ABS DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 391 of 537

REMOVAL

Referring

to

Figure

BR

29

remove

parts

in

numerical

order

enumerated

1

cD

2

BR17S

Fig

BR

29

Removal

method

of

Mcuter

Vae

DISASSEMBLY

When

disassembling

Master

Vac

ob

serve

the

following

instructions

a

Thoroughly

clean

mud

or

dust

from

Master

Vac

b

Extreme

care

should

be

taken

not

to

allow

dirt

dust

water

or

any

other

foreign

matter

into

any

com

ponent

parts

Be

sure

to

select

a

clean

place

before

disassembly

or

assembly

c

Mark

mating

joints

so

that

they

may

be

installed

exactly

in

their

original

positions

d

Keep

all

disassembled

parts

arranged

properly

so

that

they

may

readily

be

assembled

at

any

time

e

Clean

rubber

parts

and

synthetic

resin

parts

in

alcohol

f

Mter

all

disassembled

parts

are

cleaned

in

a

suitable

clean

solvent

place

on

a

clean

work

bench

Use

care

not

to

allow

dirt

and

dust

to

come

into

contact

with

these

parts

1

Install

spacer

on

rear

shell

spacer

temporarily

Place

Master

Vac

in

a

vise

Use

soft

jaws

2

Remove

clevis

and

lock

nut

De

tach

valve

body

guard

rW

ID

1

Clevis

2

Lock

nut

3

Valve

body

guard

BRD7S

Fig

BR

30

Removing

rear

hell

Brake

System

3

Identify

front

shell

and

rear

shell

clearly

so

that

they

may

be

reassem

bled

in

their

original

positions

from

which

they

were

withdrawn

Bolts

attached

on

dashboard

are

not

the

same

in

pitch

4

Using

Master

Vac

Wrench

ST08080000

remove

rear

shell

seal

assembly

and

disassemble

diaphragm

plate

assembly

front

shell

assembly

diaphragm

spring

and

push

rod

assem

bly

f

Q

BA076

Fig

BR

31

Removing

reor

shell

Rear

shell

seal

Pry

off

retainer

with

use

of

screw

driver

as

shown

and

detach

bearing

and

seal

Note

Do

not

disassemble

seal

assem

bly

unless

absolutely

necessary

Whenever

this

is

to

be

removed

use

care

not

to

damage

it

BRD7S

Fig

BR

32

Removing

retainer

Diaphragm

plate

Place

diaphragm

plate

assembly

on

a

clean

work

bench

Detach

dia

phragm

from

groove

in

plate

as

shown

BR

16

BA079

FlIf

BR

33

Separating

diaphragm

2

Using

a

screwdriver

as

shown

evenly

pry

air

silencer

retainer

until

it

is

detached

from

diaphragm

plate

as

sembly

Note

Never

use

a

hammer

to

remove

this

retainer

since

this

win

be

the

sure

y

of

damaging

it

BA322

Fig

