compression ratio DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 21 of 537

Yellow

line

Spark

delay

valve

to

distributor

Spark

delay

valve

to

vacuum

tube

Distributor

to

vacuum

tube

Vacuum

tube

to

carburetor

Vacuum

tube

to

canister

Green

line

Anti

backfire

valve

to

intake

mani

fold

Air

control

valve

to

emergency

air

relief

valve

Intake

manifold

to

vacuum

hose

connector

Intake

manifold

to

canister

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

I

Warm

up

engine

sufficiently

2

Disconnect

all

spark

plugs

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Properly

attach

a

compression

tester

to

spark

plug

hole

in

cylinder

being

tested

Engine

Tune

up

I

ET010

Different

compression

in

two

or

more

cylinders

usually

indicates

an

improperly

seated

valve

or

broken

piston

ring

9

Low

compression

in

cylinders

can

result

from

worn

piston

rings

This

condition

may

usually

be

accompanied

by

excessive

fuel

consumption

TEST

RESULT

If

compression

in

one

or

more

cylinders

is

low

pour

a

small

quantity

of

engine

oil

into

cylinders

through

the

spark

plug

holes

and

retest

com

pression

I

If

adding

oil

increases

the

com

pression

pressure

the

chances

are

that

rings

are

faulty

2

If

pressure

stays

low

probable

cause

is

that

valve

is

sticking

or

seating

improperly

3

If

cylinder

compression

in

any

two

adjacent

cylinders

is

low

and

if

adding

oil

does

not

help

the

compres

sian

there

is

leakage

past

the

gasket

surface

Oil

and

water

in

combustion

cham

bers

can

result

from

leakage

IGNITION

AND

FUEL

SYSTEM

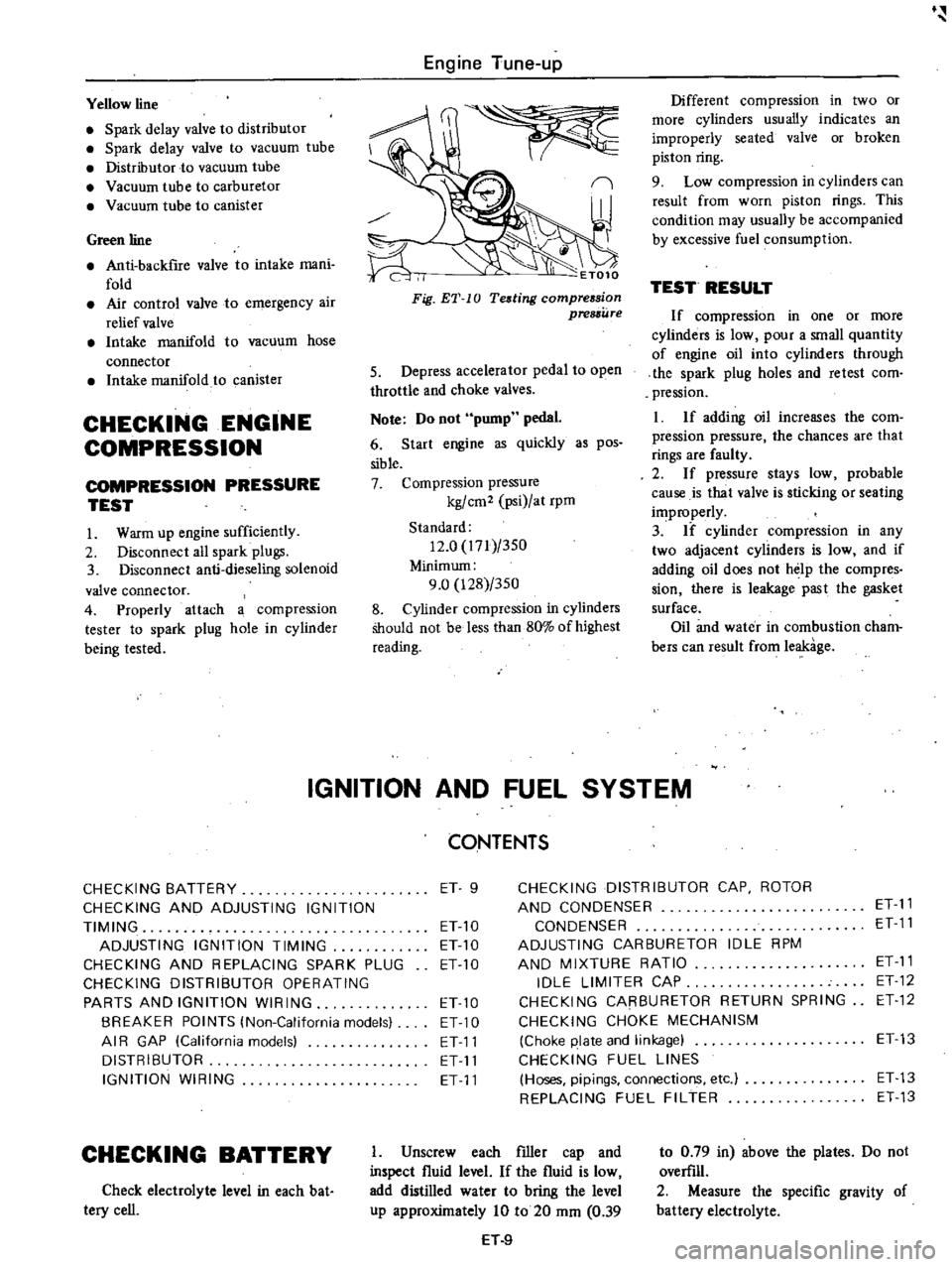

Fig

ET

10

Teding

compression

pressure

5

Depress

accelerator

pedal

to

open

throttle

and

choke

valves

Note

Do

not

pump

pedal

6

Start

engine

as

quickly

as

pos

sible

7

Compression

pressure

kg

cm2

psi

at

rpm

Standard

12

0

171

350

Minimum

9

0

128

350

8

Cylinder

compression

in

cylinders

Should

not

be

less

than

80

of

highest

