belt DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 485 of 537

m

J

c

@

@

r

1

I

I

I

II

U

j

J

r

U

I

IT

L

U

L

L

@

Qj

flll

I

1

I

I

1

lL

to

t

l

Q

1

To

room

Jamp

cable

2

To

light

switch

3

To

fuse

4

To

tachometer

or

clock

5

To

hazard

flasher

unit

6

To

stop

lamp

switch

7

To

ignition

switch

8

To

hazard

switch

9

To

tU

and

dimmer

switch

10

To

check

connector

11

To

AMP

M

T

only

11

To

combination

instrument

Non

California

mode15

except

for

Canada

13

To

combination

meter

14

To

flasher

unit

IS

To

kickdown

switch

AfT

only

16

To

hand

brake

switch

17

To

heater

motor

18

To

illumination

control

rheostat

19

To

wiper

switch

light

switch

illumination

lamp

20

To

wiper

switch

21

To

cigar

lighter

22

To

heater

control

illumination

lamp

23

To

radio

24

To

heater

control

25

To

belt

and

E

G

R

warning

lamp

Non

California

models

or

floor

te

peratuJe

California

models

26

To

heater

control

illumination

lamp

27

To

buzzer

28

To

belt

warning

timer

U

S

A

Olodels

29

To

indicator

lamp

AfT

only

30

To

cooler

harness

31

To

wiptr

motor

32

To

door

switch

R

H

33

To

engine

compartment

harness

34

To

floor

harness

E

m

S

@

o

J

o

Q

m

CD

n

Ql

en

I

i

3

Page 487 of 537

G

t

Q8

Gt

Gt

t

Q

8

Gt

d8

t

QR

8

t

QR

LQR

8

@

RB

1ii

@

@

Gt

tp

o

c

l

T

S

O

i

CD

LQR

t

Q8

RB

8

G

8

Bt

J

rJl

1

3

1

1

0

instrUment

haltl

s

1

To

cooler

harnesS

fo

floor

sensor

California

models

ou

y

4

To

driver

belt

switch

5

To

tank

unit

6

1

0

side

marker

lamp

R

H

7

to

reat

combination

lamp

R

H

To

i

cens

e

amp

9

To

rear

combination

tarnP

L

lt

10

10

side

market

lamp

L

ll

8

@

c

8

ill@

Page 492 of 537

REFRIGERATION

SYSTEM

If

you

were

to

paint

your

finger

with

alcohol

your

finger

would

feel

cold

This

is

because

the

liquid

alcohol

takes

heat

away

from

your

finger

while

it

evaporates

If

a

quickly

evapo

rating

liquid

such

as

alcoliol

is

placed

in

a

container

inside

a

box

the

tem

f

Outside

air

U

Condenser

J6G1

i

i

1

1

t1

1

ilill

I

I

J

JJ

LlJ

i

l

7

U

Receiver

dryer

h

w

t

CONDENSER

The

condenser

is

installed

to

the

front

of

the

radiator

The

heated

and

compressed

refrigerant

gas

from

the

Air

Conditioning

