wheel DODGE DAKOTA 2008 3.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: DAKOTA, Model: DODGE DAKOTA 2008 3.GPages: 426, PDF Size: 6.39 MB

Page 296 of 426

Weight Ratings)º for the website address that contains

the necessary information for your specific drivetrain.

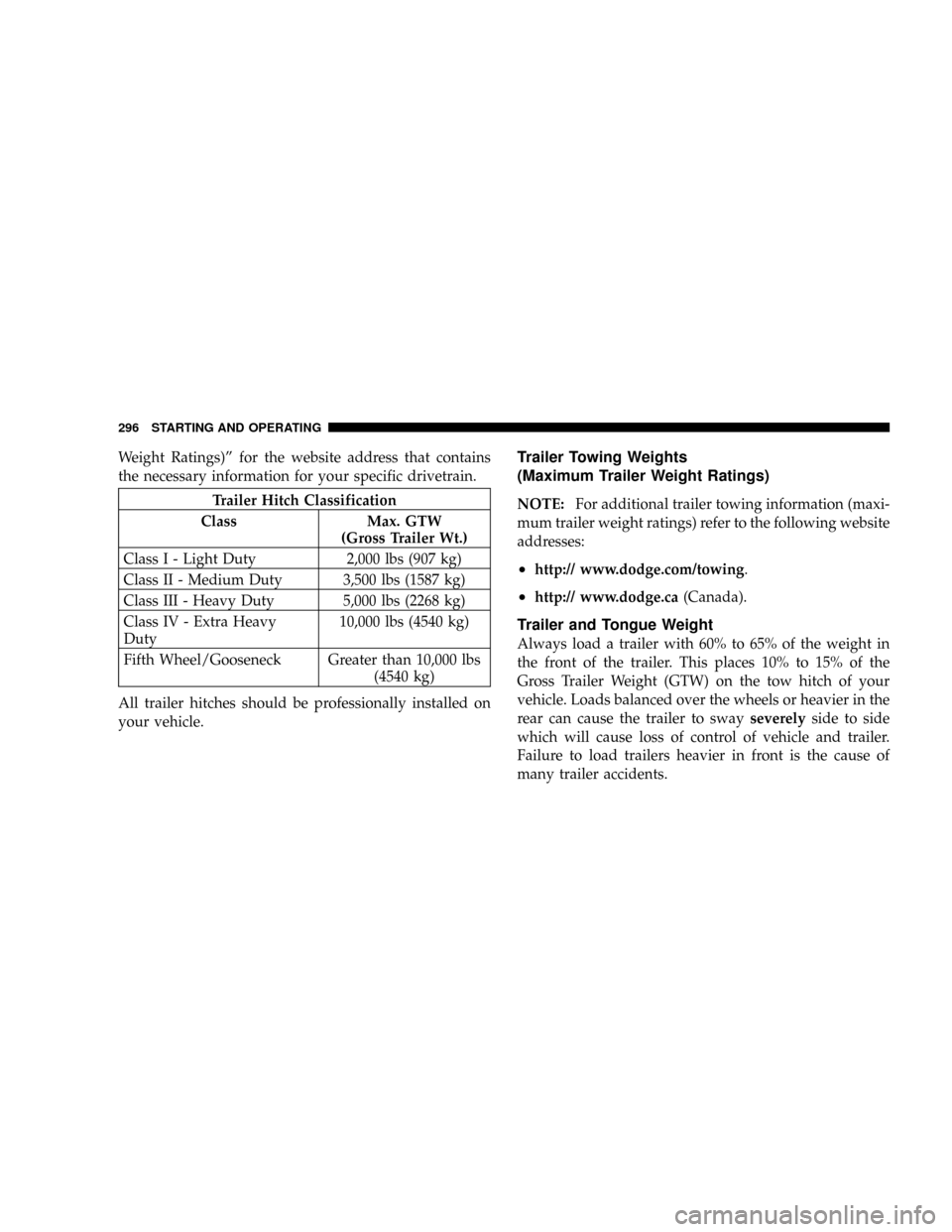

Trailer Hitch Classification

Class Max. GTW

(Gross Trailer Wt.)

Class I - Light Duty 2,000 lbs (907 kg)

Class II - Medium Duty 3,500 lbs (1587 kg)

Class III - Heavy Duty 5,000 lbs (2268 kg)

Class IV - Extra Heavy

Duty10,000 lbs (4540 kg)

Fifth Wheel/Gooseneck Greater than 10,000 lbs

(4540 kg)

All trailer hitches should be professionally installed on

your vehicle.

