relay DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 29 of 537

OPERATI

NG

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

C

D

D

ADJUSTMENT

CHECKING

a

C

D

D

CIRCUIT

WITH

FUNCTION

TEST

CONNECTOR

Manual

transmission

models

I

Check

for

continuity

between

@

and@

at

a

speed

of

zero

km

Refer

to

Figure

ET

30

B

C

D

D

circuit

is

functioning

properly

if

continuity

exists

and

volt

meter

reading

is

0

volt

d

c

in

step

2

below

If

continuity

does

not

exist

check

for

disconnected

connector

and

or

faulty

amplifier

speed

detecting

switch

or

B

C

D

D

solenoid

valve

2

Check

for

presence

of

voltage

across

@

and

@

at

a

speed

of

more

than

16

km

h

10

MPH

Refer

to

Figure

ET

31

Conduct

this

test

by

one

of

the

following

two

methods

i

Raising

up

rear

axle

housing

with

stand

2

Chassis

dynamometer

test

If

voltmeter

reading

is

0

volt

at

a

speed

of

more

than

16

km

h

10

MPH

circuit

is

functioning

prop

erly

If

voltmeter

reading

is

not

0

volt

check

for

disconnected

connector

burned

fuse

faulty

amplifier

B

C

D

D

solenoid

valve

or

speed

detecting

switch

3

If

by

above

checks

faulty

part

or

unit

is

located

it

should

be

removed

and

tested

again

If

necessary

replace

Automatic

transmission

models

I

With

inhibitor

switch

ON

UN

or

P

position

check

for

presence

of

voltage

across

@

and

@

Refer

to

Figure

ET

30

If

voltmeter

reading

is

12

volts

d

c

B

C

D

D

circuit

is

func

tioning

properly

Engine

Tune

up

If

voltmeter

reading

is

zero

check

for

disconnected

connector

faulty

solenoid

valve

or

inhibitor

switch

erly

If

ohmmeter

reading

is

32

ohms

or

above

check

for

poor

connection

of

connector

faulty

B

C

D

D

sole

noid

valve

or

inhibitor

relay

3

If

by

above

checks

faulty

part

or

unit

is

located

it

should

be

removed

and

tested

again

If

necessary

replace

2

With

inhibitor

switch

OFF

41

2

D

or

R

position

check

for

resistance

between

@

and

@

Refer

to

Figure

ET

31

If

ohmmeter

reading

is

25

ohms

or

below

circuit

is

functioning

prop

l

E

r

1

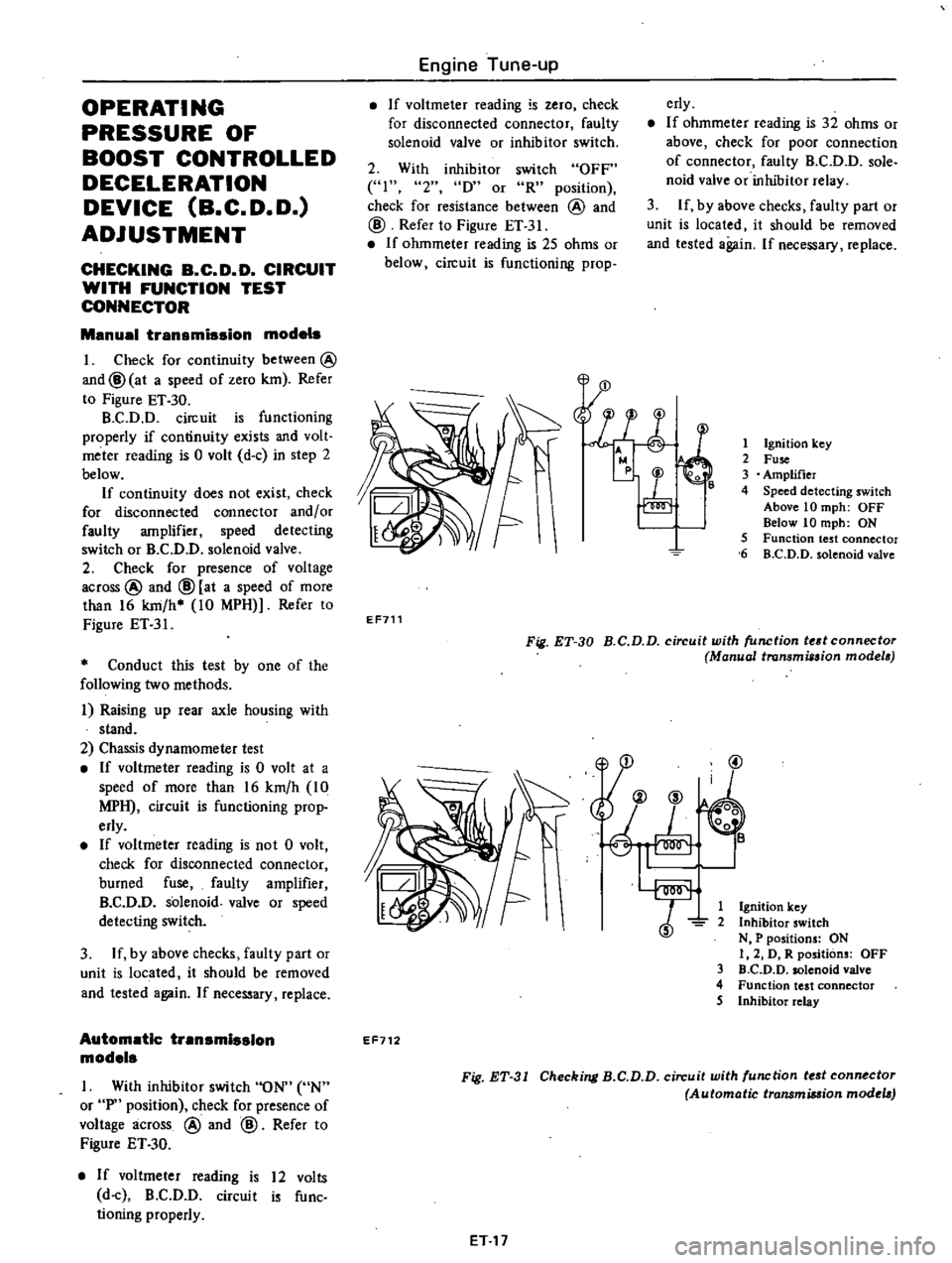

Ignition

key

2

Fuse

3

Amplifier

4

Speed

detecting

switch

Above

10

mph

OFF

Below

10

mph

ON

5

Function

test

connector

6

B

C

D

D

solenoid

valve

EF711

Fig

ET

30

B

C

D

D

circuit

with

function

tedconnectoT

Manual

transmission

modela

@

1

Ignition

key

2

Inhibitor

switch

N

P

positions

ON

I

2

D

R

positions

OFF

3

D

C

D

D

solenoid

valve

4

Function

test

connector

5

Inhibitor

relay

EF712

Fig

ET

31

Checking

B

C

D

D

circuit

with

function

tf

st

connf

ctor

Automatic

transmiMion

modtla

ET

17

Page 36 of 537

Replace

bulb

if

bulb

is

burned

ou

t

If

bulb

is

not

burned

trace

wireis

back

to

ignition

switch

Repair

or

replace

if

necessary

2

Be

sure

that

floor

temperature

is

cool

below

800C

1760F

before

carrying

out

the

following

procedure

1

Remove

rear

seat

2

Ignition

switch

is

turned

to

the

Temperature

sensing

switch

Temperature

warning

lamp

Contact

close

Off

Contact

open

On

Note

Avoid

heating

floor

tempera

ture

sensing

switch

directly

If

lamp

does

not

glow

check

floor

temperature

sensing

switch

connector

for

continuity

with

a

circuit

tester

If

continuity

should

exist

after

heated

surrounding

areas

of

floor

tern

rv

wnTP

sen

cinq

S

Vitch

reolace

tem

perature

sensing

switch

If

continuity

does

not

exist