perature

inside

the

box

will

drop

This

is

because

the

alcohol

is

evaporated

absorbing

the

heat

from

the

air

insidc

the

box

If

the

gaseous

alcohol

is

collected

and

cooled

with

cold

water

it

will

be

changed

back

into

a

liquid

by

absorption

of

its

heat

by

the

cold

water

The

cooler

operates

on

this

princi

Compressor

t

q

ttLJ

IrJ

Evaporator

It

J

1

J

f

9

d

lUr

I

Expansion

valve

V7777

J

High

pressure

lLLLLL

l

gas

I

I

High

pressure

liquid

t

u

compressor

condenses

to

a

liquid

by

being

cooled

by

air

passing

between

the

fins

of

the

condenser

1

GJ

7

vlmnn

iii

plI

d1i

1il

Ac459

Fig

AC

3

Condenser

AC3

pIe

The

liquid

used

is

the

refrigerant

R

12

The

heat

inside

the

passenger

compartment

is

absorbed

by

changing

the

refrigerant

from

a

liquid

to

a

gas

and

then

dissipated

to

the

outside

by

changing

the

refrigerant

from

a

gas

back

to

a

liquid

The

refrigeration

system

is

shown

in

Figure

AC

2

Low

pressurt

liquid

1

I

L2

Low

pressure

gas

Inside

air

li

r

L

Blower

motor

AC458

Fig

AC

2

Refrigeration

cycle

COMPRESSOR

The

compressor

is

installed

to

the

side

of

the

engine

and

is

driven

by

crank

pulley

through

a

belt

The

refrig

erant

gas

leaving

the

evaporator

is

forced

out

to

the

condenser

by

com

pressor

and

the

low

pressure

refrig

erant

gas

is

compressed

to

a

high

pressure

and

high

temperature

The

driving

force

is

transmitted

by

an

electrical

clutch

Because

engine

rpm

is

very

low

during

idling

the

clutch

will

not

transmit

the

driving

force

thus

ensuring

smooth

engine

idling

Page 497 of 537

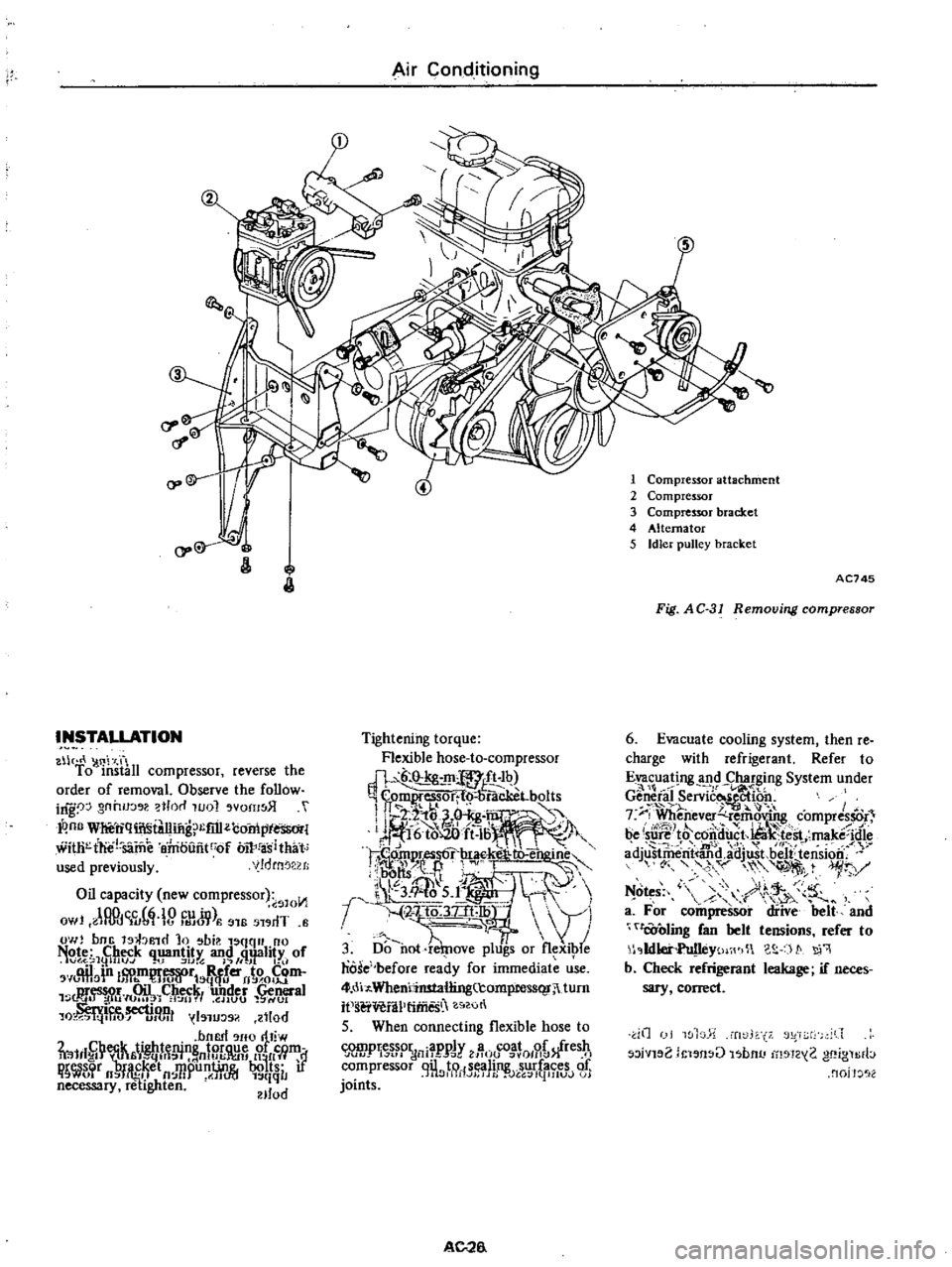

REFRIGERAi

H

R

12

COMPRESSOR

OIL

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

GENERAL

SERVICE

INSTRUCTION

SAFETY

PRECAUTIONS

EV

ACUA

TlNG

AND

CHARGING

SYSTEM

HANDLING

MANIFOLD

GAUGE

HANDLING

SERVICE

VALVE

HANDLING

CAN

TAP

DISCHARGING

SYSTEM

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

This

refrigerant

is

usually

available

in

a

small

can

or

a

cylinder

In

either

case

it

is

liquefied

under

high

pressure

in

the

container

Refrigerant

evaporates

easily

has

a

low

evaporation

point

and

moreover

since

the

latent

heat

of

the

refrigerant

is

large

it

can

abSorb

a

large

amount

of

