wheel DODGE DART 2015 PF / 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2015, Model line: DART, Model: DODGE DART 2015 PF / 1.GPages: 164, PDF Size: 25.19 MB

Page 100 of 164

TRAILER TOWING WEIGHTS (MAXIMUM TRAILER WEIGHT RATINGS)

NOTE:

Trailer towing is not recommended for the 1.4L turbo engine.

Engine/TransmissionFrontal Area Max. GTW(Gross Trailer Wt.)Max. Tongue Wt.(See Note)

2.0L and 2.4LAuto/Man22 sq ft(2.04 sq m)1,000 lbs(450 kg)150 lbs(50 kg)

Refer to local laws for maximum trailer towing speeds.

NOTE: The trailer tongue weight must be considered as part of the combined weight ofoccupants and cargo and should never exceed the weight referenced on the Tire and LoadingInformation placard. Refer to “Tire Safety Information” in “Starting and Operating” for furtherinformation.

RECREATIONAL TOWING (BEHIND MOTORHOME, ETC.)

Towing This Vehicle Behind Another Vehicle

Towing ConditionWheels OFF theGroundManualTransmission

1.4L TurboEngine WithAutomaticTransmission(DDCT)

2.0L/2.4LEngine WithAutomaticTransmission

Flat Tow NoneTr a n s m i s s i o n i nNEUTRALTr a n s m i s s i o n i nNEUTRALNOTALLOWED

Dolly Tow

FrontNOT ALLOWED NOT ALLOWEDNOTALLOWED

RearNOT ALLOWED NOT ALLOWEDNOTALLOWED

On TrailerAllOKOKOK

NOTE:When recreationally towing your vehicle, always follow applicable state and provincial laws.Contact state and provincial Highway Safety offices for additional details.

UTILITY

98

Page 101 of 164

NOTE:

Vehicles equipped with a manual transmission or a DDCT transmission (1.4L turbo

engine) may be recreationally towed (flat towed) at any legal highway speed, for any

distance, if the transmission is inNEUTRAL.ForvehicleswithDDCTtransmission(1.4L

turbo automatic), refer to "Shift Lever Override" in "What to Do in Emergencies" for

instructions on shifting the transmission into NEUTRAL when the ignition is OFF. If the

ignition is left in the ACC position, it may be helpful to disconnect the negative battery

cable (and secure it away from the battery post), to avoid draining the battery.

CAUTION!

•DO NOTflat tow any 2.0L or 2.4L engine vehicle equipped with an automatic

transmission. Damage to the drivetrain will result. If these vehicles require towing,

make sure all the wheels are OFF the ground.

•Donotdollytowthisvehicle.Useofatowingdollycancausesignificantdamageto

your vehicle. Damage from improper towing is not covered under the New Vehicle

Limited Warranty.

•Towingthisvehicleinviolationoftheaboverequirementscancausesevere

transmission damage. Damage from improper towing is not covered under the New

Vehicle Limited Warranty.

UTILITY

99

Page 103 of 164

NOTE:

AFTER INFLATION, THE VEHICLE MAY NEED TO BE DRIVEN FOR 20 MINUTES

BEFORE THE FLASHING LIGHT WILL TURN OFF.

Please note that the TPMS is not a substitute for proper tire maintenance, and it is the

driver’s responsibility to maintain correct tire pressure, even if under-inflation has not

reached the level to trigger illumination of the TPMS low tire pressure telltale.

Yo u r v e h i c l e h a s a l s o b e e n e q u i p p e d w i t h a T P M S m a l f u n c t i o n i n d i c a t o r t o i n d i c a t e w h e n

the system is not operating properly. The TPMS malfunction indicator is combined with

the low tire pressure telltale.

When the system detects a malfunction, the telltale will flash for approximately one

minute and then remain continuously illuminated. This sequence will continue upon

subsequent vehicle start-ups as long as the malfunction exists. When the malfunction

indicator is illuminated, the system may not be able to detect or signal low tire pressure

as intended. TPMS malfunctions may occur for a variety of reasons, including the

installation of replacement or alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS malfunction telltale after

replacing one or more tires or wheels on your vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to continue to function properly.

