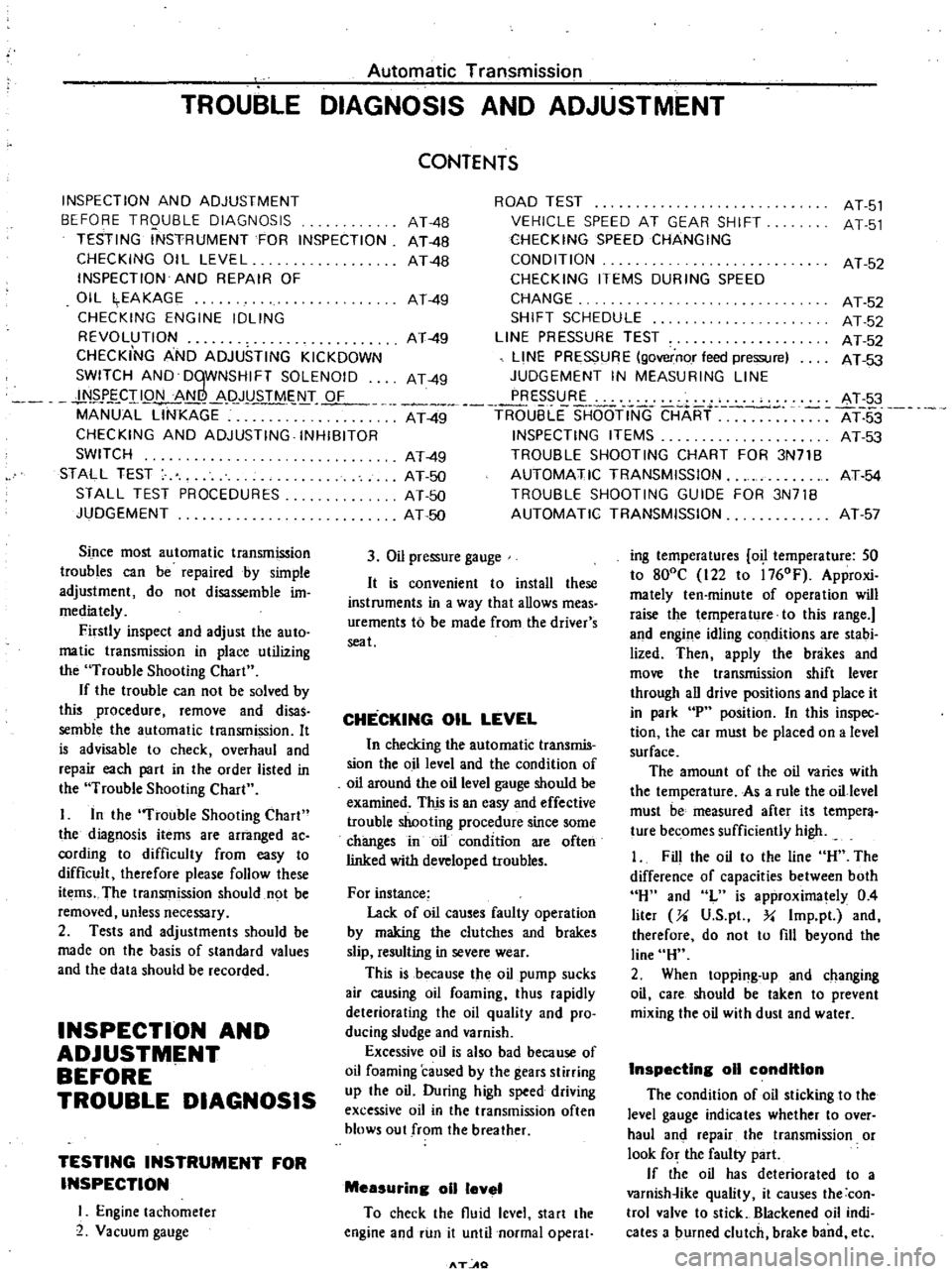

The

control

valve

assembly

receives

oil

from

the

pump

and

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

outputs

More

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

as

line

pressure

build

up

the

line

pressure

is

fed

out

from

the

control

valve

assembly

through

various

direc

AT

6

tion

changeover

valves

including

ON

OFF

valve

and

regulator

valves

are

newly

reformed

to

a

throllle

system

oil

pressure

and

operate

other

valves

Finally

the

line

pressure

is

transmilled

to

the

required

dutch

or

brake

servo

pisJon

unit

in

response

to

the

individu

af

running

conditions

after

re

ejving

signals

from

the

va

uum

diaphragm

downshift

solenoid

governor

V

dlvc

and

or

manual

linkage

Page 269 of 537

3

Jit

f

ng

valve

24

1

3

L

l

r

I

Js

I

i

ilr

t

pressure

6

when

shif

ing

from

3rd

to

2nd

at

D

range

Thus

the

throttle

of

line

pressure

6

reduces

the

shock

generated

fro

shifting

A

plug

in

the

SSV

left

end

readjust

the

throttle

piessu

e

I

6

which

varies

depending

on

the

engine

throttle

con

dition

to

a

throttle

pressure

19

suiled

to

the

sp

ed

change

control

Moreover

the

plug

is

a

valve

which

applies

line

P

esspre

13

in

lieu

of

the

throttle

pressure

to

the

SSV

and

the

FSV

when

kickdowri

is

performed

When

the

throttle

pressure

16

is

applied

to

the

left

side

of

this

plug

and

the

plug

is

epressed

toward

the

right

a

slight

space

is

formed

from

the

throttle

pressure

6

10

19

A

throt

tIepressu

19

w

1iFh

is

lower

by

the

pressure

loss

equivalent

to

this

space

is

rH

1

Pressure

Odifier

valve

PMV

I

Compared

to

the

operating

pressure

required

in

starting

th

vehicle

the

ppwer

trimsinitting

capacity

of

the

clutch

that

is

required

operating

pres

sure

may

be

lower

when

the

vehicle

is

once

started

When

the

line

pressure

is

retained

at

a

high

level

up

to

a

high

vehicle

speed

shock

gerieraled

from

the

shirring

increases

arid

the

oil

pump

loss

also

jncrdases

In

order

to

prevent

his

the

t

lrott

le

pressure

must

be

l

