fuel cap DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 6 of 537

General

Information

L

GENERAL

INFORMATION

CONTENTS

MOOEL

VARIATION

GI

3

APPROXIMATE

REFILL

CAPACITIES

GI

B

IDENTIFICATION

NUMBERS

GI

5

RECOMMENDED

FUEL

GI

B

LIFTING

POINTS

AND

TOWING

GI

B

RECOMMENDED

LUBRICANTS

GI

8

LIFTING

POINTS

GI

B

RECOMMENDED

SAE

VISCOSITY

SUPPORTABLE

POINTS

GI

7

NUMBER

GI

8

TOWING

GI

7

LUBRICANT

SPECIFICATIONS

GI

g

TIE

DOWN

GI

7

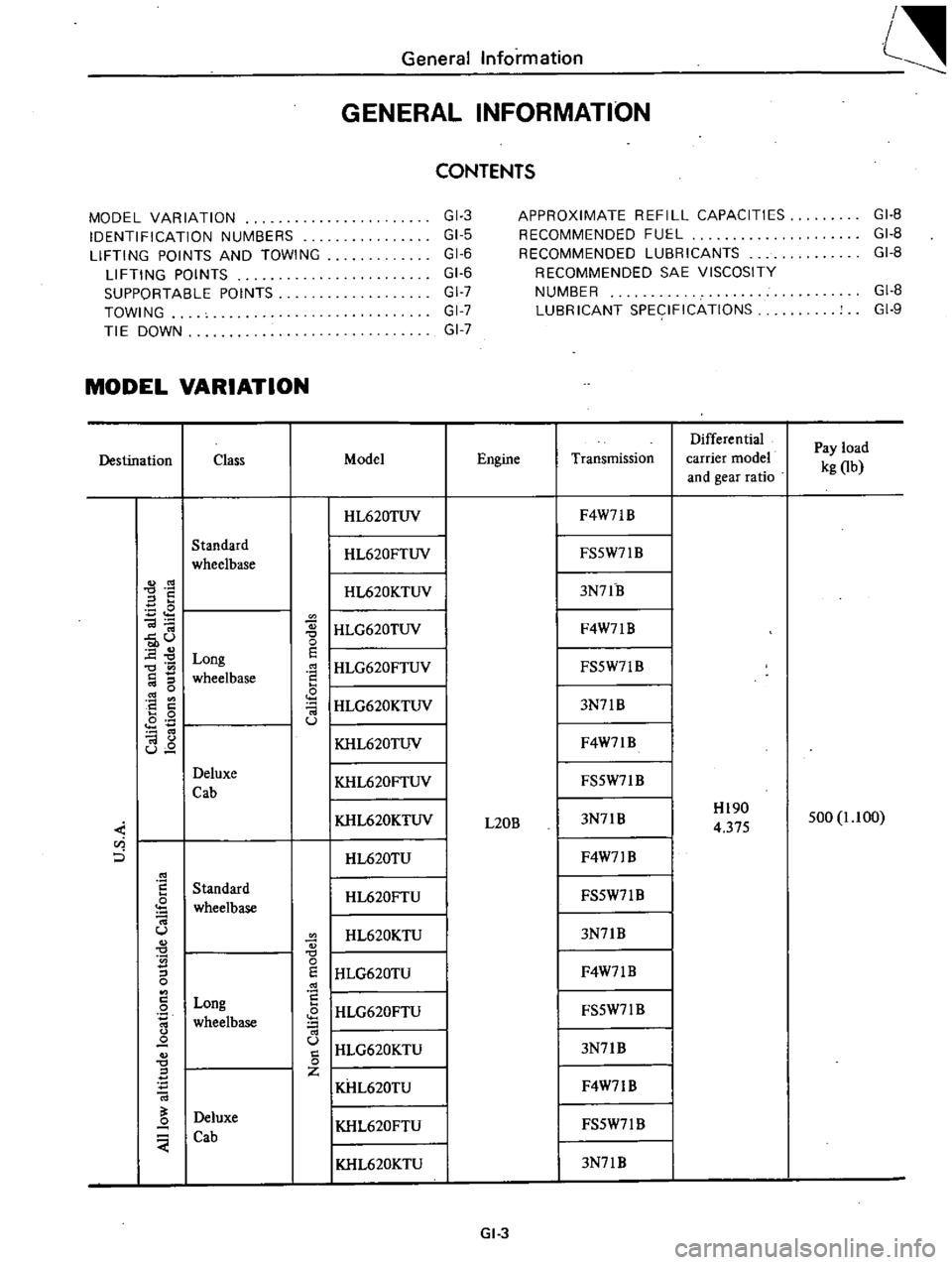

MODEL

VARIATION

Differential

Pay

load

Destination

Class

Model

Engine

Transmission

carrier

model

kg

Ob

and

gear

ratio

I

HL620TUV

F4W7lB

Standard

I

HL620FTUV

FS5W71

B

wheelbase

S

I

HL620KTUV

3N7lB

E

I

HLG620TUV

Ol

F4W7lB

u

0

0

E

Long

E

I

HLG620FTUV

0

FS5W71B

wheelbase

0

I

HLG620KTUV

8

a

3N7lB

0

Ol

0

u

I

KHL620TUV

Ol

F4W7lB

u

Deluxe

I

KHL620FTUV

FS5W7lB

Cab

KHL620KTUV

3N7lB

Hl90

500

1

1

00

L20B

4

375

u

i

0

HL620TU

F4W71

B

Standard

HL620FTU

FS5W7l

B

wheelbase

U

HL620KTU

3N7lB

S

0

I

HLG620TU

0

E

F4W7lB

0

8

Long

I

HLG620FTU

0

FS5W7lB

wheelbase

IHLG620KTU

Q

u

3N7lB

0

0

Z

KHL620TU

F4W71B

Deluxe

Q

KHL620FTU

FS5W7l

B

Cab

I

KHL620KTU

3N7lB

GI

3

Page 11 of 537

General

Information

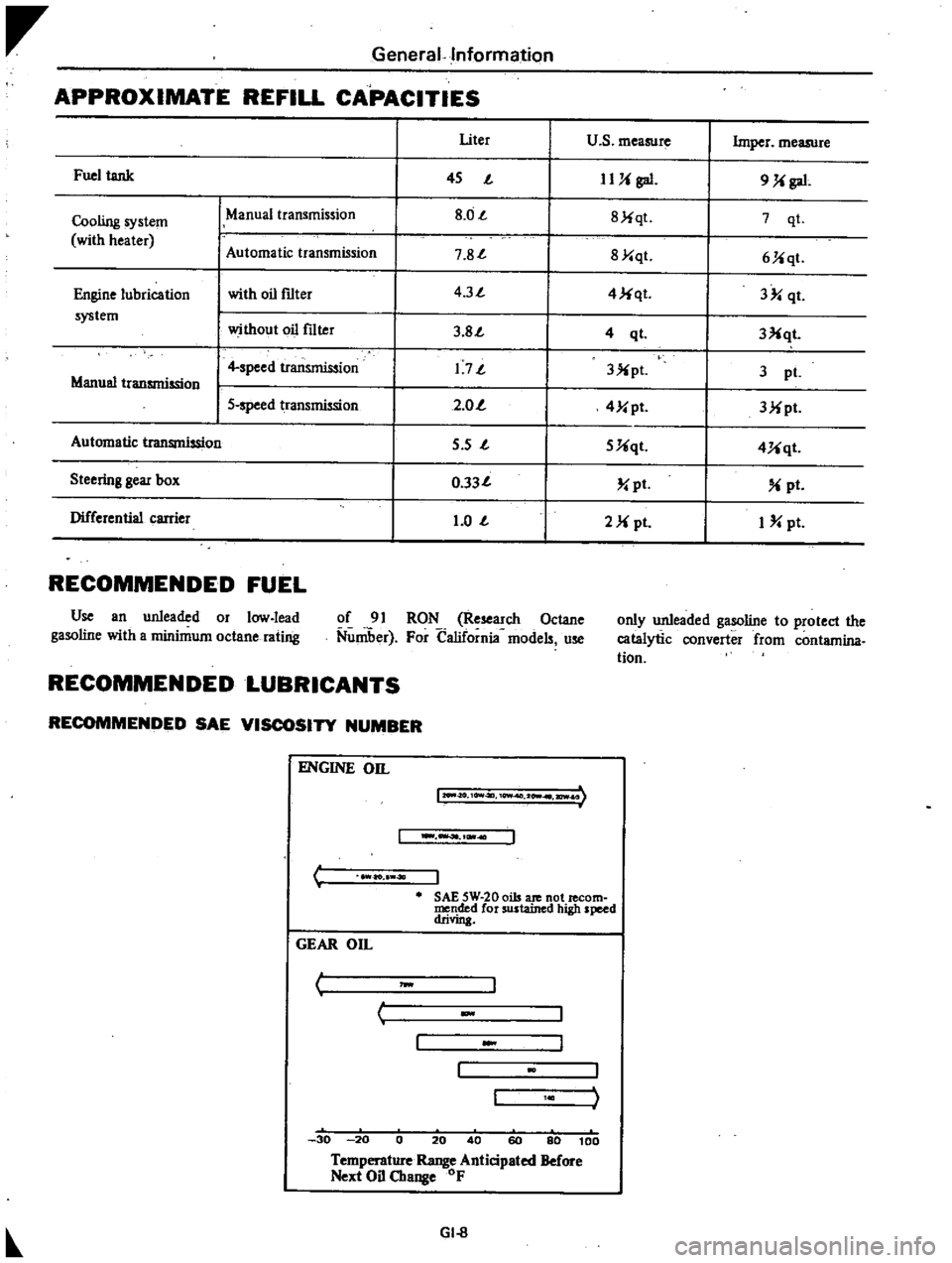

APPROXIMATE

REFILL

CAPACITIES

I

Uter

u

s

measure

Imper

measure

Fuel

tank

I

45

J

IUi

gal

9

Ji

gal

Cooling

system

ManUal

transmission

I

8

0J

I

8Jiqt

7

qt

with

heater

Automatic

tr

smission

I

7

8J

I

8Y

qt

6Jiqt

Engine

lubrication

with

oil

f1lter

I

4

3J

I

4

Ji

qt

3

qt

system

without

oil

f1lter

I

3

8J

I

3Xqt

4

ql

I

4

speed

transmission

I

1

7J

I

3X

pl

3

pI

Manual

transmission

I

5

speed

transmission

I

2

0

I

4Y

pt

3Mpt

Automatic

transmission

I

5

s

J

I

5Uqt

4Uqt

Steering

gear

box

I

0

33J

I

pt

pt

Differential

carrier

I

1

0

J

I

2M

pI

I

pt

RECOMMENDED

FUEL

Use

an

unleaded

or

low

lead

gasoline

with

a

minimum

octane

rating

of

91

RON

Research

Octane

Nuniber

For

California

models

use

