Group 8d DODGE DURANGO 1998 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 7 of 193

Downloaded from www.Manualslib.com manuals search engine OIL PAN

DESCRIPTION

The engine oil pan is made of laminated steel and

has a single plane sealing surface. The sandwich

style oil pan gasket has an integrated windage tray

and steel carrier. The sealing area of the gasket is

molded with rubber and is designed to be reused as

long as the gasket is not cut, torn or ripped.

STRUCTURAL DUST COVER

DESCRIPTION

The structural dust cover is made of die cast alu-

minum and joins the lower half of the transmission

bell housing to the engine bedplate.

OPERATION

The structural cover provides additional power-

train stiffness and reduces noise and vibration.

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is made of a composite mate-

rial and features long runners which maximizes low

end torque. The intake manifold uses single plane

sealing which consist of eight individual press in

place port gaskets to prevent leaks. Eight studs and

two bolts are used to fasten the intake to the head.

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are log style with a pat-

ented flow enhancing design to maximize perfor-mance. The exhaust manifolds are made of high

silicon molybdenum cast iron. A perforated core

graphite exhaust manifold gasket is used to improve

sealing to the cylinder head. The exhaust manifolds

are covered by a three layer laminated heat shield

for thermal protection and noise reduction. The heat

shields are fastened with a torque prevailing nut

that is backed off slightly to allow for the thermal

expansion of the exhaust manifold.

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐINTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either per-

formance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

Refer to the Service DiagnosisÐPerformance chart

and the Service DiagnosisÐMechanical chart for pos-

sible causes and corrections of malfunctions. Refer to

Group 14, Fuel System for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following diagnosis:

²Cylinder Compression Pressure Test.

²Cylinder Combustion Pressure Leakage Test.

²Engine Cylinder Head Gasket Failure Diagnosis.

²Intake Manifold Leakage Diagnosis.

DN4.7L ENGINE 9 - 7

DESCRIPTION AND OPERATION (Continued)

Page 8 of 193

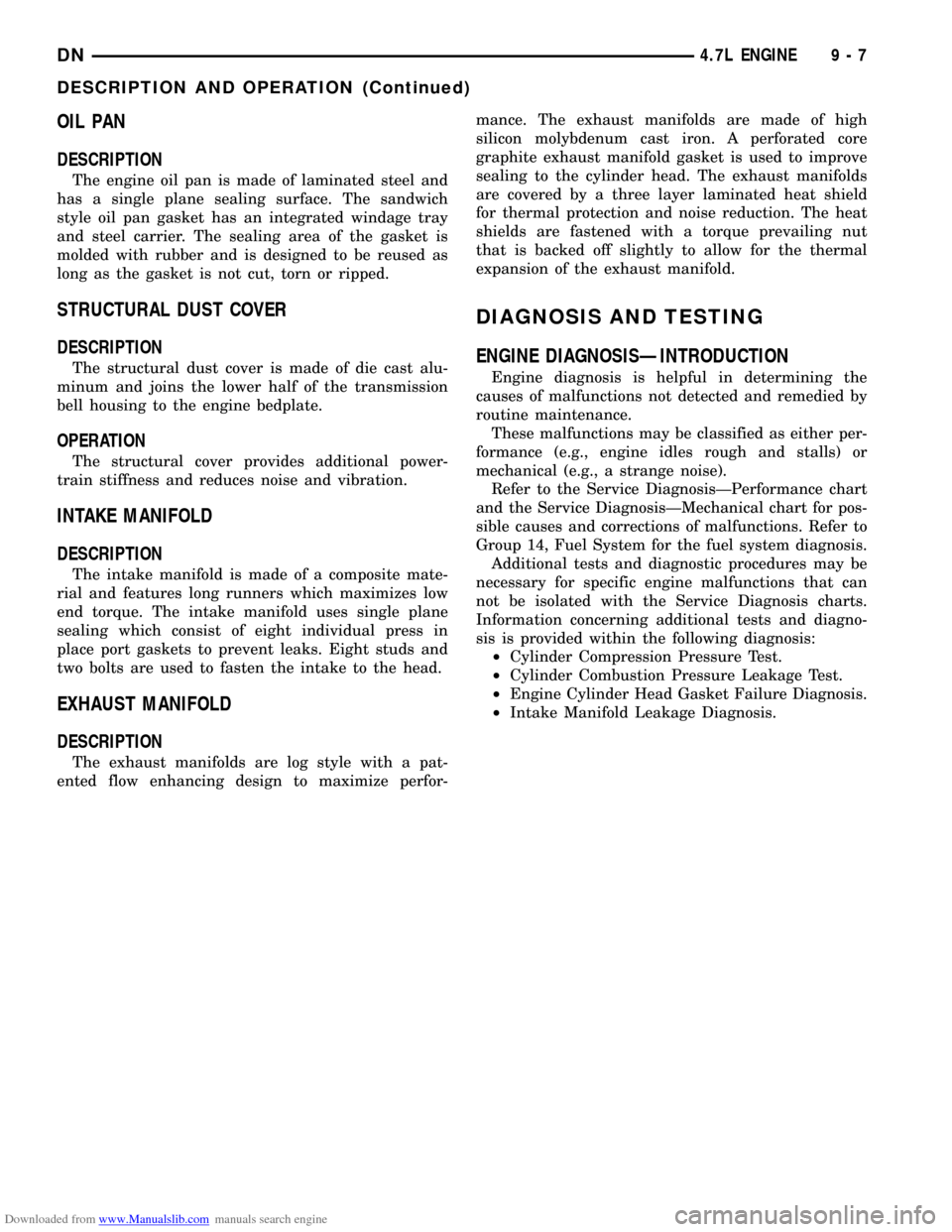

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. Refer to Group 8A, Battery/

Starter/ Charging System

Diagnostics.

4. Moisture on ignition wires and

distributor cap.4. Wipe wires and cap clean and

dry.

