fuel DATSUN PICK-UP 1977 Manual PDF

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 219 of 537

Engine

Removal

Installation

ENGINE

REMOVAL

AND

INSTAllATION

REMOVAL

INSTALLATION

ENGINE

MOUNTING

INSULATORS

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

them

separately

After

re

moval

engine

can

be

separated

from

transntission

assembly

Notes

a

Be

sure

to

hoist

engine

and

jack

up

transmission

in

a

safe

manner

b

Use

fender

cove

to

protect

vehicle

body

1

Remove

battery

2

Scribe

hood

hinge

location

for

proper

reinstallation

and

remove

hood

Note

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

3

Drain

radiator

coolant

4

Disconnect

upper

and

lower

radiator

hoses

from

engine

5

Remove

two

oil

cooler

hoses

from

lower

end

of

radiator

Auto

ma

tic

transmission

models

only

6

Remove

radiator

shroud

7

Remove

four

bolts

securing

radia

tor

and

detach

radiator

Note

Always

tighten

securing

bolt

at

upper

right

hand

side

together

with

body

harness

terminal

8

Remove

carburetor

air

cleaner

as

follows

Remove

fresh

air

duct

Remove

hot

air

duct

Loosen

air

cleaner

band

bolt

and

air

cleaner

supporting

bolts

Disconnect

air

cleaner

ta

air

pump

hose

Disconnect

air

cleaner

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cleaner

to

air

control

valve

hose

California

models

only

CONTENTS

ER

2

ER

3

ER

3

FRONT

INSULATOR

REAR

INSULATOR

TIGHTENING

TORQUE

ER

4

ER

4

ER

4

Disconnect

air

deaner

to

A

B

valve

hose

Disconnect

air

cleaner

ta

vacuum

hoses

Note

Protect

carburetor

from

dust

and

foreign

matter

by

placing

cover

over

air

inlet

opening

9

Disconnect

fuel

pump

to

fuel

fdter

hose

and

return

hose

10

Disconnect

carbon

canister

hose

on

engine

side

II

Disconnect

air

pump

air

C1eaner

to

al

p

p

hose

12

Disconnect

following

cables

wires

and

hoses

Engine

ground

cable

Accelerator

wire

at

carburetor

High

tension

cable

between

ignition

coil

and

distributor

Wire

to

distributor

at

body

ter

minal

Wire

to

oil

pressure

switch

Wires

to

thermal

transmitter

Wires

to

B

C

p

D

cut

solenoid

Non

California

models

only

auto

choke

heater

and

anti

dieseling

solenoid

Wires

to

alternator

Wires

to

starter

motor

Heater

inlet

and

outlet

hoses

if

so

equipped

Vacuum

hose

of

Master

Vac

at

in

taJce

manifold