BR

34

Removing

air

silencer

retainer

3

Pull

out

valve

plunger

stop

key

and

withdraw

silencer

and

plunger

assembly

Note

To

remove

valve

plunger

stop

key

properly

proceed

as

follows

With

key

hole

facing

down

lightly

push

valve

operating

rod

simulta

neously

while

applying

vibration

to

it

BA180

Fig

BR

35

Pulling

out

top

key

Page 405 of 537

Condition

Wheel

wobbles

Unevenly

or

excessively

worn

tire

Tire

squeals

Wheel

and

Tire

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Improper

tire

pressure

Damaged

tire

or

distorted

wheel

rim

Unbalanced

wheel

Loose

wheel

nuts

Worn

or

damaged

wheel

bearing

or

excessive

play

of

wheel

bearing

Improper

front

wheel

alignment

Worn

or

damaged

ball

joint

Excessive

steering

linkage

play

or

worn

steering

linkage

Loose

steering

linkage

connection

Broken

suspension

spring

Damaged

shock

absorber

Improper

tire

rotation

Improper

tire

pressure

Unbalanced

wheel

Improperly

adjusted

brake

Improper

wheel

alignment

Excessively

distorted

or

improperly

installed

suspension

link

High

speed

on

curves

Sudden

start

and

improper

speed

due

to

rapid

acceleration

or

improper

brake

ap

plication

Improper

tire

pressure

Improper

front

wheel

alignment

Distorted

knuckle

or

suspension

link

WT

5

Corrective

action

Measure

and

adjust

Repair

or

replace

Balance

Tighten

Correct

play

or

replace

wheel

bearing

Align

Replace

Adjust

Or

replace

Tighten

nuts

to

rated

torque

or

replace

worn

parts

if

any

Replace

Replace

Conduct

tire

rotation

periodically

Measure

and

adjust

Balance

or

replace

Adjust

Align

Repair

replace

or

if

necessary

reinstall

Reduce

speed

Follow

correct

and

proper

driving

manner

Measure

and

adjust

Align

Repair

or

replace

Page 420 of 537

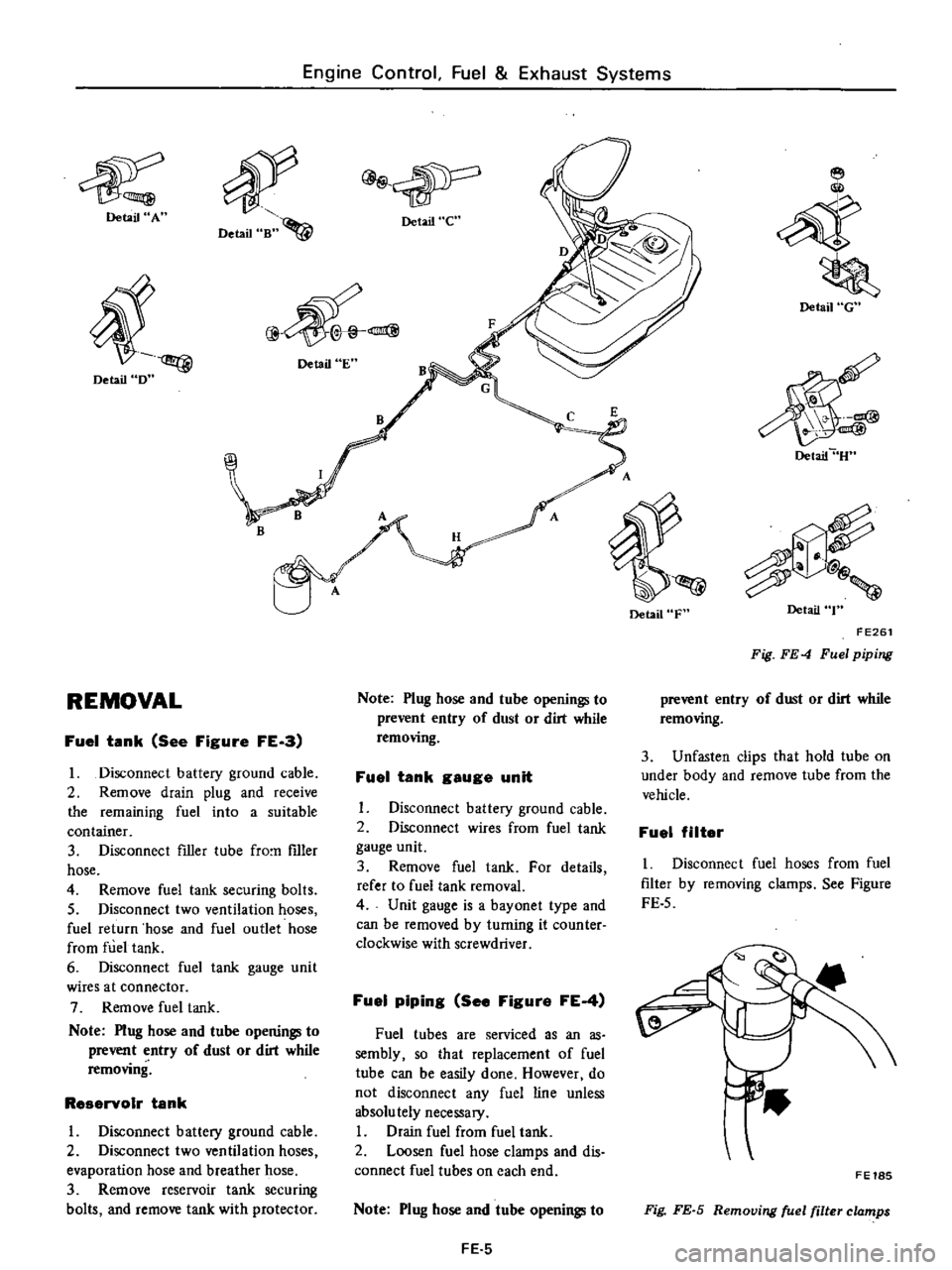

Detail

A

Detail

D

REMOVAL

Engine

Control

Fuel

Exhaust

Systems

Detail

Bn

4

Detail

e

@

Detail

E

B

Fuel

tank

See

Figure

FE

a

I

Disconnect

battery

ground

cable

2

Remove

drain

plug

and

receive

the

remaining

fuel

into

a

suitable

container

3

Disconnect

filler

tube

fro

filler

hose

4

Remove

fuel

tank

securing

bolts

5

Disconnect

two

ventilation

hoses

fuel

return

hose

and

fuel

outlet

hose

from

fuel

tank

6

Disconnect

fuel

tank

gauge

unit

wires

at

connector

7

Remove

fuel

tank

Note

Plug

hose

and

tube

opening

l

to

prevent

entry

of