only

unleaded

gasoline

to

protect

the

catalytic

converter

from

contamina

tion

RECOMMENDED

LUBRICANTS

RECOMMENDED

SAE

VISCOSITY

NUMBER

C

ENGINE

on

12O

II

O

10Vt4ll

10Wf

2

I

ICWI

I

ao

40

J

SAE

5W

20

oils

ate

not

lecom

mended

for

sustained

high

speed

drivin

GEAR

On

I

J

w

c

30

20

0

20

40

60

80

100

Temperature

Range

Anticipated

Before

Next

Oil

Change

OF

GI

8

Page 21 of 537

Yellow

line

Spark

delay

valve

to

distributor

Spark

delay

valve

to

vacuum

tube

Distributor

to

vacuum

tube

Vacuum

tube

to

carburetor

Vacuum

tube

to

canister

Green

line

Anti

backfire

valve

to

intake

mani

fold

Air

control

valve

to

emergency

air

relief

valve

Intake

manifold

to

vacuum

hose

connector

Intake

manifold

to

canister

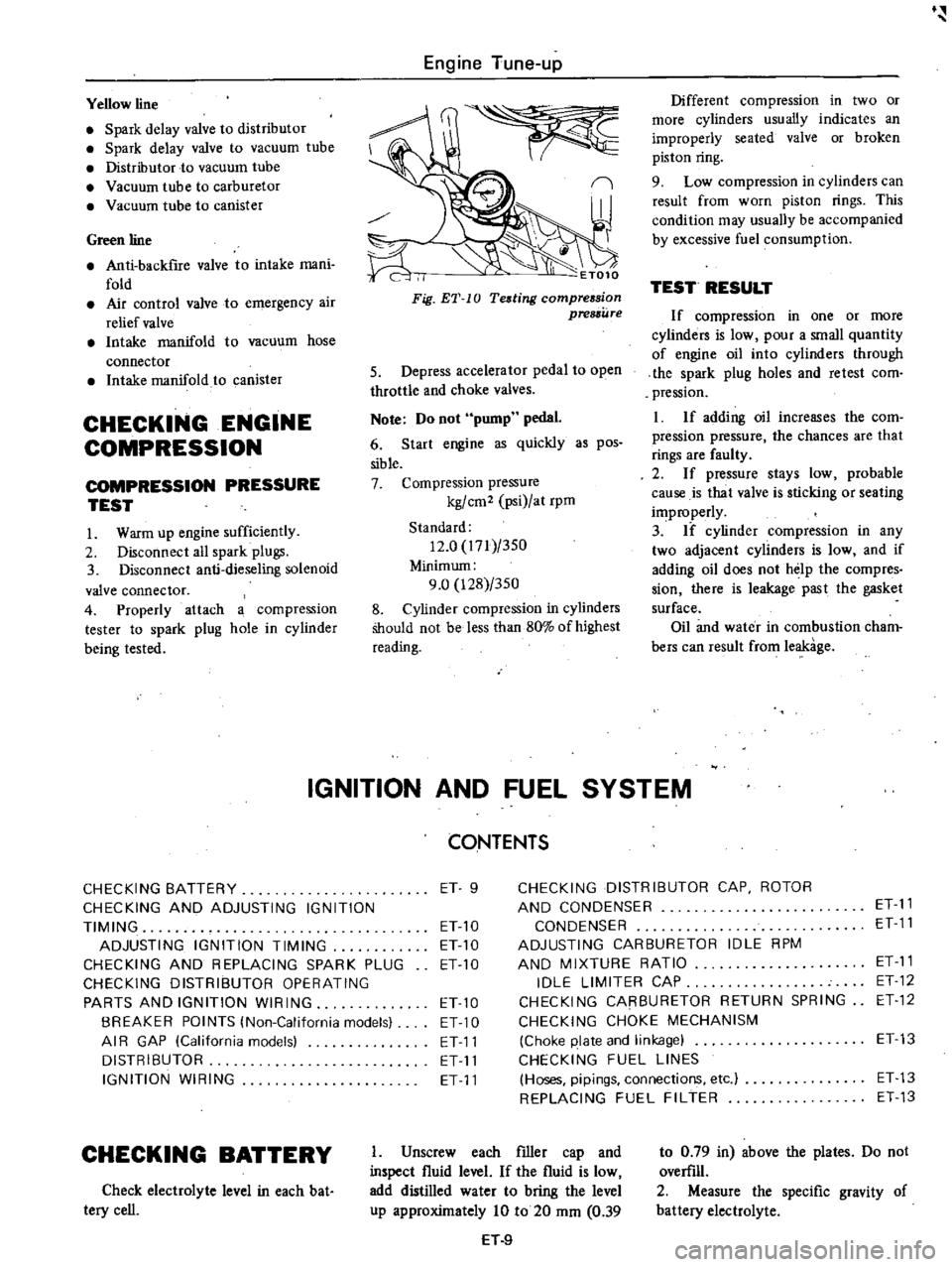

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

I

Warm

up

engine

sufficiently

2

Disconnect

all

spark

plugs

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Properly

attach

a

compression

tester

to

spark

plug

hole

in

cylinder

being

tested

Engine

Tune

up

I

ET010

Different

compression

in

two

or

more

cylinders

usually

indicates

an

improperly

seated

valve

or

broken

piston

ring

9

Low

compression

in

cylinders

can

result

from

worn

piston

rings

This

condition

may

usually

be

accompanied

by

excessive

fuel

consumption

TEST

RESULT

If

compression

in

one

or

more

cylinders

is

low

pour

a

small

quantity

of

engine

oil

into

cylinders

through

the

spark

plug

holes

and

retest

com

pression

I

If

adding

oil

increases

the

com

pression

pressure

the

chances

are

that

rings

are

faulty

2

If

pressure

stays

low

probable

cause

is

that

valve

is

sticking

or

seating

improperly

3

If

cylinder

compression

in

any

two

adjacent

cylinders

is

low

and

if

adding

oil

does

not

help

the

compres

sian

there

is

leakage

past

the

gasket

surface

Oil

and

water

in

combustion

cham

bers

can

result

from

leakage

IGNITION

AND

FUEL

SYSTEM

Fig

ET

10

Teding

compression

pressure

5

Depress

accelerator