trace

the

wiring

back

to

relay

or

check

the

following

step

3

Repair

or

replace

wire

s

if

necessary

Note

The

floor

temperature

sensing

switch

may

be

heated

through

the

floor

by

a

proper

heater

3

Turn

ignition

switch

to

the

IG

position

anf

disconnect

floor

temper

ature

sensing

connector

The

lamp

should

remain

on

If

not

check

floor

4

0

3

UJ

GJO

Engine

Tune

up

IGU

position

3

Ensure

that

floor

tem

perature

warning

lamp

goes

out

4

Heat

surrounding

areas

of

floor

temperature

sensing

switch

with

a

proper

heater

to

ensure

that

floor

temperature

warning

lamp

glows

when

floor

is

heated

to

lh

specifications

as

shown

in

the

table

below

Floor

temperature

Below

1050C

22IOF

Above

1050C

2210F

temperature

relay

for

continuity

with

a

circuit

tester

Referring

to

the

following

floor

temperature

relay

if

relay

is

normal

trace

wire

s

back

to

ignition

switch

Repair

faulty

wiring

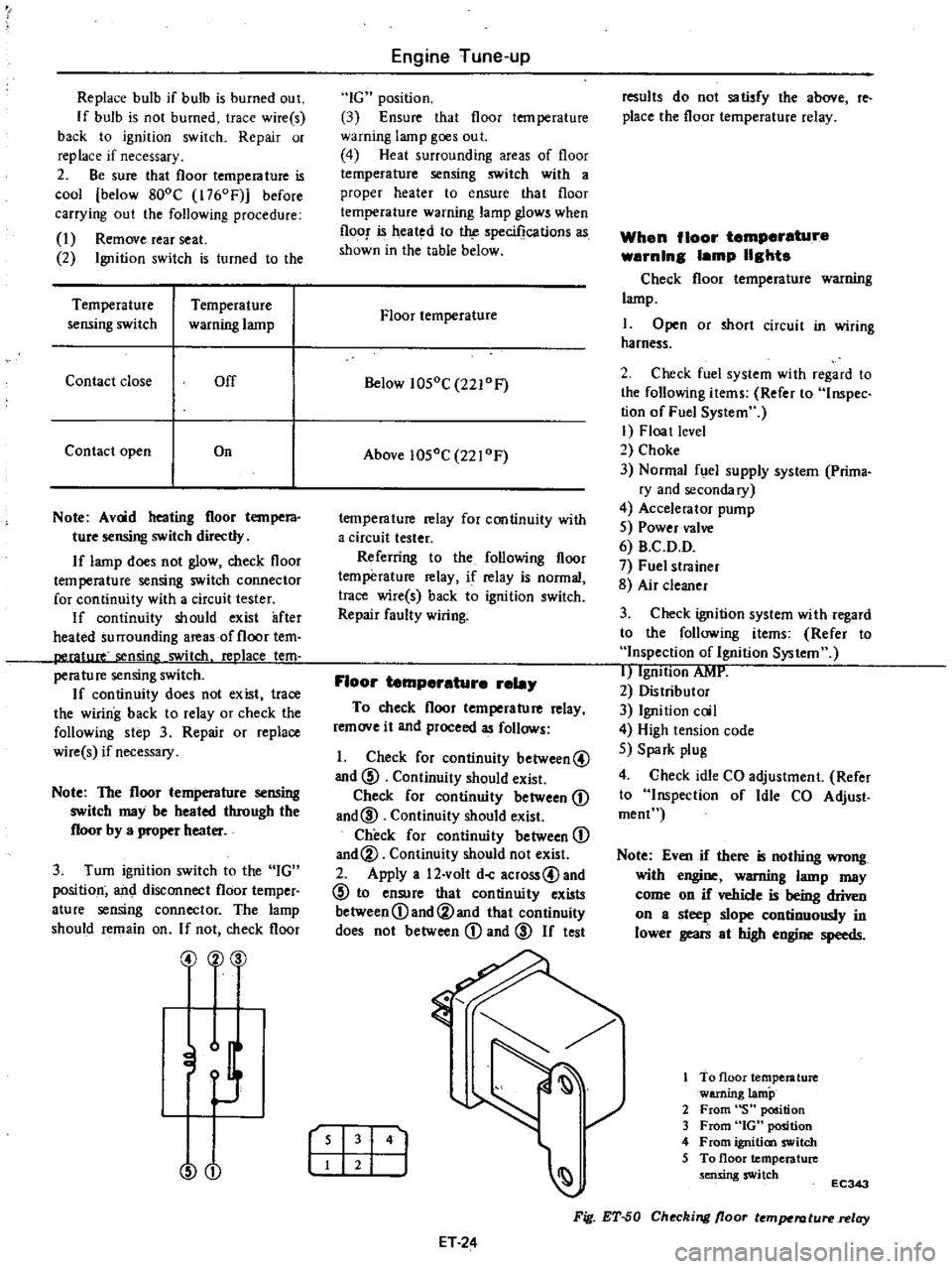

Floor

temperature

rela

To

check

floor

temperature

relay

remove

it

and

proceed

as

follows

1

Check

for

continuity

between@

and

@

Continuity

should

exist

Check

for

continuity

between

D

and@

Continuity

should

exist

Check

for

continuity

between

D

and@

Continuity

should

not

exist

2

Apply

a

12

volt

doC

across@and

@

to

ensure

that

continuity

exists

between

D

and@and

that

continuity

does

not

between

D

and

@

If

test

r

I

141

ET

24

results

do

not

satisfy

the

above

reo

place

the

floor

temperature

relay

When

floor

temperature

warnln8

lamp

118hts

Check

floor

temperature

warning

lamp

I

Open

or

short

circuit

in

wiring

harness

2

Check

fuel

system

with

regard

to

the

following

items

Refer

to

Inspec

tion

of

Fuel

System

I

Floa

t

level

2

Choke

3

Normal

fuel

supply

system

Prima

ry

and

secondary

4

Accelerator

pump

5

Power

valve

6

B

C

D

D

7

Fuel

strainer

8

Air

cleaner

3

Check

ignition

system

with

regard

to

the

following

items

Refer

to

Inspection

of

Ignition

System

I

IgnItion

AMI

2

Distributor

3

Ignition

coil

4

High

tension

code

5

Spark

plug

4

Check

idle

CO

adjustment

Refer

to

Inspection

of

Idle

CO

Adjust

roeoC

Note

Even

if

there

is

nothing

wrong

with

engine

warning

lamp

may

come

on

if

vehicle

is

being

driven

on

a

steep

slope

continuously

in

lower

gears

at

high

engine

speeds

To

floor

temperature

warning

lamp

2

From

S

position

3

From

GOt

position

4

From

ignition

switch

5

To

floor

temperature

sensing

switch

EC343

Fig

ET

50

Checking

floor

temperature

relay

Page 116 of 537

ELECTRIC

AUTOMATIC

CHOKE

An

electric

heater

wanns

a

bi

metal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

time

elapsed

the

warm

up

condi

tion

of

the

engine

and

the

outside

ambient

temperature

When

outside

ambient

temperature

is

above

operating

temperature

the

automatic

choke

control

serves

to

fur

ther

reduce

exhaust

gasemission

during

warm

up

by

automatically

selecting

one

of

the

two

choke

opera

tion

modes

fast

acting

or

slow

acting

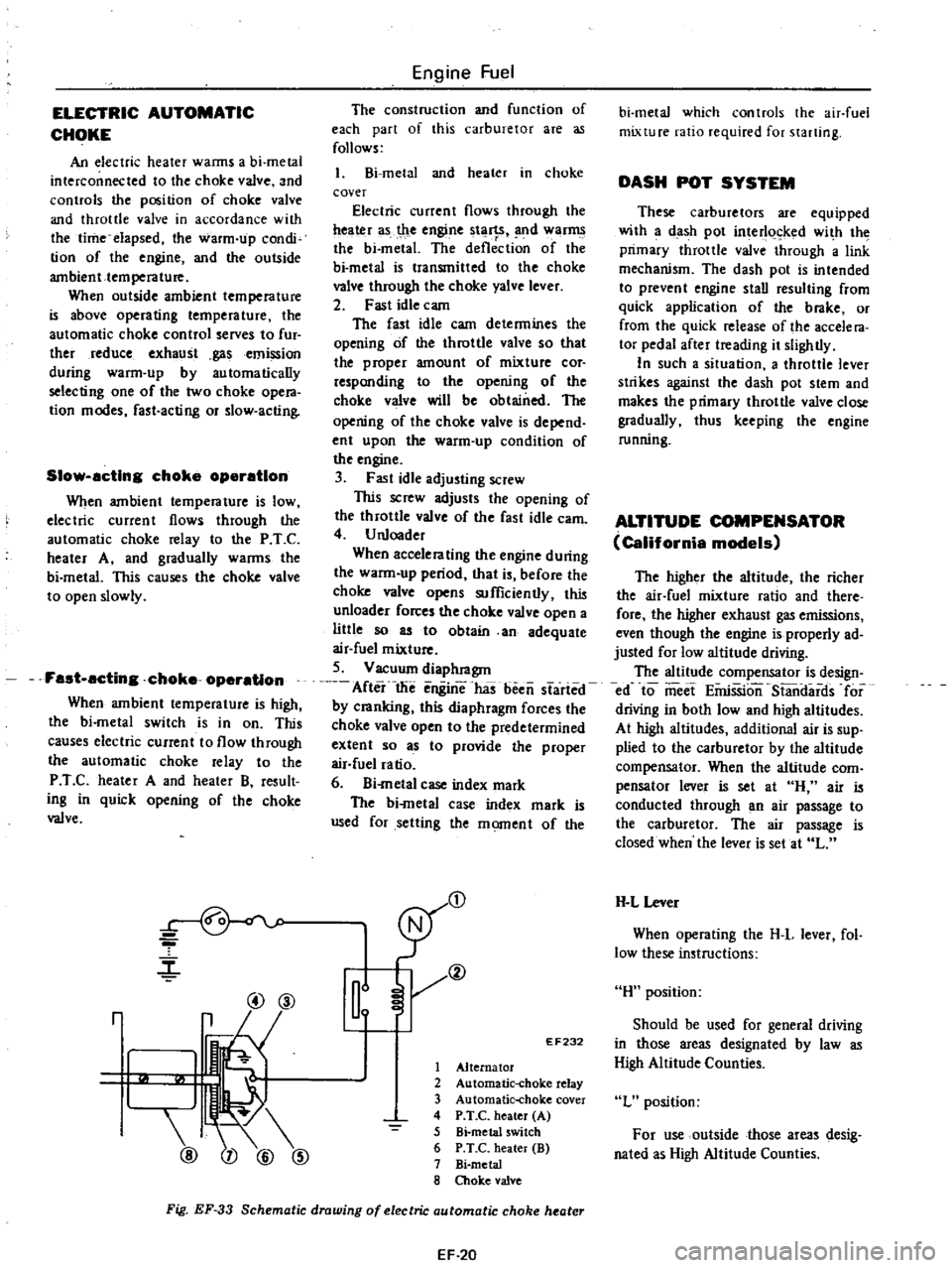

Slow

acting

choke

operation

When

ambient

temperature

is

low

electric

current

flows

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

gradually

warms

the

bi

metal

This

causes

the

choke

valve

to

open

slowly

Fast

acting

choke

operation

When

ambient

temperature

is

high

the

bi

metal

switch

is

in

on

This

causes

electric

current

to