dust

or

dirt

while

removing

ReservoIr

tank

1

Disconnect

battery

ground

cable

2

Disconnect

two

ventilation

hoses

evaporation

hose

and

breather

hose

3

Remove

reservoir

tank

securing

bolts

and

remove

tank

with

protector

Note

Plug

hose

and

tube

opening

l

to

prevent

entry

of

dust

or

dirt

while

removing

Fuel

tank

gauge

unit

Disconnect

battery

ground

cable

2

Disconnect

wires

from

fuel

tank

gauge

unit

3

Remove

fuel

tank

For

details

refer

to

fuel

tank

removal

4

Unit

gauge

is

a

bayonet

type

and

can

be

removed

by

turning

it

counter

clockwise

with

screwdriver

Fuel

piping

See

Figure

FE

4

Fuel

tubes

are

serviced

as

an

as

sembly

so

that

replacement

of

fuel

tube

can

be

easily

done

However

do

not

disconnect

any

fuel

line

unless

absolu

tely

necessary

I

Drain

fuel

from

fuel

tank

2

Loosen

fuel

hose

clamps

and

dis

connect

fuel

tubes

on

each

end

Note

Plug

hose

and

tube

openings

to

FE

5

Detail

F

Detail

G

Detail

U

Detail

T

FE261

Fig

FE

4

Fuel

piping

prevent

entry

of

dust

or

dirt

while

removing

3

Unfasten

clips

that

hold

tube

on

under

body

and

remove

tube

from

the

vehicle

Fuel

filter

I

Disconnect

fuel

hoses

from

fuel

filter

by

removing

clamps

See

Figure

FE

5

FE18S

Fig

FE

S

Removing

fuel

filter

clamps

Page 450 of 537

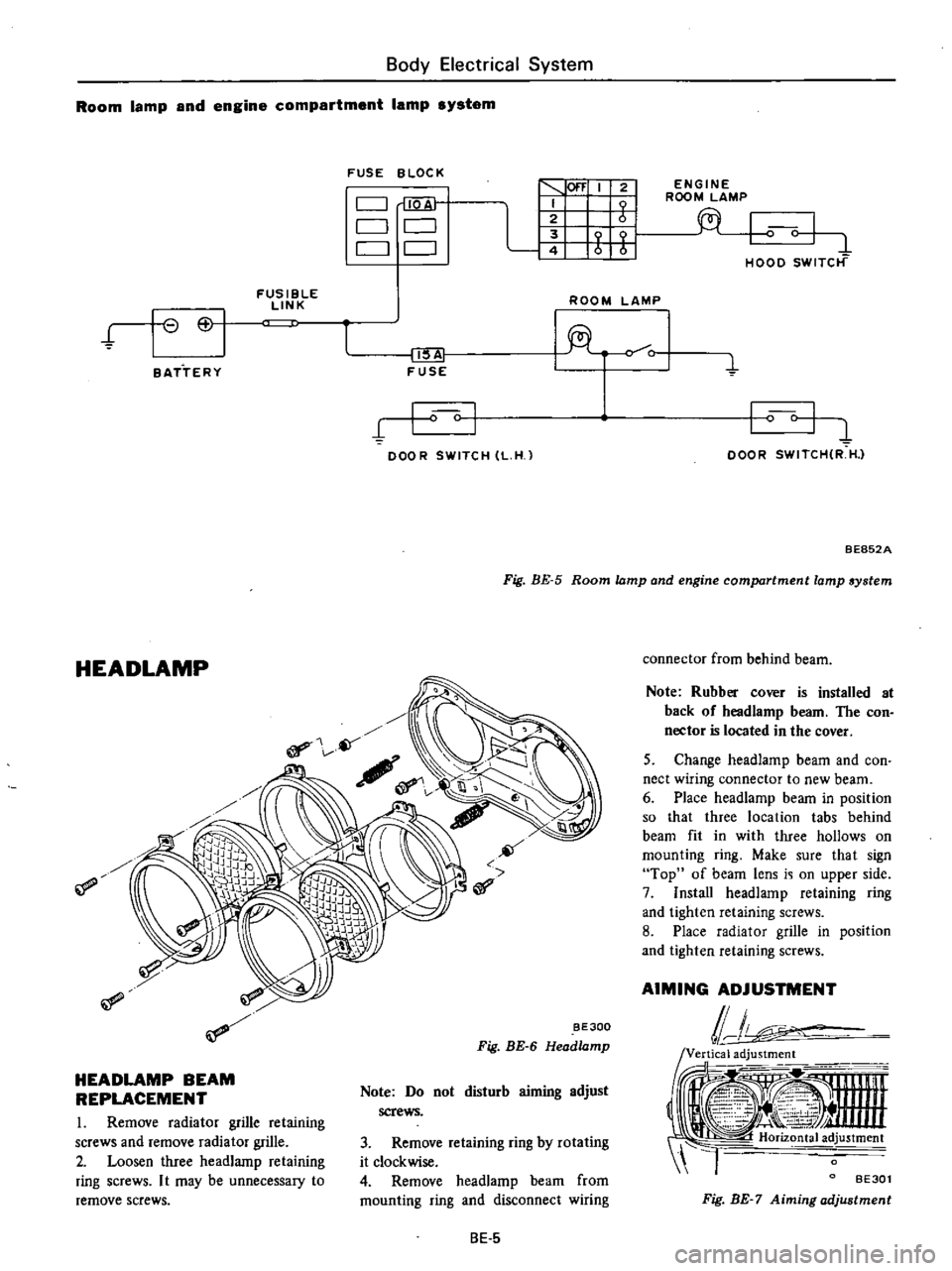

Body

Electrical

System

Room

lamp

and

engine

compartment

lamp

system

FUSE

BLOC

K

C

J

QA

C

J

CJ

CJ

CJ

1

100

I

2

I

I

t1

Wf

t

fi

FUSIBLE

LINK

ROOM

LAMP

t

I

6

I

II

lA

FUSE

o

C

1

BATTERY

I

I

DOOR

SWITCH

L

H

l

ENGINE

ROOM

LAMP

I

0

I

1

HOOD

SWITCt

f

I

c

I

DOOR

SWITCHIR

H

l

Fig

BE

5

Room

lamp

and

engine

compartment

lamp

system

BE852A

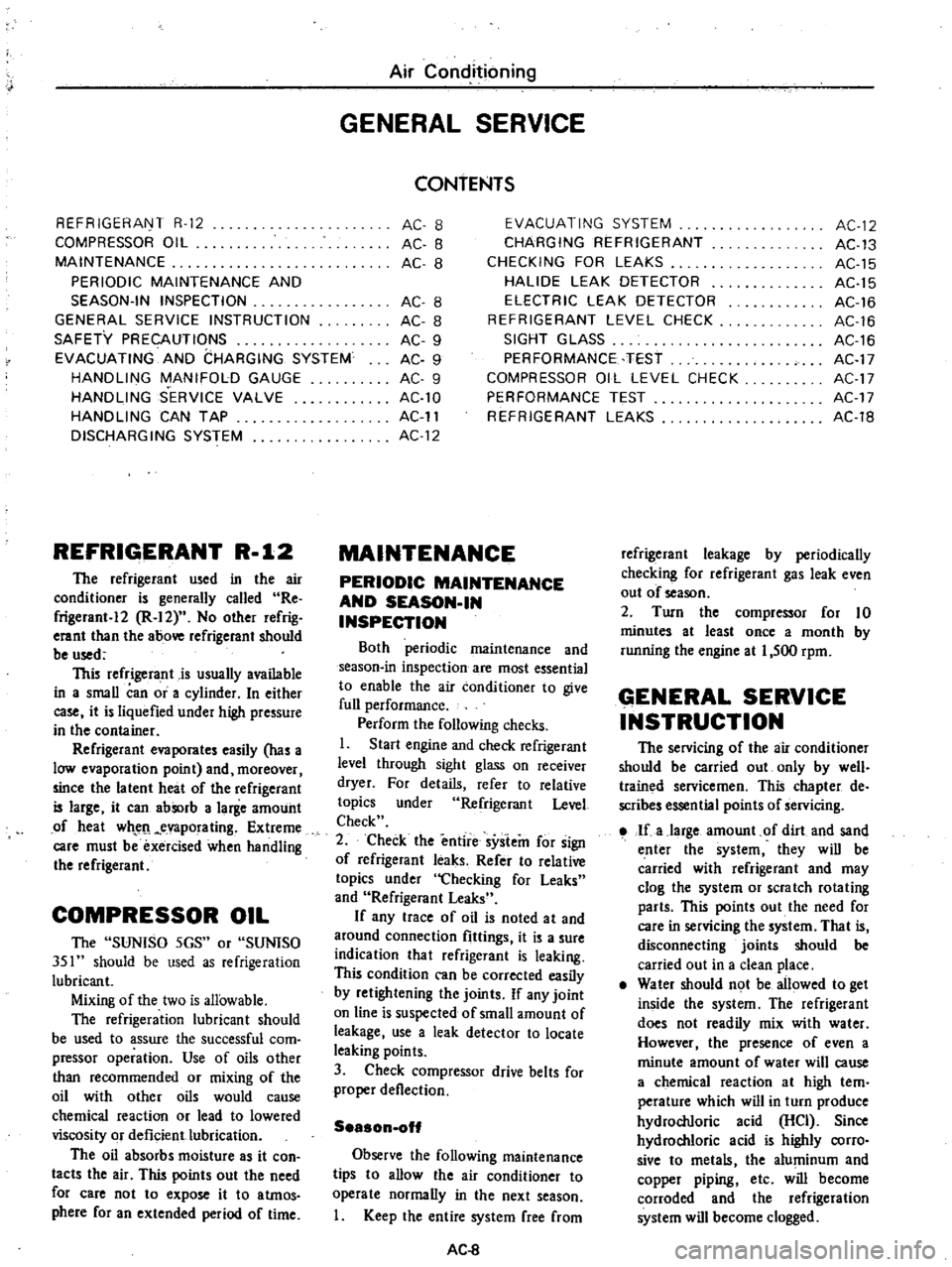

HEADLAMP

if

BE300

Fig

BE

6

Head

amp

HEADLAMP

BEAM

REPLACEMENT

I

Remove

radiator

grille

retaining

screws

and

remove

radiator

grille

2

Loosen

three

headlamp

retaining

ring

screws

I

t

may

be

unnecessary

to

remove

screws

Note

Do

not

disturb

aiming

adjust

screws

3

Remove

retaining

ring

by

rotating

it

clockwise

4

Remove

headlamp

beam

from

mounting

ring

and

disconnect

wiring

8E

5

connector

from

behind

beam

Note

Rubber

cover

is

installed

at

back

of

headlamp

beam

The

con

nector

is

located

in

the

cover

5

Change

headlamp

beam

and

con

nect

wiring

connector

to

