fuel DATSUN PICK-UP 1977 Manual Online

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 423 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

Non

California

models

I

Remove

exhaust

tube

U

bolt

clamp

2

Break

sealant

off

at

front

tube

to

main

muffler

connectio

n

3

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

4

Remove

front

tube

heat

insulator

5

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

When

disconnecting

the

exhaust

tube

connections

pay

attention

to

the

following

point

I

Break

old

se

lant

off

at

t

1e

connection

by

lightly

tapping

around

the

tube

witlJ

a

hammer

and

twisting

muffler

See

Figures

FE

7

and

FE

8

2

Using

a

rubber

hammer

tap

on

the

front

end

of

muffler

while

pushing

it

toward

rear

The

mumer

assembly

can

then

be

taken

out

See

Figure

FE

9

FE187

Fig

FE

7

Breaking

Bealant

FEl88

Fig

FE

8

Twisting

muffler

ijl

4

FE189

Fig

FE

9

Tapping

muffler

with

Q

rubber

hammer

California

models

I

Remove

all

heat

insulators

2

Remove

exhaust

tube

U

bolt

clamp

3

Break

sealant

off

at

center

tube

to

main

muffler

connection

4

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

5

Remove

bolts

securing

catalytic

converter

to

center

tube

and

remove

center

tube

mounting

bolts

Then

detach

center

tube

6

Remove

bolts

and

nuts

securing

catalytic

converter

to

front

tube

and

detach

catalytic

converter

7

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

INSPECTION

I

Check

muffler

and

tubes

for

cracks

Qr

damage

Replace

any

part

that

is

damaged

beyond

limits

2

Replace

bracket

and

mounting

insulator

that

are

cracked

fatigued

or

sweated

FE

8

INSTALLATION

Install

the

exhaust

system

assembly

in

reverse

order

of

removal

Observe

the

following

Notes

a

Insert

front

tube

until

it

touches

emboss

b

When

there

is

110

clearance

between

front

tube

and

floor

or

propeUer

shaft

turn

tube

along

center

line

of

tube

in

the

manifold

connecting

unit

and

obtain

proper

clearance

c

Check

all

tube

connections

for

ex

haust

gas

leaks

and

entire

system

for

unusual

noises

with

engine

running

d

After

installation

check

that

mounting

brackets

and

mounting

rubbers

are

free

from

undue

stress

If

any

of

the

above