flow

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

heater

B

result

ing

in

quick

opening

of

the

choke

valve

r

@@

r

@

Engine

Fuel

The

construction

and

function

of

each

part

of

this

carburetor

are

as

follows

l

Bi

metal

and

heater

in

choke

cover

Electric

current

flows

through

the

ttea

r

as

t

le

engine

tl

1

SI

nd

war

the

bi

metal

The

deflection

of

the

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

yalve

lever

2

Fast

idle

cam

The

fast

idle

cam

determines

the

opening

of

the

throttle

valve

so

that

the

proper

amount

of

mixture

cor

responding

to

the

opening

of

the

choke

valve

will

be

obtained

The

opening

of

the

choke

valve

is

depend

ent

upon

the

warm

up

condition

of

the

engine

3

Fast

idle

adjusting

screw

This

screw

adjusts

the

opening

of

the

throttle

valve

of

the

fast

idle

earn

4

U

nloader

When

accelerating

the

engine

during

the

warm

up

period

that

is

before

the

choke

valve

opens

sufficiently

this

unloader

forces

the

choke

valve

open

a

liUle

so

as

to

obtain

an

adequate

air

fuel

mixture

5

Vacuum

diaphragm

After

the

enginThas

been

started

by

cranking

this

diaphragm

forces

the

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

the

proper

air

fuel

ratio

6

Bi

metal

case

index

mark

The

bi

metal

case

index

mark

is

used

for

setting

the

moment

of

the

D

Il

EF232

1

Alternator

2

Automatic

choke

relay

3

Automatic

choke

cover

4

P

T

C

heater

A

5

Bi

metal

switch

6

P

T

C

heater

B

7

Bi

metal

8

Choke

valve

Fig

EF

33

Schematic

drawing

of

electric

automatic

choke

heater

EF

20

bi

metal

which

controls

the

air

fuel

mixture

ratio

required

for

starting

DASH

POT

SYSTEM

These

carburetors

are

equipped

with

a

dash

pot

interl

ked

wi

h

the

primary

throttle

valve

through

a

link

mechanism

The

dash

pot

is

intended

to

prevent

engine

stall

resulting

from

quick

application

of

the

brake

or

from

the

quick

release

of

the

accele

ra

tor

pedal

after

treading

it

slightly

In

such

a

situation

a

throttle

lever

strikes

against

the

dash

pot

stem

and

makes

the

primary

throttle

valve

close

gradually

thus

keeping

the

engine

running

ALTITUDE

COMPENSATOR

California

models

The

higher

the

altitude

the

richer

the

air

fuel

mixture

ratio

and

there

fore

the

higher

exhaust

gas

emissions

even

though

the

engine

is

properly

ad

justed

for

low

altitude

driving

The

altitude

compensator

is

design

ed

to

meet

EiiriSSion

S13ndards

for

driving

in

both

low

and

high

altitudes

At

high

altitudes

additional

air

is

sup

plied

to

the

carburetor

by

the

altitude

compensator

When

the

altitude

com

pensator

lever

is

set

at

H

air

is

conducted

through

an

air

passage

to

the

carburetor

The

air

passage

is

closed

when

the

lever

is

set

at

L

H

L

Lever

When

operating

the

H

L

lever

fol

low

these

instructions

H

position

Should

be

used

for

general

driving

in

those

areas

designated

by

law

as

High

Altitude

Counties

L

position

For

use

outside

those

areas

desig

nated

as

High

Altitude

Counties

Page 120 of 537

ELECTRIC

AUTOMATIC

CHOKE

Checklna

automatic

choke

heater

circuit

with

function

test

connector

Caution

Do

not

altach

test

leads

of

a

circuit

tester

to

those

other

than

designated

Refer

to

figure

Ef

43

I

With

engine

not

running

check

for

continuity

between

A

and

B

as

shown

in

figure

Ef

43

If

continuity