new

beam

6

Place

headlamp

beam

in

position

so

that

three

location

tabs

behind

beam

fit

in

with

three

hollows

on

mounting

ring

Make

sure

that

sign

Top

of

beam

lens

i

i

on

upper

side

7

Install

headlamp

retaining

ring

and

tighten

retaining

screws

8

Place

radIator

grille

in

position

and

tighten

retaining

screws

AIMING

ADJUSTMENT

lJ

ii

i

tooi

1

Ji

Y

4

nnn

4

I

Horiz

tal

ad

justment

l

BE30l

Fig

BE

7

Aiming

adjustment

Page 492 of 537

REFRIGERATION

SYSTEM

If

you

were

to

paint

your

finger

with

alcohol

your

finger

would

feel

cold

This

is

because

the

liquid

alcohol

takes

heat

away

from

your

finger

while

it

evaporates

If

a

quickly

evapo

rating

liquid

such

as

alcoliol

is

placed

in

a

container

inside

a

box

the

tem

f

Outside

air

U

Condenser

J6G1

i

i

1

1

t1

1

ilill

I

I

J

JJ

LlJ

i

l

7

U

Receiver

dryer

h

w

t

CONDENSER

The

condenser

is

installed

to

the

front

of

the

radiator

The

heated

and

compressed

refrigerant

gas

from

the

Air

Conditioning

perature

inside

the

box

will

drop

This

is

because

the

alcohol

is

evaporated

absorbing

the

heat

from

the

air

insidc

the

box

If

the

gaseous

alcohol

is

collected

and

cooled

with

cold

water

it

will

be

changed

back

into

a

liquid

by

absorption

of

its

heat

by

the

cold

water

The

cooler

operates

on

this

princi

Compressor

t

q

ttLJ

IrJ

Evaporator

It

J

1

J

f

9

d

lUr

I

Expansion

valve

V7777

J

High

pressure

lLLLLL

l

gas

I

I

High

pressure

liquid

t

u

compressor

condenses

to

a

liquid

by

being

cooled

by

air

passing

between

the

fins

of

the

condenser

1

GJ

7

vlmnn

iii

plI

d1i

1il

Ac459

Fig

AC

3

Condenser

AC3

pIe

The

liquid

used

is

the

refrigerant

R

12

The

heat

inside

the

passenger

compartment

is

absorbed

by

changing

the

refrigerant

from

a

liquid

to

a

gas

and

then

dissipated

to

the

outside

by

changing

the

refrigerant

from

a

gas

back

to

a

liquid

The

refrigeration

system

is

shown

in

Figure

AC

2

Low

pressurt

liquid

1

I

L2

Low

pressure

gas

Inside

air

li

r

L

Blower

motor

AC458

Fig

AC

2

Refrigeration

cycle

COMPRESSOR

The

compressor

is

installed

to

the

side

of

the

engine

and

is

driven

by

crank

pulley

through

a

belt

The

refrig

erant

gas

leaving

the

evaporator

is

forced

out

to

the

condenser

by

com

pressor

and

the

low

pressure

refrig

