air condition DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 21 of 537

Yellow

line

Spark

delay

valve

to

distributor

Spark

delay

valve

to

vacuum

tube

Distributor

to

vacuum

tube

Vacuum

tube

to

carburetor

Vacuum

tube

to

canister

Green

line

Anti

backfire

valve

to

intake

mani

fold

Air

control

valve

to

emergency

air

relief

valve

Intake

manifold

to

vacuum

hose

connector

Intake

manifold

to

canister

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

I

Warm

up

engine

sufficiently

2

Disconnect

all

spark

plugs

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Properly

attach

a

compression

tester

to

spark

plug

hole

in

cylinder

being

tested

Engine

Tune

up

I

ET010

Different

compression

in

two

or

more

cylinders

usually

indicates

an

improperly

seated

valve

or

broken

piston

ring

9

Low

compression

in

cylinders

can

result

from

worn

piston

rings

This

condition

may

usually

be

accompanied

by

excessive

fuel

consumption

TEST

RESULT

If

compression

in

one

or

more

cylinders

is

low

pour

a

small

quantity

of

engine

oil

into

cylinders

through

the

spark

plug

holes

and

retest

com

pression

I

If

adding

oil

increases

the

com

pression

pressure

the

chances

are

that

rings

are

faulty

2

If

pressure

stays

low

probable

cause

is

that

valve

is

sticking

or

seating

improperly

3

If

cylinder

compression

in

any

two

adjacent

cylinders

is

low

and

if

adding

oil

does

not

help

the

compres

sian

there

is

leakage

past

the

gasket

surface

Oil

and

water

in

combustion

cham

bers

can

result

from

leakage

IGNITION

AND

FUEL

SYSTEM

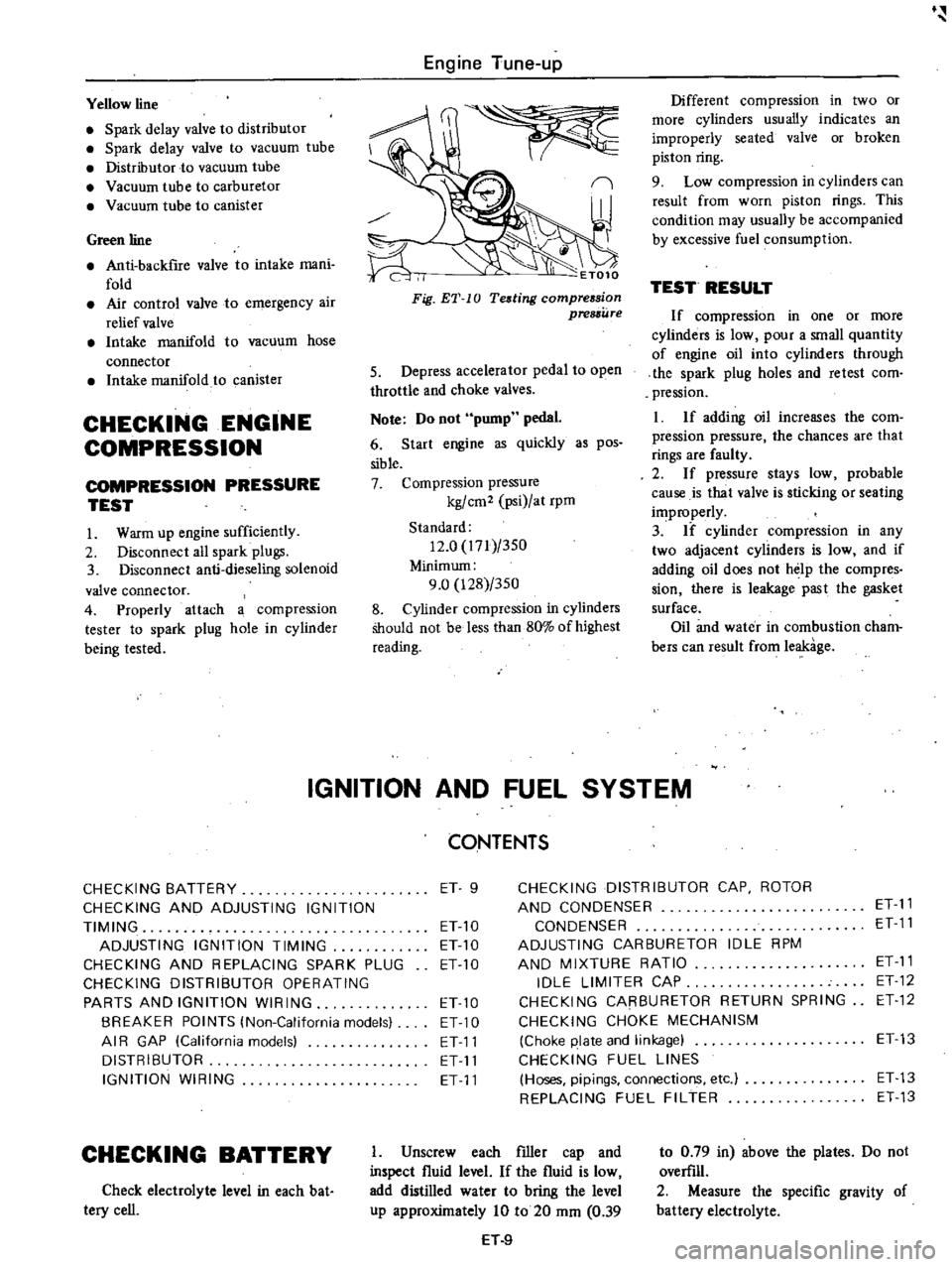

Fig

ET

10

Teding

compression

pressure

5

Depress

accelerator

pedal

to

open

throttle

and

choke

valves

Note

Do

not

pump

pedal

6

Start

engine

as

quickly

as

pos

sible

7

Compression

pressure

kg

cm2

psi

at

rpm

Standard

12

0

171

350

Minimum

9

0

128

350

8

Cylinder

compression

in

cylinders

Should

not

be

less

than

80

of

highest

reading

CONTENTS

CHECKING

BATTERY

ET

9

CHECKING

DISTRIBUTOR

CAP

ROTOR

CHECKING

AND

ADJUSTING

IGNITION

AND

CONDENSER

ET

11

TIMING

ET

10

CONDENSER

ET

11

ADJUSTING

IGNITION

TIMING

ET10

ADJUSTING

CARBURETOR

IDLE

RPM

CHECKING

AND

REPLACING

SPARK

PLUG

ETlO

AND

MIXTURE

RATIO

ET

11

CHECKING

DISTRIBUTOR

OPERATING

IDLE

LIMITER

CAP

ET

12

PARTS

AND

IGNITION

WIRING

ETlO

CHECKING

CARBURETOR

RETURN

SPRING

ET

12

BREAKER

POINTS

lNon

California

models

ET

10

CHECKING

CHOKE

MECHANISM

AI

R

GAP

lCalifornia

models

ET11

Choke

plate

and

linkage

ET13

DISTRIBUTOR

ET

11

CHECKING

FUEL

LINES

IGNITION

WIRING

ET

11

Hoses

pipings

connections

etc

ET

13

REPLACING

FUEL

FILTER

ET

13

CHECKING

BATTERY

Check

electrolyte

level

in

each

bat

tery

cell

I

Unscrew

each

filler

cap

and

inspect

fluid

level

If

the

fluid

is

low

add

distilled

water

to

bring

the

level

up

approximately

10

to

20

mm