pedal

to

open

throttle

and

choke

valves

Note

Do

not

pump

pedal

6

Start

engine

as

quickly

as

pos

sible

7

Compression

pressure

kg

cm2

psi

at

rpm

Standard

12

0

171

350

Minimum

9

0

128

350

8

Cylinder

compression

in

cylinders

Should

not

be

less

than

80

of

highest

reading

CONTENTS

CHECKING

BATTERY

ET

9

CHECKING

DISTRIBUTOR

CAP

ROTOR

CHECKING

AND

ADJUSTING

IGNITION

AND

CONDENSER

ET

11

TIMING

ET

10

CONDENSER

ET

11

ADJUSTING

IGNITION

TIMING

ET10

ADJUSTING

CARBURETOR

IDLE

RPM

CHECKING

AND

REPLACING

SPARK

PLUG

ETlO

AND

MIXTURE

RATIO

ET

11

CHECKING

DISTRIBUTOR

OPERATING

IDLE

LIMITER

CAP

ET

12

PARTS

AND

IGNITION

WIRING

ETlO

CHECKING

CARBURETOR

RETURN

SPRING

ET

12

BREAKER

POINTS

lNon

California

models

ET

10

CHECKING

CHOKE

MECHANISM

AI

R

GAP

lCalifornia

models

ET11

Choke

plate

and

linkage

ET13

DISTRIBUTOR

ET

11

CHECKING

FUEL

LINES

IGNITION

WIRING

ET

11

Hoses

pipings

connections

etc

ET

13

REPLACING

FUEL

FILTER

ET

13

CHECKING

BATTERY

Check

electrolyte

level

in

each

bat

tery

cell

I

Unscrew

each

filler

cap

and

inspect

fluid

level

If

the

fluid

is

low

add

distilled

water

to

bring

the

level

up

approximately

10

to

20

mm

0

39

H

9

to

0

79

in

above

the

plates

Do

not

overfill

2

Measure

the

specific

gravity

of

battery

electrolyte

Page 34 of 537

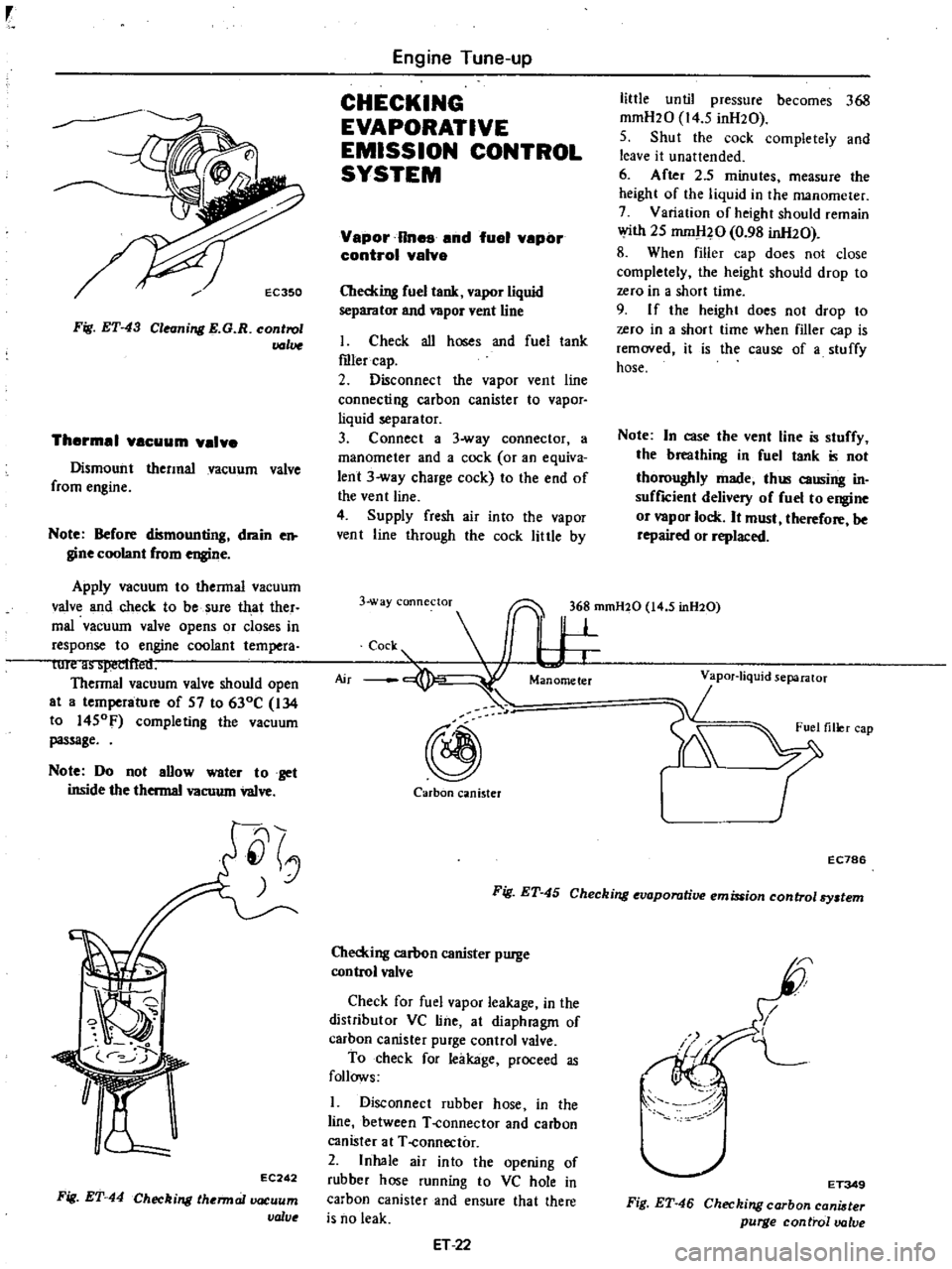

r

EC350

Fig

ET

43

Cleanill

l

E

G

R

control

lJ

Jlue

Thermal

VBCuum

valve

Dismount

thermal

vacuum

valve

from

engine

Note

Before

dismounting

drain

e

gine

coolant

from

engine

Apply

vacuum

to

thermal

vacuum

valve

and

check

to

be

sure

that

ther

mal

vacuum

valve

opens

or

closes

in

response

to

engine

coolant

tempera

lurt

i1

i

iYCl

lt

lt

U

Thermal

vacuum

valve

should

open

at

a

temperature

of

57

to

630C

134

to

1450F

completing

the

vacuum

passage

Note

Do

not

aUow

water

to

get

inside

the

thermal

vacuum

valve

EC

242

Fig

ET

44

Checkill

lthermallXlCuum

valve

Engine

Tune

up

CHECKING

