sensor DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 27 of 537

Engine

Tune

up

EC284

When

installing

this

valve

ensure

that

it

properly

oriented

This

valve

should

be

replaced

periodically

Refer

to

Maintenance

Schedule

I

To

distribut0

From

carburetor

Yl

r

EC278

l

Fig

ET

24

Operation

of

spark

delay

value

I

I

Carburetor

side

Distributor

side

rJmlL

lr

EC346

Fig

ET

25

Checking

spark

delay

value

Distributor

side

Brown

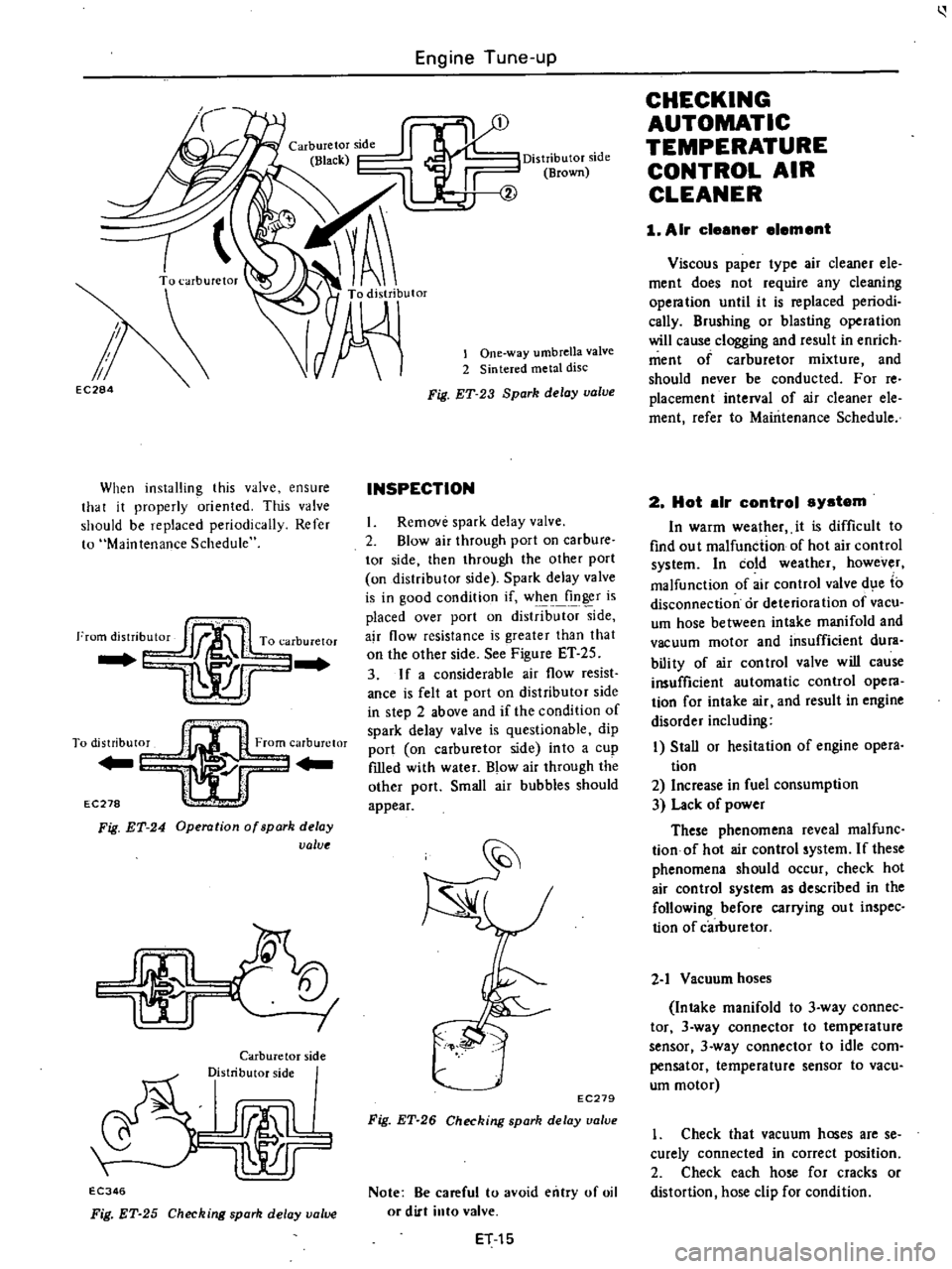

lOne

way

umbrella

valve

2

Sintered

metal

disc

Fig

ET

23

Spark

delay

valve

INSPECTION

I

Remove

spark

delay

valve

2

Blow

air

through

port

on

carbure

tor

side

then

through

the

other

port

on

distributor

side

Spark

delay

valve

is

in

good

condition

if

when

finger

is

placed

over

port

on

distrib

side

ajr

flow

resistance

is

greater

than

that

on

the

other

side

See

Figure

ET

25

3

If

a

considerable

air

flow

resist

ance

is

felt

at

port

on

distributor

side

in

step

2

above

and

if

the

condition

of

spark

delay

valve

is

questionable

dip

port

on

carburetor

side

into

a

cup

fIlled

with

water

Blow

air

through

the

other

port

Small

air

bubbles

should

appear

EC279

Fig

ET

26

Checking

spark

delay

ualue

Note

Be

careful

to

avoid

entry

of

oil

or

dirt

into

valve

ET

15

CHECKING

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

1

Air

cleener

element

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

opera

tion

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Schedule

2

Hot

elr

control

system

In

warm

wealher

it

is

difficult

to

find

ou

t

malfunction

of

hot

air

control

system

In

cold

weather

however

malfunction

of

air

control

valve

d

e

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bili

ty

of

air

con

trol

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

opera

tion

2

Increase

in

fuel

consumption

3

Lack

of

power

These

phenomena

reveal

malfunc

tionof

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

ou

t

inspec

tion

of

carburetor

2

1

Vacuum

hoses

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

1

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

position

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Page 28 of 537

Note

Vacuum

hose

position

R

R

side

of

Nissan

mark

on

the

top

of

sensor

for

intake

manifold

L

R

side

of

the

mark

is

for

vacuum

rootor

2

2

Vacuum

motor

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

position

EF213

Fig

ET

27

Impecting

lJalv

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

Engine

Tune

up

EF217

Fig

ET

28

lmpecting

value

position

Correct

pC6ition

of

air

control

valve

is

the

reverse

of

paragraph

I

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

is

