headlamp DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 448 of 537

A

melted

fusible

link

can

be

de

tected

either

by

visual

inspection

or

by

feeling

with

finger

tip

If

its

condition

is

questionable

use

circuit

tester

or

test

lamp

as

required

to

conduct

continuity

test

This

continuity

test

can

be

performed

in

the

same

manner

as

for

any

conventional

fuse

Body

Electrical

System

Notes

a

If

fusible

link

should

melt

it

is

possible

that

critical

circuit

power

supply

or

large

current

carrying

circuit

is

shorted

In

such

a

case

carefully

check

and

eliminate

cause

of

problem

b

Never

wrap

periphery

of

fusible

link

with

vinyl

tape

Extreme

care

should

be

taken

with

this

link

to

ensure

that

it

does

not

come

into

contact

with

any

other

wiring

har

ness

or

vinyl

or

rubber

parts

c

BEB49A

Fig

BE

2

Fusible

link

LIGHTING

AND

SIGNAL

LAMP

SYSTEM

DESCRIPTION

LIGHTING

SYSTEM

CIRCUIT

DIAGRAM

HEADLAMP

HEAD

LAMP

BEAM

REPLACEMENT

AIMING

ADJUSTMENT

FRONT

COMBINATION

LAMP

BUL8

REPLACEMENT

REMOVAL

AND

INSTALLATION

SIDE

MARKER

LAMP

BUL8

REPLACEMENT

REMOVAL

AND

INSTALLATION

ROOM

LAMP

BULB

REPLACEMENT

REMOVAL

AND

INSTALLATION

REAR

COMBINATION

LAMP

BULB

REPLACEMENT

REMOVAL

AND

INSTALLATION

LICENSE

LAMP

BULB

REPLACEMENT

REMOVAL

AND

INSTALLATION

ENGINE

COMPARTMENT

LAMP

LIGHTING

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

ILLUMINATION

CONTROL

RHEOSTAT

REMOVAL

AND

INSTALLATION

CONTENTS

BE

4

BE

4

BE

5

BE

5

BE

5

8E

7

BE

7

BE

7

8E

7

BE

7

8E

7

BE

8

BE

B

8E

8

BE

8

8E

8