5. Faulty ignition cables. 5. Replace as necessary.

6. Faulty coil or control unit. 6. Refer to Group 8D, Ignition

System.

7. Incorrect spark plug gap. 7. Refer to Group 8D, Ignition

System.

8. Incorrect ignition timing. 8. Refer to Group 8D, Ignition

System.

9. Dirt or water in fuel system. 9. Clean system and replace fuel

filter.

10. Faulty fuel pump, relay or

wiring.10. Refer to Group 14, Fuel System.

ENGINE STALLS OR ROUGH IDLE 1. Idle speed set to low. 1. Refer to Group 14, Fuel System.

2. Idle mixture to lean or to rich. 2. Refer to Group 14, Fuel System.

3. Vacuum leak. 3. Inspect intake manifold and

vacuum hoses, repair or replace as

necessary.

4. Worn or burned distributor rotor. 4. Replace distributor rotor.

5. Incorrect ignition wiring. 5. Install correct wiring.

6. Faulty coil. 6. Refer to Group 8D, Ignition

System.

7. EGR valve leaking. 7. Refer to Group 25, Emissions

Control System.

8. Incorrect cam timing. 8. Refer to Valve Timing in this

section.

9 - 8 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 9 of 193

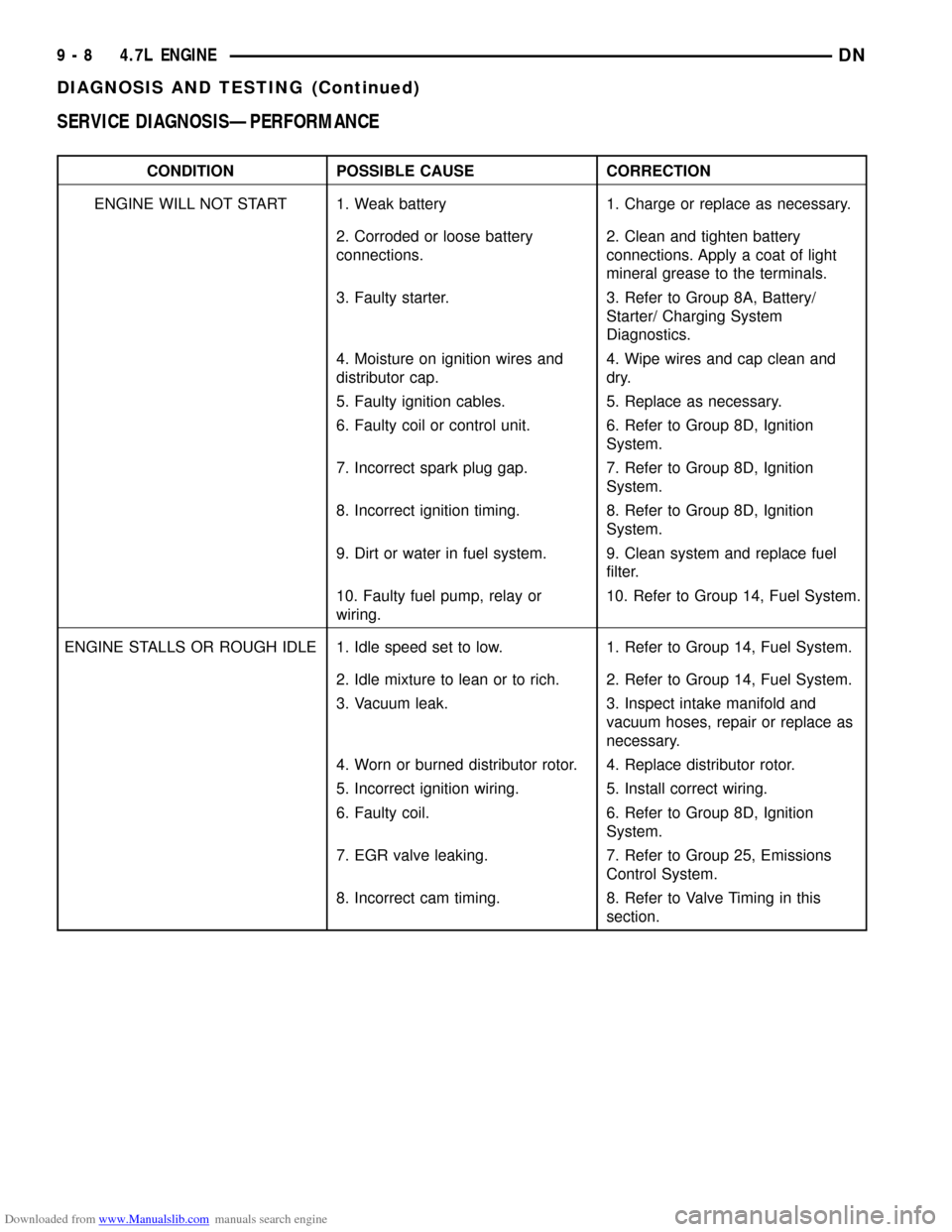

Downloaded from www.Manualslib.com manuals search engine CONDITION POSSIBLE CAUSE CORRECTION

ENGINE LOSS OF POWER 1. Incorrect ignition timing. 1. Refer to Group 8D, Ignition

System.

2. Worn or burned distributor rotor. 2. Replace distributor rotor.

3. Worn distributor shaft. 3. Refer to Group 8D, Ignition

System.

4. Dirty or incorrectly gapped spark

plugs.4. Refer to Group 8D, Ignition

System.

5. Dirt or water in fuel system. 5. Clean system and replace fuel

filter.

6. Faulty fuel pump. 6. Refer to Group 14, Fuel System.

7. Blown cylinder head gasket. 7. Replace cylinder head gasket.

8. Low compression. 8. Test compression, repair as

necessary.

9. Burned, warped or pitted valves. 9. Replace as necessary.

10. Plugged or restricted exhaust

system.10. Inspect and replace as

necessary.

