suspension DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 358 of 537

s

Install

tension

rod

at

rear

end

tighten

nut

to

make

the

distance

of

rubber

bushing

to

be

33

4

mm

1

315

in

and

torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

6

Install

tension

rod

bracket

to

chassis

frame

bracket

and

torque

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

When

two

rubber

bushings

are

dif

ferent

in

size

arrange

adjusting

nut

Standard

dimension

is

11

0

mOl

0

433

in

as

shown

in

Figure

FA

16

Torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

Il

0

11

0

0

433

t

lP

33

4

1

315

I

11

0

0

433

1

0

11

0

0

433

Adjusting

nut

Y

i

w

36

6

l

441

Unit

mm

in

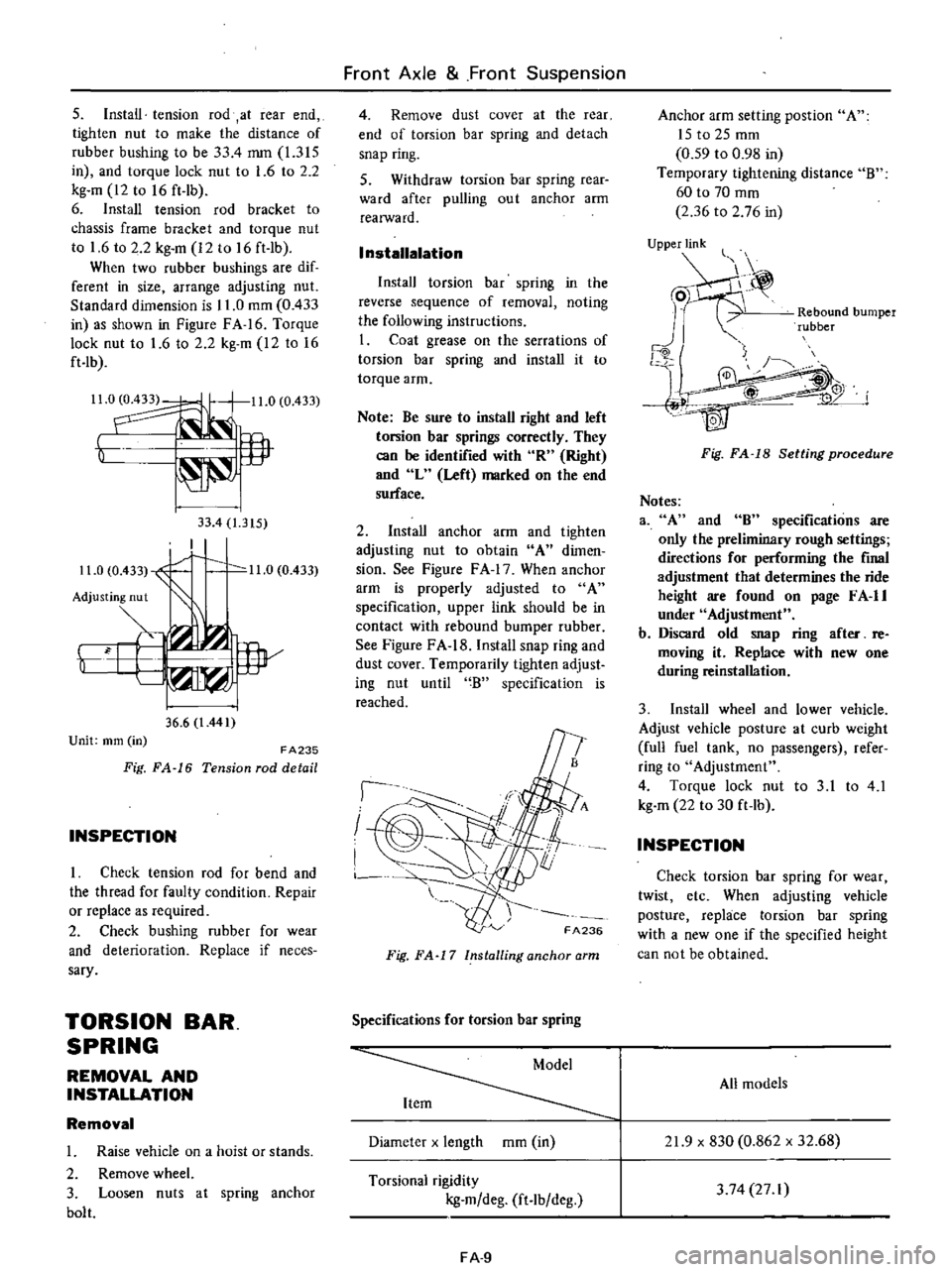

FA235

Fig

FA

16

Tension

rod

detail

INSPECTION

I

Check

tension

rod

for

bend

and

the

thread

for

faulty

condition

Repair

or

replace

as

required

2

Check

bushing

rubber

for

wear

and

deterioration

Replace

if

neces

sary

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

Removal

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

nuts

at

spring

anchor

bolt

Front

Axle

Front

Suspension

4

Remove

dust

cover

at

the

rear

end

of

torsion

bar

spring

and

detach

snap

ring

S

Withdraw

torsion

bar

spring

rear

ward

after

pulling

ou

t

anchor

arm

realWard

I

nstallalation

Install

torsion

bar

spring

in

the

reverse

sequence

of

removal

noting

the

following

instructions

I

Coat

grease

on

the

serrations

of

torsion

bar

spring

and

install

it

to

torque

arm

Note

Be

sure

to

install

right

and

left

torsion

bar

springs

correctly

They

can

be

identified

with

R

Right

and

L

Left

marked

on

the

end

surface

2

Install

anchor

arm

and

tighten

adjusting

nut

to

