ABS DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 3 of 537

FOREWORD

This

service

manual

has

been

prepared

for

the

purpose

of

assisting

service

personnel

of

authorized

NISSAN

DATSUN

dealers

fu

providing

effective

service

and

maintenance

of

the

1977

Datsun

Pick

up

Since

proper

maintenance

and

service

are

absolutely

essential

fu

satisfying

the

Datsun

owners

this

inan

la1

should

be

kept

fu

a

handy

place

for

ready

reference

and

should

be

carefuny

studied

This

man

la1

fucludes

procedures

for

ma

futenance

ac

1justrnents

minor

service

operations

remowl

and

installation

and

for

disassembly

and

assembly

of

components

Some

of

these

service

operations

require

the

use

of

Special

Tools

especially

designed

for

effectiveperfonnance

of

service

operations

The

special

tools

are

presented

in

the

SE

section

As

you

read

through

the

maintenance

procedures

in

this

service

manual

you

will

occasionally

corne

across

paragraphs

headed

NOTE

or

CAUTION

A

NOTE

is

supplemental

infortl1ation

that

is

important

to

B

particular

procedure

CAUTION

warns

of

steps

that

must

be

fonowed

to

prevent

personal

injury

and

Qr

damage

to

some

part

of

your

DATSUN

The

Quick

Reference

Index

on

the

first

page

enables

the

user

to

quickly

locate

the

desired

section

At

the

beginning

of

each

individual

section

is

a

table

of

contents

which

gives

the

page

number

on

which

each

major

subject

begins

An

index

is

placed

at

the

beginning

of

each

major

subject

within

the

section

All

information

illustrations

and

specifications

contained

in

this

manual

are

based

on

the

latest

product

information

available

at

the

time

of

publication

approval

If

YOUT

DATSUN

model

differs

from

the

specifications

contained

in

this

manual

consult

your

NlSSAN

DATSUN

dealer

for

information

Rights

for

alteratiohat

any

time

of

specifications

and

methods

are

reserved

liability

for

any

personal

injury

or

property

damage

occasioned

by

the

use

of

this

service

man

la1

in

effecting

maintenance

or

repair

of

your

Datsun

is

in

no

way

assumed

by

Nissan

M9tor

Co

Ltd

Accordingly

anyone

using

a

service

procedure

or

tool

which

is

not

specifically

w

mended

by

Nissan

must

fust

completely

satisfy

himself

that

neither

his

safety

nor

the

vehicle

s

safety

wi11be

jeopardized

by

the

service

method

selected

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

@

1976

N1SSAN

MOTOR

CO

LTD

Printed

in

Japan

Page 163 of 537

3

Check

ignition

system

with

regard

to

the

following

items

Refer

to

Inspection

of

Ignition

System

1

Ignition

AMP

2