erant

gas

is

compressed

to

a

high

pressure

and

high

temperature

The

driving

force

is

transmitted

by

an

electrical

clutch

Because

engine

rpm

is

very

low

during

idling

the

clutch

will

not

transmit

the

driving

force

thus

ensuring

smooth

engine

idling

Page 497 of 537

REFRIGERAi

H

R

12

COMPRESSOR

OIL

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

GENERAL

SERVICE

INSTRUCTION

SAFETY

PRECAUTIONS

EV

ACUA

TlNG

AND

CHARGING

SYSTEM

HANDLING

MANIFOLD

GAUGE

HANDLING

SERVICE

VALVE

HANDLING

CAN

TAP

DISCHARGING

SYSTEM

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

This

refrigerant

is

usually

available

in

a

small

can

or

a

cylinder

In

either

case

it

is

liquefied

under

high

pressure

in

the

container

Refrigerant

evaporates

easily

has

a

low

evaporation

point

and

moreover

since

the

latent

heat

of

the

refrigerant

is

large

it

can

abSorb

a

large

amount

of

heat

wh

err

e

vaporating

Extreme

care

must

be

exercised

when

handling

the

refrigerant

COMPRESSOR

OIL

The

SUNISO

5GS

or

SUNISO

351

should

be

used

as

refrigeration

lubricant

Mixing

of

the

two

is

allowable

The

refrigeration

lubricant

should

be

used

to

assure

the

successful

com

pressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrication

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

Air

Conditioning

GENERAL

SERVICE

CONTENTS

EVACUATING

SYSTEM

CHARGING

REFRIGERANT

CHECKING

FOR

LEAKS

HALIDE

LEAK

DETECTOR

ELECTRIC

LEAK

DETECTOR

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

PERFORMANCE

TEST

COMPRESSOR

OIL

LEVEL

CHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

AC

8

AC

8

AC

8

AC

8

AC

8

AC

9

AC

9

AC

9

AC10

AC

11

AC

12

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

Both

periodic

maintenance

and

season

in

inspection

are

most

essential

to

enable

the

air

conditioner

to

give

full

performance

Perform

the

following

checks

Start

engine

and

check

refrigerant

level

through

sight

glass

on

receiver

dryer

For

details

refer

to

relative

topics

under

Refrigerant

Level

Check

2

Check

the

entire

sysiein

for

sign

of

refrigerant

leaks

Refer

to

relative

topics

under

Checking

for

Leaks

and

Refrigerant

Leaks

If

any

trace

of

oil

is

noted

at

and

around

connection

fittings

it

is

a

sure

indication

that

refrigerant

is

leaking

This

condition

can

be

corrected

easily

by

retightening

the