obtain

A

dimen

sion

See

Figure

F

A

17

When

anchor

arm

is

properly

adjusted

to

A

specification

upper

link

should

be

in

contact

with

rebound

bumper

rubber

See

Figure

FA

18

Install

snap

ring

and

dust

cover

Temporarily

tighten

adjust

ing

nut

until

B

specification

is

reached

I

I

I

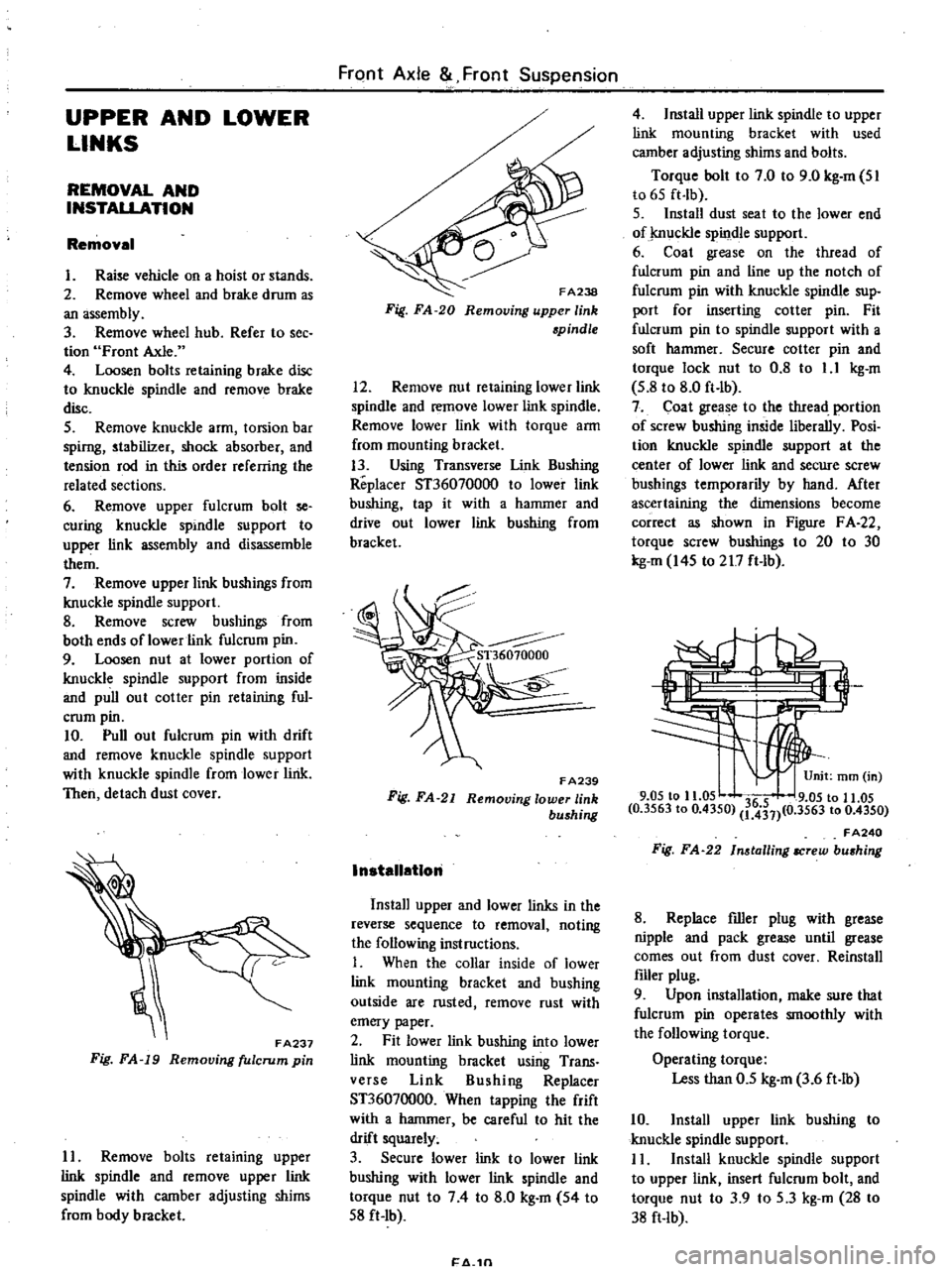

FA236

Fig

FA

17

Installing

anchor

arm

Specifications

for

torsion

bar

spring

Diameter

x

length

mOl

in

Torsional

rigidity

kg

m

deg

ft

lb

deg

FA

9

Anchor

arm

setting

post

ion

A

ISt02Smm

0

59

to

0

98

in

Temporary

tightening

distance

B

60

to

70

mOl

2

36

to

2

76

in

UjPPje

Rebound

bumper

rubber

j

4W

Fig

FA

18

Setting

procedure

Notes

3

A

and

8

specifications

are

only

the

preliminary

rough

settings

directions

for

performing

the

final

adjustment

that

determines

the

ride

height

are

found

on

page

F

A

II

under

Adjustment

b

Discard

old

snap

ring

after

re

moving

it

Replace

with

new

one

during

reinstallation

3

Install

wheel

and

lower

vehicle

Adjust

vehicle

posture

at

curb

weight

full

fuel

tank

no

passengers

refer

ring

to

Adjustment

4

Torque

lock

nut

to

3

1

to

4

1

kg

m

22

to

30

ft

lb

INSPECTION

Check

torsion

bar

spring

for

wear

twist

etc

When

adjusting

vehicle

posture

replace

torsion

bar

spring

with

a

new

one

if

the

specified

height

can

not

be

obtained

All

models

21

9

x

830

0

862

x

32

68

3

74

27

I

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

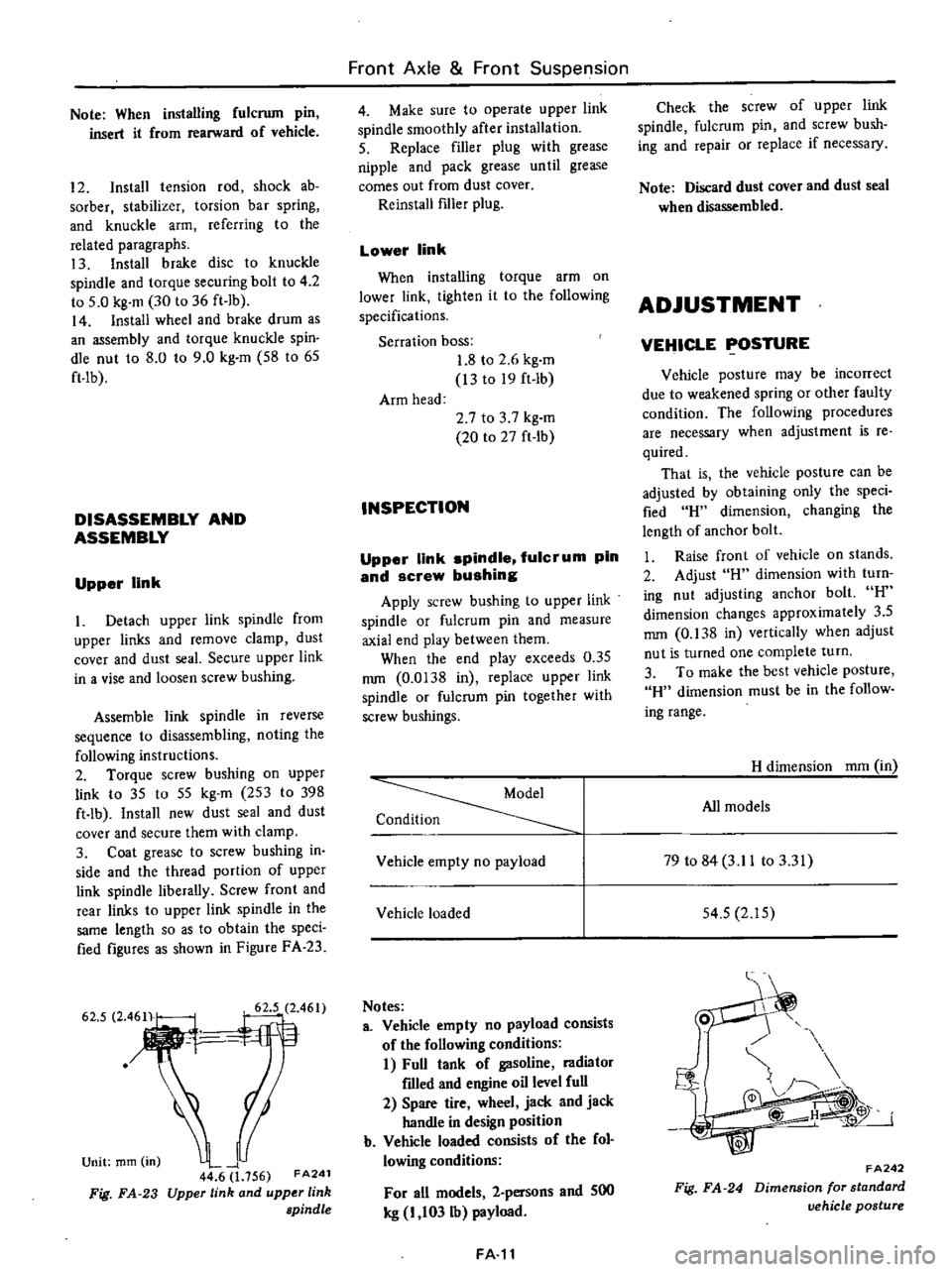

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

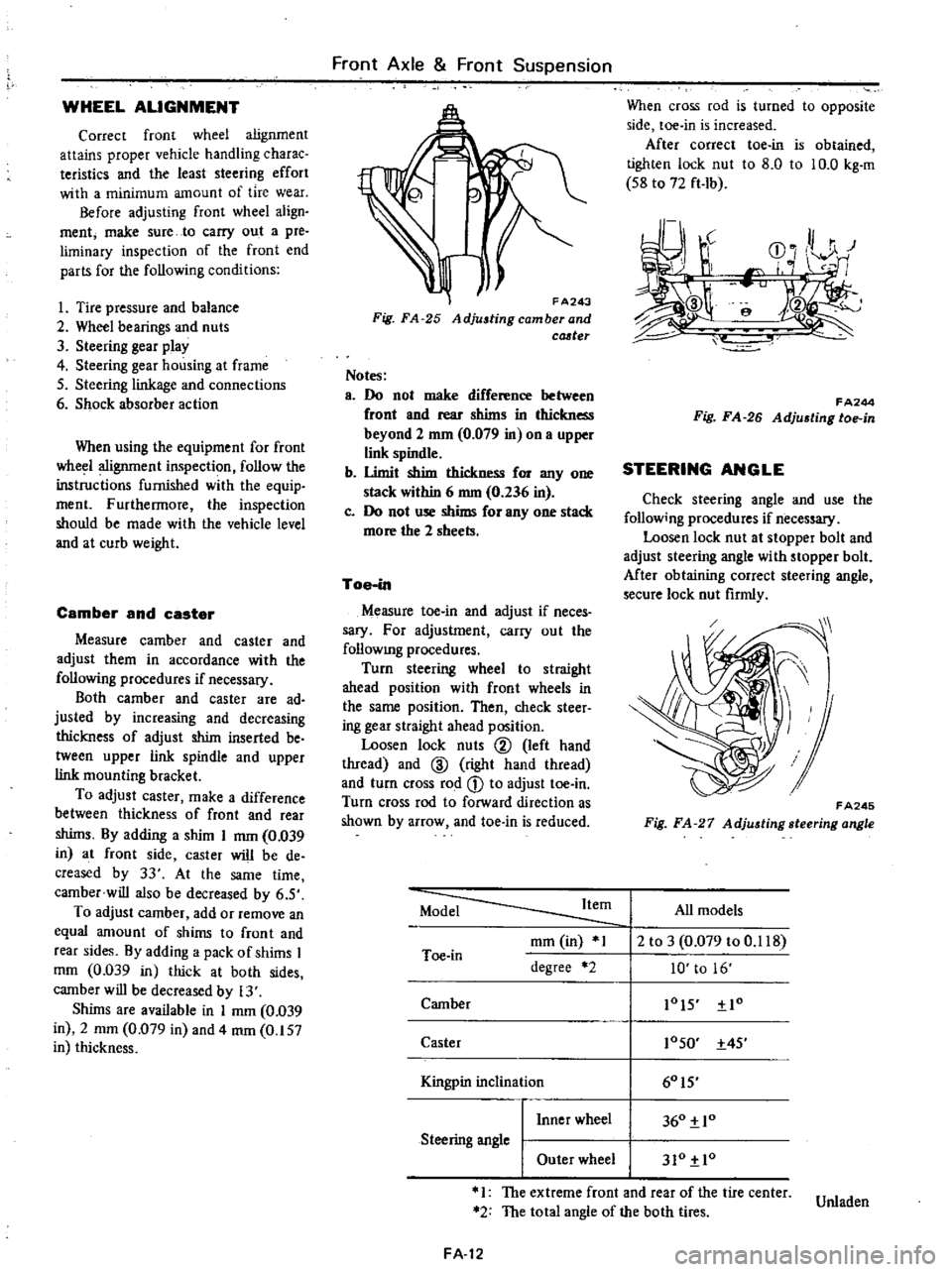

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

figures

as

shown

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re