heat

wh

err

e

vaporating

Extreme

care

must

be

exercised

when

handling

the

refrigerant

COMPRESSOR

OIL

The

SUNISO

5GS

or

SUNISO

351

should

be

used

as

refrigeration

lubricant

Mixing

of

the

two

is

allowable

The

refrigeration

lubricant

should

be

used

to

assure

the

successful

com

pressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrication

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

Air

Conditioning

GENERAL

SERVICE

CONTENTS

EVACUATING

SYSTEM

CHARGING

REFRIGERANT

CHECKING

FOR

LEAKS

HALIDE

LEAK

DETECTOR

ELECTRIC

LEAK

DETECTOR

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

PERFORMANCE

TEST

COMPRESSOR

OIL

LEVEL

CHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

AC

8

AC

8

AC

8

AC

8

AC

8

AC

9

AC

9

AC

9

AC10

AC

11

AC

12

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

Both

periodic

maintenance

and

season

in

inspection

are

most

essential

to

enable

the

air

conditioner

to

give

full

performance

Perform

the

following

checks

Start

engine

and

check

refrigerant

level

through

sight

glass

on

receiver

dryer

For

details

refer

to

relative

topics

under

Refrigerant

Level

Check

2

Check

the

entire

sysiein

for

sign

of

refrigerant

leaks

Refer

to

relative

topics

under

Checking

for

Leaks

and

Refrigerant

Leaks

If

any

trace

of

oil

is

noted

at

and

around

connection

fittings

it

is

a

sure

indication

that

refrigerant

is

leaking

This

condition

can

be

corrected

easily

by

retightening

the

joints

If

any

joint

on

line

is

suspected

of

small

amount

of

leakage

use

a

leak

detector

to

locate

leaking

points

3

Check

compressor

drive

belts

for

proper

deflection

Season

off

Observe

the

following

maintenance

tips

to

allow

the

air

conditioner

to

operate

normally

in

the

next

season

I

Keep

the

entire

system

free

from

AC

8

AC12

AC

13

AC15

AC15

AC16

AC

16

AC16

AC

17

AC17

AC

17

AC18

refrigerant

leakage

by

periodically

checking

for

refrigerant

gas

leak

even

out

of

season

2

Turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

c

ENERAL

SERVICE

INSTRUCTION

The

servicing

of

the

air

conditioner

should

be

carried

out

only

by

well

trained

servicemen

This

chapter

de

scribes

essential

points

of

servicing

Jf

a

Jarge

amount

of

dirt

and

sand

enter

the

system

they

will