Distributor

Emission

Control

System

3

Ignition

coil

4

High

tension

code

5

Spark

plug

4

Check

idle

CO

adjustment

Refer

to

Inspection

of

Idle

CO

Adjustment

Note

Even

if

there

is

nothing

wrong

with

engine

the

warning

lamp

may

come

on

if

vebicle

is

being

driven

on

a

steep

slope

continuously

in

lower

gears

at

high

engine

speeds

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CONTENTS

DESCRIPTION

OPERATION

INSPECTION

FUEL

TANK

VAPOR

LIQUID

SEPARATOR

AND

VAPOR

VENT

LINE

DESCRIPTION

The

evaporative

emission

control

system

is

used

to

reduce

hydrocarbons

emitted

to

the

atmosphere

from

the

fuel

system

This

reduction

of

hydro

EC

30

EC

30

EC

31

CARBON

CANISTER

PURGE

CONTROL

VALVE

CARBON

CANISTER

FILTER

FUEL

TANK

VACUUM

RELIEF

VALVE

IEC

32

IEC

32

EC

32

EC

31

carbons

is

accomplished

by

activated

charcoals

in

the

carbon

canister

This

system

is

made

up

to

the

following

I

Fuel

tank

with

positive

sealing

filler

cap

@

2

Vapor

liquid

separator

3

Vapor

vent

line

4

Carbon

canister

5

Vacuum

signal

line

6

Canister

purge

line

5

OPERATION

Fuel

vapors

from

the

sealed

fuel

tank

are

led

into

the

carbon

canister

1

Fuel

tank

2

Fuel

nIler

cap

with

vacuum

relief

valve

3

liquid

vapor

separator

4

Vapor

vent

line

5

Canister

purge

line

6

Vacuum

signal

line

7

Carbon

canister

EF274

Fig

EC

76

Schematic

drawing

of

l

Iaporotive

emiaion

control6ydem

The

canister

is

fined

with

activated

charcoals

to

absorb

the

fuel

vapors

EC

30

when

the

engirie

is

at

rest

or

at

idlin

ll

See

Figure

EC

77

Page 232 of 537

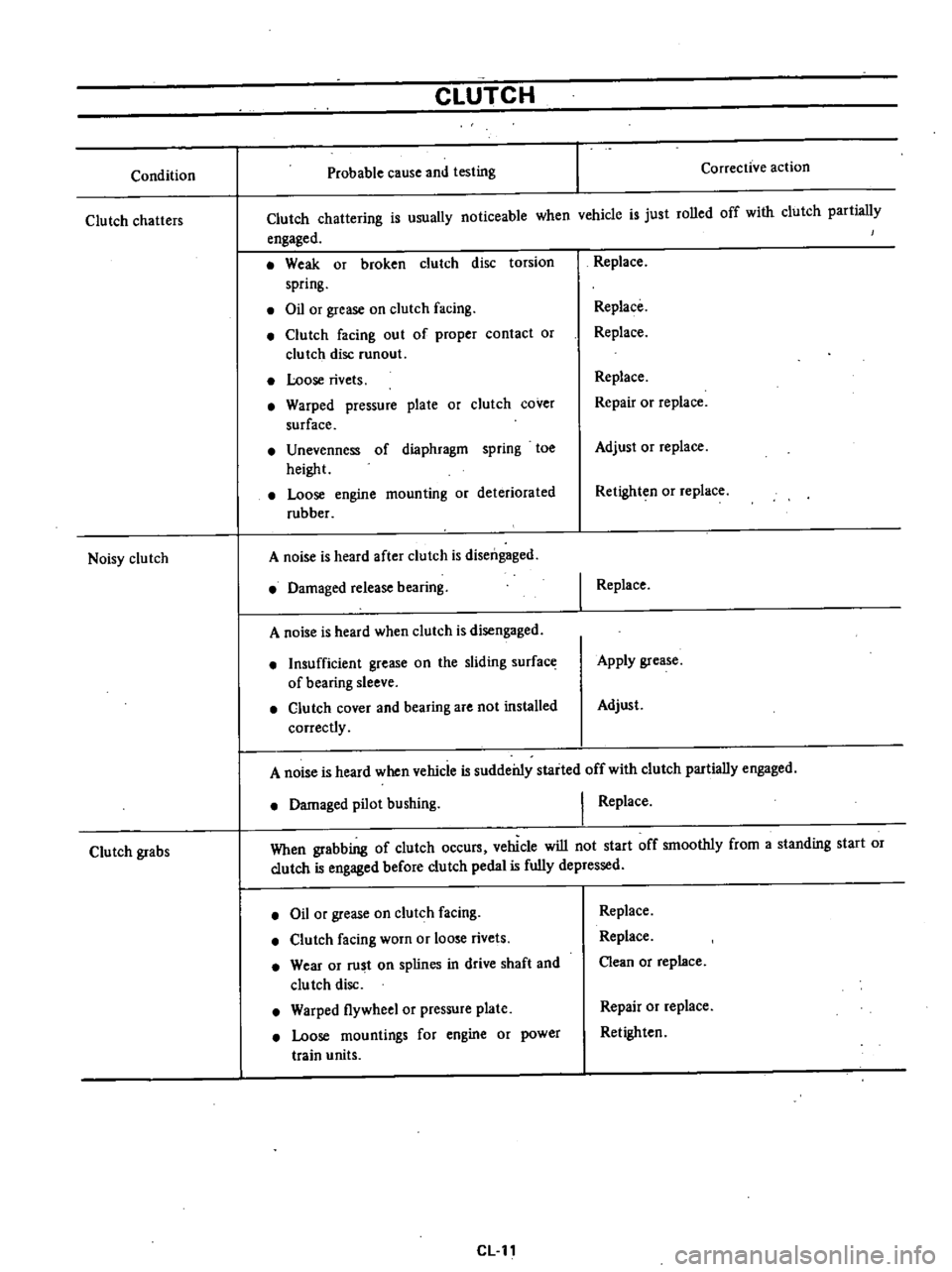

Condition

Clutch

chatters

Noisy

clutch

Clutch

grabs

CLUTCH

Probable

cause

and

testing

Corrective

action

Clutch

chattering

is

usually

noticeable

when

vchicle

is

just

rolled

off

with

clutch

partially

engaged

Weak

or

broken

clutch

disc

torsion

spring

Oil

or

grease

on

clutch

facing

Clutch

facing

out

of

proper

contact

or

clutch

disc

runout

Loose

rivets

Warped

pressure

plate

or

clutch

cover

surface

Unevenness

of

diaphragm

spring

toe

height

Loose

engine

mounting

or

deteriorated

rubber

A

noise

is

heard

after

clutch

is

disengaged

Damaged

release

bearing

A

noise

is

heard

when

clutch

is

disengaged

Insufficient

grease

on

the

sliding

surface

of

bearing

sleeve

Clutch

cover

and

bearing

are

not

installed

correctly

Replace

Replace

Replace

Replace

Repair

or

replace

Adjust

or

replace

Retighten

or

replace

I

Replace

Apply

grease

Adjust

A

noise

is

heard

when

vehicle

is

suddei11y

staited

off

with

clutch

partially

engaged

Damaged

pilot