11. Faulty ignition cables. 11. Replace as necessary.

12. Faulty coil. 12. Refer to Group 8D, Ignition

System.

13. Incorrect cam timing. 13. Refer to Valve Timing in this

section.

ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. Refer to Group 8D, Ignition

System.

2. Incorrect ignition timing. 2. Refer to Group 8D, Ignition

System.

3. Dirt in fuel system. 3. Clean fuel system.

4. Burned, warped or pitted valves. 4. Replcae as necessary.

5. Faulty coil. 5. Refer to Group 8D, Ignition

System.

6. Incorrect cam timing. 6. Refer to Valve Timing in this

section.

ENGINE MISSES AT HIGH SPEED 1. Spark plugs dirty or incorrectly

gapped.1. Refer to Group 8D, Ignition

System.

2. Worn Distributor Shaft. 2. Refer to Group 8D, Ignition

System.

3. Worn or burned distributor rotor. 3. Replace distributor rotor.

4. Faulty coil. 4. Refer to Group 8D, Ignition

System.

5. Incorrect ignition timing. 5. Refer to Group 8D, Ignition

System.

6. Dirt or water in fuel system. 6. Clean system and replace fuel

filter.

7. Incorrect cam timing. 7. Refer to Valve Timing in this

section.

DN4.7L ENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 10 of 193

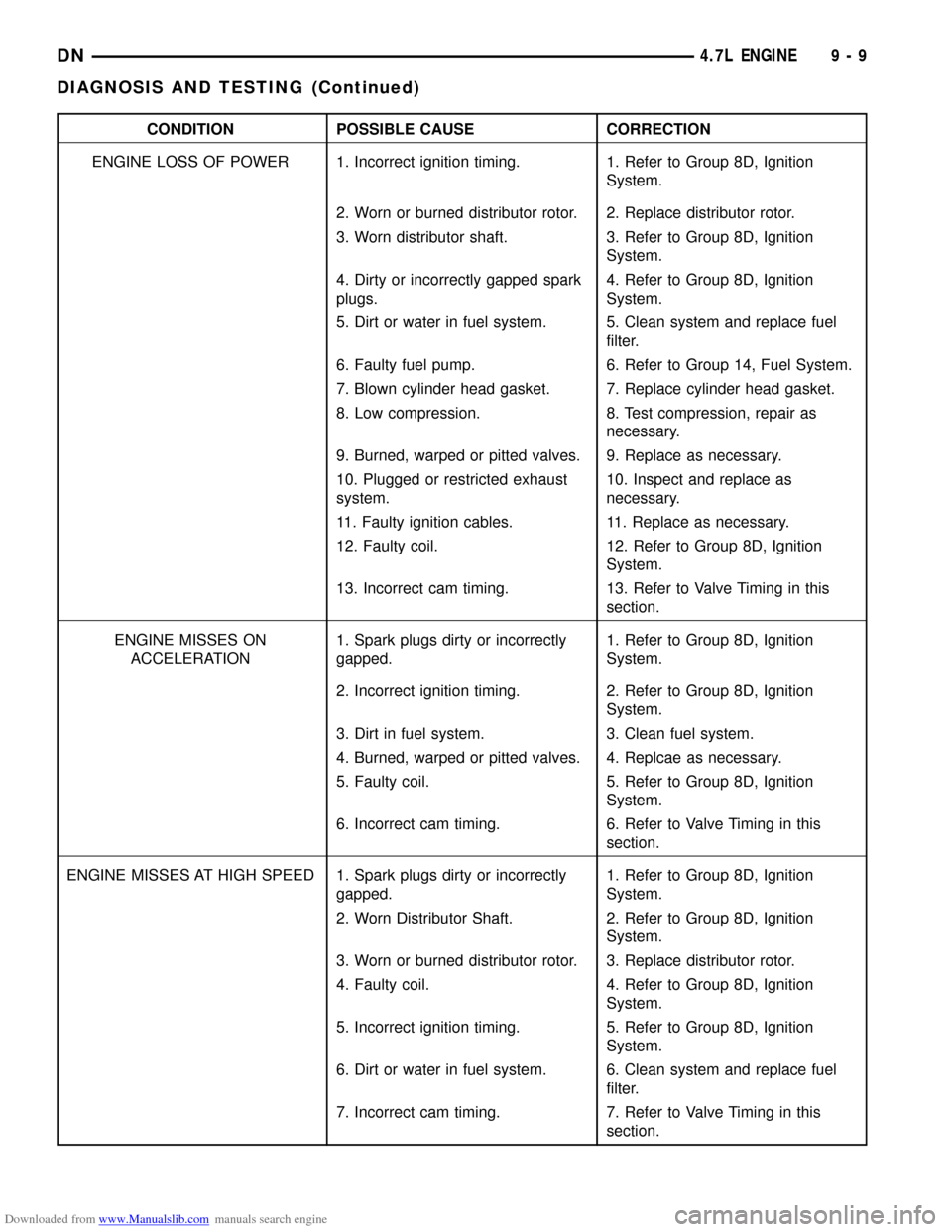

Downloaded from www.Manualslib.com manuals search engine SERVICE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in

crankcase.1. Refer to Group 0, Lubrication and

Maintenance.

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive

wear.

4. Dirt in lash adjusters. 4. Clean lash adjusters.

5. Bent push rods. 5. Replace as necessary.

6. Worn rocker arms. 6. Replace as necessary.

7. Worn tappets 7. Replace as necessary.

8. Worn valve guides. 8. Refer to Valve Service in this

section.

9. Excessive runout of valve seats

on valve faces.9. Service valves and valve seats.

Refer to Valve Service in this

section.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

maintenance.

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

maintenance.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal

out-of-round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Refer to Group 0, Lubrication and

maintenance.

2. Low oil pressure. 2. Refer to Group 0, Lubrication and

maintenance.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Excessive end play. 5. Check No. 3 main bearing for

wear on flanges.

