AUX DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 266 of 537

the

space

from

I

to

IS

increases

space

from

15

to

the

drain

port

simultaneously

decreases

As

a

resull

governor

pressure

of

15

increases

and

the

governor

pressure

is

balanced

with

the

sum

of

centrifugal

force

and

spring

force

The

governor

pressure

thus

changes

in

response

to

the

vehicle

speed

change

centrifugal

force

Operation

of

prlmar

governor

valve

The

valve

is

an

ON

OFF

valve

which

closes

the

governor

pressure

IS

regulated

by

the

secondary

gover

nor

valve

when

the

vehicle

reaches

the

minimum

speed

and

when

the

vehicle

speed

exceeds

a

certain

level

the

governor

opens

and

forwards

the

gov

ernor

pressure

15

to

the

control

valve

When

the

vehicle

is

stopped

the

governor

pressure

is

zero

However

when

the

vehicle

is

running

slowly

this

valve

is

depressed

to

Ihe

center

and

the

groove

to

15

is

closed

since

the

governor

pressure

applied

to

the

ring

shaped

area

is

higher

than

the

centrifugal

force

of

this

valve

When

the

governor

speed

exceeds

a

certain

revolution

the

governor

pressure

in

the

circuit

15

also

increases

How

ever

as

the

centrifugal

force

increases

and

exceeds

the

governor

pressure

this

valve

moves

toward

the

outside

and

the

governor

pressure

is

transmitted

to

the

circuil

5

Two

different

valves

are

employed

in

the

governor

so

that

it

will

inde

pendently

control

the

speed

at

high

and

low

speeds

That

is

within

the

low

speed

range

the

governor

pressure

is

not

generated

because

of

the

primary

valve

whereas

at

the

high

speed

range

above

the

breaking

point

governor

pressure

is

regulated

by

the

secondary

valve

The

breaking

point

is

the

point

at

which

the

function

of

one

of

the

governor

is

transferred

to

the

other

as

the

speed

changes

from

the

low

speed

to

the

high

speed

range

Automatic

Transmission

To

onlml

valve

l

Governor

pre

S1I

1I5

j

I

Q

J

J

f

1

1

CID

l

l

m

Line

pressure

t

D@

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

AT090

4

Oil

di

lributor

5

Output

sh

lft

Fig

AT

7

Cr05s

sectionallliew

of

governor

CONTROL

VALVE

ASSEMBLY

Ai09

Fig

AT

S

Output

shaft

with

oil

distributor

and

overnor

r

@

@

0

aBUlllI8

iUQlli

V

JlAU

I

Oil

distributor

2

Governor

nlve

body

A

T092

3

Primary

governor

valve

4

Secondary

governol

valve

Fig

A

T

9

Exploded

view

of

governor

Flow

cbar

of

control

valve

system

Oil

from

pump

Regulator

valve

1

I

i

j

Throttle

valve

I

I

l

Manual

valve

I

I

I

I

I

I

I

L

n

L

j

Speed

change

valve

I

I

t

t

I

I

I

I

I

I

Governor

I

I

valve

I

I

I

L

L

1

II

Auxiliary

valve

Line

pressure

j

Clutch

and

brake

The

control

valve

assembly

receives

oil

from

the

pump

and

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

outputs

More

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

as

line

pressure

build

up

the

line

pressure

is

fed

out

from

the

control

valve

assembly

through

various

direc

AT

6

tion

changeover

valves

including

ON

OFF

valve

and

regulator

valves

are

newly

reformed

to

a

throllle

system

oil

pressure

and

operate

other

valves

Finally

the

line

pressure

is

transmilled

to

the

required

dutch

or

brake

servo

pisJon

unit

in

response

to

the

individu

af

running

conditions

after

re

ejving

signals

from

the

va

uum

diaphragm

downshift

solenoid

governor

V

dlvc

and

or

manual

linkage

Page 273 of 537

HYDRAULIC

SYSTEM

AND

MECHANICAL

OPERATION

The

operating

system

of

oil

pres

sure

in

each

range

is

described

below

The

oil

pressure

in

each

circuit

shown

in

the

illustration

is

classified

as

follows

according

to

the

function

fhe

numeraJs

show

the

circuit

num

bers

Pressure

source

of

the

line

7

Operating

Iinc

prcssure

for

friction

elements

123456

8910

1112

Auxiliary

line

pressurc

13

Throttle

system

pressure

16

17

18

19

Others

14

15

Oil

pump

discharge

hole

7

Cd

Torque

converter

pressure

14

Rear

iutch

prc

surc

1

FTOOI

c1

tL

h

prc

ur

It

J

1

011

pump

Sllctlon

hole

M

IIJ1iIII

Automatic

Transmission

Fig

AT

21

Identification

of

oil

channels

in

oil

pump

AT105

Oil

pump

suction

hole

ATl06

Fig

AT

22

Identification

of

oil

channels

in

case

front

face

I

o

Oil

pump

dischar

hole

7

I9JM

c

Torque

converter

f

Os

I

1L

0

ervo

Ie

ease

pressure

14

0

pressure

10

Rear

clutch

Servo

t

ightening

ho

L

pressure

l

0

1

pressure

9

lJ

L

I

c

I

Front

clutch

IT

0

LIO

reverse

brake

pressure

12

U

r

FT

II

pressure

11

rrOil

pump

suction

hol

J

C

Jf

JC

O

Governor

pressure

15

Governor

feed

pressure

l

An07

Fig

AT

23

Identification

of

oil

channels

in

case

face

AT

13

Page 323 of 537

Automatic

Transmission

SERVICE

DATA

AND

SPECIFICATIONS

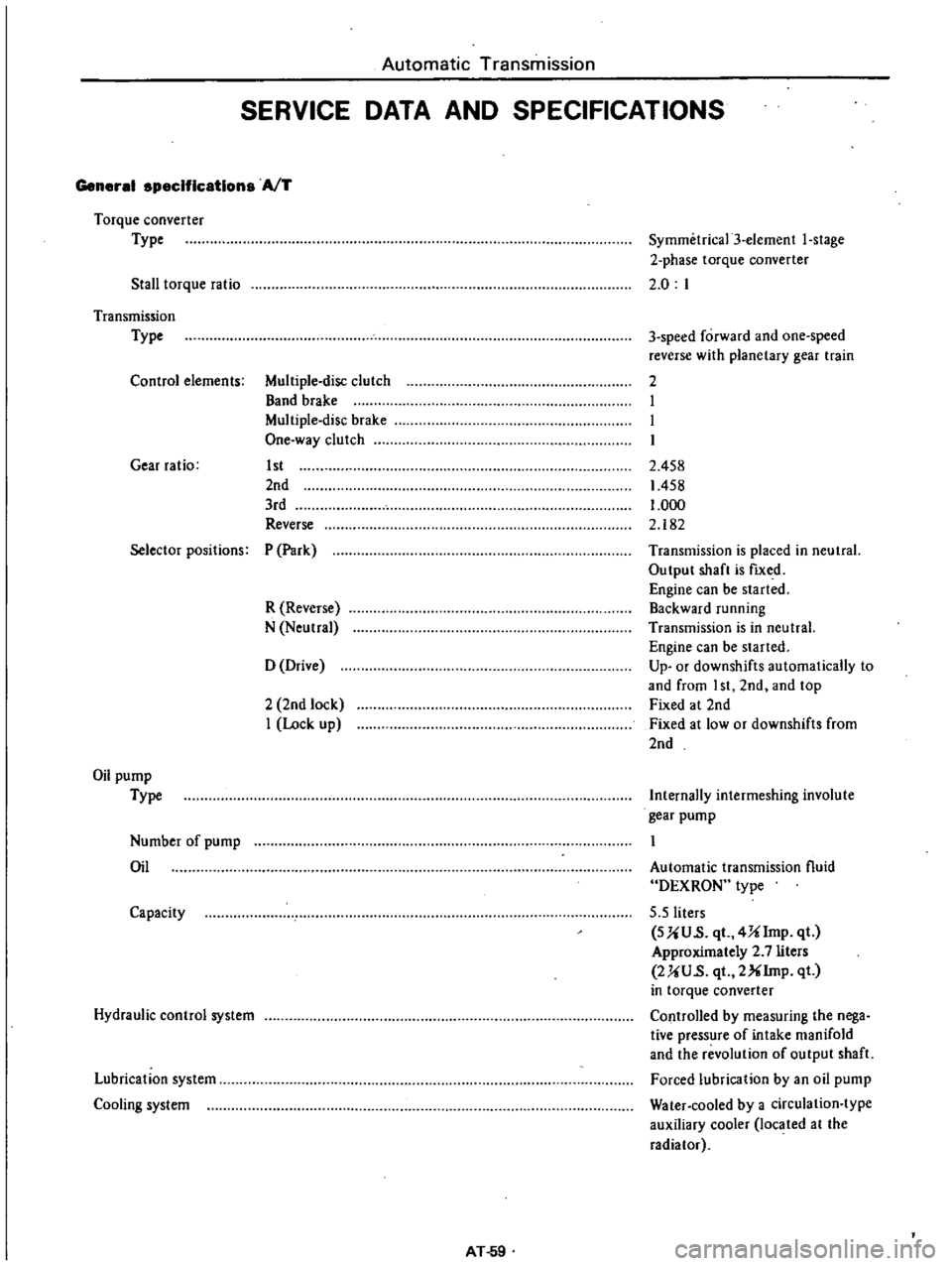

General

specifications

AfT

Torque

converter

Type

Stall

torque

ratio

Symmetrica13

element

I

stage

2

phase

torque

converter

2

0

I

Transmission

Type

Control

elements

Multiple

disc

clutch

Band

brake

Multiple

disc

brake

One

way

clutch

Gear

ratio

1st

2nd

3rd

Reverse

3

speed

forward

and

one

speed

reverse

with

planetary

gear

train

2

I

I

I

2

458

1458

1

000

2

182

Selector

positions

P

Park

R

Reverse

N

Neutral

Transmission

is

placed

in

neutral

Output

shaft

is

fIXed

Engine

can

be

started

Backward

running

Transmission

is

in

neutral

Engine

can

be

started

Up

or

downshifts

automatically

to

and

from

I

st

2nd

and

top

Fixed

at

2nd

Fixed

at

low

or

downshifts

from

2nd

o

Drive

2

2nd

lock

I

Lock

up

Oil

pump

Type

Internally

intermeshing

involute

gear

pump

Number

of

pump

Oil

Automatic

transmission

fluid

DEXRON

type

5

5

liters

SUU

s

qt

4Ulmp

qt

Approximately

2

7

liters

2UU

s

qt

2XIrnp

qt

in

torque

converter

Controlled

by

measuring

the

nega

tive

pressure

of

intake

manifold

and

the

revolution

of

output

shaft

Forced

lubrication

by

an

oil

pump

Water

cooled

by

a

circulation

type

auxiliary

cooler

located

at

the

radiator

Capacity

Hydraulic

control

system

Lubrication

system

Cooling

system

AT

59