bushing

I

Replace

When

grabbing

of

clutch

occurs

vehicle

will

not

start

off

smoothly

from

a

standing

start

or

clutch

is

engaged

before

clutch

pedal

is

fully

depressed

Oil

or

grease

on

clutch

facing

Clutch

facing

worn

or

loose

rivets

Wear

or

rust

on

splines

in

drive

shaft

and

clu

tch

disc

Warped

flywheel

or

pressure

plate

Loose

mountings

for

engine

or

power

train

units

CLll

Replace

Replace

Clean

or

replace

Repair

or

replace

Retighten

Page 276 of 537

R

RANGE

REVERSE

In

R

range

the

front

clutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

stationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

Automatic

Transmission

R

Fig

AT

26

Power

tranamis

ion

during

R

range

m

i

1

A

TOBS

Fig

A

T

21

Optrationof

each

mechanism

during

R

range

When

the

manual

valve

V

is

posi

Clutch

Low

Band

servo

One

tioned

at

R

range

the

oil

having

the

Gear

Partina

Ranae

re

ne

way

line

pressure

7

is

directed

to

line

ralio

Front

Rear

brake

Openlion

Relulie

clutch

plwl

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

Park

on

on

low

and

reverse

brake

after

being

Ruene

2

182

on

on

on

introduced

into

line

pressure

circuit

Neutral

12

through

the

I

st

2nd

shift

valve

ID

The

pressure

in

the

circuit

op

DI

Low

2

458

on

on

erates

the

release

side

of

the

band

servo

and

the

front

c1u

tch

after

being

Driowe

D2

Second

1

458

on

on

led

to

line

pressure

circuit

0

D3

Top

1

000

on

on

on

through

the

2nd

3rd

shift

valve

@

2

Second

1

458

The

throttle

pressure

I

6

and

the

line

on

on

pressure

6

which

vary

with

the

12

Second

S8

on

on

degree

of

accelerator

pedal

depression

II

Low

2

458

both

act

the

pressure

regulator

on

on

on

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

Rn

range

the

governor

pressure

is

absent

making

all

such

valves

as

the

1st

2nd

shift

valve

ID

lnd

3rd

shift

valvc

@

and

pressurc

modifier

valve

inoperative

AT16

Page 280 of 537

Automatic

Transmission

R

RANGE

REVERSE

R

In

R

range

the

front

dutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

Slationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

f

When

Ihe

manual

valve

CV

is

posi

tioned

at

R

range

Ihe

oil

having

Ihe

line

pressure

7

is

directed

to

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

line

pressure

circuit

12

through

the

I

st

2nd

shift

valve

@

The

pressure

in

Ihe

circuit

op

erates

the

release

side

of

the

band

servo

and

the

front

clutch

after

being

led

to

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throtlle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

