water pump DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 71 of 537

30

Install

heatshieid

plate

on

mani

fold

assembly

31

Install

air

gallery

pipe

on

ex

haust

manifold

32

Install

manifold

gasket

and

manifold

assembly

on

cylinder

head

Tightening

torque

1

2to

1

6kg

m

8

7

to

11

6

ft

lb

33

Install

blow

by

gas

pipe

on

cyl

inder

block

and

tighten

with

rear

engine

slinger

34

Install

thermostat

housing

gas

ket

thermostat

housing

and

thermo

stat

35

Install

thermal

vacuum

valve

on

thermostat

housing

Before

installing

apply

a

liquid

packing

slightly

to

the

threads

36

Install

FJ

C

D

bracket

on

cylin

der

head

37

Install

E

G

R

passage

and

E

G

R

valve

on

intake

manifold

38

Connect

E

G

R

tube

to

E

G

R

tube

and

exhaust

manifold

39

Install

check

valve

on

air

gallery

pipe

40

Install

air

cleaner

bracket

on

intake

manifold

41

Install

air

control

valve

on

air

cleaner

bracket

California

models

42

Install

vacuum

and

fuel

tubes

combined

on

cylinder

head

43

Install

distributor

assembly

44

Install

heatshield

plate

joint

seat

and

carburetor

Carbure10r

tightening

torque

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lb

Note

When

instalUng

joint

seat

be

sure

to

put

the

duct

into

primary

hole

in

intake

manifold

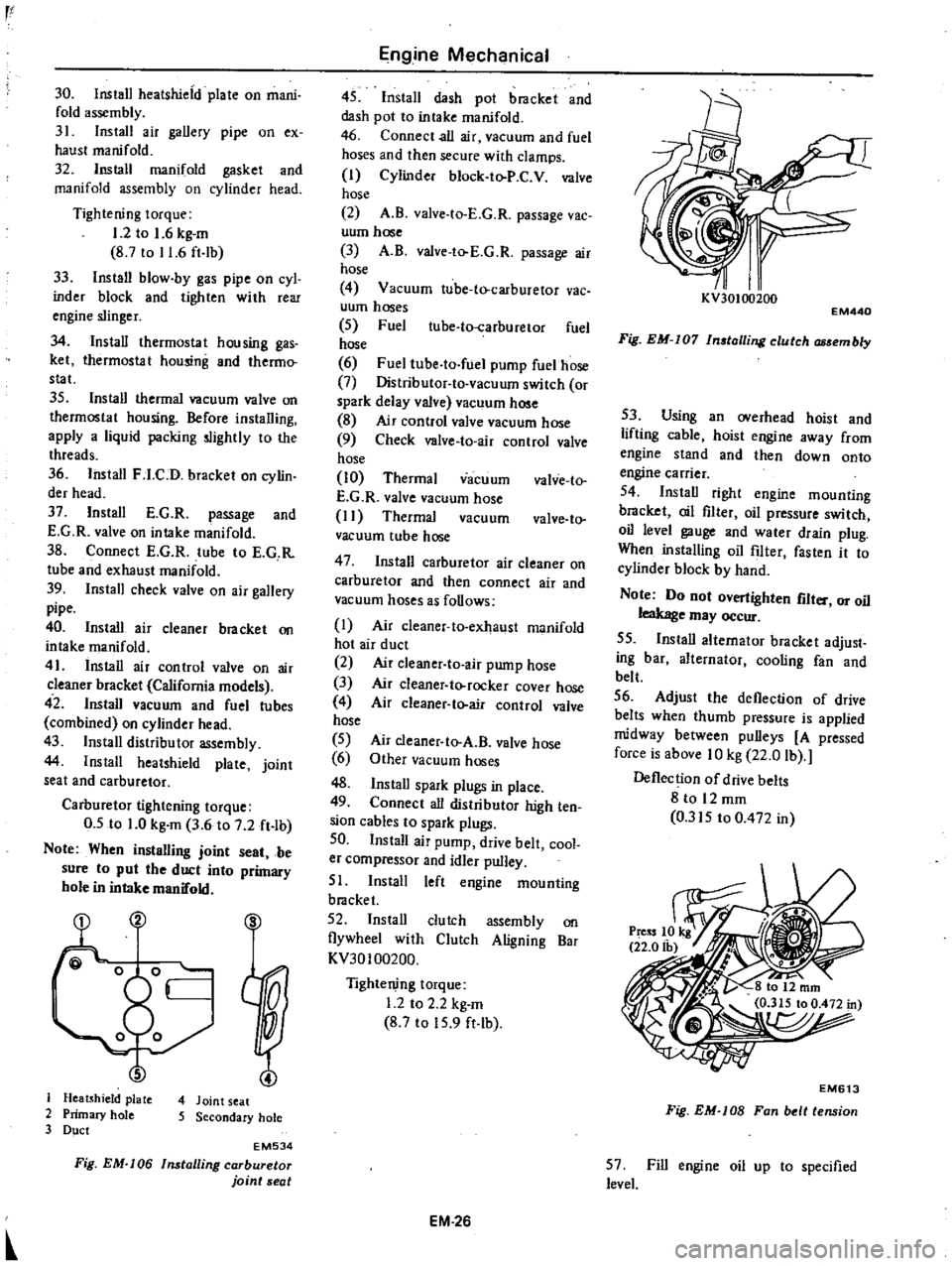

S

J

Heatshield

plate

4

Joint

seat

2

Primary

hole

5

Secondary

hole

3

Duct

EM534

Fig

EM

I06

Installing

carburetor

joint

seat

Engine

Mechanical

45

Install

dash

pot

bracket

and

dash

pot

to

intake

manifold

46

Connect

all

air

vacuum

and

fuel

hoses

and

then

secure

with

clamps

I

Cylinder

block

to

P

C

V

valve

hose

2

A

B

valve

to

E

G

R

passage

vac

uum

hose

3

A

B

valve

to

E

G

R

passage

air

hose

4

Vacuum

tube

to

carburetor

vac

uum

hoses

5

Fuel

ube

to

carburetor

fuel

hose

6

Fuel

tube

to

fuel

pump

fuelhose

7

Distributor

to

vacuum

switch

or

spark

delay

valve

vacuum

hose

8

Air

control

valve

vacuum

hose

9

Check

valve

to

air

control

valve

hose

10

Thermal

vacuum

valve

to

E

G

R

valve

vacuum

hose

I

I

Thermal

vacuum

valve

to

vacuum

tube

hose

47

Install

carburetor

air

cleaner

on

carburetor

and

then

connect

air

and

vacuum

hoses

as

follows

I

Air

cleaner

to

exhaust

manifold

hot

air

duct

2

Air

c1eaner

to

air

pump

hose

3

Air

cleaner

to

rocker

cover

hose

4

Air

cleaner

to

air

control

valve

hose

5

6

48

Install

spark

plugs

in

place

49

Connect

all

distributor

high

ten

sion

cables

to

spark

plugs

50

Install

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

51

Install

left

engine

mounting

bracket

52

Install

clutch

assembly

on

flywheel

with

Clutch

Aligning

Bar

KV30100200

Air

cleaner

to

A

B

valve

hose

Other

vacuum

hoses

Tightening

torque

1

2

to

2

2

kg

m

8

7

to

15

9

ft

lb

EM

26

I

I

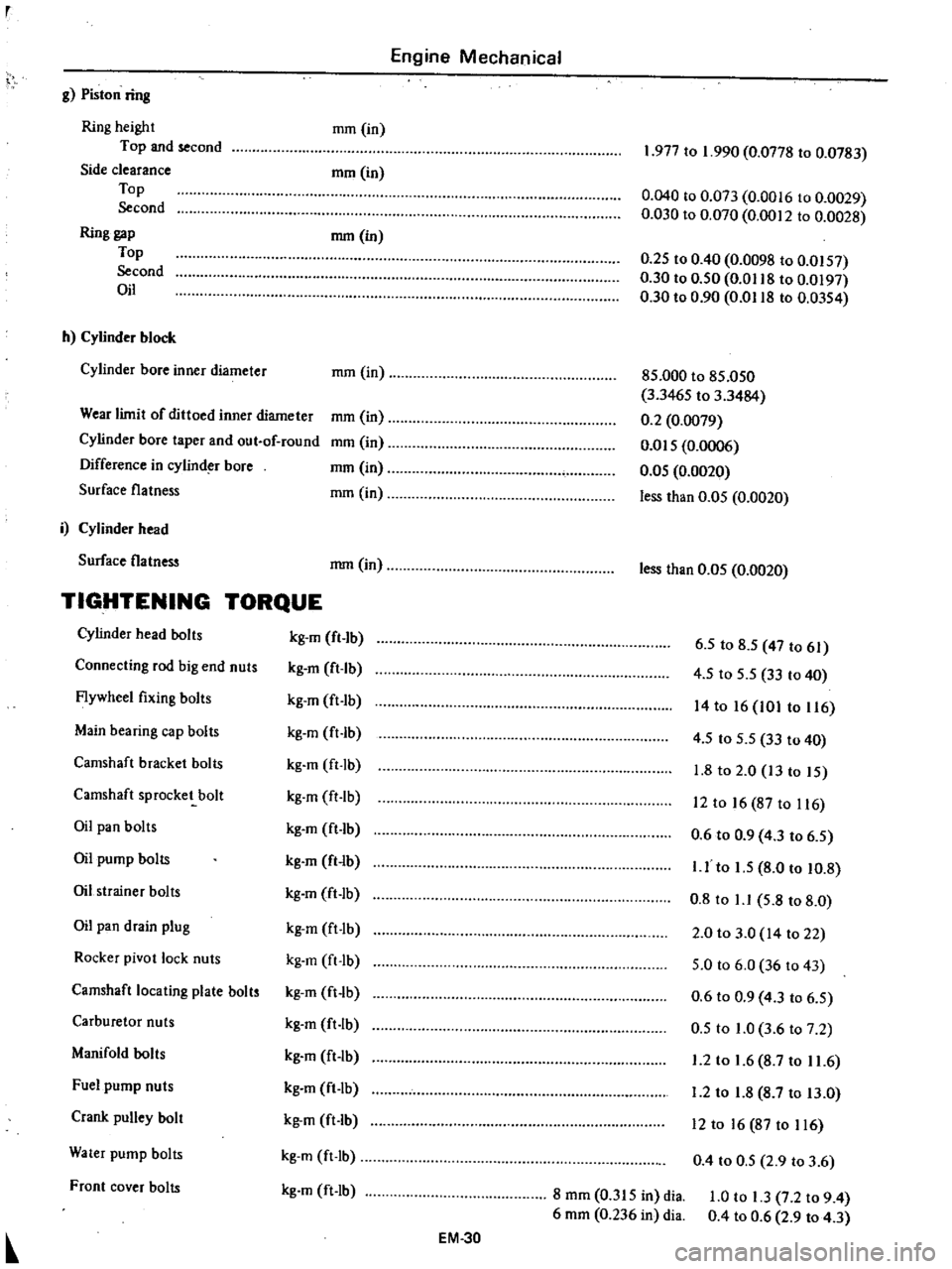