open

posi

tion

as

descnbed

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

of

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

sensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

1

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

1

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

ET

16

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

to

facilitate

smooth

opera

tion

of

air

con

trol

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

following

test

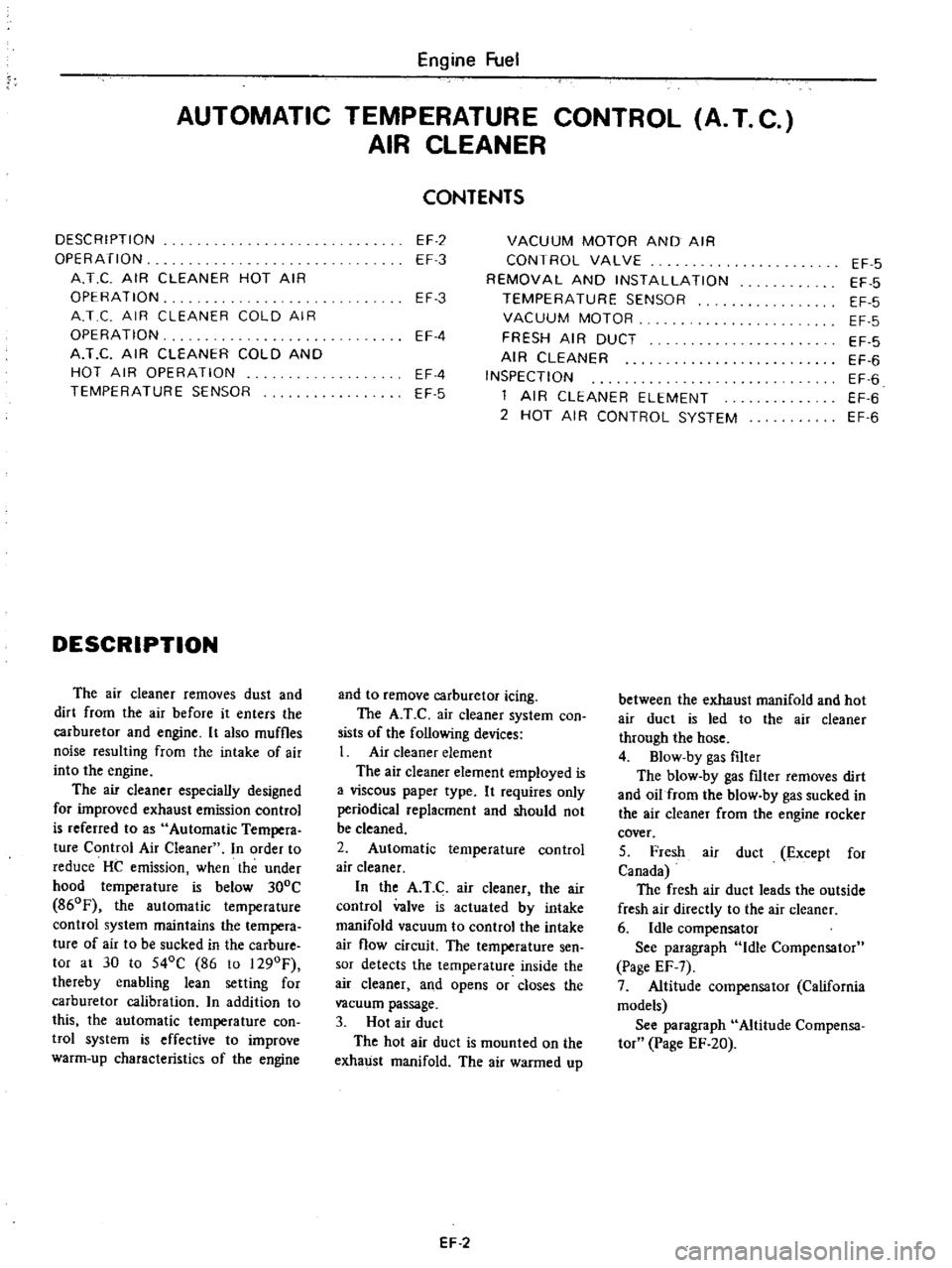

4

Remove

air

cleaner

cover

Set

temperature

sensing

element

of

ther

mistor

or

thermometer

to

a

position

where

tempera

ture

around

sensor

can

be

measured

In

this

case

fix

wiring

of

thermistor

or

thermometer

on

the

bot

tom

surface

of

air

cleaner

with

adhe

sive

tape

in

such

a

manner

that

the

set

position

of

temperature

sensing

ele

ment

will

not

be

affected

by

airflow

Then

install

air

cleaner

cover

EF221

Fig

ET

29

Checking

temperotur

e

ensor

5

Carry

out

test

as

described

in

steps

I

2

and

3

above

When

air

control

valve

begins

to

open

to

under

hood

air

inlet

side

severa

minutes

after

engine

starting

read

the

indica

tion

of

thermistor

or

thermometer

If

reading

falls

within

the

working

tern

perature

range

of

temperature

sensor

the

sensor

is

normaL

If

reading

ex

ceeds

the

range

replace

the

sensor

with

new

one

Note

Before

replacing

temperature

sensor

check

idle

compensator

as

described

in

Section

EF

page

EF

8

Page 41 of 537

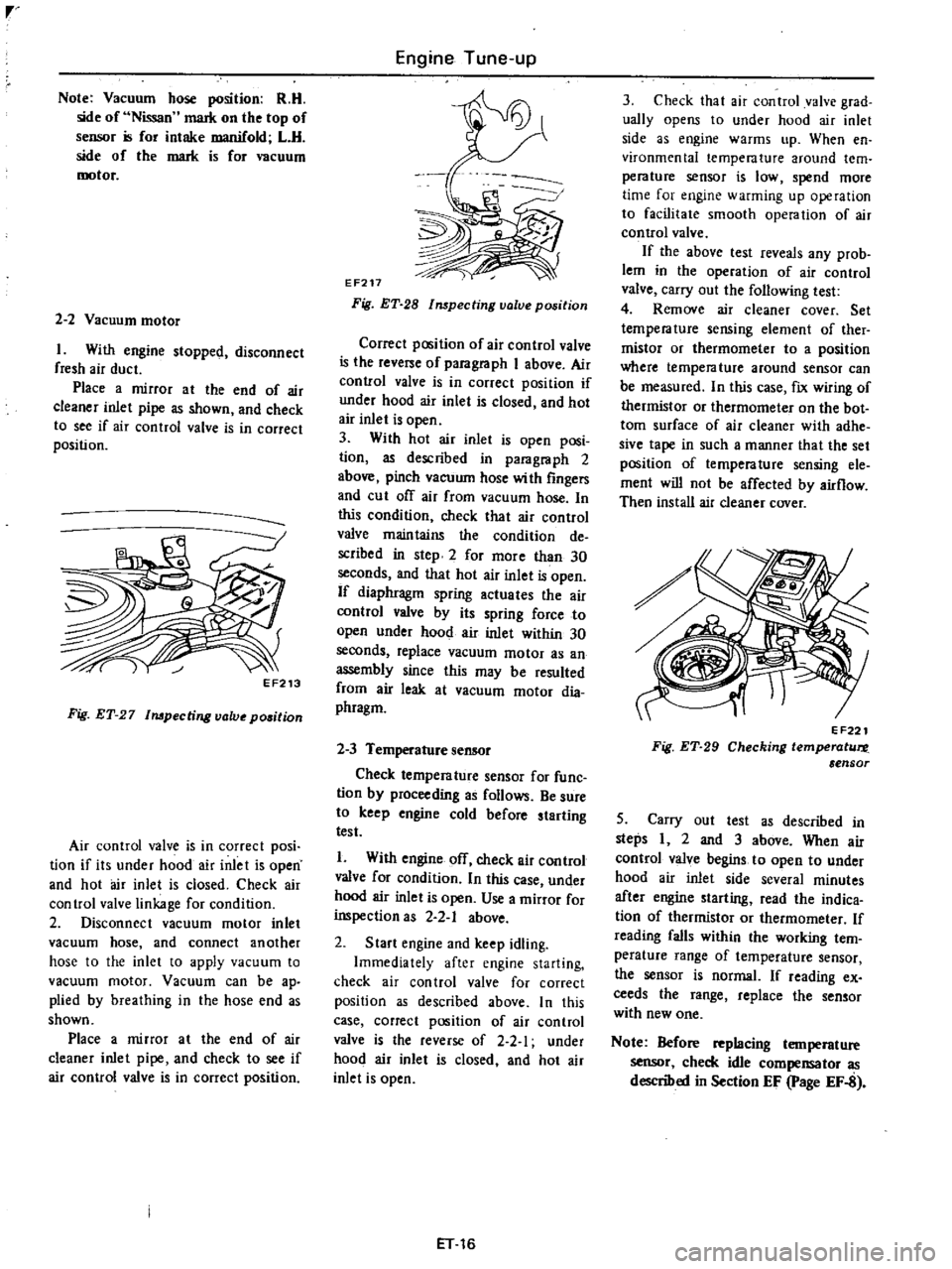

Condition

IMPROPER

ENGINE

IDLING

Fuel

system

out

of

order

Low

compression

Others

High

engine

idle

speed

Engine

Tune

up

Probable

cause

Clogged

or

damaged

carburetor

jets

Incorrect

idle

adjustment

Clogged

air

cleaner

filter

Damaged

manifold

gaskets

or

carburetor

insulator

Improper

float

level

adjustment

Loose

air

hoses

or

air

fuel

mixture

hoses

of

carburetor

Malfunctioning

carburetor

choke

Malfunctioning

anti

backfire

valve

Malfunctioning

automatic

temperature

con

trol

air

cleaner

Inoperative

idle

compensator

Carbon

canister

purge

line

hose

damaged

or

disconnected

Stick

E

F

E

valve

shaft

Incorrect

valve

clearance

Extremely

low

revolution

Faulty

malfunction

of

the

ignition

system

spark

plug

high

tension

cable

breaker

point

ignition

coil

etc

Incorrect

basic

ignition

timing

Malfunction

of

choke

valve

or

linkage

Malfunction

of

vacuum

motor

sensor

or

hoses

of

air

cleaner

Incorrect

idle

adjustment

Clogged

air

cleaner

fdter

Malfunction

of

idle

compensator

of

air

cleaner

Malfunction

of

E

G

R

control

valve

Loose

manifold

and

cylinder

head

bolts

Dragged

accelerator

linkage

Incorrect

idle