parts

is

not

installed

properly

excessive

noises

or

vibrations

may

be

transmitted

to

the

vehicle

body

e

Tightening

torque

Exhaust

manifold

to

front

tube

nut

1

9

to

2

5

kg

m

14

to

18

ft

lb

U

bolt

securing

nut

1

9

to

2

1

kg

m

14

to

15

ft

lb

Mounting

bracket

bolt

1

0

to

1

2

kg

m

710

9

ft

lb

Front

tube

mounting

bracket

bolt

california

models

1

9

to

2

1

kg

m

14

to

15

ft

lb

Catalytic

converter

to

front

and

center

tube

bolt

California

models

3

2

to

4

3

kg

m

23

to

31

ft

Ib

If

exhaust

tubes

are

separated

at

connection

t

renew

muffler

assembly

etc

use

the

Genuine

Nissan

Sealant

Exhaust

Sealant

Kit

20720

N2225

or

equivalent

See

Figure

FE

IO

to

eliminate

gas

leakage

at

the

joint

Be

sure

to

observe

the

following

Page 424 of 537

Engine

Control

Fuel

Exhaust

Systems

I

Wipe

clean

all

the

contact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muffler

assembly

as

an

assembled

unit

on

the

vehicle

3

Insert

front

tube

until

it

touches

emboss

m

b

nlfrnnjj

mm

lJ

Ij

@L

J

FE263

Fig

FE

ll

Exhawt

tube

connection

4

Torque

nut

securing

the

male

and

female

tubes

at

the

connection

Tightening

torque

is

1

6

to

2

0

kg

m

12

to

14

ft

lb

5

Squeeze

approximately

5

CC

0

31

cu

in

of

sealant

into

injection

from

sealant

tube

See

Figure

FE

12

Sealant

tube

polyethylene

Injector

Fig

FE

IO

Exhaust

sealant

kit

Be

sure

to

place

cap

back

to

sealant

tube

since

sealant

will

dry

Approximately

5

cc

0

31

Cll

in

FE1l1

Fig

FE

12

Squeezing

sealant

to

injec

tor

6

Position

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

begins

to

flow

out

of

the

slit

of

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Figure

FE

13

After

injecting

wash

injector

thoroughly

in

clean

water

to

remove

all

traces

of

sealant

FE191

Fig

FE

13

Injecting

sealant

FE

9

7

Start

engine

and

let

it

idle

slowly

for

ten

minutes

minimum

to

hilfden

sealant

with

the

heat

of

exhaust

gas

8

Check

the

condition

of

sealant

before

driving

the

vehicle

It

is

also

essential

that

the

vehicle

should

not

be

accelerated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

Noles

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