KV30100200

EM440

Fig

EM

I07

In

talling

clutch

embly

53

Using

an

overhead

hoist

and

lifting

cable

hoist

engine

away

from

engine

stand

and

then

down

onto

engine

carrier

54

Install

right

engine

mounting

bracket

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

When

installing

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

flit

or

oil

leakage

may

occur

55

Install

alternator

bracket

adjust

ing

bar

alternator

cooling

fan

and

belt

56

Adjust

the

deflection

of

drive

belts

when

thumb

pressure

is

applied

midway

between

pulleys

A

pressed

force

is

above

10

kg

22

0

lb

Deflection

of

drive

belts

8

to

12

mm

0

315

to

0

472

in

EM613

Fig

EM

lOB

Fan

belt

tension

57

Fill

engine

oil

up

to

specified

level

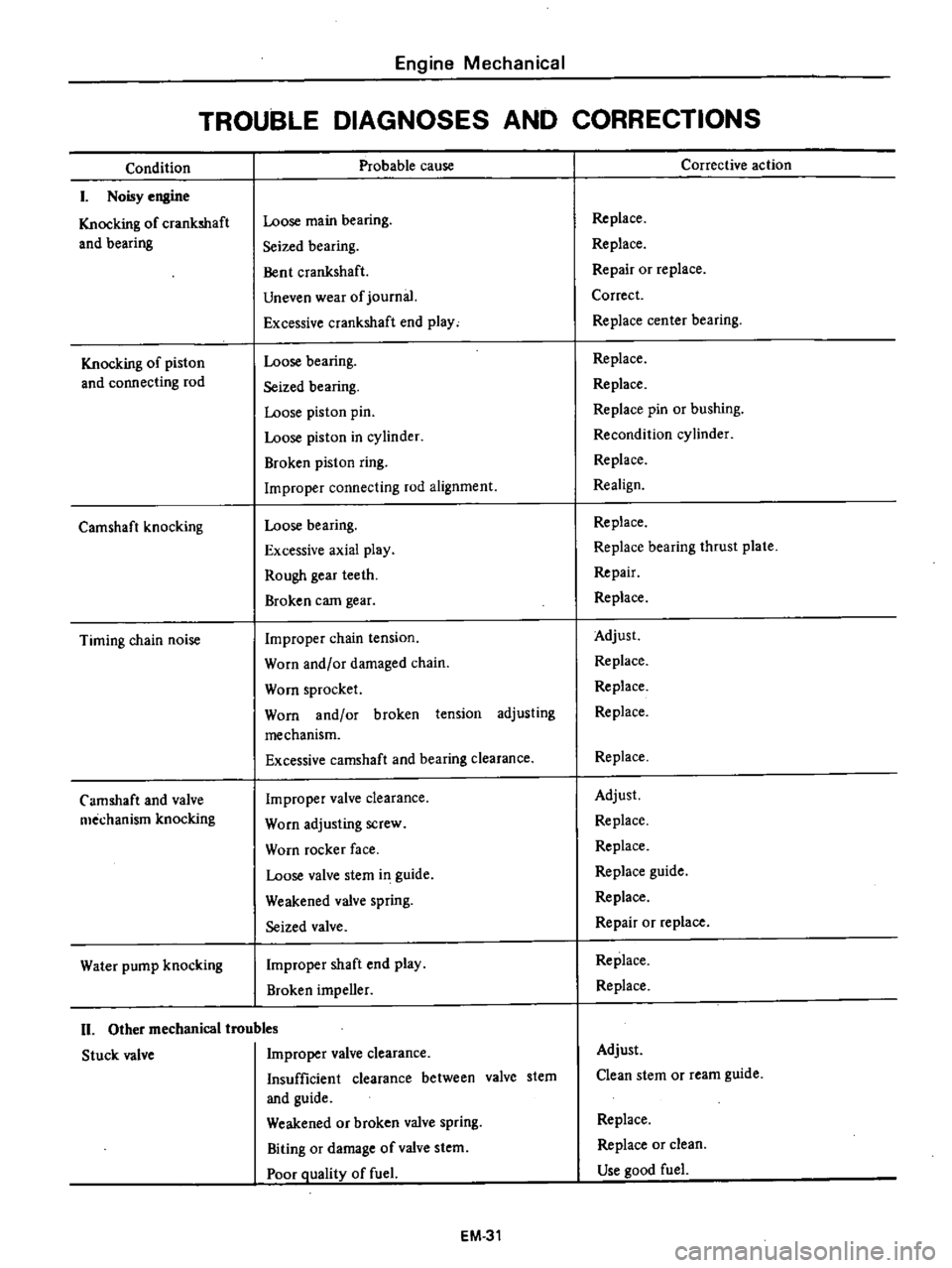

Page 75 of 537

Engine

Mechanical

g

Piston

ring

Ring

height

Top

and

second

Side

clearance

Top

Second

Ring

gap

Top

Second

Oil

mm

in

mrn

in

mm

in

h

Cylinder

block

Cylinder

bore

inner

diameter

mm

in

Wear

limit

of

dittoed

inner

diameter

Cylinder

bore

taper

and

out

of

round

Difference

in

cylind

bore

Surface

flatness

mm

in

mm

in

mm

in

mm

in

i

Cylinder

head

Surface

flatness

mm

in

TIGHTENING

TORQUE

Cylinder

head

bolts

kg

m

fl

lb

Connecting

rod

big

end

nuts

kg

m

ft

Ib

Flywheel

fixing

bolts

kg

m

ft

Ib

Main

bearing

cap

bolts

kg

m

ft

lb

Camshaft

bracket

bolts

kg

m

ft

lb

Camshaft

sprocket

bolt

kg

m

ft

lb

Oil

pan

bolts

kg

m

ft

1b

Oil

pump

bolts

kg

m

ft

lb

Oil

strainer

bolts

kg

m

ft

lb

Oil

pan

drain

plug

kg

m

ft

lb

Rocker

pivot

lock

nuts

kg

m

ft

Ib

Camshaft

locating

plate

bolts

kg

m

ft

lb

Carburetor

nuts

kg

m

ft

lb

Manifold

bolts

kg

m

ft

lb

Fuel

pump

nuts

kg

m

ft

lb

Crank

pulley

bolt

kg

m

ft

lb

Water

pump

bolts

kg

m

ft

Ib

Front

cover

bolts

kg

m

ft

lb

EM

30

1

977

to

1

990

0

0778

to

0

0783

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

0

0012

to

0

0028

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0118

to

0

0197

0

30

to

0

90

0

0118

to

0

0354

85

000

to

85

050

3

3465

to

3

3484

0

2

0

0079

om

5

0

0006

0

05

0

0020

less

than

0

05

0

0020

less

than

0

05

0

0020

6

5

to

8

5

47

to

61

4

5

to

5

5

33

to

40

14

to

16

101

to

116

4

5

to

5

5

33

to

40

1

8

to

2

0

13

to

15

12

to

16

87

to

116

0

6

to

0

9

4

3

to

6

5

I

J

to

1

5

8

0

to

10

8

0

8

to

1

1

5

8

to

8

0

2

0

to

3

0

14

to

22

5

0

to

6

0

36

to

43

0

6

to

0

9

4

3

to

6

5

0

5

to

1

0

3

6

to

7

2

1

2

to

1

6

8

7

to

11

6

1

2

to

1

8

8

7

to

13

0

12

to

16

87

to

116

0

4

to

0

5

2

9

to

3

6

8

mm

0

315

in

dia

6

mm

0

236

in

dia

1

0

to

1

3

7

2

to

9

4

0

4

to

0

6

2

9

to

4

3

Page 76 of 537

Engine

Mechanical

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

I

