flat tire DODGE DURANGO 2020 User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 243 of 464

STARTING AND OPERATING241

RIM SIZE

This is the rim size that is appropriate for the tire

size listed.

INFLATION PRESSURE

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full

GAWR.

CURB WEIGHT

The curb weight of a vehicle is defined as the

total weight of the vehicle with all fluids,

including vehicle fuel, at full capacity

conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb

weight values are determined by weighing your

vehicle on a commercial scale before any

occupants or cargo are added.

LOADING

The actual total weight and the weight of the

front and rear of your vehicle at the ground can

best be determined by weighing it when it is

loaded and ready for operation. The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has

not been exceeded. The weight on the front and

rear of the vehicle should then be determined

separately to be sure that the load is properly

distributed over the front and rear axle.

Weighing the vehicle may show that the GAWR

of either the front or rear axles has been

exceeded but the total load is within the

specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate

until the specified weight limitations are met.

Store the heavier items down low and be sure

that the weight is distributed equally. Stow all

loose items securely before driving.

Improper weight distributions can have an

adverse effect on the way your vehicle steers

and handles and the way the brakes operate.

TRAILER TOWING

In this section you will find safety tips and

information on limits to the type of towing you

can reasonably do with your vehicle. Before

towing a trailer, carefully review this information

to tow your load as efficiently and safely as

possible.

To maintain the New Vehicle Limited Warranty

coverage, follow the requirements and

recommendations in this manual concerning

vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions

will assist you in understanding the following

information:

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total allowable weight of your

vehicle. This includes driver, passengers, cargo

and tongue weight. The total load must be

limited so that you do not exceed the GVWR.

Refer to “Vehicle Loading/Vehicle Certification

Label” in this chapter for further information.CAUTION!

Do not load your vehicle any heavier than the

GVWR or the maximum front and rear GAWR.

If you do, parts on your vehicle can break, or

it can change the way your vehicle handles.

This could cause you to lose control. Also

overloading can shorten the life of your

vehicle.

5

20_WD_OM_EN_USC_t.book Page 241

Page 248 of 464

246STARTING AND OPERATING

NOTE:

The trailer tongue weight must be considered

as part of the combined weight of occupants

and cargo, and should never exceed the

weight referenced on the Tire and Loading

Information placard. Refer to “Tires” in

“Servicing And Maintenance” for further

information.

The manufacturer does not recommend

using the run flat feature while driving a

vehicle loaded at full capacity or towing a

trailer.

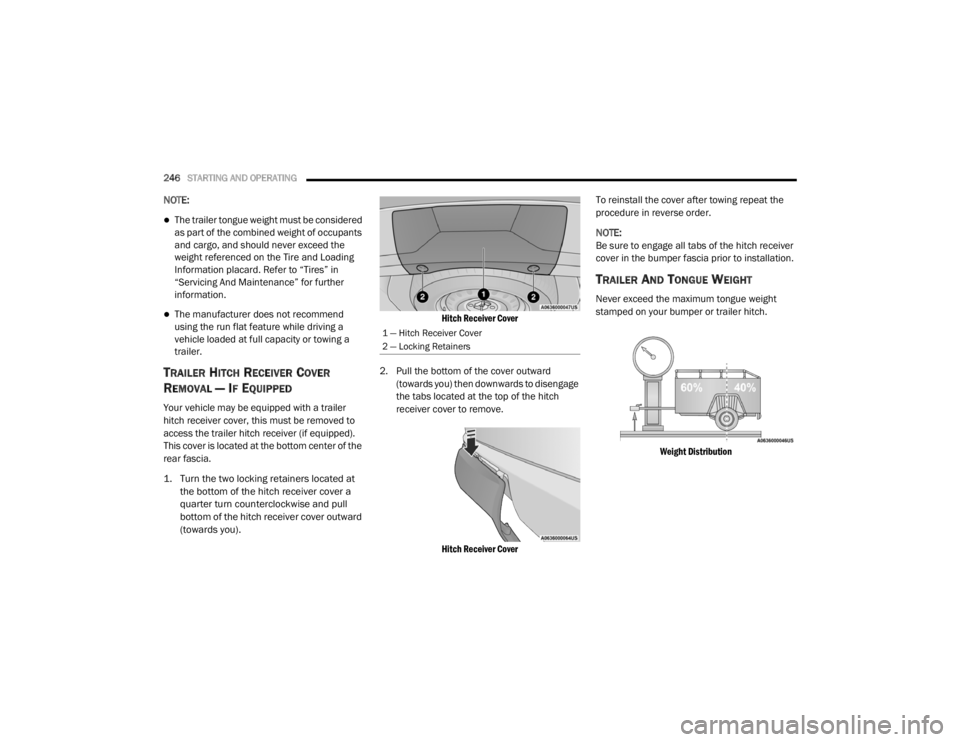

TRAILER HITCH RECEIVER COVER

R

EMOVAL — IF EQUIPPED

Your vehicle may be equipped with a trailer

hitch receiver cover, this must be removed to

access the trailer hitch receiver (if equipped).

