wheel DODGE DAKOTA 2008 3.G Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: DAKOTA, Model: DODGE DAKOTA 2008 3.GPages: 426, PDF Size: 6.39 MB

Page 320 of 426

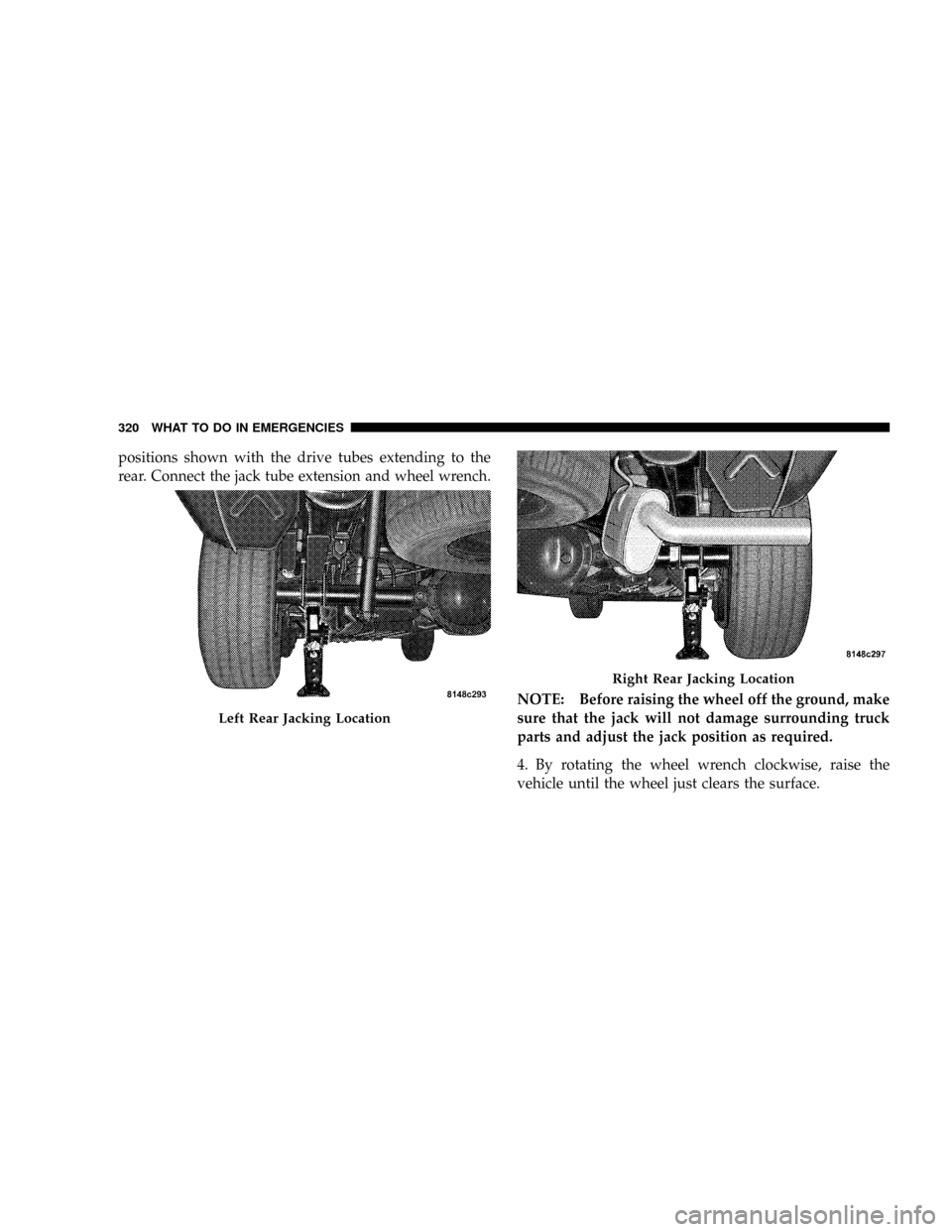

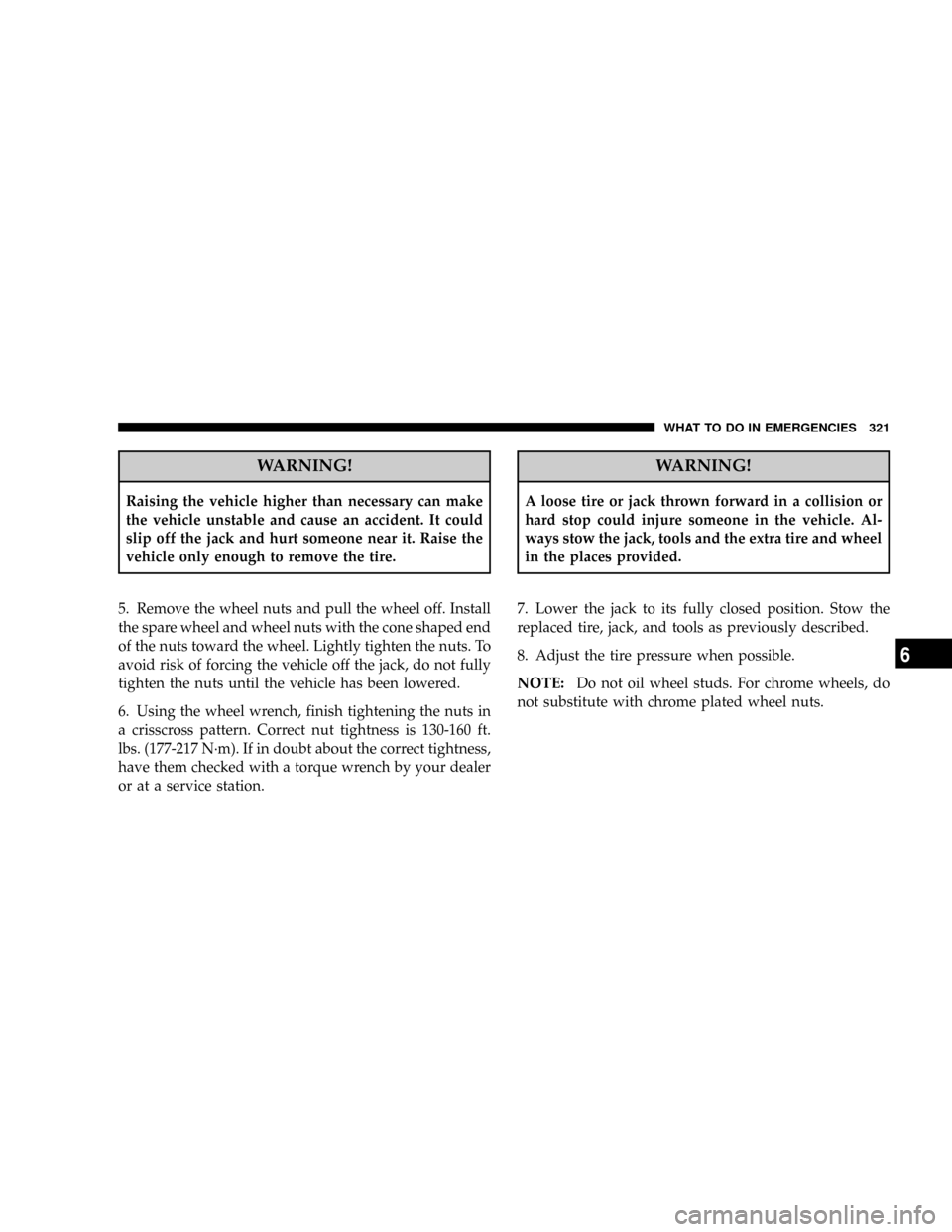

positions shown with the drive tubes extending to the

rear. Connect the jack tube extension and wheel wrench.

NOTE: Before raising the wheel off the ground, make

sure that the jack will not damage surrounding truck

parts and adjust the jack position as required.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

Left Rear Jacking Location

Right Rear Jacking Location

320 WHAT TO DO IN EMERGENCIES

Page 321 of 426

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel. Lightly tighten the nuts. To

avoid risk of forcing the vehicle off the jack, do not fully

tighten the nuts until the vehicle has been lowered.

6. Using the wheel wrench, finish tightening the nuts in

a crisscross pattern. Correct nut tightness is 130-160 ft.

lbs. (177-217 N´m). If in doubt about the correct tightness,

have them checked with a torque wrench by your dealer

or at a service station.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack, tools and the extra tire and wheel

in the places provided.

7. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

8. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

WHAT TO DO IN EMERGENCIES 321

6

Page 322 of 426

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to be

raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely careful of

motor traffic.

²To assure that spare tires, flat or inflated are securely

stowed, spares must be stowed with the value stem

facing the ground.

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Rotate the winch mechanism until the wheel is drawn

into place against the underside of the vehicle. Continue

to rotate until you feel the winch mechanism slip or click

3 times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

To Stow the Flat or Spare: Wheel retainer does not fit

through the center of the aluminum wheel. The tire must

be stored in a safe manner in the bed of the truck.

322 WHAT TO DO IN EMERGENCIES

Page 325 of 426

6. Start the engine in the vehicle which has the booster

battery, let the engine idle a few minutes, then start the

engine in the vehicle with the discharged battery.

7. When removing the jumper cables, reverse the above

sequence exactly. Be careful of the moving belts and fan.

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting out

the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

FREEING A STUCK VEHICLE

If vehicle becomes stuck in snow, sand, or mud, it can

often be moved by a rocking motion. Move the gear

selector rhythmically between FIRST and REVERSE,

while applying slight pressure to the accelerator.

The least amount of accelerator pedal pressure to main-

tain the rocking motion without spinning the wheels or

racing the engine is most effective. Allow the engine to

idle with the transmission selector in NEUTRAL for at

least one minute after every five rocking-motion cycles.

This will minimize overheating and reduce the risk of

transmission failure during prolonged efforts to free a

stuck vehicle.

WHAT TO DO IN EMERGENCIES 325

6

Page 327 of 426

CAUTION!

Tow hooks are for emergency use only, to rescue a

vehicle stranded off road. Do not use tow hooks for

tow truck hookup or highway towing. You could

damage your vehicle.

TOWING A DISABLED VEHICLE

Proper towing or lifting equipment is required to prevent

damage to your vehicle. Use of safety chains is recom-

mended.Attach towing device to main structural mem-

bers of the vehicle Ð not to bumpers or associated

brackets. State and local laws applying to vehicles

under tow must be observed.

Four-Wheel Drive Vehicles

The manufacturer recommends towing with all wheels

OFFthe ground. Acceptable methods are to tow the

vehicle on a flatbed or with one end of the vehicle raised

and the opposite end on a towing dolly.

Two-Wheel Drive Vehicles

Provided that the transmission is operable, tow with the

transmission in Neutral and the ignition key in the OFF

position along with the front wheels raised and the rear

wheels on the ground. The speed must not exceed 30

mph (50 km/h) and the distance must not exceed 15

miles (25 km).

WHAT TO DO IN EMERGENCIES 327

6

Page 328 of 426

If the vehicle is to be towed more than 15 miles (25 km )

or faster than 30 mph, it must be towed on a flatbed, or

with the rear wheels raised and the front wheels on the

ground, or with the front end raised and the rear wheels

on a towing dolly.NOTE:Towing the vehicle, with the rear wheels on the

ground, at more than 30 mph (50 km/h) or for more than

15 miles (25 km ) can cause severe transmission damage.

328 WHAT TO DO IN EMERGENCIES

Page 348 of 426

Front Suspension Ball Joints

The ball joints and seals should be inspected whenever

the vehicle is serviced for other reasons. Damaged seals

should be replaced to prevent leakage or contamination

of the grease.

Drive Shaft Constant Velocity Joints

All four wheel drive models are equipped with four

constant velocity joints. Periodic lubrication of these

joints is not required. However, the joint boot should be

inspected for external leakage or damage periodically. If

external leakage or damage is evident, the joint boot and

grease should be replaced immediately. Continued op-

eration could result in failure of the joint due to water

and dirt contamination of the grease. This would require

complete replacement of the joint assembly. Refer to the

Service Manual for the detailed replacement procedure.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors and hood hinges, should be lubricated

periodically to assure quiet, easy operation and to protect

against rust and wear. Prior to the application of any

lubricant, the parts concerned should be wiped clean to

remove dust and grit; after lubricating excess oil and

grease should be removed. Particular attention should

also be given to hood latching components to insure

proper function. When performing other underhood ser-

vices, the hood latch, release mechanism and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

348 MAINTAINING YOUR VEHICLE

Page 365 of 426

²If a lot of driving is done on gravel roads, consider

mud or stone shields behind each wheel.