hanged

over

with

the

operation

of

the

governor

pressure

15

to

reduce

Ihe

line

pressure

The

PMV

is

used

for

this

purposc

Automatic

Transmission

generated

the

piessure

loss

is

adde

d

to

the

spring

force

and

the

plug

is

lhus

forced

back

from

the

right

to

the

left

When

this

pressure

19

increases

ex

cessively

the

plug

is

further

depressed

toward

the

left

space

from

the

lhrot

tle

pressure

19

to

the

drain

circuit

13

increases

and

the

throttle

press

ure

19

decreases

Thus

the

plug

is

balanced

imd

the

throttle

pressure

19

is

reduced

to

Ii

certain

value

against

the

throttle

pressure

6

Wheri

performing

kickdowri

the

SDV

moves

a

high

line

pressure

is

led

to

the

circuit

19

from

the

line

pressure

circuit

13

which

had

been

drained

the

plug

is

forced

toward

the

left

and

circuit

19

becomes

equal

to

the

line

pressure

13

I

W

15

I

A

TOgS

Fig

iT

13

2nd

3rd

shift

vallJe

I

When

the

governor

pressuie

IS

which

is

applied

to

the

right

side

of

the

PMV

is

low

the

valve

is

forced

toward

the

right

by

the

throttle

ines

sure

16

applied

to

the

area

differ

ence

of

the

value

and

the

spring

foice

and

t

he

circuit

from

circuit

16

to

circuit

18

is

closed

However

when

vehicle

speed

increases

andl

the

gaver

nor

pressure

15

exceeds

a

certain

level

the

governor

pressure

toward

the

left

which

is

applied

to

the

right

side

exceeds

the

spring

force

and

the

throt

tle

pressure

16

toward

thc

right

the

valve

is

depressed

loward

the

lefi

and

the

throttle

pressure

is

led

from

circuit

AT

9

16

to

circuit

18

This

throttle

pressure

18

is

applied

to

the

top

of

the

PRV

and

the

force

of

the

line

pressure

source

7

is

reduced

Contra

rily

when

the

vehicle

speed

decreases

arid

the

governor

ipressure

15

de

creases

the

force

toward

the

fight

exceeds

ithe

governor

pressure

the

valve

is

forced

back

toward

the

right

and

the

throttle

pressure

18

is

drained

to

the

spring

unit

This

valve

is

sWitched

when

the

throttle

pressure

and

the

governor

pressure

are

high

or

when