Wires

for

back

up

lamp

switch

Cable

to

speedometer

13

Remove

transmission

control

linkage

from

transmission

Manual

transmission

models

I

Detach

rubber

boot

2

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

ER

2

Fig

ER

l

Automatic

transmission

models

I

Disconnect

selector

range

lever

from

manual

shaft

2

Disconnect

wires

at

inhibitor

switch

and

down

shift

solenoid

14

Air

conditioner

equipped

models

need

following

procedures

1

After

removing

flexible

hose

support

remove

four

comi

ressor

se

curing

bolts

Then

move

the

com

pressor

to

battery

support

2

Remove

vacuum

hoses

of

F

LC

D

solenoid

valve

3

Remove

F

LC

D

actuator

15

Remove

two

bolts

securing

clutch

operating

cylinder

Then

dis

connect

operating

cylinder

and

flexi

ble

tube

as

an

assembly

Manual

transmission

models

only

16

Disconnect

front

exhaust

tube

from

exhaust

manifold

17

Remove

propeller

shaft

I

Disconnect

propeller

shaft

center

bearing

bracket

from

third

crossmember

2

Disconnect

propeller

shaft

from

companion

flange

of

differential

carrier

3

Remove

propeller

shaft

from

transmission

and

plug

up

rear

end

of

extension

housing

of

transmission

to

prevent

oil

leakage

18

Attach

a

suitable

wire

or

chain

to

lift

engine

19

Remove

front

engine

mounting

bolts

at

engine

mounting

front

sup

port

Page 257 of 537

Manual

Transmission

I

TROUBLE

DIAGNOSES

AND

CORREGTIONS

Condition

Difficult

to

intel11lesh

gears

Causes

Jor

difficu

t

gear

shifting

are

classi

fied

to

troubles

concerning

control

system

and

transniissioo

When

gear

shift

lever

is

heavy

and

it

is

difficult

to

shift

gears

clutch

disengagement

may

also

be

unsmooth

First

make

sure

that

clutch

operates

correctly

and

inspect

transmissi

o

Gear

slips

out

of

mesh

In

most

cases

this

trouble

occurs

when

interlock

b

all

check

ball

and

or

spring

is

worn

or

weakened

or

when

control

system

is

faulty

In

this

case

the

trouble

cannot

be

corrected

by

replacing

gears

and

therefore

trouble

shooting

must

be

carried

out

care

fully

It

should

also

be

noted

that

gear

slips

out

of

mesh

due

to

vibration

generated

by

weakened

fron

t

and

rear

engine

mounts

Noise

When

noise

occurs

with

engine

idling

and

ceases

when

clutch

is

disengaged

or

when

noise

occurs