This cover is located at the bottom center of the

rear fascia.

1. Turn the two locking retainers located at

the bottom of the hitch receiver cover a

quarter turn counterclockwise and pull

bottom of the hitch receiver cover outward

(towards you).

Hitch Receiver Cover

2. Pull the bottom of the cover outward (towards you) then downwards to disengage

the tabs located at the top of the hitch

receiver cover to remove.

Hitch Receiver Cover

To reinstall the cover after towing repeat the

procedure in reverse order.

NOTE:

Be sure to engage all tabs of the hitch receiver

cover in the bumper fascia prior to installation.

TRAILER AND TONGUE WEIGHT

Never exceed the maximum tongue weight

stamped on your bumper or trailer hitch.

Weight Distribution

1 — Hitch Receiver Cover

2 — Locking Retainers

20_WD_OM_EN_USC_t.book Page 246

Page 250 of 464

248STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h)

when towing while using a full size spare tire.

Proper tire inflation pressures are essential

to the safe and satisfactory operation of your

vehicle. Refer to “Tires” in “Servicing And

Maintenance” for proper tire inflation proce -

dures.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. Refer to

“Tires” in “Servicing And Maintenance” for

the proper inspection procedure.

When replacing tires, refer to “Tires” in

“Servicing And Maintenance” for the proper

tire replacement procedures. Replacing tires

with a higher load carrying capacity will not

increase the vehicle's GVWR and GAWR

limits.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake

system or vacuum system of your vehicle

with that of the trailer. This could cause inad -

equate braking and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer

with electronically actuated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an

electronic brake controller is not required.

Trailer brakes are recommended for trailers

over 1,000 lbs (453 kg) and required for

trailers in excess of 2,000 lbs (907 kg).

Vehicles with trailers should not be parked

on a grade. When parking, apply the

parking brake on the tow vehicle. Put the

tow vehicle transmission in PARK (P). For

four-wheel drive vehicles, make sure the

transfer case is not in NEUTRAL (N). Always,

block or "chock" the trailer wheels.

GCWR must not be exceeded.

Total weight must be distributed between

the tow vehicle and the trailer such that the

following four ratings are not exceeded

:

GVWR

GTW

GAWR

Tongue weight rating for the trailer

hitch utilized.

WARNING! (Continued)

WARNING!

Do not connect trailer brakes to your

vehicle's hydraulic brake lines. It can over -

load your brake system and cause it to fail.

You might not have brakes when you need

them and could have an accident.

Towing any trailer will increase your stop -

ping distance. When towing, you should

allow for additional space between your

vehicle and the vehicle in front of you.

Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lbs

(453 kg) loaded, it should have its own

brakes and they should be of adequate

capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake

pedal effort, and longer stopping distances.

20_WD_OM_EN_USC_t.book Page 248

Page 264 of 464

262IN CASE OF EMERGENCY

NOTE:

Your vehicle may be transmitting data as

authorized by the subscriber.

The SOS and ASSIST buttons will only func -

tion if you are connected to an operable LTE

(voice/data) or 4G (data) network. Other

Uconnect services will only be operable if

your SiriusXM Guardian™ service is active

and you are connected to an operable LTE

(voice/data) or 4G (data) network. ASSIST Call

The ASSIST Button is used to automatically

connect you to any one of the following support

centers:

Roadside Assistance – If you get a flat tire, or

need a tow, just push the ASSIST button and

you will be connected to a representative for

assistance. Roadside Assistance will know

what vehicle you’re driving and its location.

Additional fees may apply for roadside assis

-

tance.

SiriusXM Guardian™ Customer Care –

In-vehicle support for SiriusXM Guardian™.

Vehicle Customer Care – Total support for all

other vehicle issues.

SOS Call

1. Push the SOS Call button on the Rearview Mirror.

NOTE:

In case the SOS Call button is pushed in error,

there will be a 10 second delay before the SOS

Call system initiates a call to a SOS operator. To cancel the SOS Call connection, push the

SOS call button on the Rearview Mirror or press

the cancellation button on the Device Screen.