be

carried

with

refrigerant

and

may

clog

the

system

or

scratch

rotating

parts

This

points

out

the

need

for

care

in

servicing

the

system

That

is

disconnecting

joints

should

be

carried

out

in

a

dean

place

Water

should

not

be

allowed

to

get

inside

the

system

The

refrigerant

does

not

readily

mix

with

water

However

the

presence

of

even

a

minute

amount

of

water

will

cause

a

chemical

reaction

at

high

tem

perature

which

will

in

turn

produce

hydrochloric

acid

HCl

Since

hydrochloric

acid

is

highly

corro

sive

to

metals

the

aluminum

and

copper

piping

etc

will

become

corroded

and

the

refrigeration

system

will

become

clogged

Page 510 of 537

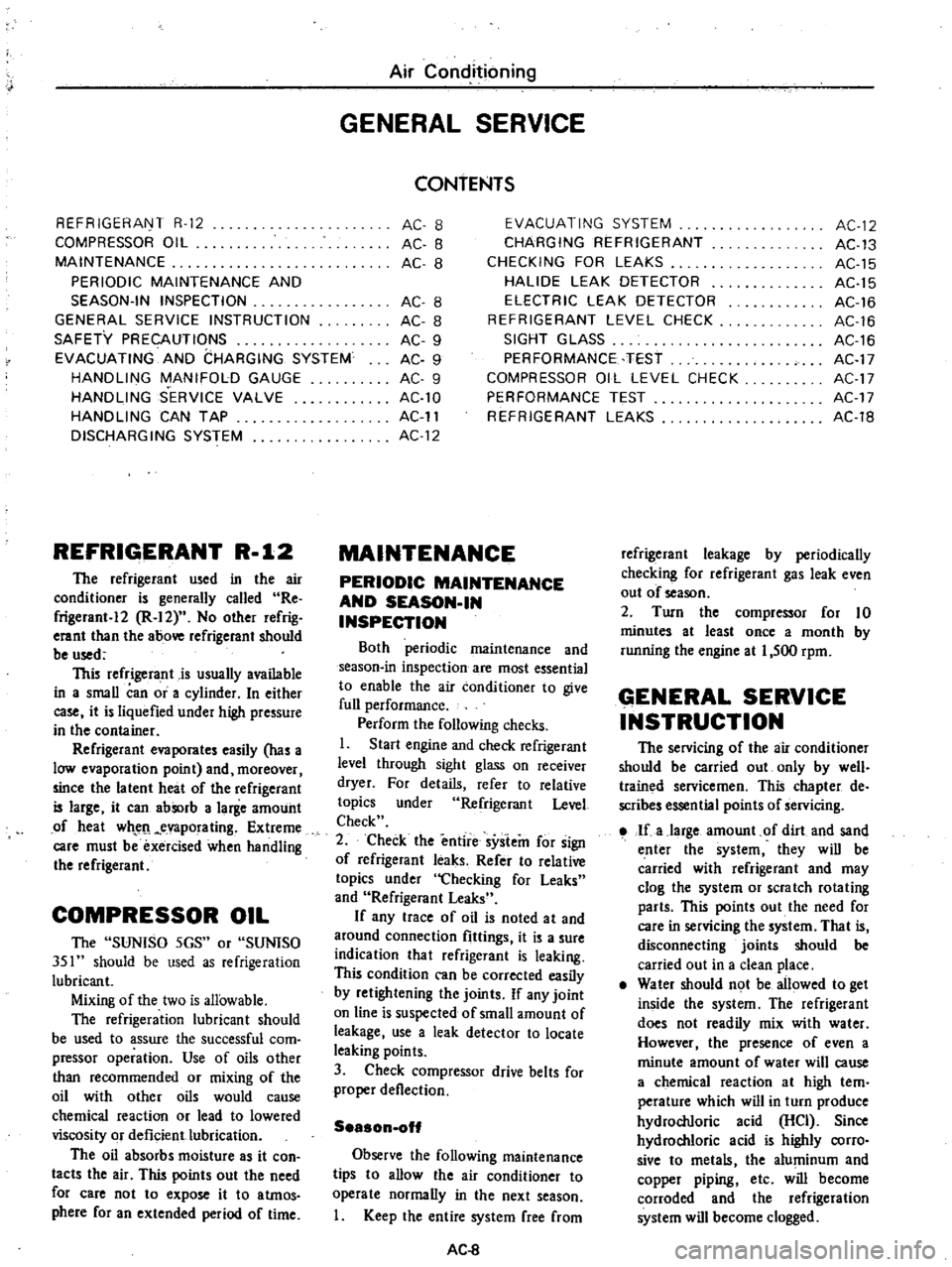

Air

Conditioning

PERFORMANCE

TEST

DIAGNOSES

Condition

Discharge

air

too

warm

a

Both

discharge

and

suction

pres

sure

too

high

b

Both

discharge

and

suction

pres

sure

too

low

c

Discharge

pressure

too

high

and

suction

pressure

too

low

d

Suction

pressure

too

high

and

discharge

pressure

too

low

e

Discharge

pressure

normal

and

suction

pressure

too

high

t

Discharge

pressure

normal

and

luction

pressure

too

low

g

Suction

pressure

normal

and

discharge

pressure

too

high

h

Both

discharge

and

suction

pres

sure

normal

Air

conditioning

is

operating

properly

Discharge

air

normal

or

too

cold

a

Discharge

pressure

normal

and

suction

pressure

too

low

Probable

cause

Air

mixed

with

refrigerant

in

system

Overcharge

of

refrigerant

Loose

fan

belt

or

engine

over

heating

Obstructed

or

dirty

condenser

fins

Insufficient

refrigerant

charge

Over

filling

of

compressor

oil

Damaged

compressor

valve

or

pack

ing

Loose

compressor

drive

belt

Clutch

slippage

Faulty

expansion

valve

Clogged

expansion

valve

strainer

Water

has

frozen

at

expansion

valve

Faulty

expansion

valve

Faults

of

both

a

and

h

exist

Air

leaks

from

engine

com

partment

Restricted

air

flow

through

evapo

ratof

Slow

blower

motor

speed

AC

21

Corrective

action

Evacuate

and

charge

system

Discharge

some

of

refrigerant

to

correct

level

Adjust

fan

belt

or

check

cooling

system

Clean

exterior

surface

with

water

Add

refrigerant

Drain

oil

and

correct

oil

level

Refer

to

Compressor

oil

level

check

Repair

or

replace

compressor

Refer