NOTE:

Ti r e p r e s s u r e s c h a n g e b y a p p r o x i m a t e l y 1 p s i ( 7 k P a ) p e r 1 2 ° F ( 7 ° C ) o f a i r t e m p e r a t u r e

change. Keep this in mind when checking tire pressure inside a garage, especially in the

Winter. Example: If garage temperature is 68°F (20°C) and the outside temperature is

32°F (0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style. Aftermarket wheels can

cause sensor damage. Do not use tire sealant from a can, or balance beads if your

vehicle is equipped with a TPMS, as damage to the sensors may result.

WHAT TO DO IN EMERGENCIES

101

Page 110 of 164

JACKING AND TIRE CHANGING — IF EQUIPPED

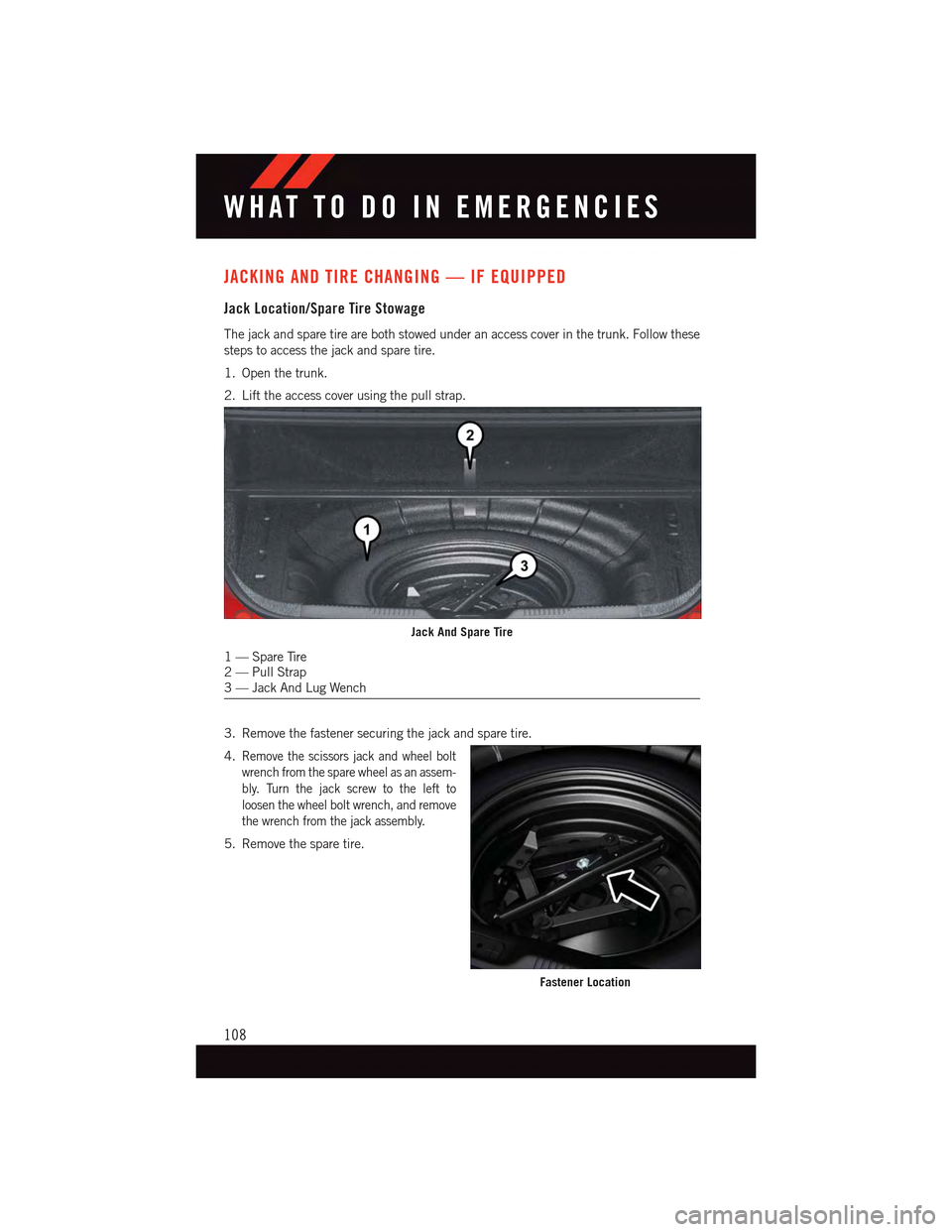

Jack Location/Spare Tire Stowage

The jack and spare tire are both stowed under an access cover in the trunk. Follow these

steps to access the jack and spare tire.