Termination of the SOS Call will turn off the

green LED light on the Rearview Mirror.

2. The LED light located between the ASSIST

and SOS buttons on the Rearview Mirror will

turn green once a connection to a SOS

operator has been made.

3. Once a connection between the vehicle and a SOS operator is made, the SOS Call

system may transmit the following

important vehicle information to a SOS

operator: Indication that the occupant placed a

SOS Call

The vehicle brand

The last known GPS coordinates of the

vehicle

4. You should be able to speak with the SOS operator through the vehicle audio system

to determine if additional assistance is

needed.

WARNING!

ALWAYS obey traffic laws and pay attention to

the road. ALWAYS drive safely with your hands

on the steering wheel. You have full

responsibility and assume all risks related to

the use of the features and applications in

this vehicle. Only use the features and

applications when it is safe to do so. Failure

to do so may result in an accident involving

serious injury or death.

20_WD_OM_EN_USC_t.book Page 262

Page 278 of 464

276IN CASE OF EMERGENCY

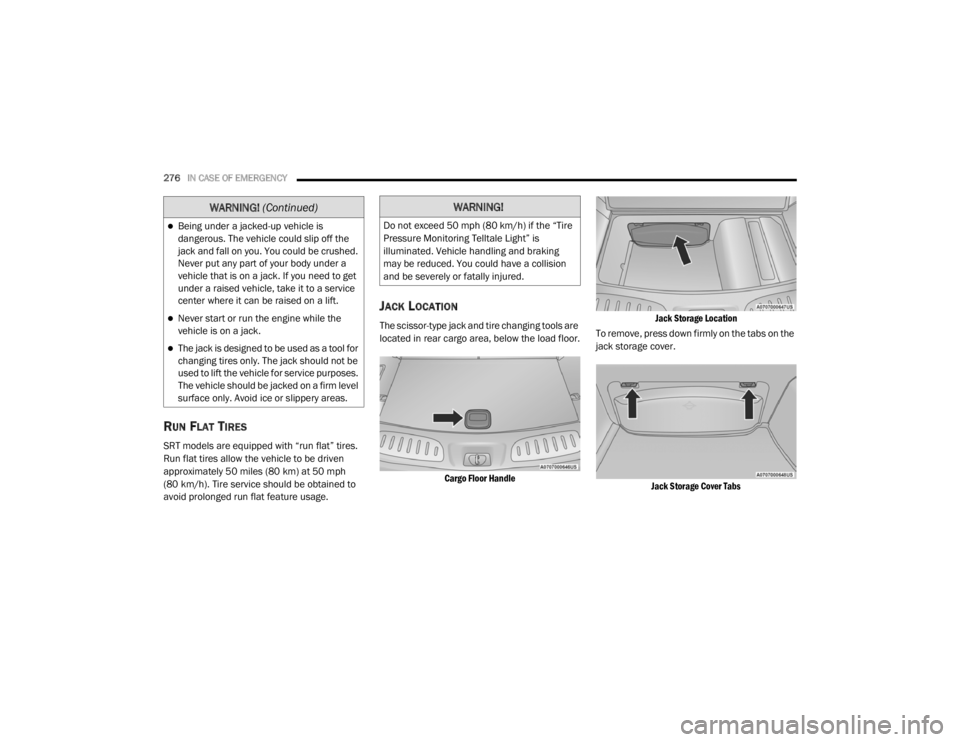

RUN FLAT TIRES

SRT models are equipped with “run flat” tires.

Run flat tires allow the vehicle to be driven

approximately 50 miles (80 km) at 50 mph

(80 km/h). Tire service should be obtained to

avoid prolonged run flat feature usage.

JACK LOCATION

The scissor-type jack and tire changing tools are

located in rear cargo area, below the load floor.

Cargo Floor Handle Jack Storage Location

To remove, press down firmly on the tabs on the

jack storage cover.

Jack Storage Cover Tabs

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING! (Continued)WARNING!

Do not exceed 50 mph (80 km/h) if the “Tire

Pressure Monitoring Telltale Light” is

illuminated. Vehicle handling and braking

may be reduced. You could have a collision

and be severely or fatally injured.

20_WD_OM_EN_USC_t.book Page 276

Page 282 of 464

280IN CASE OF EMERGENCY

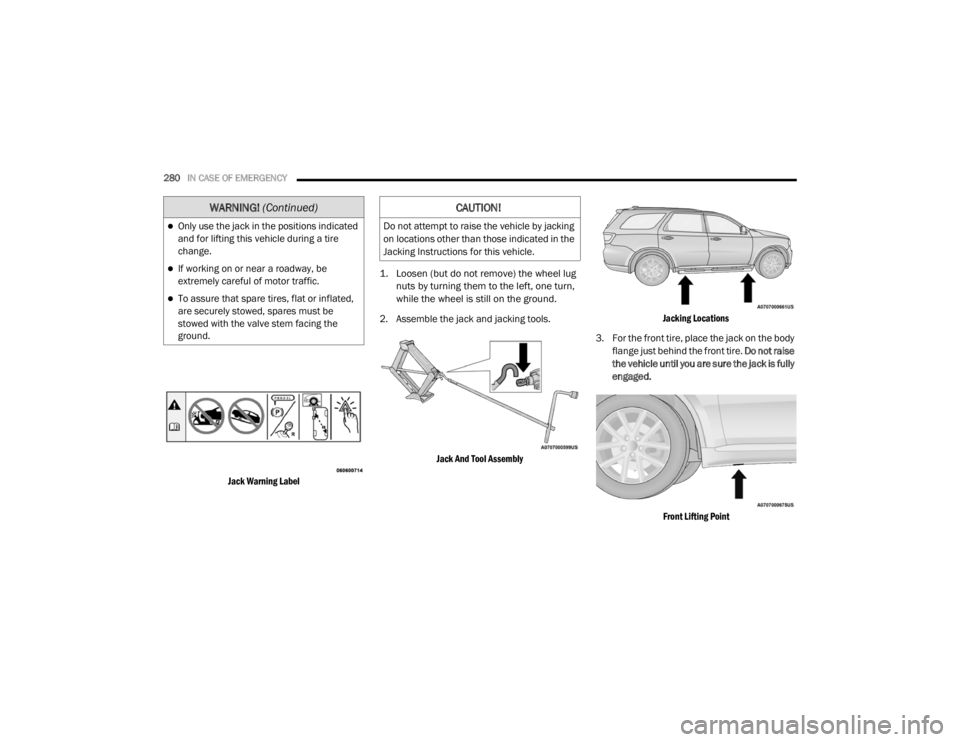

Jack Warning Label

1. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

2. Assemble the jack and jacking tools.

Jack And Tool Assembly Jacking Locations

3. For the front tire, place the jack on the body flange just behind the front tire. Do not raise

the vehicle until you are sure the jack is fully

engaged.