acceJerator

pedal

depression

both

act

on

the

prcssure

regulator

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

slldl

valves

as

the

J

SI

2nd

shift

valve

@

2nd

3rd

shift

valvc

@

and

pressure

modifier

valve

j

inoperative

C

Fig

AT

26

Power

transmi

ion

during

R

range

A

TOS5

Fig

AT

27

Operation

attach

mechanism

during

R

range

G

Clutch

Low

A

Band

servo

One

Parkin

Ran

no

wa

plwl

ratio

Front

Rear

brake

Operllioo

Rdr

ue

clutch

k

on

on

Revctte

1

181

on

on

on

Neutnl

DI

Low

1

418

on

on

Driw

D2

Second

1

458

on

on

DJ

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

II

Low

2

458

on

on

AT

16

Page 317 of 537

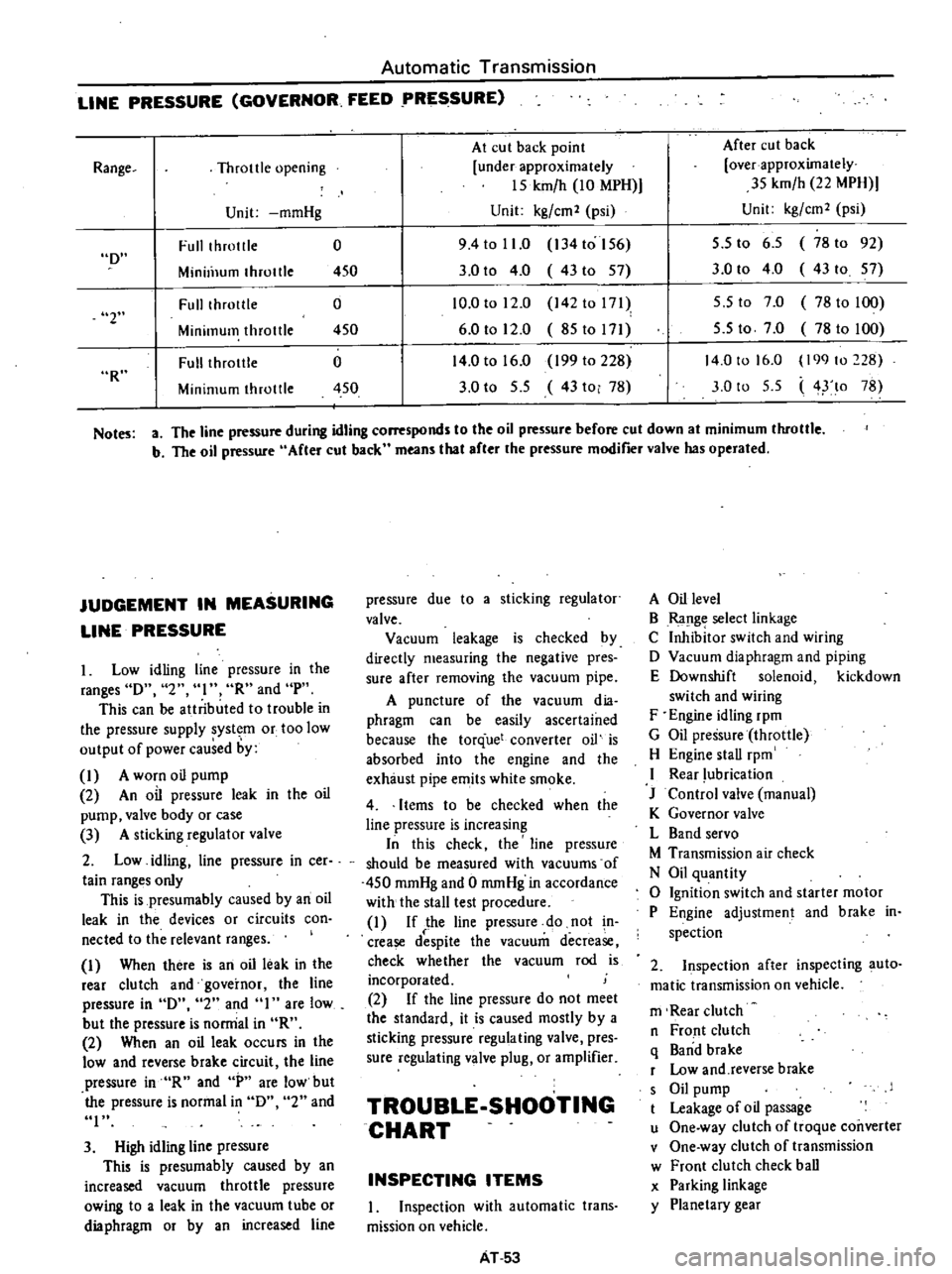

Automatic

Transmission

LINE

PRESSURE

GOVERNOR

FEED

PRESSURE

At

cut

back

point

After

cut

back

Throttle

opening

under

approximately

over

approximately

15

kmfh

10

MPH

35

kmfh

22

MPH

Unit

mmHg

Unit

kgfcm2

psi

Unit

kgfcm2

psi

Full

throtlle

0

9

4

to

11

0

134

to

156

5

5

to

6

5

78

to

92

Minill1um

throttle

450

3

0

to

4

0

43to

57

3

0

to

4

0

43

to

57

Fulllhrotlle

0

10

0

to

12

0

142

to

171

5

5

to

7

0

78

to

100

Minimum

throttle

450

6

0

to

12

0

85to171

5

5

to

7

0

78

to

100

Full

throtlle

0

14

0

to

16

0

199

to

228

14

0

to

16

0

199

to

228

Minimum

throttle

450

3

0

to

5

5

43

to

78

3

0

to

5

5

4

lo

78

Range

D

2

R

Notes

a

The

line

pressure

during

idling

corresponds

to

the

oil

pressure

before

cut

down

at

minimum

throttle

b

The

oil

pressure

After

cut

back

means

that

after

the

pressure

modifier

valve

has

operated

JUDGEMENT

IN

MEASURING

LINE

PRESSURE

Low

idling

line

pressure

in

the

ranges

D

2

I

R

and

pH

This

can

be

atlributed

to

trouble

in

the

pressure

supply

system

or

too

low

output

of

power

caused

by

I

A

worn

oil

pump

2

An

oil

pressure

leak

in

the

oil

pump

valve

body

or

case

3

A

sticking