1. Open the trunk.

2. Lift the access cover using the pull strap.

3. Remove the fastener securing the jack and spare tire.

4.Remove the scissors jack and wheel bolt

wrench from the spare wheel as an assem-

bly. Turn the jack screw to the left to

loosen the wheel bolt wrench, and remove

the wrench from the jack assembly.

5. Remove the spare tire.

Jack And Spare Tire

1—SpareTire2—PullStrap3—JackAndLugWench

Fastener Location

WHAT TO DO IN EMERGENCIES

108

Page 111 of 164

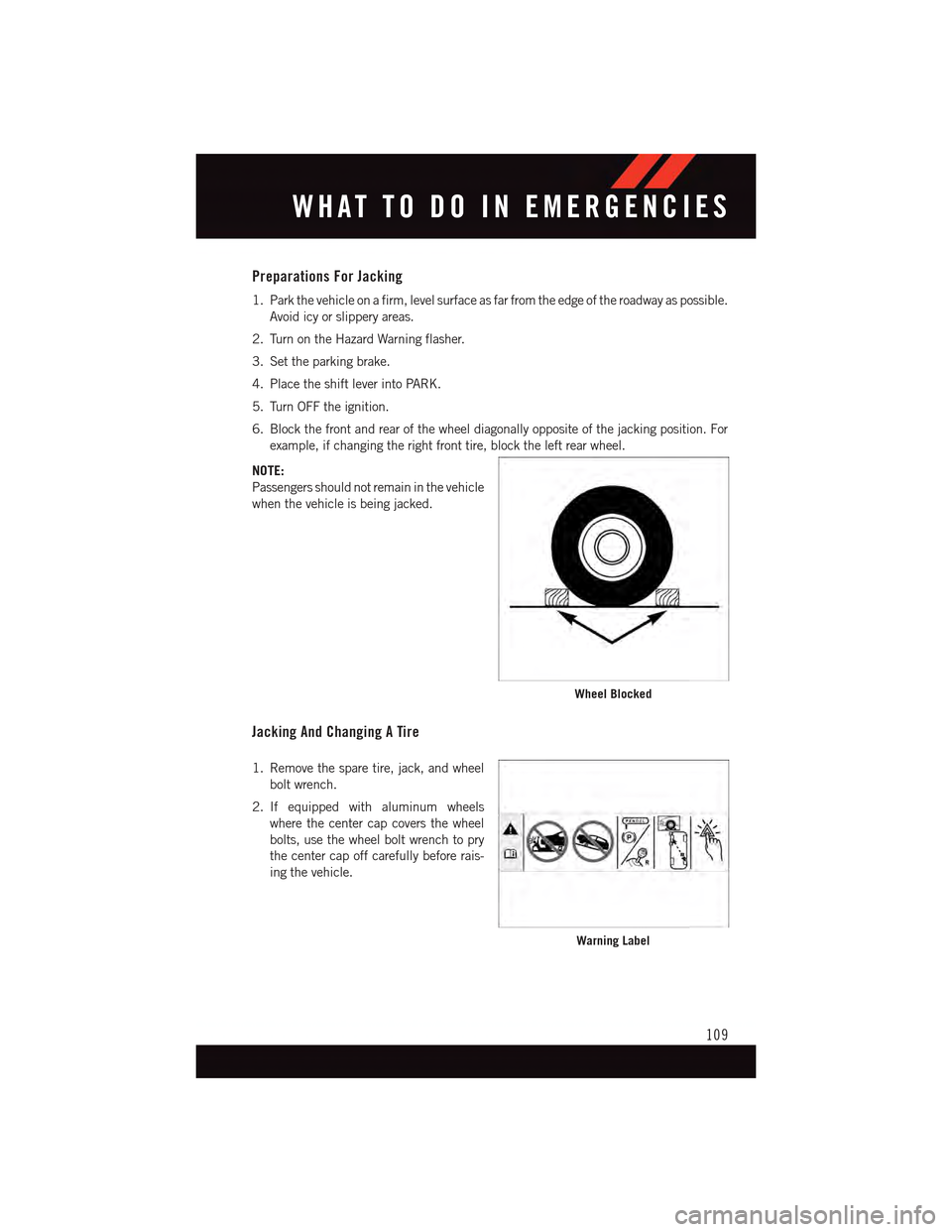

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as possible.

Avoid icy or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

6. Block the front and rear of the wheel diagonally opposite of the jacking position. For

example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Jacking And Changing A Tire

1. Remove the spare tire, jack, and wheel

bolt wrench.