Noisy

engine

Knocking

of

crankshaft

and

bearing

Knocking

of

piston

and

connecting

rod

Camshaft

knocking

Timing

chain

noise

Camshaft

and

valve

mechanism

knocking

Water

pump

knocking

Probable

cause

Loose

main

bearing

Seized

bearing

Bent

crankshaft

Uneven

wear

of

journal

Excessive

crankshaft

end

play

Loose

bearing

Seized

bearing

Loose

piston

pin

Loose

piston

in

cylinder

Broken

piston

ring

Improper

connecting

rod

alignment

Loose

bearing

Excessive

axial

play

Rough

gear

teeth

Broken

eam

gear

Improper

chain

tension

Worn

and

or

damaged

chain

Worn

sprocket

Worn

and

or

broken

tension

adjusting

mechanism

Excessive

camshaft

and

bearing

clearance

Improper

valve

clearance

Worn

adjusting

screw

Worn

rocker

face

Loose

valve

stem

i1

1

guide

Weakened

valve

spring

Seized

valve

Improper

shaft

end

play

Broken

impeller

II

Other

mechanical

troubles

Stuck

valve

Improper

valve

clearance

Insufficient

clearance

between

valve

stem

and

guide

Weakened

or

broken

valve

spring

Biting

or

damage

of

valve

stem

Poor

Quality

of

fuel

EM

31

Corrective

action

Replace

Replace

Repair

or

replace

Correct

Replace

cen

ter

bearing

Replace

Replace

Replace

pin

or

bushing

Recondition

cylinder

Replace

Realign

Replace

Replace

bearing

thrust

plate

Repair

Replace

Adjust

Replace

Replace

Replace

Replace

Adjust

Replace

Replace

Replace

guide

Replace

Repair

or

replace

Replace

Replace

Adjust

Clean

stem

or

ream

guide

Replace

Replace

or

clean

Use

ood

fuel

Page 91 of 537

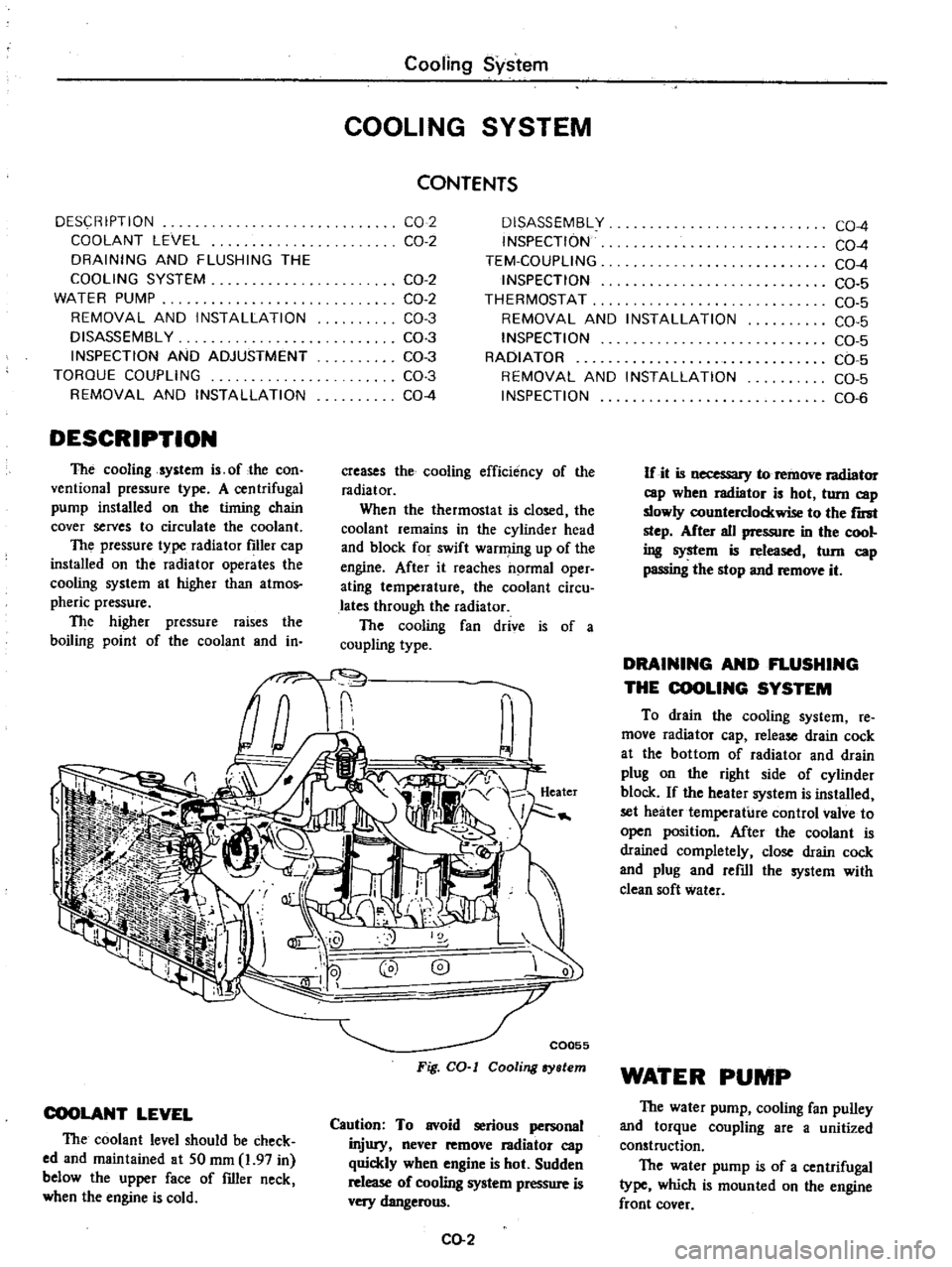

DESCRIPTION

COOLANT

LEVEL

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

WATER

PUMP

REMOVAL

AND

INSTALLATION

DISASSEMBLY

INSPECTION

AND

ADJUSTMENT

TORQUE

COUPLING

REMOVAL

AND

INSTALLATION

DESCRIPTION

The

cooling

system

is

of

the

con

ventional

pressure

type

A

centrifugal

pump

installed

on

the

timing

chain

cover

serves

to

circulate

the

coolant

The

pressure

type

radiator

filler

cap

installed

on

the

radiator

operates

the

cooling

system

at

higher

than

atmos

pheric

pressure

The

higher

pressure

raises

the

boiling

point

of

the

coolant

and

in

Cooling

System

COOLING

SYSTEM

CONTENTS

CO

2

CO

2

OISASSEMBL

Y

INSPECTION

TEM

COUPLlNG

INSPECTION

THERMOSTAT

REMOVAL

AND

INSTALLATION

INSPECTION

RADIATOR

REMOVAL

AND

INSTALLATION

INSPECTION

CO

2

CO

2

CO

3

CO

3

CO

3

CO

3

CO

4

creases

the

cooling

efficiency

of

the

radiator

When

the

thermostat

is

closed

the

coolant

remains

in

the

cylinder

head

and

block

for

swift

warming

up

of

the

engine

After

it

reaches

normal

oper

ating

temperature

the

coolant

circu

lates

through

the

radiator

The

cooling

fan

drive

is

of

a

coupling

type

COOLANT

LEVEL

The

coolant

level

should

be

check

ed

and

maintained

at

SO

mm

1

97

in

below

the

upper

face

of

filler

neck

when

the

engine

is

cold

C0055

Fig

CO

I

Cooling