above

400C

I040F

A

sealant

hardened

above

4QoC

I040F

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

becomes

hardened

because

of

low

temperatures

wann

the

sealant

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

tube

at

a

temperature

over

400C

1040F

for

a

long

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

i

Page 428 of 537

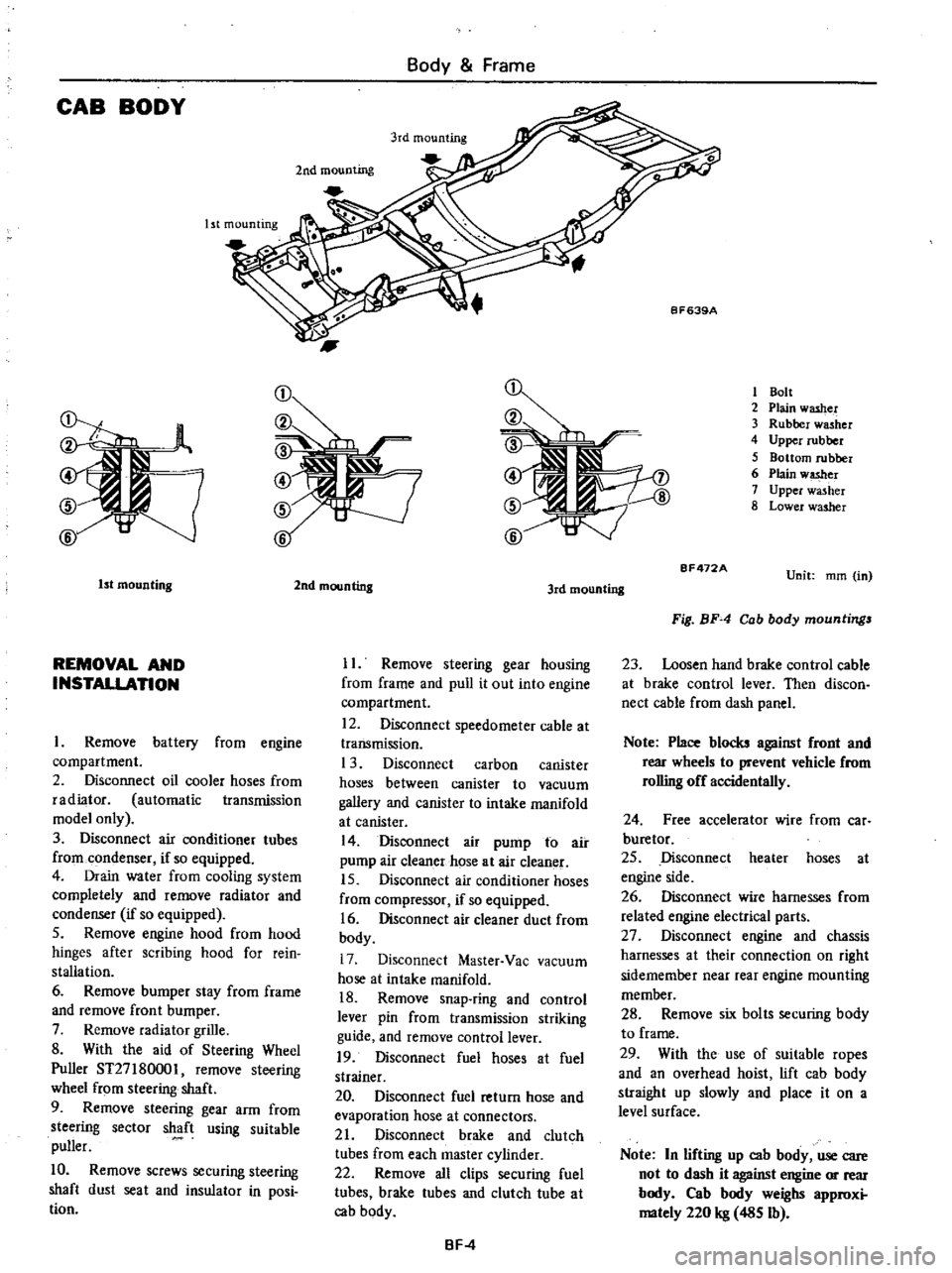

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

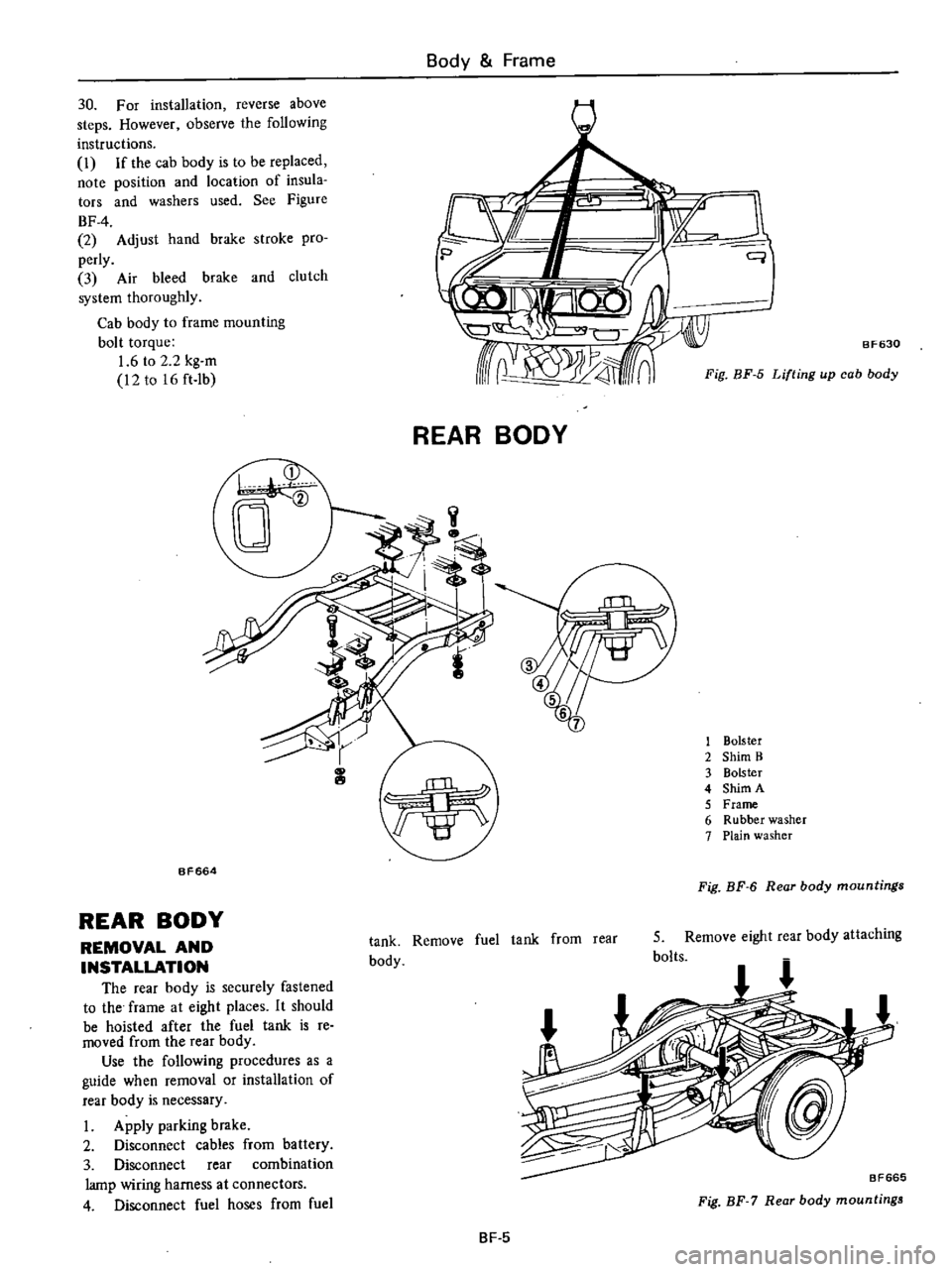

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib

Page 429 of 537

Body

Frame

30

For

installation

reverse

above

steps

However

observe

the

following

instructions

i

If

the

cab

body

is

to

be

replaced

note

position

and

location

of

insula

tors

and

washers

used

See

Figure

BF

4

2

Adjust

hand

brake

stroke

pro

perly

3

Air

bleed

brake

and

clutch

system

thorougWy

Cab

body

to

frame

mounting

bolt

torque

1

6

to

2

2

kg

m

12

to

16

ft

Ib

o

i

k

q

1Q

j

b

crru

V

J

8F630

rr

1

4

n

Fig

BF

5

Lifting

up

cab

body

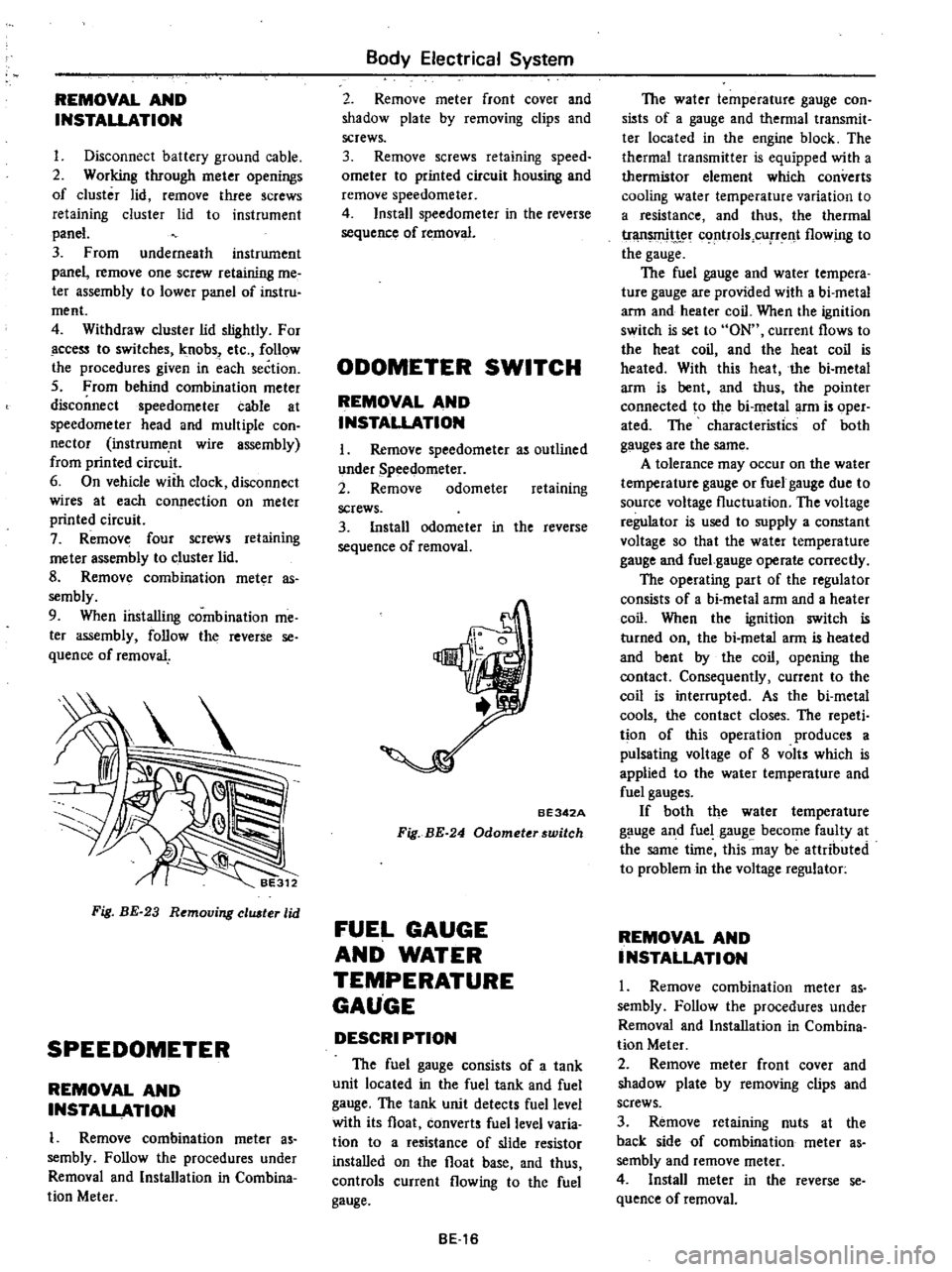

REAR

BODY

1

Bolster

2

Shim

B

3

Bolster

4

Shim

A

5

Frame

6

Rubber

washer

7

Plain

washer

BF664

Fig

BF

6

Rear

body

mountings

REAR

BODY

REMOVAL

AND

INSTALLATION

The

rear

body

is

securely

fastened

to

the

frame

at

eight

places

It

should

be

hoisted

after

the

fuel

tank

is

re

moved

from

the

rear

body

Use

the

following

procedures

as

a

guide

when

removal

or

installation

of

rear

body

is

necessary

I

Apply

parking

brake

2

Disconnect

cables

from

battery

3

Disconnect

rear

combination

lamp

wiring

harness

at

connectors

4

Disconnect

fuel

hoses

from

fuel

tank

Remove

fuel

tank

from

rear

body

5

Remove

eight

rear

body

attaching

bolts

BF665

Fig

BF

7

Rear

body

mountings

BF

5

Page 459 of 537

Body

Electrical

System

METERS

AND

GAUGES

COMBINATION

METER

COMBINATION

METER

CIRCUIT

DIAGRAM

REMOVAL

AND

INSTALLATION

SPEEDOMETER

REMOVAL

AND

INSTALLATION

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRIPTION

REMOVAL

AND

INSTALLATION

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

01

L

PRESSURE

SWITCH

COMBINATION

METER

COMBINATION

METER

CIRCUIT

DIAGRAM

@

BE6828

CONTENTS

BE

14

BE

14

BE

16

BE

16

BE

16

BE

16

8E

16

BE