2. If equipped with aluminum wheels

where the center cap covers the wheel

bolts, use the wheel bolt wrench to pry

the center cap off carefully before rais-

ing the vehicle.

Wheel Blocked

Warning Label

WHAT TO DO IN EMERGENCIES

109

Page 112 of 164

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove, the

wheel bolts on the wheel with the flat tire. Turn the wheel bolts counterclockwise one

turn while the wheel is still on the ground.

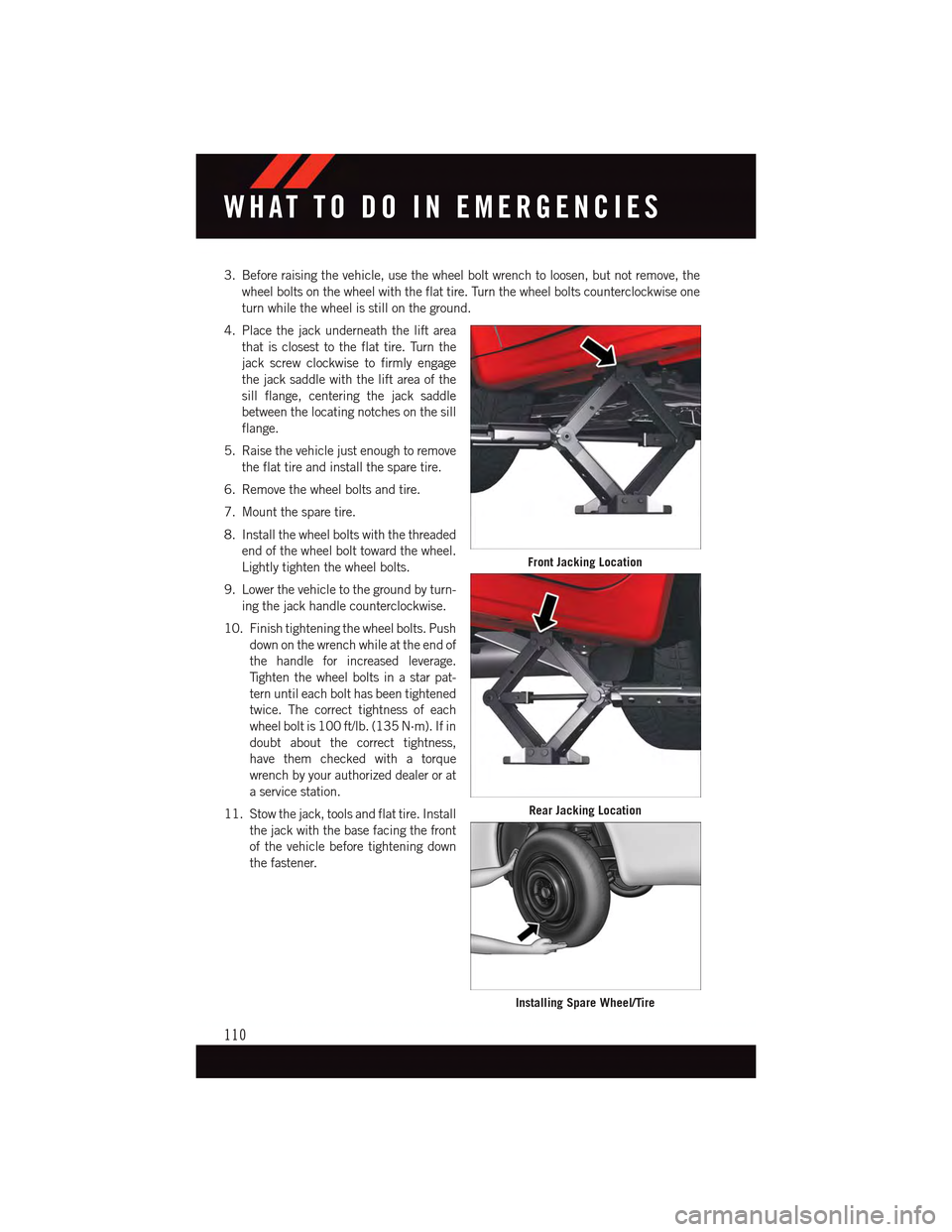

4. Place the jack underneath the lift area

that is closest to the flat tire. Turn the

jack screw clockwise to firmly engage

the jack saddle with the lift area of the

sill flange, centering the jack saddle

between the locating notches on the sill

flange.