Trailer Towing Weights

(Maximum Trailer Weight Ratings)

NOTE:For additional trailer towing information (maxi-

mum trailer weight ratings) refer to the following website

addresses:

²http:// www.dodge.com/towing.

²http:// www.dodge.ca(Canada).

Trailer and Tongue Weight

Always load a trailer with 60% to 65% of the weight in

the front of the trailer. This places 10% to 15% of the

Gross Trailer Weight (GTW) on the tow hitch of your

vehicle. Loads balanced over the wheels or heavier in the

rear can cause the trailer to swayseverelyside to side

which will cause loss of control of vehicle and trailer.

Failure to load trailers heavier in front is the cause of

many trailer accidents.

296 STARTING AND OPERATING

Page 299 of 426

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transmission in

P for Park. With a manual transmission, shift the

transmission into reverse. And with four-wheel-drive

vehicles, make sure the transfer case is not in neutral.

Always, block or9chock9the trailer wheels.

²GCWR must not be exceeded.

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR2. GTW

3. GAWR

4. Tongue weight rating for the trailer hitch utilized

(This requirement may limit the ability to always

achieve the 10% to 15% range of tongue weight as a

percentage of total trailer weight).

Towing Requirements Ð Tires

þ

Do not attempt to tow a trailer while using a compact

spare tire.

þProper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle. Refer to the

Tires±General Information section of this manual on

Tire Pressures for proper tire inflation procedures.

þAlso, check the trailer tires for proper tire inflation

pressures before trailer usage.

STARTING AND OPERATING 299

5

Page 305 of 426

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.)

Recreational Towing 2WD Models

Recreational towing of 2WD models is not allowable.

Towing the vehicle with the transmission in Neutral can

cause severe transmission damage. Removal of the drive-

shaft for towing is not recommended, since this would

allow fluid to drain from the transmission.

Recreational Towing 4WD Models

CAUTION!

Internal damage to the transfer case will occur if a

front or rear wheel lift is used when recreational

towing.

CAUTION!

The transfer case must be shifted into Neutral (N) for

recreational towing. The Neutral (N) selection button

is located on the lower left hand corner of the 4WD

Control Switch. Shifts into and out of transfer case

Neutral (N) can take place with the selector switch in

any mode position.

Automatic Transmissions must be placed in P (Park)

position for recreational towing.

Manual Transmissions must be placed in gear (for

example, 4th gear) for recreational towing. Failure to

follow these procedures can cause severe transmis-

sion and/or transfer case damage.

Recreational Towing Procedure

Use the following procedure to prepare your vehicle for

recreational towing.

STARTING AND OPERATING 305

5

Page 310 of 426

CAUTION!

²Do not use a bumper mounted clamp-on tow bar

on your vehicle. The bumper face bar will be

damaged.

²Do not disconnect the rear driveshaft because

fluid will leak from the transfer case and damage

internal parts.

EQUIPMENT IDENTIFICATION PLATE

The equipment Identification Plate is located on the hood

inner surface.

The following information about your vehicle is dis-

played on this plate: Model, Wheelbase, Vehicle Identifi-

cation Number, Truck Order Number, and code numbers

with descriptions of all production and special equip-

ment on the truck as shipped from the factory.

NOTE:Always refer to the equipment identification

plate when ordering parts.

310 STARTING AND OPERATING

Page 311 of 426

WHAT TO DO IN EMERGENCIES

CONTENTS

mHazard Warning Flasher..................312

mAdding Fuel..........................312

mChanging A Flat Tire....................313

NJack Location........................313

NRemoving The Spare Tire................315

NTire Changing Procedure................318mJump Starting.........................323

mFreeing A Stuck Vehicle..................325

mEmergency Tow Hooks Ð If Equipped........326

mTowing A Disabled Vehicle................327

NFour-Wheel Drive Vehicles...............327

NTwo-Wheel Drive Vehicles...............327

6

Page 312 of 426

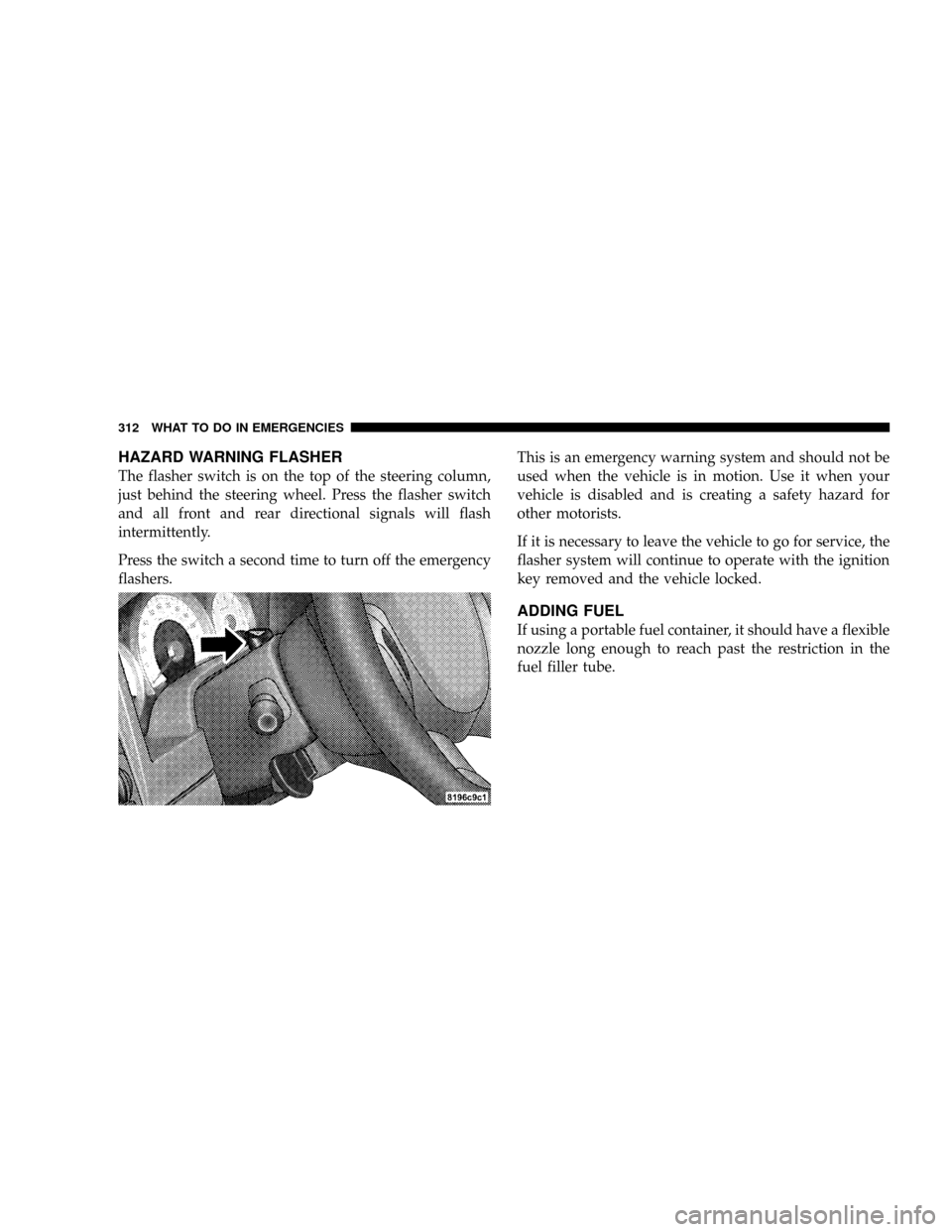

HAZARD WARNING FLASHER

The flasher switch is on the top of the steering column,

just behind the steering wheel. Press the flasher switch

and all front and rear directional signals will flash

intermittently.

Press the switch a second time to turn off the emergency

flashers.This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

ADDING FUEL

If using a portable fuel container, it should have a flexible

nozzle long enough to reach past the restriction in the

fuel filler tube.

312 WHAT TO DO IN EMERGENCIES

Page 315 of 426

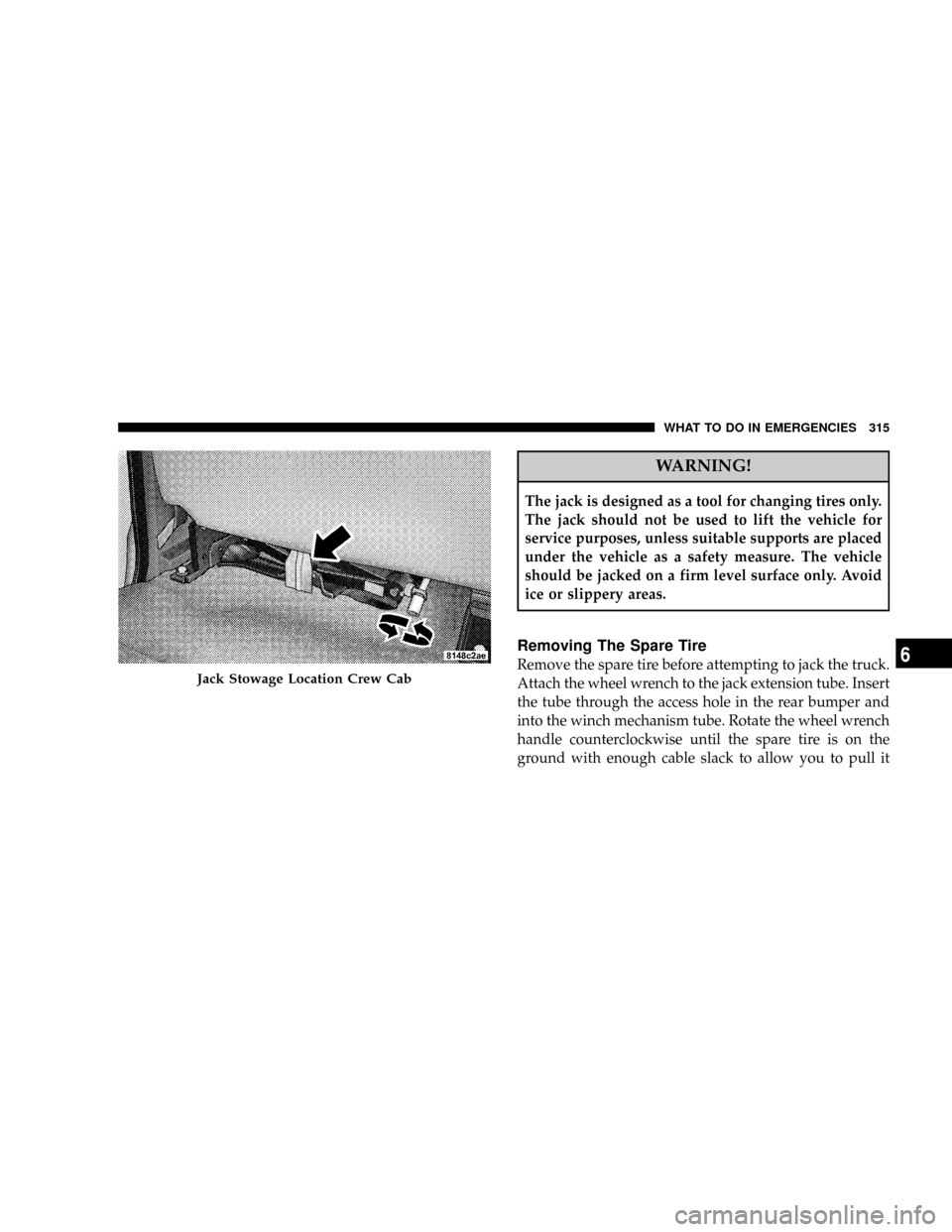

WARNING!

The jack is designed as a tool for changing tires only.

The jack should not be used to lift the vehicle for

service purposes, unless suitable supports are placed

under the vehicle as a safety measure. The vehicle

should be jacked on a firm level surface only. Avoid

ice or slippery areas.

Removing The Spare Tire

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole in the rear bumper and

into the winch mechanism tube. Rotate the wheel wrench

handle counterclockwise until the spare tire is on the

ground with enough cable slack to allow you to pull itJack Stowage Location Crew Cab