reading

CONTENTS

CHECKING

BATTERY

ET

9

CHECKING

DISTRIBUTOR

CAP

ROTOR

CHECKING

AND

ADJUSTING

IGNITION

AND

CONDENSER

ET

11

TIMING

ET

10

CONDENSER

ET

11

ADJUSTING

IGNITION

TIMING

ET10

ADJUSTING

CARBURETOR

IDLE

RPM

CHECKING

AND

REPLACING

SPARK

PLUG

ETlO

AND

MIXTURE

RATIO

ET

11

CHECKING

DISTRIBUTOR

OPERATING

IDLE

LIMITER

CAP

ET

12

PARTS

AND

IGNITION

WIRING

ETlO

CHECKING

CARBURETOR

RETURN

SPRING

ET

12

BREAKER

POINTS

lNon

California

models

ET

10

CHECKING

CHOKE

MECHANISM

AI

R

GAP

lCalifornia

models

ET11

Choke

plate

and

linkage

ET13

DISTRIBUTOR

ET

11

CHECKING

FUEL

LINES

IGNITION

WIRING

ET

11

Hoses

pipings

connections

etc

ET

13

REPLACING

FUEL

FILTER

ET

13

CHECKING

BATTERY

Check

electrolyte

level

in

each

bat

tery

cell

I

Unscrew

each

filler

cap

and

inspect

fluid

level

If

the

fluid

is

low

add

distilled

water

to

bring

the

level

up

approximately

10

to

20

mm

0

39

H

9

to

0

79

in

above

the

plates

Do

not

overfill

2

Measure

the

specific

gravity

of

battery

electrolyte

Page 39 of 537

Engine

Tune

up

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

CANNOT

CRANK

ENGINE

OR

SLOW

CRANKING

Improper

grade

oil

Discharged

battery

Faulty

battery

Loose

fan

belt

Malfunction

in

charge

system

Wiring

connection

loose

in

starting

circuit

Faulty

ignition

switch

Faulty

starler

motor

Trouble

shooting

procedure

on

starting

circuit

Switch

on

the

starting

motor

with

light

ON

When

light

goes

off

or

dims

considerably

a

Check

battery

b

Check

connection

and

cable

c

Check

starter

motor

When

light

stays

bright

Corrective

action

Replace

with

proper

grade

oiL

Charge

battery

Replace

Adjust

Inspect

Correct

Repair

or

replace

Repair

or

replace

a

Check

wiring

connection

between

battery

and

starter

motor

b

Check

ignition

switch

c

Check

starter

motor

ENGINE

WILL

CRANK

NORMALLY

BUT

WILL

NOT

START

In

this

case

the

following

trouble

causes

may

exist

but

in

many

cases

ignition