Page 361 of 537

WHEEL

ALIGNMENT

Correct

front

wheel

alignment

attains

proper

vehicle

handling

charac

teristics

and

the

least

steering

effort

with

a

minimum

amount

of

tire

wear

Before

adjusting

front

wheel

align

ment

make

sure

to

carry

out

a

pre

liminary

inspection

of

the

front

end

parts

for

the

following

conditions

1

Tire

pressure

and

balance

2

Wheel

bearings

and

nuts

3

Steering

gear

play

4

Steering

gear

housing

at

frame

S

Steering

linkage

and

connections

6

Shock

absorber

action

When

using

the

equipment

for

front

wheel

alignment

inspection

follow

the

inst

c

tions

furnished

with

the

equip

ment

Furthennore

the

inspection

should

be

made

with

the

vehicle

level

and

at

curb

weight

Camber

and

caster

Measure

camber

and

caster

and

adjust

them

in

accordance

with

the

following

procedures

if

necessary

Both

camber

and

caster

are

ad

justed

by

increasing

and

decreasing

thickness

of

adjust

shim

inserted

be

tween

upper

link

spindle

and

upper

link

mounting

bracket

To

adjust

caster

make

a

difference

between

thickness

of

front

and

rear

shims

By

adding

a

shim

I

mm

0

039

in

at

front

side

caster

will

be

de

creased

by

33

At

the

same

time

camber

will

also

be

decreased

by

6

S

To

adjust

camber

add

or

remove

an

equal

amount

of

shims

to

front

and

rear

sides

By

adding

a

pack

of

shims

I

mOl

0

039

in

thick

at

both

sides

camber

will

be

decreased

by

13

Shims

are

available

in

I

mm

0

039

in

2

mOl

0

079

in

and

4

mOl

0

157

in

thickness

Front

Axle

Front

Suspension

FA243

Fig

FA

25

Adjustingcamberand

cCJ

ter

Notes

a

Do

not

make

difference

between

front

and

rear

shims

in

thickness

beyond

2

mm

0

079

in