ry

lem

Caution

To

avoid

serious

personal

injury

never

remove

I3diator

cap

quickly

when

engine

is

hot

Sudden

release

of

cooling

system

pressure

is

very

dangerous

CO

2

CO

4

CO

4

CO

4

CO

5

CO

5

CO

5

CO

5

CO

5

CO

5

CO

6

If

it

is

necessary

to

remove

radiator

cap

wben

radiator

is

hot

turn

cap

slowly

counterclockwise

to

the

r

step

After

all

pressure

in

the

cool

ing

system

is

released

tom

cap

passing

the

stop

and

remove

it

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

To

drain

the

cooling

system

re

move

radiator

cap

release

drain

cock

at

the

bottom

of

radiator

and

drain

plug

on

the

right

side

of

cylinder

block

If

the

heater

system

is

installed

set

heater

temperature

control

valve

to

open

position

After

the

coolant

is

drained

completely

close

drain

cock

and

plug

and

refill

the

system

with

clean

soft

water

WATER

PUMP

The

water

pump

cooling

fan

pulley

and

torque

coupling

are

a

unitized

construction

The

water

pump

is

of

a

centrifugal

type

which

is

mounted

on

the

engine

front

cover

Page 92 of 537

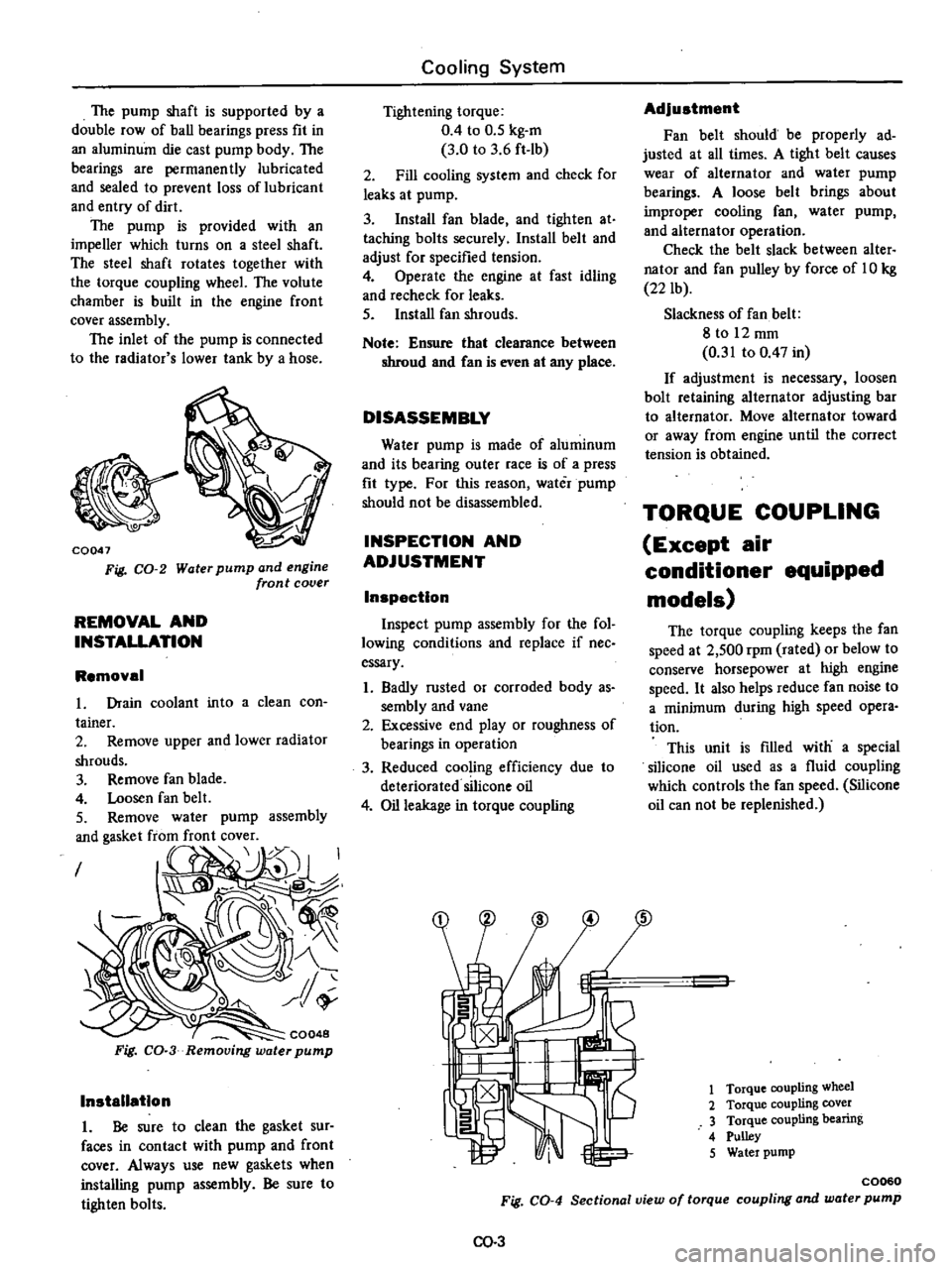

The

pump

shaft

is

supported

by

a

double

row

of

ball

bearings

press

fit

in

an

aluminum

die

cast

pump

body

The

bearings

are

permanently

lubricated

and

sealed

to

prevent

loss

of

lubricant

and

entry

of

dirt

The

pump

is

provided

with

an

impeller

which

turns

on

a

steel

shaft

The

steel

shaft

rotates

together

with

the

torque

coupling

wheeL

The

volute

chamber

is

built

in

the

engine

front

cover

assembly

The

inlet

of

the

pump

is

connected

to

the

radiator

s

lower

tank

by

a

hose

i

o

CQ047

Fig

CO

2

Water

pump

and

engine

front

cover

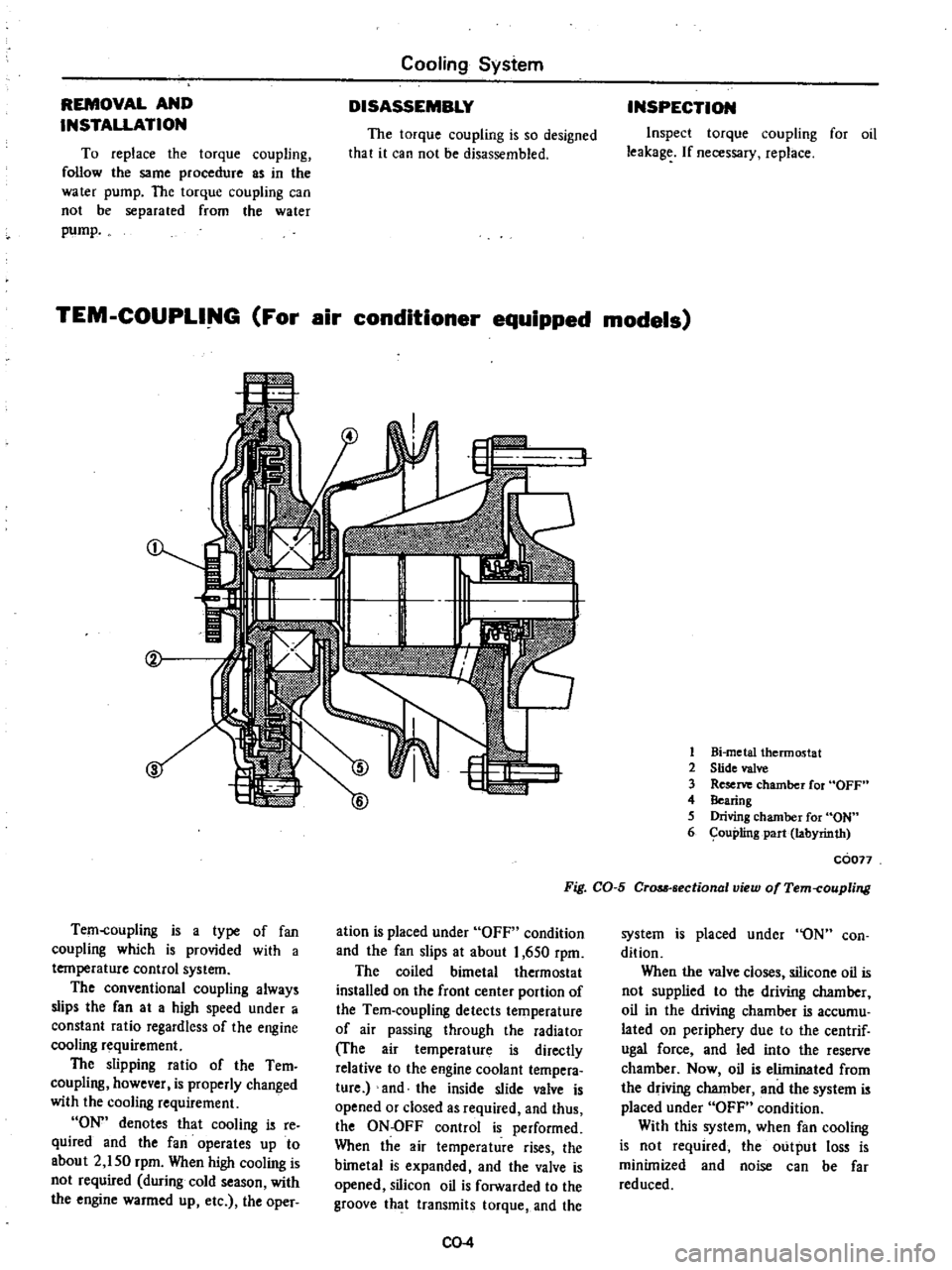

REMOVAL

AND

INSTALLATION

Removal

in

to

a

clean

con

assembly

I

CQ048

Fig

CO

3

Removing

water

pump

Installation

1

Be

sure

to

clean

the

gasket

sur

faces

in

contact

with

pump

and

front

cover

Always

use

new

gaskets

when

installing

pump

assembly

Be

sure

to

tighten

bolts

Cooling

System

Tightening

torque

0

4

to

0

5

kg

m

3

0

to

3

6

ft

lb

2

Fill

cooling

system

and

check

for

leaks

at

pump

3

Install

fan

blade

and

tighten

at

taching

bolts

securely

Install

belt

and

adjust

for

specified

tension

4

Operate

the

engine

at

fast

idling

and

recheck

for

leaks

5

Install

fan

shrouds

Note

Ensure

that

clearance

between

shroud

and

Can

is

even

at

any

place

DISASSEMBLY

Water

pump

is

made

of

aluminum

and

its

bearing

outer

race

is

of

a

press

fit

type

For

this

reason

water

pump

should

not

be

disassembled

INSPECTION

AND

ADJUSTMENT

Inspection

Inspect

pump

assembly

for

the

fol

lowing

conditions

and

replace

if

nee

essary

1

Badly

rusted

or

corroded

body

as

sembly

and

vane

2

Excessive

end

play

or

roughness

of

bearings

in

operation

3

Reduced

cooling