regulator

valve

2

Low

idling

line

pressure

in

cer

tain

ranges

only

This

is

presumably

caused

by

an

oil

leak

in

the

devices

or

circuits

con

nected

to

the

relevant

ranges

I

When

there

is

an

oil

leak

in

the

rear

clutch

and

governor

the

line

pressure

in

D

2

and

I

are

low

but

the

pressure

is

norrrial

in

R

2

When

an

oil

leak

occurs

in

the

low

and

reverse

brake

circuit

the

line

pressure

in

R

and

P

are

low

but

the

pressure

is

normal

in

D

2

and

I

3

High

idling

line

pressure

This

is

presumably

caused

by

an

increased

vacuum

throttle

pressure

owing

to

a

leak

in

the

vacuum

tube

or

dia

phragm

or

by

an

increased

line

pressure

due

to

a

sticking

regulator

valve

Vacuum

leakage

is

checked

by

directly

measuring

the

negative

pres

sure

after

removing

the

vacuum

pipe

A

puncture

of

the

vacuum

dia

phragm

can

be

easily

ascertained

because

the

torque

converter

oil

is

absorbed

into

the

engine

and

the

exhaust

pipe

emits

white

smoke

4

Items

to

be

checked

when

the

line

pressure

is

increasing

In

this

check

the

line

pressure

should

be

measured

with

vacuums

of

450

mmHg

and

0

mmHg

in

accordance

with

the

stall

test

procedure

I

If

the

line

pressure

do

not

n

crease

despite

the

vacuum

decrease

check

whether

the

vacuum

rod

is

incorporated

2

If

the

line

pressure

do

not

meet

the

standard

it

is

caused

mostly

by

a

sticking

pressure

regulating

valve

pres

sure

regulating

valve

plug

or

amplifier

TROUBLE

SHOOTING

CHART

INSPECTING

ITEMS

1

Inspection

with

automatic

trans

mission

on

vehicle

AT

53

A

Oil

level

B

Ra

lge

select

linkage

C

Inhibitor

switch

and

wiring

D

Vacuum

diaphragm

and

piping

E

Downshift

solenoid

kickdown

switch

and

wiring

F

Engine

idling

rpm

G

Oil

pressure

throttle

H

Engine

stall

rpm

I

Rear

lubrication

J

Control

valve

manual

K

Governor

valve

L

Band

servo

M