5. Raise the vehicle just enough to remove

the flat tire and install the spare tire.

6. Remove the wheel bolts and tire.

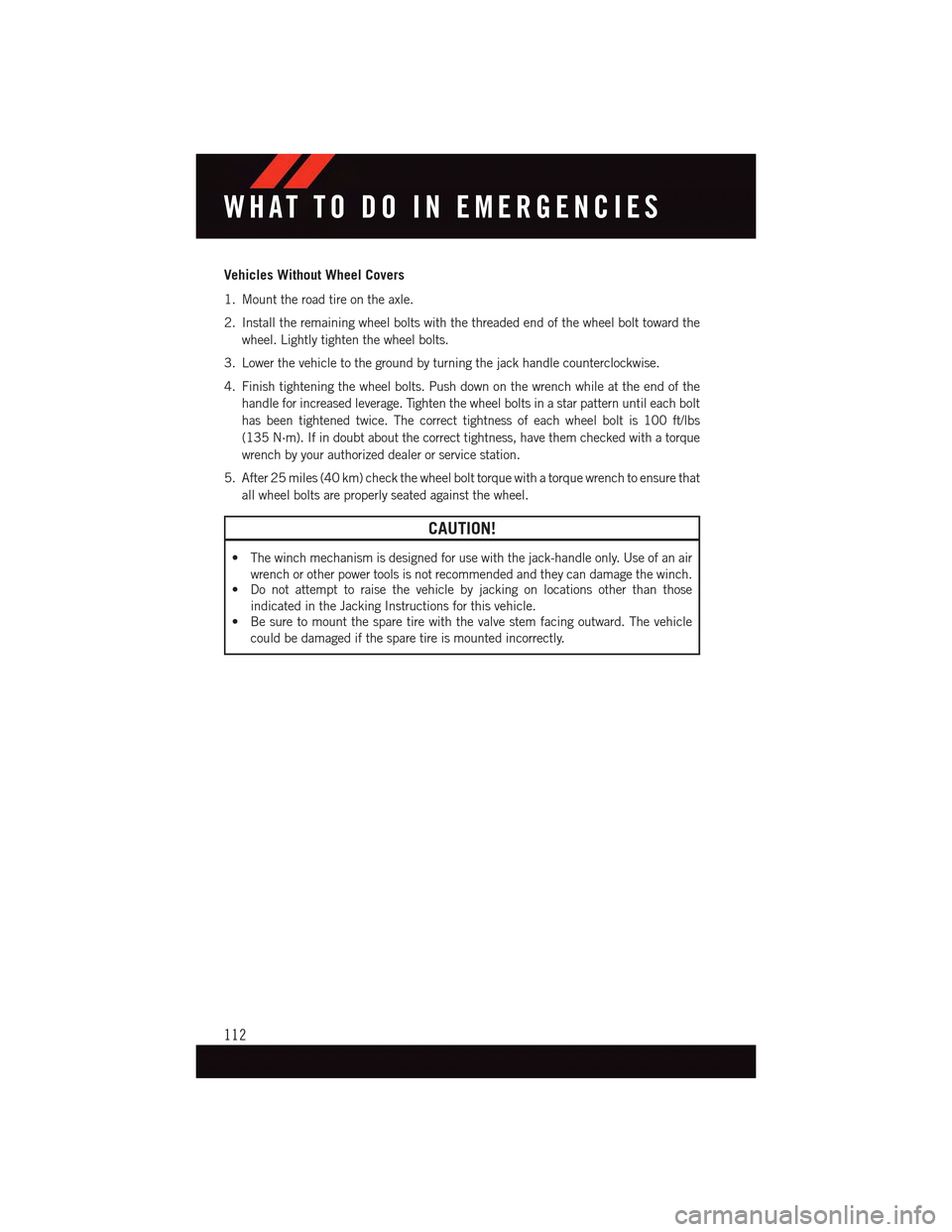

7. Mount the spare tire.

8. Install the wheel bolts with the threaded

end of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

9. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e w h e e l b o l t s i n a s t a r p a t -

tern until each bolt has been tightened

twice. The correct tightness of each

wheel bolt is 100 ft/lb. (135 N·m). If in

doubt about the correct tightness,

have them checked with a torque

wrench by your authorized dealer or at

aservicestation.