tIiey

are

both

Tow

i

i

I

11

18

16

n

r

I

I

15

AT099

Fig

AT

14

Pre

ure

modifier

valve

Vacuum

thro

le

valve

VTV

The

vacuum

t

rottle

valve

is

a

regula

tor

valve

whiCh

uses

the

line

pressure

7

for

the

pressure

source

and

regulates

the

throttle

pressure

16

I

which

is

proportioned

t

the

force

of

the

vacuum

diaphragm

The

vacuum

dia

phragm

yories

depending

on

the

engine

throt

le

condition

negative

pressure

in

the

inta

e

line

When

the

line

pressure

7

is

ap

plied

to

the

bottom

through

the

valve

hole

and

the

v

a

ve

is

forced

upward

space

from

the

line

pressure

7

to

the

throttle

pressure

16

is

dosed

and

the

space

from

the

Ihrottle

pressure

16

to

the

drain

circuit

17

is

about

to

open

In

this

operation

the

throttle

pressure

16

becomes

lower

than

the

linep

s

ureY

btthe

p

e

sur

9

iv

alenl

of

the

loss

of

space

and

Ihe

force

depressing

tlie

rod

if

the

vaeuum

diaphragm

is

balanced

wit

Ii

thethrot

tie

pressure

16

a

pplied

upward

tOlthe

bottom

When

the

erigine

torque

is

high

Ihe

negative

pressure

in

the

intake

iirie

rises

tending

ioward

atmospheric

pressure

and

the

force

of

the

rod

to

depress

the

valve

increases

As

a

result

the

valve

is

depressed

downward

the

Page 312 of 537

Automatic

Transmission

TROUBLE

DIAGNOSIS

AND

ADJUSTMENT

INSPECTION

AND

ADJUSTMENT

BEFORE

TRQUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

CHECKING

OIL

LEVEL

INSPECTION

AND

REPAIR

OF

OIL

EAKAGE

CHECKING

ENGINE

IDLING

REVOLUTION

CHECKING

AND

ADJUSTING

KICKDOWN

SWITCH

AND

DqWNSHIFT

SOLENOID

N

J

J

CII

Q

t

L

8li

p

JYSTMs

T

OF

MANUAL

LINKAGE

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

STALL

TEST

STALL

TEST

PROCEDURES

JUDGEMENT

Since

most

automatic

transmission

troubles

can

be

repaired

by

simple

adjustment

do

not

disassemble

im

mediately

Firstly

inspect

and

adjust

the

auto

matic

transmission

in

place

utilizing

the

Trouble

Shooting

Chart

If

the

trouble

can

not

be

solved

by

this

procedure

remove

and

disas

semble

the

automatic

transmission

It

is

advisable

to

check

overhaul