WHAT TO DO IN EMERGENCIES 315

6

Page 316 of 426

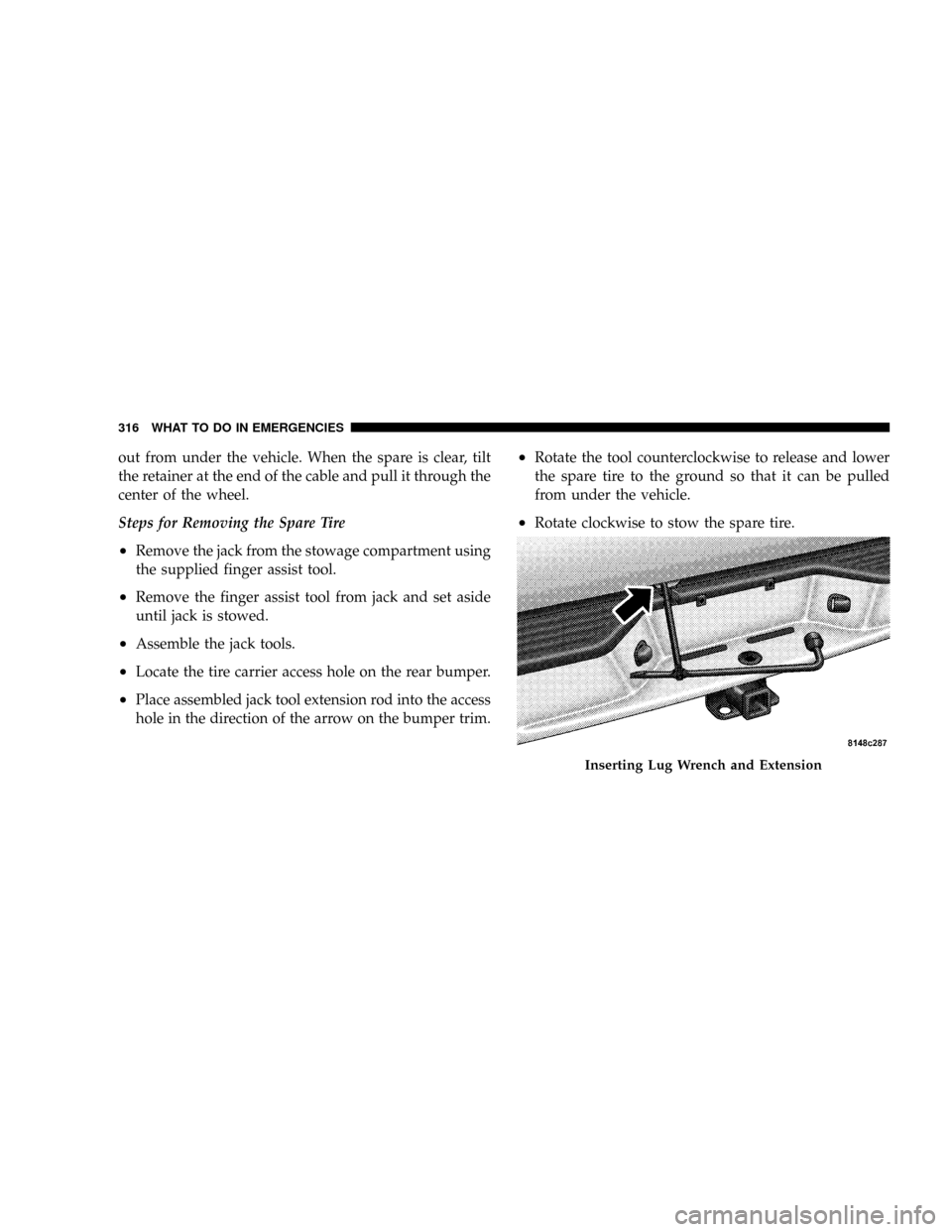

out from under the vehicle. When the spare is clear, tilt

the retainer at the end of the cable and pull it through the

center of the wheel.

Steps for Removing the Spare Tire

²Remove the jack from the stowage compartment using

the supplied finger assist tool.

²Remove the finger assist tool from jack and set aside

until jack is stowed.

²Assemble the jack tools.

²Locate the tire carrier access hole on the rear bumper.

²Place assembled jack tool extension rod into the access

hole in the direction of the arrow on the bumper trim.

²Rotate the tool counterclockwise to release and lower

the spare tire to the ground so that it can be pulled

from under the vehicle.

²Rotate clockwise to stow the spare tire.

Inserting Lug Wrench and Extension

316 WHAT TO DO IN EMERGENCIES

Page 318 of 426

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service center

where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The scissor

jack is designed as a tool for changing tires on this vehicle

only. It is not recommended that the jack be used for

service purposes or to lift more than one wheel at a time.

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the gear

selector in PARK (automatic transmission). On Four

Wheel Drive vehicles, shift the transfer case to the ª4Lº

position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the Hazard Warning Flasher.