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

Vapor

Rnes

and

fuel

vepor

control

valve

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

I

Check

all

hoses

and

fuel

tank

roler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

with

25

mm

l20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thl

causing

in

suffICient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connectoT

36

mmH20

14

5

inH20

c

s

I

W

@

Carbon

canister

r

EC786

Fig

ET

45

Checking

evaporative

emission

control

By

tem

Checking

carbon

canister

purge

control

valve

Check

for

fuel

vapor

leakage

in

the

distributor

VC

line

at

diaphragm

of

carhon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

1

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

VC

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET

22

I

I

L

I

ET349

Fig

ET

46

Checking

carbon

cani

ter

purge

control

valve

Page 35 of 537

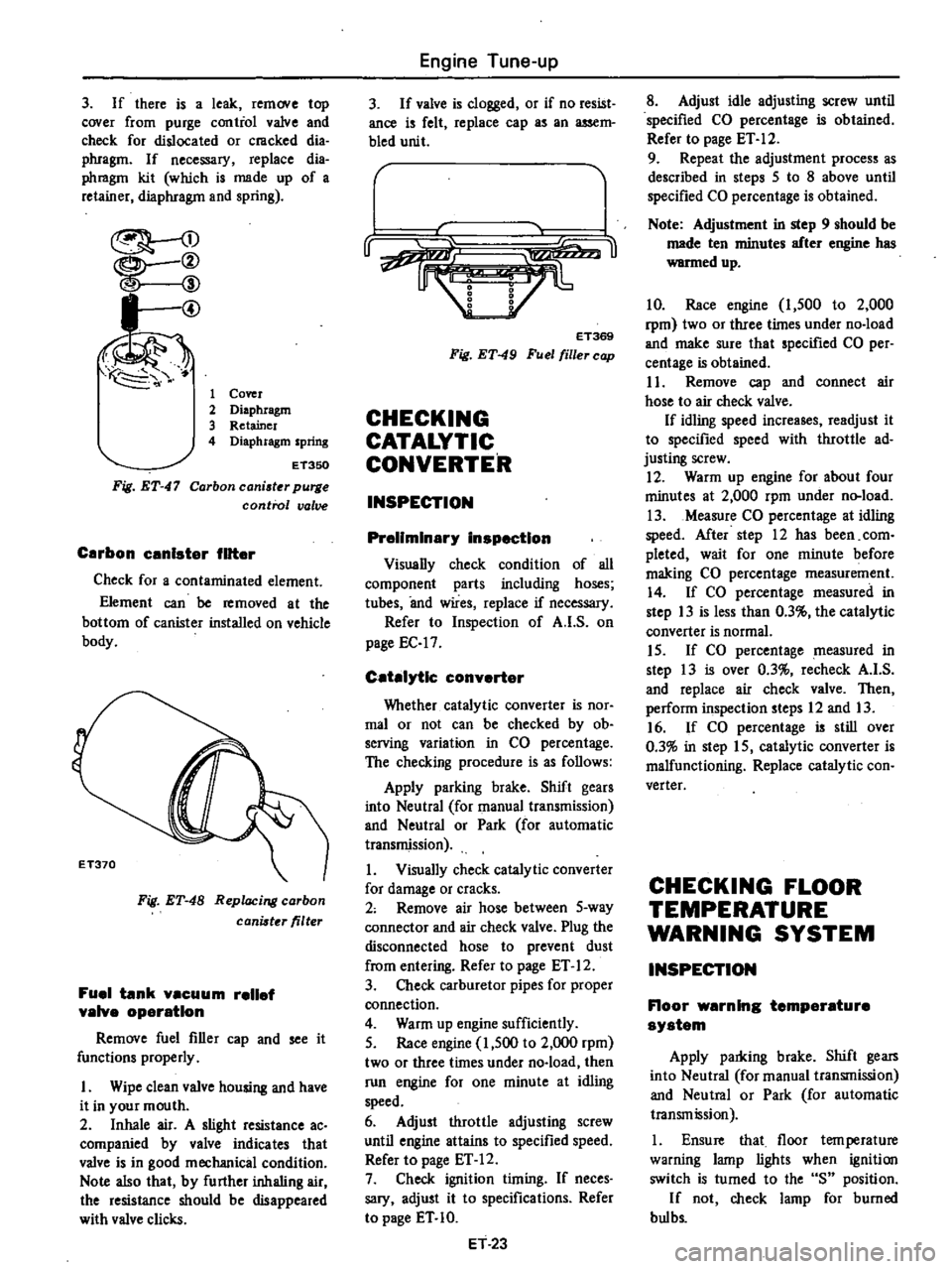

3

If

there

is

a

leak

remove

top

cover

from

purge

contiol

valve

and

check

for

dislocated

or

cmcked

dia

phragm

If

necessary

replace

dia

phmgm

kit

which

is

made

up

of

a

retainer

diaphragm

and

spring

I

@

1

Cover

2

Diaphragm

3

Retainer

4

Diaphragm

spring

Fig

ET

47

ET350

Carbon

caniater

purge

control

valve

Carbon

unlster

filter

Check

for

a

contaminated

element

Element

can

be

removed

at

the

bottom

of

canister

installed

on

vehicle

body

Fig

ET

48

Replacing

carbon

canister

filter

Fuel

tank

vacuum

relief

valve

operation

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

Engine

Tune

up

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

r

u

ET369

Fig

ET

49

Fuel

filler

cap

CHECKING

CATALYTIC

CONVERTER

INSPECTION

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

hoses

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nOf

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

12

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

Refer

to

page

ET

10

ET

23

8

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adjustment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