and

repair

each

part

in

the

order

listed

in

the

Trouble

Shooting

Chart

I

In

the

Trouble

Shooting

Chart

the

diagnosis

items

are

arranged

ac

cording

to

difficulty

from

easy

to

difficult

therefore

please

follow

these

items

The

transmission

should

not

be

removed

unless

necessary

2

Tests

and

adjustments

should

be

made

on

the

basis

of

standard

values

and

the

data

should

be

recorded

INSPECTION

AND

ADJUSTMENT

BEFORE

TROUBLE

DIAGNOSIS

TESTING

INSTRUMENT

FOR

INSPECTION

I

Engine

tachometer

2

Vacuum

gauge

ROAD

TEST

VEHICLE

SPEED

AT

GEAR

SHIFT

CHECKING

SPEED

CHANGING

CONDITION

CHECKING

ITEMS

DURING

SPEED

CHANGE

SHIFT

SCHEDULE

LINE

PRESSURE

TEST

LINE

PRESSURE

governor

feed

pressure

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

At

49

TR6

uBLE

SHOOTINC

CHART

INSPECTING

ITEMS

TROUBLE

SHOOTING

CHART

FOR

3N71B

AUTOMATIC

TRANSMISSION

TROUBLE

SHOOTING

GUIDE

FOR

3N71B

AUTOMATIC

TRANSMISSION

CONTENTS

AT

4B

AT

48

AT

4B

AT

49

AT

49

AT

49

AT

49

AT

50

AT

50

AT

50

3

Oil

pressure

gauge

It

is

convenient

to

install

these

instruments

in

a

way

that

allows

meas

urements

to

be

made

from

the

driver

s

seat

CHECKING

OIL

LEVEL

In

checking

the

automatic

transmis

sion

the

o

illevel

and

the

condition

of

oil

around

the

oil

level

gauge

should

be

examined

This

is

an

easy

and

effective

trouble

shooting

procedure

since

some

changes

in

oil

condition

are

often

linked

with

developed

troubles

For

instance

Lack

of

oil

causes

faulty

operation

by

making

the

clutches

and

brakes

slip

resulting

in

severe

wear

This

is

because

the

oil

pump

sucks

air

causing

oil

foaming

thus

rapidly

deteriorating

the

oil

quality

and

pro

ducing

sludge

and

varnish

Excessive

oil

is

also

bad

because

of

oil

foaming

caused

by

the

gears

stirring

up

the

oil

During

high

speed

driving

excessive

oil

in

the

transmission

often

blows

out

from

the

breather

Measuring

011

level

To

check

the

fluid

level

start

the

engine

and

run

it

until

normal

operat

T

AO

AT

51

AT

51

AT

52

AT

52

AT

52

AT

52

AT

53

AT

3

AT

53