system

or

fuel

system

is

in

trouble

Ignition

system

in

trouble

Fuel

system

in

troubk

Valve

mechanism

does

not

work

properly

Low

compussion

Trouble

shooting

procedure

Check

spark

plug

firstly

by

following

procedure

Disconnect

high

tension

cable

from

one

spark

plug

and

hold

it

about

10

mm

0

39

in

from

the

engine

metal

part

and

crank

the

engine

Good

spark

occurs

Check

spark

plug

b

Check

ignition

timing

c

Check

fuel

system

d

Check

cylinder

compression

Check

the

current

f10

in

primary

circuit

Very

high

current

Inspect

primary

circuit

for

short

Check

breaker

poiIit

operation

except

tran

sistor

ignition

system

No

spark

occurs

ET

27

Page 47 of 537

Engine

Mechanical

GENERAL

DESCRIPTION

MODEL

L20B

ENGINE

CYLINDER

BLOCK

CRANKSHAFT

PISTON

AND

CONNECTING

ROD

CYLINDER

HEAD

CONTENTS

EM

2

EM

3

EM

3

EM

3

EM

3

CAMSHAFT

VALVE

MECHANISM

CAMSHAFT

DRIVE

MANIFOLDS

out

smooth

dependable

power

The

cylinder

block

is

cast

as

a

single

unit

and

featllres

deep

skirting

This

engine

is

equipped

with

a

single

2

barrel

downdraft

carburetor

that

in

corporates

a

special

device

to

control

emissions

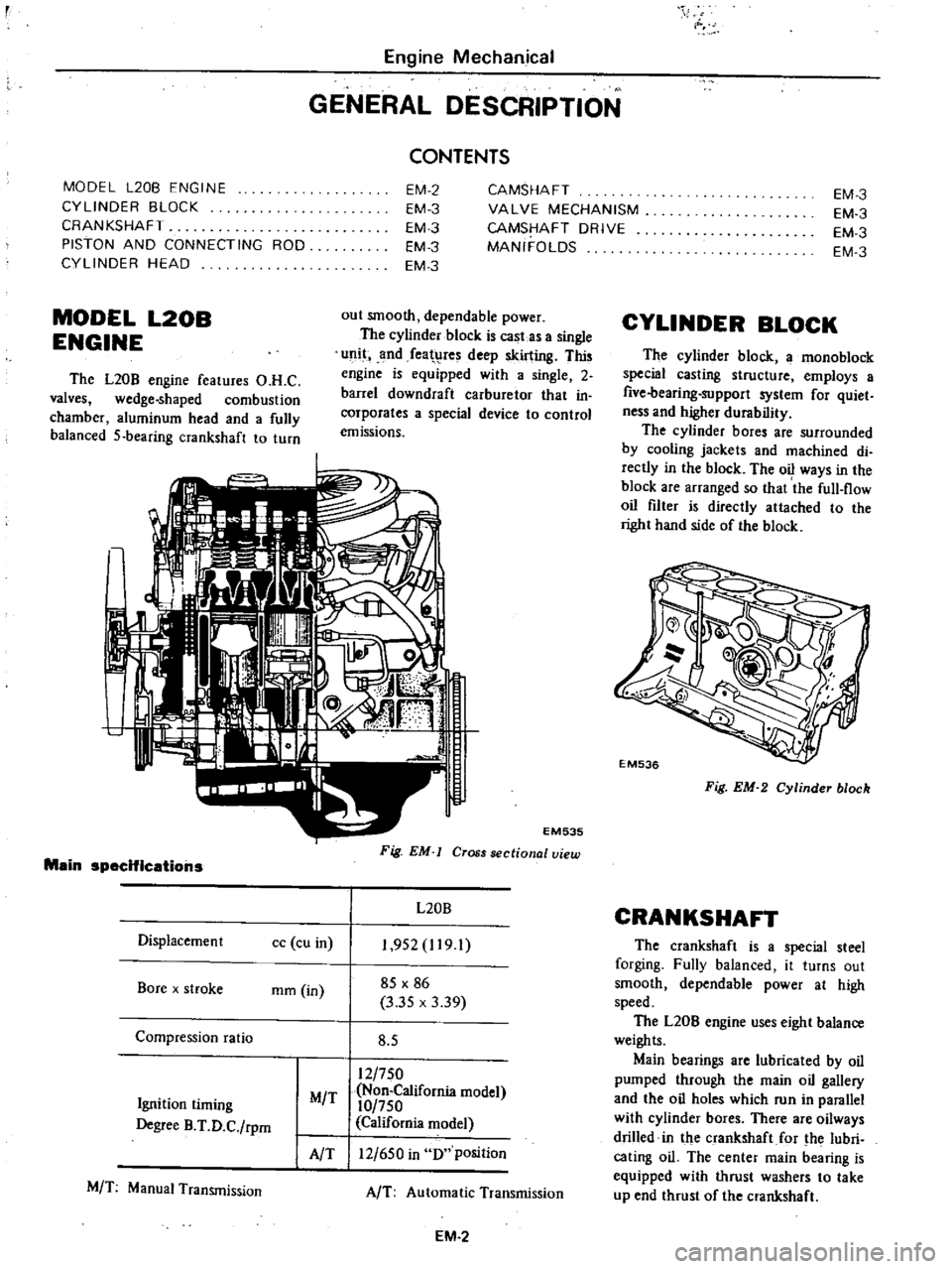

MODEL

L20B

ENGINE

The

L20B

engine

features

O

H

C

valves

wedge

shaped

combustion

chamber

aluminum

head

and

a

fully

balanced

5

bearing

crankshaft

to

turn

Main

specifications

Oisplacemen

t

cc

cu

in

Bore

x

stroke

mm

in

Compression

ratio

Ignition

timing

Degree

B

T

O

C

rpm

MIT

AlT

MIT

Manual

Transmission

EM535

Fig

EM

Cross

sectional

view

L20B

1

952

1191

85

X

86

3

35

x

3

39

8

5

12

750

Non

California

model

10

750

California

model

12

650

in

0

position

AIT

Automatic

Transmission

EM

2

EM

3

EM

3

EM

3

EM

3

CYLINDER

BLOCK

The

cylinder

block

a

mono

block

special

casting

structure

employs

a

five

bearing

support

system

for

quiet

ness

and

higher

durability

The

cylinder

bores

are

surrounded

by

cooling

jackets

and

machined

di