6. Crankshaft journal out-of round. 6. Service or replace crankshaft.

7. Loose flywheel or torque

converter.7. Tighten to correct torque

9 - 10 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 12 of 193

Downloaded from www.Manualslib.com manuals search engine Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Secure the throttle in the wide-open position.

(4) Disable the fuel system. (Refer to Group 14,

Fuel System for the correct procedure)

(5) Disconnect the ignition coil.

(6) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(7) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylin-

ders.

Refer to Engine Specifications for the correct

engine compression pressures.

CYLINDER HEAD GASKET FAILURE DIAGNOSIS

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

²Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

²Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

CYLINDER-TO-CYLINDER LEAKAGE TEST

To determine if an engine cylinder head gasket is

leaking between adjacent cylinders, follow the proce-

dures in Cylinder Compression Pressure Test in this

section. An engine cylinder head gasket leaking

between adjacent cylinders will result in approxi-

mately a 50±70% reduction in compression pressure.

CYLINDER-TO-WATER JACKET LEAKAGE TEST

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING WITH COOLANT PRES-

SURE CAP REMOVED.

VISUAL TEST METHOD

With the engine cool, remove the coolant pressure

cap. Start the engine and allow it to warm up until

thermostat opens.

If a large combustion/compression pressure leak

exists, bubbles will be visible in the coolant.COOLING SYSTEM TESTER METHOD

WARNING: WITH COOLING SYSTEM TESTER IN

PLACE, PRESSURE WILL BUILD UP FAST. EXCES-

SIVE PRESSURE BUILT UP, BY CONTINUOUS

ENGINE OPERATION, MUST BE RELEASED TO A

SAFE PRESSURE POINT. NEVER PERMIT PRES-

SURE TO EXCEED 138 kPa (20 psi).

Install Cooling System Tester 7700 or equivalent to

pressure cap neck. Start the engine and observe the

tester's pressure gauge. If gauge pulsates with every

power stroke of a cylinder a combustion pressure

leak is evident.

CHEMICAL TEST METHOD

Combustion leaks into the cooling system can also

be checked by using Bloc-Chek Kit C-3685-A or

equivalent. Perform test following the procedures

supplied with the tool kit.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner.

(6)

Calibrate the tester according to the manufacturer's

instructions. The shop air source for testing should main-

tain 483 kPa (70 psi) minimum, 1,379 kPa (200 psi) maxi-

mum and 552 kPa (80 psi) recommended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to the Cylinder Combustion Pressure Leak-

age Test Diagnosis chart.

9 - 12 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 14 of 193

Downloaded from www.Manualslib.com manuals search engine filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

REAR SEAL AREA LEAKSÐINSPECTION

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces. See Group 9, Engines, for

proper repair procedures of these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible thecrankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, Refer to Group

9, EnginesÐCrankshaft Rear Oil Seals, for proper

replacement procedures.

HYDRAULIC LASH ADJUSTER NOISE

DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) Turn engine off and let set for a few minutes

before restarting. Repeat this several times after

engine has reached normal operating temperature.

(4) Low oil pressure.

(5) The oil restrictor in cylinder head gasket or the

oil passage to the cylinder head is plugged with

debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head and cam on camshaft at

base circle. Depress part of rocker arm over adjuster.

Normal adjusters should feel very firm. Spongy

adjusters can be bottomed out easily.

b. Remove suspected lash adjusters, and replace.

c. Before installation, make sure adjusters are at

least partially full of oil. This can be verified by little

or no plunger travel when lash adjuster is depressed.

9 - 14 4.7L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 18 of 193

Downloaded from www.Manualslib.com manuals search engine Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

CYLINDER BOREÐHONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

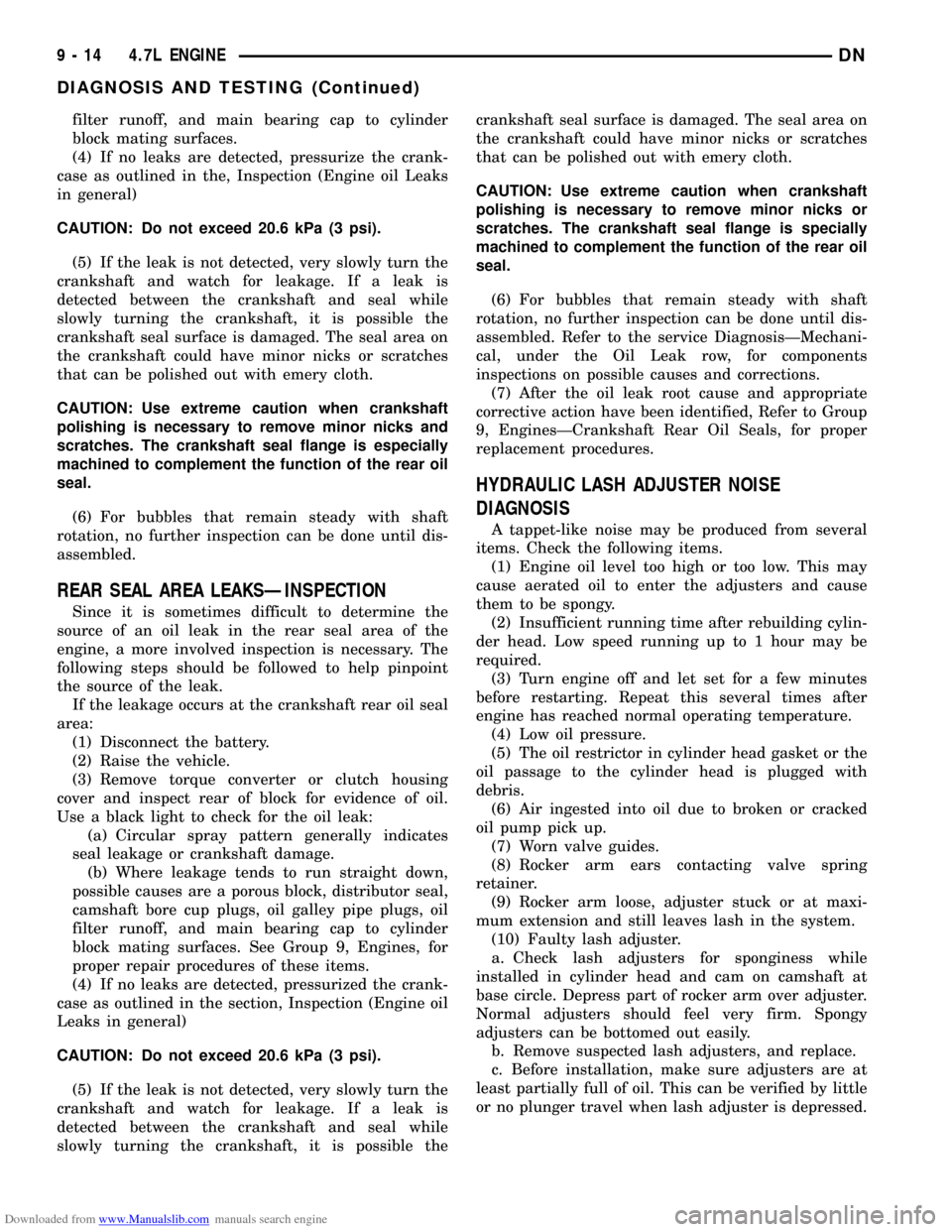

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 9).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the battery negative cable.

(3) Inspect air cleaner, induction system and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the

engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

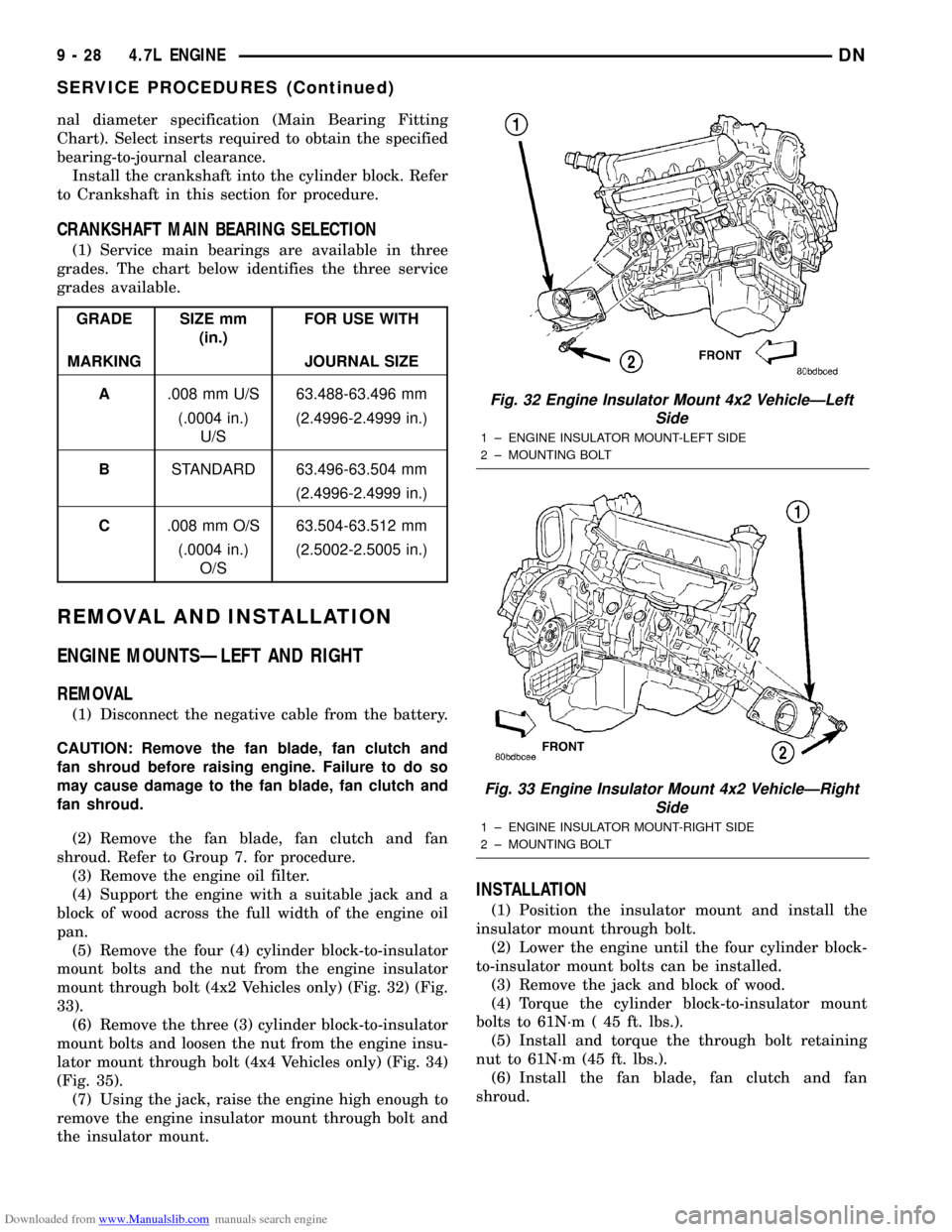

Fig. 8 Oil Filter Sealing SurfaceÐTypical

1 ± SEALING SURFACE

2 ± RUBBER GASKET

3 ± OIL FILTER

Fig. 9 Cylinder Bore Crosshatch Pattern

1 ± CROSSHATCH PATTERN

2 ± INTERSECT ANGLE

9 - 18 4.7L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 28 of 193

Downloaded from www.Manualslib.com manuals search engine nal diameter specification (Main Bearing Fitting

Chart). Select inserts required to obtain the specified

bearing-to-journal clearance.

Install the crankshaft into the cylinder block. Refer

to Crankshaft in this section for procedure.

CRANKSHAFT MAIN BEARING SELECTION

(1) Service main bearings are available in three

grades. The chart below identifies the three service

grades available.