on

a

upper

link

spindle

b

Umit

shim

thickness

for

anyone

stack

within

6

nun

0

236

in

c

Do

not

use

shims

for

anyone

stack

more

the

2

sheets

Toe

in

Measure

toe

in

and

adjust

if

neces

sary

For

adjustment

carry

out

the

follOWIng

procedures

Turn

steering

wheel

to

straight

ahead

position

with

front

wheels

in

the

same

position

Then

check

steer

ing

gear

straight

ahead

position

Loosen

lock

nuts

@

left

hand

thread

and

ID

right

hand

thread

and

turn

cross

rod

CD

to

adjust

toe

in

Turn

cross

rod

to

forward

direction

as

shown

by

arrow

and

toe

in

is

reduced

When

cross

rod

is

turned

to

opposite

side

toe

in

is

increased

After

correct

toe

in

is

obtained

tighten

lock

nut

to

8

0

to

10

0

kg

m

S8

to

72

ft

Ib

r

J

r

CD

0

HI

r

I

e

f

FA244

Fig

FA

26

Adju6ting

toe

in

STEERING

ANGLE

Check

steering

angle

and

use

the

follow

ng

procedures

if

necessary

Loosen

lock

nut

at

stopper

bolt

and

adjust

steering

angle

with

stopper

bolt

Mter

obtaining

correct

steering

angle

secure

lock

nut

firmly

FA245

Fig

FA

27

Adjusting

steering

angle

Model

Item

All

models

mOl

in

1

2

to

3

0

079

to

0

118

Toe

in

degree

2

10

to

16

Camber

lOIS

Io

Caster

10SO

4S

I

60IS

Kingpin

inc

inal10n

I

Inner

wheel

360

10

Steering

angle

I

Outer

wheel

310

10

1

The

extreme

front

and

rear

of

the

tire

center

Unladen

2

The

total

angle

of

the

both

tires

FA

12

Page 362 of 537

Front

Axle

Front

Suspension

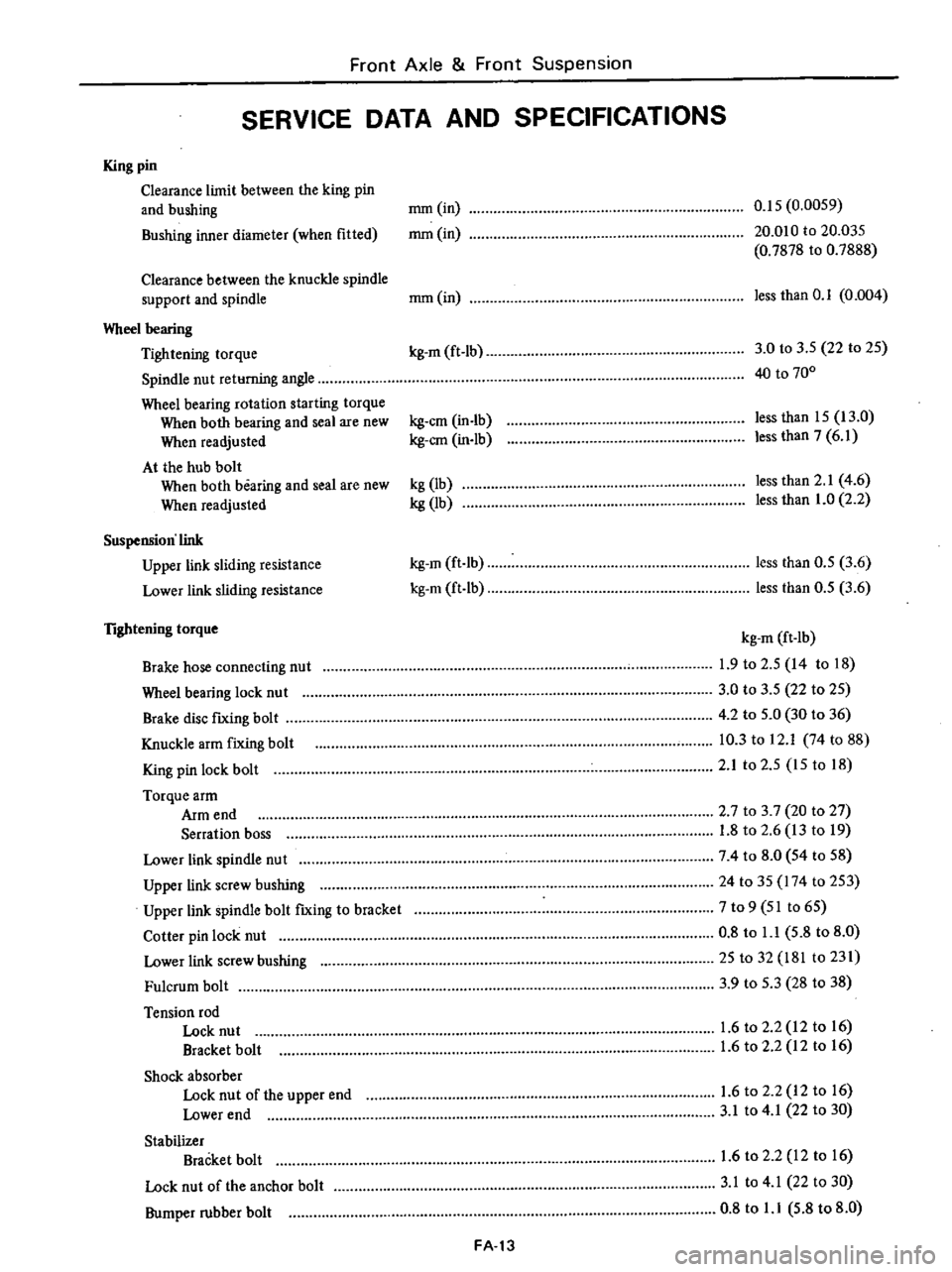

SERVICE

DATA

AND

SPECIFICATIONS

King

pin

Clearance

limit

between

the

king

pin

and

bushing

mm

in

0

15

0

0059

Bushing

inner

diameter

when

fitted

mm

in

20

010

to

20

035

0

7878

to

0

7888