while

shifting

gears

it

is

an

indicati90

that

th

e

noise

is

from

transmis

sion

t

Transmission

may

fa

ule

during

engine

idling

Check

air

fuel

mixture

and

ignition

timing

After

above

procedure

readjust

engine

idling

Probable

cause

Worn

gear

shaft

and

or

bearing

Insufficient

operating

stroke

due

to

worn

or

loose

sliding

part

Faulty

or

damaged

synchronizer

Worn

interlock

ball

Worn

check

ball

and

or

weakened

or

broken

spring

Wom

fork

rod

ball

groove

Wom

or

damaged

bearing

Worn

or

damaged

gear

Insufficient

or

improper

lubricant

Oil

leaking

due

to

faulty

oil

seal

or

sealant

clogged

breather

etc

Worn

bearing

High

humming

occurs

at

a

high

speed

Damaged

bearing

Cyclic

knocking

sound

occurs

also

at

a

19W

speed

Worn

spline

Worn

bushing

j

MT

23

Corrective

action

Replace

pair

or

replace

Replace

Replace

Replace

Replace

Replace

Replace

Add

oil

or

replace

with

designated

oil

Clean

Of

replace

Replace

Replace

Replace

Replace

Page 358 of 537

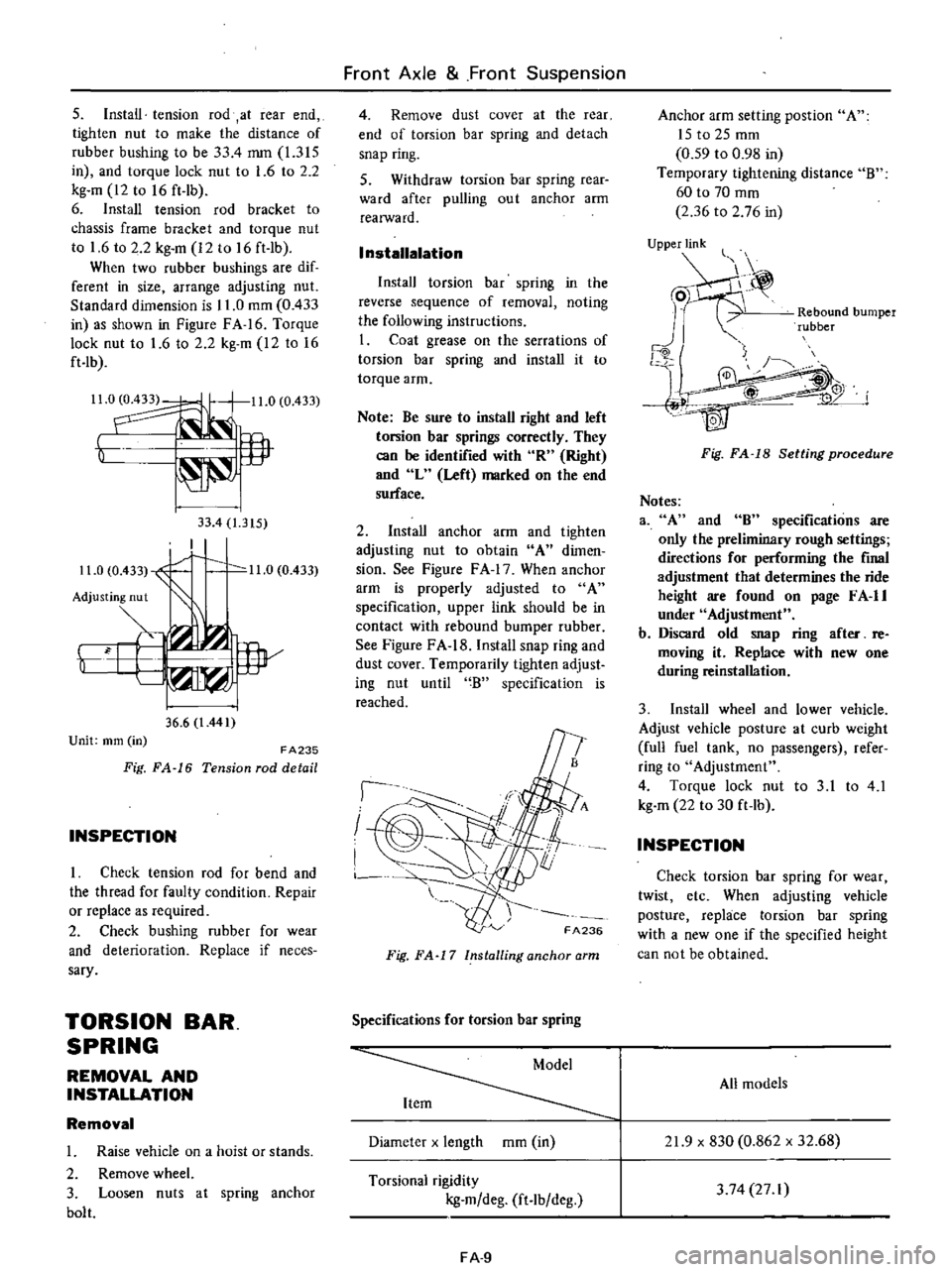

s

Install

tension

rod

at

rear

end

tighten

nut

to

make

the

distance

of

rubber

bushing

to

be

33

4

mm

1

315

in

and

torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

6

Install

tension

rod

bracket

to

chassis

frame

bracket

and

torque

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

When

two

rubber

bushings

are

dif

ferent

in

size

arrange

adjusting

nut

Standard

dimension

is

11

0

mOl

0

433

in

as

shown

in

Figure

FA

16

Torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

Il

0

11

0

0

433

t

lP

33

4

1

315

I

11

0

0

433

1

0

11

0

0

433

Adjusting

nut

Y

i

w

36

6

l

441

Unit

mm

in

FA235

Fig

FA

16

Tension

rod

detail

INSPECTION

I

Check

tension

rod

for

bend

and

the

thread

for

faulty

condition

Repair

or

replace

as

required

2

Check

bushing

rubber

for

wear

and

deterioration

Replace

if

neces

sary

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

Removal

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

nuts

at

spring

anchor

bolt

Front

Axle

Front

Suspension

4

Remove

dust

cover

at

the

rear

end

of

torsion

bar

spring

and

detach

snap

ring

S

Withdraw

torsion

bar

spring

rear

ward

after

pulling

ou

t

anchor

arm

realWard

I

nstallalation

Install

torsion

bar

spring

in

the

reverse

sequence