to

Compressor

Adjust

Repair

Refer

to

Compressor

Reinstall

sensing

bulb

correctly

to

keep

it

tight

to

pipe

Replace

Clean

strainer

Evacuate

and

charge

system

Replace

Correct

sealing

Clean

evaporator

fins

Check

and

repair

blower

motor

and

wiring

Page 512 of 537

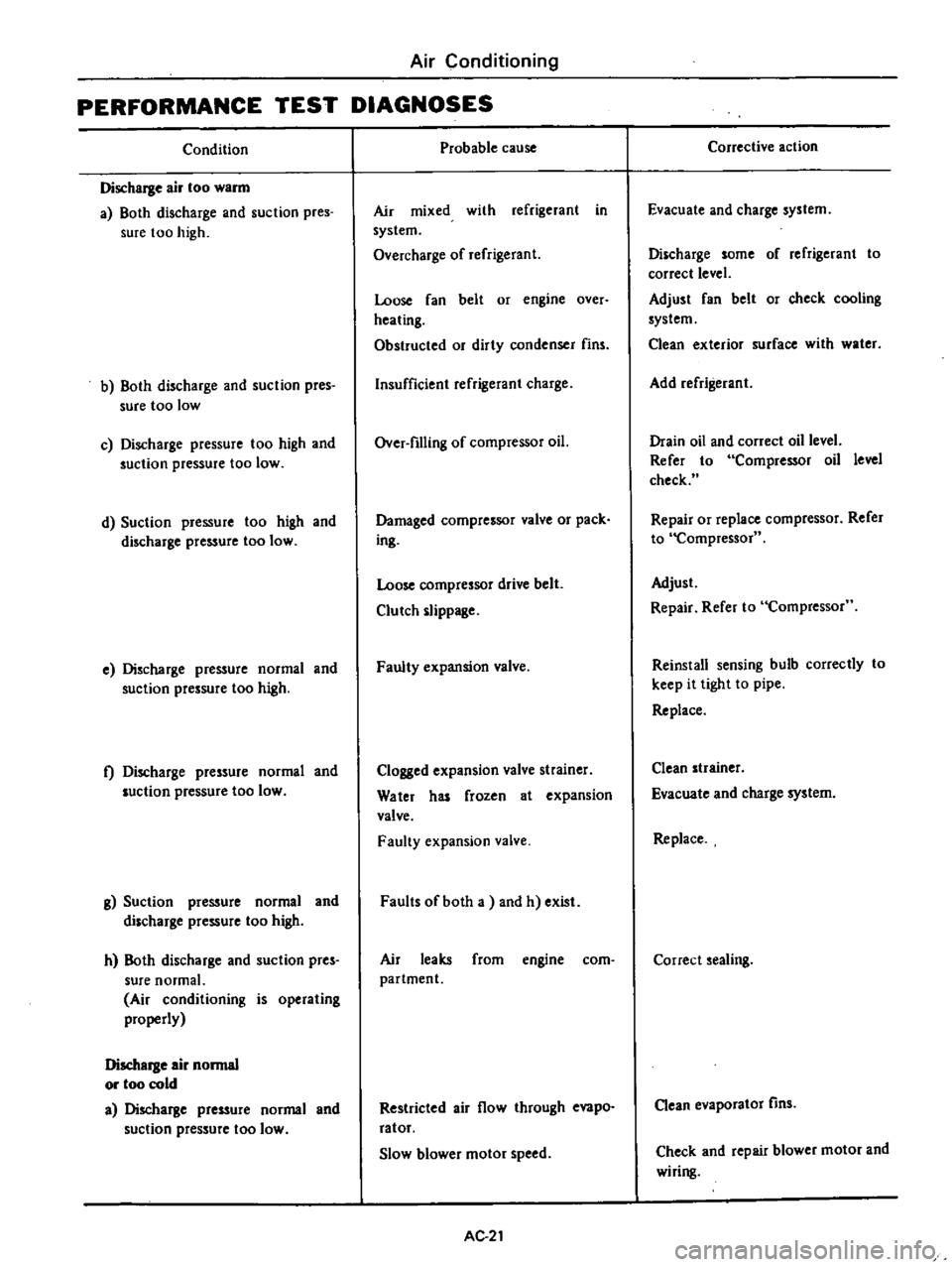

Air

Conditioning

NOISE

DIAGNOSES

NOISY

I

I

I

Set

fan

switch

on

2

Change

the

engine

rpm

frequently

Detect

the

source

of

noise

I

From

engine

compartment

From

cabin

Cooling

unit

j

Check

the

resonant

sound

when

the

engine

rpm

is

changed

I

I

No

resonant

sound

Compressor

itself

makes

noise

j

Blower

motor

makes

noise

Replace

or

repair

blower

Resonant

sound

Repeat

compressor

clutch

ON

and

OFF

This

checking

can

be

performed

by

changing

engine

rpm

while

fan

switch

is

set

at

ON

Retighten

compressor

bracket

bolt

If

piping

is

resonating

add

clip

Noisy

only

when

clutch

is

engaged

Noisy

when

clutch

is

not

engaged

I

Check

drive

belt

for

slackness

Check

for

loose

compressor

mounting

bolts

I

I

Remove

compressor

belt

then

turn

compressor

pulley

by

hand

If

noise

is

heard

repair

com

pressor

clutch

If

OK

If

loose

Compressor

itself

makes

noise

Repair

or

replace

compressor

Retighten

or

adjust

Nl1

Page 514 of 537

Air

Conditioning

REMOVAL

AND

INSTALLATION

COMPRESSOR

REMOVAL

INSTALLATION

IDLER

PULLEY

FAN

BELT

TENSION

ADJUSTMENT

REMOVAL

AND

INSTALLATION

INSPECTION

COOLING

UNIT

REMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

RECEIVER

DRYER

AND

PIPING

COMPRESSOR

REMOVAL

I

Remove

battery

2

Disconnect

compressor

lead

wire

at

connector

3

Loosen

idler

pulley

lock

nut

then

adjusting

bolt

Remove

compressor

drive

belt

from

compressor

pulley

AC477

Fig

AC

28

Removing

drive

belt

4

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

CONTENTS

AC

25

AC25

AC26

AC

27

AC

27

AC27

AC

27

AC27

AC

27

AC

2B

AC

29

AC

29

REMOVAL

AND

INSTALLATION

INSPECTION

WIRING

HARNESS

AND

COMPONENTS

WIRING

DIAGRAM

MAINTENANCE

MAIN

RELAY

COMPRESSOR

RELAY

FAN

SWITCH

RESISTOR

FOR

FAN

SWITCH

THERMO

SWITCH

F

I

C

D

SOLENOID

VALVE

AC29

AC29

AC30

AC30

AC31

AC31

AC31

AC31

AC32

AC32

AC

32

5

Remove

flexible

hose

fixing

plate

and

disconnect

low

and

high

pressure

flexible

hoses

from