11. Stow the jack, tools and flat tire. Install

the jack with the base facing the front

of the vehicle before tightening down

the fastener.

Front Jacking Location

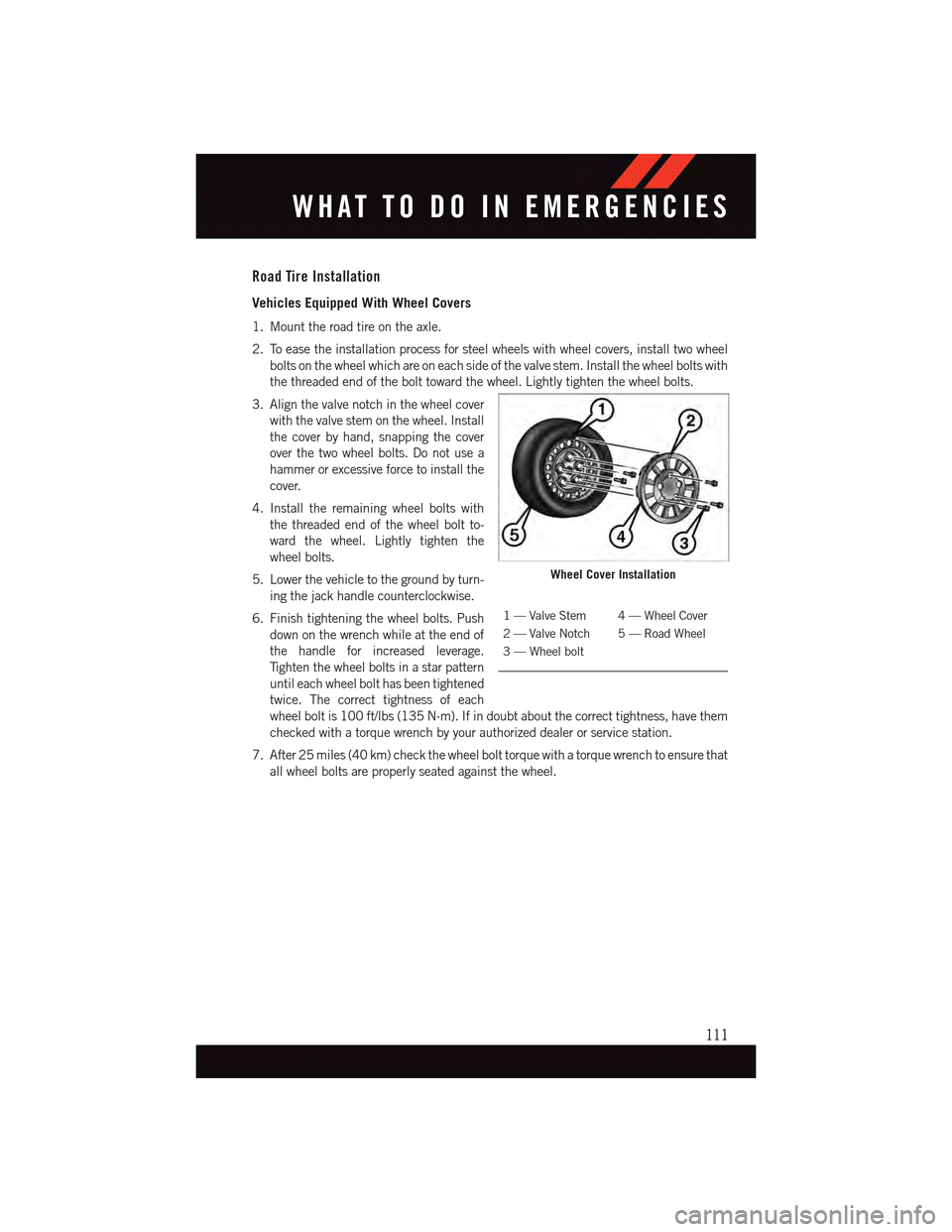

Rear Jacking Location

Installing Spare Wheel/Tire

WHAT TO DO IN EMERGENCIES

110

Page 113 of 164

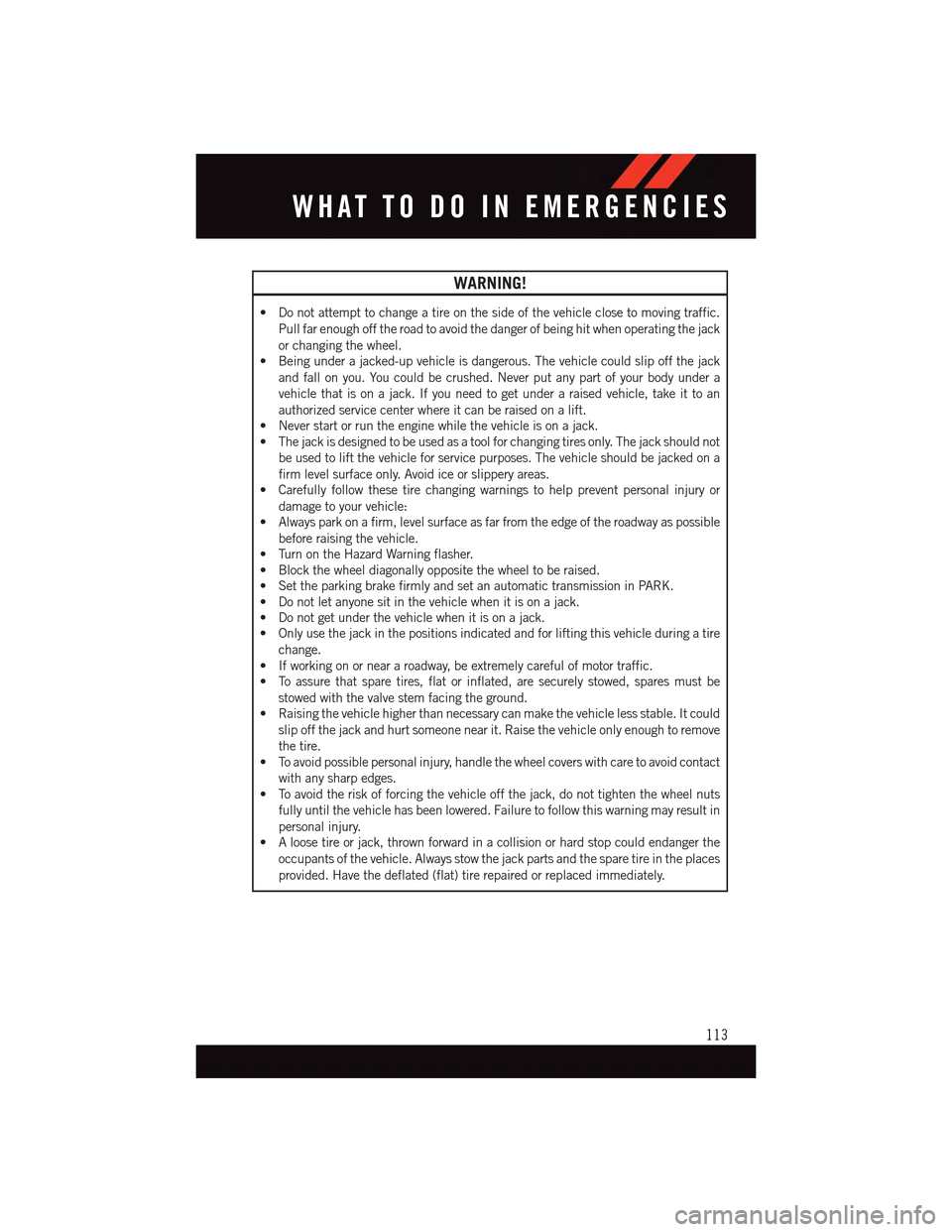

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two wheel

bolts on the wheel which are on each side of the valve stem. Install the wheel bolts with

the threaded end of the bolt toward the wheel. Lightly tighten the wheel bolts.

3. Align the valve notch in the wheel cover

with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two wheel bolts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining wheel bolts with

the threaded end of the wheel bolt to-

ward the wheel. Lightly tighten the

wheel bolts.

5. Lower the vehicle to the ground by turn-

ing the jack handle counterclockwise.

6. Finish tightening the wheel bolts. Push

down on the wrench while at the end of

the handle for increased leverage.

Ti g h t e n t h e w h e e l b o l t s i n a s t a r p a t t e r n

until each wheel bolt has been tightened

twice. The correct tightness of each

wheel bolt is 100 ft/lbs (135 N·m). If in doubt about the correct tightness, have them

checked with a torque wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that

all wheel bolts are properly seated against the wheel.

