lock DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 8 of 537

IDENTIFICATION

NUMBERS

The

unit

and

vehicle

numbers

are

stamped

and

registered

at

the

factory

The

engine

and

vehicle

identifica

tion

numbers

are

used

on

legal

docu

ments

These

numbers

are

used

for

factory

communications

such

as

Technical

Reports

Warranty

Claims

Service

Journals

and

other

informa

tion

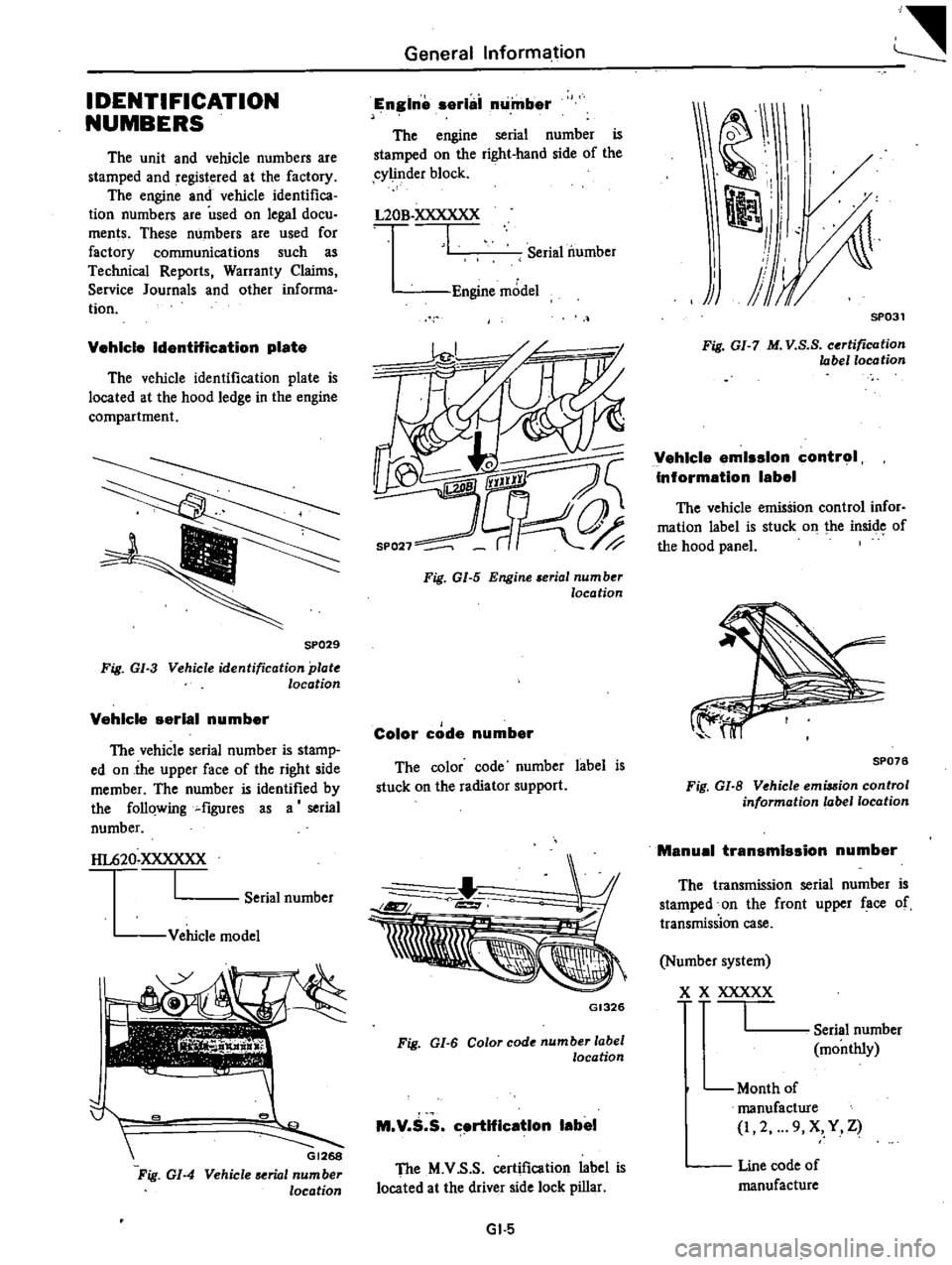

Vehicle

IdentHication

plate

The

vehicle

identification

plate

is

located

at

the

hood

ledge

in

the

engine

compartment

SP029

Fig

GI

3

Vehicle

identification

plat

location

Vehicle

serial

number

The

vehicle

serial

number

is

stamp

ed

on

the

upper

face

of

the

right

side

member

The

number

is

identified

by

the

follQwing

flgUres

as

a

serial

number

HL620

XXXXXX

I

Serial

number

Vehicle

model

j

e

G1268

Vehicle

serial

number

location

Fig

GI

4

General

Informa

tion

Engine

serllii

number

The

engine

serial

number

is

stamped

on

the

right

hand

side

of

the

cylinder

block

L20B

XXXXXX

I

Serial

number

Engine

model

k

Color

code

number

The

color

code

number

label

is

stuck

on

the

radiator

support

GI326

Fig

01

6

Color

code

number

label

location

M

V

S

S

c

rtlflcatlon

label

The

M

V

S

S

certification

label

is

located

at

the

driver

side

lock

pillar

Gl

5

tW

I

1

I

il

j

SP031

Fig

GI

7

M

V

S

S

certification

label

location

Vehicle

emission

control

Information

label

The

vehicle

emission

control

infor

mation

label

is

stuck

on

the

insicre

of

the

hood

panel

SP076

Fig

GI

B

Vehicle

emia

ion

control

information

label

location

Manual

transmission

number

The

transmission

serial

number

is

stamped

on

the

front

upper

face

of

transmission

case

Number

system

x

X

XXXXX

I

Serial

number

monthly

Month

of

manufacture

2

9

X

Y

Z

Line

code

of

manufacture

Page 9 of 537

Fig

GI

9

Manual

trammiuion

number

location

Automatic

transmission

number

The

transmission

serial

number

is

attached

to

the

right

hand

side

of

transmission

case

Numbering

system

X

XXXXX

I

Serial

number

monthly

Month

of

manufacture

I

2

9

X

Y

Z

last

figure

of

year

of

manufacture

AT344

Fig

01

10

Automatic

trammi

sion

number

location

LIFTING

POINTS

AND

TOWING

LIFTING

POINTS

Screw

jack

Before

using

the

jack

proceed

a

follows

Generallnforml

ition

Apply

parking

brake

firmly

and

block

rear

wheels

if

the

front

of

the

vehicle

is

to

be

raised

Notes

a

Never

get

under

the

vehicle

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

frame

or

rear

axle

case

when

you

have

to

get

beneath

the

vehicle

b

In

no

event

should

the

jack

be

applied

to

any

points

except

the

following

specified

portions

When

jacking

up

the

front

side

place

a

screw

jack

under

side

frame

about

520

nun

20

5

in

at

rear

of

front

axle