joints

If

any

joint

on

line

is

suspected

of

small

amount

of

leakage

use

a

leak

detector

to

locate

leaking

points

3

Check

compressor

drive

belts

for

proper

deflection

Season

off

Observe

the

following

maintenance

tips

to

allow

the

air

conditioner

to

operate

normally

in

the

next

season

I

Keep

the

entire

system

free

from

AC

8

AC12

AC

13

AC15

AC15

AC16

AC

16

AC16

AC

17

AC17

AC

17

AC18

refrigerant

leakage

by

periodically

checking

for

refrigerant

gas

leak

even

out

of

season

2

Turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

c

ENERAL

SERVICE

INSTRUCTION

The

servicing

of

the

air

conditioner

should

be

carried

out

only

by

well

trained

servicemen

This

chapter

de

scribes

essential

points

of

servicing

Jf

a

Jarge

amount

of

dirt

and

sand

enter

the

system

they

will

be

carried

with

refrigerant

and

may

clog

the

system

or

scratch

rotating

parts

This

points

out

the

need

for

care

in

servicing

the

system

That

is

disconnecting

joints

should

be

carried

out

in

a

dean

place

Water

should

not

be

allowed

to

get

inside

the

system

The

refrigerant

does

not

readily

mix

with

water

However

the

presence

of

even

a

minute

amount

of

water

will

cause

a

chemical

reaction

at

high

tem

perature

which

will

in

turn

produce

hydrochloric

acid

HCl

Since

hydrochloric

acid

is

highly

corro

sive

to

metals

the

aluminum

and

copper

piping

etc

will

become

corroded

and

the

refrigeration

system

will

become

clogged

Page 498 of 537

Water

in

the

system

will

ice

the

orifice

when

the

high

pressure

re

frigerant

is

changed

to

low

pressure

refrigerant

by

expansion

valve

etc

and

will

obstruct

the

refrigerant

flow

The

following

items

are

general

instructions

to

be

closely

observed

in

servicing

the

system

I

When

a

system

line

is

discon

nected

plug

the

opening

immediately

This

is

especially

necessary

to

prevent

moisture

condensation

from

forming

in

the

line

and

to

keep

out

dirt

and

dust

It

is

also

necessary

to

keep

the

line

at

and

above

surrounding

air

temperatures

at

all

times

When

con

necting

system

lines

do

not

attempt

to

remove

the

plug

from

the

opening

until

ready

for

immediate

use

2

Always

keep

the

working

place

clean

and

dry

and

free

from

dirt

and

dust

Wipe

water

off

with

a

clean

cloth

3

Have

all

necessary

tools

in