16

BE

16

BE

16

8E

17

BE

17

BE

17

Turn

signal

indicator

lamp

L

H

OIL

0

BEAM

BE

14

Meter

illumination

lamps

M

T

only

9

9

Turn

sq

nal

indicator

lamp

lL

J

R

H

Tj

O

iJ

I

l

g

r

i

o

I

l8

J

CHARGE

WARNING

LAMP

DESCRIPTION

HAND

BRAKE

WARNING

LAMP

DESCRIPTION

HAND

BRAKE

SWITCH

METER

ILLUMINATION

INDICATOR

AND

WARNING

BULBS

REMOVAL

AND

INSTALLATION

8ULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

SPEEDOMETER

WATER

TEMPERATURE

AND

FUEL

GAUGES

OIL

PRESSURE

AND

CHARGE

WARNING

LAMPS

Voltage

regulator

TEMP

FUEL

CHG

0

BRK

C

I

Speedometer

2

Thermometer

3

Fuel

meter

4

Tachometer

Option

5

Cluster

lid

6

Speedometer

cable

7

Speed

switch

amplifier

Manual

transmission

only

BE

17

BE

17

BE

18

BE

18

8E

18

8E

18

BE

18

BE

18

BE

18

BE

18

BE

19

BE

20

Q

Speed

switch

BE856A

Fig

BE

21

Ci1

Cuit

diagram

of

combination

meter

Page 460 of 537

Body

Electrical

System

Circuit

diagram

of

combination

meter

system

BATTERY

r

G

0

J

J

Z2

lIa

I

LlJ

I

Z

J

Z

a

z

J

z

Z

i

g

o

a

I

LlJ

I

ll

B

S

M

D

LIGHT

i

i

RELAY

i2i

mm

S

FROM

J

e

AMP

l1

l1

J

J

00

LlJLlJ

z

z

B

COO

CUT

n

SOLENOID

i

OIL

f

PRESSURE

SWITCH

THERMAL

a

TRANSMITTER

I

FUSIBLE

r

LINK

IGNITION

SWITCH

0

1

lOA

I

g

KG

lOA

r

I

15A

t

15A

i

7

5a

z

u

a

a

I

04LlJ

l1

J

o

02

u

3

FUEL

TANK

J

VOLTAGE

REGULATOR

HAND

BRAKE

SWITCH

J

Jon

0

j

Z

a

l

I

I

I

l

ll

Z

ll

Z

LlJ

LlJ

J

a

J

a

I

I

I

I

1

1

Zza

a

00

a

a

LlJLlJ

ll

ll

a

a

HAZARD

FLASHER

UNIT

L

J

HAZAR

D

SWITCH

I

OFF

ONI

l

I

I

I

2

I

I

3

I

14

61

I

5

6

16

9

I

76

I

FLASHER

UNIT

CJ

TO

LIGHT

IOFF

RELAY

B

l

TERMINAL

I

I

I

LIGHT

SWITCH

21

X

X

BEB57

A

Fig

BE

22

Circuit

diagram

of

combination

meter

ayatt

m

TURN

SIGNAL

SWITCH

I

L

RI

lFLA

I

IR

R

I

IR

L

I

IF

R

u

I

IF

L

u

I

FROM

L1GHT

RELAY

DIMMER

SWITCH

BE

15

Page 461 of 537

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

2

Working

through

meter

openings

of

cluster

lid

remove

three

screws

retaining

cluster

lid

to

instrument

panel

3

From

underneath

instrument

panel

remove

one

screw

retaining

me

ter

assembly

to

lower

panel

of

instru

ment

4

Withdraw

cluster

lid

slightly

For