compressor

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

flexible

hose

and

compressor

joint

openings

immediately

after

disconnection

to

prevent

entry

of

dust

moisture

laden

air

etc

Fig

AC

29

Disconnecting

ftexible

hoses

from

compressor

6

Remove

bolts

securing

fuel

tube

to

compressor

attachment

AC

25

Y

1

L

AC744

7

Remove

four

bolts

securing

com

pressor

to

its

bracket

Compressor

and

attachment

can

now

be

detached

as

an

assembly

Notes

a

There

are

a

total

of

four

bolts

two

on

upper

side

of

bracket

and

two

on

lower

side

of

compreSsor

Loosen

upper

bolts

and

remove

lower

bolts

When

removing

upper

bolts

securely

hold

compressor

with

one

hand

b

When

installing

temporarily

tighten

upper

bolts

then

tighten

lower

bolts

Page 515 of 537

2

R

C7

c

L

PJJ

I

8

INSTALLATION

a

c

J

l

i

rp

To

install

compressor

reverse

the

order

of

removal

Observe

the

follow

ing

nhlJo

e

trorf

1001

vom

R

i

n3

Wheliqli

liiAniitg

fiil

l

in

pt

l

witlil

tiiel

sam

efuouiitITof

b11

1fasitlult

used

previously

v

d

rnl

2

Oil

capacity

new

compressor

O

910

1

owt

llllt

blj

f

H

w

s

013

5

rlT

s

0

111

boc

19

bB1rllo

bi2

qqll

no

e

l

bffik

kuanM

mpdi

x

of

Jli

oln

L

il

m

1IlffiiOrb

fler

ot

oldm

F

n

Cheo

f

undeF

r

n

al

1

aQ

r1tIU

Jt

t31

HClJI1

t

JIVU

i

rlUI

1o

ifm

ft

q

t

VI

31U

S

ltlod

bnM

UfO

l

W

kldf

CJiJi

ti

WIf

nl

L

llil

g

ncn

d

oressor

M

et

illpuntinl

botts

if

l9Wul

fb

i

l

fI

I

l

1Ttio

l

qqlJ

necessary

re

Ighten

I

d

210

Air

Conditioning

Tightening

torque

Flexible

hose

to

compressor

dl

t

kg

J

l

IQ

1

Tf

es

oriti

ra

Lbolts

IbP

fo

o15g

m

J

r

f6i

o

20

i

il

f

J

rt

I

r

aGket

engine

Dons

1

1

0

1

1

3

16

5

l11fd

1l

V

f

42

3

3U

llif

Yl

I

u

y

j

3

D

not

remove

IJgs

orflexibie

1i6

e

before

ready

for

immediate

use

4l

di

Wheniiinstallingccomptess

i

turn

it

serWfiPtiffies

SlOt

5

When

connecting

flexible

hose

to

9mPr

ssor

apD

v

a

coat

of

Hfresh

JU

UI

l1Il

t

2

JIUU

uOHltl

r

fl

compressor

0

1

to

fs

aHn

lurfaces

of

1n

1l11

JJ

J

f

PJU

Ht

UlUJ

jJ

joints

AC

26

5

1

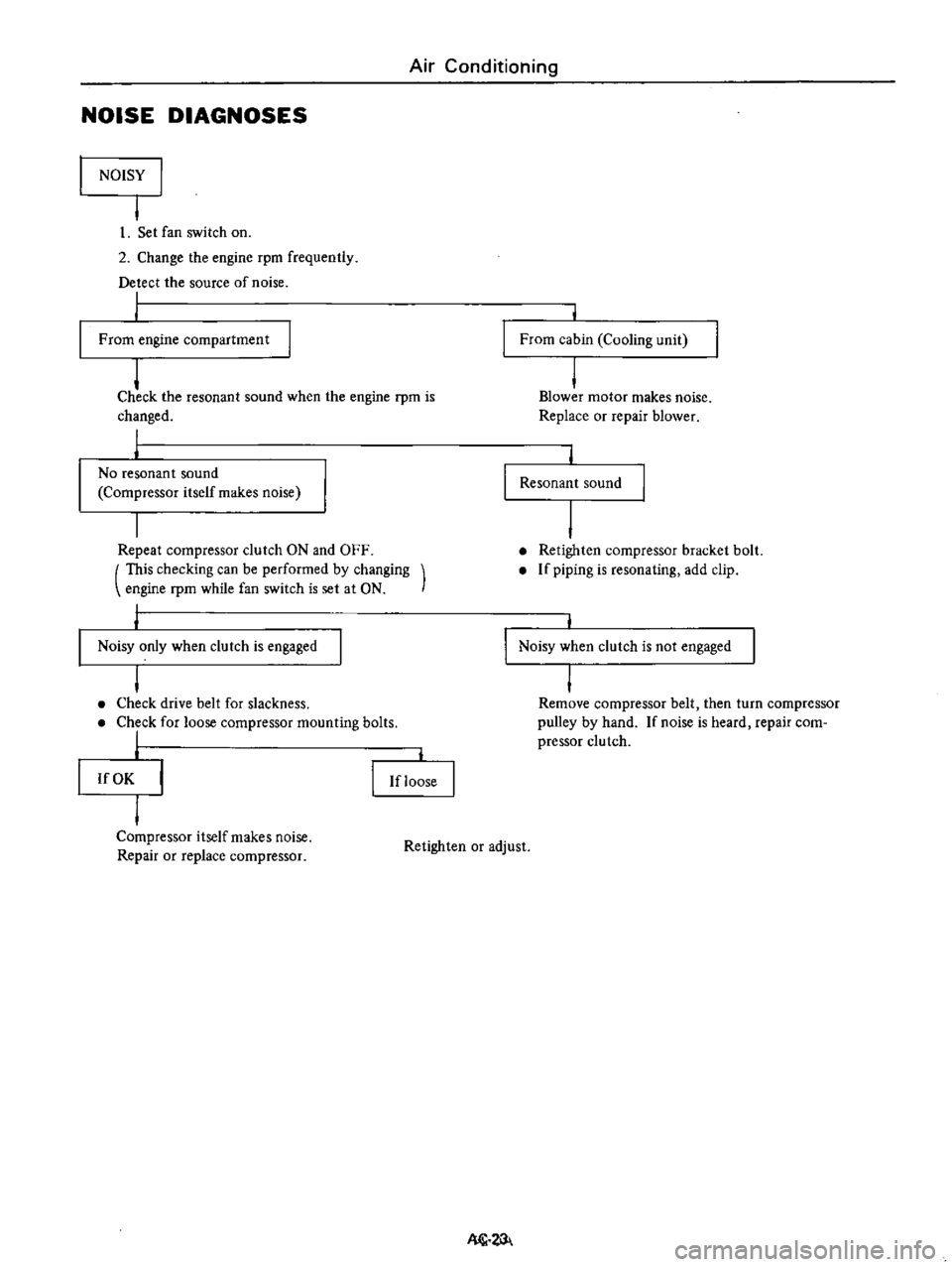

Compressor

attachment

2

Compressor

3

Compressor

bracket

4

AHernator

5

Idler

pulley

bracket

AC745

Fig

AC

31

Removing

compressor

6

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

l

r

Gen

efal

Servic

ectioo

f

iI

t

7

F

Whenever

remoV

J

compres

r

be

su

J

t8

C6itiu

t

Ua

t

st

make

idie

mV

i

1rJ

adjustril

rit

and

adjwt

beJf

tension

yv

1

r

Y

N

o

s

9

r

h

v

a

For

compressor

diive

belt

and

tOoling

fan

belt

tensions

refer

to

1

Ildlet

Yt

j

WI

c

S

t

q

b

Cheok

refrigerant

leakage

if

neces

sary

correct

dO

I

wl

Tw

l

rt

f

r2

iVl

2

i

l

n

U

l

bnu

1

1Z

2

gf

ign

rb

nojJ

2

Page 516 of 537

IDLER

PULLEY

FAN

BELT

TENSION

ADJUSTMENT

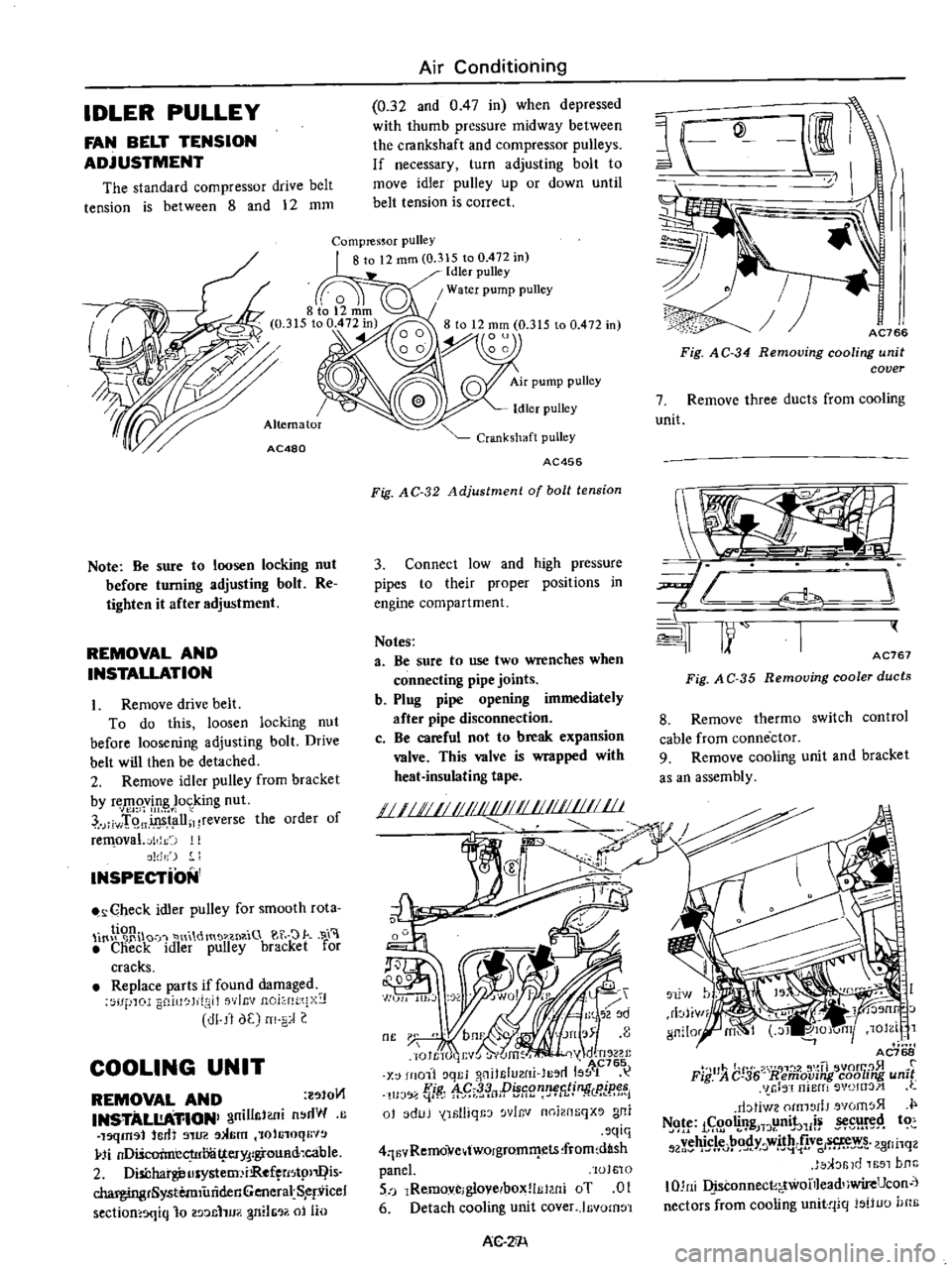

The

standard

compressor

drive

belt

tension

is

between

8

and

12

mm

AC480

Note

Be

sure

to

loosen

locking

nut

before

turning

adjusting

bolt

Re

tighten

it

after

adjustment

REMOVAL

AND

INSTALLATION

Remove

drive

belt

To

do

this

loosen

locking

nut

before

loosening

adjusting

bolt

Drive

belt

will

then

be

detached

2

Remove

idler

pulley

from

bracket

by

r

J1e

vM

or

king

nut

jiwT

9ff

t

llil

reverse

the

order

of

rerr

oval

jldJ

1

t

Jldr

J

I

INSPECTiON

Oheck

idler

pulley

for

smooth

rota

tion

G

0

llfHt

H

Y

d

H

u

t

1

W

n

l

ot

Jrk

H

l

Check

i

ler

pulley

bracket

for

cracks

Replace

arts

iffound

damaged

c

f

lOJ

gD

IlI

J

l

gtt

flvlnv

nOj

IH

q

g

cll

dE

m

J

COOLING

UNIT

REMOVAL

AND

oM1

INSTALl

A

1lIONI

gnillslUli

n

dW

C

19qm91

crft

llU2

3

6rn

f01

Gl0ql

pj

nDiScoimecprlY

i

ferY

lgroUR

hable

2

Disbhargiou

y

tem

iRefrflsll

Qis

chargingrSystemiillidenGeneral

S

ervicel

sectiom5qiq

10

2

9

fl

1U

n

1Ii

2

oj

liD

Air

Conditioning

0

32

and

0

47

in

when

depressed

with

thumb

pressure

midway

between

the

crankshaft

and

compressor

pulleys

If

necessary

turn

adjusting

bolt

to

move

idler

pulley

up

or

down

until

belt

tension

is

correct

Idler

pulley

Crankshaft

pulley

AC456

Fig

AC

32

Adjustment

of

bolt

tension

3

Connect

low

and

high

pressure

pipes

to

their

proper

positions

in

engine

compartment

Notes

3

Be

sure

to

use

two

wrenches

when

connecting

pipe

joints

b

Plug

pipe

opening

immediately

after

pipe

disconnection

c

Be

careful

not

to

break

expansion

valve

This

valve

is

wrapped

with

heat

insulating

tape

0

J

JWu

J

1

2

ld

m

bm

Ufl

J51

8

I

1

lEldgJ

v

Jwm

j

y

d

n

l2u

1

C765

X

fIlO

1i

qJ

j

gnjlcfu2fIJ

lc

rf

1551

1UJ

flip

1h

tqnPfffi2n

Wfi

i

V1c

ip

j

at

3duJ

lsIliqr

J

wlr

v

n

irWfiqX

ani

qiq

4q

v

Remo

e

tworgromll

ets

from

dash

panel

lots

n

5

lRemove

glovelbox

lBl

n1

oT

0

6

Detach

cooling

unit

cover

Icyom

n

AC

ZA

AC766

Fig

AC

34

Removing

cooling

unit

cover

7

Remove

three

ducts

from

cooling

unit

i

j

l

I

11

AC767

Fig

A

C

35

Removing

cooler

ducts

8

Remove

thermo

switch

control

cable

from

conne

ctor

9

Remove

cooling

unit

and

bracket

as

an

assembly

J

t

AC768

F

lIJAh

Cr

P

3

6

R

1

7

fi

vorr

l

l51

r

Ig

emo

vmg

coo

mg

um

r

n

I1iBITJ

0HJ

Jl

t

rbtivl2

Ofm

IIfj

wom

51

f

H

f

L

ol

IJgjjJpn

1I

SH

tc

vehicle

bn

y

with

five

rews

q

2tl

G

i

O

r

Jv

a8f1l1

J

a

I

ld

1

51

b

nc

IOJni

QisconnecEf

twonleadliwif

eUcon

1

nectars

from

cooling

unitqiq

s

iuo

UHf

Page 522 of 537

DESCR

IPTIDN

COMPRESSOR

CLUTCH

REMOVAL

INSTAllATION

DISASSEMBLY

ASSEMBLY

INSPECTION

DESCRIPTION

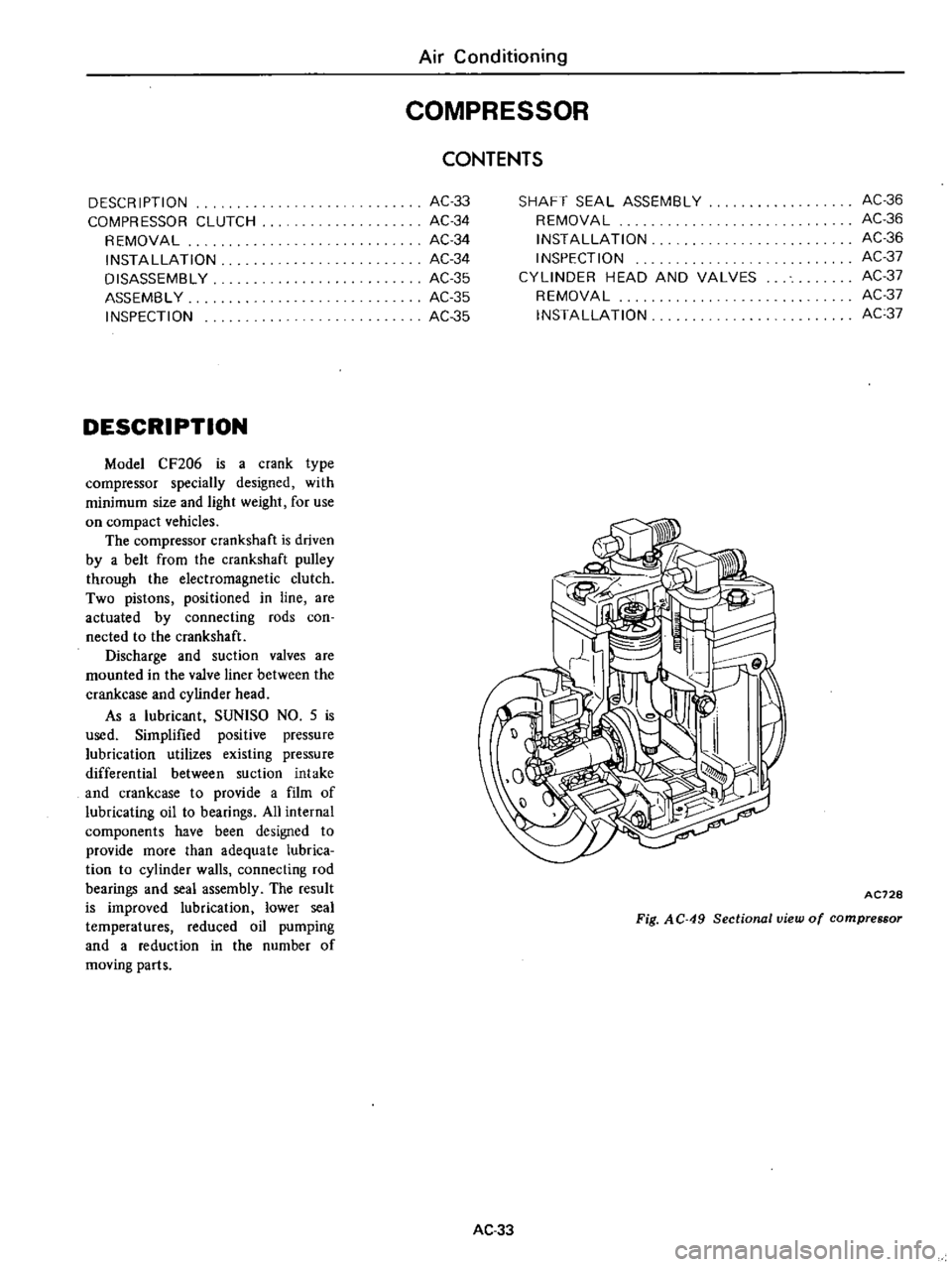

Model

CF206

is

a

crank

type

compressor

specially

designed

with

minimum

size

and

light

weight

for

use

on

compact

vehicles

The

compressor

crankshaft

is

driven

by

a

belt

from

the

crankshaft

pulley

through

the

electromagnetic

clutch

Two

pistons

positioned

in

line

are

actuated

by

connecting

rods

coo

nected

to

the

crankshaft

Discharge

and

suction

valves

are

mounted

in

the

valve

liner

between

the

crankcase

and

cylinder

head

As

a

lubricant

SUNlSO

NO

5

is

used

Simplified

positive

pressure

lubrication

utilizes

existing

pressure

differential

between

suction

intake

and

crankcase

to

provide

a

film

of

lubricating

oil

to

bearings

All

internal

components

have

been

designed

to

provide

more

than

adequate

lubrica

tion

to

cylinder

walls

connecting

rod

bearings

and

seal

assembly

The

result

is

improved

lubrication

lower

seal

temperatures

reduced

oil

pumping

and

a

reduction

in

the

number

of

moving

parts

Air

Conditioning

COMPRESSOR

AC33

AC34

AC34

AC34

AC35

AC

35

AC35

CONTENTS

SHAFT

SEAL

ASSEMBLY

REMOVAL

INSTAllATION

INSPECTION

CYLINDER

HEAD

AND

VALVES

REMOVAL

INSTAllATION

AC36

AC36

AC36

AC37

AC37

AC37

AC37

AC728

Fig

AC

49

Sectional

view

of

compressor

AC33