exists

heater

is

func

tioning

properly

If

continuity

d

s

not

exist

check

for

disconnected

connector

or

open

P

T

e

heater

circuit

2

With

engine

running

at

idle

check

for

presence

of

voltage

across

A

and

B

as

shown

in

figure

EF

43

If

voltmeter

reading

is

12

volts

d

c

heater

circuit

is

functioning

properly

If

vohmeter

reading

is

zero

check

for

disconnected

connector

open

circuit

or

faulty

automatic

choke

relay

3

Replace

faulty

parts

J

j

N

j

EF710

1

ignition

key

2

Automatic

choke

relay

Engine

stop

OFF

Engine

start

ON

3

Automatic

choke

heateI

4

Function

test

connector

5

Altema

tor

Fig

EF

43

Checking

oulomalic

choke

heater

circuit

with

fu

nc

non

led

connector

Engine

Fuel

Automatic

choke

I

Before

starting

engine

fully

de

press

al

celerator

pedaJ

to

ensure

that

choke

valve

doses

properly

Push

choke

valve

with

a

finger

and

heck

for

binding

3

Check

0

be

sure

that

bi

rnetal

cover

index

mark

is

set

at

the

cen

leT

of

choke

housing

index

mark

a

s

shown

in

Figure

EF

44

Note

Do

not

set

b

metal

cover

index

mark

at

any

position

except

the

center

of

choke

housing

index

marl

tE

jL

J

Thermostat

cover

Bi

metal

chamber

2

Thermostat

housing

3

Groove

ET034

Fig

EF

44

Bi

metol

tting

4

Check

automatic

choke

heater

source

wiring

for

proper

connection

then

start

engine

5

After

warming

up

the

engine

see

that

choke

valve

is

fully

open

6

If

automatic

choke

heater

source

wiring

is

normal

and

choke

valve

does

not

operate

after

warm

up

replace

hi

metal

co

t

er

Automatic

choke

relay

I

Remove

automatic

choke

relay

Auto

choke

heater

relay

EF278

Fig

EF

45

Location

of

automatic

choke

relay

EF

24

2

Make

an

operational

check

of

automatic

choke

relay

as

shown

in

Figure

EF

46

Apply

2

volts

d

c

across

termi

nals

I

and

3

to

ensure

that

i

ontinuity

exists

between

terminals

2

and

4

Check

t

lal

continuity

does

not

exist

between

terminals

2

and

4

when

no

voltage

is

applied

across

them

If

results

satisfies

the

above

automatic

choke

relay

is

functioning

properly

if

not

replace

choke

relay

1

2

3

y

4

EF723

Fig

EF

46

Checking

automatic

choke

relay

Automatic

choke

heater

I

Measure

resistance

of

choke

heater

as

shown

in

figure

EF

47

spe

ified

re

s

an

ce

is

3

7

to

8

9

ohms

F

EF261

Fig

EF

47

Automatic

choke

heater

check

2

If

measured

value

is

not

within

the

specification

replace

bi

metal

cover

INTERLOCK

OPENING

OF

PRIMARY

AND

SECONDARY

THROTnE

VALVE

Figure

EF

48

shows

primary

throt

tie

valve

opened

SO

When

primary

throtlle

valve

is

opened

50

the

adjust

plate

integrated

with

throttle

valve

is

in

contact

with

return

plate

at

A

Page 122 of 537

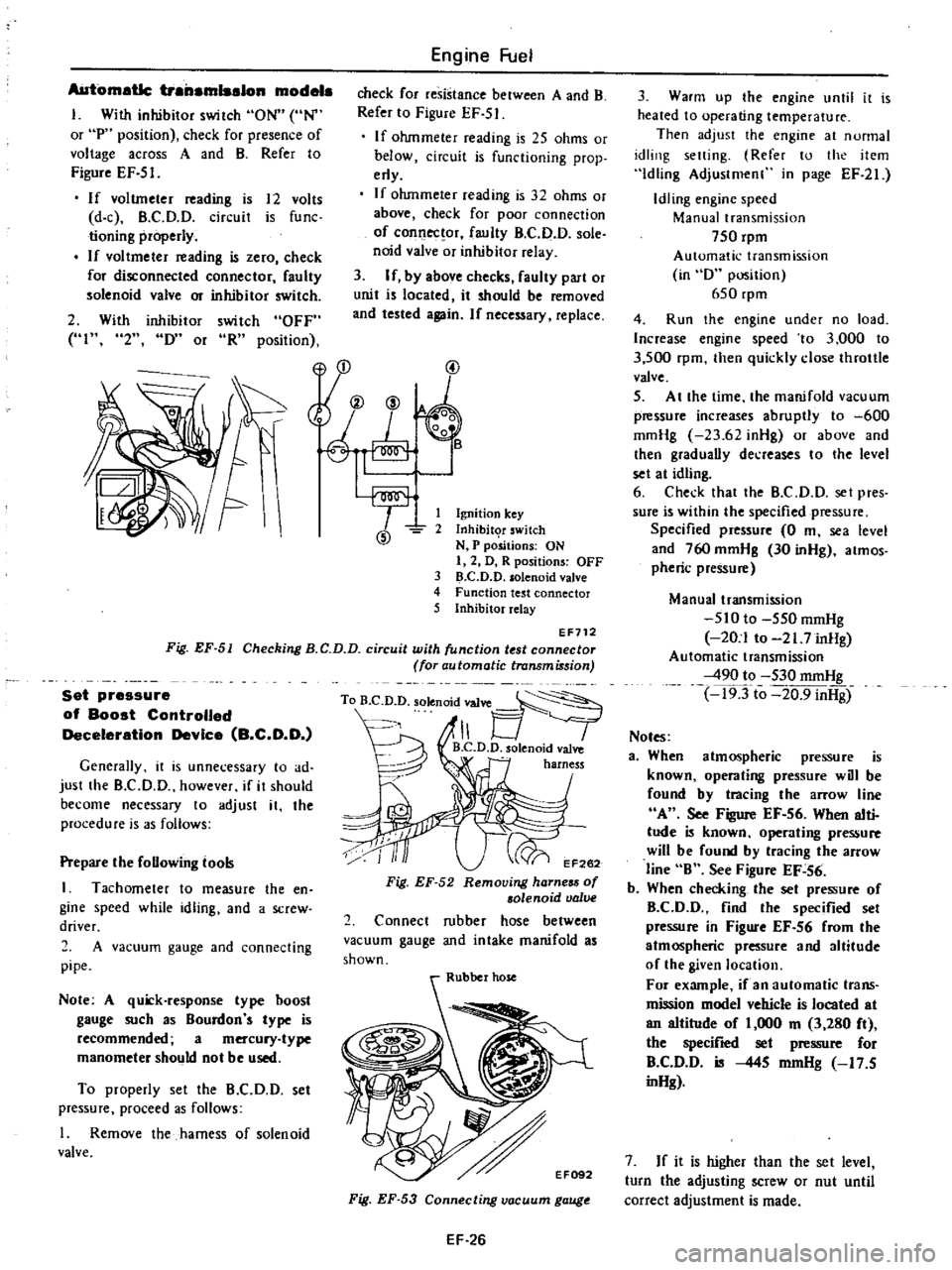

AUtomatic

trailamlsalon

modela

I

With

inhibitor

switch

ON

UN

or

P

position

check

for

presence

of

voltage

across

A

and

B

Refer

to

Figure

EF

51

If

voltmeter

ading

is

12

volts

d

c

B

C

D

O

circuit

is

func

tioning

properly

If

vol

tmeter

ading

is

zero

check

for

disconnected

connector

faulty

solenoid

valve

m

inhibitor

switch

2

With

inhibitor

switch

OFF

HI

2

IY

or

oR

position

Engine

Fuel

check

for

resistance

between

A

and

B

Refer

to

Figure

EF

51

If

ohmmeter

reading

is

25

ohms

or

below

circuit

is

functioning

prop

erly

If

ohmmeter

reading

is

32

ohms

or

above

check

for

poor