AT

53

AT

54

AT

57

ing

temperatures

o

temperature

SO

to

800C

122

to

l760F

Approxi

mately

ten

minute

of

operation

will

raise

the

temperature

to

this

range

and

engine

idling

conditions

are

stabi

lized

Then

apply

the

brakes

and

move

the

transmission

shift

lever

through

all

drive

positions

and

place

it

in

park

P

position

In

this

inspec

tion

the

car

must

be

placed

on

a

level

surface

The

amount

of

the

oil

varies

with

the

temperature

As

a

rule

the

oil

level

must

be

measured

after

its

temper

ture

becomes

sufficiently

high

1

Fill

the

oil

to

the

line

H

The

difference

of

capacities

between

both

H

and

L

is

approximately

0

4

liter

Ji

V

S

p

Y

Imp

pl

and

therefore

do

not

to

fill

beyond

the

line

H

2

When

topping

up

and

changing

oil

care

should

be

taken

to

prevent

mixing

the

oil

with

dust

and

water

InspectIng

011

condition

The

condition

of

oil

sticking

to

the

level

gauge

indicates

whether

to

over

haul

and

repair

the

transmission

or

look

for

the

faulty

part

If

the

oil

has

deteriorated

to

a

varnish

ike

quality

it

causes

the

con

trol

valve

to

stick

Blackened

oil

indi

cates

a

burned

clutch

brake

band

etc

Page 316 of 537

CHECKING

SPEED

CHANGING

CONDITION

The

driver

s

feeling

during

gear

changes

should

also

be

checkedatten

tively

I

A

sharp

shock

or

unSffioothness

is

felt

during

a

gear

change

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

These

indicate

that

the

tIuottle

pressure

is

too

low

or

some

valve

connected

to

the

throttle

is

faulty

h

k

100

1

1

2

I

2

J

I

1

2

I

I

I

2

3

oo

I

c

I

E

I

I

300

I

Z

5

L

mmHg

t

1

400

I

I

1

Output

shaft

speed

rpm

20

30

40

50

60

70

80

90100

00

io

3

0

40

0

60

Vehicle

speed

R

4

315

r

0

321

6

00

14

ATll0

Fig

AT

111

Shift

IChedule

Automatic

Transmission

SHI

SCHEDULE

500

CHECKING

ITEMS

DURING

km

hO

1O

SPEED

CHANGE

I

In

D

range

gear

changes

DI

D2

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kickdown

operates

properly

3

By

moving

the

lever

from

D

to

I

gear

changes

D

2

1

2

1