of

removal

noting

the

following

instructions

I

Coat

grease

on

the

serrations

of

torsion

bar

spring

and

install

it

to

torque

arm

Note

Be

sure

to

install

right

and

left

torsion

bar

springs

correctly

They

can

be

identified

with

R

Right

and

L

Left

marked

on

the

end

surface

2

Install

anchor

arm

and

tighten

adjusting

nut

to

obtain

A

dimen

sion

See

Figure

F

A

17

When

anchor

arm

is

properly

adjusted

to

A

specification

upper

link

should

be

in

contact

with

rebound

bumper

rubber

See

Figure

FA

18

Install

snap

ring

and

dust

cover

Temporarily

tighten

adjust

ing

nut

until

B

specification

is

reached

I

I

I

FA236

Fig

FA

17

Installing

anchor

arm

Specifications

for

torsion

bar

spring

Diameter

x

length

mOl

in

Torsional

rigidity

kg

m

deg

ft

lb

deg

FA

9

Anchor

arm

setting

post

ion

A

ISt02Smm

0

59

to

0

98

in

Temporary

tightening

distance

B

60

to

70

mOl

2

36

to

2

76

in

UjPPje

Rebound

bumper

rubber

j

4W

Fig

FA

18

Setting

procedure

Notes

3

A

and

8

specifications

are

only

the

preliminary

rough

settings

directions

for

performing

the

final

adjustment

that

determines

the

ride

height

are

found

on

page

F

A

II

under

Adjustment

b

Discard

old

snap

ring

after

re

moving

it

Replace

with

new

one

during

reinstallation

3

Install

wheel

and

lower

vehicle

Adjust

vehicle

posture

at

curb

weight

full

fuel

tank

no

passengers

refer

ring

to

Adjustment

4

Torque

lock

nut

to

3

1

to

4

1

kg

m

22

to

30

ft

lb

INSPECTION

Check

torsion

bar

spring

for

wear

twist

etc

When

adjusting

vehicle

posture

replace

torsion

bar

spring

with

a

new

one

if

the

specified

height

can

not

be

obtained

All

models

21

9

x

830

0

862

x

32

68

3

74

27

I

Page 416 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

l

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

FE

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEMS

ENGINE

CONTROL

SYSTEM

FUEL

SYSTEM

EXHAUST

SYSTEM

FE

2

FE

4

FE

6

Page 417 of 537

Engine

Control

Fuel

Exhaust

Systems

ENGINE

CONTROL

SYSTEM

CONTENTS

DESCRIPTION

REMOVAL

AND

INSTAllATION

INSPECTION

ADJUSTMENT

FE

2

FE

3

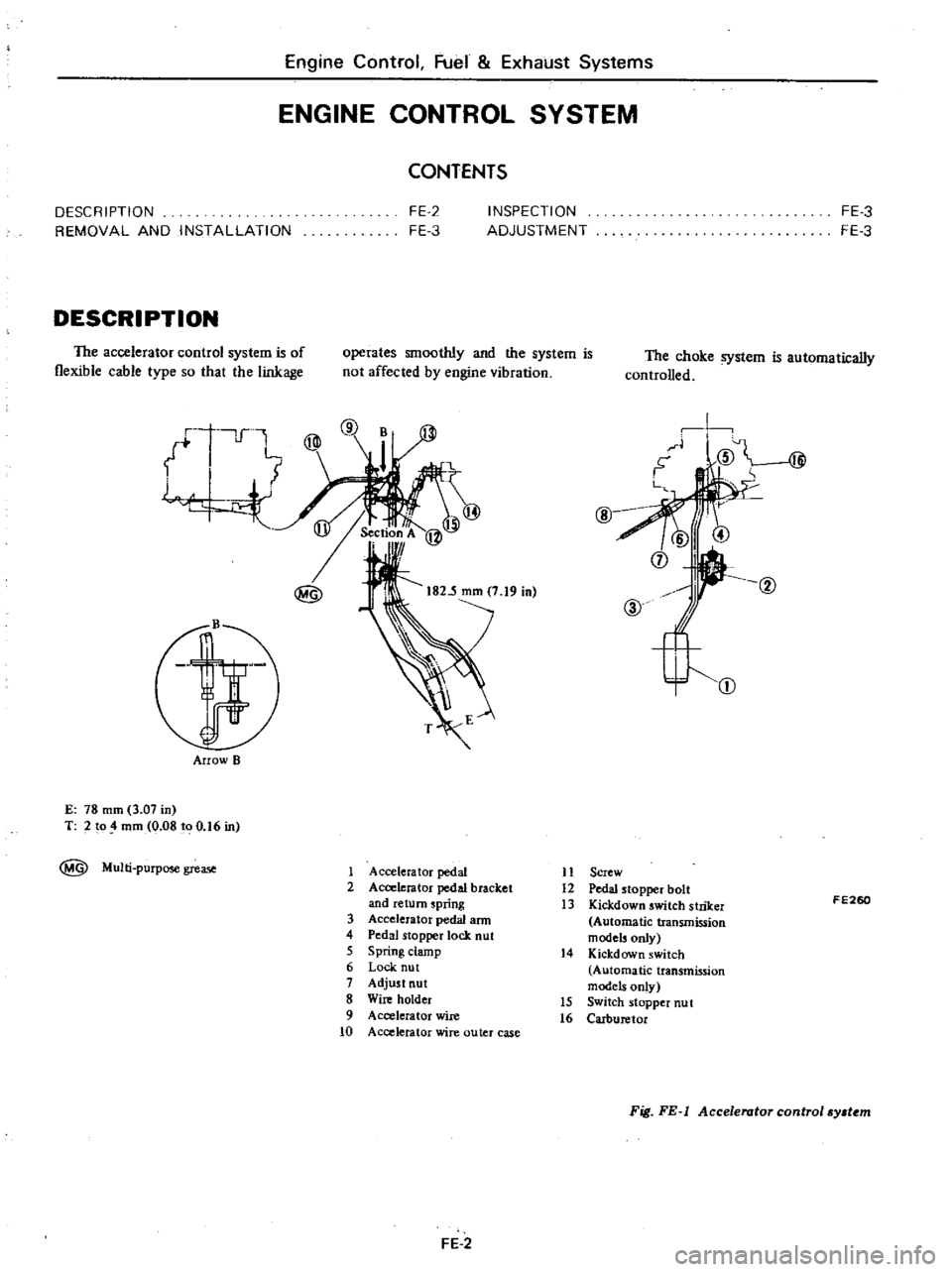

DESCRIPTION

The

accelerator

control

system

is

of

flexible

cable

type

so

that

the

linkage

operates

smoothly

and

the

system