pre

paration

beforehand

and

have

tools

clean

and

dry

4

The

compressor

oil

will

easily

absorb

moisture

when

exposed

to

air

Immediateiy

close

the

opening

of

the

container

after

use

It

is

also

necessary

to

observe

the

following

notes

Notes

a

The

oil

should

not

be

transfused

from

a

container

into

another

as

the

failure

will

possibly

cause

mois

ture

to

mix

with

the

oil

b

The

used

oil

should

not

be

returned

into

a

container

c

The

oil

should

not

be

used

if

its

state

of

preservation

is

not

clear

enough

5

When

connecting

or

disconnect

ing

pipes

from

the

refrigeration

sys

tem

use

two

wrenches

One

wrench

is

used

for

holding

the

fixing

nut

in

place

while

the

other

for

turning

the

mating

flare

nut

Failure

to

do

so

may

result

in

a

twisted

tube

or

may

damage

connection

6

Also

use

care

not

to

give

scratches

to

the

seating

surface

at

connections

A

small

scratch

on

the

seating

surface

Air

Conditioning

may

be

the

cause

of

gas

leakage

Before

connecting

pipes

be

sure

to

give

coating

of

compressor

oil

to

the

sea

ting

surfaces

SAFETY

PRECAUTIONS

I

Since

direct

contact

of

the

liquid

refrigerant

with

your

skin

will

cause

frostbite

always

be

careful

when

handling

the

refrigerant

Wear

gloves

or

wrap

a

piece

of

cloth

around

service

valve

to

protect

your

fingers

against

frostbite

by

refrigerant

If

any

of

the

refrigerant

should

get

into

your

eyes

when

charging

the

refrigerant

splash

your

eyes

with

cool

water

to

raise

the

temperature

gradually

Apply

a

protec

tive

film

to

the

eye

to

avoid

infection

Do

not

rub

your

eyes

Consult

an

eye

specialist

Always

wear

goggles

or

glasses

to

protect

your

eyes

when

working

around

the

system

Should

refrigerant

strikes

your

body

splash

on

cool

water

and

apply

a

protective

film

2

The

refrigerant

service

container

has

a

safe

strength

However

if

han

dled

incorrectiy

it

wili

explode

Therefore

always

follow

the

instruc

tions

on

the

label

In

particular

never

stpre

it

in

a

hot

location

above

S20C

l250F

or

drop

it

from

a

high

height

3

The

refrigerant

gas

is

odorless

and

colorless

and

breathing

may

become

difficult

due

to

the

lack

of

oxygen

Since

the

refrigerant

gas

is

heavier

than

air

and

will

lay

close

to

the

floor

be

especially

careful

when

handling