adjustment

Malfunction

of

B

CDD

system

Malfunction

of

speed

switch

and

harness

ET

29

Corrective

action

Clean

or

replace

Adjust

Replace

element

Replace

gasket

or

insulator

Adjust

Check

for

loose

connections

Check

and

adjust

Check

for

loose

connection

of

vacuum

hose

Check

A

r

C

air

cleaner

Check

for

connection

of

idle

compensator

hose

or

replace

idle

compen

tor

Connect

or

replace

Repair

Previously

mentioned

Adjust

Adjust

Replace

Adjust

Adjust

Check

for

loose

hoses

Replace

system

com

ponents

if

necessary

Adjust

idle

speed

Replace

air

cleaner

fdter

Replace

Clean

or

replace

Retighten

bolts

Check

and

correct

accelerator

linkage

Adjust

idle

speed

Check

for

loose

vacuum

hose

and

harness

connections

Adjust

or

replace

if

necessary

Check

for

loose

connections

Repair

or

replace

if

necessary

Page 98 of 537

Engine

Fuel

AUTOMATIC

TEMPERATURE

CONTROL

A

T

C

AIR

CLEANER

DESCRIPTION

OPERATION

A

T

C

AIR

CLEANER

HOT

AIR

OPERATION

A

T

C

AIR

CLEANER

COLD

AIR

OPERATION

A

T

C

AIR

CLEANER

COLD

AND

HOT

AIR

OPERATION

TEMPERATURE

SENSOR

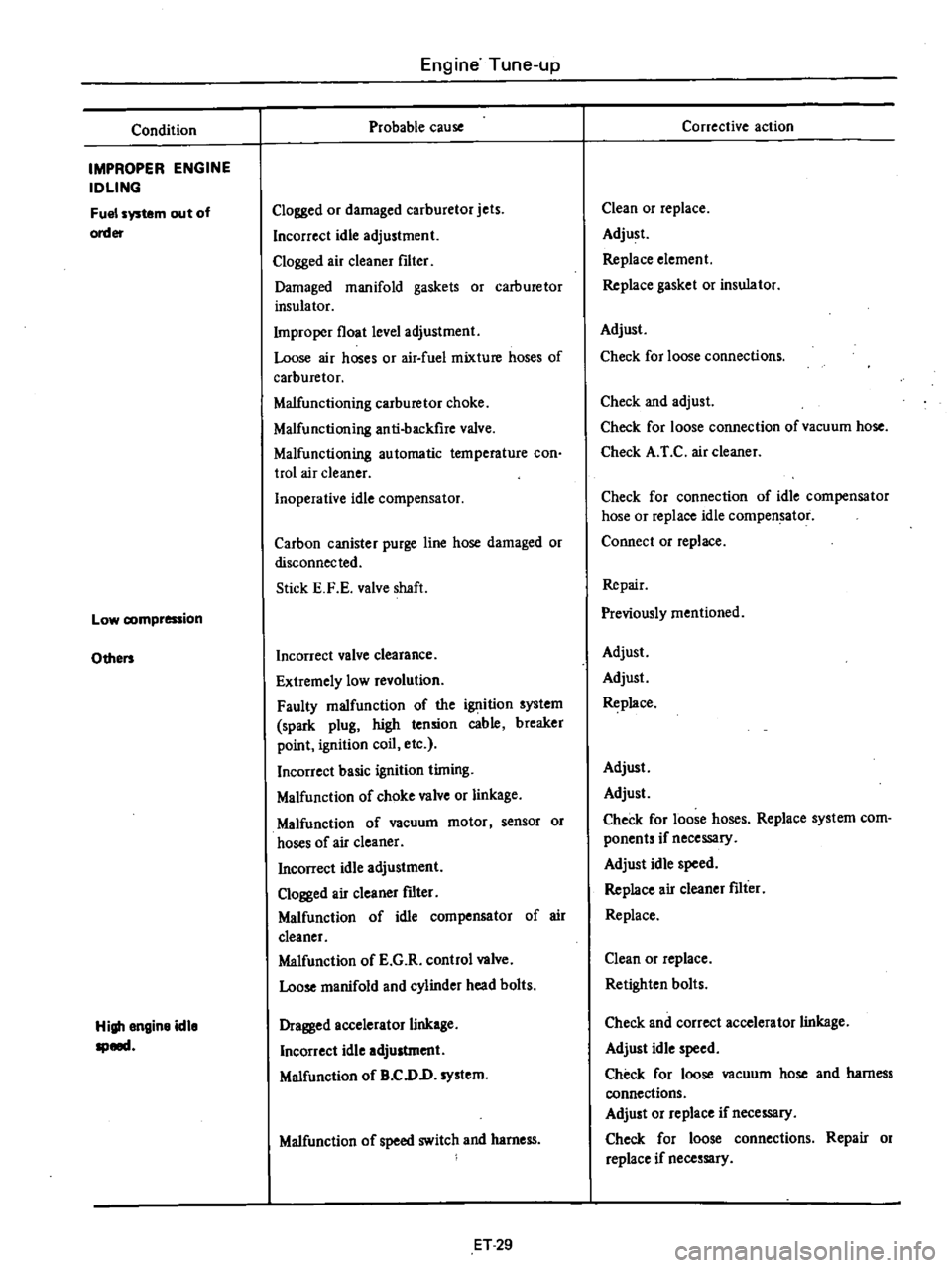

DESCRIPTION

The

air

cleaner

removes

dust

and

dirt

from

the

air

before

it

enters

the

carburetor

and

engine

It

also

muffles

noise

resulting

from

the

intake

of

air

into

the

engine

The

air

cleaner

especially

designed

for

improved

exhaust

emission

control

is

referred

to

as

Automatic

Tempera

ture

Control

Air

Cleaner

In

order

to

reduce

HC

emission

when

the

under

hood

temperature

is

below

300C

860F

the

automatic

temperature

control

system

maintains

the

tempera

ture

of

air

to

be

sucked

in

the

carbure

tor

at

30

to

540C

86

to

1290F

thereby

enabling

lean

setting

for

carburetor

calibration

n

addition

to

this

the

automatic

temperature

con

twl

system

is

effective

to

improve

warm

up

characteristics

of

the

engine

CONTENTS

EF

2

EF

3

VACUUM

MOTOR

AND

AIR

CONTROL

VALVE

REMOVAL

AND

INSTALLATION

TEMPERATURE

SENSOR

VACUUM

MOTOR

FRESH

AIR

DUCT

AIR

CLEANER

INSPECTION

1

AIR

CLEANER

ELEMENT

2

HOT

AIR

CONTROL

SYSTEM

EF

3

EF

4

EF

4

EF

5

and

to

remove

carburetor

icing

The

A

T

C

air

cleaner

system

con

sists

of

the

following

devices

1

Air

cleaner

element

The

air

cleaner

element

employed

is

a

viscous

paper

type

It

requires

only

periodical

replacment

and

should

not

be

cleaned

2

Automatic

temperature

control

air

cleaner

In

the

A

T

C

air

cleaner

the

air

control

valve

is

actuated

by

intake

manifold

vacuum

to

control

the

intake

air

flow

circuit

The

temperature

sen

sor

detects

the

temperature

inside

the

air

cleaner

and

opens

or

closes

the

vacuum

passage

3

Hot

air

duct

The