ccess

to

switches

knobs

etc

follow

the

procedures

given

in

each

section

5

From

behind

combination

meter

disconnect

speedometer

cable

at

speedometer

head

and

multiple

con

nector

instrume

nt

wire

assembly

from

printed

circuit

6

On

vehicle

with

clock

disconnect

wires

at

each

connection

on

meter

printed

circuit

7

Remove

four

screws

retaining

me

ter

assembly

to

cluster

lid

8

Remov

combination

meter

as

sembly

9

When

installing

combination

me

ter

assembly

follow

the

reverse

se

quence

of

removal

Fig

BE

23

Removing

eluster

lid

SPEEDOMETER

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

Body

Electrical

System

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

screws

retaining

speed

ometer

to

printed

circuit

housing

and

remove

speedometer

4

Install

speedometer

in

the

reverse

sequence

of

removal

ODOMETER

SWITCH

REMOVAL

AND

INSTALLATION

I

Remove

speedometer

as

outlined

under

Speedometer

2

Remove

odometer

retaining

screws

3

Install

odometer

in

the

reverse

sequence

of

removal

BE342A

Fig

BE

24

Odometerswitch

FUEL

GAUGE

AND

WATER

TEMPERATURE

GAUGE

DESCRI

PTION

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

gauge

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

varia

tion

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

gauge

BE16

The

water

temperature

gauge

con

sists

of

a

gauge

and

thermal

transmit

ter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

tr

t

c

rtrols

cUfTent

flowing

to

the

gauge

The

fuel

gauge

and

water

tempera

ture

gauge

are

provided

with

a

bi

metal

arm

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bi

metal

arm

is

bent

and

thus

the

pointer

connected

to

the

bi

metal

arm

is

oper

ated

The

characteristics

of

both

gauges

are

the

same

A

tolerance

may

occur

on

the

water

temperature

gauge

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

water

temperature

gauge

and

fuel

gauge

operate

correctly

The

operating

part

of

the

regulator

consists

of

a

bi

metal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

bi

metal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bi

metal

cools

the

contact

closes

The

repeti

tion

of

this

operation

produces

a

pulsating

voltage

of

8

volts

which

is

applied

to

the