connection

of

connec

or

faulty

B

C

D

D

sole

noid

valve

or

inhibitor

relay

3

If

by

above

checks

faulty

part

or

unit

is

located

it

should

be

moved

and

tested

again

If

necessary

replace

yu

@

@

1

Ignition

key

2

Inhibit

T

switch

N

P

positions

ON

I

2

D

R

positions

OFF

3

D

C

D

D

solenoid

valve

4

Function

test

connector

5

Inhibitor

relay

EF712

Fig

EF

51

Checking

B

C

D

D

circuit

with

unction

t

st

connector

for

automatic

transmi

sion

Set

pressure

of

Boost

Controlled

Deceleration

Device

B

C

D

O

Generally

it

is

unnecessary

to

ad

just

the

B

CD

D

however

if

it

should

become

necessary

to

adjust

it

the

procedure

is

3S

follows

Prepare

the

foUowing

tool

I

Tachometer

to

measure

the

en

gine

speed

while

idling

and

a

screw

driver

2

A

vacuum

gauge

and

connecting

pipe

Note

A

quick

response

type

hoost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

To

properly

set

the

B

C

D

D

set

pressure

proceed

as

follows

I

Remove

the

harness

of

solenoid

valve

To

B

D

D

solenoid

valve

1

B

C

D

D

olenoid

valve

harness

EF262

Fig

EF

52

Removing

harness

of

solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

as

shown

Fig

EF

53

Connecting

vacuum

gauge

EF

26

3

Warm

up

the

engine

until

it

is

heated

to

operating

temperature

Then

adjust

the

engine

at

nunnal

idling

setting

Refer

to

the

item

Idling

Adjustmenl

in

page

EF

21

Idling

engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

4

Run

the

engine

under

no

load

Increase

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

5

At

the

time

the

manifold

vacuum

p

ssure

increases

abruptly

to

600

mmHg

23

62

inHg

or

above

and

then

graduaUy

decreases

to

the

level

set

at

idling

6

Check

that

the

B

C

D

D

set

pres

sure

is

within

the

specified

pressure

Specified

pressure

0

m

sea

level

and

760

mmHg

30

inHg

atmos

pheric

pressu

Manual

transmission

510

to

550

mmHg

20

1

to

21

7

inHg

Automatic

transmission

490

to

530

mmHg

19Tto

20

9

inHg

Notes

a

When

atmospheric

pressure

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

A

See

Figure

EF

56

When

alti

tude

is

known

operating

pressure

will

be

found

by

tracing

the

arrow

line

B

See

Figu

EF

56

b

When

checking

the

set

pressu

of

B

CD

D

find

the

specified

set

pressu

in

Figure

EF

56

from

the

atmospheric

pressure

and

altitude

of

the

given

location

For

example

if

an

automatic

trans

mission

model

vehicle

is

located

at

an

altitude

of

1

000

m

3

280

ft

the

specified

set

p

ssu

for

B

C

D

D

is

445

mmHg

17

5

inHg

7

If

it

is

higher

than

the

set

level

turn

the

adjusting

screw

or

nut

until

correct

adjustment

is

made

Page 125 of 537

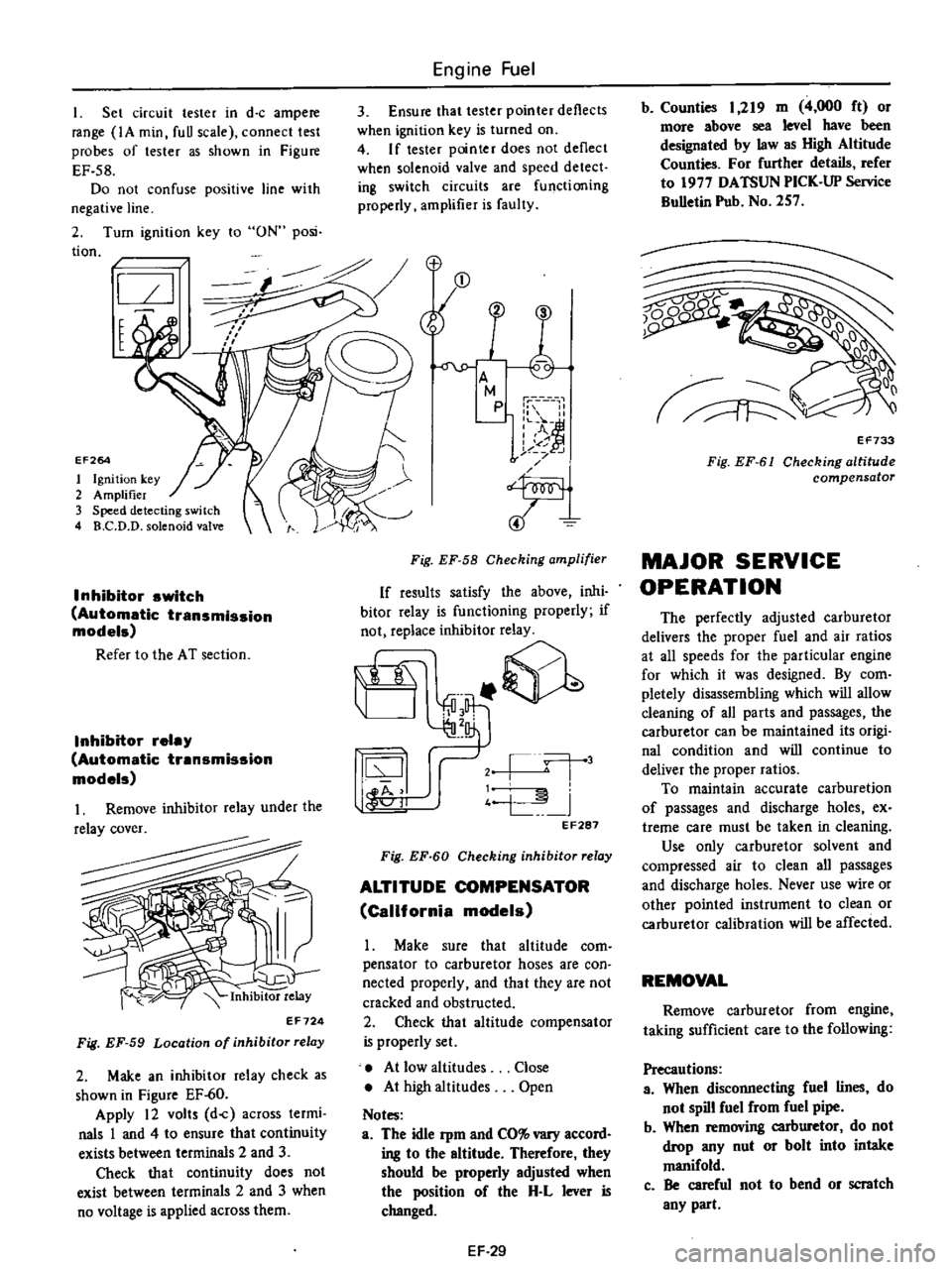

I

Set

circuit

tester

in

d

c

ampere

range

IA

min

fuU

scale

connect

test

probes

of

tester

as

shown

in

Figure

EF

58

Do

not

confuse

positive

line

with

negative

line

2

Turn

ignition

key

to

ON

posi

tion

I

t

EF264

1

Ignition

key

2

Amplifier

3

Speed

detecting

switch

4

B

C

D

D

solenoid

valve

Inhibitor

switch

Automatic

transmission

models

Refer

to

the

AT

section

Inhibitor

relay

Automatic

transmission

models

Inhibitor

relay

EF724

Fig

EF

59

Location

of

inhibitor

relay

2

Make

an

inhibitor

relay

check

as

shown

in

Figure

EF

60

Apply

12

volts

d

c

across

termi

nals

1

and

4

to

ensure

that

continuity

exists

between

terminals