hot

air

duct

is

mounted

on

the

exhaust

manifold

The

air

warmed

up

EF

2

EF

5

EF

5

EF

5

EF

5

EF

5

EF

6

EF

6

EF

6

EF

6

between

the

exhaust

manifold

and

hot

air

duct

is

led

to

the

air

cleaner

through

the

hose

4

Blow

by

gas

filter

The

blow

by

gas

nIter

removes

dirt

and

oil

from

the

blow

by

gas

sucked

in

the

air

cleaner

from

the

engine

rocker

cover

5

Fresh

air

duct

Except

for

Canada

The

fresh

air

duct

leads

the

outside

fresh

air

directly

to

the

air

cleaner

6

Idle

compensator

See

paragraph

Idle

Compensator

Page

EF

7

7

Altitude

compensator

California

models

See

paragraph

Altitude

Compensa

tor

Page

EF

20

Page 99 of 537

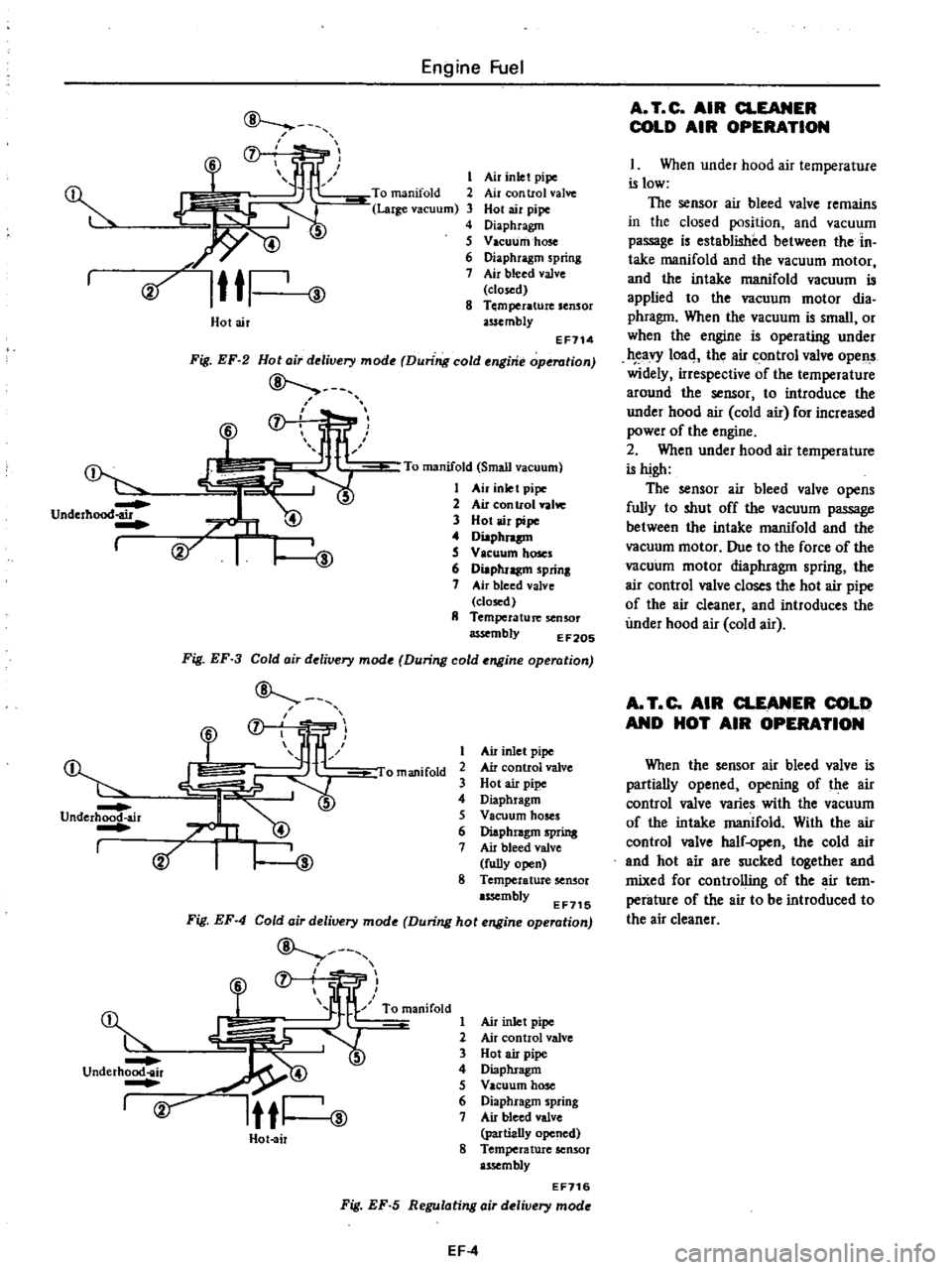

Engine

Fuel

@

1

Fresh

air

duct

Except

for

Canada

2

Air

inlet

pipe

3

Vacuum

motor

assembly

4

Air

control

valve

5

Hot

air

pipe

6

Idle

compensator

7

Blow

by

gas

fiI

teT

8

Temperature

sensor

assembly

9

Altitude

compensator

California

models

EF713

Fig

EF

1

Automatic

temperature

control

air

cleaner

OPERATION

The

automatic

temperature

control

system

of

the

air

cleaner

is

controlled

by

the

inlet

air

temperature

and

the

load

condition

of

the

engine

The

inlet

air

temperature

is

detected

by

the

sensor

and

the

vacuum

motor

is

actu

ated

by

the

engine

intake

vacuum

Under

hood

air

Sensor

vacuum

at

Air

control

valve

Sensor

operation

temperature

vacuum

motor

side

operation

Below

60

mmHg

Open

cold

air

Below

300C

2

36

inHg

860

F

Close

Above

210

mmHg

Close

hot

air

8

27

inHg

30

to

540C

Half

open

Open

86

to

1290

F

cold

air

hot

air

Above

55

oC

Open

cold

air

Open

1310F

A

T

C

AIR

CLEANER

HOT

AIR

OPERATION

When

the

under

hood

air

tempera

ture

is

low

the

sensor

air

bleed

valve

remains

in

the

closed

position

and

establishes

vacuum

passage

between

the

intake

manifold

and

vacuum

motor

With

this

condition

the

vacu

urn

at

the

intake

manifold

side

actu

ates

the

air

control

valve

attached

to

the

vacuum

motor

diaphragm

to

intro

duce

hot

air

into

the

air

cleaner

through

the

hot

air

duct

on

the

ex

haust

manifold

EF

3

Page 100 of 537

Underhood

air

I

@

Dr

Underhood

air

I

Engine

Fuel

f

f

l

l

ID

s

6

Cif

Ittl

ID

Air

inlet

pipe

Air

con

trol

valve

Hot

air

pipe

Diaphragm

Vacuum

hose

Diaphragm

spring

Air

bleed

valve

closed

Temperature

sensor

assembly

Holair

EF114

Fig

EF

2

Hota

r

delivery

mode

During

cold

engine

operation

7

To

manifold

Small

vacuum

1

Air

inlet

pipe

2

Air

con

trol

valw

3

Hot

air

pipe

4

Diaphnp

S

V

leuum

hoses

6

Diaphragm

prinl

7

Air

bleed

valve

closed

II

Temperature

senSOr

assembly

EF20S

Fig

EF

3

Cold

air

delivery

mode

During

cold

engine

operation

f

1

J

liP

omanifold

2

@

Air

inlet

pipe

Air

control

valve

Hot

air

pipe

Diaphragm

Vacuum

hoses

Diaphragm

spring

Air

bleed

valve

fully

open

8

Temperature

sensor

assembly

EF715

Fig

EF

4

Cold

air

delivery

mode

During

hot

engine

operation

ID

@

f

fjr

R

lfl

ow

2

underh

r

5

rv

Itti

ID

Hot

air

Air

inlet

pipe

Air

control

valve

Hot

air

pipe

Diaphragm

Vacuum

hose

Diaphragm

spring

Air

bleed

valve

partially

opened

8

Temperature

sensor

assembly

EF716

Fig

EF

5

Regulating

air

delivery

mode

EF

4

A

T

C

AIR

CLEANER

COLD

AIR

OPERATION

I

When

under

hood

air

temperature

is

low

The

sensor

air

bleed

valve

remains

in

the

closed

position

and

vacuum

passage

is

established

between

the

in

take

manifold

and

the

vacuum

motor

and

the

intake

manifold

vacuum

is

applied

to

the

vacuum

motor

dia

phragm

When

the

vacuum

is

small

or

when

the

engine

is

operating

under

eavy

1004

the

air

control

valve

opens

widely

irrespective

of

the

temperature

around

the

sensor

to

introduce

the

under

hood

air

cold

air

for

increased

power

of

the

engine

2

When

under

hood

air

temperature

is

high

The

sensor

air

bleed

valve

opens

fully

to

shut

off

the

vacuum

passage

between

the

intake

manifold

and

the

vacuum

motor

Due

to

the

force

of

the

vacuum

motor

diaphragm

spring

the

air

control

valve

closes

the

hot

air

pipe

of

the

air

cleaner

and

introduces

the

under

hood

air

cold

air

A

T

C

AIR

CLEANER

COLD

AND

HOT

AIR

OPERATION

When

the

sensor

air

bleed

valve

is

partially

opened

opening

of

the

air

control

valve

varies

with

the

vacuum

of

the

intake

manifold

With

the

air

control

valve

half

open

the

cold

air

and

hot

air

are

sucked

together

and

mixed

for

controlling

of

the

air

tem

perature

of

the

air

to

be

introduced

to

the

air

cleaner

Page 101 of 537

TEMPERATURE

SENSOR

The

temperature

sensor

is

attached

to

the

inside

of

the

air

cleaner

The

bimetal

built

in

the

sensor

detects

the

under

hood

air

temperature

and

opens

or

closes

the

vacuum

passage

in

the

sensor

The

construction

of

the

tempera

ture

sensor

is

shown

in

the

following

CD

V

00

@

I

I

@

j

I

I

1

Protector

cover

Screw

Adjusting

frame

Air

temperature

bi

metal

Rivet

Valve

seat

frame

Lower

frame

Air

bleed

valve

Gasket

Fig

EF

6

Temperature

senior

EF206

VACUUM

MOTOR

AND

AIR

CONTROL

VALVE

The

vacuum

pressure

which

varies

with

opening

of

the

carburetor

throt

tle

acts

upon

the

vacuum

motor

dia

phragm

The

valve

shaft

attached

to

the

diaphragm

is

then

moved

up

or

down

in

response

to

the

vacuum

on

the

diaphragm

This

movement

of

the

valve

shaft