warmed

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

I

1

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

Warm

up

engine

for

about

four

minutes

at

2

000

rpm

under

n

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

com

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalylic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

converter

is

malfunctioning

Replace

catalytic

con

verter

CHECKING

FLOOR

TEMPERATURE

WARNING

SYSTEM

INSPECTION

Floor

warning

temperature

system

Apply

parldng

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Ensure

that

floor

tern

perature

warning

lamp

lights

when

ignition

switch

is

turned

to

the

S

position

If

not

check

lamp

for

burned

bul

bs

Page 40 of 537

Engine

Tune

up

Condition

Probable

cause

Low

or

no

current

Ign

tion

system

out

of

order

Burned

distributor

point

Improper

point

gap

Faulty

condenser

Leak

at

rotor

cap

and

rotor

Faulty

spark

plug

Improper

ignition

timing

Faulty

ignition

coil

Disconnection

of

high

tension

cable

Loose

connection

or

disconnection

in

primary

circuit

Fuel

system

out

of

order

Lack

offuel

Dirty

fuel

strainer

Dirty

or

clogged

fuel

pipe

Fuel

pump

will

not

work

properly

Carburetor

choke

will

not

work

properly

Improper

adjustment

of

float

level

Improper

idling

Dirty

or

clogged

carburetor

Clogged

breather

pip

of

fuel

tank

Malfunctioning

an

ti

dieseling

solenoid

valve

Incorrect

sparle

plug

tightening

or

faulty

gasket

Improper

grade

engine

oil

or

low

viscosity

Incorrect

valve

clearance

Compression

leak

from

valve

seat

Sticky

valve

stem

Weak

or

damaged

valve

springs

Compression

leak

at

cylinder

head

gasket

Sticking

or

damaged

piston

ring

Worn

piston

ring

or

cylinder

Trouble

ooting

procedure

Pour

the

engine

oil

from

plug

hole

and

then

measure

cylinder

compression

Compression

increases

Compression

does

not

change

Low

comp

ion

ET

28

Corrective

action

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Repair

or

replace

Adjust

Replace

Clean

or

replace

aean

adjust

plug

gap

or

replace

Adjust

Replace

Replace

Repair

or

replace

Supply

Replace

Clean

Repair

or

replace

Check

and

adjust

Correct

Adjust

Disassemble

and

clean

Repair

and

clean

Check

for

loose

terminal

or

wire

harness

Tighten

to

normal

torque

or

replace

gasket

Replace

with

proper

grade

oil

Adjust

Remove

cyljnder

head

and

lap

valves

Correct

or

replace

valve

and

valve

guide

Replace

valve

springs

Replace

gasket

Replace

piston

rings

Overhaul

engine

Malfunctiong

cylinder

or

piston

ring

Compression

leaks

from

valve

cylinder

head

or

head

gasket

Except

transistor

ignition

system

Page 42 of 537