efficiency

due

to

deteriorated

silicone

oil

4

Oil

leakage

in

torque

coupling

Adjustment

Fan

belt

should

be

properly

ad

justed

at

all

times

A

tight

belt

causes

wear

of

alternator

and

water

pump

bearings

A

loose

belt

brings

about

improper

cooling

fan

water

pump

and

alternator

operation

Check

the

belt

slack

between

alter

nator

and

fan

pulley

by

force

of

10

kg

22

lb

Slackness

of

fan

belt

8

to

12

mm

0

31

to

0

47

in

If

adjustment

is

necessary

loosen

bolt

retaining

alternator

adjusting

bar

to

alternator

Move

alternator

toward

or

away

from

engine

until

the

correct

tension

is

obtained

TORQUE

COUPLING

Except

air

conditioner

equipped

models

The

torque

coupling

keeps

the

fan

speed

at

2

500

rpm

rated

or

below

to

conserve

horsepower

at

high

engine

speed

It

also

helps

reduce

fan

noise

to

a

minimum

during

high

speed

opera

tion

This

unit

is

filled

with

a

special

silicone

oil

used

as

a

fluid

coupling

which

controls

the

fan

speed

Silicone

oil

can

not

be

replenished

1

Torque

coupling

wheel

2

Torque

coupling

cover

3

Torque

coupling

bearing

4

Pulley

5

Water

pump

C0060

Fig

CO

4

Sectional

view

of

torque

coupling

and

water

pump

00

3

Page 93 of 537

REMOVAL

AND

INSTALLATION

To

replace

the

torque

coupling

follow

the

same

procedure

as

in

the

water

pump

The

torque

coupling

can

not

be

separated

from

the

water

pump

Cooling

System

DISASSEMBLY

The

torque

coupling

is

so

designed

that

it

can

not

be

disassembled

INSPECTION

Inspect

torque

coupling

for

oil

leakage

If

necessary

replace

TEM

COUPLl

G

For

air

conditioner

equipped

models

Tem

coupling

is

a

type

of

fan

coupling

which

is

provided

with

a

temperature

control

system

The

conventional

coupling

always

slips

the

fan

at

a

high

speed

under

a

constant

ratio

regardless

of

the

engine

cooling

requirement

The

slipping

ratio

of

the

Tern

coupling

however

is

properly

changed

with

the

cooling

requirement

ON

denotes

that

cooling

is

re

quired

and

the

fan

operates

up

to

about

2

150

rpm

When

high

cooling

is

not

required

during

cold

season

with

the

engine

warmed

up

etc

the

oper

w

6

I

1

Bi

metal

thermostat

2

Slide

valve

3

Reserve

chamber

for

OFF

4

Bearing

5

Driving

chamber

for

ON

6

ouplingpart

labyrinth

coon

Fig

CO

5

CrQM

sectional

view

of

Tem

coupling

ation

is

placed

under

OFF

condition

and

the

fan

slips

at

about

1

650

rpm

The

coiled

bimetal

thermostat

installed

on

the

front

center

portion

of

the

Tem

coupling

detects

temperature

of

air

passing

through

the

radiator

The

air

temperature

is

directly

relative

to

the

engine

coolant

tempera

ture

and

the

inside

slide

valve

is

opened

or

closed

as

required

and

thus

the

ON

OFF

control

is

performed

When

the

air

temperature

rises

the

bimetal

is

expanded

and

the

valve

is