Transmission

air

check

N

Oil

quantity

o

Ignition

switch

and

starter

motor

P

Engine

adjustment

and

brake

in

spection

2

Inspection

after

inspecting

auto

matic

transmission

on

vehicle

m

Rear

clutch

n

Front

clutch

q

Band

brake

r

Low

and

reverse

brake

s

Oil

pump

t

Leakage

of

oil

passage

u

One

way

clutch

of

troque

coilVerter

v

One

way

clutch

of

transmission

w

Front

clutch

check

ball

x

Parking

linkage

y

Planetary

gear

Page 351 of 537

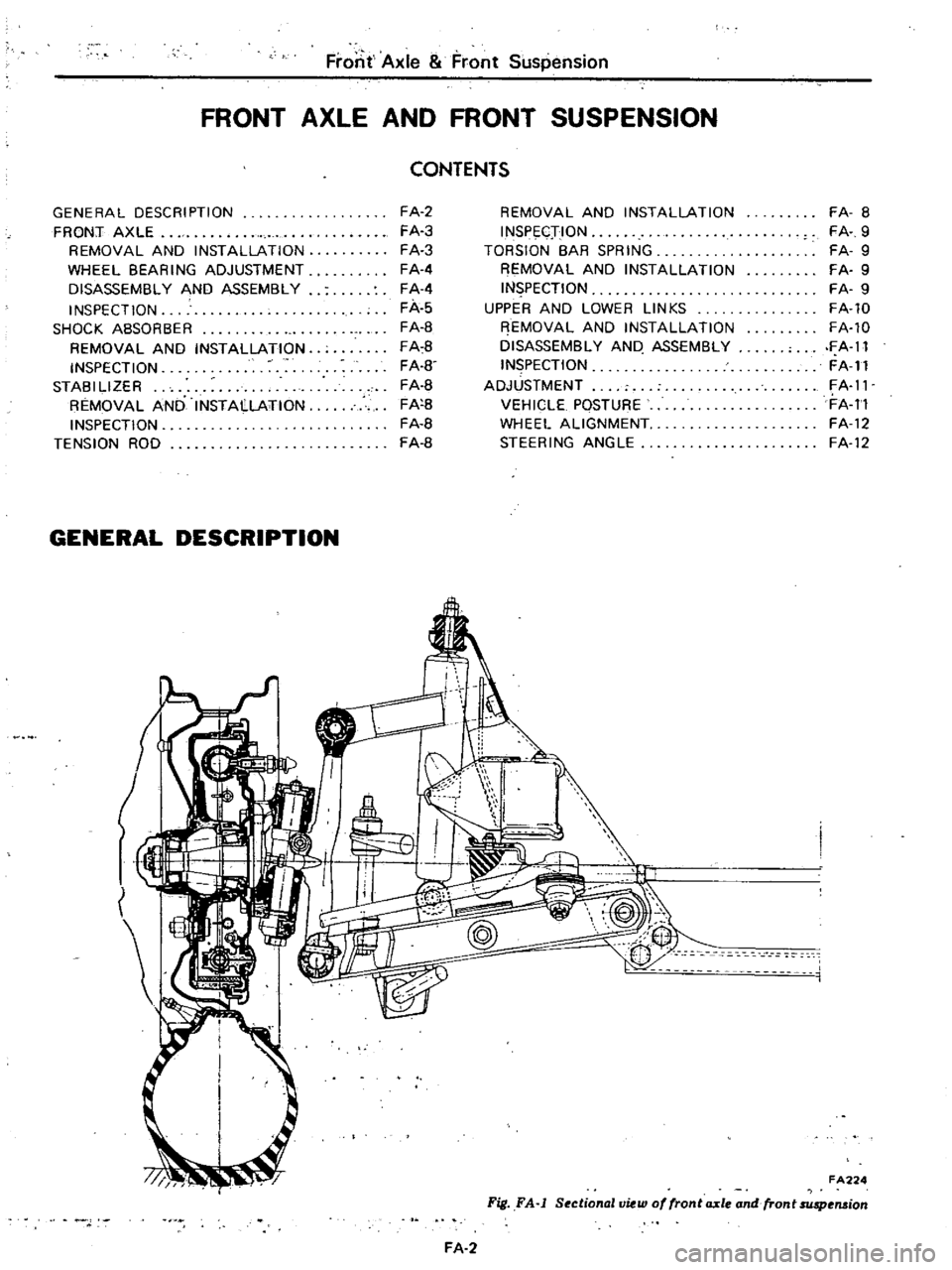

Front

Axle

Front

Suspension

FRONT

AXLE

AND

FRONT

SUSPENSION

CONTENTS

GENERAL

DESCRIPTION

FRONT

AXLE

REMOVAL

AND

INSTALLATION

WHEEL

BEARING

ADJUSTMENT

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

SHOCK

ABSORBER

REMOVAL

AND

INSTALLATION

INSPECTION

STABILIZER

REMOVAL

AND

INSTALLATION

INSPECTION

TENSION

ROD

FA

2

FA

3

FA

3

FA

4

FA

4

FA

5

FA

8

FA

8

FA

8

FA

8

FA

8

FA

8

FA

8

REMOVAL

AND

INSTALLATION

INSPECTION

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

INSPECTION

UPPER

AND

LOWER

LINKS

FjEMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

ADJUSTMENT

VEHICLE

POSTURE

WHEEL

ALIGNMENT

STEERING

ANGLE

GENERAL

DESCRIPTION

uUl

FA

8

FA

9

FA

9

FA

9

FA

9

FA

10

FA

l0

FA

ll

FA

ll

FA

Il

FA

ll

FA

12

FA

12

FA224

Fig

FA

j

SectionallJiew

of

fronta

xle

and

fron

t

suspension

FA

2

Page 352 of 537

The

design

of

the

front

suspension

adopts

the

independent

double

wishbone

type

suspension

used

the

torsion

bar

spring

Both

the

upper

and

lower

links

are

installed

on

the

bracket

which

is

welded

on

the

frame

A

1d

the

above

links

swing

to

allow

the

knuckle

spindle

to

move

freely

in

a

vertical

dimension

The

top

and

bottom

of

the

knuckle

spindle

support

are

connected

to

the

upper

link

through

rubber

bushing

and

to

the

lower

lick

through

screw

bushing

The

tension

rod

held

by

the

brack

ets

on

the

chassis

frame

and

lower