water

temperature

and

fuel

gauges

If

both

the

water

temperature

gauge

and

fuel

gauge

become

faulty

at

the

same

time

this

may

be

attributed

to

problem

in

the

voltage

regulator

REMOVAL

AND

INSTALLATION

1

Remove

combination

meter

as

sembly

Follow

the

procedures

under

Removal

and

Installation

in

Combina

tion

Meter

2

Remove

meter

front

cover

and

shadow

plate

by

removing

clips

and

screws

3

Remove

retaining

nuts

at

the

back

side

of

combination

meter

as

sembly

and

remove

meter

4

Install

meter

in

the

reverse

se

quence

of

removal

Page 462 of 537

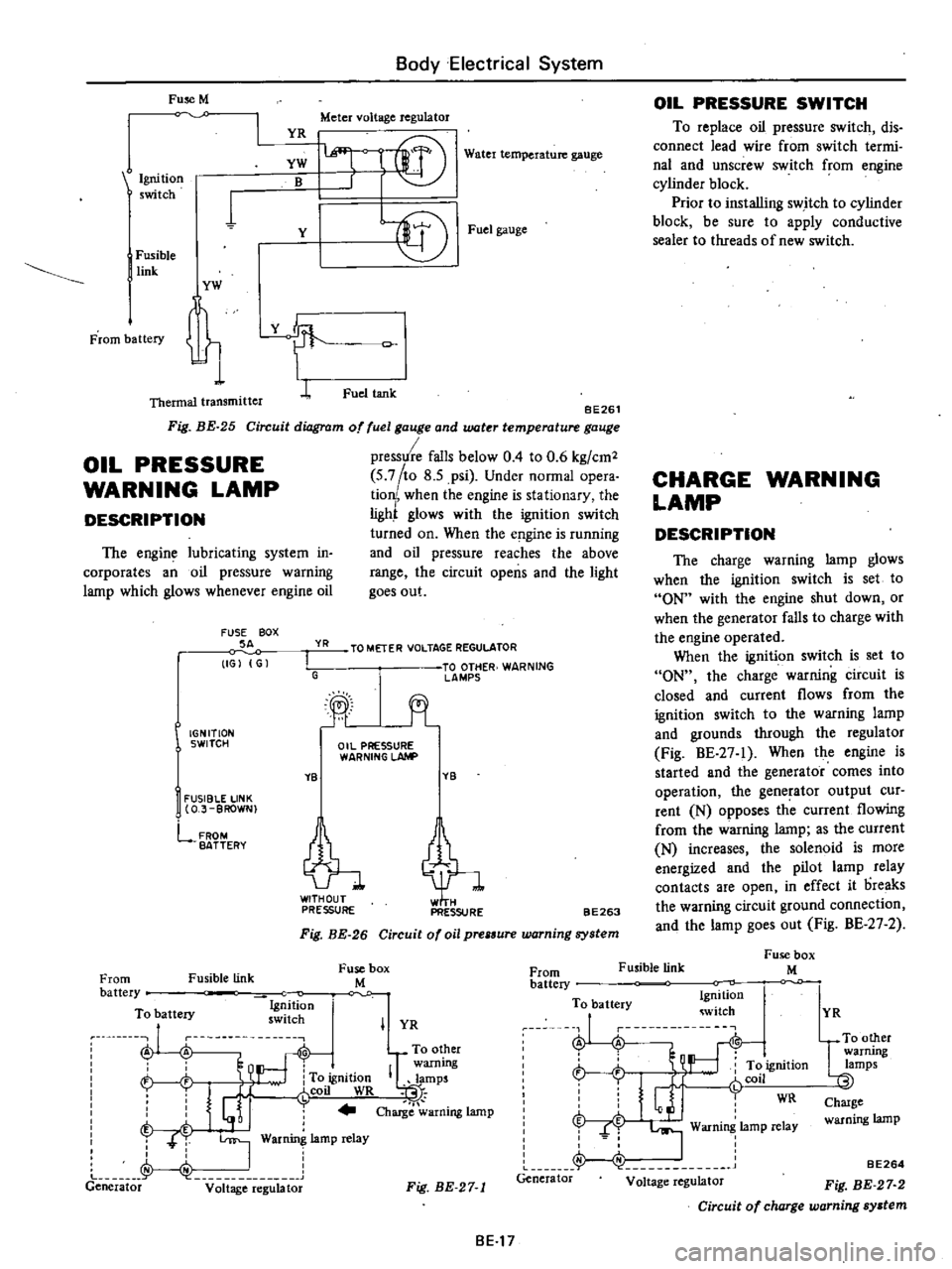

Fuse

M

Body

Electrical

System

YR

Meter

voltage

regulator

Water

temperature

gauge

BE261

Circuit

diagram

of

fuel

gauge

and

water

temperature

gauge

pressure

falls

below

0

4

to

0

6

kg

cm2

5

7

to

8

5

psi

Under

normal

opera

tion

when

the

engine

is

stationary

the

ligh

glows

with

the

ignition

switch

turned

on

When

the

e

gine

is

running

and

oil

pressure

reaches

the

above

range

the

circuit

opens

and

the

light

goes

out

Ignition

switch

YW

B

1

Y

I

Fusible

link

YW

t

Thermal

transmitter

L

Fig

BE

25

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

The

engine

lubricating

system

in

corporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

FUSE

BOX

SA

IGJ

G

YR

I

G

IGNITION

SWITCH

YB

I

FUSIBLE

LINK

O

J

BROWN

lffi

l

f

r@

Fuel

gauge

Fuel

tank

TO

METER

VOLTAGE

REGULATOR

TO

OTHER

WARNING

lAMPS

jt

Oil

PRESSURE

WARNING

LAhlP

YB

tl

PRESSURE

PRESSURE

FROM

BATTERY

BE263

Fig

BE

26

Circuit

of

oil

prelSure

warning

system

Fusible

link

Fuse

box

M

OIL

PRESSURE

SWITCH

To

replace

oil

pressure

switch

dis

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

from

engine

cylinder

block

Prior

to

installing

switch

to

cylinder

block

be

sure

to

apply

conductive

sealer

to

threads

of

new

switch

CHARGE

WARNING

LAMP

DESCRIPTION

The

charge

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

with

the

engine

shut

down

or

when

the

generator

falls

to

charge

with

the

engine

operated

When

the

ignition

switch

is

set

to

ON

the

charge

warning

circuit

is

closed

and

current

flows

from

the

ignition

switch

to

the

warning

lamp

and

grounds