REMOVAL AND INSTALLATION

ENGINE MOUNTSÐLEFT AND RIGHT

REMOVAL

(1) Disconnect the negative cable from the battery.

CAUTION: Remove the fan blade, fan clutch and

fan shroud before raising engine. Failure to do so

may cause damage to the fan blade, fan clutch and

fan shroud.

(2) Remove the fan blade, fan clutch and fan

shroud. Refer to Group 7. for procedure.

(3) Remove the engine oil filter.

(4) Support the engine with a suitable jack and a

block of wood across the full width of the engine oil

pan.

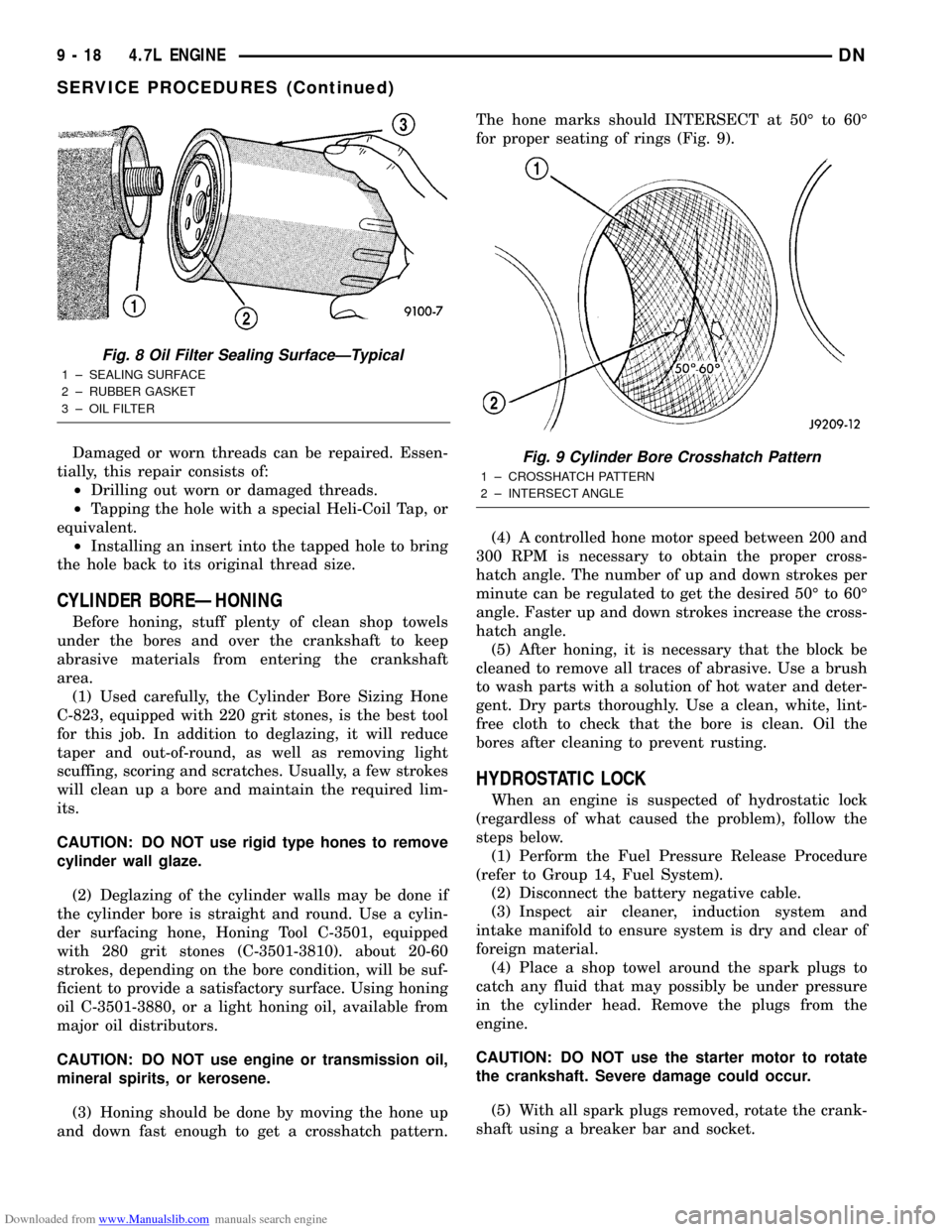

(5) Remove the four (4) cylinder block-to-insulator

mount bolts and the nut from the engine insulator

mount through bolt (4x2 Vehicles only) (Fig. 32) (Fig.

33).

(6) Remove the three (3) cylinder block-to-insulator

mount bolts and loosen the nut from the engine insu-

lator mount through bolt (4x4 Vehicles only) (Fig. 34)

(Fig. 35).

(7) Using the jack, raise the engine high enough to

remove the engine insulator mount through bolt and

the insulator mount.

INSTALLATION

(1) Position the insulator mount and install the

insulator mount through bolt.

(2) Lower the engine until the four cylinder block-

to-insulator mount bolts can be installed.

(3) Remove the jack and block of wood.

(4) Torque the cylinder block-to-insulator mount

bolts to 61N´m ( 45 ft. lbs.).

(5) Install and torque the through bolt retaining

nut to 61N´m (45 ft. lbs.).

(6) Install the fan blade, fan clutch and fan

shroud.

GRADE SIZE mm

(in.)FOR USE WITH

MARKING JOURNAL SIZE

A.008 mm U/S 63.488-63.496 mm

(.0004 in.)

U/S(2.4996-2.4999 in.)

BSTANDARD 63.496-63.504 mm

(2.4996-2.4999 in.)

C.008 mm O/S 63.504-63.512 mm

(.0004 in.)

O/S(2.5002-2.5005 in.)