actuates

the

air

control

valve

to

control

the

temperature

of

the

air

to

be

introduced

into

the

air

cleaner

pr

to

I

1

Valve

spring

00

2

Diaphragm

@

3

Retainer

E

F

207

4

Valve

shaft

Fig

EF

7

Vacuum

motor

REMOVAL

AND

INSTALLATION

TEMPERATURE

SENSOR

Removal

Using

pliers

flatten

clip

con

Engine

Fuel

neeting

vacuum

hose

to

sensor

vacuum

tube

I

Pipe

2

Calch

3

Fixed

with

adhesive

4

Hose

5

Tab

6

Clip

7

Gasket

EC019

Fig

EF

B

Removal

of

semor

2

Disconnect

hose

from

sensor

3

Take

off

clip

from

sensor

vacuum

tube

and

dismount

sensor

body

from

air

cleaner

Note

The

gasket

between

sensor

and

air

cleaner

is

bonded

to

the

air

cleaner

side

and

should

not

be

removed

Inatallatlon

Mount

sensor

on

the

specified

position

For

mounting

position

of

sensor

see

the

following

EF717

Fig

EF

9

lalling

se

or

2

Insert

clip

into

vacuum

tube

of

sensor

After

installing

each

vacuum

hose

secure

hose

with

the

clip

Note

Be

sure

to

install

vacuum

hose

correctly

Correct

position

is

R

H

side

to

Nissan

mark

at

the

top

face

of

sensor

for

intake

manifold

L

H

side

for

vacuum

motor

VACUUM

MOTOR

1

Remove

screws

securing

vacuum

motor

to

air

cleaner

2

Disconnect

valve

shaft

attached

to

vacuum

motor

diapluagm

from

air

control

valve

and

remove

cacuum

motor

assembly

from

air

cleaner

3

To

install

reverse

the

removal

procedure

FRESH

AIR

DUCT

I

Disconnect

fresh

air

duct

at

air

cleaner

2

Fresh

air

duct

is

provided

with

projections

on

its

air

inlet

side

end

Hold

fresh

air

duct

with

a

hand

and

carefully

pull

out

from

radiator

core

support

while

turning

it

in

either

direction

3

To

install

reverse

the

removal

procedure

Be

sure

to

insert

projec

lions

of

fresh

air

duct

securely

into

mounting

hole

in

radiator

core

sup

port

EF518

EF

5

Fresh

air

duct

Air

cleaner

Duct

mounting

hole

Radiator

Radiator

core

support

Fig

EF

I0

Removal

of

fresh

air

duct

Page 102 of 537

r

AIR

CLEANER

1

Loosen

bolts

securing

air

cleaner

to

air

cleaner

bracket

2

Loosen

air

cleaner

lock

bolt

and

remove

air

cleaner

from

carburetor

Disconnect

the

following

hoses

when

dismounting

air

cleaner

Under

hood

air

inlet

hose

Hot

air

inlet

hose

Vacuum

hose

Sensor

to

intake

manifold

Vacuum

hose

Sensor

to

vacuum

motor

Vacuum

hose

Idle

compensator

to

intake

manifold

Hose

Air

pump

to

air

cleaner

Hose

AB

valve

to

air

cleaner

Hose

Carburetor

to

air

cleaner

Blow

by

hose

Air

cleaner

to

rocker

cover

Hose

Air

control

vaive

to

air

cleaner

California

models

only

3

To

install

reverse

the

removal

procedure

INSPECTION

1

AIR

CLEANER

ELEMENT

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