through

the

regulator

Fig

BE

27

1

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

cur

rent

N

opposes

th

current

flowing

from

the

warning

lamp

as

the

current

N

increases

the

solenoid

is

more

energized

and

the

pilot

lamp

relay

contacts

are

open

in

effect

it

oreaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

Fig

BE

27

2

Fusible

link

Fuse

box

M

From

battery

To

battery

Ig

ition

ru

nu

swllch

A

A

To

other

warning

h

To

ignition

IQlamps

i

J

r

coil

WR

t

I

j

Charge

warning

lamp

T

T

I

War

lamp

relay

J

I

Generator

v

it

ge

e

g

bt

From

battery

To

battery

Ignition

witch

J

i

L

r

t

ft

ignition

r

Glj

fCOil

WR

f

I

Warning

lamp

relay

Generator

Voltage

regulator

I

YR

Fig

BE

27

1

BE17

YR

UTO

other

warrung

lamps

Charge

warning

lamp

BE264

Fig

BE

27

2

Circuit

of

charge

warning

system

Page 464 of 537

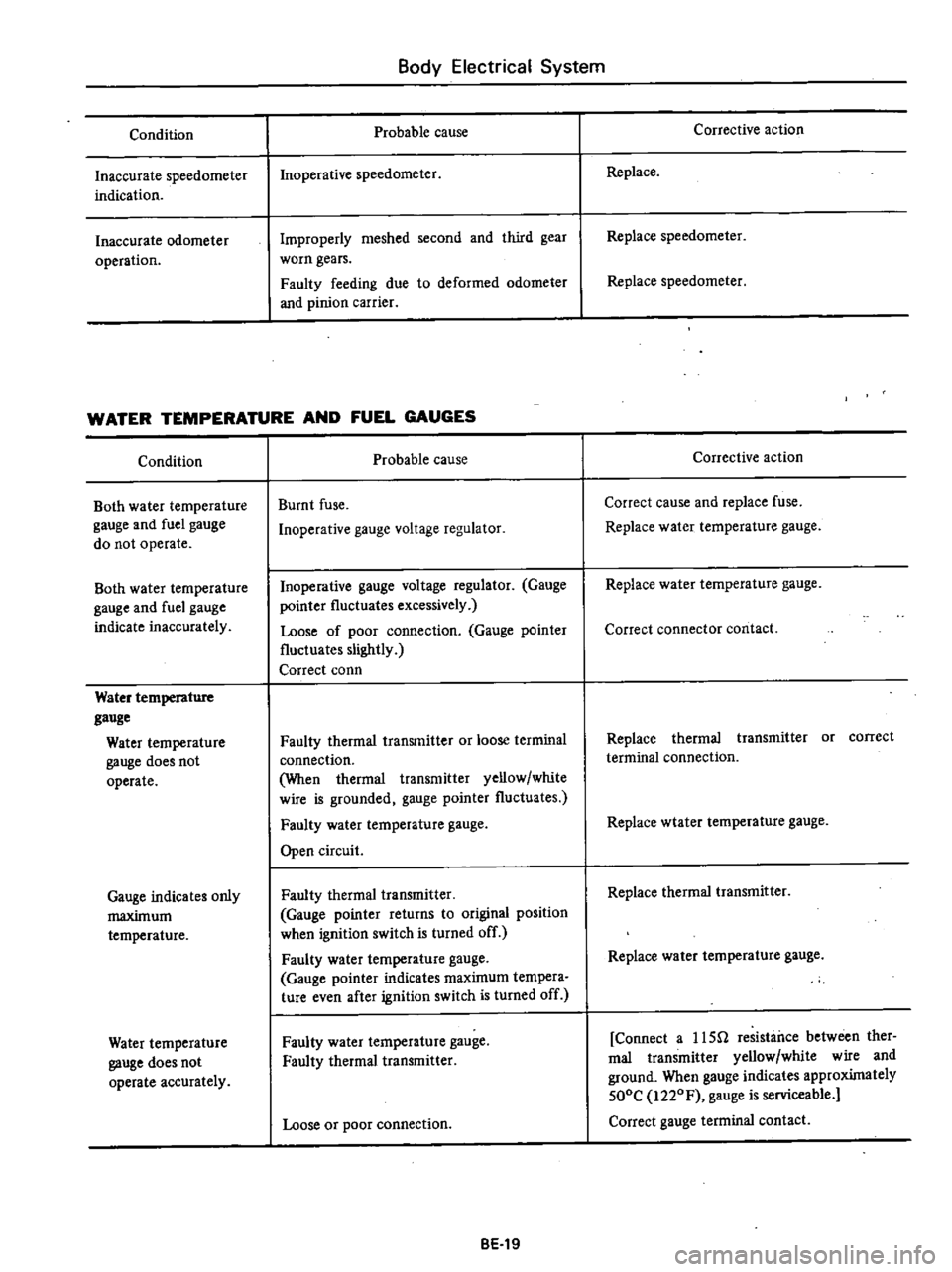

Condition

Inaccurate

speedometer

indication

Inaccurate

odometer

operation

Body

Electrical

System

Probable

cause

Inoperative

speedometer

Improperly

meshed

second

and

third

gear

worn

gears

Faulty

feeding

due

to

deformed

odometer

and

pinion

carrier

WATER

TEMPERATURE

AND

FUEL

GAUGES

Condition

Both

water

temperature

gauge

and

fuel

gauge

do

not

operate

Both

water

temperature

gauge

and

fuel

gauge

indicate

inaccurately

Water

temperature

gauge

Water

temperature

gauge

does

not

operate

Gauge

indicates

only

maximum

temperature

Water

temperature

gauge

does

not

operate

accurately

Probable

cause

Burnt

fuse

Inoperative

gauge

voltage

regulator

Inoperative

gauge

voltage

regulator

Gauge

pointer

fluctuates

excessively

Loose

of

poor

connection

Gauge

pointer

fluctuates

slightly

Correct

conn

Faulty

thermal

transmitter

or

loose

terminal

connection

When

thermal

transmitter

yellow

white

wire

is

grounded

gauge

pointer

fluctuates

Faulty

water

temperature

gauge

Open

circuit

Faulty

thermal

transmitter

Gauge

pointer

returns

to

original

position

when

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Gauge

pointer

indicates

maximum

tempera

ture

even

after

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Faulty

thermal

transmitter

Loose

or

poor

connection

BE

19

Corrective

action

Replace

Replace