center

WT012

Fig

GI

ll

Front

lifting

point

When

jacking

up

the

rear

side

place

a

screw

jack

under

rear

axle

case

close

to

the

side

of

rear

spring

WH077

Fig

GI

12

Reor

lifting

point

Notes

a

When

the

yellow

mark

appean

on

the

screw

jack

it

indicates

the

maximum

permissible

height

Do

not

jack

up

further

b

When

the

jack

is

at

lower

llinit

do

not

add

large

force

downward

GI

6

YeDow

mark

WHOSO

Fig

GI

13

Warning

ogai

t

over

stroke

Garage

Jack

Note

When

carrying

out

operntions

with

a

garage

jack

be

sure

to

support

the

vehicle

withstands

in

a

safe

manner

When

jacking

up

the

front

end

apply

garage

jack

to

front

cross

member

or

center

portion

of

sus

pension

member

When

jacking

up

the

rear

end

apply

the

jack

to

rear

axle

case

r

J

uc

I

GI075

n9

Fig

GI

14

Front

lifting

point

GI076

Fig

GI

15

Rear

lifting

point

Page 19 of 537

Engine

Tune

up

BASIC

MECHANICAL

SYSTEM

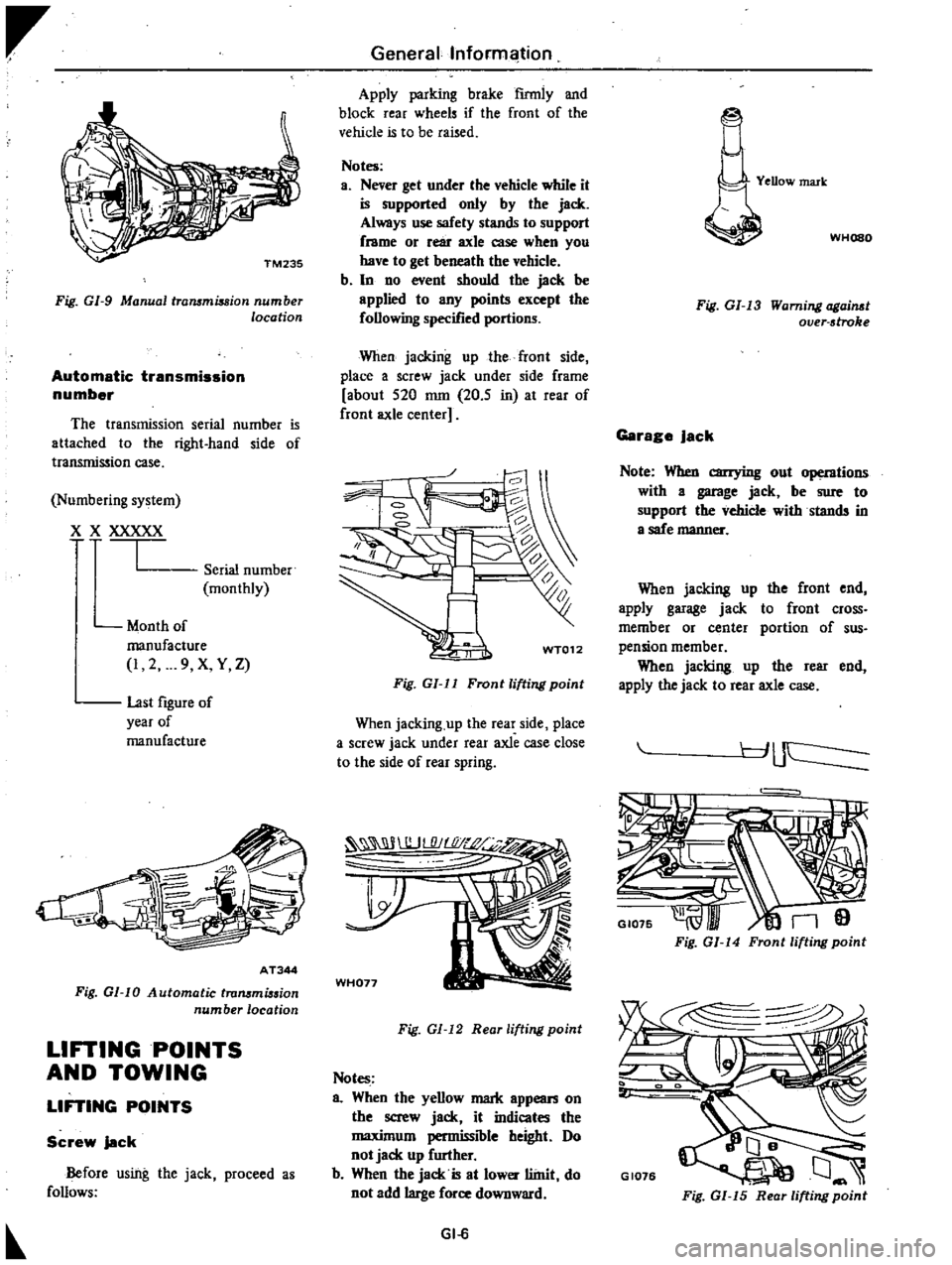

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

CHECKING

AND

ADJUSTING

DRIVE

BELT

RETIGHTENING

CYLINDER

HEAD

BOLTS

MANIFOLD

NUTS

AND

CARBURETOR

SECURING

NUTS

CHECKING

ENGINE

OIL

REPLACING

OIL

FILTER

CHANGING

ENGINE

COOLANT

ADJUSTING

INTAKE

AND

EXHAUST

VALVE

CLEARANCE

Note

After

tightening

cylinder

head

bolts

adjust

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

is

impossible

when

the

engine

is

in

oper

ation

1

Loosen

pivot

locking

nu

t

and

turn

pivot

screw

until

the

specified

clearance

is

obtained

while

cold

Using

service

tool

tighten

pivot

locking

nut

securely

after

adjustment

and

recheck

the

clearance

2

Warm

up

engine

for

at

least

several

minutes

and

stop

it

Measure

valve

clearance

while

hot

If

out

of

specifications

adjust

Unit

mm

in

Intake

0

20

0

008

Cold

Exhaust

0

25

0

010

Intake

0

25

OmO

Wann

I

Exhaust

0

30

0

012

STl

064000

I

ET009

Fig

ET

5

Adjusting

valve

clearance

CONTENTS

ET

7

PERMANENT

ANTI

FREEZE

COOLANT

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

INSPECTION

OF

RADIATOR

CAP

COOLING

SYSTEM

PRESSURE

TEST

CHECKING

VACUUM

FITTINGS

HOSES

AND

CONNECTIONS

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

TEST

RESULT

ET

7

ET7

ET

B

ET

B

ET

B

CHECKING

AND

ADJUSTING

DRIVE

BELT

ET

B

ET

B

ET

B

ET

B

ET

B

ET

9

ET

9

ET

9

2

Normal

drive

belt

deflection

is

8

to

12

mm

0

315

to

0

472

in

when

moderate

thumb

pressure

is

applied

midway

between

pulleys

1

Check

for

cracks

or

damage

Re

place

if

necessary

Compressor

pulley

8

to

12

mm

0

315

to

0

472

in

Idler

pulley

Water

pump

pulley

8

to

12

mm

0

315

to

0

472

in

Air

pump

pulley

Alternator

AC456

Fig

ET

6

Driue

belt

tension

RETIGHTENING

CYLINDER

HEAD

BOLTS

MANIFOLD

NUTS

AND

CARBURETOR

SECURING

NUTS

Tightening

torque

Cylinder

head

bolts

1st

turn

4

0

kg

m

29

ft

Ib

2nd

turn

6

0

kg

m

43

ft

Ib

3rd

turn

6

5

to

8

5

kg

m

47

to

61

ft

lb

Refer

to

the

following

tightening

torque

specifications

ET

7

Page 22 of 537

p

r

ET002

Fig

E1

11

Checking

specific

gravity

of

bottery

electrolyre

Clean

top

of

battery

and

terminals

with

a

solution

of

bakin

soda

and

Pennissible

value

Frigid

climates

Over

1

22

Tropical

climates

lOver

1

18

Other

climates

lOver

1

20

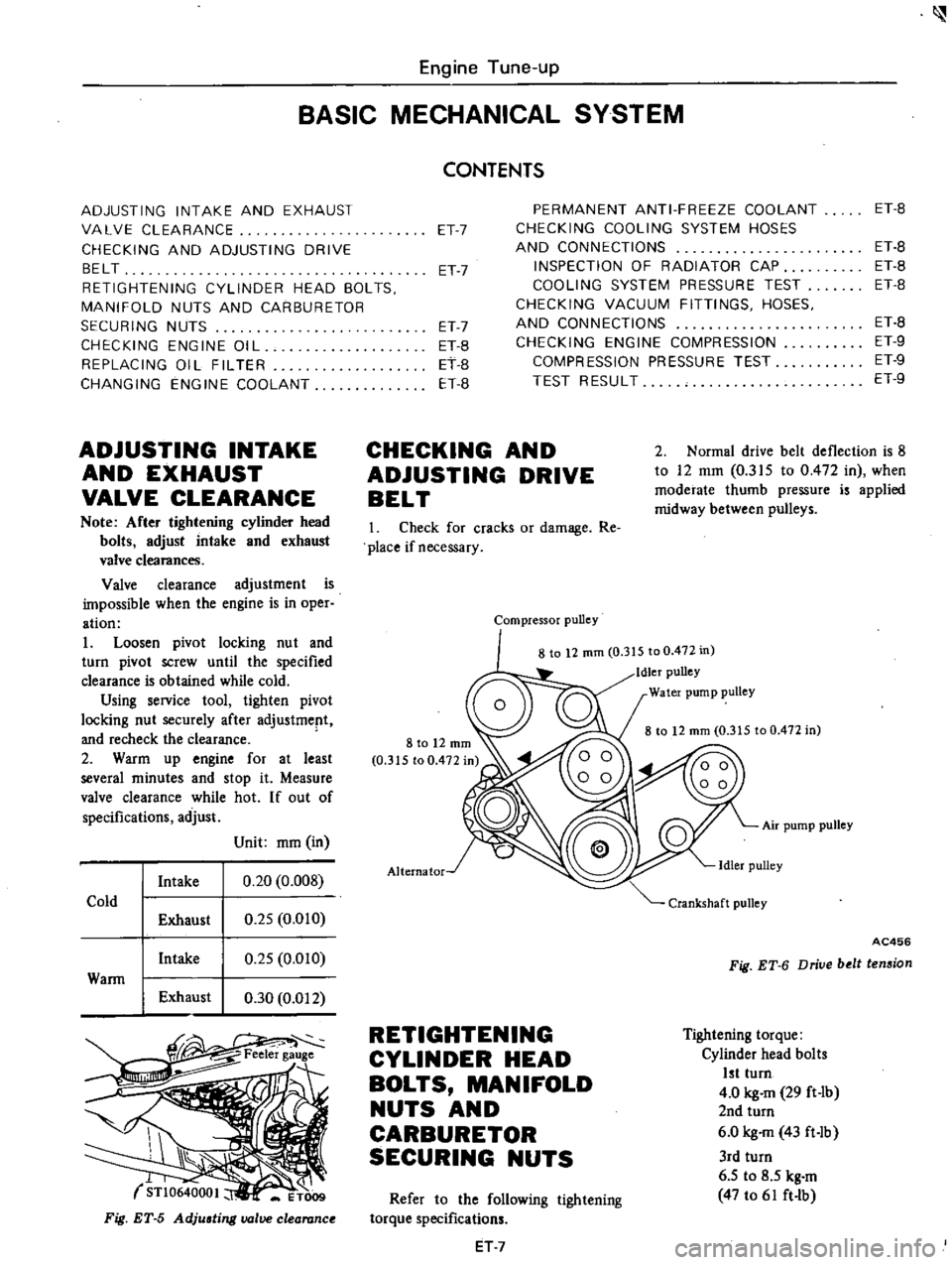

CHECKING

AND

ADJUSTING

IGN

ITIONTIM

iNG

AD

IUSTING

IGNITION

TIMING

I

Check

spark

plugs

and

distributor

breaker

points

for

condition

2

Thoroughly

remove

dirt

and

dust

from

timing

mark

on

crank

pulley

and

timing

indicator

on

front

cover

3

Warin

up

engine

sufficiently

4

Imtalla

timing

light

on

No

I

cylinder

spark

plug

wire

and

install

a

tachometer

5

Set

idling

spero

toapproxintate

y

750

rpm

6

Check

ignition

timing

with

a

timing

light

if

it

is

specified

value

If

necessary

adjust

it

as

follows

1

Loosen

setscrew

until

distribu

tor

can

be

moved

by

hand

2

Adjust

ignition

timing

to

speci

fied

value

3

0

Lock

distributor

setscrew

ai1d

make

sure

that

timing

is

correc

Engine

Tune

up

water

Rinse

off

and

dry

with

com

pressed

air

Top

of

battery

must

be

clean

to

prevent

current

leakage

be

tween

terminals

and

from

positive

terminal

to

hold

down

clamp

In

addition

to

current

leakage

pro

longed

accumulation

of

acid

and

dirt

o

n

top

If

l

l

ry

may

ca

u

iCbli

t

rj

I

g

of

the

material

covering

connector

straps

and

corrosion

of

straps

After

tightening

terminals

coat

them

with

petrolatum

vaseline

to

protect

them

from

corrosion

Full

charge

value

at

200C

680F

1

28

1

23

1

26

oo

I

ET169

Fig

ET

13

Checking

ignition

timing

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

models

100

750

rpIll

California

models

Automatic

transmission

120

650

rpin

in

0

position

ET

10

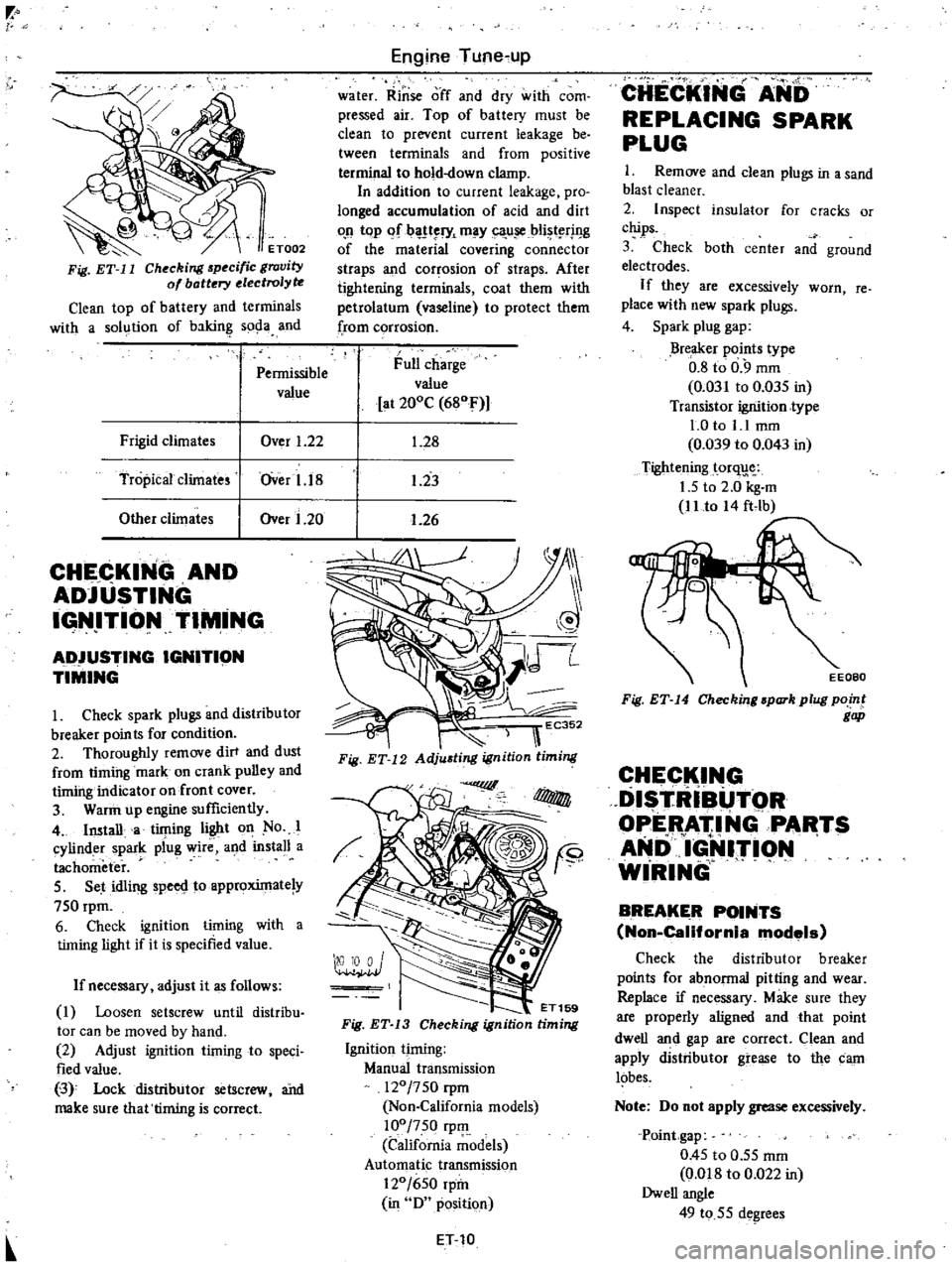

CHECKING

ANb

REPLACING

SPARK

PLUG

I

Remove

and

clean

plugs

in

a

sand

blast

cleaner

2

Inspect

insulator

for

cracks

or

chips

3

Check

both

center

and

ground

electrodes

If

they

are

excessively

worn

re

place

with

new

spark

plugs

4

Spark

plug

gap

Breaker

points

type

0

8

to

0

9

mm

0

031

to

0

035

in

Transistor

ignition

type

1

0

to

1

1

mm

0

039

to

0

043

in

Tightening

torq

1

5

to

2

0

kg

m

11

to

A4

ft

lb

Fig

ET

14

Checking

spark

plug

point

gap

CHECK

I

G

DISTRIBUTOR

OPERATING

PARTS

AND

1

lrI9N

WIRING

BREAKER

POINTS

Non

California

models

Check

the

distributor

breaker

points

for

abnonnal

pitting

and

wear

Replace

if

necessary

Make

sure

they

are

properly

aligned

and

that

point

dwell

and

gap

are

correct

Clean

and

apply

distributor

grease

to

the

carn

lobes

Note

00

not

apply

grease

excessively

Point

gap

0

45

to

0

55

mm

Om8

to

0

022

in

Owell

angle

49

to

55

degrees

Page 23 of 537

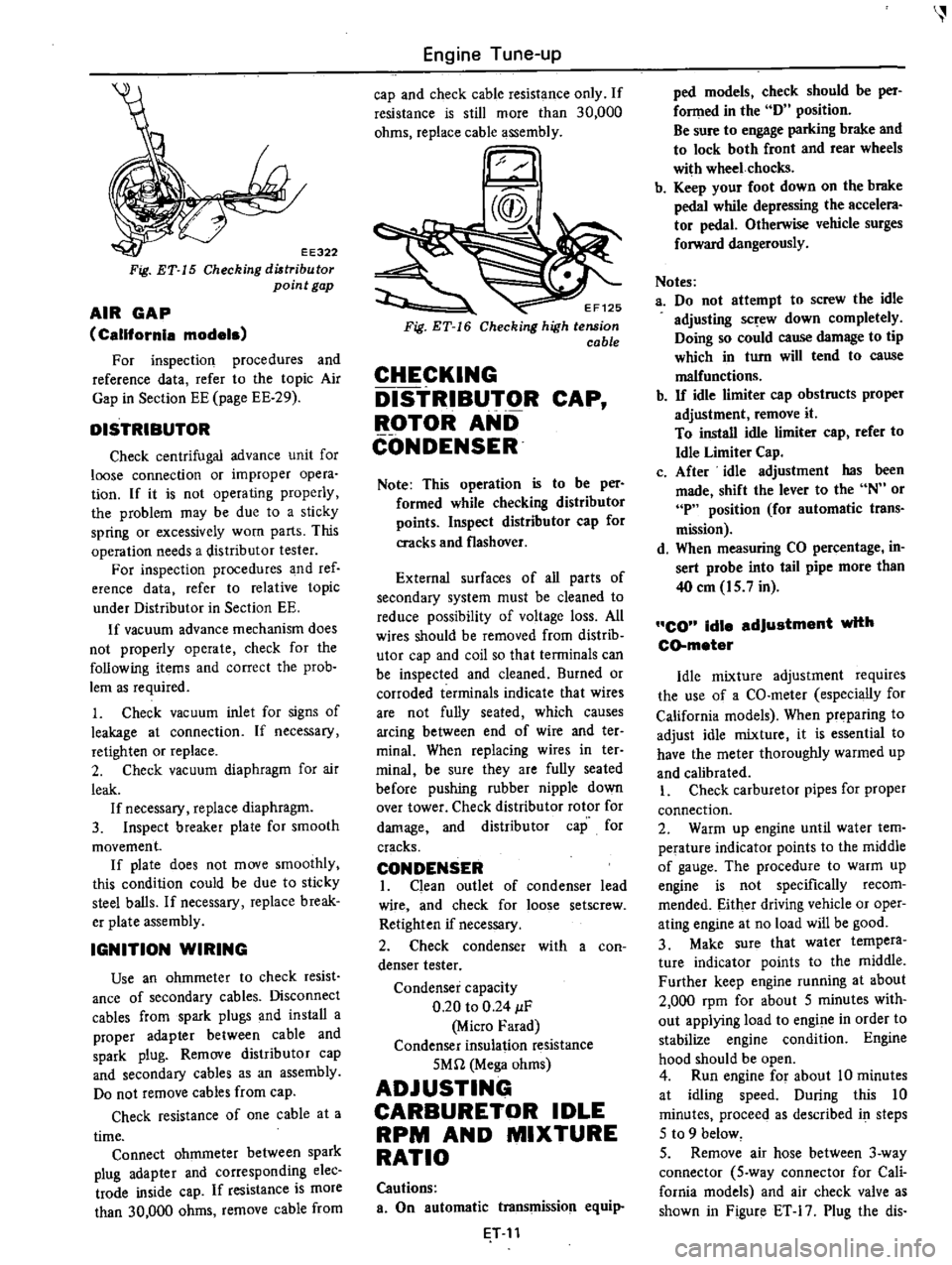

EE322

Fig

ET

15

Checking

diltribu

tor

point

gap

AIR

GAP

California

models

For

inspection

procedures

and

reference

data

refer

to

the

topic

Air

Gap

in

Section

EE

page

EE

29

DISTRIBUTOR

Check

centrifugal

advance

unit

for

loose

connection

or

improper

opera

tion

If

it

is

not

operating

properly

the

problem

may

be

due

to

a

sticky

spring

or

excessively

worn

parts

This

operation

needs

a

distributor

tester

For

inspection

procedures

and

ref

erence

data

refer

to

relative

topic

under

Distributor

in

Section

EE

If

vacuum

advance

mechanism

does

not

properly

operate

check

for

the

following

items

and

correct

the

prob

lem

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

connection

If

necessary

retighten

or

replace

2

Check

vacuum

diaphragm

for

air

leak

If

necessary

replace

diaphragm

3

Inspect

breaker

plate

for

smooth

movement

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

If

necessary

replace

break

er

plate

assembly

IGNITION

WIRING

Use

an

ohmmeter

to

check

resist

ance

of

secondary

cables

Disconnect

cables

from

spark

plugs

and

install

a

proper

adapter

between

cable

and

spark

plug

Remove

distributor

cap

and

secondary

cables

as

an

assembly

Do

not

remove

cables

from

cap

Check

resistance

of

one

cable

at

a

time

Connect

ohmmeter

between

spark

plug

adapter

and

corresponding

elec

trade

inside

cap

If

resistance

is

more

than

30

000

ohms

remove

cable

from

Engine

Tune

up

cap

and

check

cable

resistance

only

If

resistance

is

still

more

than

30

000

ohms

replace

cable

assembly

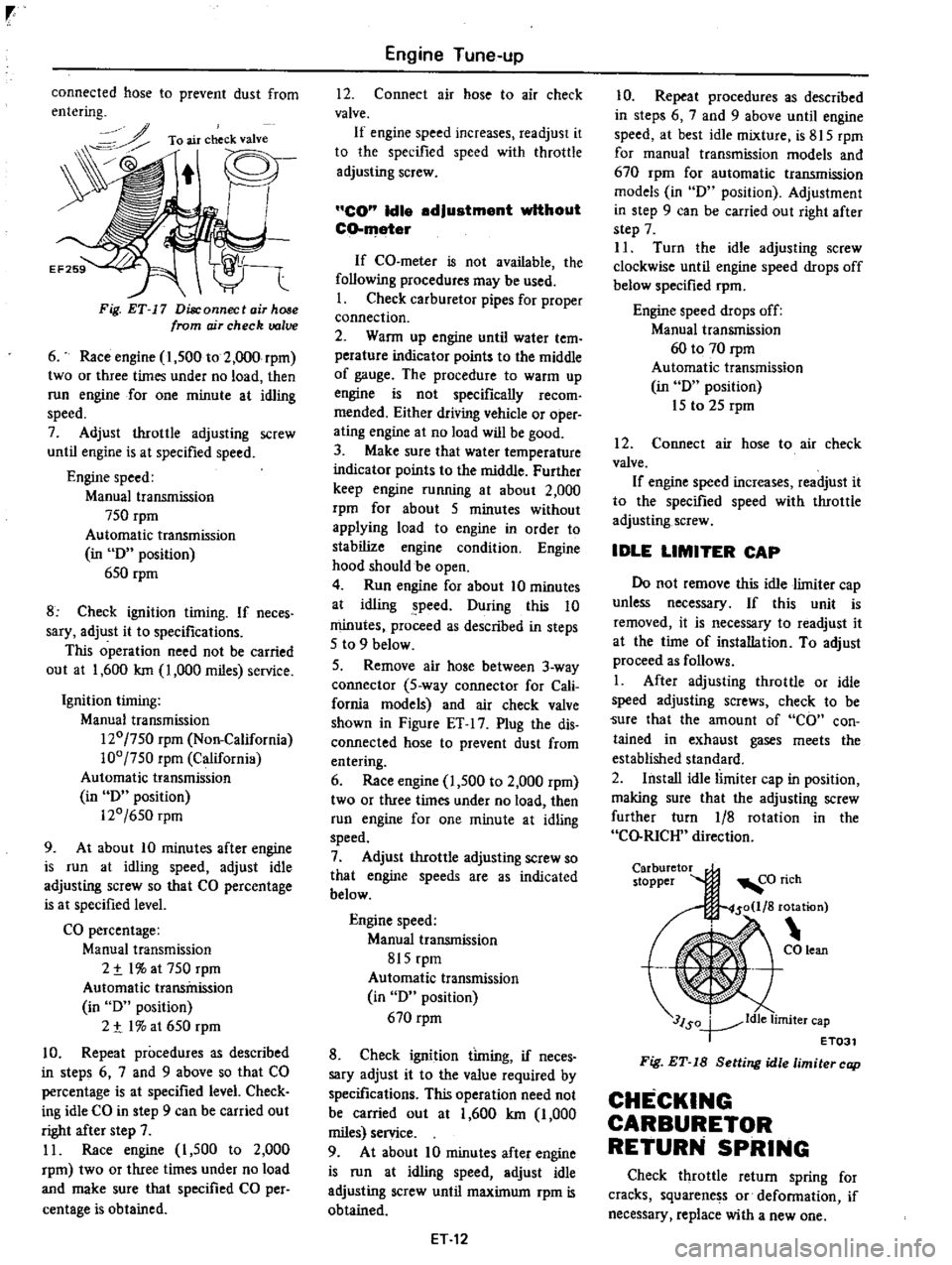

EF125

Checking

high

tension

cable

CHECKING

DISTRIBUTOR

CAP

ROTOR

AND

CONDENSER

Note

This

operation

is

to

be

per

formed

while

checking

distributor

points

Inspect

distributor

cap

for

cracks

and

flashover

External

surfaces

of

all

parts

of

secondary

system

must

be

cleaned

to

reduce

possibility

of

voltage

loss

All

wires

should

be

removed

from

distrib

utor

cap

and

coil

so

that

terminals

can

be

inspected

and

cleaned

Burned

or

corroded

terminals

indicate

that

wires

are

not

fully

seated

which

causes

arcing

between

end

of

wire

and

ter

minal

When

replacing

wires

in

ter

minai

be

sure

they

are

fully

seated

before

pushing

rubber

nipple

down

over

tower

Check

distributor

rotor

for

damage

and

distributor

cap

for

cracks

CONDENSER

I

Clean

outlet

of

condenser

lead

wire

and

check

for

loose

setscrew

Retighten

if

necessary

2

Check

condenser

with

a

con

denser

tester

Condenser

capacity

0

20

to

0

24

IF

Micro

Farad

Condenser

insulation

resistance

5Mn

Mega

ohms

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

Cautions

a

On

automatic

transmission

equip

T

11

ped

models

check

should

be

per

fonned

in

the

D

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Keep

your

foot

down

on

the

brake

pedal

while

depressing

the

accelera

tor

pedal

Otherwise

vehicle

surges

forward

dangerously

Notes

a

Do

not

attempt

to

screw

the

idle

adjusting

sc

ew

down

completely

Doing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctions

b

If

idle

limiter

cap

obstructs

proper

adjustment

remove

it

To

install

idle

limiter

cap

refer

to

Idle

Limiter

Cap

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

position

for

automatic

trans

mission

d

When

measuring

CO

percentage

in

sert

probe

into

tail

pipe

more

than

40

em

15

7

in

CO

idle

adjustment

with

CD

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

I

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

tempera

ture

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

with

out

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceeq

as

described

i

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

as

shown

in

Figure

ET

17

Plug

the

dis

Page 24 of 537

r

connected

hose

to

prevent

dust

from

entering

To

air

check

valve

Fig

ET

17

Disconnect

air

hose

from

ojr

check

valve

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

D

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

I

at

750

rpm

Automatic

transmission

in

D

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

11

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

Engine

Tune

up

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

CO

Idle

adjustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

connection

2

Wann

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

peed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

modeis

and

air

check

valve

shown

in

Figure

ET

17

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

ET

12

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

II

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

IDLE

LIMITER

CAP

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

readjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

After

adjusting

throttle

or

idle

speed

adjusting

screws

check

to

be

Sure

that

the

amount

of

CO

con

tained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

further

turn

1

8

rotation

in

the

CO

RICH

direction

Carburetor

stopper

3lSo

ldle

limiter

cap

T

ET031

Fig

ET

18

Setting

idle

limiter

cap

CHECKING

CARBURETOR

RETURN

SPRING

Check

throttle

return

spring

for

cracks

squarene

s

or

defonnation

if

necessary

replace

with

a

new

one

Page 26 of 537

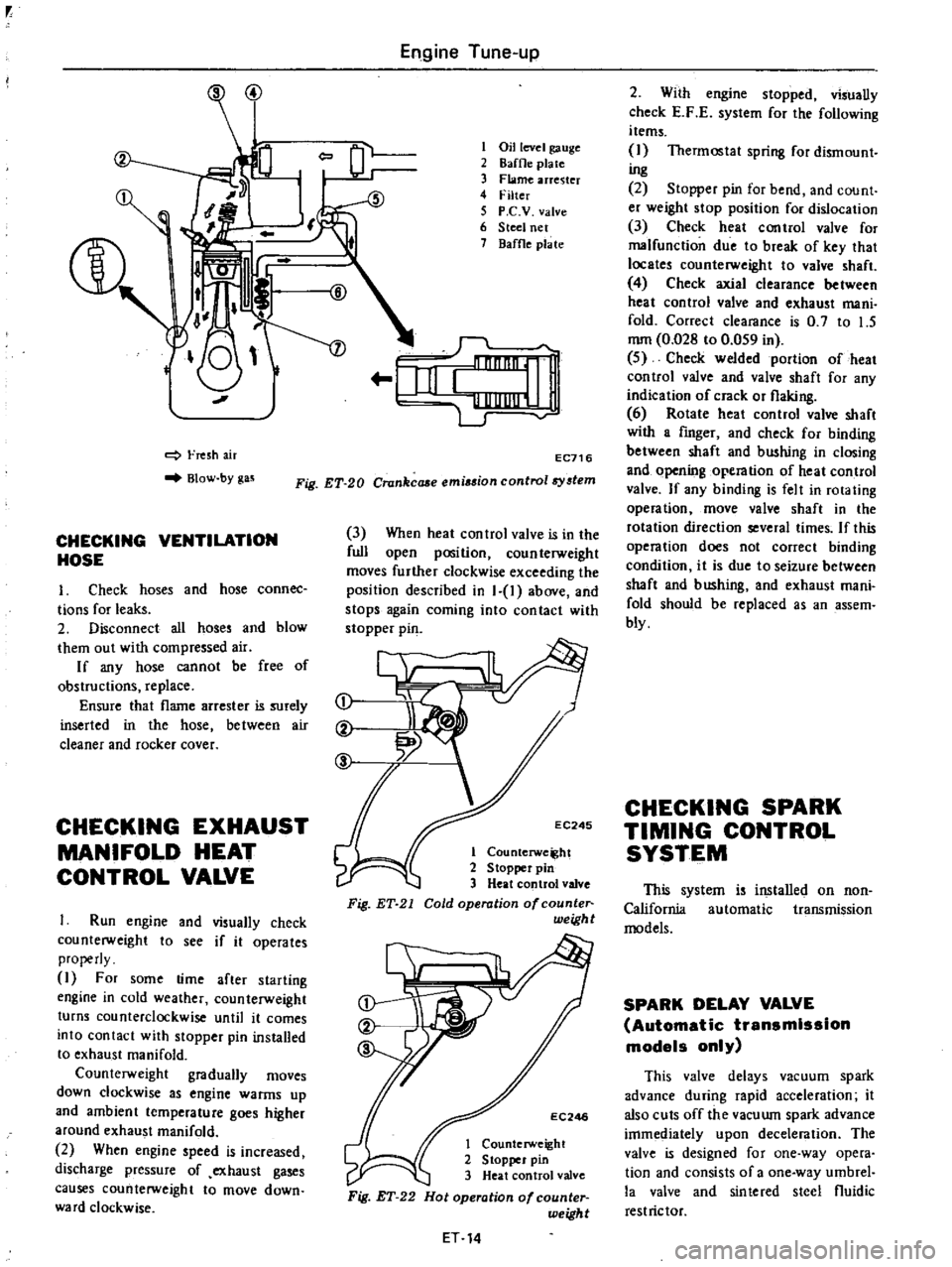

Fresh

air

Blow

by

gas

CHECKING

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

blow

them

out

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

the

hose

between

air

cleaner

and

rocker

cover

CHECKING

EXHAUST

MANIFOLD

HEAT

CONTROL

VALVE

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

2

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

Engine

Tune

up

CoOl

1

Oil

level

gauge

2

8affle

pia

te

3

Flame

arrester

4

Filter

5

P

C

V

valve

6

Steel

net

7

Baffle

plate

1fiI

o

EC716

Fig

ET

20

Crankcaae

emi

ion

control8

tem

3

When

heat

control

valve

is

in

the

full

open

position

counterweight

moves

further

clockwise

exceeding

the

position

described

in

1

1

above

and

stops

again

coming

into

contact

with

stopper

pin

ct

t

C

EC245

1

Counterwe

ht

2

Stopper

pin

3

Heat

control

valve

Fig

ET

21

Cold

operation

of

counte

weigh

t

EC246

1

Counterweight

2

Stopper

pin

3

Heat

control

valve

Fig

ET

22

Hot

operation

of

counter

weight

ET

14

2

With

engine

stopped

visually

check

E

F

E

system

for

the

following

items

I

Thermostat

spring

for

dismount

ing

2

Stopper

pin

for

bend

and

count

er

weight

stop

position

for

dislocation

3

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

4

Check

axial

clearance

between

heat

control

valve

and

exhaust

mani

fold

Correct

clearance

is

0

7

to

1

5

mm

0

028

to

0

059

in

5

Check

welded

portion

of

heat

control

valve

and

valve

shaft

for

any

indication

of

crack

or

flaking

6

Rotate

heat

control

valve

shaft

with

a

fmger

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

CHECKING

SPARK

TIMING

CONTROL

SYSTEM

This

system

is

installed

on

non

California

automatic

transmission

models

SPARK

DELAY

VALVE

Automatic

transmission

models

only

This

valve

delays

vacuum

spark

advance

during

rapid

acceleration

it

also

cuts

off

the

vacuwn

spark

advance

imme

iately

upon

deceleration

The

valve

is

designed

for

one

way

opera

tion

and

consists

of

a

one

way

umbrel

la

valve

and

sintered

steel

fluidic

restrictor

Page 30 of 537

r

ADJUSTMENT

OF

SET

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

C

D

D

Generally

it

is

unnecessary

to

ad

just

the

B

C

D

D

however

if

it

should

become

necessary

to

adjust

it

the

procedure

is

as

follows

Prepare

the

foUowlnB

tools

I

Tachometer

to

measure

the

en

gine

speed

while

idling

and

a

screw

driver

2

A

vacuum

gauge

connecting

pipe

Note

A

qui

k

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

To

properly

set

the

B

C

D

D

set

pressure

proceed

as

follows

I

Remove

the

harness

of

solenoid

valve

TO

D

D

solenrod

VT

FJ

1

B

C

D

D

solenni

valve

harness

J

ri

y

EF262

F

g

ET

32

Removing

harneS5

of

solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

as

shown

Fig

ET

33

Connecting

vacuum

gauge

3

Warm

up

the

engine

until

it

is

heated

to

operating

temperature

Then

adjust

the

engine

at

normal

Engine

Tune

up

idling

setting

Refer

to

the

item

Idling

Adjustment

in

page

ET

II

Idling

engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

4

Run

the

engine

under

no

load

Increase

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

5

At

the

time

the

manifold

vacuum

pressure

increases

abruptly

to

600

mmHg

23

62

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

6

Check

that

the

B

C

D

D

set

pres

sure

is

within

the

specified

pressure

Specified

pressure

0

m

sea

level

and

760

mmHg

30

inHg

atmos

pheric

pressure

Manual

transmission

510

to

550

mmHg

20

1

to

21

7

inHg

Automatic

transmission

490

to

530

mmHg

19

3

to

20

9

inHg

Note

When

checking

the

set

pressure

of

B

C

D

D

find

the

specified

set

pressure

in

Figure

IT

36

from

the

atmospheric

pressure

and

altitutde

of

the

given

location

For

example

if

a

manual

transmis

sion

model

vehicle

is

located

at

an

altitude

of

1

000

m

3

280

ft

the

specified

set

preSsure

for

B

C

D

D

445

mmHg

17

5

inHg

7

If

it

is

higher

than

the

set

level

turn

the

adjusting

screw

counter

clockwise

or

nut

clockwise

until

correct

adjustment

is

made

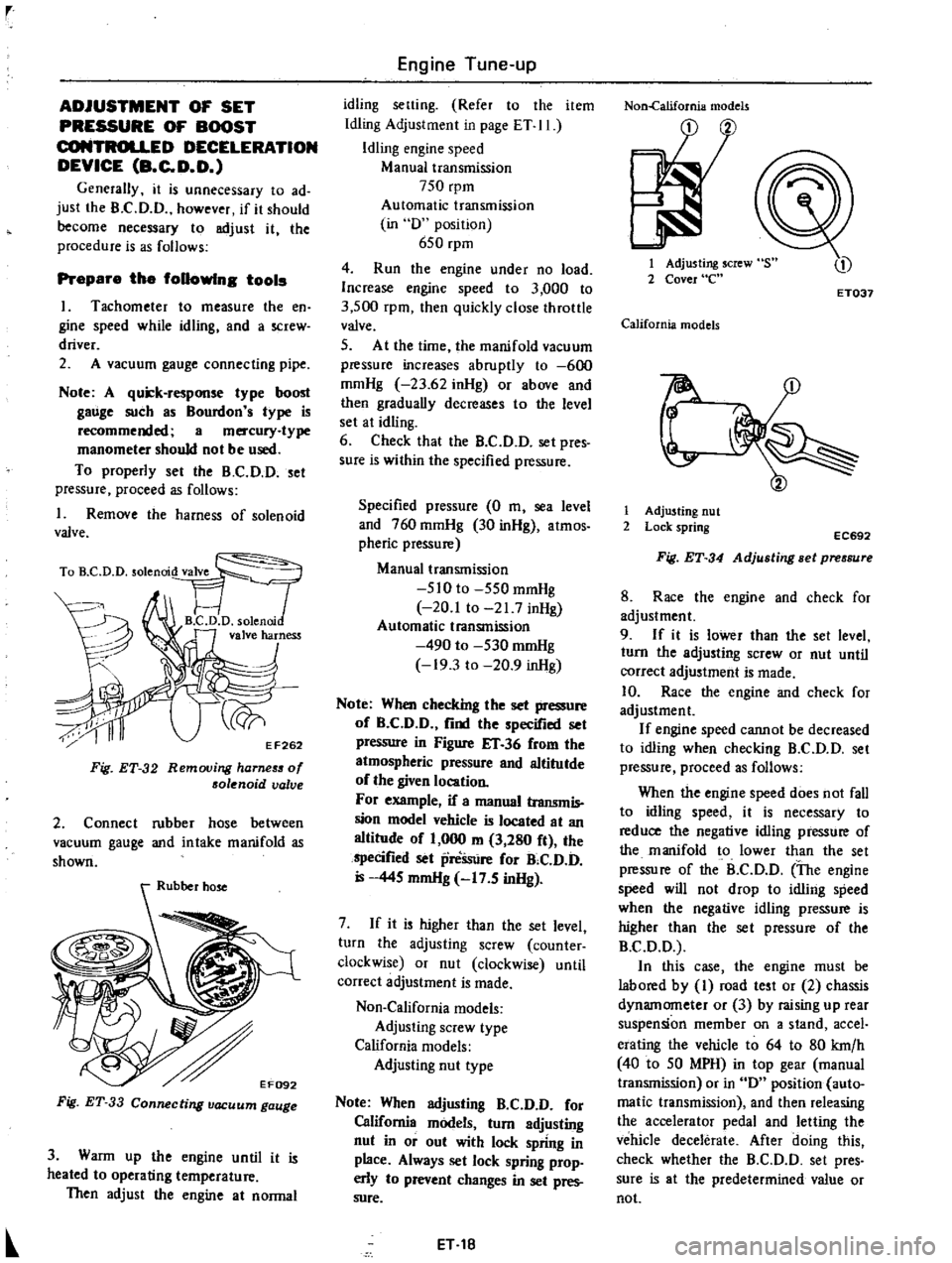

Non

California

models

Adjusting

screw

type

California

models

Adjusting

nut

type

Note

When

adjusting

B

C

D

D

for

California

models

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

prop

erly

to

prevent

changes

in

set

pres

sure

ET

18

Non

california

models

1

Adjusting

screw

2

Cover

e

ET037

California

models

r

1

Adjusting

nut

2

Lock

spring

EC692

Fig

ET

34

Adjusting

Bet

pressure

8

Race

the

engine

and

check

for

adjustment

9

If

it

is

lower

than

the

set

level

turn

the

adjusting

screw

or

nut

until

correct

adjustment

is

made

10

Race

the

engine

and

check

for

adjustment

If

engine

speed

cannot

be

decreased

to

idling

when

checking

B

C

D

D

set

pressure

proceed

as

follows

When

the

engine

speed

does

not

fall

to

idling

speed

it

is

necessary

to

reduce

the

negative

idling

pressure

of

the

manifold

to

lower

than

the

set

pressure

of

the

B

C

D

D

The

engine

speed

will

not

drop

to

idling

speed

when

the

negative

idling

pressure

is

higher

than

the

set

pressure

of

the

B

C

D

D

In

this

case

the

engine

must

be

labored

by

I

road

test

or

2

chassis

dynamometer

or

3

by

raising

up

rear

suspension

member

on

a

stand

accel

erating

the

vehicle

to

64

to

80

krn

h

40

to

50

MPH

in

top

gear

manual

transmission

or

in

D

position

auto

matic

transmission

and

then

releasing

the

accelerator

pedal

and

letting

the

vehicle

decelerate

After

doing

this

check

whether

the

B

C

D

D

set

pres

sure

is

at

the

predetermined

value

or

not

Page 34 of 537

r

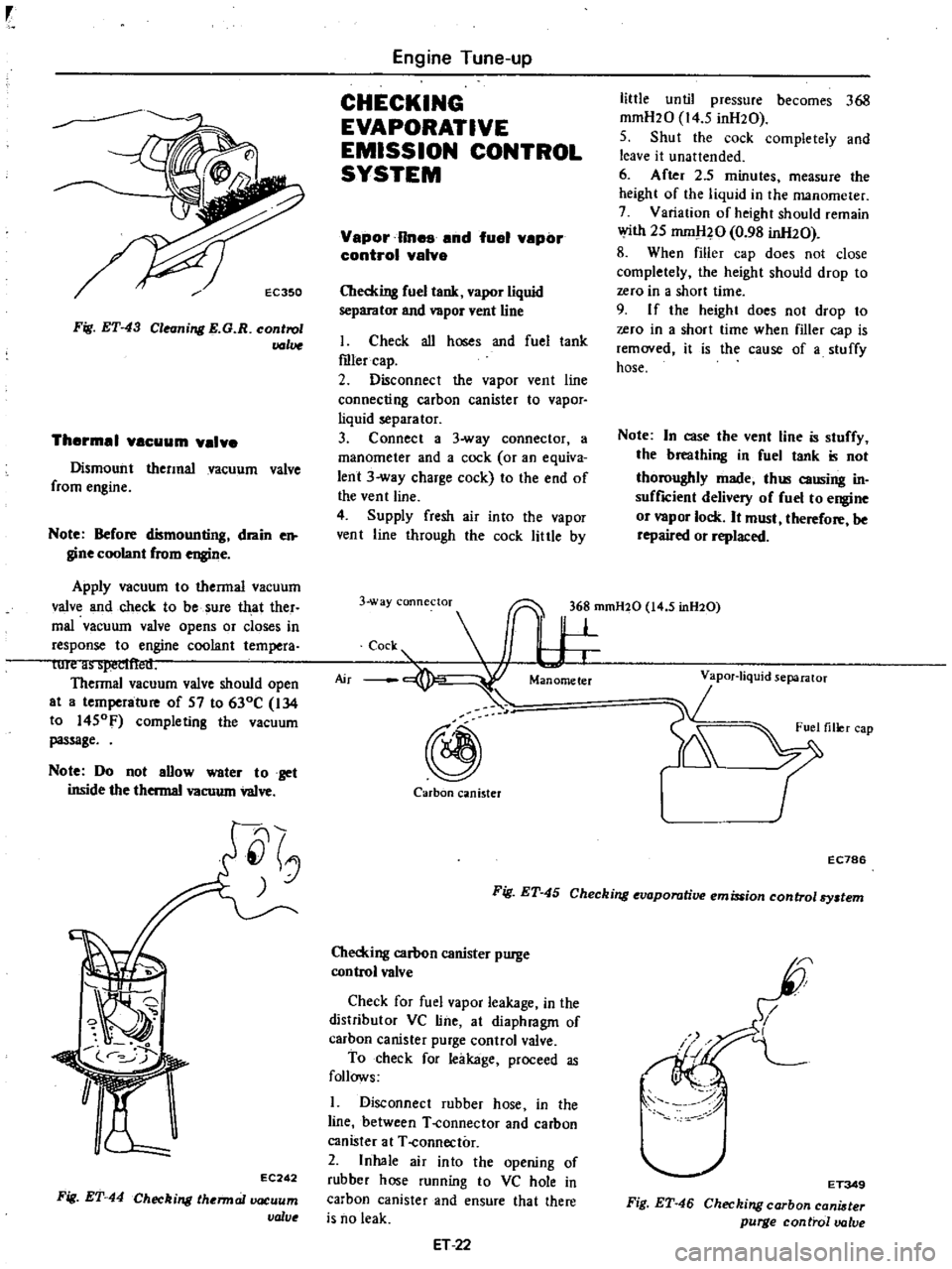

EC350

Fig

ET

43

Cleanill

l

E

G

R

control

lJ

Jlue

Thermal

VBCuum

valve

Dismount

thermal

vacuum

valve

from

engine

Note

Before

dismounting

drain

e

gine

coolant

from

engine

Apply

vacuum

to

thermal

vacuum

valve

and

check

to

be

sure

that

ther

mal

vacuum

valve

opens

or

closes

in

response

to

engine

coolant

tempera

lurt

i1

i

iYCl

lt

lt

U

Thermal

vacuum

valve

should

open

at

a

temperature

of

57

to

630C

134

to

1450F

completing

the

vacuum

passage

Note

Do

not

aUow

water

to

get

inside

the

thermal

vacuum

valve

EC

242

Fig

ET

44

Checkill

lthermallXlCuum

valve

Engine

Tune

up

CHECKING

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

Vapor

Rnes

and

fuel

vepor

control

valve

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

I

Check

all

hoses

and

fuel

tank

roler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

with

25

mm

l20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thl

causing

in

suffICient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connectoT

36

mmH20

14

5

inH20

c

s

I

W

@

Carbon

canister

r

EC786

Fig

ET

45

Checking

evaporative

emission

control

By

tem

Checking

carbon

canister

purge

control

valve

Check

for

fuel

vapor

leakage

in

the

distributor

VC

line

at

diaphragm

of

carhon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

1

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

VC

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET

22

I

I

L

I

ET349

Fig

ET

46

Checking

carbon

cani

ter

purge

control

valve

Page 44 of 537

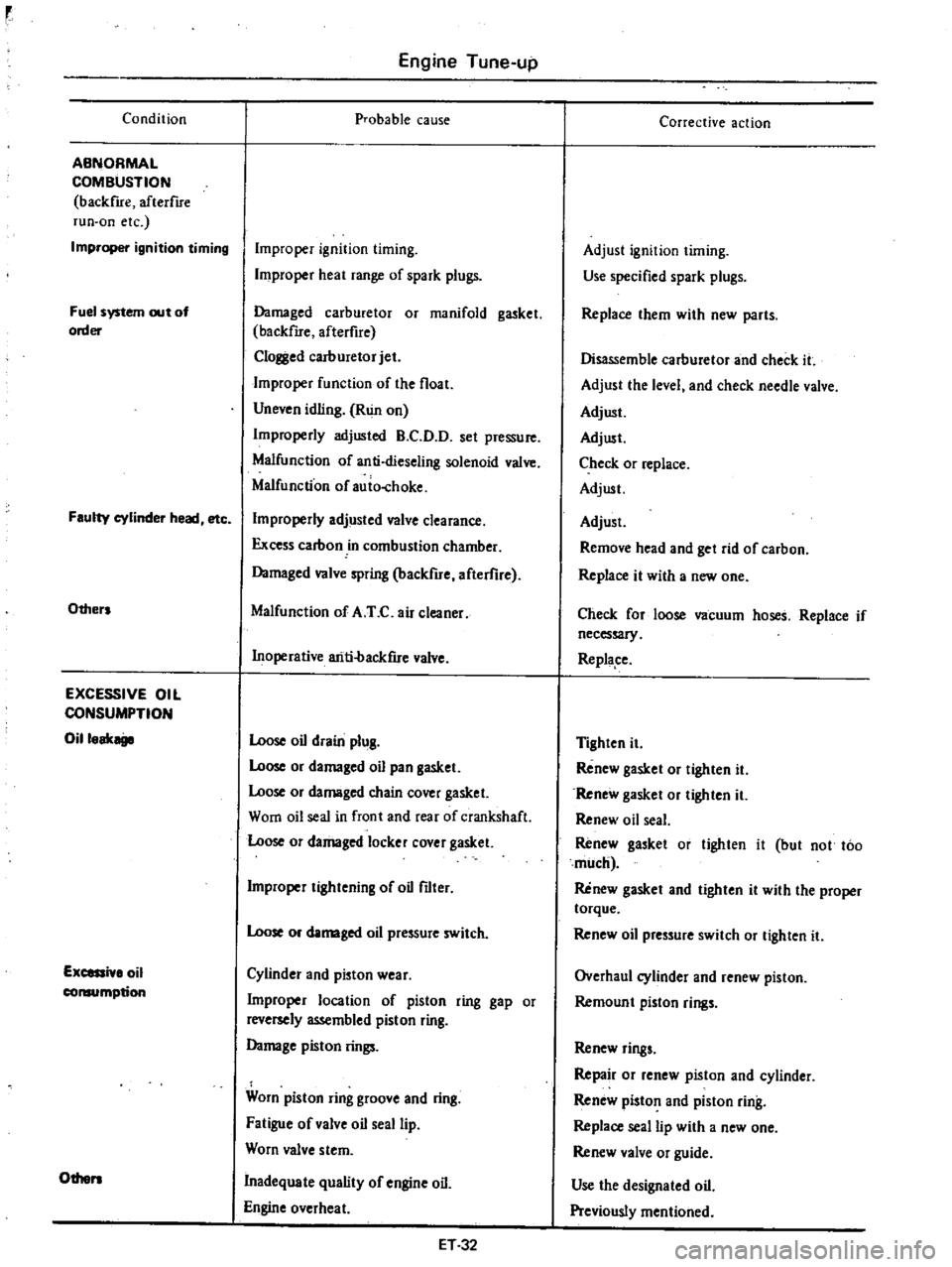

Condition

ABNORMAL

COMBUSTION

backfue

afterflre

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Faulty

cylinder

head

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilloak

Excessi

lo

oil

consumption

Others

Engine

Tune

up

probable

cause

Improper

ignition

timing

Improper

heat

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfue

afterfire

Clol

l

ed

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

B

C

D

D

set

pressure

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

auio

choke

Improperly

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Damaged

valve

spring

backfire

afterflre

Malfunction

of

A

T

C

air

cleaner

Inoperative

ariti

backfue

valve

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Worn

oil

seal

in

front

and

rear

of

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Cylinder

and

pioton

wear

Improper

location

of

piston

ring

gap

or

reversely

assembled

piston

ring

Damage

piston

rings

Worn

piston

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oil

Engine

overheat

ET32

Corrective

action

Adjust

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

with

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replape

Tighten

it

Renew

gasket

or

tighten

it

Renew

gasket

or

tighten

it

Renew

oil

seal

Renew

gasket

or

tighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Overhaul

cylinder

and

renew

piston

Remoun

t

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Use

the

designated

oil

Previously

mentioned