2

and

3

Check

that

continuity

does

not

exist

between

terminals

2

and

3

when

no

voltage

is

applied

across

them

Engine

Fuel

3

Ensure

that

tester

pointer

deflects

when

ignition

key

is

turned

on

4

If

tester

pointer

does

not

deflect

when

solenoid

valve

and

speed

detect

ing

switch

circuits

are

functioning

properly

amplifier

is

faulty

Fig

EF

58

Checking

amplifier

If

results

satisfy

the

above

inhi

bitor

relay

is

functioning

properly

if

not

replace

inhibitor

relay

it

@

j

l

j

4

L

I

44

11

oJ

EF287

Fig

EF

60

Checking

inhibitor

relay

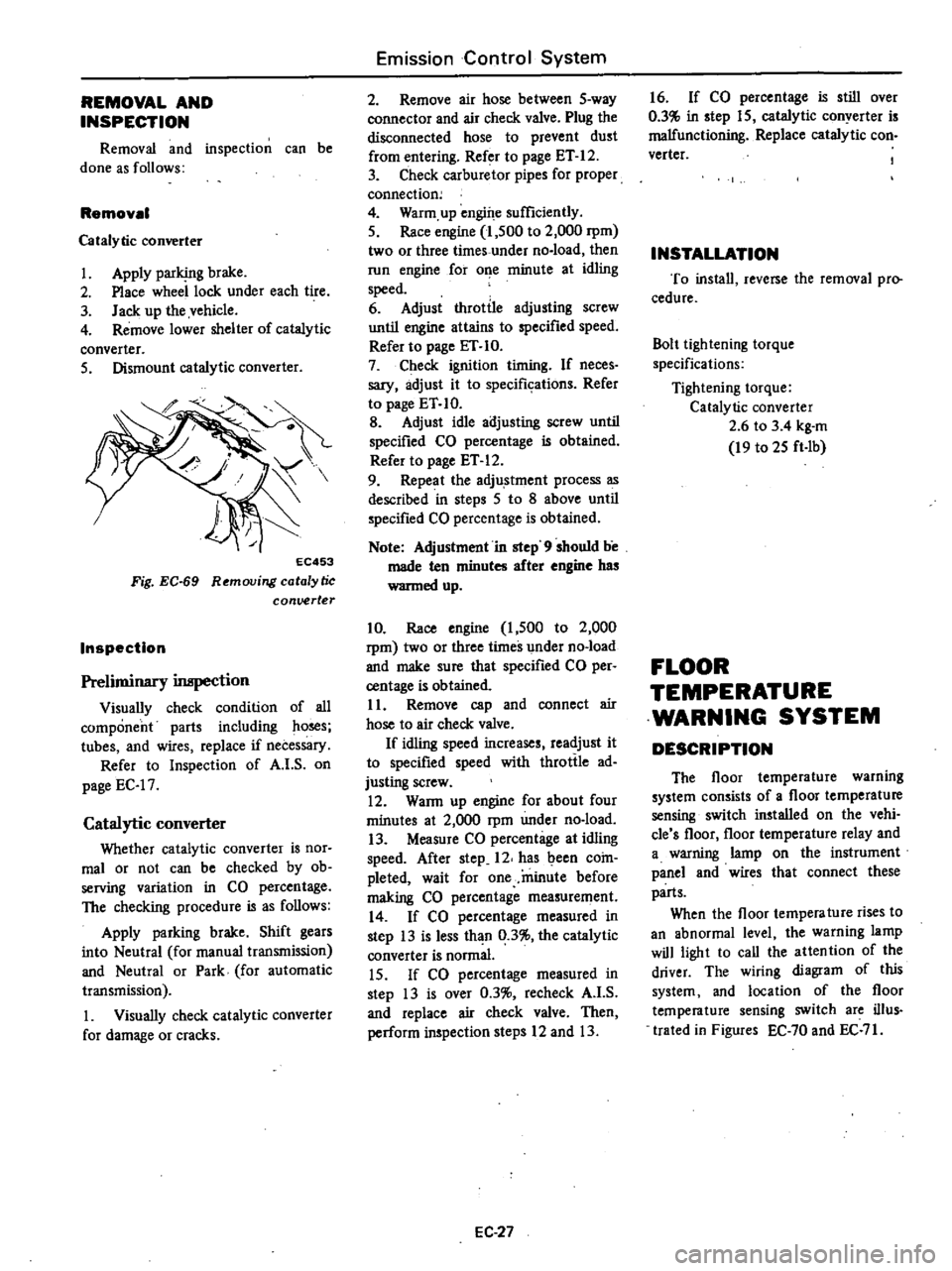

ALTITUDE

COMPENSATOR

California

models

Make

sure

that

altitude

com

pensator

to

carburetor

hoses

are

con

nected

properly

and

that

they

are

not

cracked

and

obstructed

2

Check

that

altitude

compensator

is

properly

set

At

low

altitudes

At

high

altitudes

Notes

a

The

idle

Pm

and

CO

vary

accord

ing

to

the

altitude

Therefore

they

should

be

properly

adjusted

when

the

position

of

the

H

L

lever

is

changed

Close

Open

EF

29

b

Counties

1

219

m

4

000

ft

or

more

above

sea

level

have

been

designated

by

law

as

High

Altitude

Counties

For

further

details

refer

to

1977

DATSUN

PICK

UP

Service

BuUetin

Pub

No

257

Q0

1

v

EF733

Fig

EF

61

Checking

altitude

compensator

MAJOR

SERVICE

OPERATION

The

perfectly

adjusted

carburetor

delivers

the

proper

fuel

and

air

ratios

at

all

speeds

for

the

particular

engine

for

which

it

was

designed

By

com

pletely

disassembling

which

will

allow

deaning

of

all

parts

and

passages

the

carburetor

can

be

maintained

its

origi

nal

condition

and

will

continue

to

deliver

the

proper

ratios

To

maintain

accurate

carburetion

of

passages

and

discharge

holes

ex

treme

care

must

be

taken

in

cleaning

Use

only

carburetor

solvent

and

compressed

air

to

clean

all

passages

and

discharge

holes

Never

use

wire

or

other

pointed

instrument

to

clean

or

carburetor

calibration

will

be

affected

REMOVAL

Remove

carburetor

from

engine

taking

sufficient

care

to

the

following

Precautions

a

When

disconnecting

fuel

lines

do

not

spill

fuel

from

fuel

pipe

b

When

removing

carburetor

do

not

drop

any

nut

or

bolt

into

intake

manifold

c

Be

careful

not

to

bend

or

scratch

any

part

Page 160 of 537

REMOVAL

AND

INSPECTION

Removal

and

inspection

can

be

done

as

follows

Removal

Catalytic

converter

1

Apply

parking

brake

2

Place

wheel

lock

under

each

tire

3

Jack

up

the

vehicle

4

Remove

lower

shelter

of

catalytic

converter

5

Dismount

catalytic

converter

EC453

Fig

EC

69

Removing

catalytic

conuerter

Inspection

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

ho

s

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

Emission

Control

System

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

o

e

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

10

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifkations

Refer

to

page

ET

10

B

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adju

stment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

wanned

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

11

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

WaRn

up

engine

for

about

four

minutes

at

2

000

rpm

under

no

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

coin

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalytic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