rectly

in

the

block

The

oil

ways

in

the

block

are

arranged

so

that

the

full

flow

oil

filter

is

directly

attached

to

the

right

hand

side

of

the

block

EM536

Fig

EM

2

Cylinder

block

CRANKSHAFT

The

crankshaft

is

a

special

steel

forging

Fully

balanced

it

turns

out

smooth

dependable

power

at

high

speed

The

L20B

engine

uses

eight

balance

weights

Main

bearings

are

lubricated

by

oil

pumped

through

the

main

oil

gallery

and

the

oil

holes

which

run

in

parallel

with

cylinder

bores

There

are

oilways

drilled

in

the

crankshaft

for

the

lubri

cating

oil

The

center

main

bearing

is

equipped

with

thrust

washers

to

take

up

end

thrust

of

the

crankshaft

Page 48 of 537

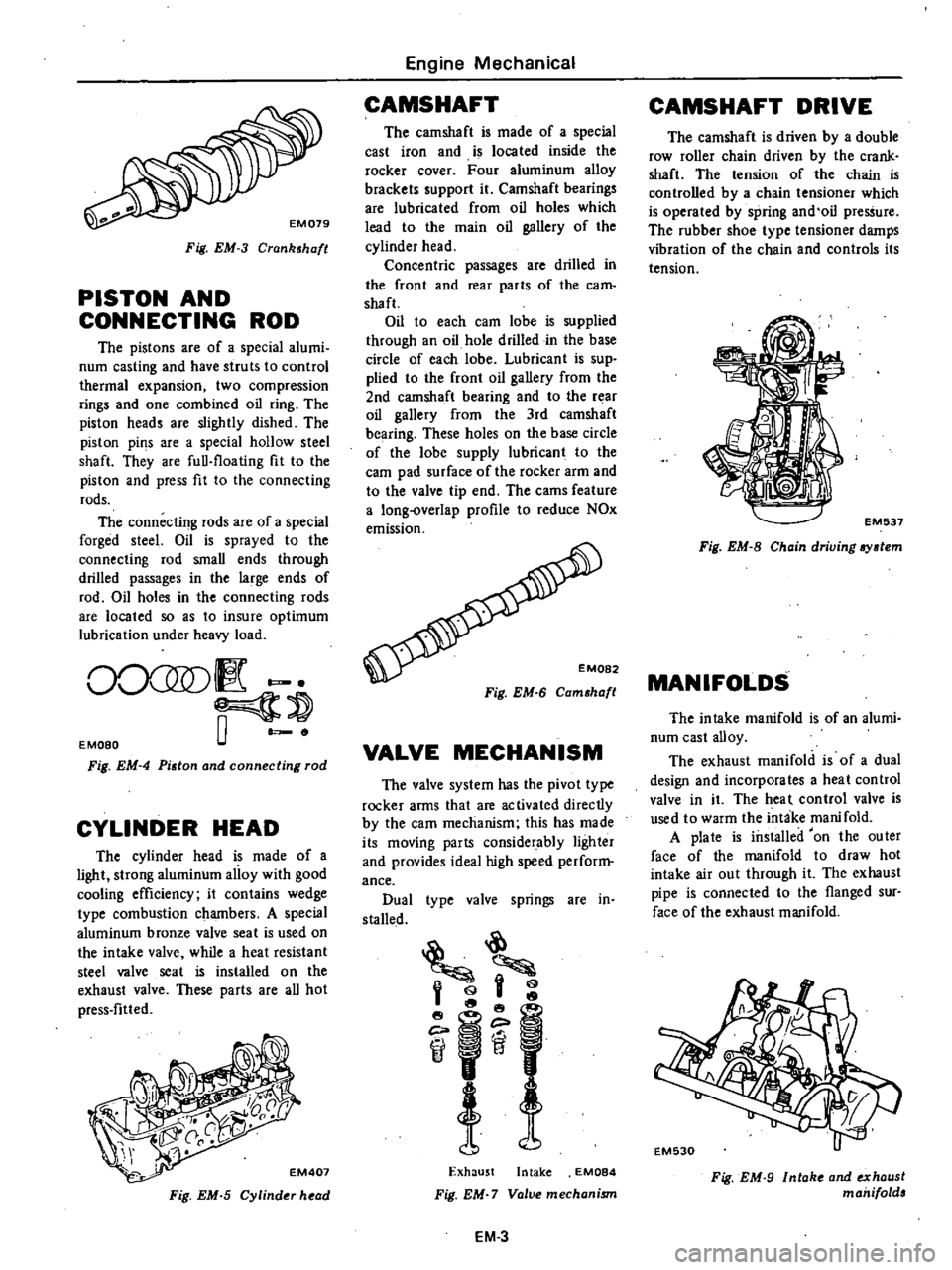

Fig

EM

3

Crankshafl

PISTON

AND

CONNECTING

ROD

The

pistons

are

of

a

special

alumi

num

casting

and

have

struts

to

control

thermal

expansion

two

compression

rings

and

one

combined

oil

ring

The

piston

heads

are

slightly

dished

The

piston

pil1S

are

a

special

hollow

steel

shaft

They

are

full

floating

fit

to

the

piston

and

press

fit

to

the

connecting

rods

The

connecting

rods

are

of

a

special

forged

steel

Oil

is

sprayed

to

the

connecting

rod

small

ends

through

drilled

passages

in

the

large

ends

of

rod

Oil

holes

in

the

connecting

rods

are

located

so

as

to

insure

optimum

lubrication

under

heavy

load

0

50

1

o

E

Moao

Fig

EM

4

Piston

and

connecting

rod

CYLINDER

HEAD

The

cylinder

head

is

made

of

a

light

strong

aluminum

alloy

with

good

cooling

efficiency

it

contains

wedge

type

combustion

chambers

A

special

aluminum

bronze

valve

seat

is

used

on

the

intake

valve

while

a

heat

resistant

steel

valve

seat

is

installed

on

the

exhaust

valve

These

parts

are

all

hot

press

fitted

EM407

Fig

EM

S

Cylinder

head

Engine

Mechanical

CAMSHAFT

The

camshaft

is

made

of

a

special

cast

iron

and

is

loca

ted

inside

the

rocker

cover

Four

aluminum

alloy

brackets