opened

silicon

oil

is

forwarded

to

the

groove

that

transmits

torque

and

the

CO

4

system

is

placed

under

ON

con

dition

When

the

valve

closes

silicone

oil

is

not

supplied

to

the

driving

chamber

oil

in

the

driving

chamber

is

accumu

lated

on

periphery

due

to

the

centrif

ugal

force

and

led

into

the

reserve

chamber

Now

oil

is

eliminated

from

the

driving

chamber

and

the

system

is

placed

under

OFF

condition

With

this

system

when

fan

cooling

is

not

required

the

output

loss

is

minimized

and

noise

can

be

far

reduced

Page 94 of 537

Conventional

COUplin9

WATER

PUMP

SPEED

F

Z

Tern

coupling

WATER

PUMP

SPEED

C0029

Fig

CO

6

Characteristic

of

Tern

coupling

INSPECTION

Check

Tem

coupling

for

oil

leakage

or

bend

of

bimetal

If

the

above

symptoms

are

found

replace

it

with

a

new

one

as

an

assembly

THERMOSTAT

A

wax

pellet

type

thermostat

is

mounted

in

the

thermostat

housing

at

the

cylinder

head

water

outlet

The

function

of

the

thermostat

is

to

control

the

flow

of

coolant

facili

tating

fast

engine

warm

up

and

regu

lating

coolant

temperature

The

ther

mostat

is

designed

to

open

and

close

at

predetermined

temperatures

and

if

not

operating

properly

should

be

re

moved

and

tested

as

described

below

REMOVAL

AND

INSTALLATION

I

Drain

coolant

partially

2

Disconnect

upper

radiator

hose

at

water

outlet

3

Remove

bolts

and

remove

water

outlet

gasket

and

thermostat

from

thermostat

housing

Fig

CO

7

Removing

therm06t

t

Cooling

System

4

After

checking

thermostat

re

install

with

a

new

housing

gasket

in

place

5

Reinstall

water

outlet

6

Replenish

coolant

and

check

for

leaks

INSPECTION

A

sticking

thermostat

will

prevent

the

cooling

system

from

functioning

properly

If

the

thermostat

sticks

in

the

open

position

the

engine

warms

up

very

slowly

If

the

thermostat

sticks

in

the

closed

position

over

heating

will

result

Therefore

the

ther

mostat

should

be

inspected

to

make

sure

that

it

is

in

good

condition

1

Measure

coolant

temperature

when

thermostat

valve

starts

to

open

2

Measure

the

maximum

lift

of

thermostat

valve

Fig

CO

S

Impecting

therm06t

t

Temperate

Frigid

Tropical

type

type

iype

Valve

opening

80

5

to

83

5

86

5

to

89

5

75

to

78

temperature

177

to

183

187

to

193

167

to

172

oC

OF

Maximum

valve

lift

8

95

8

1

00

8

90

mm

oC

in

F

0

31

203

0

31

212

0

31

194

If

thermostat

does

not

operate

at

the

above

specified

temperature

it

must

be

replaced

because

it

cannot

be

repaired

RADIATOR

The

radiator

is

a

conventional

down

flow

type

having

top

and

bottom

tanks

to

distribute

the

coolant

flow

uniformly

through

the

vertical

tube

of

radiator

core

The

radiator

filler

cap

is

designed

to

maintain

a

pre

set

pressure

0

9

kg

cm2

13

psi

above

atmospheric

pressure

The

relief