lick

wiih

rubber

bushings

bears

the

force

of

fore

and

aft

direction

The

front

end

of

the

torsion

bar

spring

is

installed

to

the

torque

arm

which

attaches

to

the

lower

link

The

opposite

end

is

installed

to

the

spring

anchor

that

secures

to

chassis

frame

firmly

The

both

ends

of

the

torsion

bar

spring

are

serrated

The

shock

absorber

is

double

action

telescopic

hydraulic

type

The

upper

stem

is

attached

to

the

bracket

of

the

chassis

frame

The

lower

insulated

bracket

is

bolted

to

the

lower

lick

The

bumper

rubber

secured

to

the

bracket

Of

the

frame

limits

the

verti

cal

motion

of

the

suspension

lick

The

knuckle

spindle

is

connecied

to

the

k

ufkle

spindle

arm

by

the

king

pin

The

king

pin

bushings

are

fitted

to

the

upper

and

lower

arm

portIOns

of

the

knuckle

spindle

and

seals

are

provided

at

the

portions

mentioned

to

keep

water

and

dirt

from

enteri

g

The

knuckle

arm

is

connected

to

the

lower

end

of

the

knuckle

spindle

to

transmit

ttLe

movement

of

the

steering

wheel

to

the

knuckle

spindle

The

wheel

hub

is

supported

by

two

taper

roller

bearings

on

the

knuckle

spindle

Tlie

brake

drum

and

wheel

are

secured

to

ihe

hub

by

the

hub

bolts

Front

Axle

Front

Suspension

FRONT

AXLE

REMOVAL

AND

INSTALLATION

Removal

I

Jack

up

and

support

vehicle

on

the

stands

at

the

frame

in

a

safe

manner

2

Remove

front

wheel

3

Re

ove

brake

hose

together

with

connector

from

wheel

cylinder

4

Remove

brake

drum

S

Remove

hub

cap

and

then

remove

cotter

pin

adjusting

cap

and

spindle

nut

from

knuckle

spindle

6

Remove

wheel

hub

outer

and

inner

wheel

bearings

bearing

washer

and

grease

seal

from

knuckle

spindle

7

Remove

brake

disc

assembly

from

the

flange

of

knuckle

spindle

8

Remove

knuckle

arm

from

knuckle

spindle

9

Remove

king

pin

lock

bolt

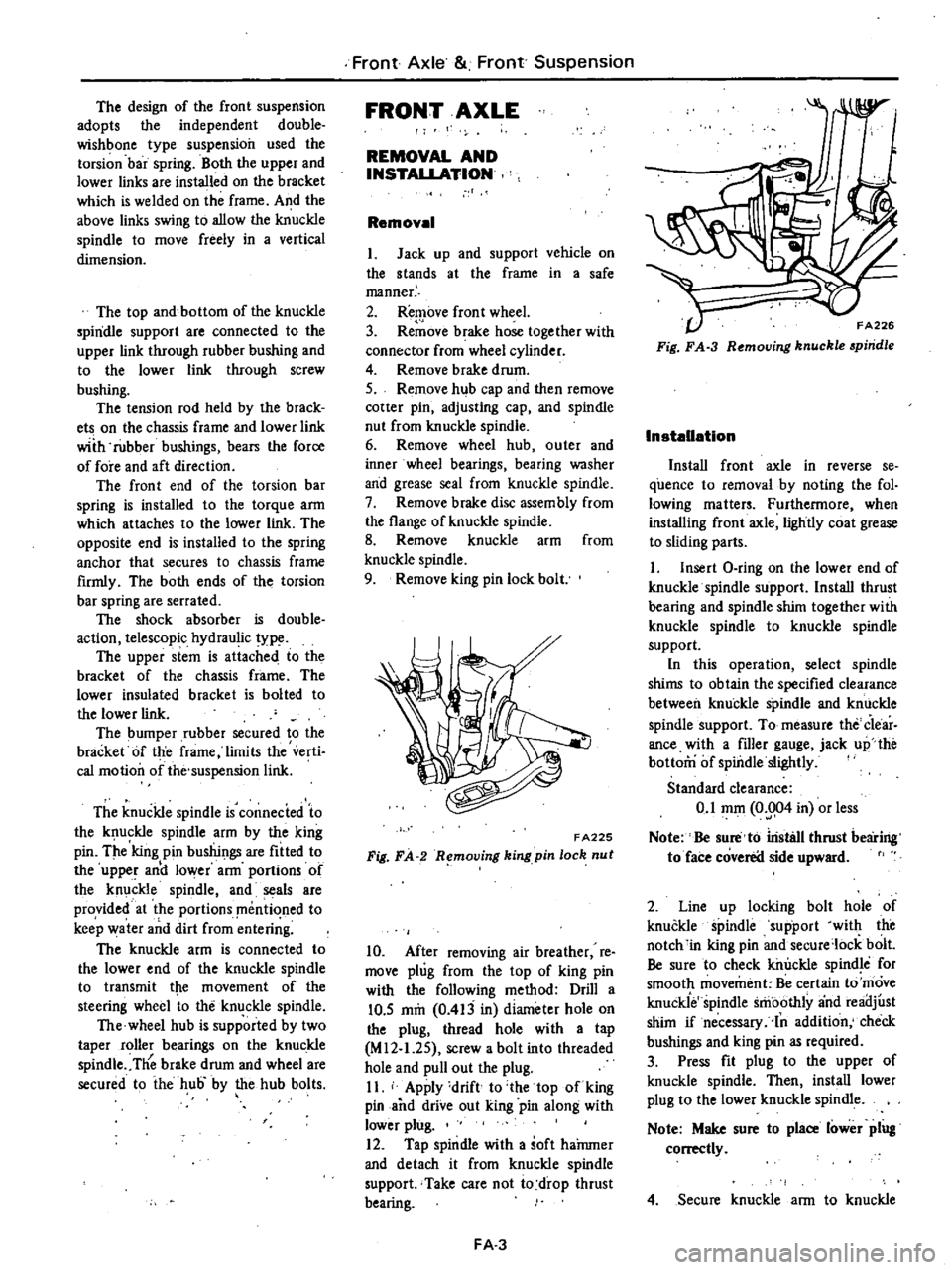

FA225