support

it

Camshaft

bearings

are

lubricated

from

oil

holes

which

lead

to

the

main

oil

gallery

of

the

cylinder

head

Concentric

passages

are

drilled

in

the

front

and

rear

parts

of

the

earn

shaft

Oil

to

each

earn

lobe

is

supplied

through

an

oil

hole

drilled

in

the

base

circle

of

each

lobe

Lubricant

is

sup

plied

to

the

front

oil

gallery

from

the

2nd

camshaft

bearing

and

to

the

rear

oil

gallery

from

the

3rd

camshaft

bearing

These

holes

on

the

base

circle

of

the

lobe

supply

lubricant

to

the

earn

pad

surface

of

the

rocker

arm

and

to

the

valve

tip

end

The

cams

feature

a

long

overlap

profile

to

reduce

NOx

emission

Fig

EM

6

Camshafl

VALVE

MECHANISM

The

valve

system

has

the

pivot

type

rocker

arms

that

are

activated

directly

by

the

earn

mechanism

this

has

made

its

moving

parts

considerably

lighter

and

provides

ideal

high

speed

perform

ance

Dual

type

valve

springs

are

in

stalled

h

@l

if

Exhaust

Intake

EM084

Fig

EM

7

Valve

mechanism

EM

3

CAMSHAFT

DRIVE

The

camshaft

is

driven

by

a

double

row

roller

chain

driven

by

the

crank

shaft

The

tension

of

the

chain

is

controlled

by

a

chain

tcosioner

which

is

operated

by

spring

and

oil

pressure

The

rubber

shoe

type

tensioner

damps

vibration

of

the

chain

and

controls

its

tension

EM537

Fig

EM

8

Chain

driving

aystem

MANIFOLDS

The

intake

manifold

is

of

an

alumi

num

cast

alloy

The

exhaust

manifold

is

of

a

dual

design

and

incorporates

a

heat

control

valve

in

it

The

heal

control

valve

is

used

to

warm

the

intake

manifold

A

plate

is

installed

on

the

outer

face

of

the

manifold

to

draw

hot

intake

air

out

through

it

The

exhaust

pipe

is

connected

to

the

flanged

sur

face

of

the

exhaust

manifold

Fig

EM

9

Intak

and

exhaust

manifolds

Page 51 of 537

r

28

Remove

cylinder

head

assembly

Use

Cylinder

Head

Bolt

Wrench

STl0120000

to

remove

cylinder

head

bolts

Loosen

bolts

from

CD

to

@

as