8E

8

8E

8

BE

8

8E

8

BE

9

BE

9

BE

9

8E

9

8E

9

8E

9

INSPECTION

KN08

ILLUMINATION

LAMP

BULB

REPLACEMENT

LAMP

BODY

REPLACEMENT

TURN

SIGNAL

AND

DIMMER

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

STOP

LAMP

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

DOOR

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

HAZARD

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

FLASHER

UNIT

REPLACEMENT

8ULB

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HEAD

LAMP

TURN

SIGNAL

LAMP

TAIL

LAMP

STOP

LAMP

AND

BACK

UP

LAMP

BE

3

1

BE

9

BE

10

BE

10

BE10

BE

10

BE

10

BE

10

BE

10

BE

10

BE

10

BE

10

BE

10

BE

11

BE

11

BE

11

BE

11

8E

11

BE

11

BE

12

BE

12

BE

12

BE

13

8E

13

Page 449 of 537

Body

Electrical

System

DESCRIPTION

LIGHTING

SYSTEM

CI

RCUIT

DIAGRAM

Headlamp

tail

lamp

and

license

lamp

system

G

o

@

LI

U

CIl

HEADl

AMP

L

H

e

FRONT

SlOE

lIIIARI

ER

LAMP

IR

H

USl

LE

LINK

CJ

lOA

CJ

154

CJ

CJ

FUSE

BLOCK

I

2

IR

n

fMP

IL

H

l

REAR

SIDE

MARKER

LAMP

R

1

1

LIGHTING

SWITCH

l

J

ll

f

1121

I

r

1

x

DIMMER

SWITCH

101

1

I

ON

t

0

I

EA

i

METE

LAMP

ILLUMINATION

LAMP

jSTOPBrURH

STOP

8

TURN

TAIL

TAIL

BSAOC

UP

RE

AR

COMBINATION

LAMP

R

H

I

J

LICE

NSf

r

LAMP

I3

BACIC

UP

TA

L

ST

OP8TURN

TAIL

STOP8TURN

REAR

COMBINATION

LAMP

ILH

I

Q

REAR

SIDE

NAR

tAMP

BEBSOA

Fig

BE

3

Headlamp

tail

lamp

and

liceme

lamp

ay6t

m

Turn

signal

hazard

warning

lamp

stop

lamp

and

back

up

lamp

system

I

HEAOLAMP

R

H

l

CR

H

Ll

lHTINIi

j

nn

A

iNAnON

8A

LAMP

BATTERY

@

4j

Jl

FRONT

COM8IfUl

1ON

LAMP

H

FUSIBLE

LINK

I

a

FUSE

BLOCK

FUSE

FROM

IGNITION

SWITCH

@

h

FRONT

COMBINATION

LAMP

L

H

REAR

COMBINATION

LAMP

R

H

BACK

UP

LAMP

T

A

I

L

SWITCH

n

8ACK

UP

E

W

P

HAZARO

FLASHER

UNIT

HAIARD

2

ON

WA

NING

SWITCH

3

r

TU

N

SIGNAL

FLASHER

UNIT

CJ

U

t

N

iH

ij

I

STOP

t

H

J

EL

L

H

I

TURN

SIGNAL

INDICATOR

LAMP

TURN

SIGNAL

SWITCH

G

BACK

UP

JTA

STOP8TURN

TAIL

STOP

8

TURN

REAR

COMelNATlON

LAMP

IL

H

I

BE851A

Fig

BE

4

Turn

signal

Juuard

warning

lamp

stop

lamp

and

back

up

lamp

system

BE

4

Page 450 of 537

Body

Electrical

System

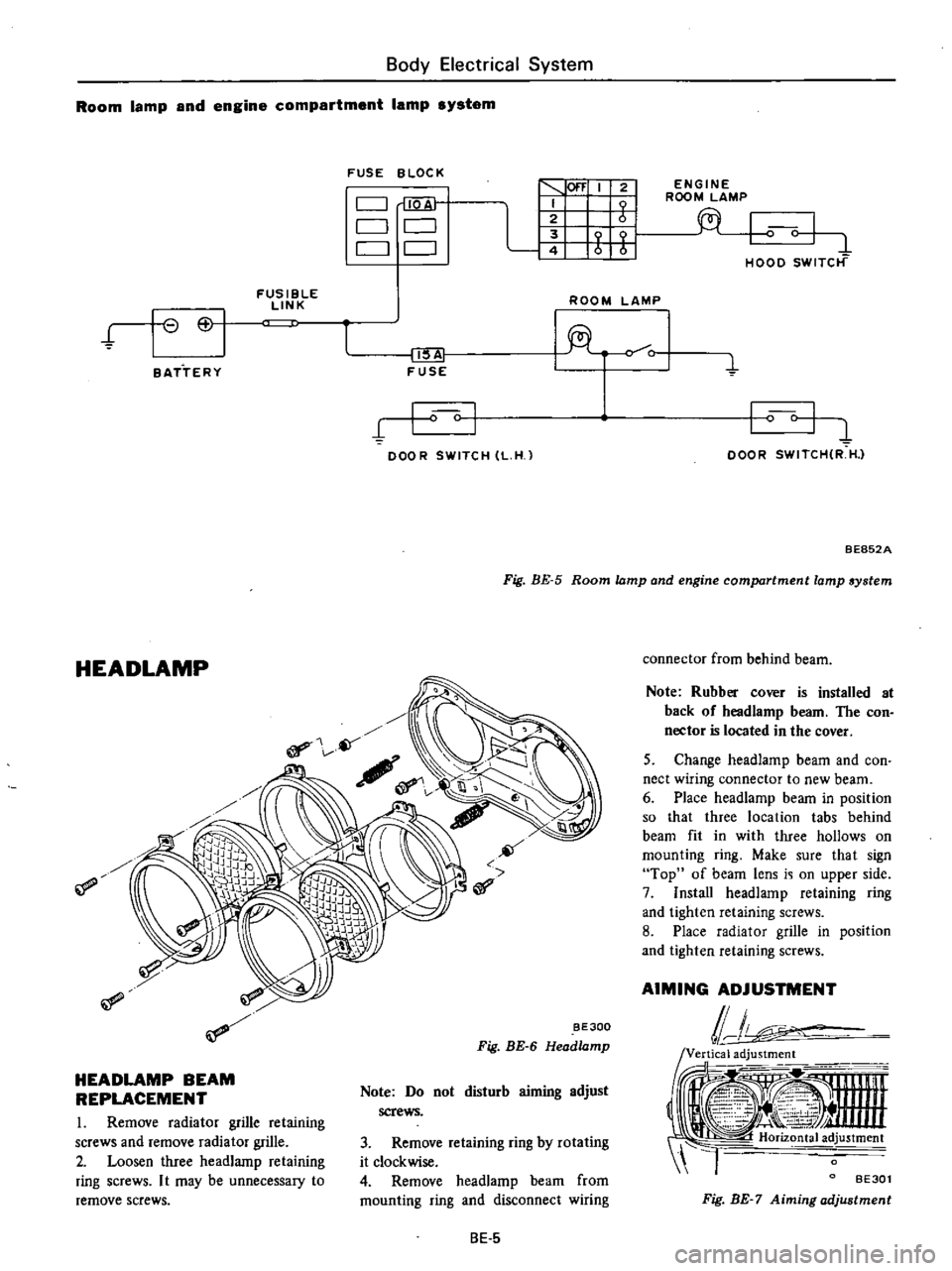

Room

lamp

and

engine

compartment

lamp

system

FUSE

BLOC

K

C

J

QA

C

J

CJ

CJ

CJ

1

100

I

2

I

I

t1

Wf

t

fi

FUSIBLE

LINK

ROOM

LAMP

t

I

6

I

II

lA

FUSE

o

C

1

BATTERY

I

I

DOOR

SWITCH

L

H

l

ENGINE

ROOM

LAMP

I

0

I

1

HOOD

SWITCt

f

I

c

I

DOOR

SWITCHIR

H

l

Fig

BE

5

Room

lamp

and

engine

compartment

lamp

system

BE852A

HEADLAMP

if

BE300

Fig

BE

6

Head

amp

HEADLAMP

BEAM

REPLACEMENT

I

Remove

radiator

grille

retaining

screws

and

remove

radiator

grille

2

Loosen

three

headlamp

retaining

ring

screws

I

t

may

be

unnecessary

to

remove

screws

Note

Do

not

disturb

aiming

adjust

screws

3

Remove

retaining

ring

by

rotating

it

clockwise

4

Remove

headlamp

beam

from

mounting

ring

and

disconnect

wiring

8E

5

connector

from

behind

beam

Note

Rubber

cover

is

installed

at

back

of

headlamp

beam

The

con

nector

is

located

in

the

cover

5

Change

headlamp

beam

and

con

nect

wiring

connector

to

new

beam

6

Place

headlamp

beam

in

position

so

that

three

location

tabs

behind

beam

fit

in

with

three

hollows

on

mounting

ring

Make

sure

that

sign

Top

of

beam

lens

i

i

on

upper

side

7

Install

headlamp

retaining

ring

and

tighten

retaining

screws

8

Place

radIator

grille

in

position

and

tighten

retaining

screws

AIMING

ADJUSTMENT

lJ

ii

i

tooi

1

Ji

Y

4

nnn

4

I

Horiz

tal

ad

justment

l

BE30l

Fig

BE

7

Aiming

adjustment

Page 451 of 537

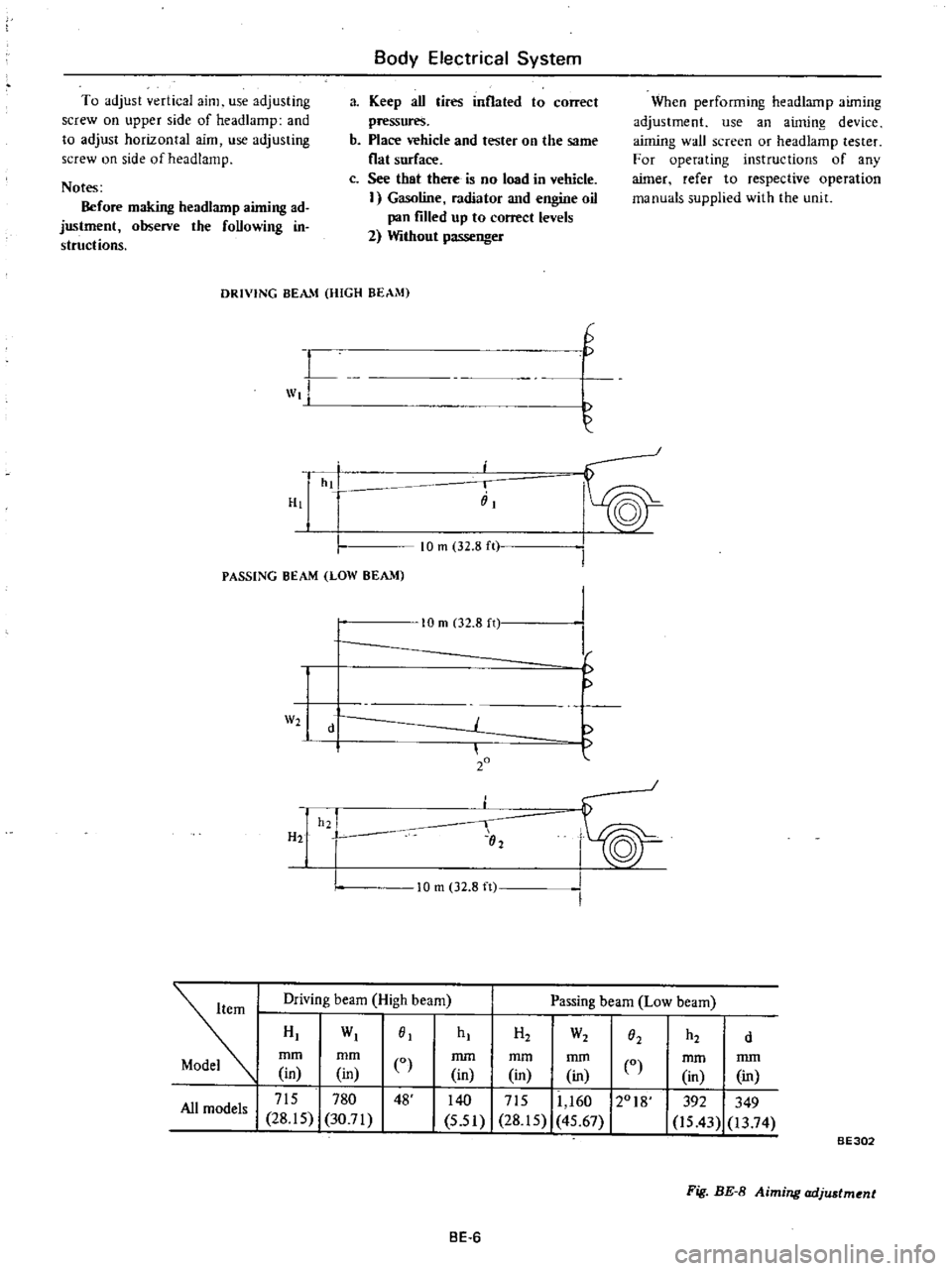

To

adjust

vertical

aim

use

adjusting

screw

on

upper

side

of

headlamp

and

to

adjust

horizontal

aim

use

adjusting

screw

on

side

of

head

lamp

Notes

Before

making

headlarnp

aiming

ad

justment

observe

the

foUowing

in

structions

Body

Electrical

System

a

Keep

aU

tires

inflated

to

correct

pressures

b

Place

vehicle

and

tester

on

the

same

flat

surface

c

See

that

there

is

no

load

in

vehicle

I

Gasoline

radiator

and

engine

oil

pan

filled

up

to

correct

levels

2

Without

passenger

When

performing

headlamp

aiming

adjustment

use

an

aiming

device

aiming

wall

screen

or

headlamp

tester

For

operating

instructions

of

any

aimer

refer

to

respective

operation

manuals

supplied

with

the

unit

DRIVING

BEAM

HIGH

BEAM

L

wt

H

G

hi

i

iiI

PASSING

BEAM

LOW

BEAM

10

m

32

8

ft

W2

H2

10

m

02

8

n

d

20

h2

I

02

I

I

f

10

m

32

8

ft

Driving

beam

High

beam

Passing

beam

Low

beam

HI

WI

01

mm

mm

CO

in

in

I

715

780

48

All

models

28

15

30

71

hI

H2

W2

h2

O2

d

mm

mm

mm

in

in

in

0

140

I

715

11

160

12018

5

51

28

15

45

67

mm

mm

in

in

392

349

is

43

13

74

BE302

Fig

BE

8

Aiming

adjustment

BE

6

Page 457 of 537

Body

Electrical

System

BULB

SPECIFICATIONS

Item

Wattage

Candlepower

Headlamp

Inner

Outer

37

5W

37

5

S0W

Front

combination

lamp

Turn

signal

and

parking

lamp

23

8W

32

3C

Side

marker

lamp

Front

Rear

8W

4C

8W

4C

Rear

combination

lamp

Turn

signal

lamp

A

B

Tail

lamp

B

C

Stop

lamp

A

B

Back

up

lamp

D

A

23W

32C

B

23j8W

32j3C

C

8W

4C

D

23W

32C

7

SW

6C

License

plate

lamp

Engine

compartment

lamp

6W

Room

lamp

5W

Combination

meter

illurnina

tion

17W

iC

x3

Knob

illumination

lamp

3

4W

2C

Heater

control

illumination

lamp

3

4W

2C

TROUBLEDIAGNOSE

AND

CORRECTIONS

HEADLAMP

Condition

Headlarnps

do

not

light

for

both

high

and

low

beams

High

beam

cannot

be

switched

to

low

beam

or

vice

versa

Probable

cause

Burnt

fuse

Loose

connection

or

open

circuit

Faulty

lighting

switch

Faulty

dimmer

switch

Faulty

light

relay

No

ground

Faulty

dimmer

switch

Faulty

light

relay

BE12

Bulb

SAE

trade

number

4001

4002

1034

67

67

1073

1034

67

1073

89

161

158

158

Corrective

action

Correct

cause

and

replace

fuse

Check

wiring

and

or

repair

connection

Conduct

continuity

test

and

replace

if

neces

sary

Check

light

relay

for

proper

operation

and

replace

if

necessary

Clean

and

tighten

ground

terminal

Conduct

continuity

test

and

replace

if

neces

sary

Check

light

relay

for

proper

operation

and

replace

if

necessary

Page 458 of 537

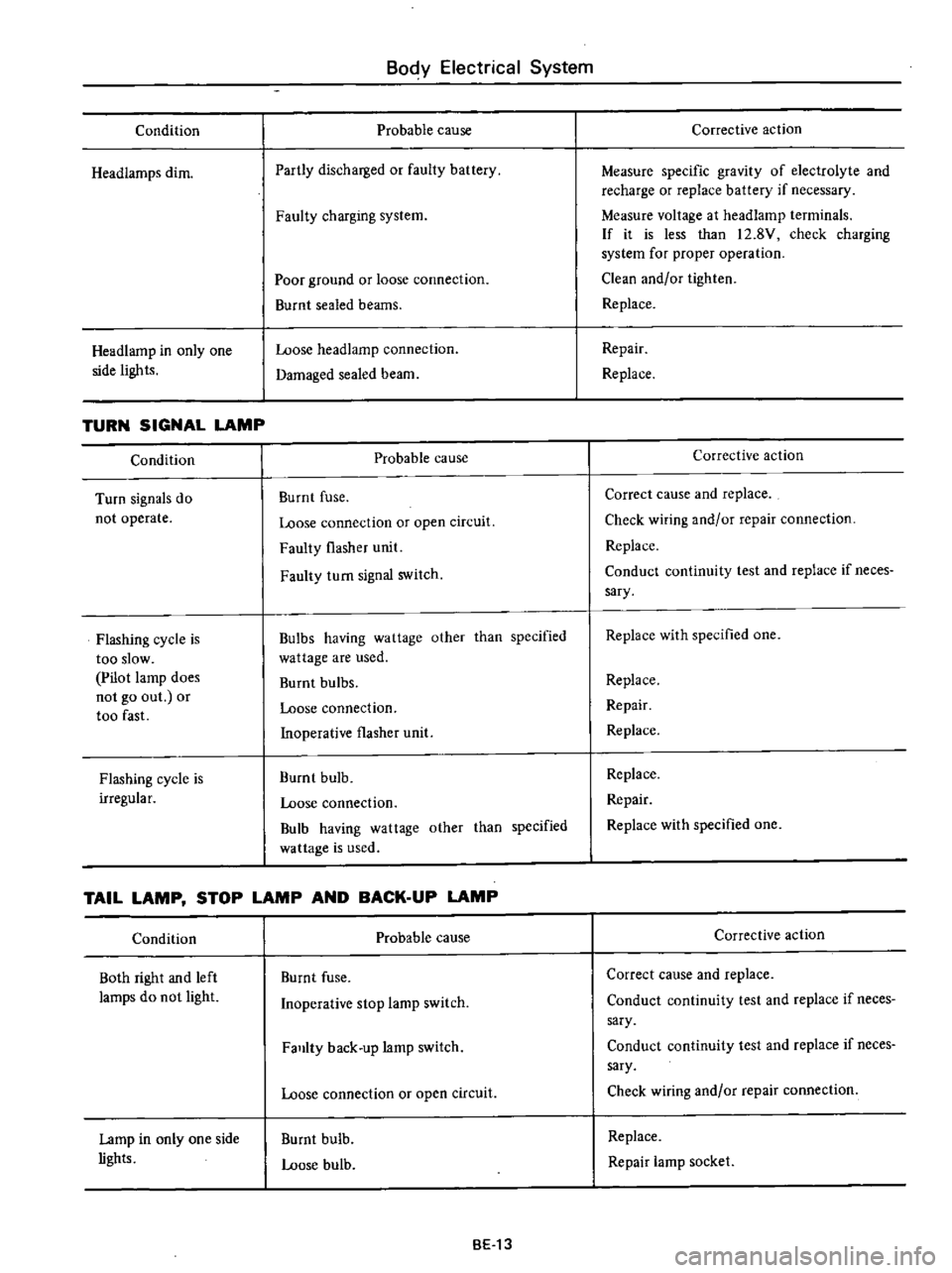

Condition

Headiamps

dim

Headlamp

in

only

one

side

lights

TURN

SIGNAL

LAMP

Condition

Turn

signals

do

not

operate

Flashing

cycle

is

too

slow

Pilot

lamp

does

not

go

out

or

too

fast

Flashing

cycle

is

irregular

Body

Electrical

System

Probable

cause

Partly

discharged

or

faulty

battery

Faulty

charging

system

Poor

ground

or

loose

connection

Burnt

sealed

beams

Loose

headlamp

connection

Damaged

sealed

beam

Probable

cause

Burnt

fuse

Loose

connection

or

open

circuit

Faulty

flasher

unit

Faulty

turn

signal

switch

Bulbs

having

wattage

other

than

specified

wattage

are

used

Burnt

bulbs

Loose

connection

Inoperative

flasher

unit

Burnt

bulb

Loose

connection

Bulb

having

wattage

other

than

specified

wa

ttage

is

used

TAIL

LAMP

STOP

LAMP

AND

BACK

UP

LAMP

Condition

Both

right

and

left

lamps

do

not

light

Lamp

in

only

one

side

lights

Probable

cause

Burnt

fuse

Inoperative

stop

lamp

switch

Falllty

back

up

lamp

switch

Loose

connection

or

open

circuit

Burnt

bulb

Loose

bulb

BE13

Corrective

action

Measure

specific

gravity

of

electrolyte

and

recharge

or

replace

battery

if

necessary

Measure

voltage

at

headlamp

terminals

If

it

is

less

than

12

8V

check

charging

system

for

proper

operation

Clean

and

or

tighten

Replace

Repair

Replace

Corrective

action

Correct

cause

and

replace

Check

wiring

and

or

repair

connection

Replace

Conduct

continuity

test

and

replace

if

neces

sary

Replace

with

specified

one

Replace

Repair

Replace

Replace

Repair

Replace

with

specified

one

Corrective

action

Correct

cause

and

replace

Conduct

continuity

test

and

replace

if

neces

sary

Conduct

continuity

test

and

replace

if

neces

sary

Check

wiring

and

or

repair

connection

Replace

Repair

lamp

socket

Page 467 of 537

Body

Electrical

System

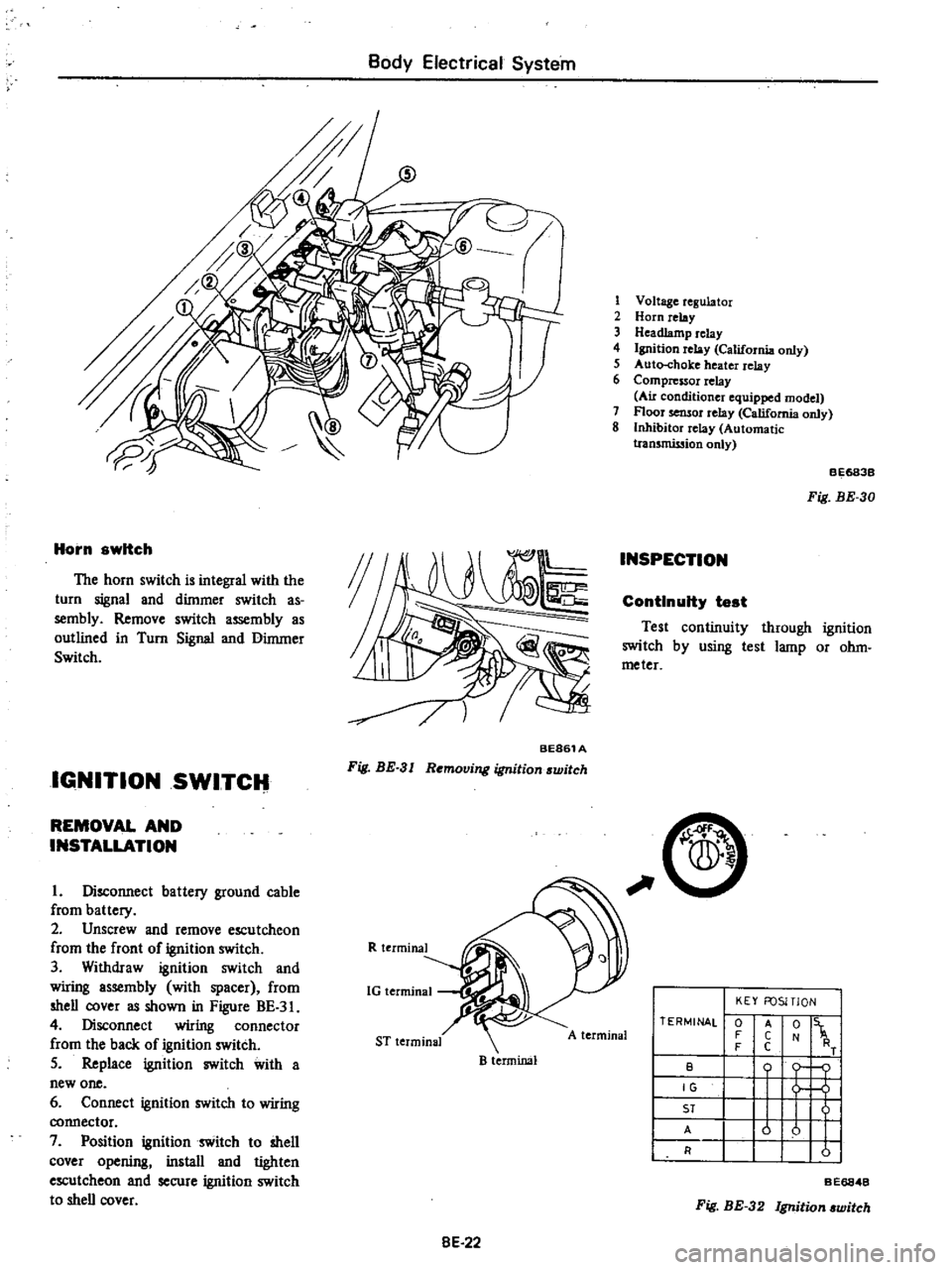

Horn

switch

The

horn

switch

is

integral

with

the

turn

signal

and

dimmer

switch

as

sembly

Remove

switch

assembly

as

outlined

in

Turn

Signal

and

Dimmer

Switch

IGNITION

SWITCH

BE861A

Fig

BE

3

I

Removing

ignition

switch

REMOVAL

AND

INSTALLATION

I

Disconnect

battery

ground

cable

from

battery

2

Unscrew

and

remove

escutcheon

from

the

front

of

ignition

switch

3

Withdraw

ignition

switch

and

wiring

assembly

with

spacer

from

shell

cover

as

shown

in

Figure

BE

3

4

Disconnect

wiring

connector

from

the

back

of

ignition

switch

5

Replace

ignition

switch

with

a

new

one

6

Connect

ignition

switch

to

wiring

connector

7

Position

ignition

switch

to

shell

cover

opening

install

and

tighten

escutcheon

and

secure

ignition

switch

to

shell

cover

R

terminal

1G

terminal

ST

terminal

B

terminal

8E

22

1

Voltage

regulator

2

Horn

relay

3

Headlamp

relay

4

Ignition

relay

California

only

5

Auto

choke

heater

relay

6

Compressor

relay

Au

conditioner

equipped

model

7

Floor

sensor

relay

California

only

8

Inhibitor

relay

Automatic

tran5mission

only

INSPECTION

BE683B

Fig

BE

30

ContInuity

test

Test

continuity

through

ignition

switch

by

using

test

lamp

or

ohm

meter

C

A

terminal