Wheel Cover Installation

1—ValveStem 4—WheelCover

2—ValveNotch 5—RoadWheel

3—Wheelbolt

WHAT TO DO IN EMERGENCIES

111

Page 114 of 164

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the

handle for increased leverage. Tighten the wheel bolts in a star pattern until each bolt

has been tightened twice. The correct tightness of each wheel bolt is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

5. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that

all wheel bolts are properly seated against the wheel.

CAUTION!

•Thewinchmechanismisdesignedforusewiththejack-handleonly.Useofanair

wrench or other power tools is not recommended and they can damage the winch.•Donotattempttoraisethevehiclebyjackingonlocationsotherthanthose

indicated in the Jacking Instructions for this vehicle.

•Besuretomountthesparetirewiththevalvestemfacingoutward.Thevehicle

could be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

112

Page 115 of 164

WARNING!

•Donotattempttochangeatireonthesideofthevehicleclosetomovingtraffic.

Pull far enough off the road to avoid the danger of being hit when operating the jack

or changing the wheel.

•Beingunderajacked-upvehicleisdangerous.Thevehiclecouldslipoffthejack

and fall on you. You could be crushed. Never put any part of your body under a

vehicle that is on a jack. If you need to get under a raised vehicle, take it to an

authorized service center where it can be raised on a lift.

•Neverstartorruntheenginewhilethevehicleisonajack.

•Thejackisdesignedtobeusedasatoolforchangingtiresonly.Thejackshouldnot

be used to lift the vehicle for service purposes. The vehicle should be jacked on a

firm level surface only. Avoid ice or slippery areas.

•Carefullyfollowthesetirechangingwarningstohelppreventpersonalinjuryor

damage to your vehicle:

•Alwaysparkonafirm,levelsurfaceasfarfromtheedgeoftheroadwayaspossible

before raising the vehicle.

•TurnontheHazardWarningflasher.

•Blockthewheeldiagonallyoppositethewheeltoberaised.

•SettheparkingbrakefirmlyandsetanautomatictransmissioninPARK.

•Donotletanyonesitinthevehiclewhenitisonajack.

•Donotgetunderthevehiclewhenitisonajack.

•Onlyusethejackinthepositionsindicatedandforliftingthisvehicleduringatire

change.

•Ifworkingonorneararoadway,beextremelycarefulofmotortraffic.

•Toassurethatsparetires,flatorinflated,aresecurelystowed,sparesmustbe

stowed with the valve stem facing the ground.

•Raisingthevehiclehigherthannecessarycanmakethevehiclelessstable.Itcould

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

•Toavoidpossiblepersonalinjury,handlethewheelcoverswithcaretoavoidcontact

with any sharp edges.

•Toavoidtheriskofforcingthevehicleoffthejack,donottightenthewheelnuts

fully until the vehicle has been lowered. Failure to follow this warning may result in

personal injury.

•Aloosetireorjack,thrownforwardinacollisionorhardstopcouldendangerthe

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES

113

Page 117 of 164

Tire Service Kit Usage Precautions

•ReplacetheTireServiceKitSealantBottle(1)andSealantHose(6)priortothe

expiration date (printed on the bottle label) to assure optimum operation of the system.

Refer to “Sealing A Tire With Tire Service Kit” section (F) “Sealant Bottle and Hose

Replacement.”

•TheSealantBottle(1)andSealantHose(6)areaonetireapplicationuse.Aftereach

use, always replace these components immediately at an authorized dealer.

•WhentheTireServiceKitsealantisinaliquidform,cleanwater,andadampclothwill

remove the material from the vehicle or tire and wheel components. Once the sealant

dries, it can easily be peeled off and properly discarded.

•Foroptimumperformance,makesurethevalvestemonthewheelisfreeofdebris

before connecting the Tire Service Kit.

•Yo u c a n u s e t h e Ti r e S e r v i c e K i t a i r p u m p t o i n f l a t e b i c y c l e t i r e s . T h e k i t a l s o c o m e s w i t h t w oneedles, located in the Accessory Storage Compartment (on the bottom of the air pump) forinflating sport balls, rafts, or similar inflatable items. However, use only the Air Pump Hose(7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such itemsto avoid injecting sealant into them. The Tire Service Kit Sealant is only intended to sealpunctures less than 1/4 inch (6 mm) diameter in the tread of your vehicle.

•DonotliftorcarrytheTireServiceKitbythehoses.

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service Kit Hoses (6) and (7) to reach the valve stem

and keep the Tire Service Kit flat on the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the

hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

115