is

not

affected

by

engine

vibration

u

l

f

L

4

@

Arrow

B

E

78

mm

3

07

in

T

2

to

4

mm

0

08

to

0

16

in

MUlti

purpose

grease

FE

3

FE

3

The

choke

system

is

automatically

controlled

i

p

@

I

@

@

CV

j

I

Accelerator

pedal

II

Screw

2

Accelerator

pedal

bracket

12

Pedal

stopper

bolt

and

return

spring

13

Kickdown

switch

striker

3

Accelerator

pedal

arm

Automatic

transmission

4

Pedal

stopper

lock

nut

models

only

5

S

pring

clamp

14

Kickdown

switch

6

Lock

nut

Automatic

transmission

7

Adjust

nut

models

only

8

Wire

holder

15

Switch

stopper

nu

t

9

Accelerator

wire

16

Carburetor

10

Accelerator

wire

outer

case

FE

2

FE260

Fig

FE

l

Accelerator

control

sy

t

m

Page 418 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

AND

INSTALLATION

Accelerator

wire

I

Remove

air

cleaner

assembly

2

Disconnect

accelerator

wire

from

carburetor

3

Loosen

lock

nut

and

disconnect

accelerator

wire

outer

case

from

wire

holder

See

Figure

FE

I

4

Remove

spring

clamp

and

discon

nect

accelerator

wire

from

accelerator

pedal

arm

S

Remove

two

screws

securing

ac

celerator

wire

outer

case

to

body

and

detach

accelerator

wire

6

To

install

reverse

the

order

of

removal

Apply

recommended

multi

purpose

grease

slightly

to

portion

MG

shown

in

Figure

FE

I

Accelerator

pedal

assembly

I

Remove

spring

clamp

then

dis

connect

accelerator

wire

from

tip

of

pedal

ann

2

Remove

two

screws

securing

ac

celerator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

See

Figure

FE

I

4

To

install

reverse

the

order

of

removal

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

ADJUSTMENT

Accelerstor

pedal

and

wire

Adjust

pedal

stopper

bolt

Section

A

so

as

to

obtain

specifi

ed

height

E

as

shown

in

Figure

FE

I

Secure

pedal

stopper

bolt

with

stopper

lock

nut

Refer

to

Figure

FE

I

E

78

mOl

3

07

in

Tightening

torque

01

nut

0

38

to

0

4S

kg

m

2

7

to

3

2

ft

b

2

Release

auto

choke

effect

since

throttle

lever

is

opened

by

fast

idle

earn

until

engine

warms

up

I

Keep

choke

valve

fully

open

with

fingers

2

Pull

throttle

lever

up

by

hand

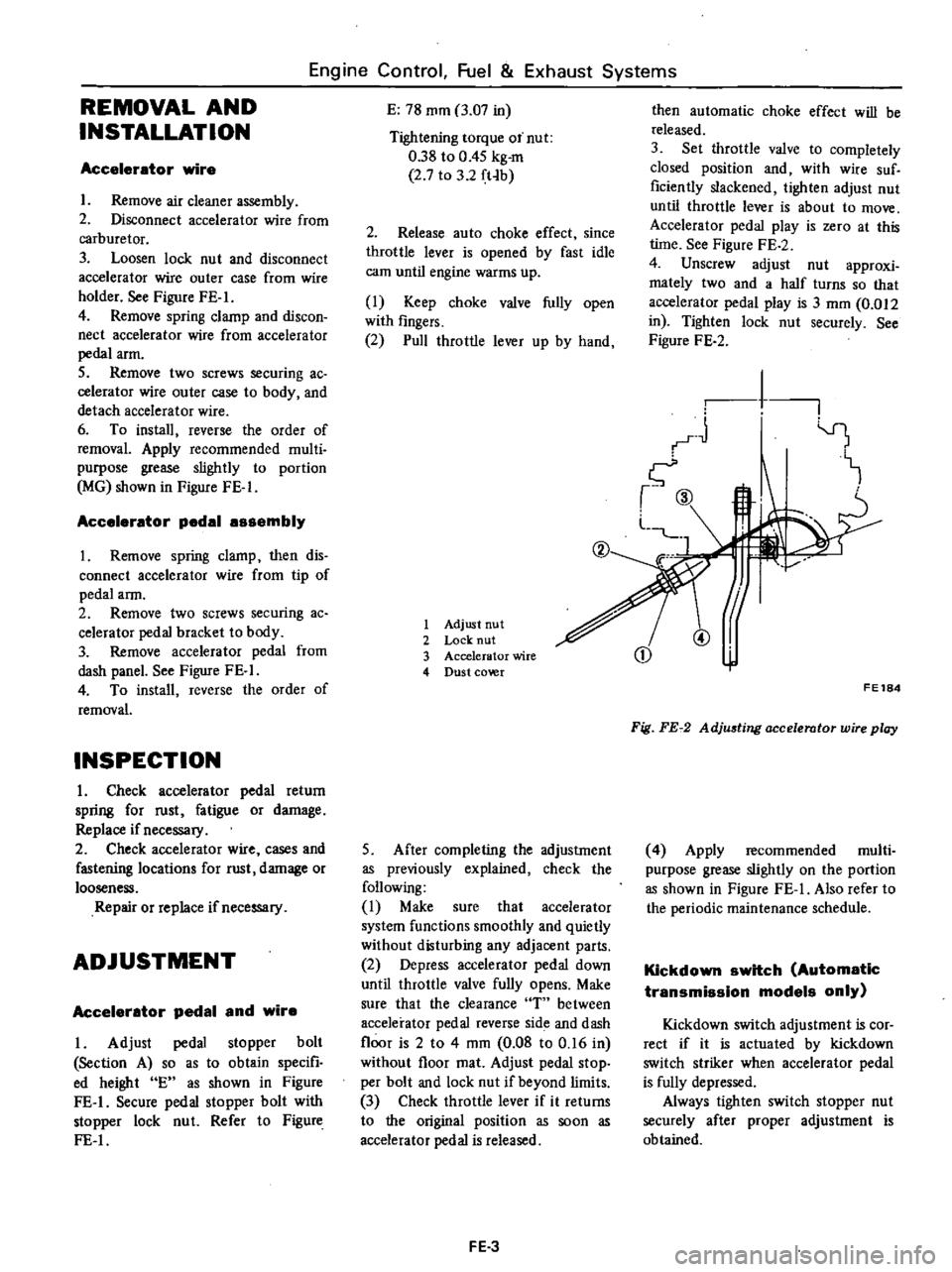

1

Adjust

nut

2

Lock

nut

3

Accelerator

wire

4

Dust

co

r

5

After

completing

the

adjustment

as

previously

explained

check

the