Clearance

between

the

knuckle

spindle

support

and

spindle

mm

in

less

than

0

1

0

004

Wheel

bearing

Tightening

torque

kg

m

ft

Ib

3

0

to

3

S

22

to

2S

Spindle

nut

returning

angle

40

to

700

Wheel

bearing

rotation

starting

torque

When

both

bearing

and

seal

are

new

kg

em

in

Ib

less

than

IS

13

0

When

readjusted

kg

em

in

lb

less

than

7

6

1

At

the

hub

bolt

When

both

bearing

and

seal

are

new

kg

lb

less

than

2

1

4

6

When

readjusted

kg

lb

less

than

1

0

2

2

Suspension

link

Upper

link

sliding

resistance

kg

m

ft

Ib

less

than

O

S

3

6

Lower

link

sliding

resistance

kg

m

ft

lb

less

than

O

S

3

6

lightening

torque

kg

m

ft

Ib

Brake

hose

connecting

nut

1

9

to

2

S

14

to

18

Wheel

bearing

lock

nu

t

3

0

to

3

5

22

to

2S

Brake

disc

fIXing

bolt

4

2

to

S

O

30

to

36

Knuckle

arm

fixing

bolt

10

3

to

12

1

74

to

88

King

pin

lock

bolt

2

1

to

2

S

IS

to

18

Torque

arm

Arm

end

2

7

to

3

7

20

to

27

Serration

boss

1

8

to

2

6

13

to

19

Lower

link

spindle

nut

74

to

8

0

S4

to

58

Upper

link

screw

bushing

24

to

35

174

to

2S3

Upper

link

spindle

bolt

fIXing

to

bracket

7

to

9

51

to

6S

Cotter

pin

lock

nut

0

8

to

l

l

5

8

to

8

0

Lower

link

screw

bushing

25

to

32

181

to

231

Fulcrum

bolt

3

9

to

S

3

28

to

38

Tension

rod

Lock

nut

1

6

to

2

2

12

to

16

Bracket

bolt

1

6

to

2

2

12

to

16

Shock

absorber

Lock

nut

of

the

upper

end

1

6

to

2

2

12

to

16

Lower

end

3

1

to

4

1

22

to

30

Stabilizer

Bracket

bolt

1

6

to

2

2

12

to

16

Lock

nut

of

the

anchor

bolt

3

1

to

4

1

22

to

30

Bumper

rubber

bolt

0

8

to

l

l

5

8

to

8

0

FA

13

Page 363 of 537

Front

Axle

Front