shown

in

Figure

EM

18

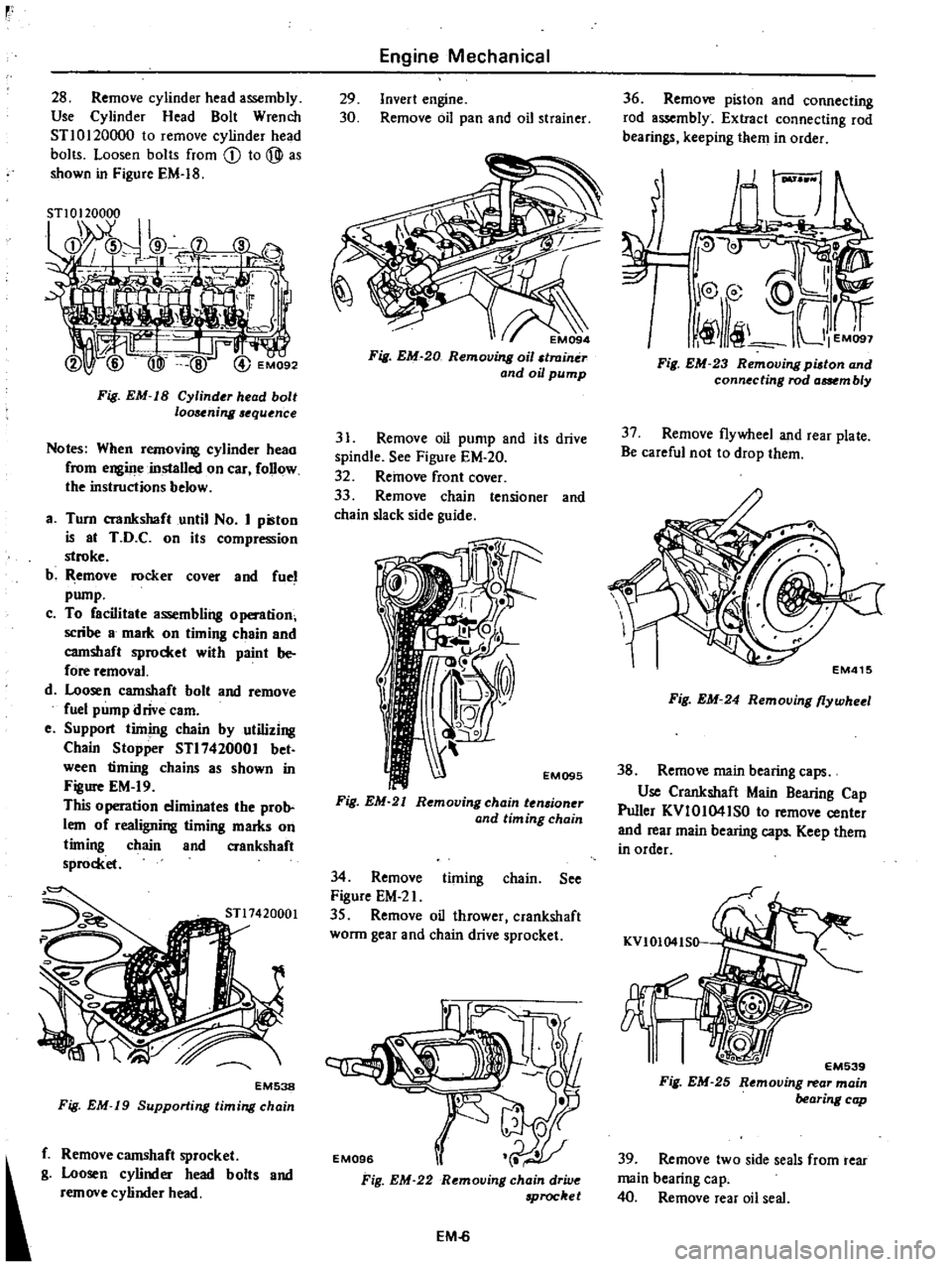

Fig

EM

IS

Cylinder

head

bolt

loosening

equence

Notes

When

removing

cylinder

heao

from

engiJJe

installed

on

car

follow

the

instructions

below

a

Turn

crankshaft

until

No

I

pilton

is

at

T

D

C

on

its

compression

stroke

b

Remove

rocker

Cover

and

fuel

pump

c

To

facilitate

assembling

o

tion

scribe

8

mark

on

timing

c

8in

and

camshaft

sprocket

with

paint

be

fore

removal

d

Loosen

camshaft

bolt

and

remove

fuel

pump

drive

earn

e

Support

timing

chain

by

utilizing

Chain

Stopper

STl7420001

bet

ween

timiilg

chains

as

shown

in

Figure

EM

19

This

0

peration

eliminates

the

prob

lem

of

realigning

timing

marks

on

timing

chain

and

crankshaft

sprocket

EM538

Fig

EM

19

Supporting

timing

chain

f

Remove

camshaft

sprocket

g

Loosen

cylinder

head

bolts

and

remove

cylinder

head

Engine

Mechanical

29

Invert

engine

30

Remove

oil

pan

and

oil

strainer

EM094

Fig

EM

20

Removing

oil

traintir

and

oil

pump

31

Remove

oil

pump

and

its

drive

spindle

See

Figure

EM

20

32

Remove

front

cover

33

Remove

chain

tensioner

and

chain

slack

side

guide

EM095

Fig

EM

21

Removing

chain

ten

ioner

and

tim

ing

chain

34

Remove

timing

chain

See

Figure

EM

2l

35

Remove

oil

thrower

crankshaft

wonn

gear

and

chain

drive

sprocket

Fig

EM

22

Removing

chain

drive

Proc

et

EM

6

36

Remove

piston

and

connecting

rod

a

mbly

Extract

connecting

rod

bearings

keeping

them

in

order

I

Fig

EM

23

Removing

pilton

and

connecting

rod

aat

m

b

y

37

Remove

flywheel

and

rear

plate

Be

careful

not

to

drop

them

EM415

Fig

EM

24

Removing

flywheel

38

Remove

main

bearing

caps

Use

Crankshaft

Main

Bearing

Cap

Puller

KVIOI04ISO

to

remove

center

and

rear

main

bearing

caps

Keep

them

in

order

KVIOI04IS0

EM539

Fig

EM

25

Removing

rear

main

bearing

cap

39

Remove

two

side

seals

from

rear

main

bearing

ca

p

40

Remove

rear

oil

seal

Page 72 of 537