following

I

Make

sure

that

accelerator

system

functions

smoothly

and

quietly

without

disturbing

any

adjacent

parts

2

Depress

accelerator

pedal

down

until

throttle

valve

fully

opens

Make

sure

that

the

clearance

T

between

accelerator

pedal

reverse

side

and

dash

floor

is

2

to

4

mm

0

08

to

0

16

in

without

floor

mat

Adjust

pedal

stop

per

bolt

and

lock

nut

if

beyond

limits

3

Check

throttle

lever

if

it

returns

to

the

original

position

as

soon

as

accelerator

pedal

is

released

FE

3

then

automatic

choke

effect

will

be

released

3

Set

throttle

valve

to

completely

closed

position

and

with

wire

suf

ficiently

slackened

lighten

adjust

nut

until

throttle

lever

is

about

to

move

Accelerator

pedal

play

is

zero

at

this

lime

See

Figure

FE

2

4

Unscrew

adjust

nut

approxi

mately

two

and

a

half

turns

so

that

accelerator

pedal

play

is

3

mOl

0

012

in

Tighten

lock

nut

securely

See

Figure

FE

2

1

I

1

CD

@

FE184

Fig

FE72

AdjU6ting

accelerator

wire

play

4

Apply

recommended

multi

purpose

grease

slightly

on

the

portion

as

shown

in

Figure

FE

I

Also

refer

to

the

periodic

maintenance

schedule

Kickdown

switch

Automatic

transmission

models

only

Kickdown

switch

adjustment

is

cor

rect

if

it

is

actuated

by

kickdown

switch

striker

when

accelerator

pedal

is

fully

depressed

Always

tighten

switch

stopper

nut

securely

after

proper

adjustment

is

obtained

Page 419 of 537

DESCRIPTION

REMOVAL

DESCRIPTION

The

fuel

tank

is4Sliters

II

Ji

U

s

gal

9

Ji

Imper

gal

in

capacity

The

tank

unit

is

mounted

to

the

right

side

of

the

rear

floor

1

Fuel

tank

2

Drain

plug

3

Filler

tube

4

RescfYOir

tank

5

Filler

hose

6

Breather

hose

7

Ventilation

hose

8

Evaporation

hose

9

Fuel

outlet

hose

and

tube

10

Fuel

tank

gauge

unit

11

Protector

12

Bracket

13

Retainer

14

Return

tube

Engine

Control

Fuel

Exhaust

Systems

FUEL

SYSTEM

CONTENTS

FE

4

FE

5

INSPECTION

INSTALLATION

FE

6

FE

6

The

filler

shutter

is

installed

to

the

filler

tube

on

California

models

The

electric

fuel

pump

is

adopted

on

air

conditioner

equipped

models

For

the

electric

fuel

pump

refer

to

Section

EF

FE194

Fig

FE

3

Fuel

tank

FE

4

Page 420 of 537

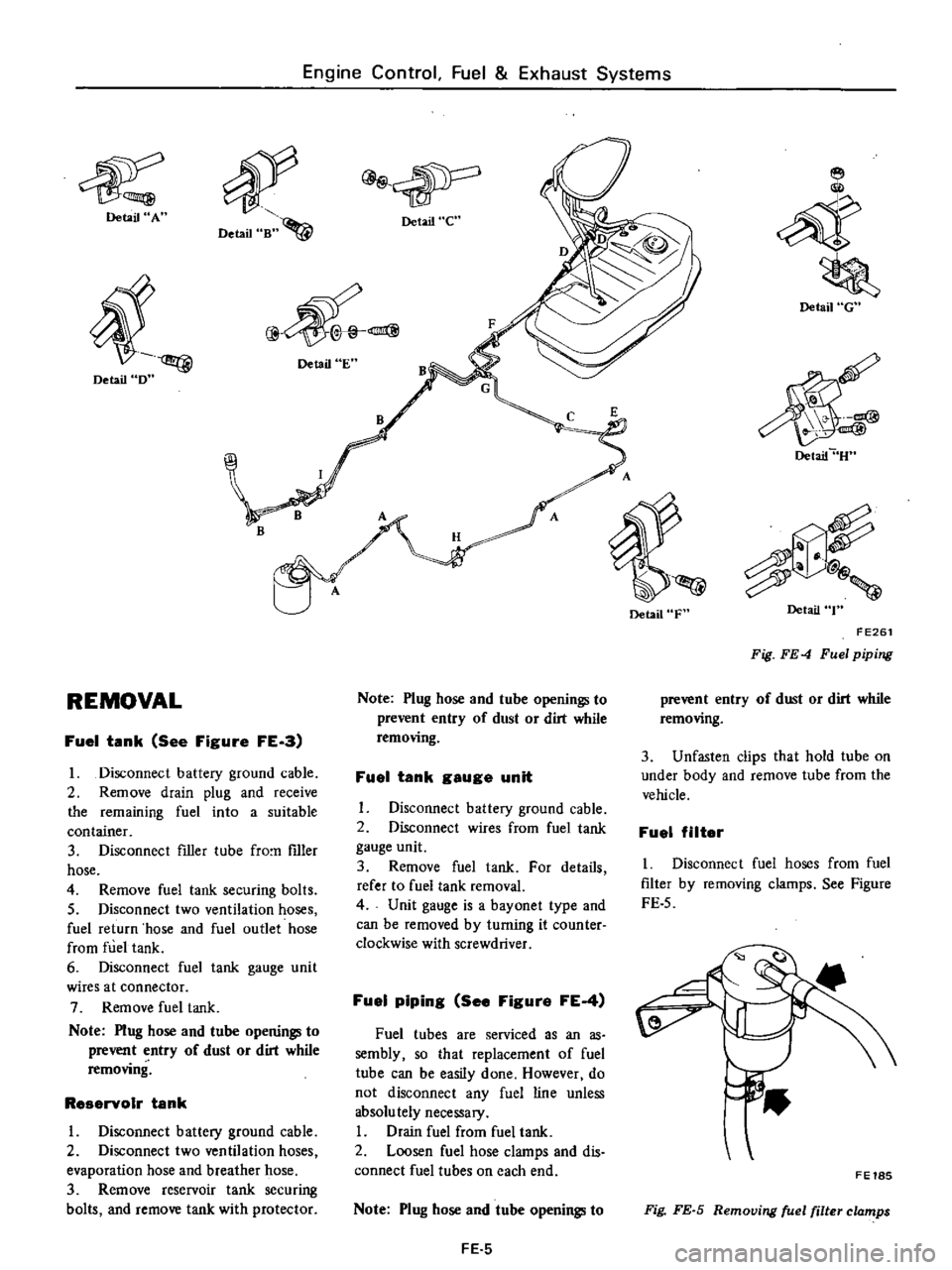

Detail

A

Detail

D

REMOVAL

Engine

Control

Fuel

Exhaust

Systems

Detail

Bn

4

Detail

e

@

Detail

E

B

Fuel

tank

See

Figure

FE

a

I

Disconnect

battery

ground

cable

2

Remove

drain

plug

and

receive

the

remaining

fuel

into

a

suitable

container

3

Disconnect

filler

tube

fro

filler

hose

4

Remove

fuel

tank

securing

bolts

5

Disconnect

two

ventilation

hoses

fuel

return

hose

and

fuel

outlet

hose

from

fuel

tank

6

Disconnect

fuel

tank

gauge

unit

wires

at

connector

7

Remove

fuel

tank

Note

Plug

hose

and

tube

opening

l

to

prevent

entry

of

dust

or

dirt

while

removing

ReservoIr

tank

1

Disconnect

battery

ground

cable

2

Disconnect

two

ventilation

hoses

evaporation

hose

and

breather

hose

3

Remove

reservoir

tank

securing

bolts

and

remove

tank

with

protector

Note

Plug

hose

and

tube

opening

l

to

prevent

entry

of

dust

or

dirt

while

removing

Fuel

tank

gauge

unit

Disconnect

battery

ground

cable

2

Disconnect

wires

from

fuel

tank

gauge

unit

3

Remove

fuel

tank

For

details

refer

to

fuel

tank

removal

4

Unit

gauge

is

a

bayonet

type

and

can

be

removed

by

turning

it

counter

clockwise

with

screwdriver

Fuel

piping

See

Figure

FE

4

Fuel

tubes

are

serviced

as

an

as

sembly

so

that

replacement

of

fuel

tube

can

be

easily

done

However

do

not

disconnect

any

fuel

line

unless

absolu

tely

necessary

I

Drain

fuel

from

fuel

tank

2

Loosen

fuel

hose

clamps

and

dis

connect

fuel

tubes

on

each

end

Note

Plug

hose

and

tube

openings

to

FE

5

Detail

F

Detail

G

Detail

U

Detail

T

FE261

Fig

FE

4

Fuel

piping

prevent

entry

of

dust

or

dirt

while

removing

3

Unfasten

clips

that

hold

tube

on

under

body

and

remove

tube

from

the

vehicle

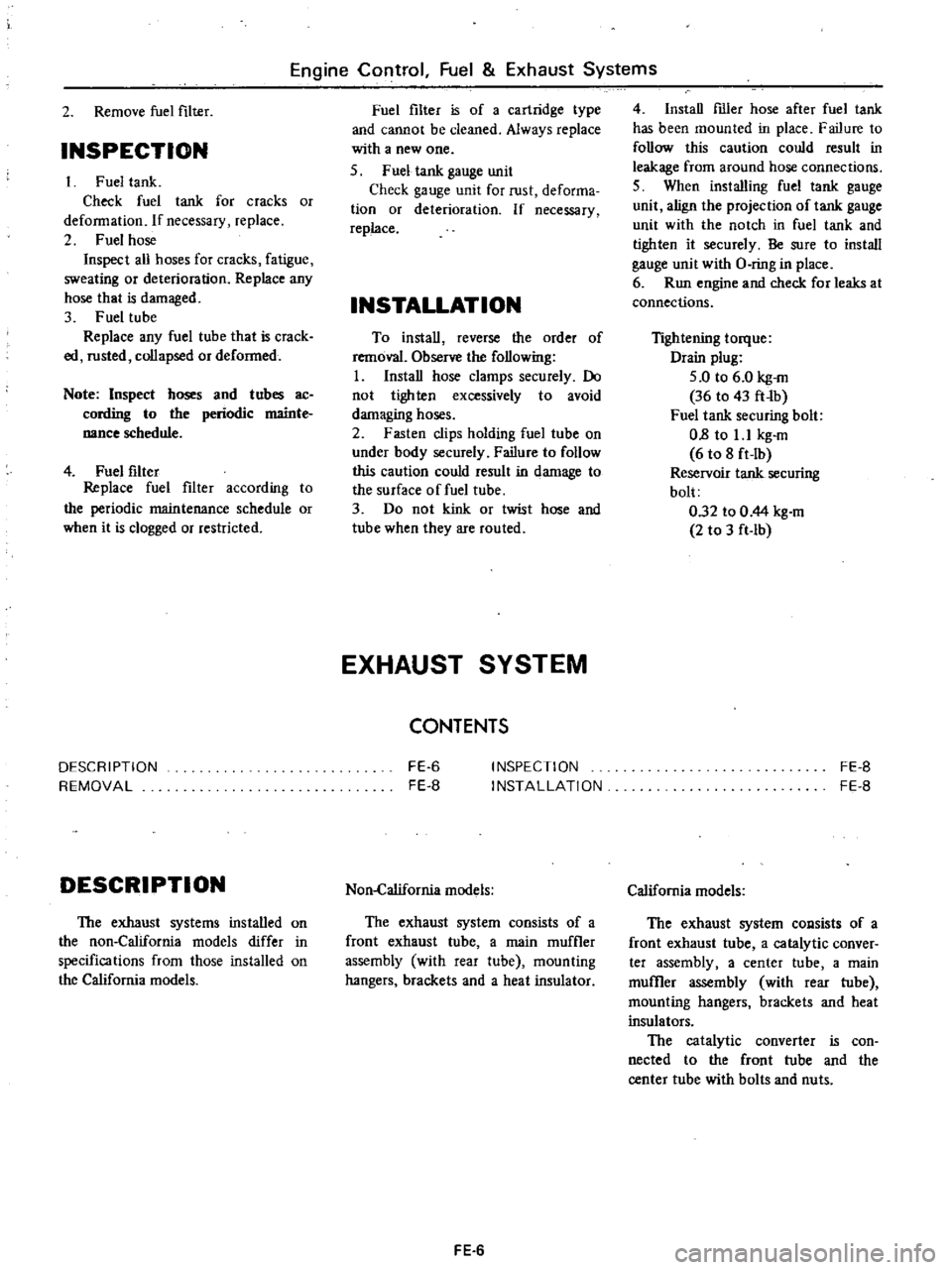

Fuel

filter

I

Disconnect

fuel

hoses

from

fuel

filter

by

removing

clamps

See

Figure

FE

5

FE18S

Fig

FE

S

Removing

fuel

filter

clamps

Page 421 of 537

Engine

Control

Fuel

Exhaust

Systems

2

Remove

fuel

filter

INSPECTION

Fuel

tanle

Check

fuel

tank

for

cracks

or

deformation

If

necessary

replace

2

Fuel

hose

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

3

Fuel

tube

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

Note

Inspect

hoses

and

tubes

ac

cording

to

the

periodic

mainte

nance

schedule

4

Fuel

filter

Replace

fuel

filter

according

to

the

periodic