are

effected

In

the

ranges

12

and

I

the

engine

braking

works

prop

erly

4

In

I

the

speed

does

not

in

crease

5

Should

be

quickly

fixed

at

2

range

6

In

P

vehicle

can

he

parked

properly

If

any

malfunction

occurs

in

second

gear

during

the

road

test

that

is

if

vehicle

shakes

drags

or

slings

while

shifting

up

from

D

directly

to

D

or

in

shifting

up

from

D

to

D2

the

brake

band

should

be

ad

justed

If

these

troubles

remain

after

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

MPH

Ii

io

LINE

PRESSURE

TEST

When

any

slipping

occurs

in

clutch

or

brake

or

the

feeling

during

a

speed

change

is

not

correct

the

line

pressure

must

be

checked

Measuring

line

pressure

is

done

by

a

pressure

gauge

attached

to

two

pres

sure

measuring

holes

after

removing

blind

plugs

located

at

transmission

case

See

Figure

AT

112

The

line

pressure

measurement

is

begun

at

idling

and

taken

step

by

step

by

enlarging

the

throttle

opening

I

A

sharp

shock

in

up

shifting

or

too

high

changing

speeds

are

caused

mostly

by

too

high

throttle

pressure

2

Slipping

or

incapability

of

opera

tion

is

mostly

due

to

oil

pressure

leakage

within

the

gear

trains

or

spool

valve

AT

S2

3

3SA

000

t

I

1

I

c

l

1

c

7

D

jf

o

CV

ATl13

1

Lige

pressure

2

Governor

feed

3

SerVo

release

pressure

Fig

AT

112

MeCJ

uring

line

preuure

Page 320 of 537

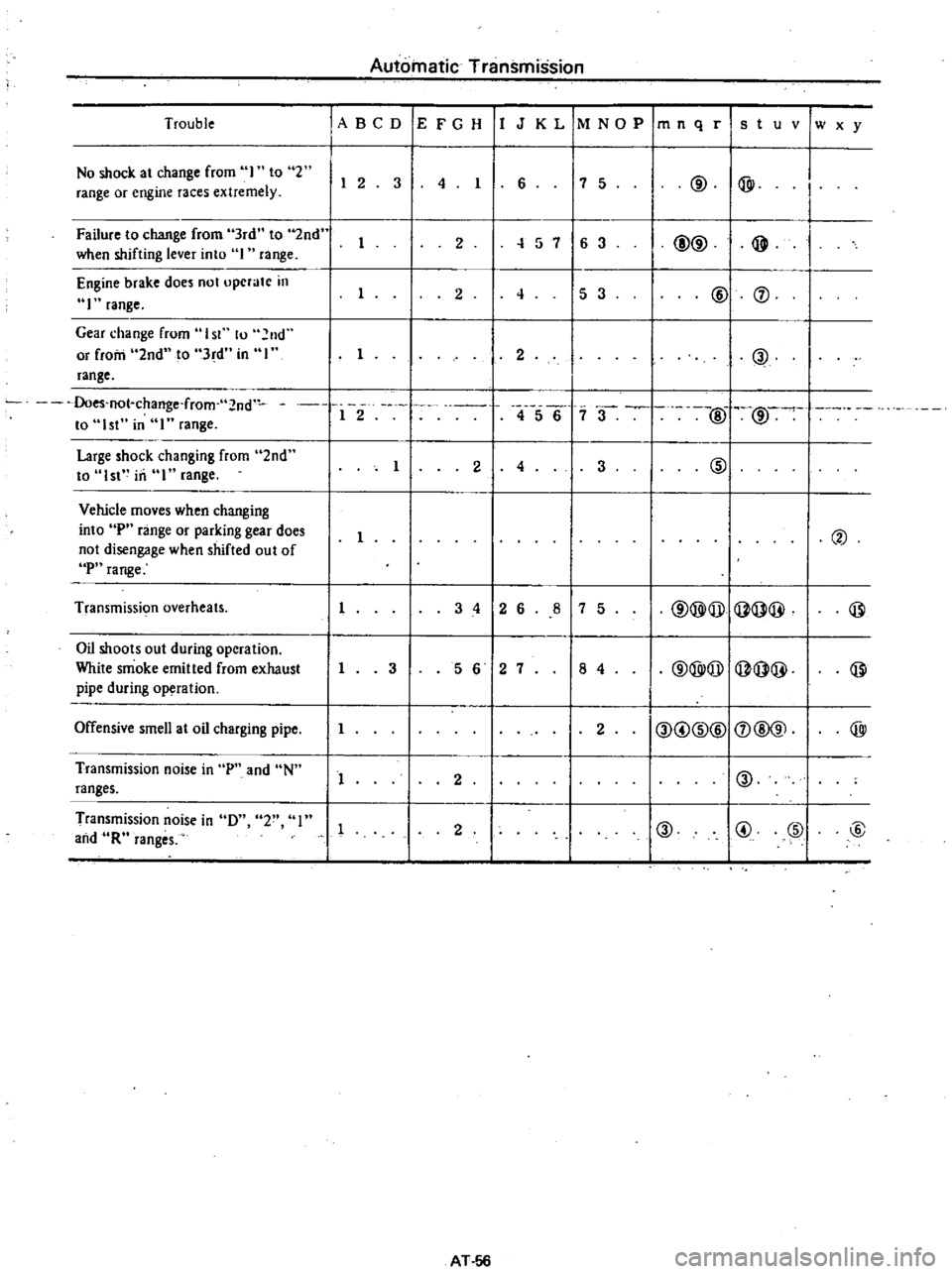

Trouble

No

shock

at

change

from

I

to

2

range

or

engine

races

extremely

Failure

to

change

from

3rd

to

2nd

when

shifting

lever

into

I

range

Engine

brake

does

not

upcrate

in

1

range

Gear

change

frum

I

sr

lu

2nd

or

from

2nd

to

3rd

in

I

range

Does

not

change

f

rom

2nd

to

1st

in

range

Large

shock

changing

from

2nd

to

1st

in

range

Vehicle

moves

when

changing

into

P

range

or

parking

gear

does

not

disengage

when

shifted

out

of

P

range

Transmissic

m

overheats

Oil

shoots

out

during

operation

White

smoke

emitted

from

exhaust

pipe

during

operation

Offensive

smell

at

oil

charging

pipe

Transmission

noise

in

p