EC

27

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

conyerter

is

malfunctioning

Replace

catalytic

con

verter

INSTALLATION

To

install

reverse

the

removal

pro

cedure

Bolt

lightening

torque

specifications

Tightening

torque

Catalytic

converter

2

6

to

3

4

kg

m

19

to

25

ft

Ib

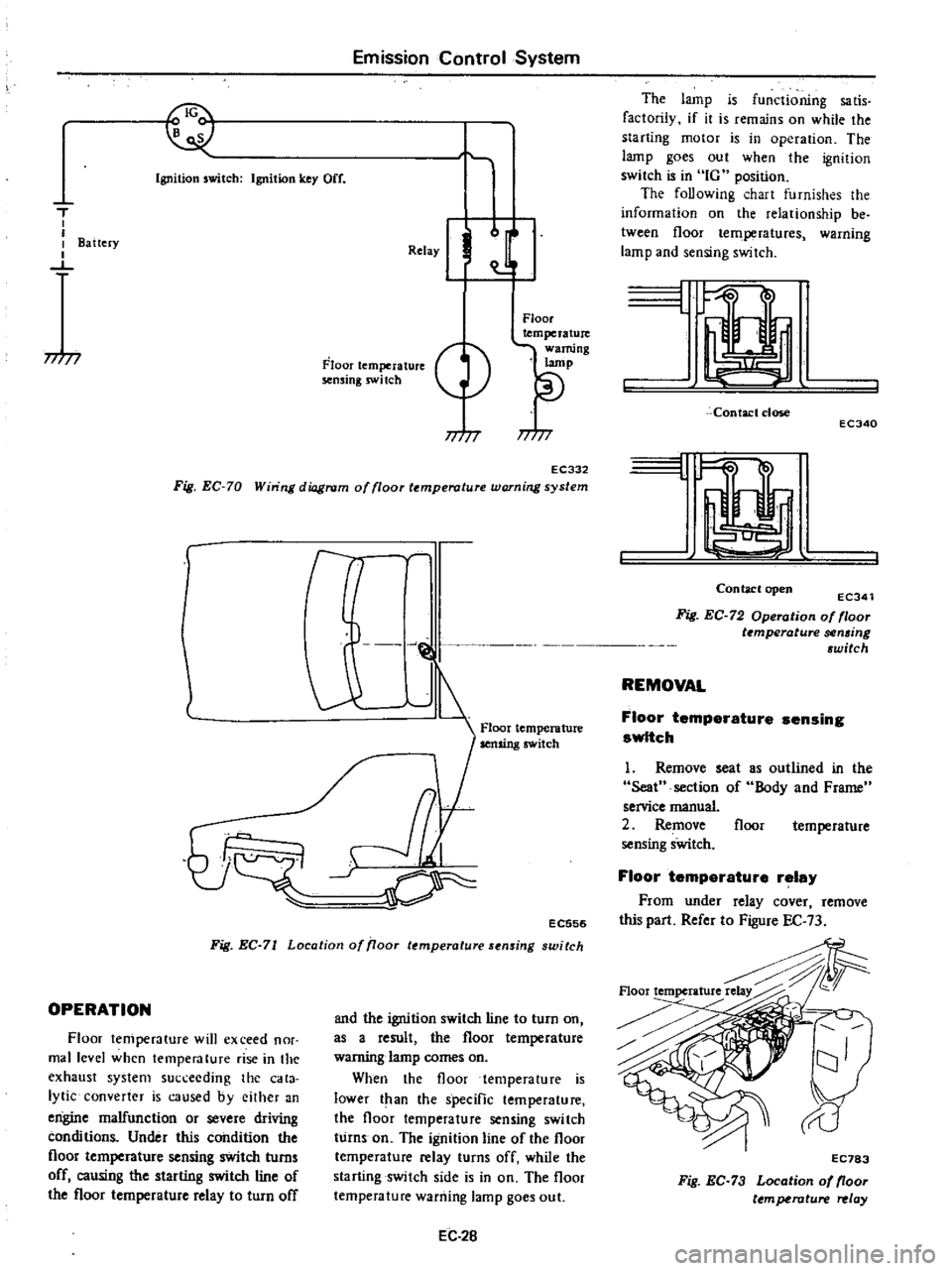

FLOOR

TEMPERATURE

WARNING

SYSTEM

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehi

cle

s

floor

floor

temperature

relay

and

a

warning

lamp

on

the

instrument

panel

and

wires

that

connect

these

parts

When

the

floor

tempera

ture

rises

to

an

abnormal

level

the

warning

lamp

will

light

to

call

the

attention

of

the

driver

The

wiring

diagram

of

this

system

and

location

of

the

floor

temperature

sensing

switch

are

ilIus

trated

in

Figures

EC

70

and

EC

71

Page 161 of 537

I

Emission

Control

System

Ignition

switch

Ignition

key

Off

T

I

I

I

Battery

I

J

77

77

Relay

J

Floor

temperature

sensing

swi

tch

Floor

temperature

warning

lamp

77

77

EC332

Fig

EC

70

Win

ng

diagram

of

floor

temperature

warning

system

r

l

J

@

1

Floor

temperature

Ij

cr

EC556

Fig

EC

71

Location

of

iJoor

temperature

sensing

switch

OPERATION

Floor

temperature

will

exceed

nor

mal

level

when

temperature

rise

in

the

exhaust

system

succeeding

the

cata

lytic

converter

is

caused

byeilher

an

engine

malfunction

or

severe

driving

conditions

Under

this

condition

the

floor

temperature

sensing

switch

turns

off

causing

the

starting

switch

line

of

the

floor

temperature

relay

to

turn

off

and

the

ignition

switch

line

to

turn

on

as

a

result

the

floor

temperature

warning

lamp

comes

on

When

the

floor

temperature

is

lower

t

an

the

specific

temperature

the

floor

temperature

sensing

switch

turns

on

The

ignition

line

of

the

floor

temperature

relay

turns

off

while

the

starting

switch

side

is

in

on

The

floor

temperature

warning

lamp

goes

out

EC

2B

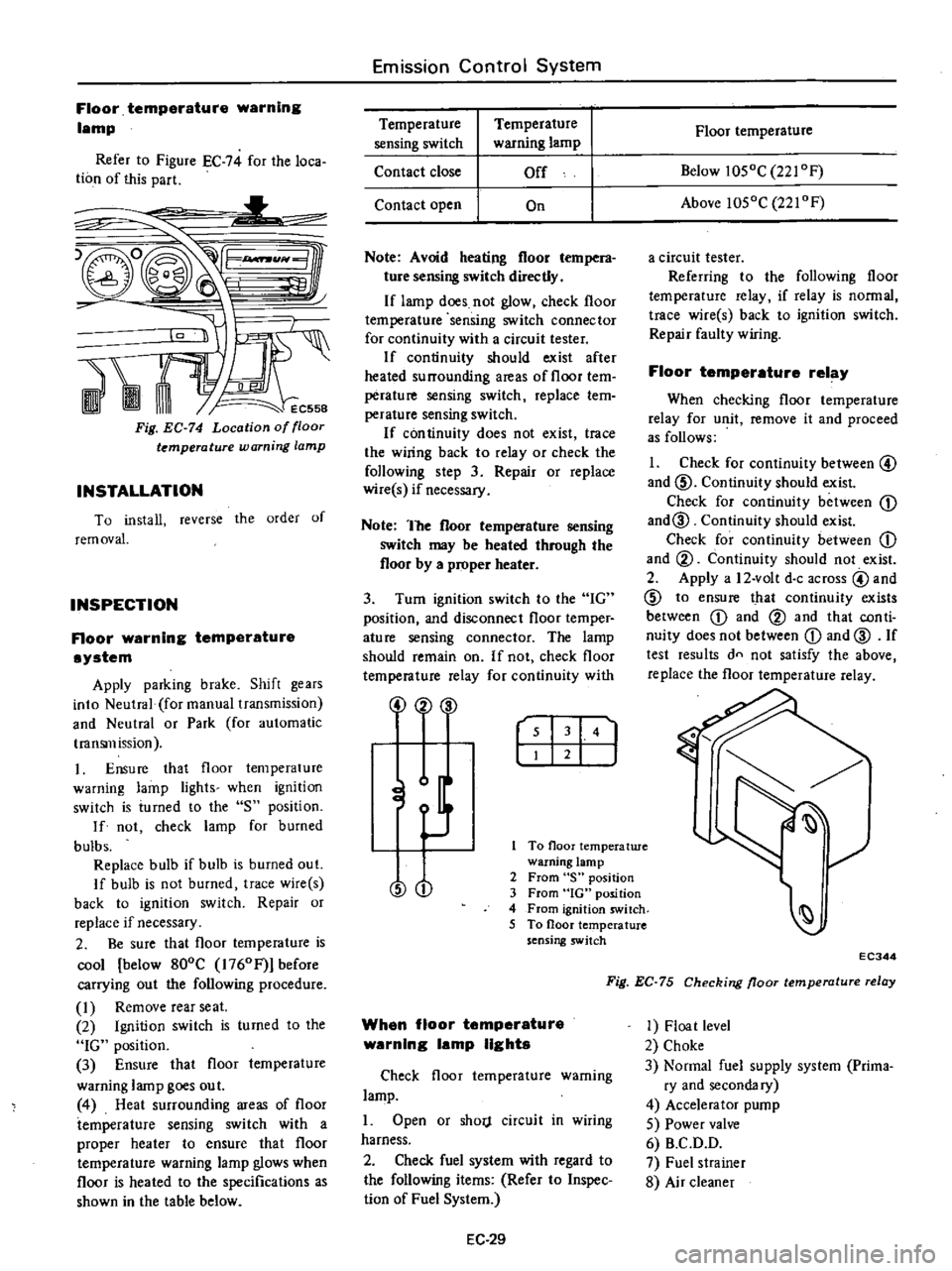

The

lamp

is

functioning

sa

tis

factorily

if

it

is

remains

on

while

the

starting

motor

is

in

operation

The

lamp

goes

out

when

the

ignition

switch

is

in

IG

position

The

foUowing

chart

furnishes

the

information

on

the

relationship

be

tween

floor

temperatures

warning

lamp

and

sensing

switch

L

Contact

close

ECJ40

I

Contaclopen

ECJ41

Fig

EC

72

Operation

of

floor

t

mperature

sen6ing

6witch

REMOVAL

Floor

temperature

sensing

switch

1

Remove

seat

Seat

section

of

service

manual

2

Remove

sensing

sWitch

as

outlined

in

the

Body

and

Frame

floor

temperature

Floor

temperature

relay

From

under

relay

cover

remove

this

part

Refer

to

Figure

EC

73

Floortemperature

EC783

Fig

EC

73

Location

of

floor

ttmperature

relay

Page 162 of 537

Floor

temparature

warning

lamp

Refer

to

Figure

EC

74

for

the

loca

tion

of

this

part

L

1t

1

RAt

Fig

EC

74

Location

of

floor

temperature

warning

lamp

INSTALLATION

To

install

reverse

the

order

of

rem

ovaL

INSPECTION

Floor

warning

temperature

system

Apply

parking

brake

Shift

gears

into

Neutral

foI

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Ensure

that

floor

temperature

warning

lamp

lights

when

ignition

switch

is

iumed

to

the

S

position

If

not

check

lamp

for

burned

bulbs

Replace

bulb

if

bulb

is

burned

out

If

bulb

is

not

burned

trace

wire

s

back

to

ignition

switch

Repair

or

replace

if

necessary

2

Be

sure

that

floor

temperature

is

cool

below

800C