operation

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Sched

ule

2

HOT

AIR

CONTROL

SYSTEM

In

warm

weather

it

is

difficult

to

find

out

malfunction

of

hot

air

control

system

In

cold

wea

thee

however

malfunction

of

air

control

valve

due

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bility

of

air

control

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

oper

ation

2

Increase

in

fuel

consumption

3

uck

of

power

Engine

Fuel

These

phenomena

reveal

malfunc

tion

of

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

out

inspec

tion

of

carburetor

2

1

Vacuum

hose

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

I

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

postion

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Note

Vacuum

hose

position

R

H

side

of

Nissan

mark

on

the

top

of

sensor

is

for

intake

manifold

L

U

side

of

the

mark

is

for

vacuum

motor

2

2

Vacuum

motor

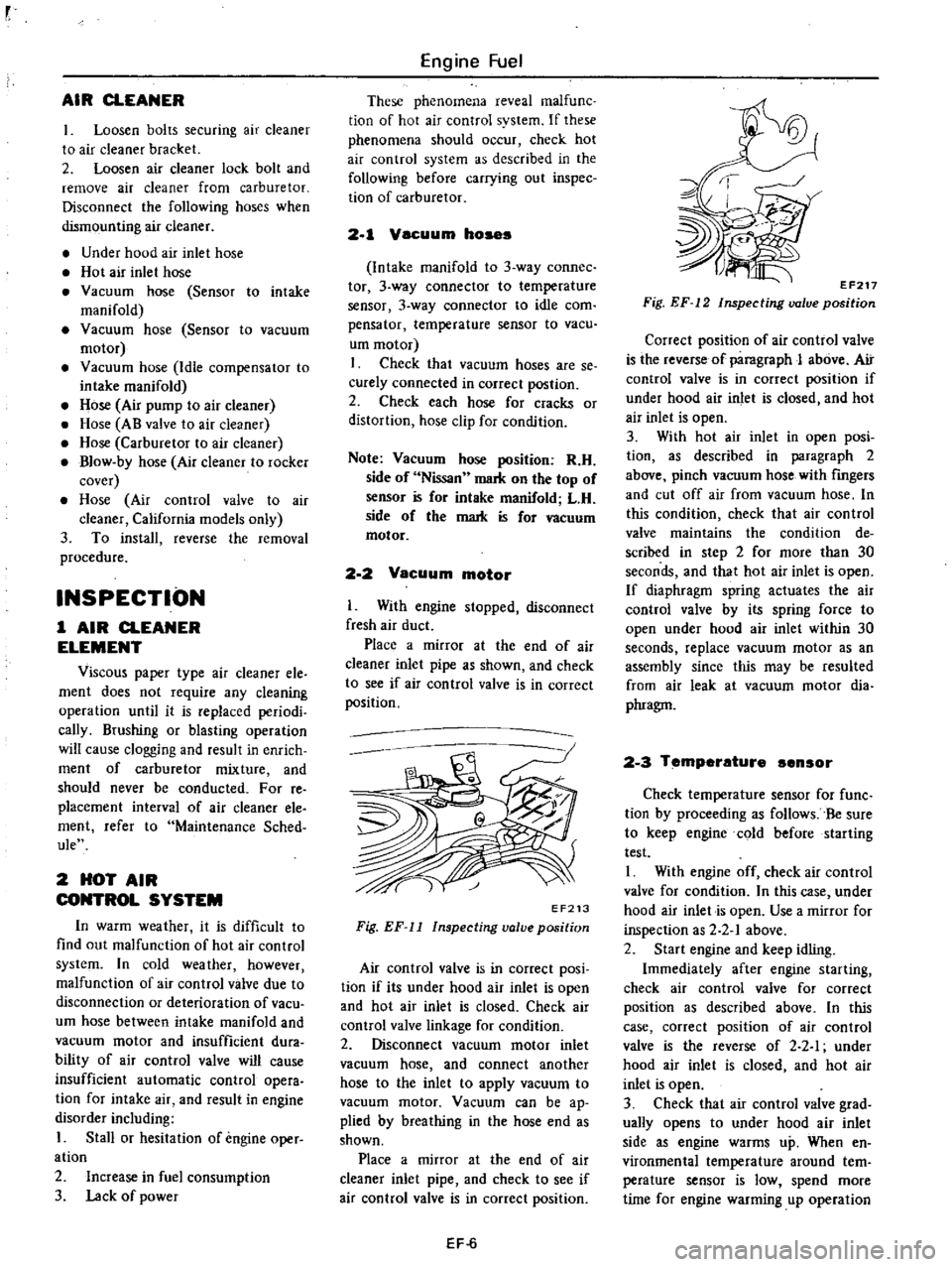

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

con

trol

valve

is

in

correct

position

EF213

Fig

EF

11

Inspecting

valve

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

EF

6

EF217

Fig

EF

12

Inspecting

valve

position

Correct

position

of

air

control

valve

is

the

reverse

of

paragraph

J

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

in

open

posi

tion

as

described

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

off

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

ensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

I

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

I

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

Page 103 of 537

to

facilitate

smooth

operation

of

air

control

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

following

test

4

Remove

air

cleaner

cover

Set

temperature

sensing

element

of

ther

mistor

or

thermometer

to

a

position

where

temperature

around

sensor

can

be

measured

In

this

case

fIx

wiring

of

thermistor

or

thermometer

on

the

bottom

surface

of

air

cleaner

with

adhesive

tape

in

such

a

manner

that

the

set

position

of

temperature

sensing

DESCRIPTION

OPERATION

DESCRIPTION

The

idle

compensator

is

basically

a

thermostatic

valve

which

functions

to

introduce

the

air

directly

from

the

air

cleaner

to

the

intake

manifold

to

compensate

for

abnormal

enrichment

of

mixture

in

high

idle

temperature

The

bi

metal

attached

to

the

idle

compensator

detects

the

temperature

of

intake

air

and

opens

or

closes

the

valve

Two

idle

compensators

having

different

temperature

characteristics

are

installed

one

opens

at

an

intake

air

temperature

of

60

to

700C

140

to

l580F

and

the

other

at

70

to

900C

158

to

1940F