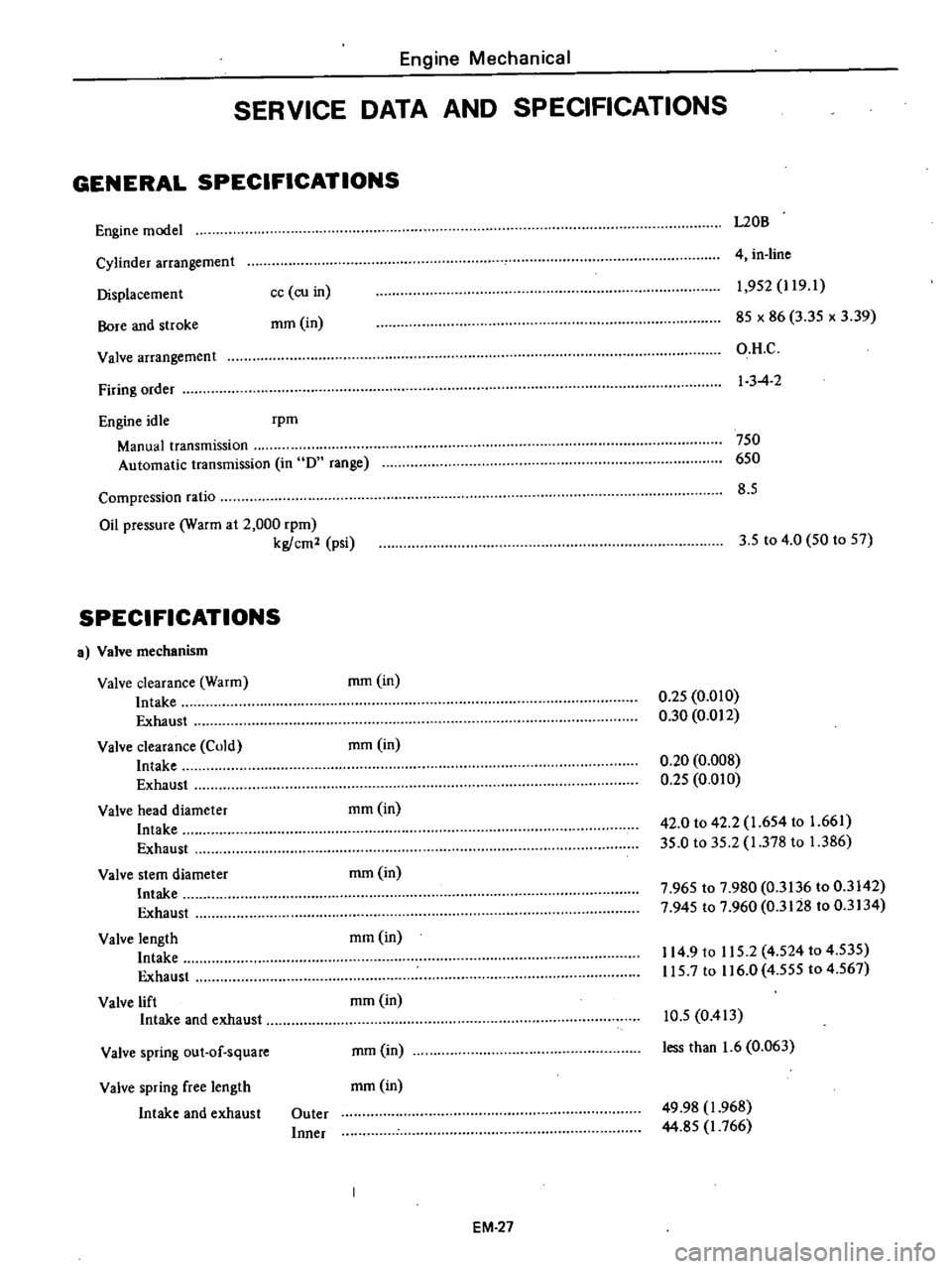

Engine

Mechanical

SERVICE

DATA

AND

SPECIFICATIONS

GENERAL

SPECIFICATIONS

Engine

model

L20B

Cylinder

arrangement

Displacemen

t

Bore

and

stroke

4

in

line

cc

co

in

mm

in

1

952

J

19

1

85

x

86

3

35

x

3

39

O

H

C

I

3

4

2

Valve

arrangement

Firing

order

Engine

idle

rpm

Manual

transmission

Automatic

transmission

in

D

range

750

650

8

5

Compression

ratio

Oil

pressure

Warm

at

2

000

rpm

kg

cm2

psi

3

5

to

4

0

50

to

57

SPECIFICATIONS

a

Valve

mechanism

Valve

clearance

Warm

Intake

Exhaust

Valve

clearance

Cold

Intake

Exhaust

Valve

head

diameter

Intake

Exhaust

Valve

stem

diameter

Intake

Exhaust

Valve

length

Intake

Exhaust

Valve

lift

Intake

and

exhaust

mm

in

0

25

0

010

0

30

0

012

mmOn

0

20

0

008

0

25

0

010

mm

in

42

0

to

42

2

1

654

to

1

661

35

0

to

35

2

1

378

to

1

386

mm

in

7

965

to

7

980

0

3136

to

0

3142

7

945

to

7

960

0

3128

to

0

3134

mmOn

114

9

to

115

2

4

524

to

4

535

115

7

to

116

0

4

555

to

4

567

mmOn

Valve

spring

out

of

square

mm

in

10

5

0

413

less

than

1

6

0

063

Valve

spring

free

length

mm

in

Intake

and

exhaust

Outer

Inner

49

98

1

968

44

85

J

766

EM

27

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 526 of 537

INSPECTION

Check

for

gas

leakage

as

follows

I

Plug

high

and

low

pressure

joints

on

compressor

with

blind

caps

2

Connect

charging

hoses

in

lines

between

manifold

gauge

and

high

and

low

pressure

service

valves

Connect

refrigerant

can

to

middle

hose

of

manifold

gauge

3

Open

valve

of

can

tap

and

charge

refrigerant

Loosen

oil

filler

plug

at

side

of

compressor

to

purge

air

out

of

compressor

4

Turn

shaft

5

or

6

turns

Then

confirm

that

pressure

does

not

decrease

on

low

pressure

gauge

If

gauge

indicates

a

pressure

decrease

there

is

a

leak

Conduct

a

leak

test

Under

such

a

condition

remove

and

then

install

parts

again

CYLINDER

HEAD

AND