Fig. 32 Engine Insulator Mount 4x2 VehicleÐLeft

Side

1 ± ENGINE INSULATOR MOUNT-LEFT SIDE

2 ± MOUNTING BOLT

Fig. 33 Engine Insulator Mount 4x2 VehicleÐRight

Side

1 ± ENGINE INSULATOR MOUNT-RIGHT SIDE

2 ± MOUNTING BOLT

9 - 28 4.7L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 30 of 193

Downloaded from www.Manualslib.com manuals search engine (6) Tighten the mount bracket to crossmember

retaining bolts (4x4 automatic transmission only) to

28 N´m (250 in. lbs.).

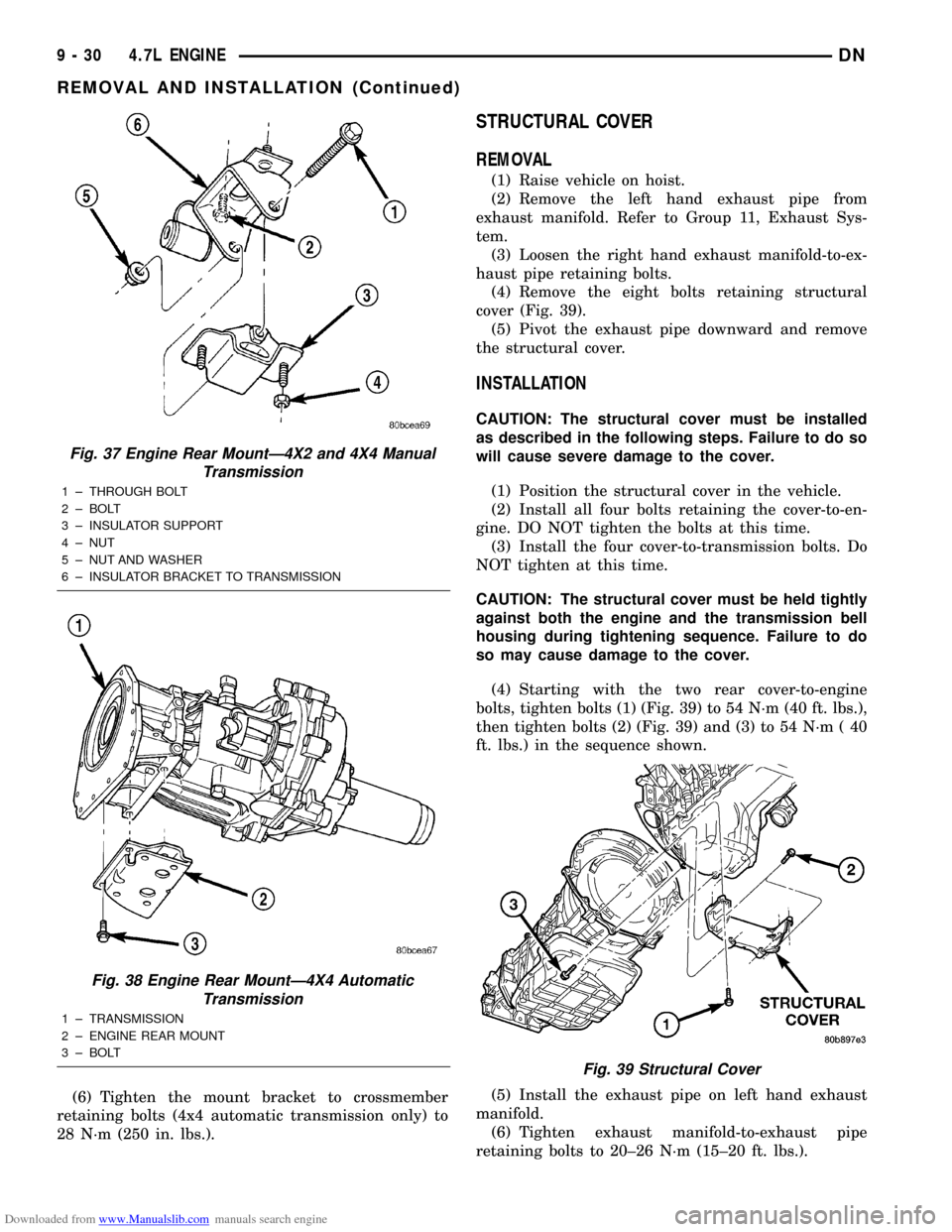

STRUCTURAL COVER

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the left hand exhaust pipe from

exhaust manifold. Refer to Group 11, Exhaust Sys-

tem.

(3) Loosen the right hand exhaust manifold-to-ex-

haust pipe retaining bolts.

(4) Remove the eight bolts retaining structural

cover (Fig. 39).

(5) Pivot the exhaust pipe downward and remove

the structural cover.

INSTALLATION

CAUTION: The structural cover must be installed

as described in the following steps. Failure to do so

will cause severe damage to the cover.

(1) Position the structural cover in the vehicle.

(2) Install all four bolts retaining the cover-to-en-

gine. DO NOT tighten the bolts at this time.

(3) Install the four cover-to-transmission bolts. Do

NOT tighten at this time.

CAUTION: The structural cover must be held tightly

against both the engine and the transmission bell

housing during tightening sequence. Failure to do

so may cause damage to the cover.

(4) Starting with the two rear cover-to-engine

bolts, tighten bolts (1) (Fig. 39) to 54 N´m (40 ft. lbs.),

then tighten bolts (2) (Fig. 39) and (3) to 54 N´m ( 40

ft. lbs.) in the sequence shown.

(5) Install the exhaust pipe on left hand exhaust

manifold.

(6) Tighten exhaust manifold-to-exhaust pipe

retaining bolts to 20±26 N´m (15±20 ft. lbs.).