valve

consisting

of

a

blow

off

valve

and

a

vacuum

valve

helps

to

prevent

the

coolant

from

boiling

by

giving

pressure

to

it

How

ever

when

the

pressure

is

reduced

below

atmospheric

pressure

the

vacu

um

valve

allows

air

to

re

enter

the

radiator

preventing

the

formation

of

a

vacuum

in

the

cooling

system

CO

5

On

models

equipped

with

auto

matic

transmission

the

oil

cooler

is

combined

with

the

radiator

to

cool

transmission

fluid

REMOVAL

AND

INSTALLATION

Drain

coolant

into

a

clean

con

tainer

2

Disconnect

radiator

upper

and

lower

hoses

On

models

with

auto

matic

transmissions

disconnect

cooler

inlet

and

outlet

lines

from

radiator

3

Remove

fan

shroud

retaining

bolts

and

remove

fan

shroud

4

Remove

front

grille

5

Remove

radiator

retaining

bolts

and

then

remove

radiator

upward

6

Install

radiator

in

the

reverse

se

quence

of

removal

Note

the

fol

lowing

I

Insert

hoses

in

their

positions

until

they

bottom

2

Ensure

that

arrow

marks

on

hoses

are

clearly

visible

from

upper

Page 96 of 537

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace

Page 141 of 537

Emission

Control

System

C

bur

tor

I

EC284

When

installing

this

valve

ensure

that

it

properly

oriented

Tlus

valve

shuuld

be

replaced

periodically

Refer

to

Maintenance

Schedule

Note

Carburetor

side

Black

DisInDutor

side

Brown

horn

distributor

To

carburetor

TOdi

ribUI0

carburClor

EC

lCiJr

Fig

EC

9

Operation

01

park

delay

value

INSPECTION

Remove

spark

delay

valve

2

Blow

air

through

port

on

carbure

tor

side

then

through

the

other

port

on

distributor

side

Spark

delay

valve

Distributor

side

1

One

way

umbrella

valve

2

Sintered

metal

disc

Fig

EC

8

Spark

delay

valve

is

in

good

condition

if

when

finger

is

placed

over

port

on

distributor

side

air

flow

resistance

is

greater

than

that

on

the

other

side

See

Figur

ET

lO

3

If

a

considerable

air

flow

resist

ance

is

fell

at

port

on

distributor

side

in

step

2

above

and

if

the

condition

of

spark

delay

valve

is

questionable

dip

port

on

carburetor

side

into

a

cup

filled

with

water

Blow

air

through

the

other

port

Small

air

bubbles

should

appear

Carburetor

side

Distributor

side

EC346

Fig

EC

IO

Checking

park

delay

valve

EC

8

EC219

Fig

EC

11

Checking

spark

d

tay

valve

Note

Be

careful

to

avoid

entry

of

oil

or

dirt

into

valve

AIR

INJECTION

SYSTEM

DESCRIPTION

The

Air

Injection

System

A

LS

is

aeSigiieino

iiiject

coin

pressed

air

sec

ODllary

air

corning

from

the

air

pump

into

the

exhaust

manifold

to

reduce

hydrocarbons

and

carbon

monoxide

in

exhaust

lri

s

through

re

combustion

There

are

two

types

of

A

I

S

One

type

is

mounted

on

California

models

and

the

other

is

on

non

California

models

The

non

California

type

con

sists

of

an

air

pump

air

cleaner

an

air

pump