TERMINAL

0

F

F

B

IG

ST

A

R

KEY

FOSITlON

t

1

o

j

u

u

I

I

A

C

C

Fig

BE

32

Ignition

witch

BE6848

Page 481 of 537

CD

m

Cl

@

D

@

I

j

1

To

instrument

harness

IS

To

battery

30

To

check

connector

2

To

full

transistor

amplifier

16

To

fusible

link

3t

To

headlamp

L

U

type

2

California

models

only

17

To

engine

harness

No

2

32

To

sido

marker

lamp

L

B

3

To

hood

switch

18

To

alternator

33

To

front

combination

lamp

L

H

4

To

engine

compartment

lamp

1

9

To

front

combination

lamp

R

n

34

To

horn

Low

ll

l

S

To

washer

motor

20

To

headlamp

R

H

type

2

3S

To

horn

High

l

l

0

6

To

auto

choke

heater

relay

1

To

side

marker

lamp

R

n

36

To

B

C

D

D

cut

olenoid

California

models

7

To

detector

dri

e

counter

22

To

headlamp

R

B

type

1

only

Non

Califunia

model

except

for

Canada

23

To

ground

37

To

block

tcrminal

distributor

California

8

To

ignition

relay

California

models

only

i4

To

thermal

transmitter

models

only

9

To

floor

sensor

relay

California

modeb

only

is

To

distributor

Non

California

models

only

38

To

ignition

coil

Non

California

models

only

n

10

To

inhibitor

relay

A

T

only

26

To

8

C

D

D

cut

solenoid

Non

California

39

To

condenser

t

II

To

head

lamp

relay

models

only

40

To

ignition

coil

and

resistor

@

12

To

horn

relay

27

To

fuel

cut

solenoid

California

models

only

OJ

v

m

13

To

voltage

regulator

28

To

auto

choke

heater

g

e

14

To

cooler

cable

29

To

headlamp

L

R

type

1

OJ

to

o

Q

m

r0

C

1

i

Ql

CIl

Il

l

3