Fig. 37 Engine Rear MountÐ4X2 and 4X4 Manual

Transmission

1 ± THROUGH BOLT

2 ± BOLT

3 ± INSULATOR SUPPORT

4 ± NUT

5 ± NUT AND WASHER

6 ± INSULATOR BRACKET TO TRANSMISSION

Fig. 38 Engine Rear MountÐ4X4 Automatic

Transmission

1 ± TRANSMISSION

2 ± ENGINE REAR MOUNT

3 ± BOLT

Fig. 39 Structural Cover

9 - 30 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 48 of 193

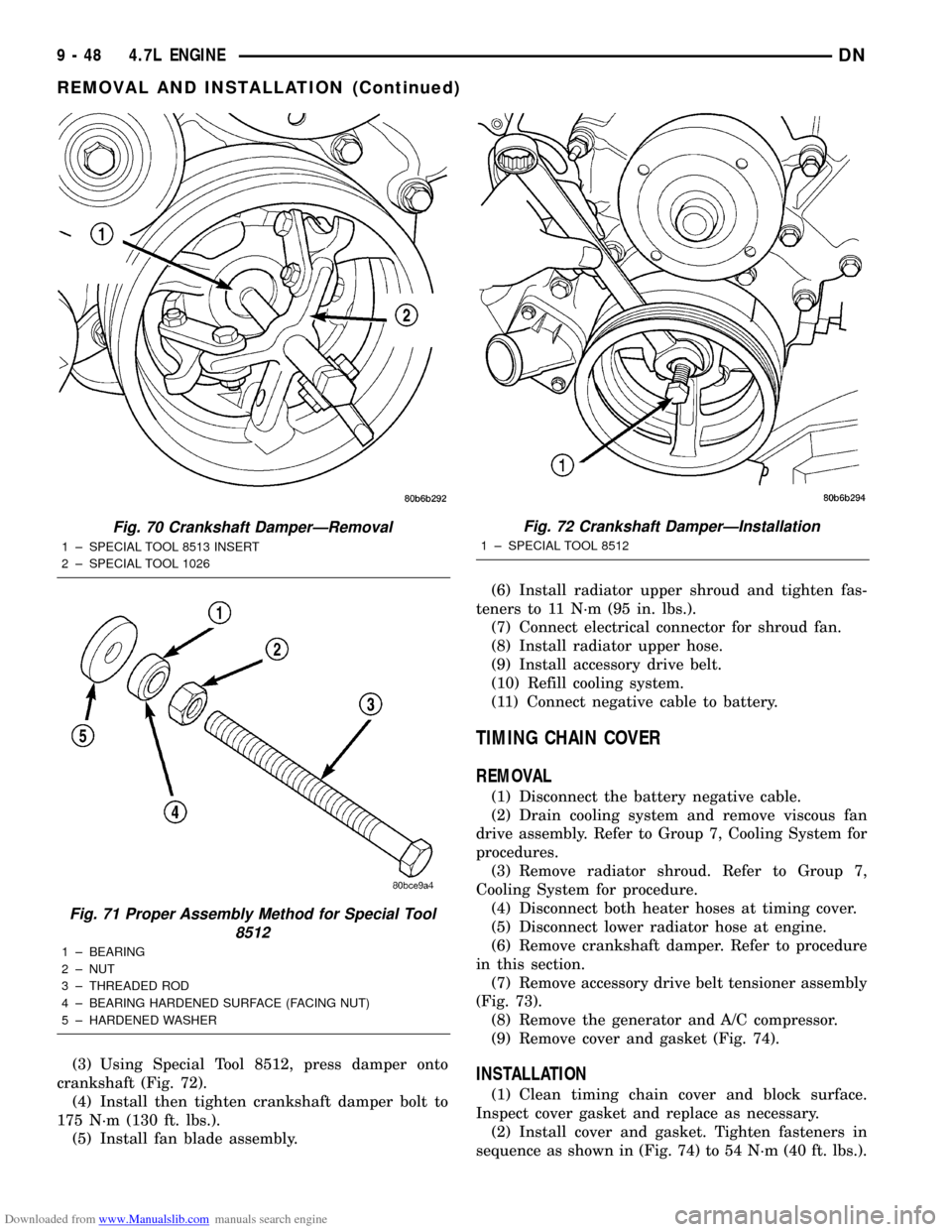

Downloaded from www.Manualslib.com manuals search engine (3) Using Special Tool 8512, press damper onto

crankshaft (Fig. 72).

(4) Install then tighten crankshaft damper bolt to

175 N´m (130 ft. lbs.).

(5) Install fan blade assembly.(6) Install radiator upper shroud and tighten fas-

teners to 11 N´m (95 in. lbs.).

(7) Connect electrical connector for shroud fan.

(8) Install radiator upper hose.

(9) Install accessory drive belt.

(10) Refill cooling system.

(11) Connect negative cable to battery.

TIMING CHAIN COVER

REMOVAL

(1) Disconnect the battery negative cable.

(2) Drain cooling system and remove viscous fan

drive assembly. Refer to Group 7, Cooling System for

procedures.

(3) Remove radiator shroud. Refer to Group 7,

Cooling System for procedure.

(4) Disconnect both heater hoses at timing cover.

(5) Disconnect lower radiator hose at engine.

(6) Remove crankshaft damper. Refer to procedure

in this section.

(7) Remove accessory drive belt tensioner assembly

(Fig. 73).

(8) Remove the generator and A/C compressor.

(9) Remove cover and gasket (Fig. 74).

INSTALLATION

(1) Clean timing chain cover and block surface.

Inspect cover gasket and replace as necessary.

(2) Install cover and gasket. Tighten fasteners in

sequence as shown in (Fig. 74) to 54 N´m (40 ft. lbs.).

Fig. 70 Crankshaft DamperÐRemoval

1 ± SPECIAL TOOL 8513 INSERT

2 ± SPECIAL TOOL 1026

Fig. 71 Proper Assembly Method for Special Tool

8512

1 ± BEARING

2 ± NUT

3 ± THREADED ROD

4 ± BEARING HARDENED SURFACE (FACING NUT)

5 ± HARDENED WASHER

Fig. 72 Crankshaft DamperÐInstallation

1 ± SPECIAL TOOL 8512

9 - 48 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)