maintenance

schedule

or

when

it

is

clogged

or

restricted

DESCRIPTION

REMOVAL

DESCRIPTION

The

exhaust

systems

installed

on

the

non

California

models

differ

in

specifications

from

those

installed

on

the

California

models

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

5

Fuel

tank

gauge

unit

Check

gauge

unit

for

rust

deforma

tion

or

deterioration

If

necessary

replace

INSTALLATION

To

install

reverse

the

order

of

removal

Observe

the

following

I

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

damaging

hoses

2

Fasten

clips

holding

fuel

tube

on

under

body

securely

Failure

to

follow

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

3

Do

not

kink

or

twist

hose

and

tube

when

they

are

routed

EXHAUST

SYSTEM

CONTENTS

FE

6

FE

8

INSPECTION

INSTAllATION

Non

California

models

The

exhaust

system

consists

of

a

front

exhaust

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

a

heat

insulator

FE

6

4

Install

fIller

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

follow

this

caution

could

result

in

leakage

from

around

hose

connections

5

When

installing

fuel

tank

gauge

unit

align

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

install

gauge

unit

with

O

ring

in

place

6

Run

engine

and

check

for

leaks

at

connections

Tightening

torque

Drain

plug

5

0

to

6

0

kg

m

36

to

43

ft

Ib

Fuel

tank

securing

bolt

0

8

to

1

I

kg

m

6

to

8

ft

Ib

Reservoir

tank

securing

bolt

032

to

0

44

kg

m

2

to

3

ft

Ib

FE

8

FE

8

California

models

The

exhaust

system

cOllsists

of

a

front

exhaust

tube

a

catalytic

conver

ter

assembly

a

center

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

heat

insulators

The

catalytic

converter

is

COD

nected

to

the

front

tube

and

the

center

tube

with

bolts

and

nuts

Page 422 of 537

Engine

Control

Fuel

Exhaust

S

t

ys

ems

Non

Califomia

model

Qf

@

Si

tr

l

Qf

Si

tIJ

i

Qf

I

l

j

l

tr

l

r

Qf

Si

i

l

l

t

1

I

tr

l

9

r

8

1Bi

1

Front

tube

2

Exhaust

tube

clamp

3

Rear

tube

assembly

4

Muffler

assembly

5

Rear

tube

mounting

6

Front

tube

mounting

California

model

6

@@

8

Qf

@

fit

J

0

I

1

2

I

7

Front

tube

Catalytic

converter

Center

tube

Muffler

assembly

Diffuser

Rear

tube

mounting

Front

tube

mounting

FE390

Fig

FE

6

E

r

ha

t

system

FE

7