0

39

H

9

to

0

79

in

above

the

plates

Do

not

overfill

2

Measure

the

specific

gravity

of

battery

electrolyte

Page 22 of 537

p

r

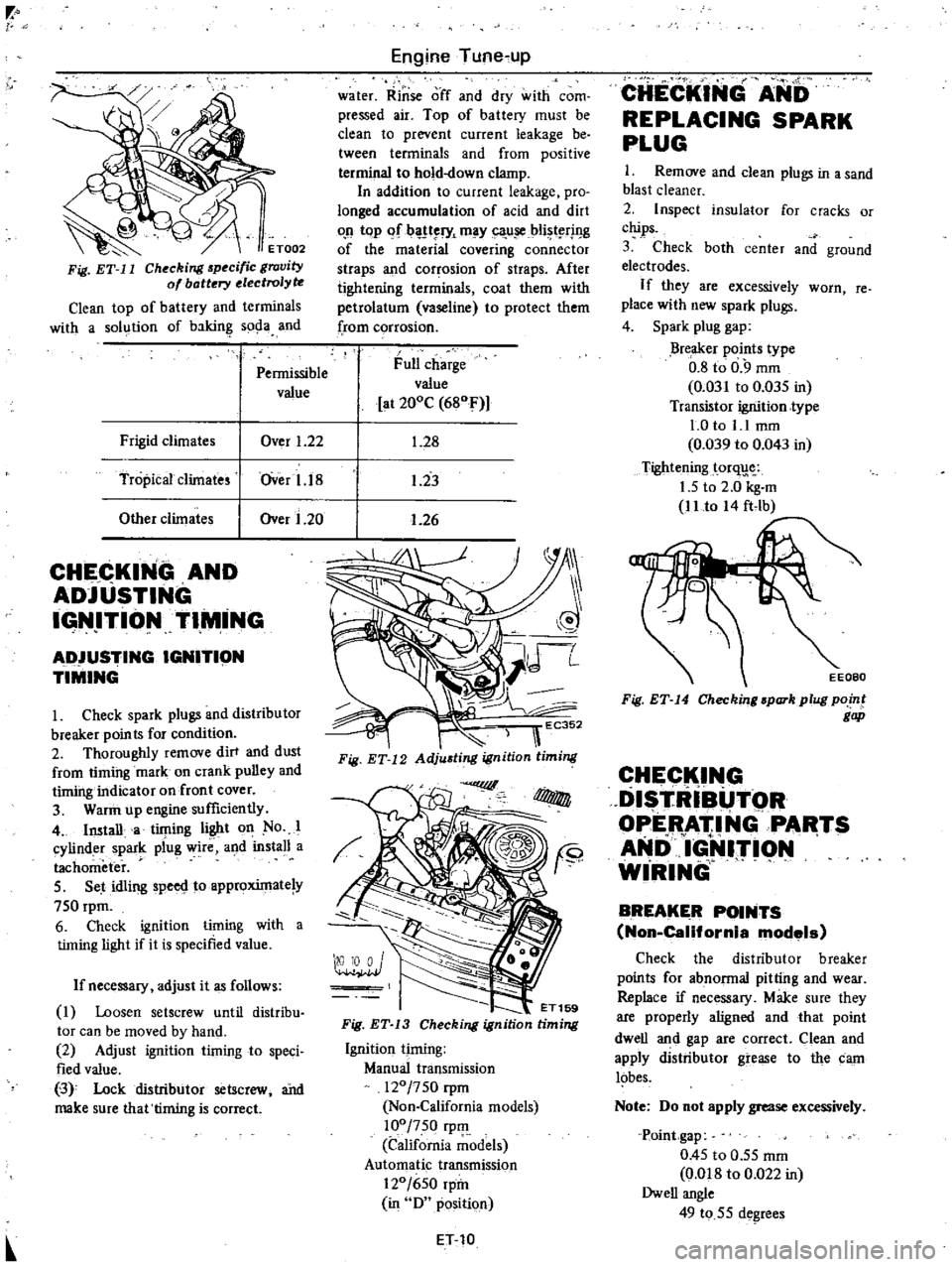

ET002

Fig

E1

11

Checking

specific

gravity

of

bottery

electrolyre

Clean

top

of

battery

and

terminals

with

a

solution

of

bakin

soda

and

Pennissible

value

Frigid

climates

Over

1

22

Tropical

climates

lOver

1

18

Other

climates

lOver

1

20

CHECKING

AND

ADJUSTING

IGN

ITIONTIM

iNG

AD

IUSTING

IGNITION

TIMING

I

Check

spark

plugs

and

distributor

breaker

points

for

condition

2

Thoroughly

remove

dirt

and

dust

from

timing

mark

on

crank

pulley

and

timing

indicator

on

front

cover

3

Warin

up

engine

sufficiently

4

Imtalla

timing

light

on

No

I

cylinder

spark

plug

wire

and

install

a

tachometer

5

Set

idling

spero

toapproxintate

y

750

rpm

6

Check

ignition

timing

with

a

timing

light

if

it

is

specified

value

If

necessary

adjust

it

as

follows

1

Loosen

setscrew

until

distribu

tor

can

be

moved

by

hand

2

Adjust

ignition

timing

to

speci

fied

value

3

0

Lock

distributor

setscrew

ai1d

make

sure

that

timing

is

correc

Engine

Tune

up

water

Rinse

off

and

dry

with

com

pressed

air

Top

of

battery

must

be

clean

to

prevent

current

leakage

be

tween

terminals

and

from

positive

terminal

to

hold

down

clamp

In

addition

to

current

leakage

pro

longed

accumulation

of

acid

and

dirt

o

n

top

If

l

l

ry

may

ca

u

iCbli

t

rj

I

g

of

the

material

covering

connector

straps

and

corrosion

of

straps

After

tightening

terminals

coat

them

with

petrolatum

vaseline

to

protect

them

from

corrosion

Full

charge

value

at

200C

680F

1

28

1

23

1

26

oo

I

ET169

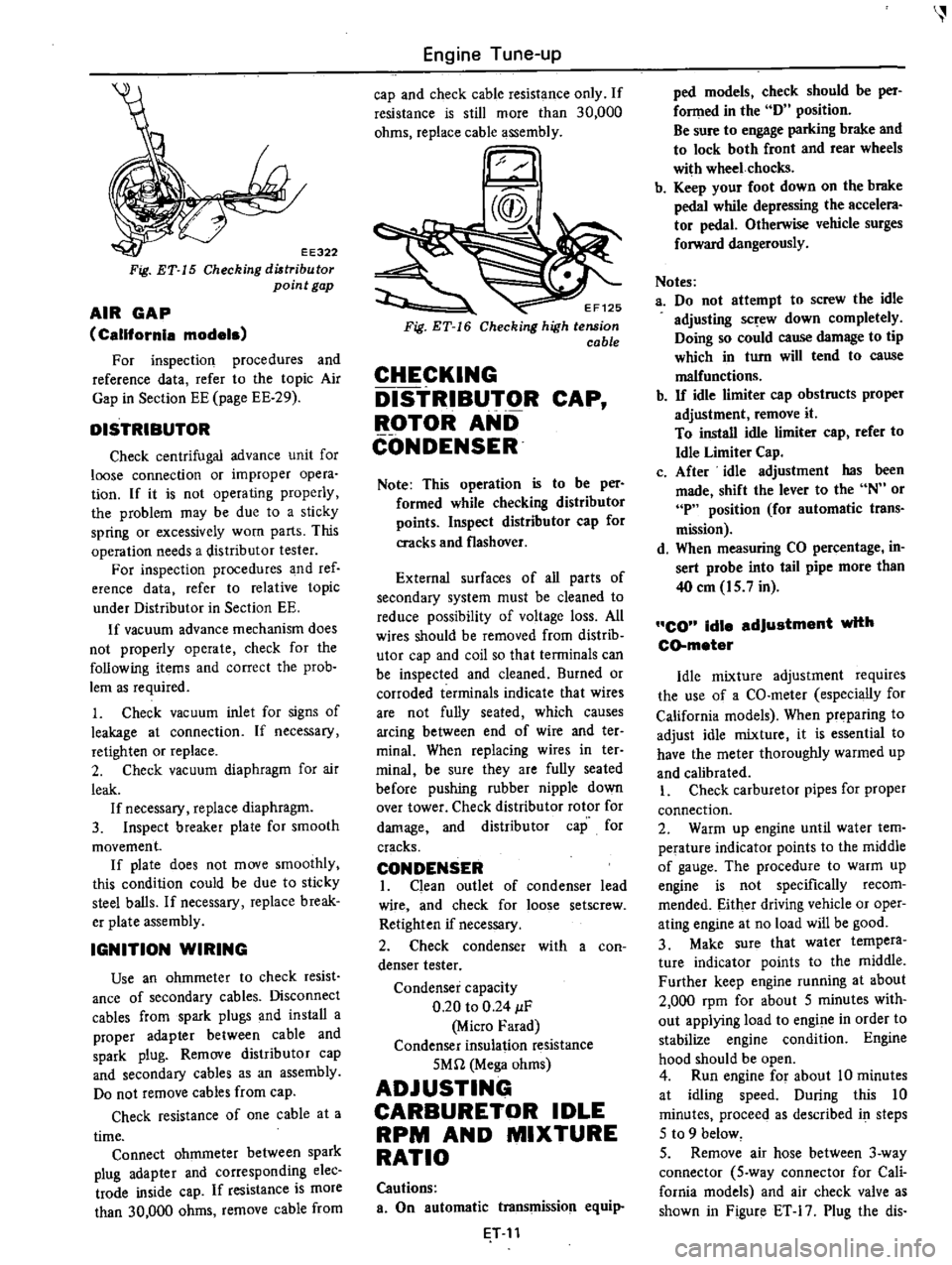

Fig

ET

13

Checking

ignition

timing

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

models

100

750

rpIll

California

models

Automatic

transmission

120

650

rpin

in

0

position

ET

10

CHECKING

ANb

REPLACING

SPARK

PLUG

I

Remove

and

clean

plugs

in

a

sand

blast

cleaner

2

Inspect

insulator

for

cracks

or

chips

3

Check

both

center

and

ground

electrodes

If

they

are

excessively

worn

re

place

with

new

spark

plugs

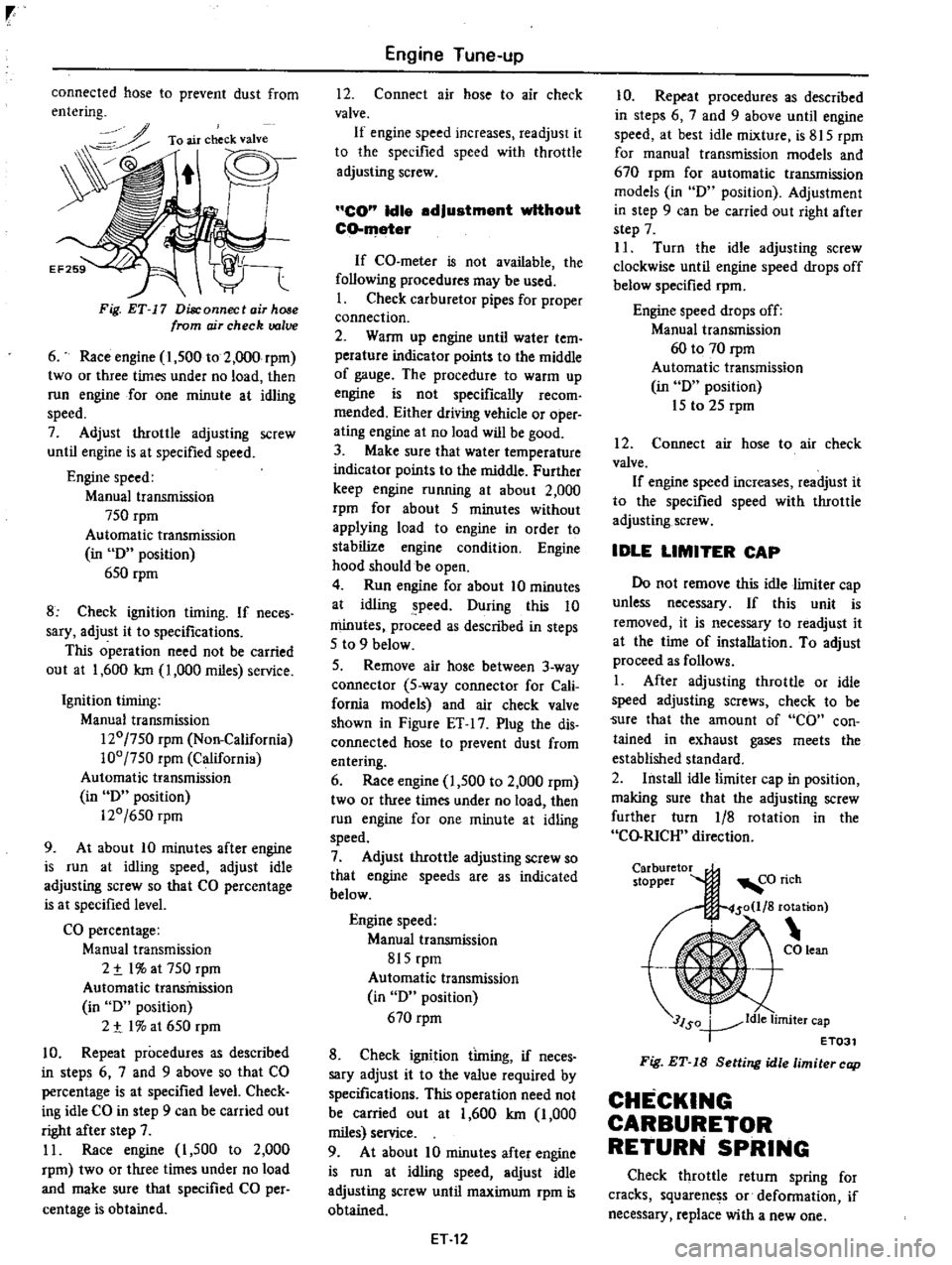

4

Spark

plug

gap

Breaker

points

type

0

8

to

0

9

mm

0

031

to

0

035

in

Transistor

ignition

type

1

0

to

1

1

mm

0

039

to

0

043

in

Tightening

torq

1

5

to

2

0

kg

m

11

to

A4

ft

lb

Fig

ET

14

Checking

spark

plug

point

gap

CHECK

I

G

DISTRIBUTOR

OPERATING

PARTS

AND

1

lrI9N

WIRING

BREAKER

POINTS

Non

California

models

Check

the

distributor

breaker

points

for

abnonnal

pitting

and

wear

Replace

if

necessary

Make

sure

they

are

properly

aligned

and

that

point

dwell

and

gap

are

correct

Clean

and

apply

distributor

grease

to

the

carn

lobes

Note

00

not

apply

grease

excessively

Point

gap

0

45

to

0

55

mm

Om8

to

0

022

in