Suspension

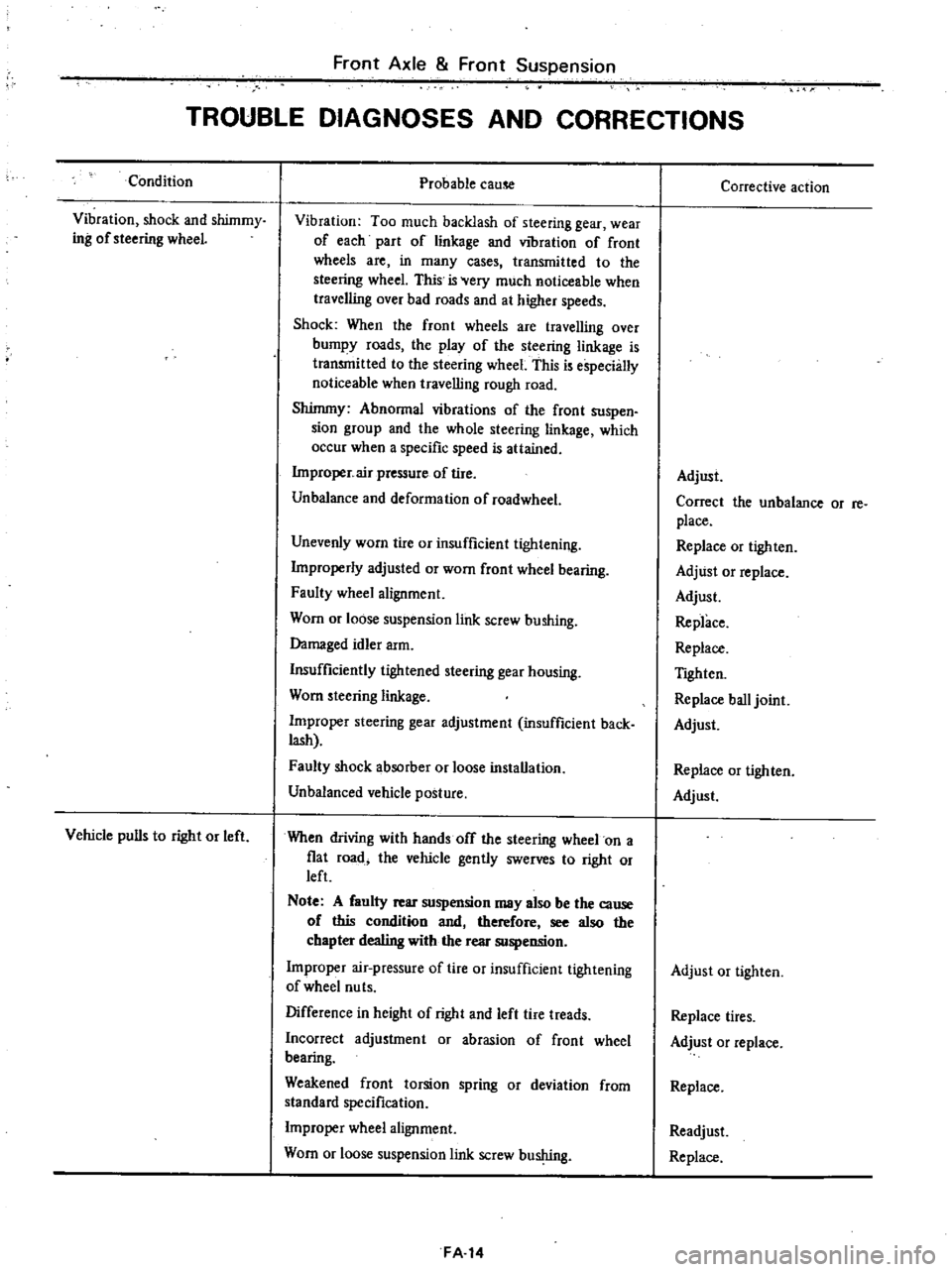

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

ing

of

steering

wheeL

Vehicle

pulls

to

right

or

left

Probable

cause

Vibration

Too

much

backlash

of

steering

gear

wear

of

each

part

of

linkage

and

vibration

of

front

wheels

are

in

many

cases

transmitted

to

the

steering

wheel

This

is

Very

much

noticeable

when

traveJling

over

bad

roads

and

at

higher

speeds

Shock

When

the

front

wheels

are

travelling

over

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

rough

road

Shimmy

Abnormal

vibrations

of

the

front

suspen

sion

group

and

the

whole

steering

linkage

which

occur

when

a

specific

speed

is

attained

Improper

air

pressure

of

tire

Unbalance

and

deformation

of

roadwheel

Unevenly

worn

tire

or

insufficient

tightening

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

Damaged

idler

arm

Insufficiently

tightened

steering

gear

housing

Worn

steering

linkage

Improper

steering

gear

adjustment

insufficient

back

lash

Faulty

shock

absorber

or

loose

installation

Unbalanced

vehicle

posture

When

driving

with

hands

off

the

steering

wheel

on

a

fiat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

condition

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Improper

air

pressure

of

tire

or

insufficient

tightening

of

wheel

nu

ts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Weakened

front

torsion

spring

or

deviation

from

standard

specification

Improper

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

FA

14

Corrective

action

Adjust

Correct

the

unbalance

or

re

place

Replace

or

tighten

Adjust

or

replace

Adjust

Replace

Replace

TIghten

Replace

ball

joint

Adjust

Replace

or

tighten

Adjust