Fig

FA

R

mol1ing

king

pin

loch

nut

10

After

removing

air

breather

re

move

plug

from

the

top

of

king

pin

with

the

following

method

Drill

a

10

5

mm

0

413

in

diameter

hole

on

the

plug

thread

hole

with

a

tap

M

12

1

2S

screw

a

bolt

into

threaded

hole

and

pull

out

the

plug

II

Apply

drift

to

the

top

of

king

pin

and

drive

out

king

pin

along

with

lower

plug

12

Tap

spindle

with

a

soft

haJnmer

and

detach

it

from

knuckle

spindle

support

Take

care

not

io

drop

thrust

bearing

FA

3

FA226

Fig

FA

3

R

moving

knuckle

piridle

Installation

Install

front

axle

in

reverse

se

quence

to

removal

by

noting

the

fol

lowing

matters

Furthermore

when

installing

front

axle

lightly

coat

grease

to

sliding

parts

I

Insert

O

ring

on

the

lower

end

of

knuckle

spindle

support

Install

thrust

bearing

and

spindle

shim

together

with

knuckle

spindle

to

knuckle

spindle

support

In

this

operation

select

spindle

shims

to

obtain

the

specified

clearance

between

knuckle

spindle

and

knuckle

spindle

support

To

measure

the

Clear

ance

with

a

filler

gauge

jack

up

the

bottom

of

spindle

slightly

Standard

clearance

0

1

mOl

0

004

in

or

less

Note

Be

sure

to

iristsll

thrust

bearing

to

face

coverea

side

upward

2

Line

up

locking

bolt

hole

of

knuckle

spindle

support

with

the

notch

in

king

pin

and

secure

lock

bolt

Be

sure

to

check

killJckle

spindle

for

smooth

movement

Be

certain

to

move

knuckie

spindle

smoothly

and

reailjust

shim

if

necessary

In

addition

check

bushings

and

king

pin

as

required

3

Press

fit

plug

to

the

upper

of

knuckle

spindle

Then

install

lower

plug

to

the

lower

knuckle

spindle

Note

Make

sure

to

place

lower

plug

conectly

4

Secure

knuckle

arm

to

knuckle

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

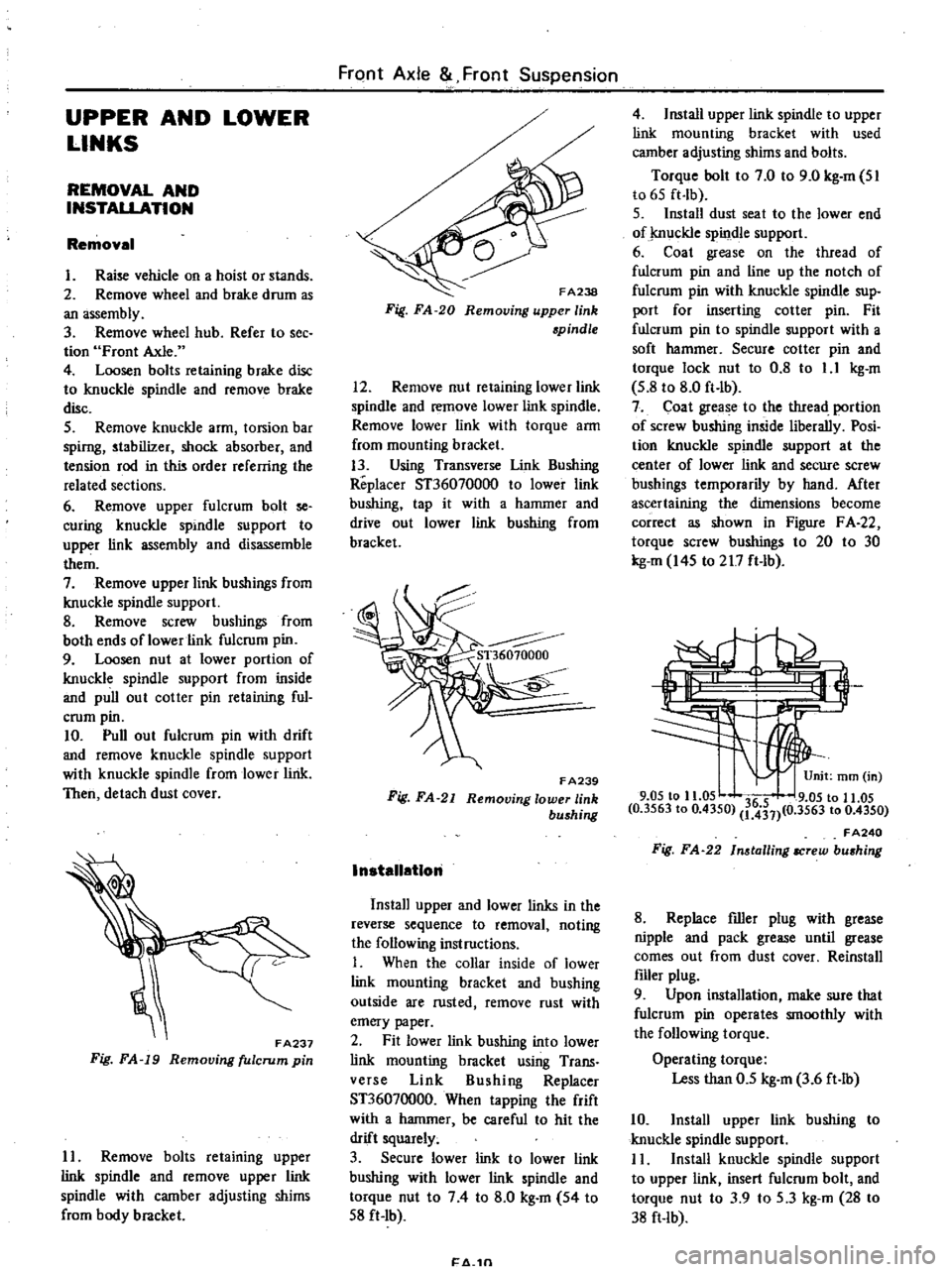

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb