window DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 435 of 537

DESCRIPTION

DOOR

REMOVAL

AND

INSTALLATION

ALIGNMENT

DOOR

TRIM

AND

SEAL

REMOVAL

AND

INSTALLATION

GLASS

RUN

REMOVAL

AND

INSTALLATION

DOOR

VENTILATOR

WINDOW

Optional

REMOVAL

AND

INSTALLATION

j

Body

Frame

DOOR

CONTENTS

BF12

BF

12

BF

12

BF12

BF12

BF12

BF13

BF

13

BF13

BF13

DOOR

GLASS

AND

REGULATOR

REMOVAL

AND

INSTALLATION

ADJUSTMENT

DOOR

LOCK

REMOVAL

AND

INSTALLATION

ADJUSTMENT

DOOR

LOCK

STRIKER

WEATHERSTRIP

DESCRIPTION

REMOVAL

AND

INSTALLATION

BF14

BF14

BF14

BF

14

BF15

BF

15

BF

15

BF

15

8F

15

BF

15

CD

CV

CID

@

@

@

1

Door

sash

2

Window

outside

weatherstrip

3

Wmdow

inside

weatherstrip

4

Door

weatherstrip

5

Rear

glass

run

rubber

6

Door

finish

holder

7

Rear

lower

sash

8

Seal

screen

9

Door

weatherstrip

clip

10

Front

glass

run

rubber

11

Lower

door

hinge

12

Upper

door

hinge

13

Front

lower

sash

14

Door

glass

15

Glazing

rubber

16

Door

glass

bottom

channel

BF030B

Fig

BF

21

Door

without

ventilator

window

BF

11

Page 436 of 537

@

I

r

L

c

@

DESCRIPTION

The

door

consists

of

inner

and

outer

panels

welded

together

to

form

a

rigid

structure

The

curved

glass

provides

greater

shoulder

room

A

door

that

incorporates

a

ventila

tor

window

is

also

available

as

an

option

The

weatherstrip

is

inserted

into

the

groove

on

the

door

sash

side

and

is

attached

by

clips

on

the

door

side

DOOR

REMOVAL

AND

INSTALLATION

I

With

door

in

full

open

position

place

a

garage

jack

or

stand

beneath

door

to

support

its

weight

when

bolts

are

removed

Place

rag

between

door

and

jack

or

stand

to

avoid

damaging

painted

surface

Body

Frame

CD

1

@

@

ID

@

AJ

@

@

@

1

Door

sash

2

Window

outside

weatherstrip

3

Window

inside

weatherstrip

4

Door

atherstrip

5

Rear

glass

run

rubber

6

Door

finish

holder

7

Rear

lower

sash

8

Seal

screen

9

Door

weatherstrip

clip

10

Front

glass

run

rubber

11

Lower

door

hinge

12

Upper

door

hinge

13

Front

lower

sash

14

Door

glass

15

Glazing

rubber

16

Door

glass

bottom

channel

11

Lower

support

18

Upper

support

19

Door

ventilator

assembly

BF031B

Fig

BF

22

Door

with

ntilator

window

Optional

BF023

Fig

BF

23

Supporting

door

2

Separate

lower

door

hinge

hole

cover

from

dash

side

trim

3

While

supporting

door

as

above

back

off

body

to

upper

and

lower

hinge

attaching

bolts

accessible

from

inside

cab

three

each

Door

can

now

be

taken

out

from

cab

body

I

t

I

l

f

p1

1

W

JJ

i

Sl

j

Fig

BF

24

Removing

door

hinge

bolt

8F

12

4

To

install

reverse

removal

pro

cedure

ALIGNMENT

Elongated

holes

three

each

in

door

hinge

and

door

lock

striker

pro

vide

for

up

and

down

forward

and

backward

and

or

sideways

adjustment

to

assure

proper

door

fit

to

door

opening

To

adjust

door

alignment

loosen

bolts

and

move

door

to

desired

posi

lion

to

obtain

a

parallel

space

between

door

sides

and

door

opening

Also

check

to

be

certain

that

weatherstrip

contacts

body

opening

evenly

to

pre

vent

entry

of

mud

and

water

DOOR

TRIM

AND

SEAL

REMOVAL

AND

INSTALLATION

1

Remove

screw

securing

inside

door

handle

escutcheon

remove

es

cutcheon

2

Remove

screws

which

hold

pull

handle

and

arm

rest

in

position

Pull

handle

and

arm

rest

can

then

be

taken

out

3

Pull

retaining

spring

off

regulator

handle

Take

out

regulator

handle

and

seat

washer

Page 437 of 537

BF640

4

When

removing

door

finish

it

is

important

that

inside

door

panel

and

door

finish

are

not

damaged

With

a

screwdriver

pry

off

re

taining

clips

exercising

care

not

to

damage

clips

I

a

I

II

I

L

jl

ld

II

Fig

BF

26

Removing

door

finish

5

Separate

water

seal

screen

from

inside

door

panel

6

To

install

reverse

removal

pro

cedure

However

observe

the

follow

ing

instalJation

notes

i

When

water

seal

screen

is

to

be

replaced

be

Sure

to

cement

it

back

into

position

securely

to

ensure

a

water

sealed

door

This

can

be

done

by

evenly

applying

adhesive

to

grooves

in

inside

door

panel

Broken

screen

Or

one

suspected

to

be

leaking

must

be

replaced

with

a

new

one

Body

Frame

1

3

Seat

washer

Regulator

handle

Retaining

spring

Fig

BF

25

Removing

regulator

handle

Adhesive

I

i

f

f

nil

Section

A

A

Ii

ir

coil

IIIII

I

J

J

iif

J

lUJ

A

A

J

J

BF641

Fig

BF

27

Adhesive

for

seal

screen

2

With

door

glass

up

set

regulator

handle

at

an

angle

shown

in

Figure

BF

28

d

1

J

900

Spring

l

BF462

Fig

BF

28

Installation

angle

of

regulator

handle

GLASS

RUN

REMOVAL

AND

INSTALLATION

I

With

door

in

full

out

position

lower

glass

all

the

way

2

Remove

pull

handle

arm

rest

and

regulator

handle

3

Remove

door

fmish

and

water

seal

screen

4

Remove

outer

and

inner

weather

strips

from

door

BF

13

5

Remove

door

glass

6

Remove

glass

run

rubbers

from

front

and

rear

lower

sashes

and

from

those

of

fixed

door

Use

caution

to

avoid

damaging

rubbers

during

removal

operation

7

Remove

front

and

rear

lower

door

sashes

when

ventilator

window

is

not

provided

8

On

vehicles

equipped

with

venti

lator

window

remove

ventilator

window

frame

and

rear

lower

door

sash

9

To

install

reverse

removal

pro

cedure

However

observe

the

follow

ing

notes

I

Before

applying

adhesive

clean

the

inside

of

door

sash

2

Apply

adhesive

to

glass

run

rubber

on

door

sash

contacting

face

and

fit

it

correctly

Particularly

care

should

be

taken

at

corners

and

contact

face

to

assure

a

good

fit

CD

CID

BF641

1

Door

sash

2

Glass

run

rubber

3

Adhesive

Fig

BF

29

Applying

adhesive

to

glass

run

ru

bber

DOOR

VENTILATOR

WINDOW

Optional

REMOVAL

AND

INSTALLATION

I

Remove

five

ventilator

window

frame

attaching

bolts

Lift

frame

out

of

door

For

detailed

procedure

refer

to

relative

topic

under

Door

Glass

and

Regulator

2

Remove

nuts

and

spring

securing

lower

end

of

ventilator

window

to

frame

3

Work

off

rivets

which

hold

upper

end

of

ventilator

window

to

frame

take

out

window

4

To

install

reverse

removal

pro

cedure

Page 438 of 537

Body

Frame

DOOR

GLASS

AND

REGULATOR

CD

REMOVAL

AND

INSTALLATION

L

Open

door

lower

glass

all

the

way

2

Remove

iflllide

door

handle

es

cutcheon

3

Remove

pull

handle

4

Remove

arm

rest

5

Remove

regulator

handle

6

Remove

door

finish

7

Peel

off

water

seal

screen

8

Work

off

outer

and

inner

weath

erstrips

from

door

being

sure

not

to

scratch

door

paint

during

operation

Use

a

suitable

plain

screwdriver

or

similar

flat

bladed

tool

io

remove

and

place

a

piece

of

rag

between

screw

driver

and

door

panel

BF643

1

Outet

weatherstrip

2

Screwdriver

3

Piece

of

rag

Fig

BF

31

Removing

outer

weather

trip

9

Remove

three

door

glass

bottom

channel

attaching

bolts

Remove

door

glass

by

lifting

it

straight

up

Fig

BF

30

Door

gl

and

regulator

10

On

door

equipped

with

venti

lator

remove

three

bolts

securing

door

glass

bottom

channel

then

let

glass

go

to

the

bottom

of

door

Remove

ventilator

frame

attaching

bolts

and

lift

frame

straight

up

out

of

door

Remove

door

glass

by

lifting

it

straight

up

11

Back

off

the

five

guide

channel

to

regulator

base

attaching

screws

Take

out

regulator

assembly

through

large

access

hole

in

inside

door

panel

DOOR

LOCK

1

Escutcheon

2

Inside

handle

3

Spring

4

Door

lock

knob

5

Knob

grommet

6

Outside

handle

7

Outside

handle

rod

j

f

ffi

I

Fig

BF

32

BF035

Removing

door

glass

12

To

install

reverse

removal

pro

cedure

ADJUSTMENT

I

In

and

out

and

fore

and

aft

ad

justment

can

be

made

by

moving

front

or

rear

sash

and

guide

channel

as

required

The

ease

with

which

window

assem

bly

raises

and

lowers

depends

on

ad

justment

of

rear

lower

sash

Rear

lower

sash

should

be

parallel

with

front

lower

sash

2

Fore

and

aft

adjustment

is

deter

mined

by

position

of

guide

channel

and

front

lower

sash

Moving

front

lower

sash

backward

reduces

play

in

window

assembly

j

CID

@

8

Nylon

nut

9

Locking

plate

ring

10

LOcking

plate

11

Door

lock

cylinder

12

Door

lock

13

Stopper

BF

14

BF410A

Fig

BF

33

Door

lock

mechonillm

Page 440 of 537

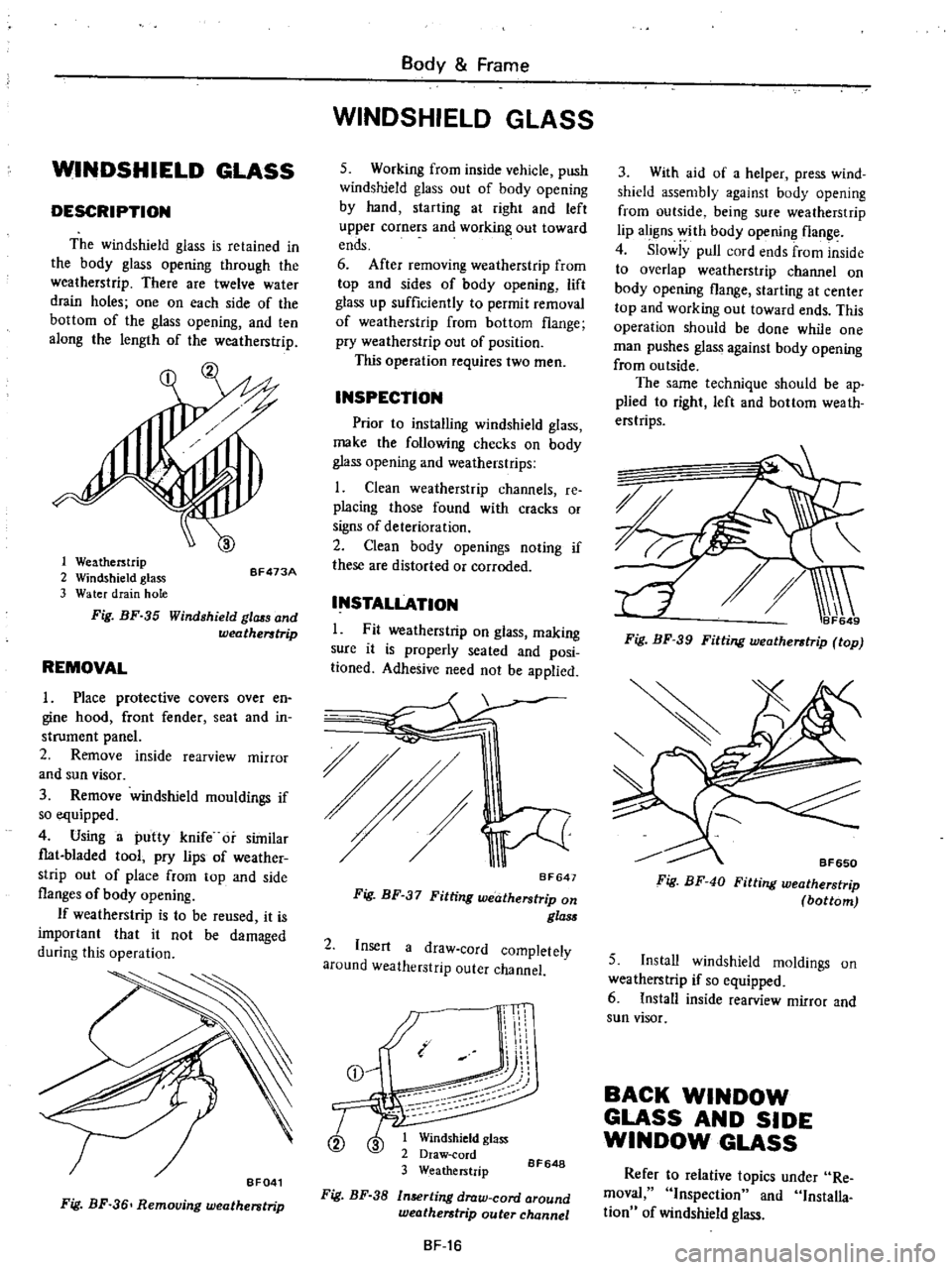

WINDSHIELD

GLASS

DESCRIPTION

The

windshield

glass

is

retained

in

the

body

glass

opening

through

the

weatherstrip

There

are

twelve

water

drain

holes

one

on

each

side

of

the

bottom

of

the

glass

opening

and

ten

along

the

length

of

the

weatherstrip

1

Weatherstrip

2

Windshield

glass

3

Water

drain

hole

Fig

BF

35

Windshield

glass

and

weatherstrip

BF473A

REMOVAL

1

Place

protective

covers

over

en

gine

hood

front

fender

seat

and

in

strument

panel

2

Remove

inside

rearview

mirror

and

sun

visor

3

Remove

windshield

mouldings

if

so

equipped

4

Using

a

putty

knife

or

similar

flat

bladed

tool

pry

lips

of

weather

strip

out

of

place

from

top

and

side

flanges

of

body

opening

If

weatherstrip

is

to

be

reused

it

is

important

that

it

not

be

damaged

during

this

operation

BF041

Fig

BF

36

Removing

weatherstrip

Body

Frame

WINDSHIELD

GLASS

5

Working

from

inside

vehicle

push

windshield

glass

out

of

body

opening

by

hand

starting

at

right

and

left

upper

COIners

and

working

out

toward

ends

6

After

removing

weatherstrip

from

top

and

sides

of

body

opening

lift

glass

up

sufficiently

to

permit

removal

of

weatherstrip

from

bottom

flange

pry

weatherstrip

out

of

position

This

operation

requires

two

men

INSPECTION

Prior

to

installing

windshield

glass

make

the

following

checks

on

body

glass

opening

and

weatherstrips

I

Clean

weatherstrip

channels

re

placing

those

found

with

cracks

or

signs

of

deterioration

2

Clean

body

openings

noting

if

these

are

distorted

or

corroded

INSTALLATION

L

Fit

weatherstrip

on

glass

making

sure

it

is

properly

seated

and

posi

tioned

Adhesive

need

not

be

applied

0

BF641

Fig

BF

37

Fitting

weatherstrip

on

glass

2

Insert

a

draw

cord

completely

around

weatherstrip

outer

channel

Q

i

I

dYii

1

Windshield

glass

2

Draw

cord

3

Weatherstrip

Fig

BF

38

In8erting

draw

cord

around

weatherstrip

outer

channel

8F648

BF

16

3

With

aid

of

a

helper

press

wind

shield

assembly

against

body

opening

from

outside

being

sure

weatherstrip

lip

aligns

ith

body

opening

flange

4

Slowly

pull

cord

ends

from

inside

to

overlap

weatherstrip

channel

on

body

opening

flange

starting

at

center

top

and

working

out

toward

ends

This

operation

should

be

done

while

one

man

pushes

glass

against

body

opening

from

outside

The

same

technique

should

be

ap

plied

to

right

left

and

bottom

wea

th

erstrips

Fig

BF

39

Fitting

weatherstrip

top

BF650

Fig

BF

40

Fitting

weatherstrip

bottom

5

Install

windshield

moldings

on

weatherstrip

if

so

equipped

6

Install

inside

rearview

mirror

and

sun

visor

BACK

WINDOW

GLASS

AND

SIDE

WINDOW

GLASS

Refer

to

relative

topics

under

Re

moval

Inspection

and

Installa

tion

of

windshield

glass

Page 442 of 537

Body

Frame

INTERIOR

TRIM

AND

CENTER

CONSOLE

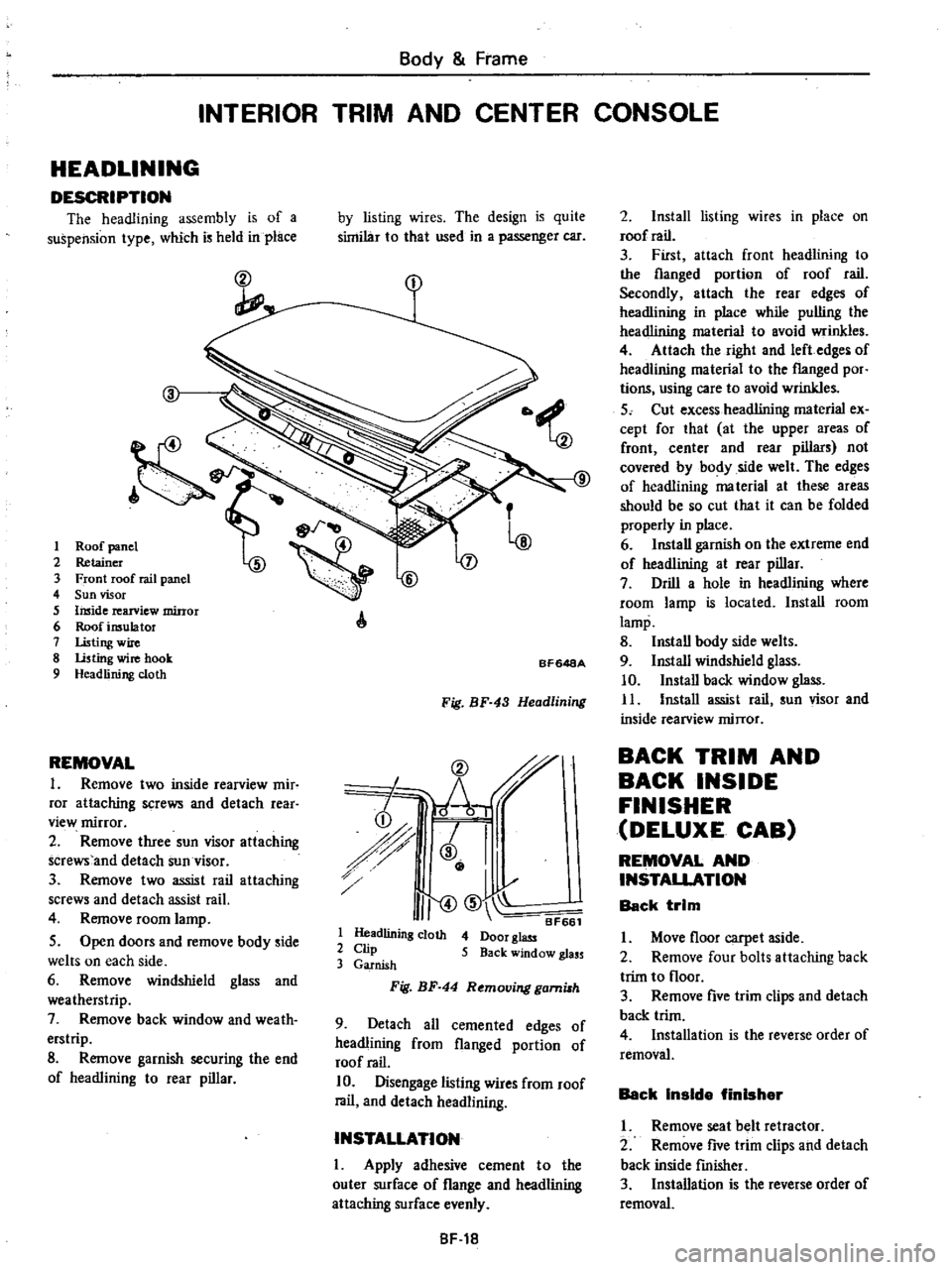

HEADLINING

DESCRIPTION

The

headlining

assembly

is

of

a

suspension

type

which

is

held

in

place

ct

I

2

3

4

5

6

7

8

9

REMOVAL

1

Remove

two

inside

rearview

mir

ror

attaching

screws

and

detach

rear

view

mirror

2

Remove

three

sun

visor

attaching

screws

and

detach

sun

visor

3

Remove

two

assist

rail

attaching

screws

and

detach

assist

rail

4

Remove

room

lamp

5

Open

doors

and

remove

body

side

welts

on

each

side

6

Remove

windshield

glass

and

weatherstrip

7

Remove

back

window

and

weath

erstrip

8

Remove

garnish

securing

the

end

of

headlining

to

rear

pillar

by

listing

wires

The

design

is

quite

similar

to

that

used

in

a

passenger

car

A

BF648A

Fig

BF

43

Headlining

CD

r

h

i

r

J

I

I

I

II

CID

BF661

1

Headlining

cloth

4

Door

glass

2

Clip

5

Back

window

glass

3

Garnish

Fig

BF

44

Removing

gami8h

9

Detach

all

cemented

edges

of

headlining

from

flanged

portion

of

roof

rail

10

Disengage

listing

wires

from

roof

rail

and

detach

headlining

INSTALLATION

I

Apply

adhesive

cement

to

the

outer

surface

of

flange

and

headlining

attaching

surface

evenly

8F

18

2

Install

listing

wires

in

place

on

roof

rail

3

First

attach

front

headlining

to

the

flanged

portion

of

roof

rail

Secondly

attach

the

rear

edges

of

headlining

in

place

while

pulling

the

headlining

material

to

avoid

wrinkles

4

Attach

the

right

and

left

edges

of

headlining

material

to

the

flanged

por

tions

using

care

to

avoid

wrinkles

5

Cut

excess

headlining

material

ex

cept

for

that

at

the

upper

areas

of

front

center

and

rear

pillars

not

covered

by

body

side

welt

The

edges

of

headlining

ma

terial

at

these

areas

should

be

so

cut

that

it

can

be

folded

properly

in

place

6

Install

garnish

on

the

extreme

end

of

headlining

at

rear

pillar

7

Drill

a

hole

in

headlining

where

room

lamp

is

located

Install

room

lamp

8

Install

body

side

welts

9

Install

windshield

glass

10

Install

back

window

glass

11

Install

assist

rail

sun

visor

and

inside

rearview

mirror

BACK

TRIM

AND

BACK

INSIDE

FINISHER

DELUXE

CAB

REMOVAL

AND

INSTALLATION

Back

trim

I

Move

floor

carpet

aside

2

Remove

four

bolts

attaching

back

trim

to

floor

3

Remove

five

trim

clips

and

detach

back

trim

4

Installation

is

the

reverse

order

of

removal

Back

Inside

finisher

I

Remove

seat

belt

retractor

2

Remove

five

trim

clips

and

detach

back

inside

fmisher

3

Installation

is

the

reverse

order

of

removal

Page 506 of 537

Notes

a

The

bubbles

seen

through

the

sight

glass

are

influenced

by

the

ambient

temperature

Since

the

bubbles

are

hard

to

show

up

in

comparatively

low

temperatures

below

200C

6S0

F

it

is

possible

that

a

slightly

larger

amount

of

refrigerant

would

be

filled

if

supplied

according

to

the

sight

glass

Be

sure

to

recheck

the

amount

when

it

exceeds

200C

680F

In

higher

temperature

the

bubbles

are

easy

to

show

up

b

When

the

screen

in

the

receiver

dryer

is

clogged

the

bubbles

will

appear

even

if

the

amount

of

refrig

erant

is

normal

In

this

case

the

outlet

side

pipe

of

the

receiver

dryer

becomes

considerably

cold

PERFORMANCE

TEST

Check

for

the

amount

of

refrigerant

in

the

system

can

be

made

by

meas

uring

pressure

on

discharge

side

The

correct

amount

of

refrigerant

is

in

the

system

if

pressure

on

the

discharge

side

is

within

the

specified

range

For

details

refer

to

Perform

ance

Test

described

later

Overcharging

will

show

up

in

higher

pressure

on

discharge

side

COMPRESSOR

OIL

LEVEL

CHECK

The

oil

used

to

lubricate

compres

sor

circulates

into

system

from

the

oil

sump

while

c9mpressor

is

operating

The

efore

to

correctly

measure

com

pressor

oil

the

amount

of

oil

flowing

to

system

must

be

considered

If

a

considerable

amount

of

leakage

of

refrigerant

gas

happens

the

leakage

of

compressor

oil

is

also

considered

There

will

be

no

compressor

oil

leak

age

from

a

completely

sealed

system

When

system

operates

under

satisfying

condition

the

compressor

oil

level

check

is

unnecessary

When

checking

the

level

of

com

pressor

oil

or

when

replacing

any

component

part

of

the

system

use

the

following

service

procedure

This

fa

cilitates

to

return

oil

to

compressor

I

Operate

compressor

at

engine

idling

speed

1

000

rpm

or

below

with

controls

set

for

maximum

cooling

Air

Conditionin

j

and

high

blower

speed

for

10

to

15

minutes

in

order

to

return

compressor

oil

to

compressor

2

Stop

the

engine

and

discharge

refrigerant

of

system

and

then

remove

compressor

from

the

vehicle

3

Remove

compressor

fIller

plug

Drain

compressor

oil

from

compres

sor

oil

sump

and

measure

the

amount

4

Compressor

oil

is

satisfactory

if

the

following

amount

of

oil

remains

in

the

compressor

Residual

oil

S5

to

128

gr

3

to

4

oz

5

Check

the

cleanliness

of

the

oil

If

the

oil

contains

chips

or

other

foreign

material

clean

oil

5ump

with

new

oil

6

Discard

the

used

oil

and

fili

with

the

same

amount

of

new

oil

Add

oil

if

found

less

than

above

amount

Fig

AC

27

Filler

plug

If

compressor

is

inoperative

due

to

faulty

compressor

or

heavy

loss

of

refrigerant

remove

compressor

and

repair

as

necessary

Then

pour

oil

up

to

correct

level

and

install

on

engine

After

above

steps

have

been

complet

ed

recheck

oil

level

drain

oil

to

correct

level

if

level

is

excessively

high

PERFORMANCE

TEST

The

cooling

performance

of

the

air

conditioner

changes

considerably

with

changes

in

surrounding

conditions

Testing

must

be

performed

using

the

correct

method

This

test

is

used

to

judge

whether

system

is

operating

cor

rectly

and

can

also

be

used

as

a

guide

in

checking

for

problems

I

Park

the

vehicle

indoors

or

in

the

shade

AC

17

2

Open

all

the

windows

of

the

vehicle

fully

However

close

the

doors

3

Open

the

hood

4

Connect

manifold

gauge

to

high

and

low

side

service

valves

of

the

system

Refer

to

Handling

Manifold

Ga

uge

5

Set

fan

control

lever

to

maxi

mum

6

Set

temperature

control

lever

to

max

cool

position

7

Start

the

engine

and

hold

engine

speed

at

1

500

rpm

S

After

the

air

conditioner

has

been

operated

for

about

10

minutes

measure

system

pressures

at

high

pres

sure

discharge

side

and

low

pressure

suction

side

9

Measure

the

temperature

of

dis

charge

air

at

outlet

grille

10

Measure

the

temperature

of

capin

11

Measure

ambient

temperature

and

humidity

one

meter

3

3

ft

away

from

condenser

front

Be

careful

not

to

expose

dry

buib

and

wet

bulb

to

direct

sunlight

12

Check

for

any

abnormalities

by

comparing

the

test

results

with

stand

ard

pressure

in

Performance

Chart

Notes

a

The

pressure

will

change

in

the

followi

g

manner

with

changes

in

conditions

When

blower

speed

is

low

dis

charge

pressure

will

drop

When

the

relative

humidity

of

in

take

air

is

low

discharge

pressure

will

drop

b

The

temperature

will

change

in

the

following

manner

with

changes

in

conditions

When

the

ambient

air

temperature

is

low

the

outlet

air

temperature

will

become

low

If

the

test

reveals

that

there

is

any

abnormality

in

system

pressure

isolate

the

cause

and

repair

by

reference

to

the

Trouble

Diagnoses

and

Cor

rections