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Readjust

Replace

Page 364 of 537

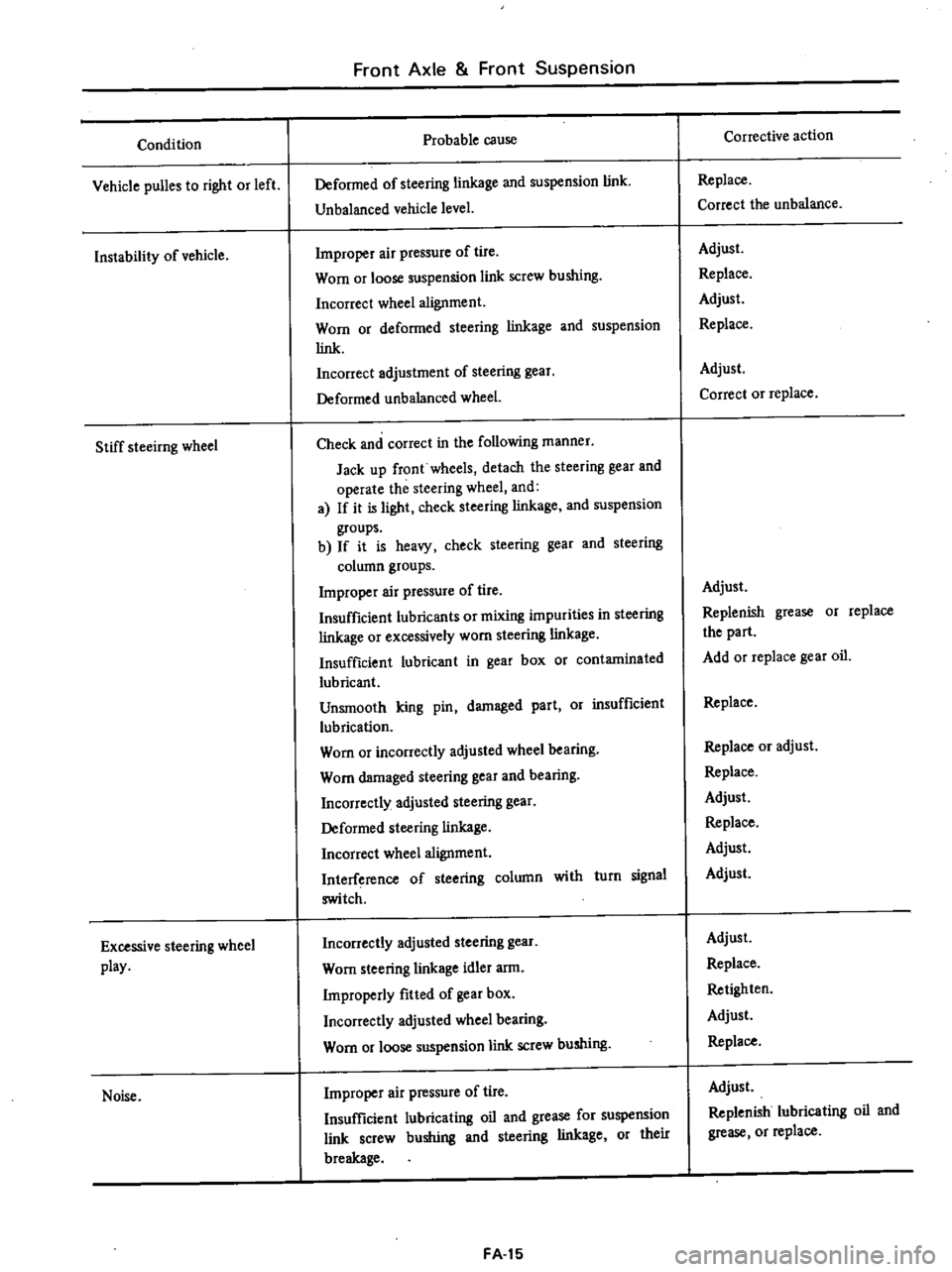

Condition

Vehicle

puBes

to

right

or

left

Instability

of

vehicle

Stiff

steeirng

wheel

Excessive

steering

wheel

play

Noise

Front

Axle

Front

Suspension

Probable

cause

Deformed

of

steering

linkage

and

suspension

link

Unbalanced

vehicle

level

Improper

air

pressure

of

tire

Worn

or

loose

suspension

link

screw

bushing

Incorrect

wheel

alignment

Worn

or

deformed

steering

linkage

and

suspension

link

Incorrect

adjustment

of

steering

gear

Deformed

unbalanced

wheel

Check

and

correct

in

the

following

manner

Jack

up

front

wheels

detach

the

steering

gear

and

operate

the

steering

wheel

and

a

If

it

is

light

check

steering

linkage

and

suspension

groups

b

If

it

is

heavy

check

steering

gear

and

steering

column

groups

Improper

air

pressure

of

tire

Insufficient

lubricants

or

mixing

impurities

in

steering

linkage

or

excessively

worn

steering

linkage

Insufficient

lubricant

in

gear

box

or

contaminated

lubricant

Unsmooth

king

pin

damaged

part

Or

insufficient

lubrication

Worn

or

incorrectly

adjusted

wheel

bearing

Worn

damaged

steering

gear

and

bearing

Incorrectly

adjusted

steering

gear

Deformed

steering

linkage

Incorrect

wheel

alignment

Interference

of

steering

column

with

turn

signal

switch

Incorrectly

adjusted

steering

gear

Worn

steering

linkage

idler

arm

Improperly

fitted

of

gear

box

Incorrectly

adjusted

wheel

bearing

Worn

or

loose

suspension

link

screw

bushing

Improper

air

pressure

of

tire

Insufficient

lubricating

oil

and

grease

for

suspension

link

screw

bushing

and

steering

linkage

or

their

breakage

FA

15

Corrective

action

Replace

Correct

the