VALVES

Insufficient

refrigerant

compression

is

likely

to

be

caused

by

damaged

head

gasket

or

damaged

valves

Prior

to

servicing

the

head

and

valve

plate

both

service

valves

should

be

opened

to

free

any

gas

pressure

which

may

be

in

the

compressor

REMOVAL

I

Remove

the

bolts

from

flanged

type

service

valves

using

Torx

Driver

Bit

Note

The

direction

of

flanged

type

service

valves

should

be

noted

for

reinstallation

AC812

Fig

AC

66

Removing

service

valves

2

Remove

the

remaining

bolts

in

the

head

Air

Conditioning

AC813

Fig

A

C

6

7

Removing

cylinder

head

bolts

3

Remove

valve

plate

and

head

from

cylinder

by

prying

or

tapping

under

the

ears

which

extend

from

valve

plate

If

head

and

valve

plate

adhere

hold

head

and

tap

valve

plate

ears

away

from

head

with

a

soft

hammer

Note

Do

not

hit

or

tap

head

to

separate

head

and

valve

plate

be

3use

damage

to

head

may

result

Fig

AC

68

Removing

valve

plate

and

head

4

When

removing

the

gaskets

use

a

sharp

edged

knife

Notes

a

In

removing

head

gasket

be

very

careful

not

to

damage

machined

sealing

surface

b

Do

not

reuse

gaskets

AC815

Fig

A

C

69

Removing

gasket

AC37

INSTALLATION

Valves

and

valve

plates

are

furnish

ed

only

as

a

complete

assembly

I

Apply

a

thin

film

of

clean

refrig

eration

oil

on

area

of

crankcase

to

be

covered

by

cylinder

gasket

2

Place

cylinder

gasket

in

position

on

cylinder

so

dowel

pins

in

crankcase

go

through

dowel

pin

holes

in

cylinder

gasket

3

Apply

a

thin

film

of

clean

refrig

eration

oil

to

top

and

bottom

valve

plate

areas

to

be

covered

by

gaskets

AC816

Fig

A

C

70

Applying

clean

refrigeration

oil

4

Place

valve

plate

in

position

on

cylinder

gasket

so

discharge

valve

as

semblies

i

e

smaller

diameter

assem

blies

with

restrainer

over

valve

reed

are

facing

up

and

locating

dowel

pins

go

through

dowel

pin

holes

in

valve

plate

Fig

A

C

71

Placing

valve

plate