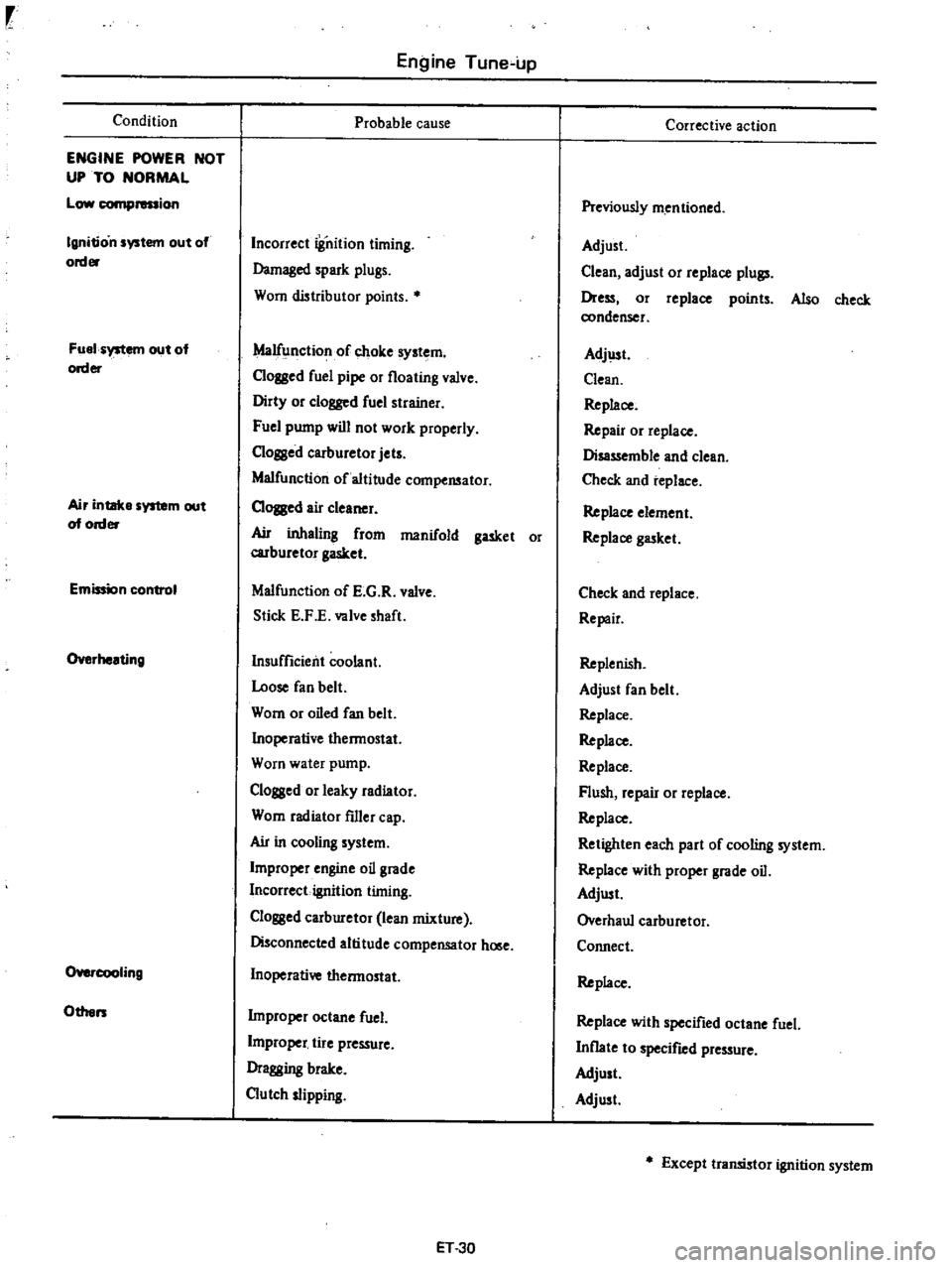

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compression

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

O

cooIing

Others

Engine

Tune

up

Probable

cause

Incorrect

iSnition

timing

Damaged

spark

plugs

Worn

distributor

points

Malfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

C10ssed

carburetor

jets

Malfunction

of

altitude

compensator

CIOJBed

air

cleaner

Ail

inhaling

from

manifold

gasket

or

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

belt

Worn

or

oiled

fan

belt

Inoperative

thermostat

Worn

water

pump

Clogged

or

leaky

radiator

Worn

radiator

filler

cap

Ail

in

cooling

system

Improper

engine

oil

grade

Incorrect

ignition

timing

Clossed

carburetor

lean

mixture

Disconnected

altitude

compensator

hOlle

Inoperative

thermostat

Improper

octane

fuel

L

j

tire

pressure

Dragging

brake

Clutch

slipping

ET

30

Corrective

action

Previously

mentioned

Adjust

Clean

adjust

or

replace

plull

Dress

or

replace

points

Also

check

condenser

Adj

lst

Clean

Replace

Repair

or

replace

Disassemble

and

clean

Check

and

replace

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Connect

Replace

Replace

with

specified

octane

fuel

Inflate

to

specified

pressure

Adjust

Adjust

Except

transistor

ignition

system

Page 51 of 537

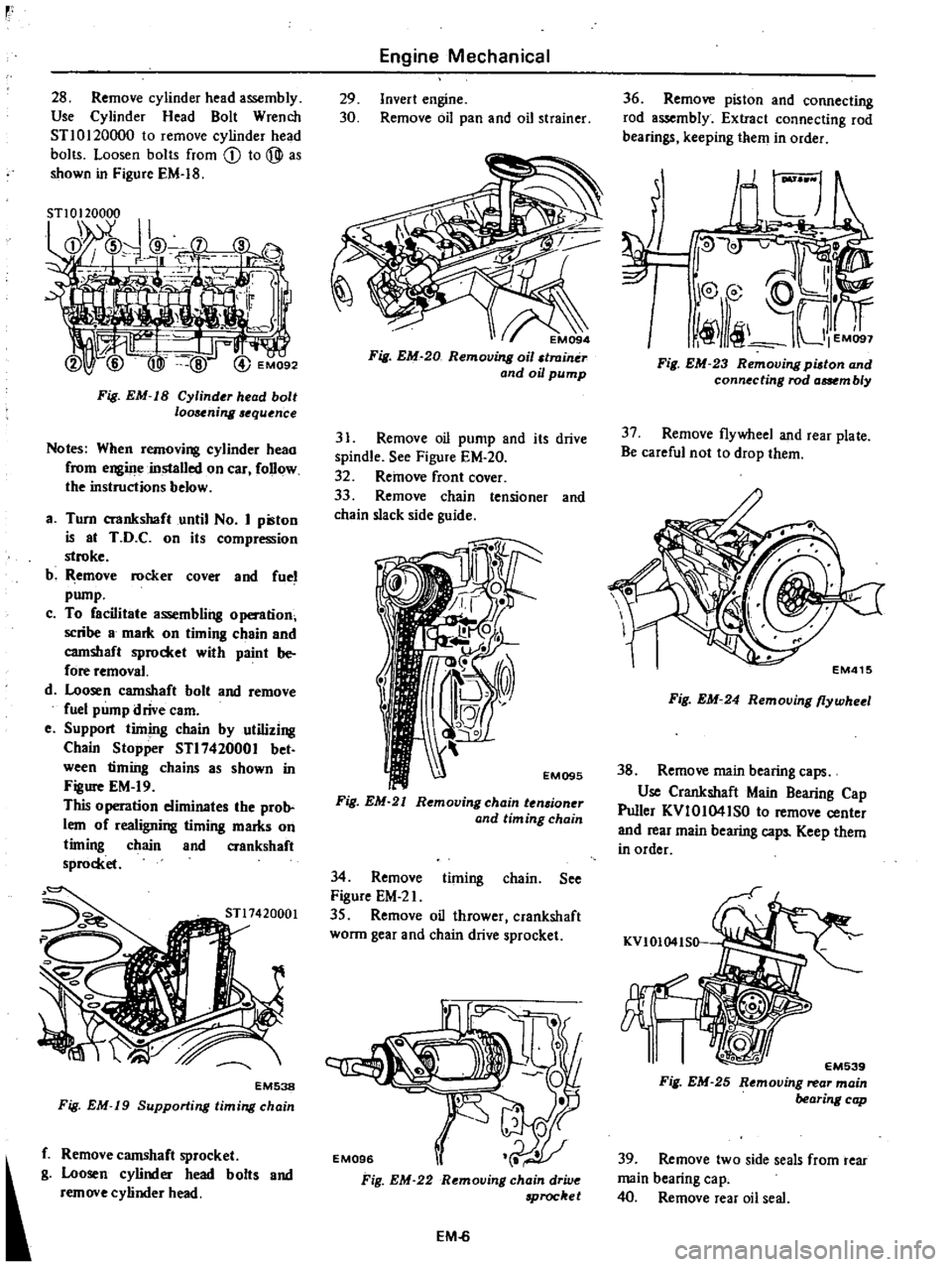

r

28

Remove

cylinder

head

assembly

Use

Cylinder

Head

Bolt

Wrench

STl0120000

to

remove

cylinder

head

bolts

Loosen

bolts

from

CD

to

@

as

shown

in

Figure

EM

18

Fig

EM

IS

Cylinder

head

bolt

loosening

equence

Notes

When

removing

cylinder

heao

from

engiJJe

installed

on

car

follow

the

instructions

below

a

Turn

crankshaft

until

No

I

pilton

is

at

T

D

C

on

its

compression

stroke

b

Remove

rocker

Cover

and

fuel

pump

c

To

facilitate

assembling

o

tion

scribe

8

mark

on

timing

c

8in

and

camshaft

sprocket

with

paint

be

fore

removal

d

Loosen

camshaft

bolt

and

remove

fuel

pump

drive

earn

e

Support

timing

chain

by

utilizing

Chain

Stopper

STl7420001

bet

ween

timiilg

chains

as

shown

in

Figure

EM

19

This

0

peration

eliminates

the

prob

lem

of

realigning

timing

marks

on

timing

chain

and

crankshaft

sprocket

EM538

Fig

EM

19

Supporting

timing

chain

f

Remove

camshaft

sprocket

g

Loosen

cylinder

head

bolts

and

remove

cylinder

head

Engine

Mechanical

29

Invert

engine

30

Remove

oil

pan

and

oil

strainer

EM094

Fig

EM

20

Removing

oil

traintir

and

oil

pump

31

Remove

oil

pump

and

its

drive

spindle

See

Figure

EM

20

32

Remove

front

cover

33

Remove

chain

tensioner

and

chain

slack

side

guide

EM095

Fig

EM

21

Removing

chain

ten

ioner

and

tim

ing

chain

34

Remove

timing

chain

See

Figure

EM

2l

35

Remove

oil

thrower

crankshaft

wonn

gear

and

chain

drive

sprocket

Fig

EM

22

Removing

chain

drive

Proc

et

EM

6

36

Remove

piston

and

connecting

rod

a

mbly

Extract

connecting

rod

bearings

keeping

them

in

order

I

Fig

EM

23

Removing

pilton

and

connecting

rod

aat

m

b

y

37

Remove

flywheel

and

rear

plate

Be

careful

not

to

drop

them

EM415

Fig

EM

24

Removing

flywheel

38

Remove

main

bearing

caps

Use

Crankshaft

Main

Bearing

Cap

Puller

KVIOI04ISO

to

remove

center

and

rear

main

bearing

caps

Keep

them

in

order

KVIOI04IS0

EM539

Fig

EM

25

Removing

rear

main

bearing

cap

39

Remove

two

side

seals

from

rear

main

bearing

ca

p

40

Remove

rear

oil

seal

Page 66 of 537

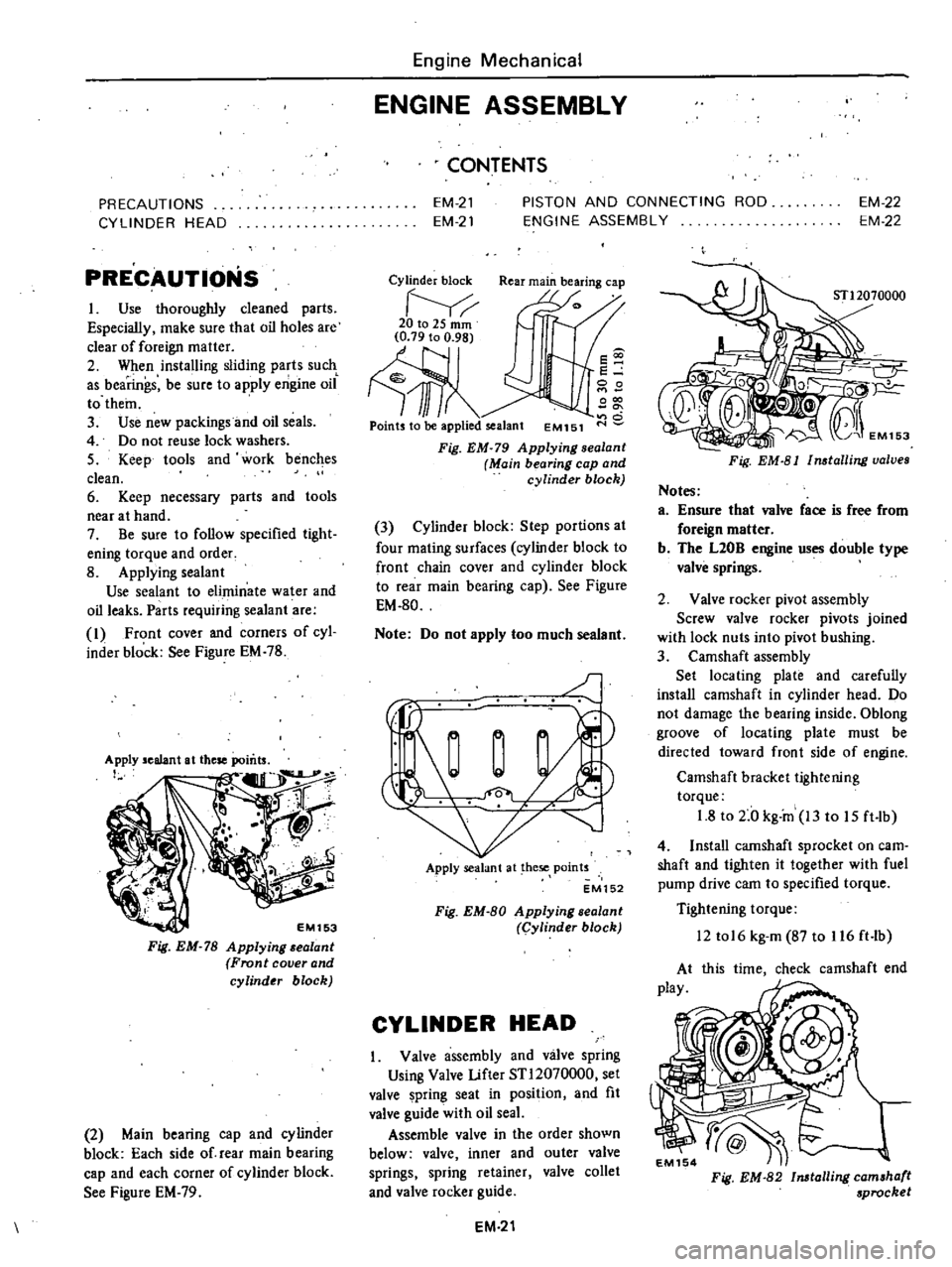

PRECAUTIONS

CYLINDER

HEAD

PRECAUTIONS

I

Use

thoroughly

cleaned

parts

Especially

make

sure

that

oil

holes

are

clear

of

foreign

matter

2

When

installing

sliding

parts

such

as

bearings

be

s

uIe

to

apply

engine

oil

to

them

3

Use

new

packing

and

oil

seals

4

Do

not

reuse

lock

washers

5

Keep

tools

and

work

benches

clean

6

Keep

necessary

parts

and

tools

near

at

hand

7

Be

sure

to

follow

specified

tight

ening

torque

and

order

8

Applying

sealant

Use

sealant

to

eliminate

water

and

oil

leaks

Parts

requiring

sealant

are

I

Front

cover

and

corners

of

cyl

inder

block

See

Figure

EM

78

EM153

Fig

EM

78

Applying

alant

Front

cover

and

cylinder

block

2

Main

bearing

cap

and

cylinder

block

Each

side

of

rear

main

bearing

cap

and

each

corner

of

cylinder

block

See

Figure

EM

79

Engine

Mechanical

ENGINE

ASSEMBLY

CONTENTS

EM

21

EM

21

PISTON

AND

CONNECTING

ROD

ENGINE

ASSEMBLY

EM

22

EM

22

Cylinder

block

Rear

main

bearing

cap

20to2Smm

Ill

Points

to

be

applied

sealant

EM151

s

e

00

000

o

Fig

EM

79

Applying

sealanl

Main

bearing

cap

and

cylinder

block

3

Cylinder

block

Step

portions

at

four

mating

surfaces

cylinder

block

to

front

chain

cover

and

cylinder

block

to

rear

main

bearing

cap

See

Figure

EM

80

Note

Do

not

apply

too

much

sealant

J

Apply

sealant

at

hese

points

EM152

Fig

EM

80

Applying

sealant

Cylinder

block

CYLINDER

HEAD

Valve

assembly

and

valve

spring

Using

Valve

Lifter

STl2070000

set

valve

pring

seat

in

position

and

fit

valve

guide

with

oil

seaL

Assemble

valve

in

the

order

shown

below

valve

inner

and

outer

valve

springs

spring

retainer

valve

collet

and

valve

rocker

guide

EM

21

Fig

EM

81

Installing

valves

Notes

a

Ensure

that

valve

face

is

free

from

foreign

matter

b

The

L20B

engine

uses

double

type

valve

springs

2

Valve

rocker

pivot

assembly

Screw

valve

rocker

pivots

joined

with

lock

nuts

into

pivot

hushing

3

Camshaft

assembly

Set

locating

plate

and

carefully

install

camshaft

in

cylinder

head

Do

not

damage

the

bearing

inside

Oblong

groove

of

locating

plate

must

be

directed

toward

front

side

of

engine

Camshaft

bracket

tightening

torque

1

8

to

2

0

kg

in

13

to

15

ft

lb

4

Install

camshaft

sprocket

on

earn

shaft

and

tighten

it

together

with

fuel

pump

drive

cam

to

specified

torque

Tightening

torque

12

tol6

kg

m

87

to

116

ft

lb

this

time

check

camshaft

end

Fig

EM

82

Installing

camshaft

sprocket

Page 75 of 537

Engine

Mechanical

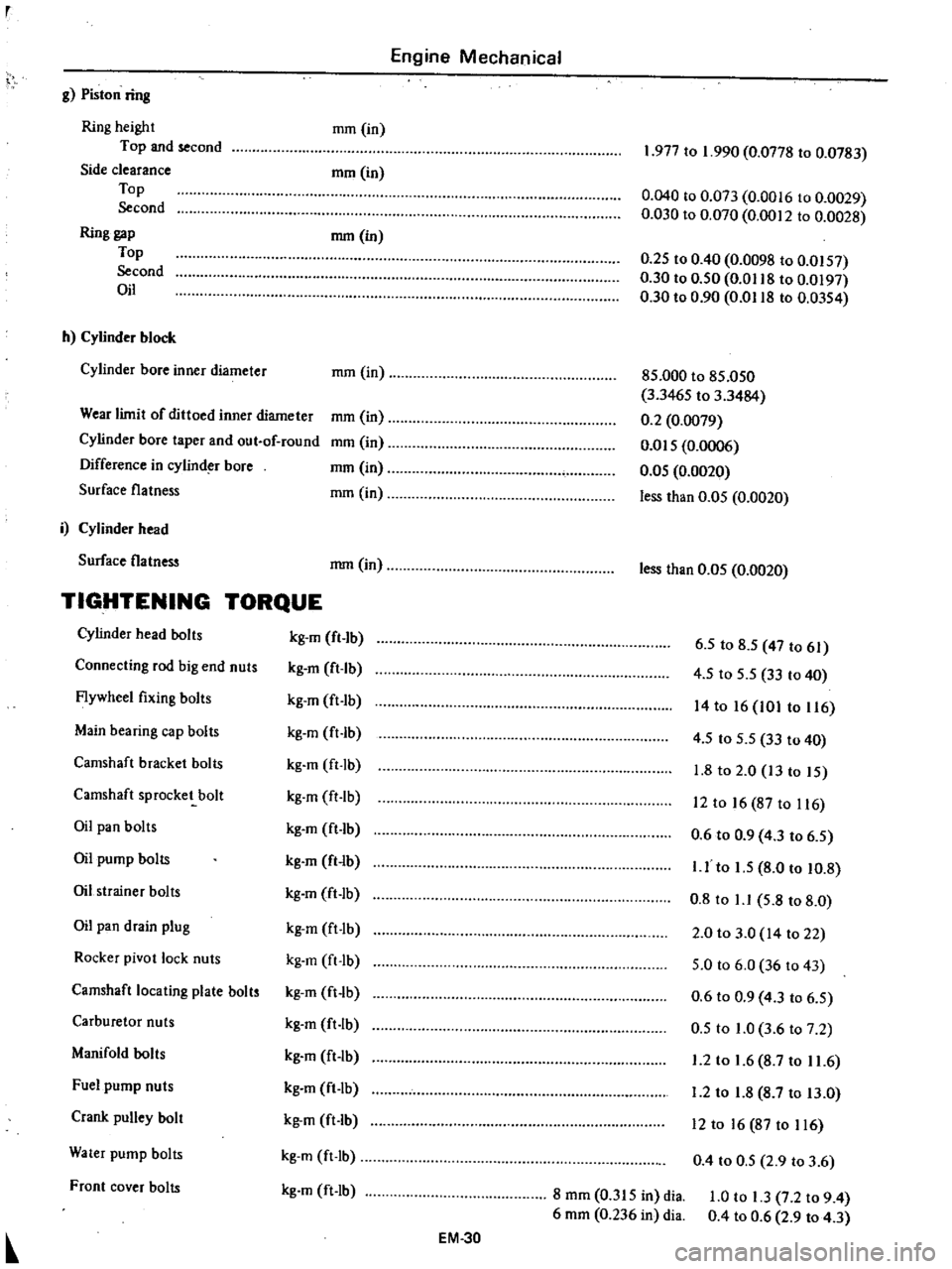

g

Piston

ring

Ring

height

Top

and

second

Side

clearance

Top

Second

Ring

gap

Top

Second

Oil

mm

in

mrn

in

mm

in

h

Cylinder

block

Cylinder

bore

inner

diameter

mm

in

Wear

limit

of

dittoed

inner

diameter

Cylinder

bore

taper

and

out

of

round

Difference

in

cylind

bore

Surface

flatness

mm

in

mm

in

mm

in

mm

in

i

Cylinder

head

Surface

flatness

mm

in

TIGHTENING

TORQUE

Cylinder

head

bolts

kg

m

fl

lb

Connecting

rod

big

end

nuts

kg

m

ft

Ib

Flywheel

fixing

bolts

kg

m

ft

Ib

Main

bearing

cap

bolts

kg

m

ft

lb

Camshaft

bracket

bolts

kg

m

ft

lb

Camshaft

sprocket

bolt

kg

m

ft

lb

Oil

pan

bolts

kg

m

ft

1b

Oil

pump

bolts

kg

m

ft

lb

Oil

strainer

bolts

kg

m

ft

lb

Oil

pan

drain

plug

kg

m

ft

lb

Rocker

pivot

lock

nuts

kg

m

ft

Ib

Camshaft

locating

plate

bolts

kg

m

ft

lb

Carburetor

nuts

kg

m

ft

lb

Manifold

bolts

kg

m

ft

lb

Fuel

pump

nuts

kg

m

ft

lb

Crank

pulley

bolt

kg

m

ft

lb

Water

pump

bolts

kg

m

ft

Ib

Front

cover

bolts

kg

m

ft

lb

EM

30

1

977

to

1

990

0

0778

to

0

0783

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

0

0012

to

0

0028

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0118

to

0

0197

0

30

to

0

90

0

0118

to

0

0354

85

000

to

85

050

3

3465

to

3

3484

0

2

0

0079

om

5

0

0006

0

05

0

0020

less

than

0

05

0

0020

less

than

0

05

0

0020

6

5

to

8

5

47

to

61

4

5

to

5

5

33

to

40

14

to

16

101

to

116

4

5

to

5

5

33

to

40

1

8

to

2

0

13

to

15

12

to

16

87

to

116

0

6

to

0

9

4

3

to

6

5

I

J

to

1

5

8

0

to

10

8

0

8

to

1

1

5

8

to

8

0

2

0

to

3

0

14

to

22

5

0

to

6

0

36

to

43

0

6

to

0

9

4

3

to

6

5

0

5

to

1

0

3

6

to

7

2

1

2

to

1

6

8

7

to

11

6

1

2

to

1

8

8

7

to

13

0

12

to

16

87

to

116

0

4

to

0

5

2

9

to

3

6

8

mm

0

315

in

dia

6

mm

0

236

in

dia

1

0

to

1

3

7

2

to

9

4

0

4

to

0

6

2

9

to

4

3