speedometer

Replace

speedometer

Corrective

action

Correct

cause

and

replace

fuse

Replace

water

temperature

gauge

Replace

water

temperature

gauge

Correct

connector

contact

Replace

thermal

transmitter

or

correct

terminal

connection

Replace

wtater

temperature

gauge

Replace

thermal

transmitter

Replace

water

temperature

gauge

Connect

a

usn

resistance

between

ther

mal

transmitter

yellow

white

wire

and

ground

When

gauge

indicates

approximately

500C

i220F

gauge

is

serviceable

Correct

gauge

terminal

contact

Page 465 of 537

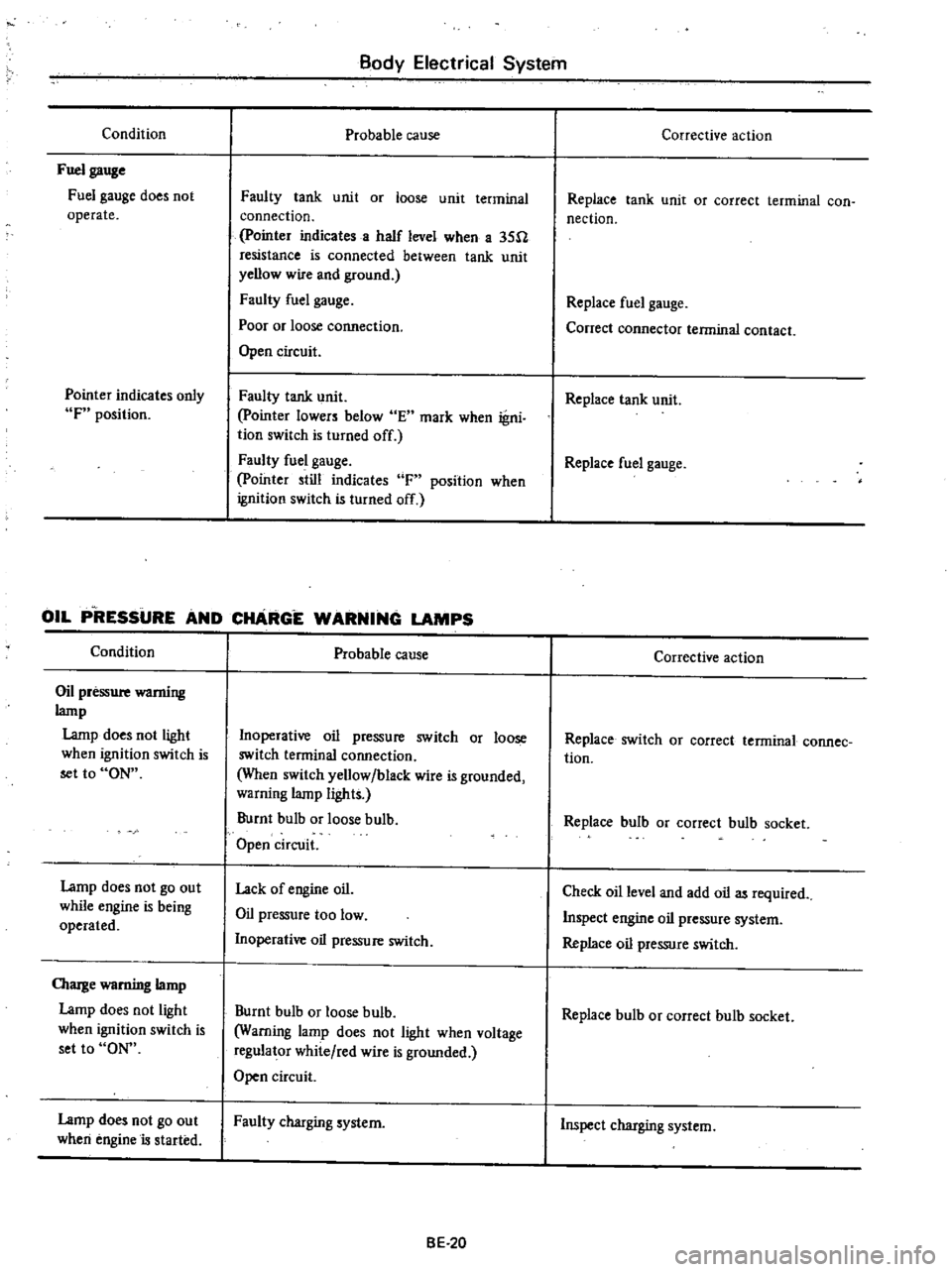

Condition

Fuel

gauge

Fuel

gauge

does

not

operate

Pointer

indicates

only

F

position

Body

Electrical

System

Probable

cause

Faulty

tank

unit

or

loose

unit

terminal

connection

pointer

indicates

a

half

level

when

a

35U

resistance

is

connected

between

tank

unit

yellow

wire

and

ground

Faulty

fuel

gauge

Poor

or

loose

cormection

Open

circuit

Faulty

tank

unit

pointer

lowers

below

E

mark

when

igni

tion

switch

Is

turned

off

Faulty

fuel

gauge

pointer

still

indicates

F

position

when

ignition

switch

is

turned

off

OIL

P

RESSURE

AND

CHARGE

WARNING

LAMPS

Condition

Oil

pressure

wamiug

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

while

engine

is

being

operated

OIarge

warning

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

when

engine

is

started

Probable

cause

Inoperative

oil

pressure

switch

or

loose

switch

terminal

connection

When

switch

yellow

black

wire

is

grounded

warning

lamp

lights

Burnt

bulb

or

loose

bulb

Open

circuit

Lack

of

engine

oil

Oil

pressure

too

low

Inoperative

oil

pressure

switch

Burnt

bulb

or

loose

bulb

Warning

lamp

does

not

light

when

voltage

regulator

white

red

wire

is

grounded

Open

circuit

Faulty

charging

system

BE

20

Corrective

action

Replace

tank

unit

or

correct

terminal

con

nection

Replace

fuel

gauge

Conect

connector

terminal

contact

Replace

tank

unit

Replace

fuel

gauge

Corrective

action

Replace

switch

OJ

correct

terminal

connee

tion

Replace

bulb

or

correct

bulb

socket

Check

oil

level

and

add

oil

as

required

Inspect

engine

oil

pressure

system

Replace

oil

pressure

switch

Replace

bulb

or

correct

bulb

socket

Inspect

charging

system