a

relief

valve

a

check

valve

an

anti

backfIre

valve

an

air

gallery

and

hoses

The

California

type

has

in

addition

to

the

components

of

the

non

California

type

an

air

control

valve

and

an

emergency

air

relief

valve

These

valves

prevent

ahnonnal

tem

perature

rise

of

the

catalytic

converter

Page 152 of 537

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

air

is

felt

E

A

R

valve

is

normaL

5

If

E

A

R

valve

does

not

function

properly

at

above

steps

replace

E

A

R

valve

To

air

pump

I

ET267

Fig

EC

46

Cheeking

E

A

R

volve

Anti

backfire

valve

A

valve

Warm

up

engine

thoroughly

2

Disconnect

hose

from

air

cleaner

and

place

a

finger

near

the

outlet

3

Run

engine

at

about

3

000

rpin

under

no

load

then

quickly

cetum

it

to

idling

If

you

feel

a

pull

or

suction

force

on

your

finger

the

anti

backfire

valve

is

functioning

normally

If

no

suction

is

felt

replace

the

anti

backflre

valve

Fig

EC

47

Checking

anti

backfire

valve

1

t

D

I

Y1

VI

I

ID

4

JO

0

2

E

C

R

control

valve

3

E

C

R

passage

4

Intake

manifold

5

Thermal

vacuum

valve

6

E

C

R

tube

7

Exhaust

manifold

Emission

Control

System

tXHAUST

GAS

RECIRCULATION

CONTROL

SYSTEM

E

G

R

DESCRIPTION

In

the

exhaust

gas

recirculation

system

a

part

of

the

exhaust

gas

is

returned

to

the

combustion

chamber

to

lower

the

spark

flame

temperature

during

combustion

This

results

in

a

reduction

of

the

nitrogen

oxide

con

ten

t

in

the

exhaust

gas

The

exhaust

gas

recirculation

sys

tem

consists

of

an

E

G

R

passage

E

G

R

con

trol

valve

thermal

vacuum

volve

E

G

R

tube

and

hose

A

warn

@

I

ing

system

which

indicates

when

the

E

G

R

control

system

must

be

in

spected

is

also

installed

in

all

620

models

except

those

bound

for

Coli

fornia

and

Canada

When

the

E

G

R

con

trol

valve

is

open

some

of

the

exhaust

gas

is

led

from

the

exhaust

manifold

to

the

E

G

R

chamber

through

the

E

G

R

passage

The

exhaust

gas

is

then

con

trolled

in

quantity

by

the

E

G

R

valve

and

is

introduced

into

the

intake

manifold

Open

c1ose

operation

of

the

E

G

R

control

valve

is

controlled

by

the

thermal

vacuum

valve

which

opera

tes

on

carburetor

vacuum

and

engine

cool

ant

temperature

EC349

Fig

EC

4

Exhaust

Gas

Recirculation

system

E

G

R

E

G

R

system

operating

Thermal

Intake

manifold

E

G

R

Remarks

E

G

R

water

temperature

oC

OF

vacuum

valve

vacuum

control

valve

Below

570C

135OF

Close

Close

Non

california

Above

MfT

models

only

Idling

Not

Above

57

to

630C

Open

70

mmHg

Close

actuated

135

to

145OF

76

inHg

California

models

Below

and

N

on

Fullthrollle

f

alifomia

AfT

Above

57

to

6

oC

models

Actua

ted

Open

Above

50

mmHg

Open

135

to

145OF

1

97

inHg

EC

19

OPERATION

Operation

of

E

G

R

system

is

as

shown

below