318 WHAT TO DO IN EMERGENCIES

Page 319 of 426

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

1. Lower and remove the spare wheel, jack, and tools

from stowage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

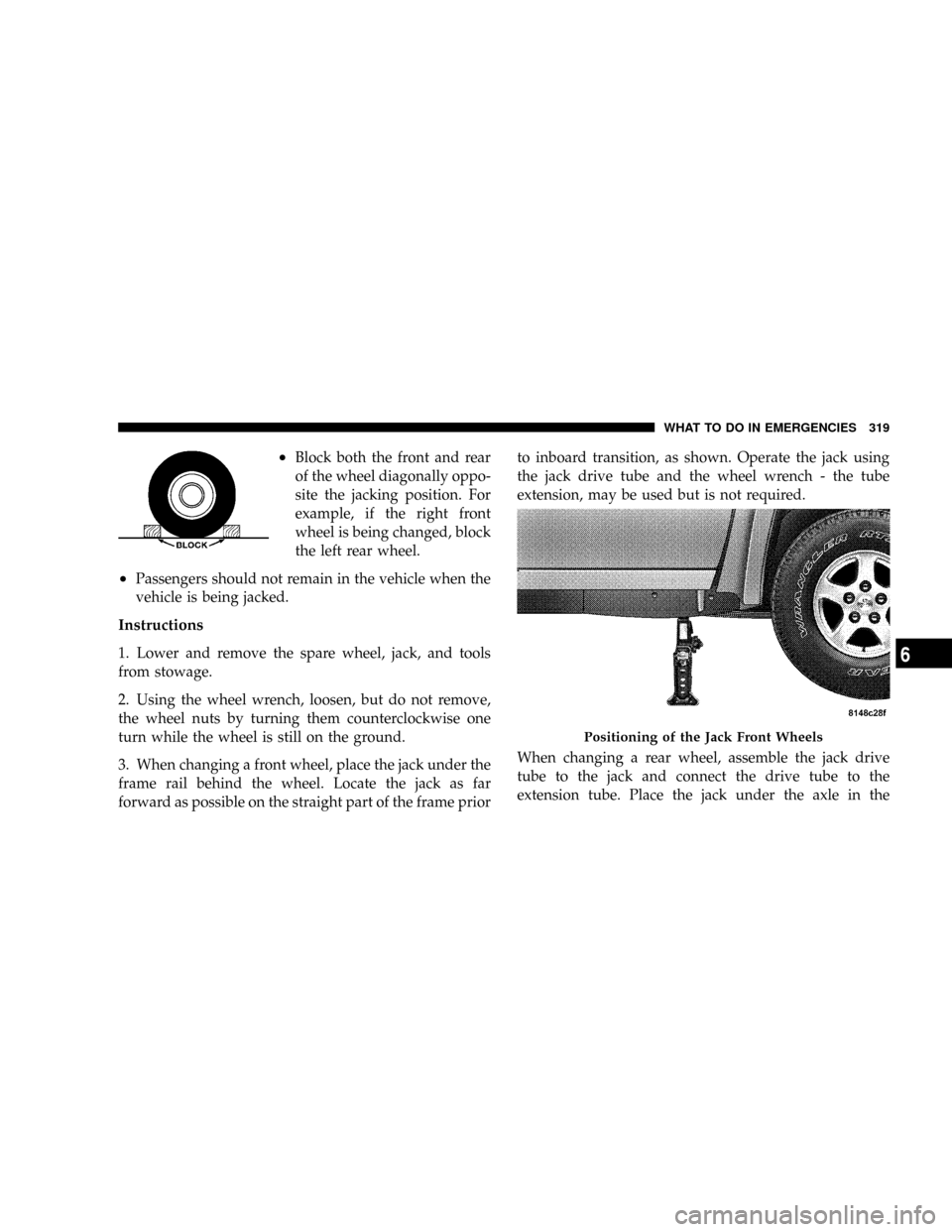

3. When changing a front wheel, place the jack under the

frame rail behind the wheel. Locate the jack as far

forward as possible on the straight part of the frame priorto inboard transition, as shown. Operate the jack using

the jack drive tube and the wheel wrench - the tube

extension, may be used but is not required.

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle in the

Positioning of the Jack Front Wheels

WHAT TO DO IN EMERGENCIES 319

6