and

N

ranges

Transmission

noise

in

D

2

I

and

R

ranges

Automatic

Transmission

ABeD

E

F

G

H

I

J

K

L

1M

NO

P

1m

n

q

r

s

t

u

v

Iw

x

y

6

7

5

@

@

I

I

2

3

4

I

I

2

1

57

6

3

@@

@

I

2

4

5

3

@

f

1

2

@

1

2

4567

3

@

2

1

3

@

2

4

I

2

I

3

4

2

6

8

7

5

@@@

Q

@@

@

I

3

5

6

2

7

8

4

@@@

Q

@@

@

1

2

O

G

@@

f

@@

@

1

2

10

I

I

2

0

G

@

@

AT

56

Page 331 of 537

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Watch

for

oil

leakage

from

trans

mission

end

Notes

a

Remove

propeller

shaft

carefully

so

as

not

to

damage

spline

sleeve

yoke

and

rear

oil

seal

b

Plug

up

the

opening

in

the

rear

of

rear

extension

housing

to

prevent

oil

from

flowing

out

To

install

reverse

the

foregoing

removal

procedure

1

Align

propeller

shaft

with

com

panion

flange

using

reference

marks

prescribed

in

removal

procedure

and

assemble

with

bolts

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

2

Insert

bolts

through

the

holes

of

center

beariug

bracket

and

torque

nuts

to

retain

center

bearing

on

cross

member

Tightening

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Primarily

do

not

disassemble

pro

peller

shaft

because

it

is

balanced

as

an

assembly

However

check

propeller

shaft

with

journal

for

movement

When

journal

does

not

move

smoothly

dis

assemble

1

Mark

propeller

shaft

and

journal

so

that

the

original

combination

can

be

restored

at

assembly

2

Remove

snap

ring

with

a

standard

screwdriver

3

Lightly

tap

base

of

yoke

with

a

hammer

and

withdraw

bearing

race

See

Figure

PD

4

PDOO5

Fig

PD

4

Remo

i

bearing

Note

When

removing

journal

from

yoke

be

careful

not

to

damage

journal

and

yoke

bole

When

disassembling

and

repairing

center

bearing

are

required

the

follow

ing

procedures

are

applied

1

Put

match

marks

on

flange

and

front

propeller

shaft

Remove

bolts

connecting

flange

yoke

to

companion

flange

2

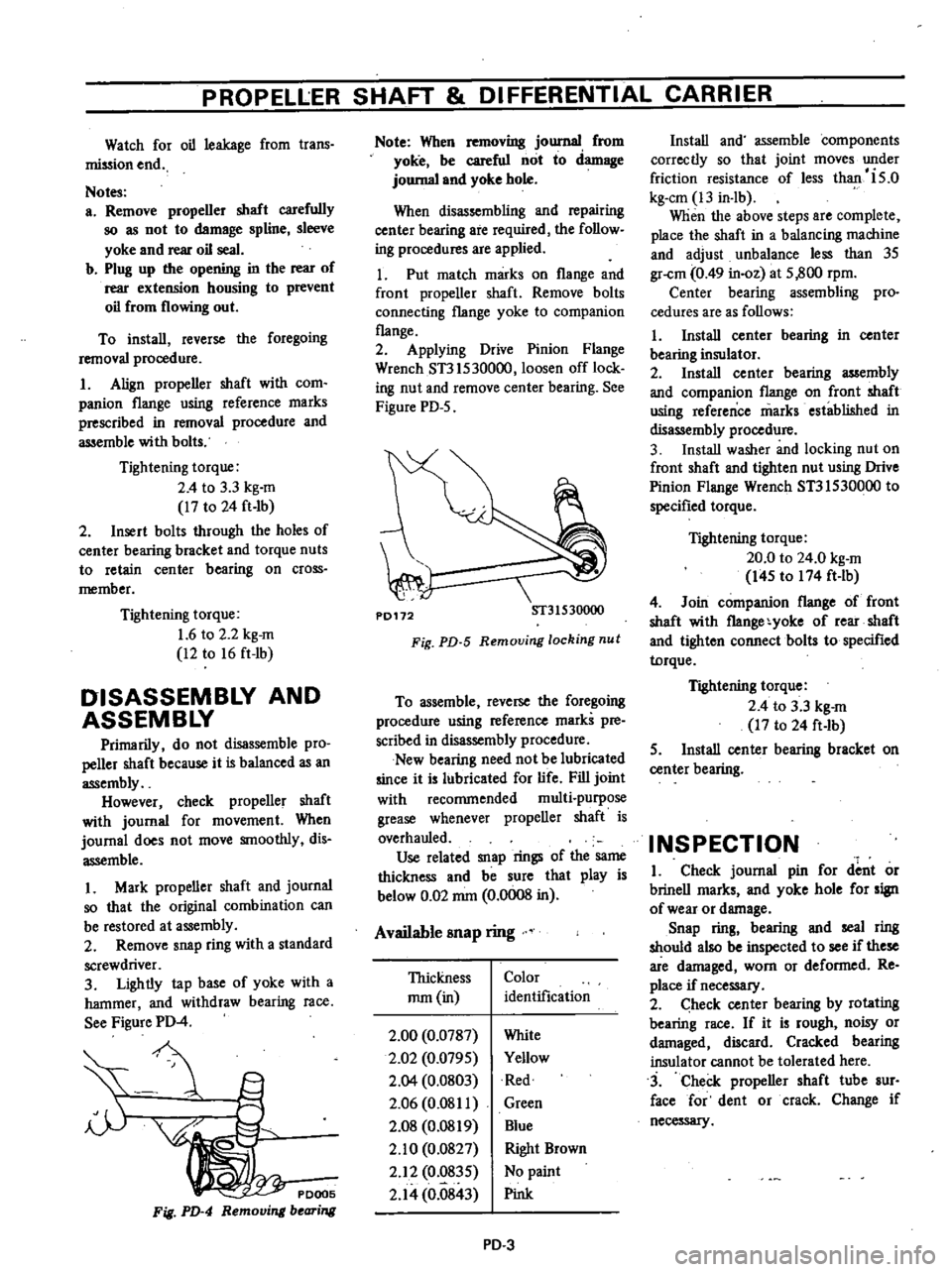

Applying

Drive

Pinion

Flange

Wrench

ST3lS30000

loosen

off

lock

ing

nut

and

remove

center

bearing

See

Figure

PD

5

P0172