OPERATION

The

construction

of

the

idle

com

pensator

is

shown

in

the

following

Engine

Fuel

element

will

not

be

affected

by

air

flow

Then

install

air

cleaner

cover

Fig

EF

13

Checking

temperature

sensor

IDLE

COMPENSATOR

CONTENTS

5

Carry

out

test

as

described

in

steps

I

2

and

3

above

When

air

control

valve

begins

to

open

to

under

hood

air

inlet

side

several

minutes

after

engine

starting

read

the

indica

tion

of

thermistor

or

thermometer

If

reading

falls

within

the

working

tern

perature

range

of

temperature

sensor

the

sensor

is

normal

If

reading

ex

ceeds

the

range

replace

the

sensor

with

new

one

Note

Before

replacing

temperature

sensor

check

idle

compensator

as

described

in

Idle

compensator

EF

7

EF

7

REMOVAL

AND

INSTALLATION

INSPECTION

EF

B

EF

8

q

EF222

1

Orifice

2

Bi

metal

3

Rubber

valve

Fig

EF

14

Structure

of

idle

compensator

Bi

metal

Intake

air

temperature

No

1

Below

600C

1400F

60

to

70

C

140

to

l580F

Above

700C

158

OF

Below

700C

1580F

70

to

900C

158

to

1940F

Above

900C

1940F

No

2

EF

7

The

idle

compensator

operates

in

response

to

the

under

hood

air

temper

ature

as

shown

below

Idle

compensator

operation

Fully

closed

Close

to

open

Fully

open

Fully

closed

Close

to

open

Fully

open

Page 467 of 537

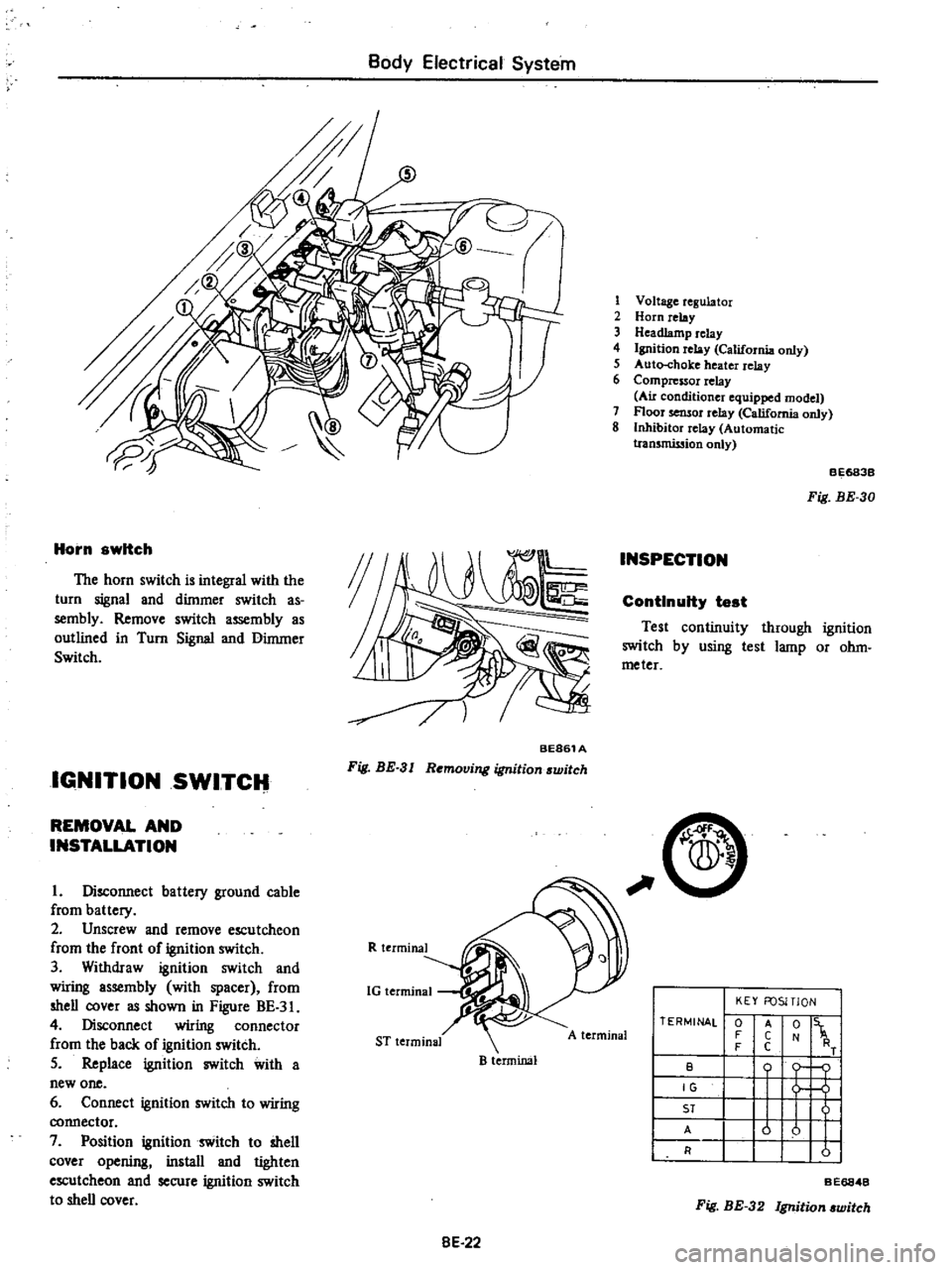

Body

Electrical

System

Horn

switch

The

horn

switch

is

integral

with

the

turn

signal

and

dimmer

switch

as

sembly

Remove

switch

assembly

as

outlined

in

Turn

Signal

and

Dimmer

Switch

IGNITION

SWITCH

BE861A

Fig

BE

3

I

Removing

ignition

switch

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

from

battery

2

Unscrew

and

remove

escutcheon

from

the

front

of

ignition

switch

3

Withdraw

ignition

switch

and

wiring

assembly

with

spacer

from

shell

cover

as

shown

in

Figure

BE

3

4

Disconnect

wiring

connector

from

the

back

of

ignition

switch

5

Replace

ignition

switch

with

a

new

one

6

Connect

ignition

switch

to

wiring

connector

7

Position

ignition

switch

to

shell

cover

opening

install

and

tighten

escutcheon

and

secure

ignition

switch

to

shell

cover

R

terminal

1G

terminal

ST

terminal

B

terminal

8E

22

1

Voltage

regulator

2

Horn

relay

3

Headlamp

relay

4

Ignition

relay

California

only

5

Auto

choke

heater

relay

6

Compressor

relay

Au

conditioner

equipped

model

7

Floor

sensor

relay

California

only

8

Inhibitor

relay

Automatic

tran5mission

only

INSPECTION

BE683B

Fig

BE

30

ContInuity

test

Test

continuity

through

ignition

switch

by

using

test

lamp

or

ohm

meter

C

A

terminal

TERMINAL

0

F

F

B

IG

ST

A

R

KEY

FOSITlON

t

1

o

j

u

u

I

I

A

C

C

Fig

BE

32

Ignition

witch

BE6848