it

in

small

confined

spaces

4

The

refrigerant

itself

is

nonflam

mable

However

a

toxic

gas

phosgene

gas

is

produced

when

it

contacts

fire

and

special

care

is

therefore

required

when

checking

for

leaks

in

the

system

with

a

halide

torch

5

Do

not

steam

clean

on

the

sys

tern

especially

condenser

since

exces

sively

high

pressure

will

build

up

in

the

system

resulting

in

explosion

of

the

system

The

above

precautions

are

essential

in

handling

of

Refrigerant

l

2

and

their

strict

observation

requires

suffi

AC

9

dent

training

Therefore

it

is

of

first

importance

that

any

other

personnel

than

a

well

trained

serviceman

should

not

be

allowed

to

handle

the

refrig

erant

EVACUATING

AND

CHARGING

SYSTEM

During

servicing

use

caution

to

keep

air

from

getting

into

refrigerant

When

air

enters

the

system

all

refriger

ant

must

be

evacuated

from

system

prior

to

charging

new

refrigerant

Air

in

refrigerant

has

the

following

delete

rious

effects

I

Since

the

condensation

tempera

ture

of

the

air

is

extremely

low

the

air

will

not

be

condensed

when

refrigerant

gas

is

condensed

in

the

condenser

and

the

air

will

thus

remain

in

gaseous

form

Consequently

the

effective

thermal

transmission

area

of

condenser

for

refrigerant

gas

will

be

red

uced

and

refrigerant

gas

to

be

condensed

will

be

red

ueed

The

pressure

rise

will

become

proportional

to

the

volume

of

the

air

in

system

2

When

air

and

refrigerant

are

mixed

in

system

a

chemical

reaction

will

be

produced

and

hydrochloric

acid

which

will

adversely

affect

the

aluminum

copper

iron

and

other

materials

in

system

may

be

generated

HANDLING

MANIFOLD

GAUGE

The

pressure

at

the

high

and

low

sides

of

system

should

be

measured

when

evacuating

and

charging

refrig

erant

and

when

diagnosing

trouble

in

the

system

The

manifold

gauge

is

used

for

these

purposes

A

manifold

gauge

has

two

pressure

gauges

a

low

pressure

gauge

and

a

high

pressure

gauge

These

gauges

are

connected

to

the

high

and

low

side

service

valves

of

system

through

flexible

charging

hoses

The

construction

of

manifold

gauge

is

shown

in

Figure

AC

13

When

valve

stem

is

fully

screwed

the

valve

is

front

seated

and

valve

path

and

the

center

path

are

blocked

When

valve

stem

is

backed

off

the

paths

are

opened