clock setting DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 24 of 537

r

connected

hose

to

prevent

dust

from

entering

To

air

check

valve

Fig

ET

17

Disconnect

air

hose

from

ojr

check

valve

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

D

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

I

at

750

rpm

Automatic

transmission

in

D

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

11

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

Engine

Tune

up

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

CO

Idle

adjustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

connection

2

Wann

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

peed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

modeis

and

air

check

valve

shown

in

Figure

ET

17

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

ET

12

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

II

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

IDLE

LIMITER

CAP

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

readjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

After

adjusting

throttle

or

idle

speed

adjusting

screws

check

to

be

Sure

that

the

amount

of

CO

con

tained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

further

turn

1

8

rotation

in

the

CO

RICH

direction

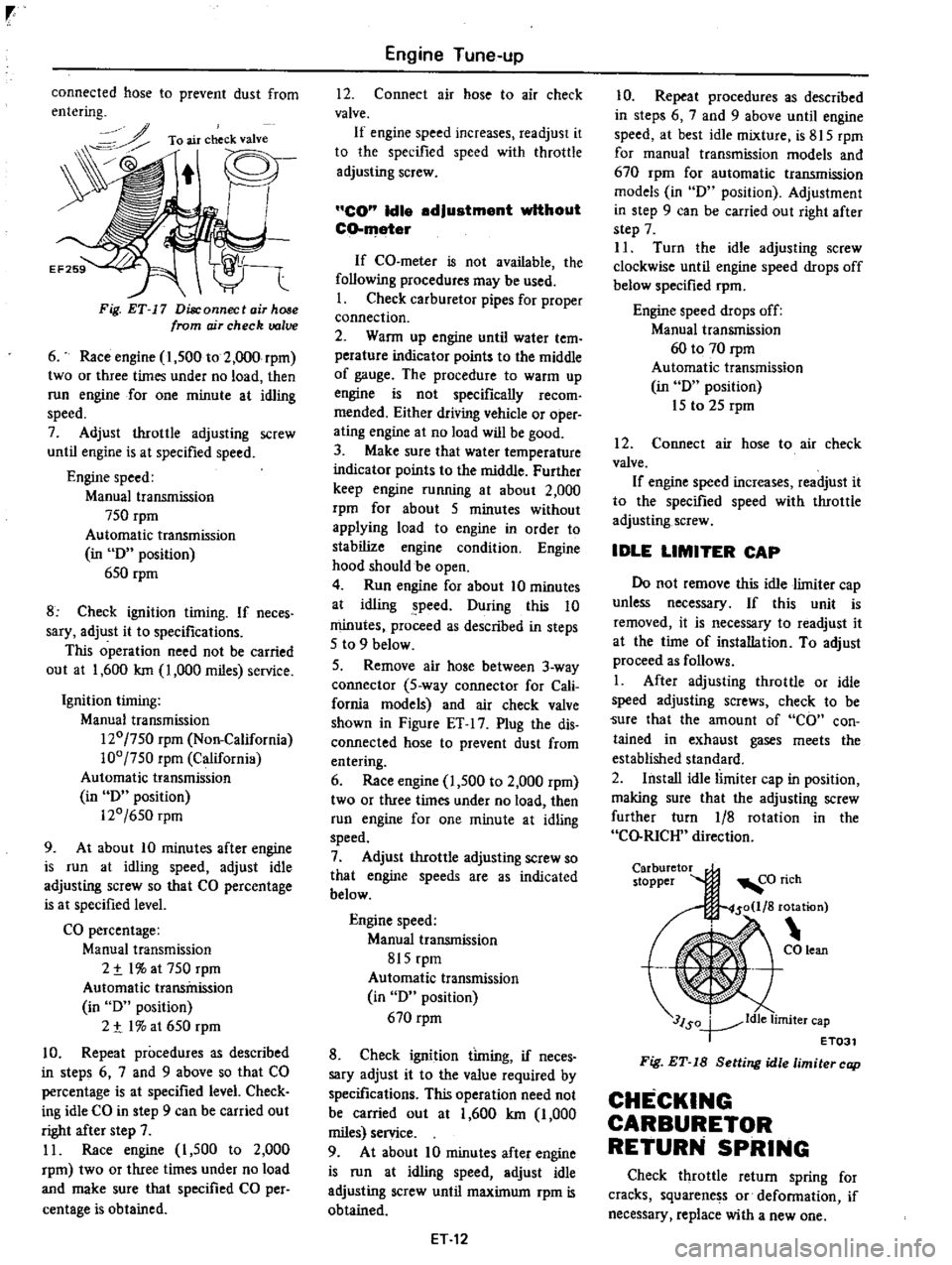

Carburetor

stopper

3lSo

ldle

limiter

cap

T

ET031

Fig

ET

18

Setting

idle

limiter

cap

CHECKING

CARBURETOR

RETURN

SPRING

Check

throttle

return

spring

for

cracks

squarene

s

or

defonnation

if

necessary

replace

with

a

new

one

Page 30 of 537

r

ADJUSTMENT

OF

SET

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

C

D

D

Generally

it

is

unnecessary

to

ad

just

the

B

C

D

D

however

if

it

should

become

necessary

to

adjust

it

the

procedure

is

as

follows

Prepare

the

foUowlnB

tools

I

Tachometer

to

measure