Owell

angle

49

to

55

degrees

Page 23 of 537

EE322

Fig

ET

15

Checking

diltribu

tor

point

gap

AIR

GAP

California

models

For

inspection

procedures

and

reference

data

refer

to

the

topic

Air

Gap

in

Section

EE

page

EE

29

DISTRIBUTOR

Check

centrifugal

advance

unit

for

loose

connection

or

improper

opera

tion

If

it

is

not

operating

properly

the

problem

may

be

due

to

a

sticky

spring

or

excessively

worn

parts

This

operation

needs

a

distributor

tester

For

inspection

procedures

and

ref

erence

data

refer

to

relative

topic

under

Distributor

in

Section

EE

If

vacuum

advance

mechanism

does

not

properly

operate

check

for

the

following

items

and

correct

the

prob

lem

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

connection

If

necessary

retighten

or

replace

2

Check

vacuum

diaphragm

for

air

leak

If

necessary

replace

diaphragm

3

Inspect

breaker

plate

for

smooth

movement

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

If

necessary

replace

break

er

plate

assembly

IGNITION

WIRING

Use

an

ohmmeter

to

check

resist

ance

of

secondary

cables

Disconnect

cables

from

spark

plugs

and

install

a

proper

adapter

between

cable

and

spark

plug

Remove

distributor

cap

and

secondary

cables

as

an

assembly

Do

not

remove

cables

from

cap

Check

resistance

of

one

cable

at

a

time

Connect

ohmmeter

between

spark

plug

adapter

and

corresponding

elec

trade

inside

cap

If

resistance

is

more

than

30

000

ohms

remove

cable

from

Engine

Tune

up

cap

and

check

cable

resistance

only

If

resistance

is

still

more

than

30

000

ohms

replace

cable

assembly

EF125

Checking

high

tension

cable

CHECKING

DISTRIBUTOR

CAP

ROTOR

AND

CONDENSER

Note

This

operation

is

to

be

per

formed

while

checking

distributor

points

Inspect

distributor

cap

for

cracks

and

flashover

External

surfaces

of

all

parts

of

secondary

system

must

be

cleaned

to

reduce

possibility

of

voltage

loss

All

wires

should

be

removed

from

distrib

utor

cap

and

coil

so

that

terminals

can

be

inspected

and

cleaned

Burned

or

corroded

terminals

indicate

that

wires

are

not

fully

seated

which

causes

arcing

between

end

of

wire

and

ter

minal

When

replacing

wires

in

ter

minai

be

sure

they

are

fully

seated

before

pushing

rubber

nipple

down

over

tower

Check

distributor

rotor

for

damage

and

distributor

cap

for

cracks

CONDENSER

I

Clean

outlet

of

condenser

lead

wire

and

check

for

loose

setscrew

Retighten

if

necessary

2

Check

condenser

with

a

con

denser

tester

Condenser

capacity

0

20

to

0

24

IF

Micro

Farad

Condenser

insulation

resistance

5Mn

Mega

ohms

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

Cautions

a

On

automatic

transmission

equip

T

11

ped

models

check

should

be

per

fonned

in

the

D

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Keep

your

foot

down

on

the

brake

pedal

while

depressing

the

accelera

tor

pedal

Otherwise

vehicle

surges

forward

dangerously

Notes

a

Do

not

attempt

to

screw

the

idle

adjusting

sc

ew

down

completely

Doing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctions

b

If

idle

limiter

cap

obstructs

proper

adjustment

remove

it

To

install

idle

limiter

cap

refer

to

Idle

Limiter

Cap

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

position

for

automatic

trans

mission

d

When

measuring

CO

percentage

in

sert

probe

into

tail

pipe

more

than

40

em

15

7

in

CO

idle

adjustment

with

CD

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

I

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

tempera

ture

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

with

out

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceeq

as

described

i

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

as

shown

in

Figure

ET

17

Plug

the

dis

Page 24 of 537

r

connected

hose

to

prevent

dust

from

entering

To

air

check

valve

Fig

ET

17

Disconnect

air

hose

from

ojr

check

valve

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

D

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

I

at

750

rpm

Automatic

transmission

in

D

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

11

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

Engine

Tune

up

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

CO

Idle

adjustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

connection

2

Wann

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

peed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

modeis

and

air

check

valve

shown

in

Figure

ET

17

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

ET

12

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

II

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

IDLE

LIMITER

CAP

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

readjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

After

adjusting

throttle

or

idle

speed

adjusting

screws

check

to

be

Sure

that

the

amount

of

CO

con

tained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

further

turn

1

8

rotation

in

the

CO

RICH

direction

Carburetor

stopper

3lSo

ldle

limiter

cap

T

ET031

Fig

ET

18

Setting

idle

limiter

cap

CHECKING

CARBURETOR

RETURN

SPRING

Check

throttle

return

spring

for

cracks

squarene

s

or

defonnation

if

necessary

replace

with

a

new

one

Page 26 of 537

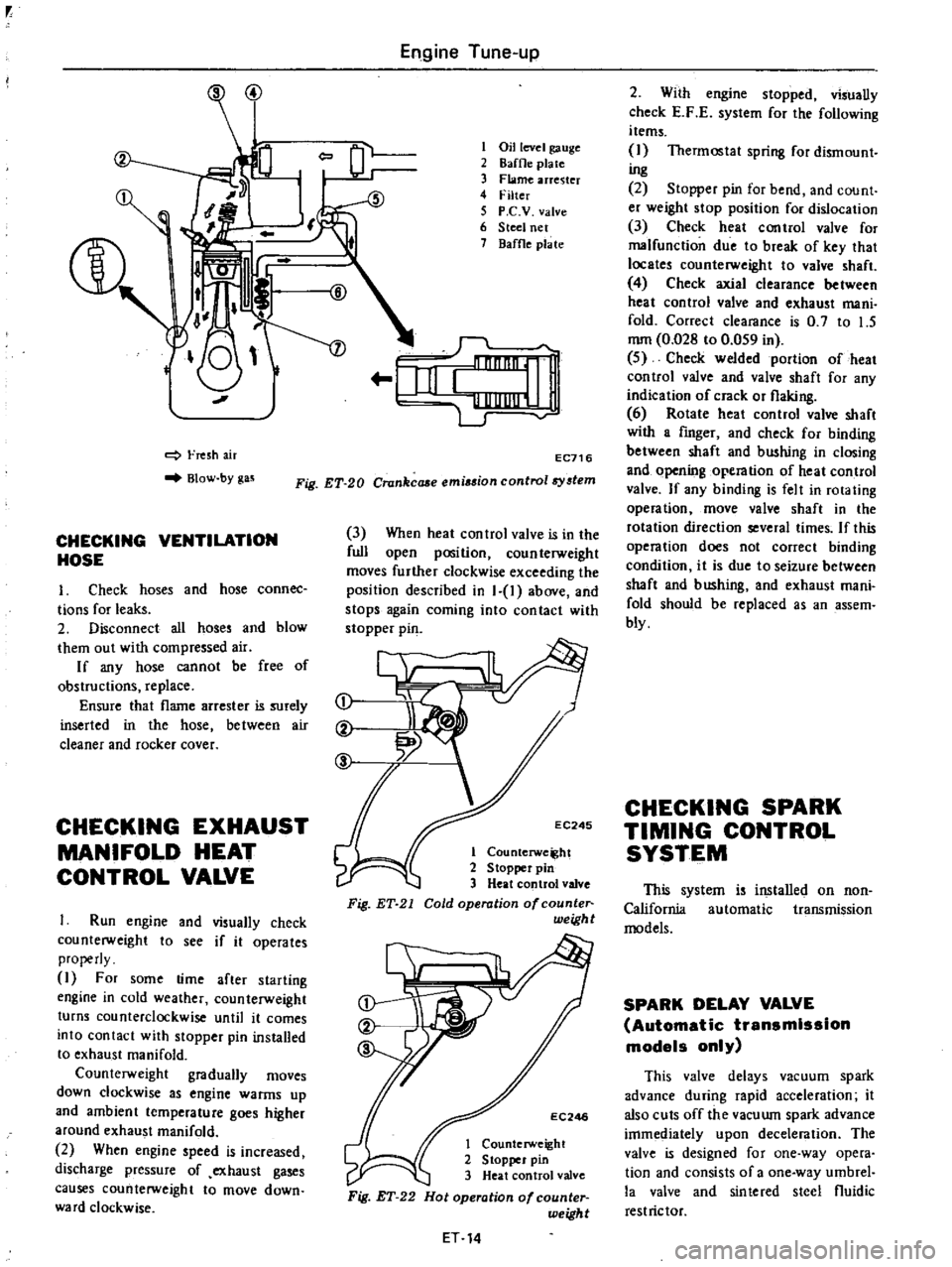

Fresh

air

Blow

by

gas

CHECKING

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

blow

them

out

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

the

hose

between

air

cleaner

and

rocker

cover

CHECKING

EXHAUST

MANIFOLD

HEAT

CONTROL

VALVE

Run

engine

and

visually

check

counterweight

to

see

if

it

operates

properly

I

For

some

time

after

starting

engine

in

cold

weather

counterweight

turns

counterclockwise

until

it

comes

into

contact

with

stopper

pin

installed

to

exhaust

manifold

Counterweight

gradually

moves

down

clockwise

as

engine

warms

up

and

ambient

temperature

goes

higher

around

exhaust

manifold

2

When

engine

speed

is

increased

discharge

pressure

of

exhaust

gases

causes

counterweight

to

move

down

ward

clockwise

Engine

Tune

up

CoOl

1

Oil

level

gauge

2

8affle

pia

te

3

Flame

arrester

4

Filter

5

P

C

V

valve

6

Steel

net

7

Baffle

plate

1fiI

o

EC716

Fig

ET

20

Crankcaae

emi

ion

control8

tem

3

When

heat

control

valve

is

in

the

full

open

position

counterweight

moves

further

clockwise

exceeding

the

position

described

in

1

1

above

and

stops

again

coming

into

contact

with

stopper

pin

ct

t

C

EC245

1

Counterwe

ht

2

Stopper

pin

3

Heat

control

valve

Fig

ET

21

Cold

operation

of

counte

weigh

t

EC246

1

Counterweight

2

Stopper

pin

3

Heat

control

valve

Fig

ET

22

Hot

operation

of

counter

weight

ET

14

2

With

engine

stopped

visually

check

E

F

E

system

for

the

following

items

I

Thermostat

spring

for

dismount

ing

2

Stopper

pin

for

bend

and

count

er

weight

stop

position

for

dislocation

3

Check

heat

control

valve

for

malfunction

due

to

break

of

key

that

locates

counterweight

to

valve

shaft

4

Check

axial

clearance

between

heat

control

valve

and

exhaust

mani

fold

Correct

clearance

is

0

7

to

1

5

mm

0

028

to

0

059

in

5

Check

welded

portion

of

heat

control

valve

and

valve

shaft

for

any

indication

of

crack

or

flaking

6

Rotate

heat

control

valve

shaft

with

a

fmger

and

check

for

binding

between

shaft

and

bushing

in

closing

and

opening

operation

of

heat

control

valve

If

any

binding

is

felt

in

rotating

operation

move

valve

shaft

in

the

rotation

direction

several

times

If

this

operation

does

not

correct

binding

condition

it

is

due

to

seizure

between

shaft

and

bushing

and

exhaust

mani

fold

should

be

replaced

as

an

assem

bly

CHECKING

SPARK

TIMING

CONTROL

SYSTEM

This

system

is

installed

on

non

California

automatic

transmission

models

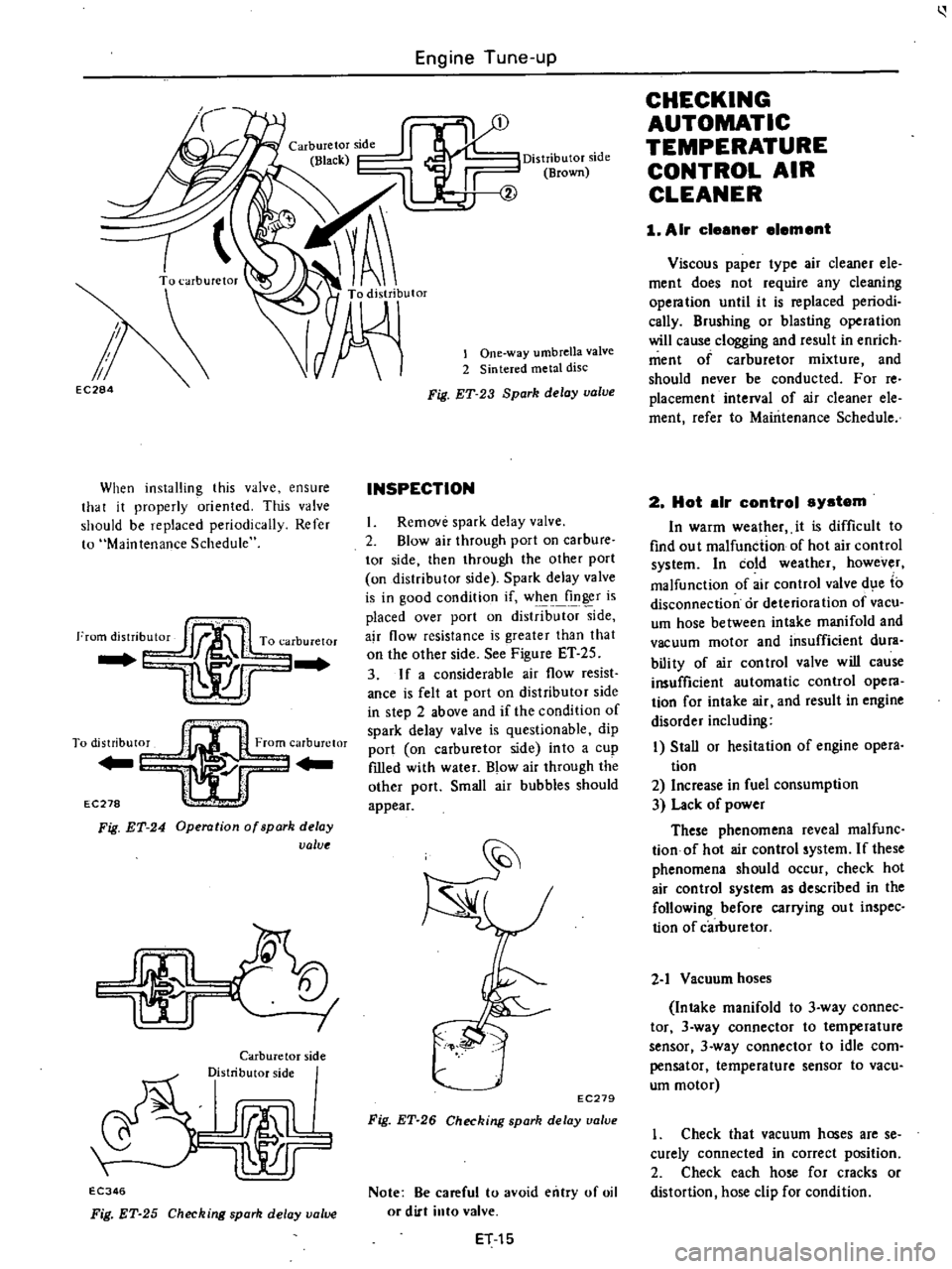

SPARK

DELAY

VALVE

Automatic

transmission

models

only

This

valve

delays

vacuum

spark

advance

during

rapid

acceleration

it

also

cuts

off

the

vacuwn

spark

advance

imme

iately

upon

deceleration

The

valve

is

designed

for

one

way

opera

tion

and

consists

of

a

one

way

umbrel

la

valve

and

sintered

steel

fluidic

restrictor

Page 27 of 537

Engine

Tune

up

EC284

When

installing

this

valve

ensure

that

it

properly

oriented

This

valve

should

be

replaced

periodically

Refer

to

Maintenance

Schedule

I

To

distribut0

From

carburetor

Yl

r

EC278

l

Fig

ET

24

Operation

of

spark

delay

value

I

I

Carburetor

side

Distributor

side

rJmlL

lr

EC346

Fig

ET

25

Checking

spark

delay

value

Distributor

side

Brown

lOne

way

umbrella

valve

2

Sintered

metal

disc

Fig

ET

23

Spark

delay

valve

INSPECTION

I

Remove

spark

delay

valve

2

Blow

air

through

port

on

carbure

tor

side

then

through

the

other

port

on

distributor

side

Spark

delay

valve

is

in

good

condition

if

when

finger

is

placed

over

port

on

distrib

side

ajr

flow

resistance

is

greater

than

that

on

the

other

side

See

Figure

ET

25

3

If

a

considerable

air

flow

resist

ance

is

felt

at

port

on

distributor

side

in

step

2

above

and

if

the

condition

of

spark

delay

valve

is

questionable

dip

port

on

carburetor

side

into

a

cup

fIlled

with

water

Blow

air

through

the

other

port

Small

air

bubbles

should

appear

EC279

Fig

ET

26

Checking

spark

delay

ualue

Note

Be

careful

to

avoid

entry

of

oil

or

dirt

into

valve

ET

15

CHECKING

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

1

Air

cleener

element

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

opera

tion

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Schedule

2

Hot

elr

control

system

In

warm

wealher

it

is

difficult

to

find

ou

t

malfunction

of

hot

air

control

system

In

cold

weather

however

malfunction

of

air

control

valve

d

e

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bili

ty

of

air

con

trol

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

opera

tion

2

Increase

in

fuel

consumption

3

Lack

of

power

These

phenomena

reveal

malfunc

tionof

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

ou

t

inspec

tion

of

carburetor

2

1

Vacuum

hoses

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

1

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

position

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Page 28 of 537

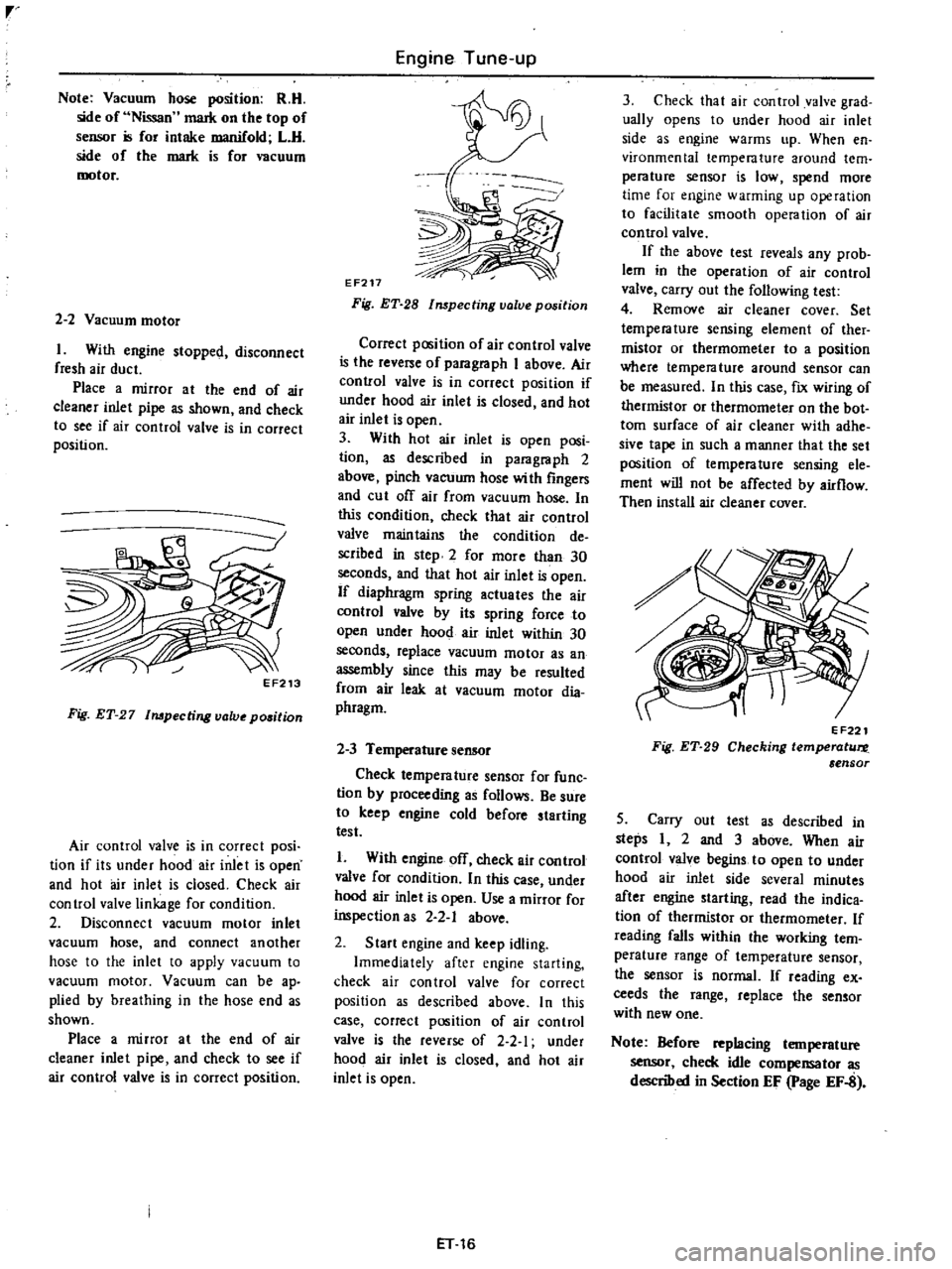

Note

Vacuum

hose

position

R

R

side

of

Nissan

mark

on

the

top

of

sensor

for

intake

manifold

L

R

side

of

the

mark

is

for

vacuum

rootor

2

2

Vacuum

motor

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

control

valve

is

in

correct

position

EF213

Fig

ET

27

Impecting

lJalv

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

Engine

Tune

up

EF217

Fig

ET

28

lmpecting

value

position

Correct

pC6ition

of

air

control

valve

is

the

reverse

of

paragraph

I

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

is

open

posi

tion

as

descnbed

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

of

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

sensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

1

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

1

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

ET

16

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

to

facilitate

smooth

opera

tion

of

air

con

trol

valve

If

the

above

test

reveals

any

prob

lem

in

the

operation

of

air

control

valve

carry

out

the

following

test

4

Remove

air

cleaner

cover

Set

temperature

sensing

element

of

ther

mistor

or

thermometer

to

a

position

where

tempera

ture

around

sensor

can

be

measured

In

this

case

fix

wiring

of

thermistor

or

thermometer

on

the

bot

tom

surface

of

air

cleaner

with

adhe

sive

tape

in

such

a

manner

that

the

set

position

of

temperature

sensing

ele

ment

will

not

be

affected

by

airflow

Then

install

air

cleaner

cover

EF221

Fig

ET

29

Checking

temperotur

e

ensor

5

Carry

out

test

as

described

in

steps

I

2

and

3

above

When

air

control

valve

begins

to

open

to

under

hood

air

inlet

side

severa

minutes

after

engine

starting

read

the

indica

tion

of

thermistor

or

thermometer

If

reading

falls

within

the

working

tern

perature

range

of

temperature

sensor

the

sensor

is

normaL

If

reading

ex

ceeds

the

range

replace

the

sensor

with

new

one

Note

Before

replacing

temperature

sensor

check

idle

compensator

as

described

in

Section

EF

page

EF

8

Page 32 of 537

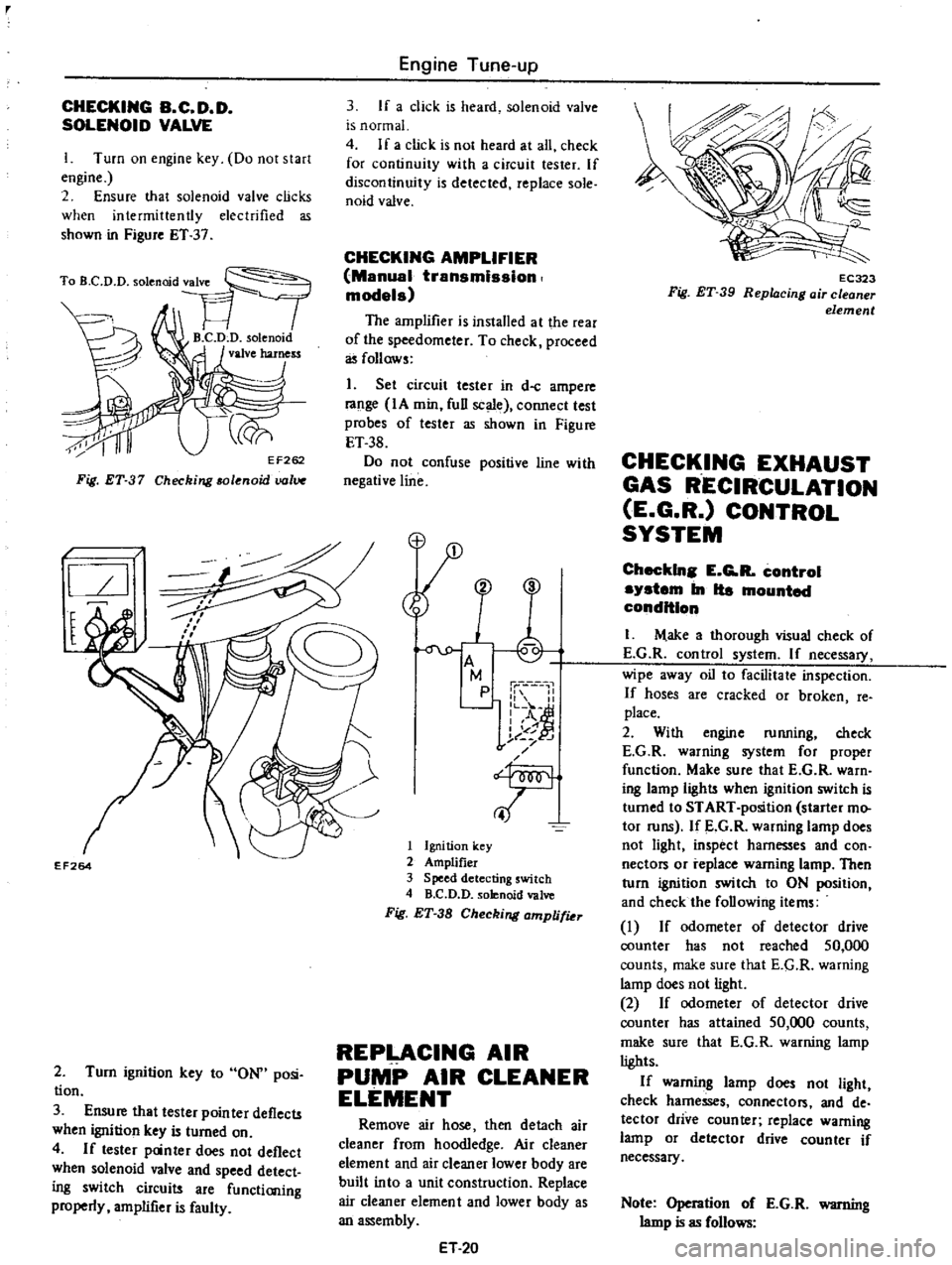

r

CHECKING

B

C

D

D

SOLENOID

VALVE

I

Turn

on

engine

key

Do

not

start

engine

2

Ensure

that

solenoid

valve

clicks

when

intermittently

electrified

as

shown

in

Figure

ET

37

Fig

ET

37

Checking

solenoid

uolV

l

I

l

EF264

2

Turn

ignition

key

to

ON

posi

tion

3

Ensure

that

tester

pointer

deflects

when

ignition

key

is

turned

on

4

If

tester

panter

does

not

deflect

when

solenoid

valve

and

speed

detect

ing

switch

circuits

are

functioning

properly

amplifier

is

faulty

Engine

Tune

up

3

If

a

click

is

heard

solenoid

valve

is

normal

4

If

a

click

is

not

heard

at

all

check

for

continuity

with

a

circuit

tester

If

discontinuity

is

detected

replace

sole

naid

valve

CHECKING

AMPLIFIER

Manual

transmission

models

The

amplifier

is

installed

at

the

rear

of

the

speedometer

To

check

proceed

as

follows

1

Set

circuit

tester

in

d

c

ampere

range

IA

min

full

scale

connect

test

probes

of

tester

as

shown

in

Figure

ET

38

Do

not

confuse

positive

line

with

negative

line

M

p

1

II

L

o

A

I

of

j

t

J

f

T

1

Ignition

key

2

Amplifier

3

Speed

detecting

switch

4

B

C

D

D

solenoid

valve

Fig

ET

38

Checking

amplifiu

REPLACING

AIR

PUMP

AIR

CLEANER

ELEMENT

Remove

air

hose

then

detach

air

cleaner

from

hoodledge

Air

cleaner

element

and

air

cleaner

lower

body

are

built

into

a

unit

construction

Replace

air

cleaner

element

and

lower

body

as

an

assembly

ET

20

EC323

Fig

ET

39

Repl4cing

air

cleaner

element

CHECKING

EXHAUST

GAS

RECIRCULATION

E

G

R

CONTROL

SYSTEM

Checkln

E

G

R

control

system

In

Ita

mounted

condition

I

M

ake

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

hoses

are

cracked

or

broken

fe

place

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

light

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

warning

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odometer

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connector

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Note

Operation

of

E

G

R

warning

lamp

is

as

follows

Page 33 of 537

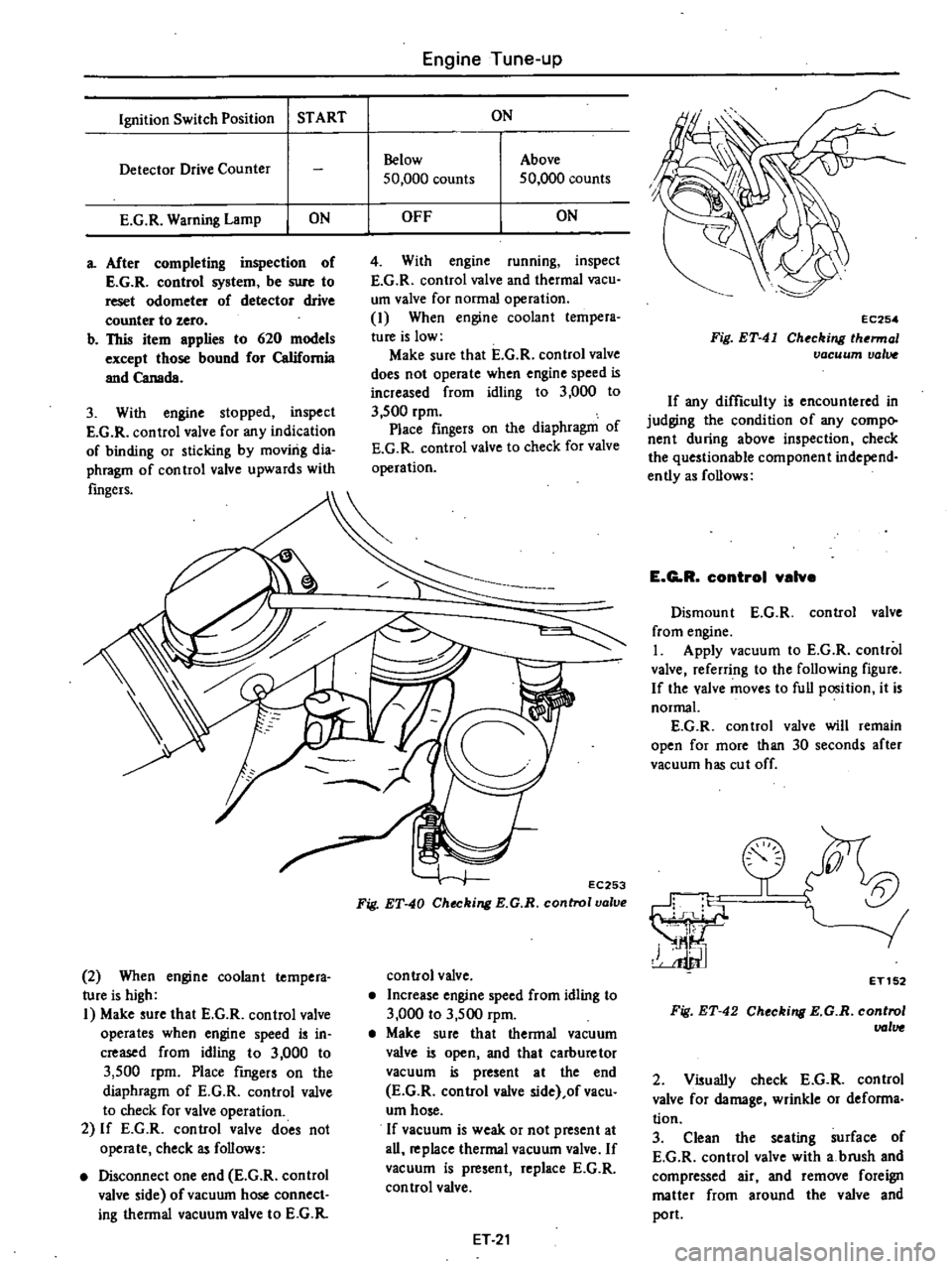

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

a

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

b

This

item

applies

to

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

movirig

dia

phragm

of

control

valve

upwards

with

fmgers

Engine

Tune

up

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacu

um

valve

for

normal

operation

I

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

ofvacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

EC253

Fig

ET

40

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

sure

that

thermal

vacuum

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

ofvacu

urn

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

con

trol

valve

ET

21

EC254

Fig

ET

41

Checking

thermal

vacuum

valw

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

0

r11

hC

J

ET152

Fig

ET

42

Checking

E

G

R

control

VGlve

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

deforma

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 35 of 537

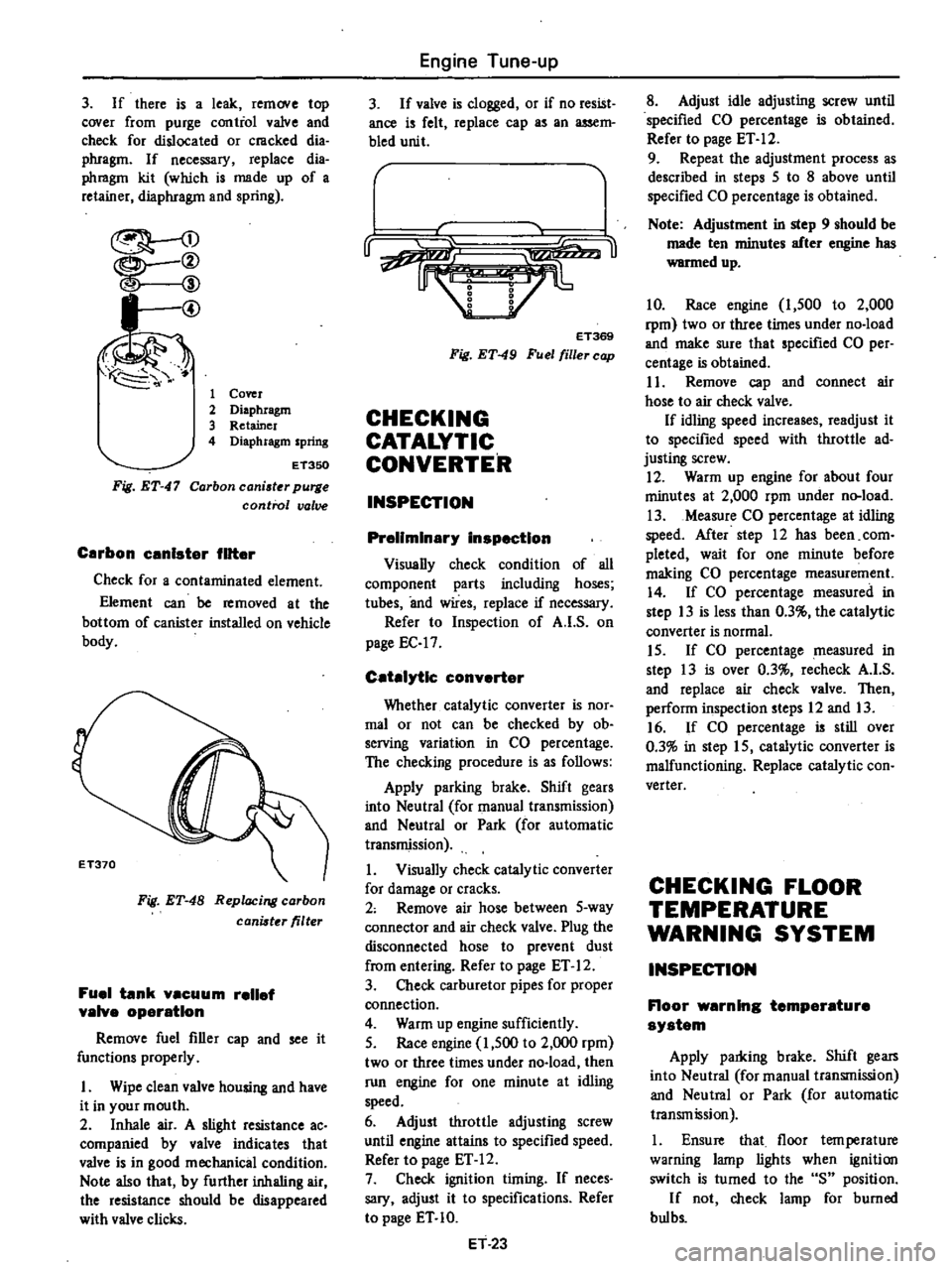

3

If

there

is

a

leak

remove

top

cover

from

purge

contiol

valve

and

check

for

dislocated

or

cmcked

dia

phragm

If

necessary

replace

dia

phmgm

kit

which

is

made

up

of

a

retainer

diaphragm

and

spring

I

@

1

Cover

2

Diaphragm

3

Retainer

4

Diaphragm

spring

Fig

ET

47

ET350

Carbon

caniater

purge

control

valve

Carbon

unlster

filter

Check

for

a

contaminated

element

Element

can

be

removed

at

the

bottom

of

canister

installed

on

vehicle

body

Fig

ET

48

Replacing

carbon

canister

filter

Fuel

tank

vacuum

relief

valve

operation

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

Engine

Tune

up

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

unit

r

u

ET369

Fig

ET

49

Fuel

filler

cap

CHECKING

CATALYTIC

CONVERTER

INSPECTION

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

hoses

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nOf

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

12

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

Refer

to

page

ET

10

ET

23

8

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adjustment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

warmed

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

I

1

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

Warm

up

engine

for

about

four

minutes

at

2

000

rpm

under

n

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

com

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalylic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

converter

is

malfunctioning

Replace

catalytic

con

verter

CHECKING

FLOOR

TEMPERATURE

WARNING

SYSTEM

INSPECTION

Floor

warning

temperature

system

Apply

parldng

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Ensure

that

floor

tern

perature

warning

lamp

lights

when

ignition

switch

is

turned

to

the

S

position

If

not

check

lamp

for

burned

bul

bs