ST31530000

Fig

PD

5

Remouing

locking

nut

To

assemble

reverse

the

foregoing

procedure

using

reference

marks

pre

scribed

in

disassembly

procedure

New

bearing

need

not

be

lubricated

since

it

is

lubricated

for

life

Fill

joint

with

recommended

multi

purpose

grease

whenever

propeller

shaft

is

overhauled

Use

related

snap

rings

of

the

same

thickness

and

be

sure

that

play

is

below

0

02

mm

0

0008

in

Available

snap

ring

Thickness

mm

in

Color

identification

2

00

0

0787

2

02

0

079S

2

Q4

0

0803

2

06

0

08

II

2

08

0

0819

2

10

0

0827

2

12

0

83S

2

14

0

0843

White

Yellow

Red

Green

Blue

Right

Brown

No

paint

Pink

PD

3

Install

and

assemble

components

correctly

so

that

joint

moves

under

friction

resistance

of

less

than

is

o

kg

em

13

in

lb

When

the

above

steps

are

complete

place

the

shaft

in

a

balancing

machine

and

adjust

unbalance

less

than

3S

gr

cm

0

49

in

oz

at

S

800

rpm

Center

bearing

assembling

pro

cedures

are

as

follows

I

Install

center

bearing

in

center

bearing

insulator

2

Install

center

bearing

assembly

and

companion

flange

on

front

shaft

usiug

reference

marks

established

in

disassembly

procedure

3

Install

washer

and

locking

nut

on

front

shaft

and

tighten

nut

using

Drive

Pinion

Flange

Wrench

ST3IS30000

to

specified

torque

Tightening

torque

20

0

to

24

0

kg

m

I4S

to

174

ft

lb

4

Join

companion

flange

of

front

shaft

with

f1ange

yoke

of

rear

shaft

and

tighten

connect

bolts

to

specified

torque

Tightening

torque

2

4

to

3

3

kg

m

17

to

24

ft

Ib

S

Install

center

bearing

bracket

on

center

bearing

INSPECTION

I

Check

journal

pin

for

dent

or

brinell

marks

and

yoke

hole

for

sign

of

wear

or

damage

Snap

ring

bearing

and

seal

ring

should

also

be

inspected

to

see

if

these

are

damaged

worn

or

deformed

Re

place

if

necessary

2

heck

center

bearing

by

rotating

bearing

race

If

it

is

rough

noisy

or

damaged

discard

Cracked

bearing

insulator

cannot

be

tolerated

here

3

Check

propeller

shaft

tube

sur

face

for

dent

or

crack

Change

if

necessary