the

en

gine

speed

while

idling

and

a

screw

driver

2

A

vacuum

gauge

connecting

pipe

Note

A

qui

k

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

To

properly

set

the

B

C

D

D

set

pressure

proceed

as

follows

I

Remove

the

harness

of

solenoid

valve

TO

D

D

solenrod

VT

FJ

1

B

C

D

D

solenni

valve

harness

J

ri

y

EF262

F

g

ET

32

Removing

harneS5

of

solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

as

shown

Fig

ET

33

Connecting

vacuum

gauge

3

Warm

up

the

engine

until

it

is

heated

to

operating

temperature

Then

adjust

the

engine

at

normal

Engine

Tune

up

idling

setting

Refer

to

the

item

Idling

Adjustment

in

page

ET

II

Idling

engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

4

Run

the

engine

under

no

load

Increase

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

5

At

the

time

the

manifold

vacuum

pressure

increases

abruptly

to

600

mmHg

23

62

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

6

Check

that

the

B

C

D

D

set

pres

sure

is

within

the

specified

pressure

Specified

pressure

0

m

sea

level

and

760

mmHg

30

inHg

atmos

pheric

pressure

Manual

transmission

510

to

550

mmHg

20

1

to

21

7

inHg

Automatic

transmission

490

to

530

mmHg

19

3

to

20

9

inHg

Note

When

checking

the

set

pressure

of

B

C

D

D

find

the

specified

set

pressure

in

Figure

IT

36

from

the

atmospheric

pressure

and

altitutde

of

the

given

location

For

example

if

a

manual

transmis

sion

model

vehicle

is

located

at

an

altitude

of

1

000

m

3

280

ft

the

specified

set

preSsure

for

B

C

D

D

445

mmHg

17

5

inHg

7

If

it

is

higher

than

the

set

level

turn

the

adjusting

screw

counter

clockwise

or

nut

clockwise

until

correct

adjustment

is

made

Non

California

models

Adjusting

screw

type

California

models

Adjusting

nut

type

Note

When