unbalance

Adjust

Replace

Adjust

Replace

Adjust

Correct

or

replace

Adjust

Replenish

grease

or

replace

the

part

Add

or

replace

gear

oil

Replace

Replace

or

adjust

Replace

Adjust

Replace

Adjust

Adjust

Adjust

Replace

Retighten

Adjust

Replace

Adjust

Replenish

lubricating

oil

and

grease

or

replace

Page 365 of 537

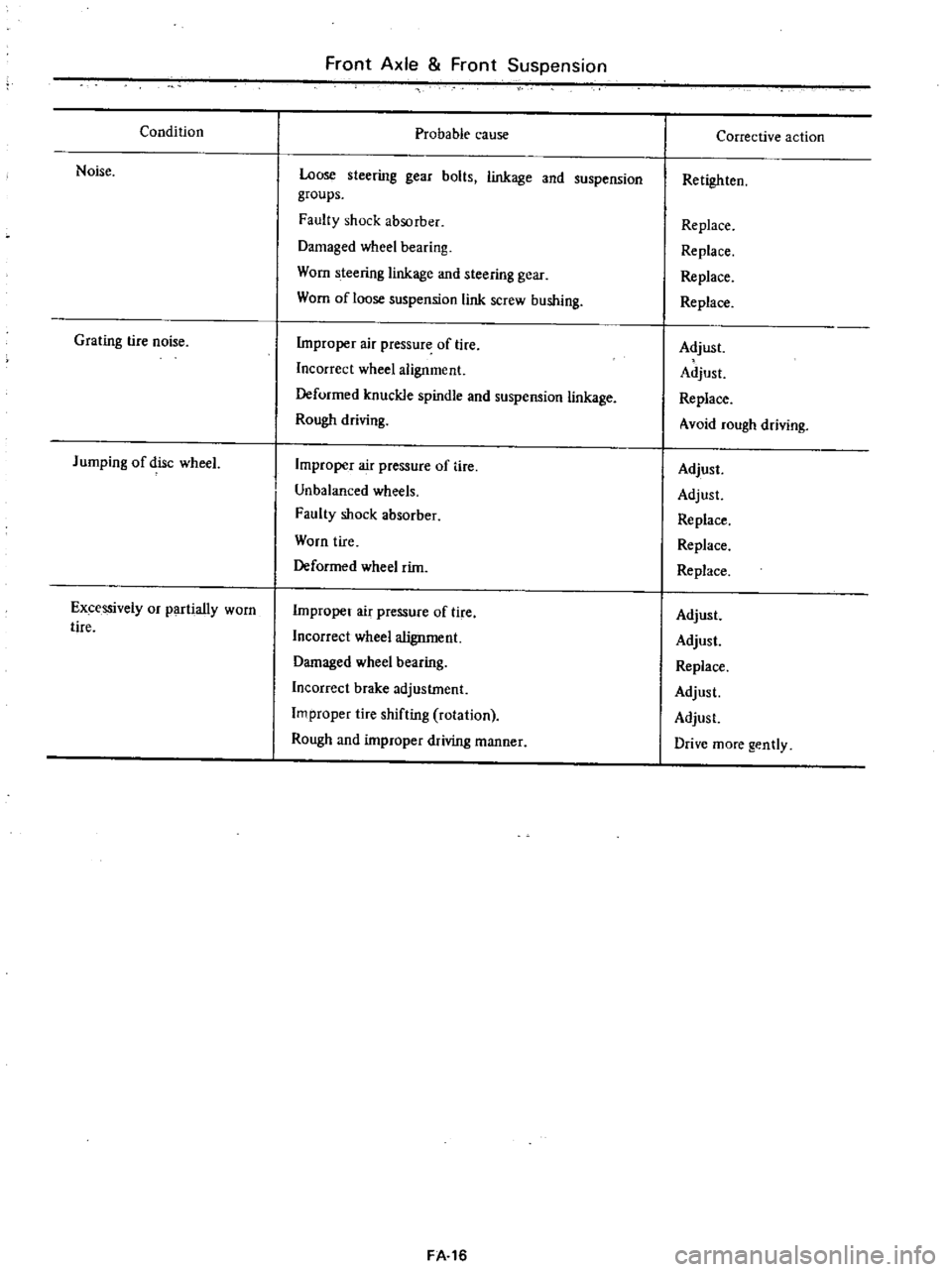

Condition

Noise

Grating

tire

noise

Jumping

of

disc

wheeL

Excessively

or

partially

worn

tire

Front

Axle

Front

Suspension

Probable

cause

Loose

steering

gear

bolts

linkage

and

suspension

groups

Faulty

shock

absorber

Damaged

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

of

loose

suspension

link

screw

bushing

Improper

air

pressure

of

lire

Incorrect

wheel

alignment

Deformed

knuckle

spindle

and

suspension

linkage

Rough

driving

Improper

air

pressure

of

tire

Unbalanced

wheels

Faulty

shock

absorber

Worn

tire

Deformed

wheel

rim

Improper

air

pressure

of

tire

Incorrect

wheel

alignment

Damaged

wheel

bearing

Incorrect

brake

adjustment

Improper

tire

shifting

rotation

Rough

and

improper

wiving

manner

FA

16

Corrective

action

Retighten

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Avoid

rough

driving

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Replace

Adjust

Adjust

Drive

more

gently

Page 366 of 537

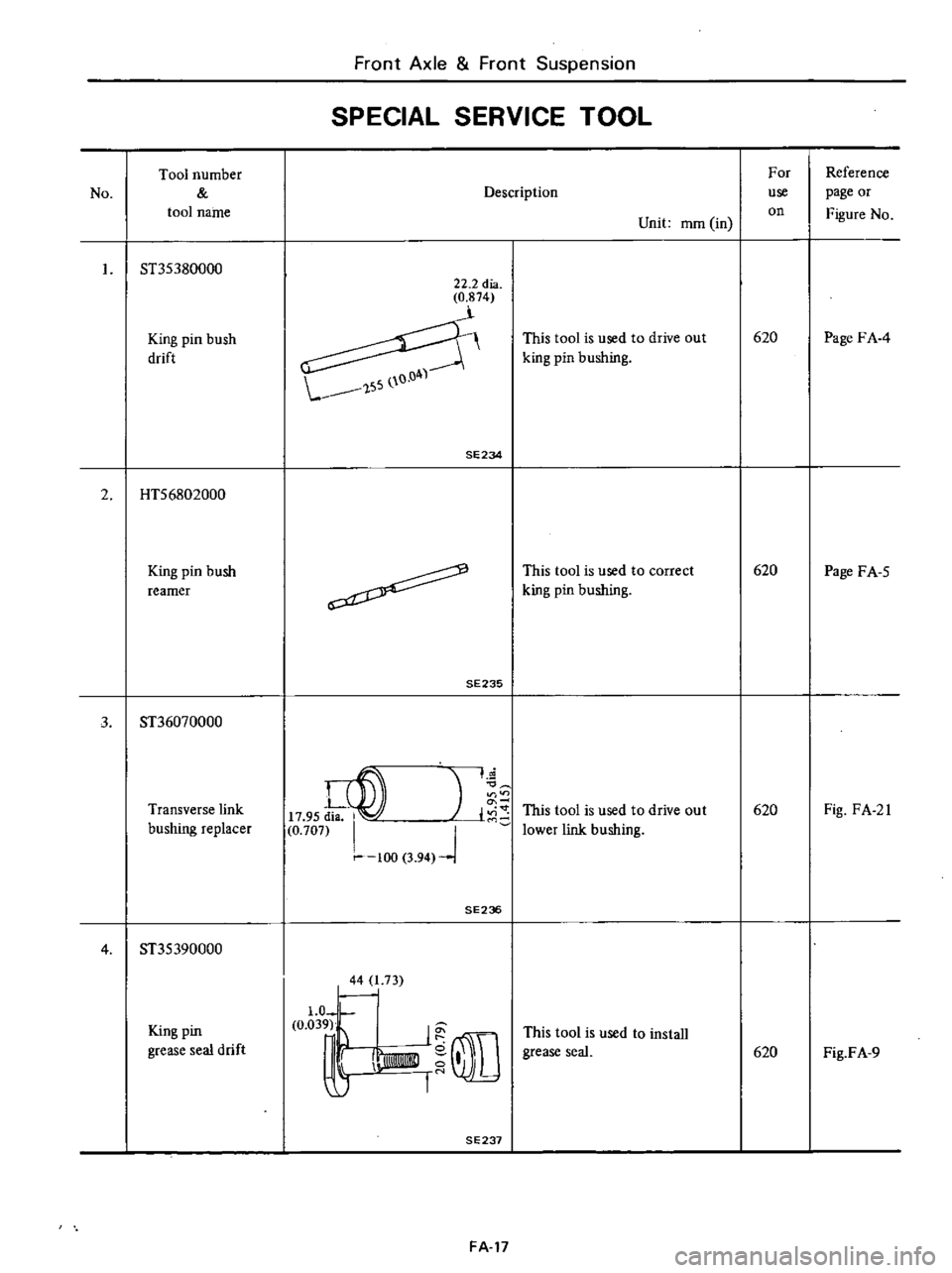

No

Tool

number

tool

name

ST35380000

King

pin

bush

drift

2

HTS6802000

King

pin

bush

reamer

Front

Axle

Front

Suspension

SPECIAL

SERVICE

TOOL

22

2

dia

0

874

SE234

FA

17

Description

Unit

mOl

in

This

tool

is

used

to

drive

out

king

pin

bushing

This

tool

is

used

to

correct

king

pin

bushing

For

use

on

620

620

Reference

page

or

Figure

No

Page

FA

4

Page

FA

S