²Use Moparttouch up paint on scratches as soon as

possible. Your dealer has touch up paint to match the

color of your vehicle.

Wheel and Wheel Trim Care

All wheels and wheel trim, especially aluminum and

chrome plated wheels should be cleaned regularly with a

mild soap and water to prevent corrosion. To remove

heavy soil, use Mopar Wheel Cleaner or select a nonabra-

sive, non-acidic cleaner. Do not use scouring pads, steel

wool, a bristle brush or metal polishes. Only Mopar

cleaners are recommended. Do not use oven cleaner.

Avoid automatic car washes that use acidic solutions or

harsh brushes that may damage the wheels' protective

finish.

YES EssentialstFabric Cleaning Procedure ± If

Equipped

YES Essentialstseats may be cleaned in the following

manner:

²Remove as much of the stain as possible by blotting

with a clean, dry towel.

²Blot any remaining stain with a clean, damp towel.

²For tough stains, apply Mopar Total Clean or a mild

soap solution to a clean, damp cloth and remove stain.

Use a fresh, damp towel to remove soap residue.

²For grease stains, apply Mopar Multi-purpose cleaner

to a clean, damp cloth and remove stain. Use a fresh,

damp towel to remove soap residue.

²Do not use any solvents or protectants on Yes Essen-

tials products.

MAINTAINING YOUR VEHICLE 365

7

Page 405 of 426

on specified government test surfaces of asphalt and

concrete. A tire marked C may have poor traction perfor-

mance.

WARNING!

The traction grade assigned to this tire is based on

straight-ahead braking traction tests, and does not

include acceleration, cornering, hydroplaning, or

peak traction characteristics.

Temperature Grades

The temperature grades are A (the highest), B, and C,

representing the tire's resistance to the generation of heat

and its ability to dissipate heat when tested under

controlled conditions on a specified indoor laboratory

test wheel. Sustained high temperature can cause thematerial of the tire to degenerate and reduce tire life, and

excessive temperature can lead to sudden tire failure. The

grade C corresponds to a level of performance, which all

passenger car tires must meet under the Federal Motor

Vehicle Safety Standard No. 109. Grades B and A repre-

sent higher levels of performance on the laboratory test

wheel than the minimum required by law.

WARNING!

The temperature grade for this tire is established for

a tire that is properly inflated and not overloaded.

Excessive speed, under inflation, or excessive load-

ing, either separately or in combination, can cause

heat buildup and possible tire failure.

IF YOU NEED CONSUMER ASSISTANCE 405

9

Page 410 of 426

CD (Compact Disc) Player................. 197

Cellular Phone..................79,197,199,209

Center High Mounted Stop Light............ 379

Center Seat Storage Compartment............ 141

Certification Label....................... 288

Changing A Flat Tire..................... 313

Charging.............................. 323

Chart, Tire Sizing........................ 254

Child Restraint......................55,56,57

Child Restraint Tether Anchors.............59,64

Child Seat.............................. 61

Circuit Breakers......................... 367

Cleaning

Wheels............................. 365

Climate Control......................... 209

Clock........................167,172,184,199

Compact Disc (CD) Maintenance............. 207

Compact Spare Tire...................... 265

Compass.............................. 130Compass Calibration..................... 130

Compass Variance....................... 131

Computer, Trip/Travel.................... 126

Console, Floor.......................... 140

Console, Overhead....................... 125

Contract, Service........................ 400

Coolant Pressure Cap (Radiator Cap).......... 353

Cooling System......................... 351

Adding Coolant (Antifreeze).............. 353

Coolant Capacity...................... 384

Coolant Level......................351,354

Disposal of Used Coolant................ 354

Drain, Flush, and Refill.................. 352

Inspection........................... 354

Points to Remember.................... 355

Pressure Cap......................... 353

Radiator Cap......................... 353

Selection of Coolant (Antifreeze)......352,384,385

Temperature Gauge..................... 158

410 INDEX