adjusting

B

C

D

D

for

California

models

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

prop

erly

to

prevent

changes

in

set

pres

sure

ET

18

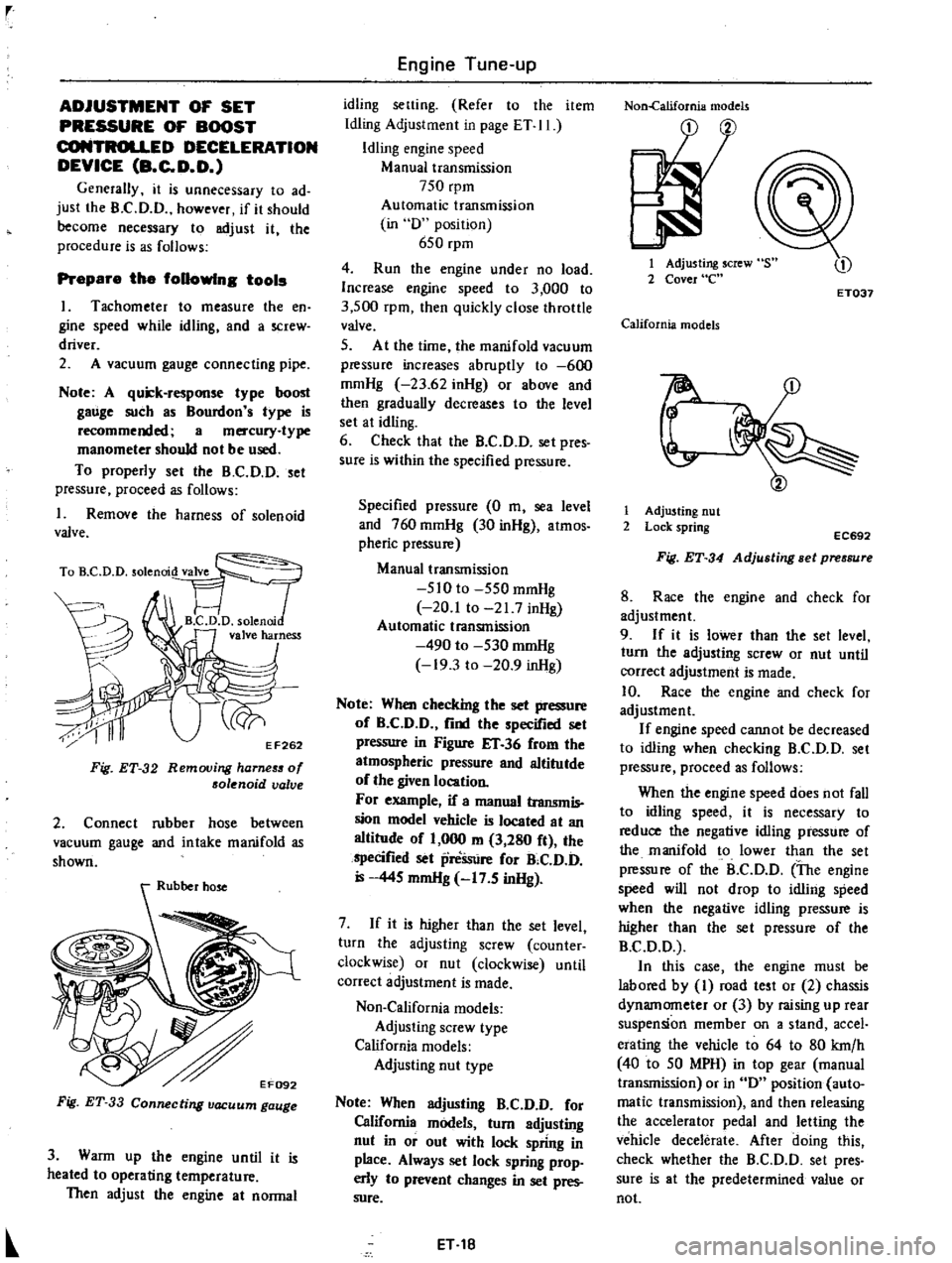

Non

california

models

1

Adjusting

screw

2

Cover

e

ET037

California

models

r

1

Adjusting

nut

2

Lock

spring

EC692

Fig

ET

34

Adjusting

Bet

pressure

8

Race

the

engine

and

check

for

adjustment

9

If

it

is

lower

than

the

set

level

turn

the

adjusting

screw

or

nut

until

correct

adjustment

is

made

10

Race

the

engine

and

check

for

adjustment

If

engine

speed

cannot

be

decreased

to

idling

when

checking

B

C

D

D

set

pressure

proceed

as

follows

When

the

engine

speed

does

not

fall

to

idling

speed

it

is

necessary

to

reduce

the

negative

idling

pressure

of

the

manifold

to

lower

than

the

set

pressure

of

the

B

C

D

D

The

engine

speed

will

not

drop

to

idling

speed

when

the

negative

idling

pressure

is

higher

than

the

set

pressure

of

the

B

C

D

D

In

this

case

the

engine

must

be

labored

by

I

road

test

or

2

chassis

dynamometer

or

3

by

raising

up

rear

suspension

member

on

a

stand

accel

erating

the

vehicle

to

64

to

80

krn

h

40

to

50

MPH

in

top

gear

manual

transmission

or

in

D

position

auto

matic

transmission

and

then

releasing

the

accelerator

pedal

and

letting

the

vehicle

decelerate

After

doing

this

check

whether

the

B

C

D

D

set

pres

sure

is

at

the

predetermined

value

or

not

Page 118 of 537

rpm

two

or

three

iimes

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjustingsqew

CO

idle

edJustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

L

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

shown

in

Figure

EF

35

Plug

the

dis

connected

hose

19

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

At

about

10

minutes

after

engine

Engine

Fuel

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

11

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

Idle

limiter

cep

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

re

moved

it

must

be

readjusted

at

lime

of

installation

To

adjust

proceed

as

follows

I

After

adjusting

throttle

or

idle

speed

adjusting

screw

check

to

be

sure

that

the

amount

of

CO

contained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

rotate

another

1

8

turn

in

the

CO

RICH

direction

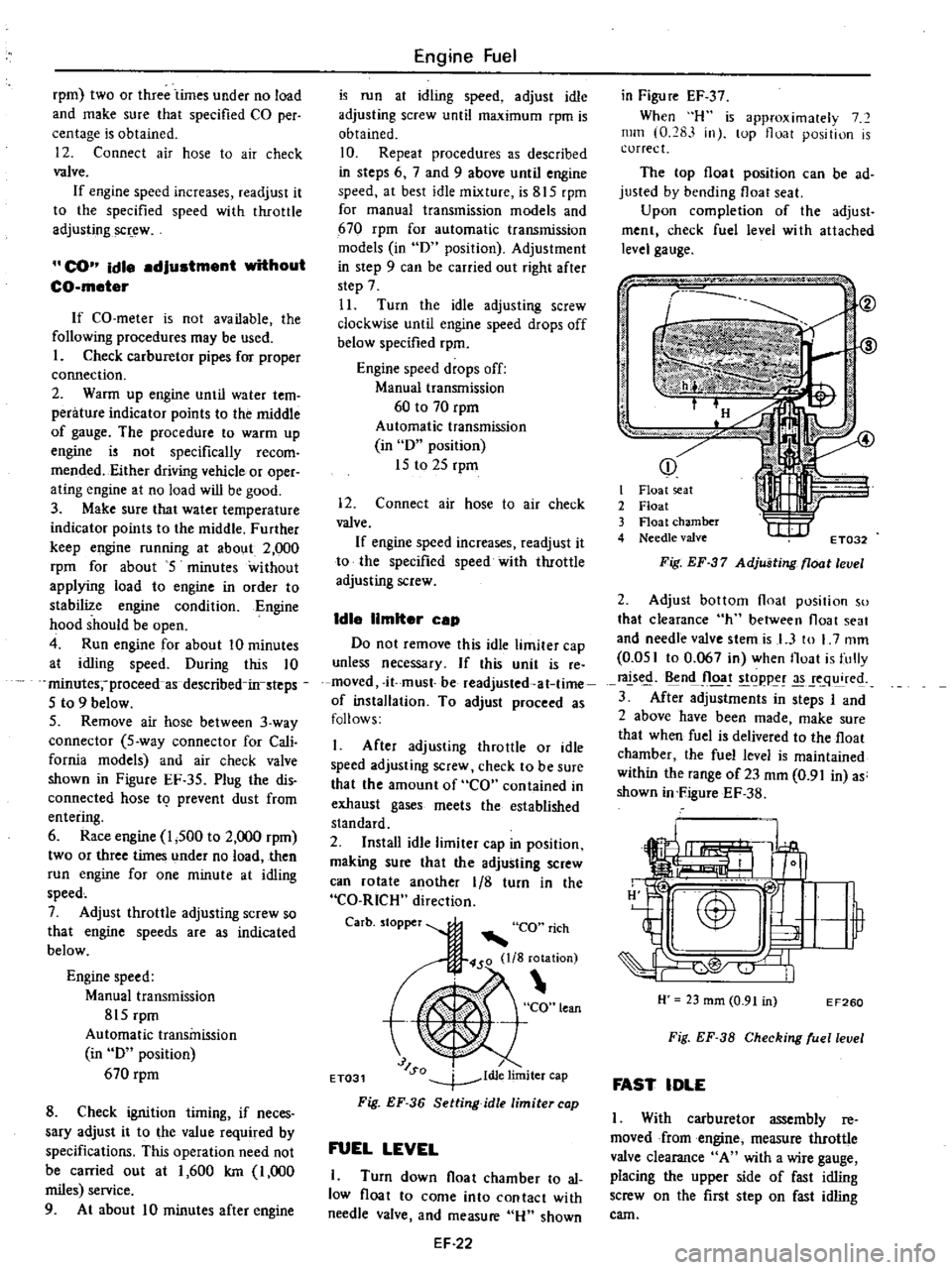

Carbo

to

per

CO

rich

450

lIS

rotation

t

CO

lean

J

SQ

dl

lim

ET031

1

e

Iter

cap

Fig

EF

36

Setting

idle

limiter

cap

FUEL

LEVEL

1

Turn

down

float

chamber

to

al

low

float

to

come

into

contact

with

needle

valve

and

measure

Hu

shown

EF

22

in

Figu

re

EF

37

When

H

is

approximalely

7

mill

0

283

in

lOp

float

position

is

correct

The

top

float

position

can

be

ad

justed

by

bending

float

seat

Upon

completion

of

the

adjust

ment

check

fuel

level

wi

th

attached

level

gauge

p

j

i

I

it

I

Float

seat

2

Float

3

Float

chamber

4

Needle

valve

t

I

IIf

ET032

Fig

EF

37

Adjusting

float

level

2

Adjust

bottom

float

position

so

that

clearance

h

between

float

seat

and

needle

valve

stemis

I

3

to

L

7

mm

0

051

to

0

067

in

when

Iloat

is

fully

rals

n

Jloa

t

goppe

q

re

3

After

adjustments

in

steps

I

and

2

above

have

been

made

make

sure

that

when

fuel

is

delivered

to

the

float

chamber

the

fuel

level

is

maintained

within

the

range

of23

mm

0

91

in

as

shown

in

FigureEF

38

H

23

mm

0

91

in

EF260

Fig

EF

38

Checking

ruellevel

FAST

IDLE

I

With

carburetor

assembly

reo

moved

from

engine

measure

throttle

valve

clearance

A

with

a

wire

gauge

placing

the

upper

side

of

fast

idling

screw

on

the

first

step

on

fast

idling

cam