1760Fj

before

carrying

out

the

following

procedure

I

Remove

rearseat

2

Ignition

switch

is

turned

to

the

IG

position

3

Ensure

that

floor

temperature

warning

lamp

goes

out

4

Heat

surrounding

areas

of

floor

temperature

sensing

switch

with

a

proper

heater

to

ensure

that

floor

temperature

warning

lamp

glows

when

floor

is

heated

to

the

specifications

as

shown

in

the

table

below

Emission

Control

System

Temperature

sensing

switch

Contact

close

Temperature

warning

lamp

Off

Contact

open

On

Note

Avoid

heating

floor

tempera

ture

sensing

switch

directly

If

lamp

does

not

glow

check

floor

temperature

sensing

switch

connector

for

continuity

with

a

circuit

tester

If

continuity

should

exist

after

heated

surrounding

areas

of

floor

tem

perature

sensing

switch

replace

tem

perature

sensing

switch

If

con

tinuity

does

not

exist

trace

the

wiring

back

to

relay

or

check

the

following

step

3

Repair

or

replace

wire

s

if

necessary

Note

The

floor

temperature

sensing

switch

may

be

heated

through

the

floor

by

a

proper

heater

3

Turn

ignition

switch

to

the

IG

position

and

disconnect

floor

temper

ature

sensing

connector

The

lamp

should

remain

on

If

not

check

floor

temperature

relay

for

continuity

with

2

00

r

I

141

J

To

floor

temperatwe

warning

lamp

2

From

S

position

3

From

IG

position

4

From

ignition

switch

5

To

floor

temperature

sensing

switch

O

When

floor

temperature

warning

lamp

lights

Check

floor

temperature

warning

lamp

1

Open

or

shorj

circuit

in

wiring

harness

2

Check

fuel

system

with

regard

to

the

following

items

Refer

to

Inspec

lion

of

Fuel

System

EC

29

Floor

temperature

Below

1050C

221

OF

Above

1050C

221

OF

a

circuit

tester

Referring

to

the

following

floor

temperature

relay

if

relay

is

normal

trace

wire

s

back

to

ignition

switch

Repair

faulty

wiring

Floor

temperature

relay

When

checking

floor

temperature

relay

for

unit

remove

it

and

proceed

as

follows

1

Check

for

continuity

between

@

and

ID

Continuity

should

exist

Check

for

continuity

between

CD

and@

Continuity

should

exist

Check

for

continuity

between

CD

and

@

Continuity

should

not

exist

2

Apply

a

12

volt

doc

across

@

and

ID

to

ensure

that

continuity

exists

between

CD

and

@

and

that

con

ti

nuity

does

not

between

CD

and

@

If

test

results

dn

not

satisfy

the

above

replace

the

floor

temperature

relay

EC344

Fig

EC

75

Checking

floor

temperature

relay

1

Float

level

2

Choke

3

Normal

fuel

supply

system

Prima

ry

and

secondary

4

Accelerator

pump

5

Power

valve

6

B

C

D

D

7

Fuel

strainer

8

Air

cleaner

Page 172 of 537

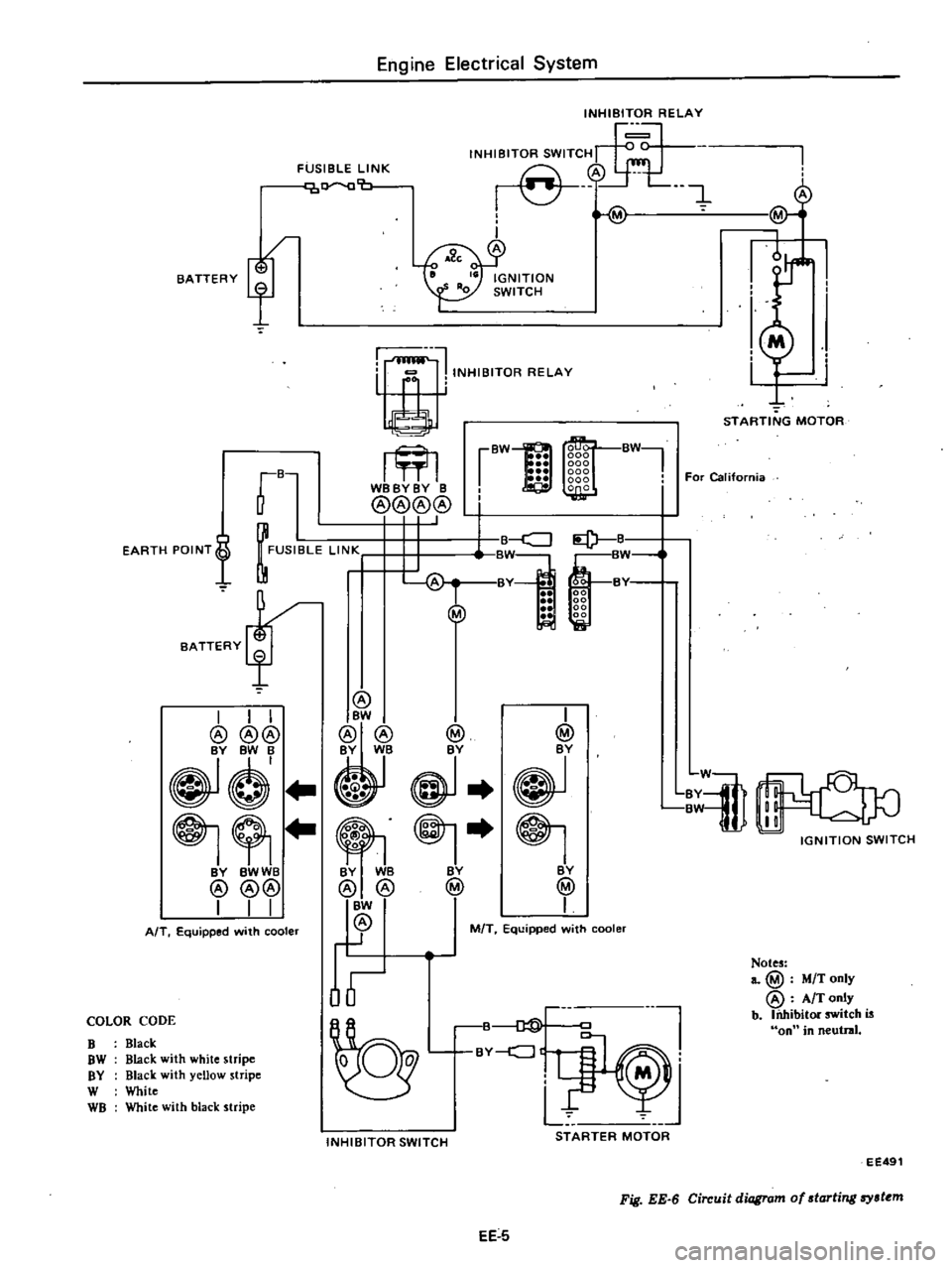

fB

WBBYBY

B

@@@@

I

I

FUSIBLE

lIN

r

T

H

BATTERY

rJ

BATTERY

f

EARTH

POINT

f

I

I

I

@@@

Y

BY

BWWB

@@@

I

I

I

AfT

E

quipped

with

cooler

COLOR

CODE

B

Black

OW

Black

with

white

stripe

BY

Black

with

yellow

stripe

W

White

WB

White

with

black

stripe

Engine

Electrical

System

FUSIBLE

LINK

1Y

O

b

INHIBITOR

RELAY

INHIBITOR

SWITCH

A

I

J

Y

@

I

A

l

rBW

j

CJ

B

W

BWI

000

000

ggg

For

California

I

Bd

f

00

00

00

00

Q

BW

B

Y

BY

WB

BY

@

@

@

BW

@

I

M

T

Equipped

with

cooler

@

I

@

BY

BY

@

I

STARTING

MOTOR

l

BY

BW

9

IGNITION

SWITCH

L

INHIBITOR

SWITCH

STARTER

MOTOR

Notes

a

@

M

T

only

@

A

T

only

b

Inhibitor

switch

is

on

in

neutral

EE

5

Fig

EE

6

Circuit

diagram

0

starting

systom

eE491