Front Lifting Point

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

20_WD_OM_EN_USC_t.book Page 280

Page 283 of 464

IN CASE OF EMERGENCY281

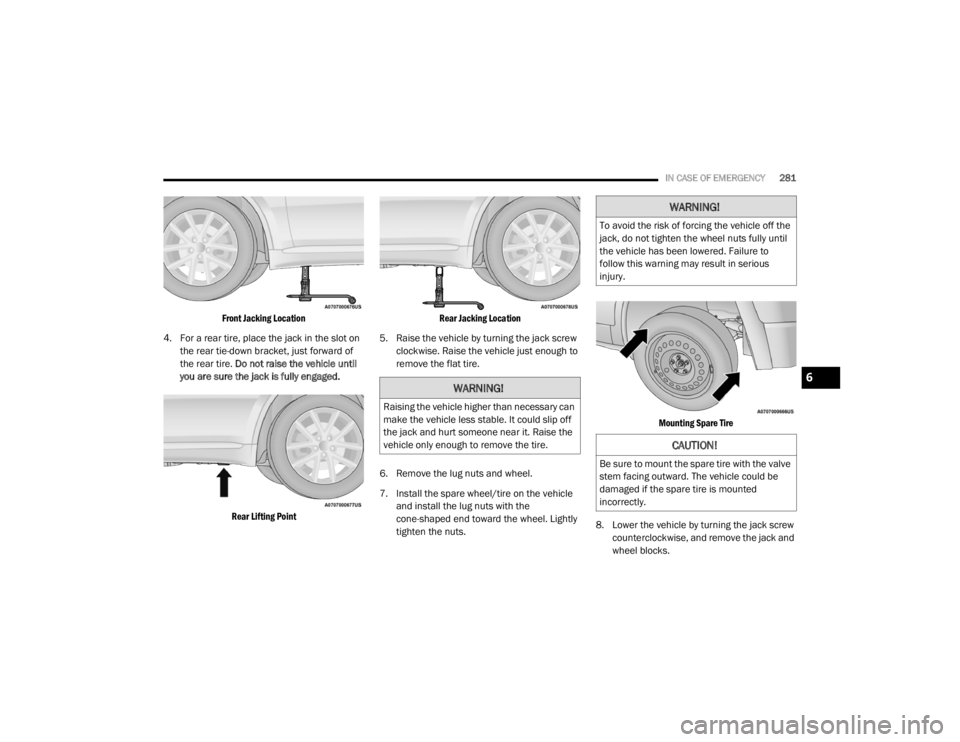

Front Jacking Location

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of

the rear tire. Do not raise the vehicle until

you are sure the jack is fully engaged.

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle just enough to

remove the flat tire.

6. Remove the lug nuts and wheel.

7. Install the spare wheel/tire on the vehicle and install the lug nuts with the

cone-shaped end toward the wheel. Lightly

tighten the nuts.

Mounting Spare Tire

8. Lower the vehicle by turning the jack screw counterclockwise, and remove the jack and

wheel blocks.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

6

20_WD_OM_EN_USC_t.book Page 281

Page 296 of 464

294

SERVICING AND MAINTENANCE

SCHEDULED SERVICING — NON-SRT

Your vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating

Conditions can cause the change oil message

to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off road environment or

is operated predominately at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.

Once A Month Or Before A Long Trip:Check engine oil level

Check windshield washer fluid level

Check the tire inflation pressures and look

for unusual wear or damage

Check the fluid levels of the coolant reservoir,

brake master cylinder and fill as needed.

Check function of all interior and exterior

lights

MAINTENANCE PLAN — NON-SRT

Required Maintenance

Refer to the Maintenance Plans on the following

pages for required maintenance.

20_WD_OM_EN_USC_t.book Page 294

Page 332 of 464

330SERVICING AND MAINTENANCE

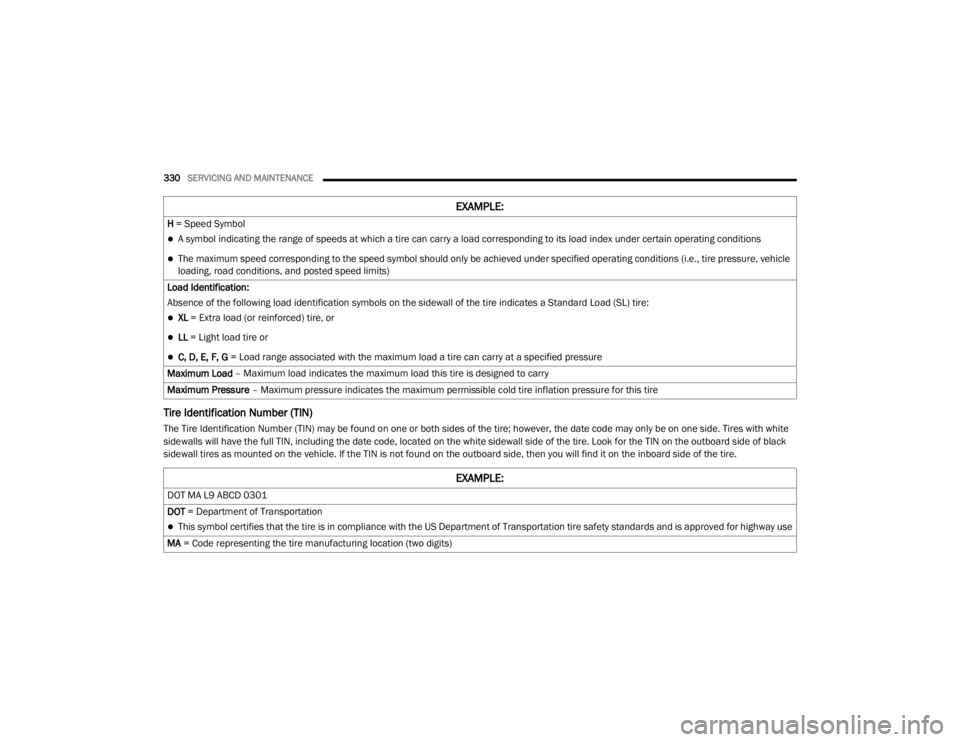

Tire Identification Number (TIN)

The Tire Identification Number (TIN) may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white

sidewalls will have the full TIN, including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black

sidewall tires as mounted on the vehicle. If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

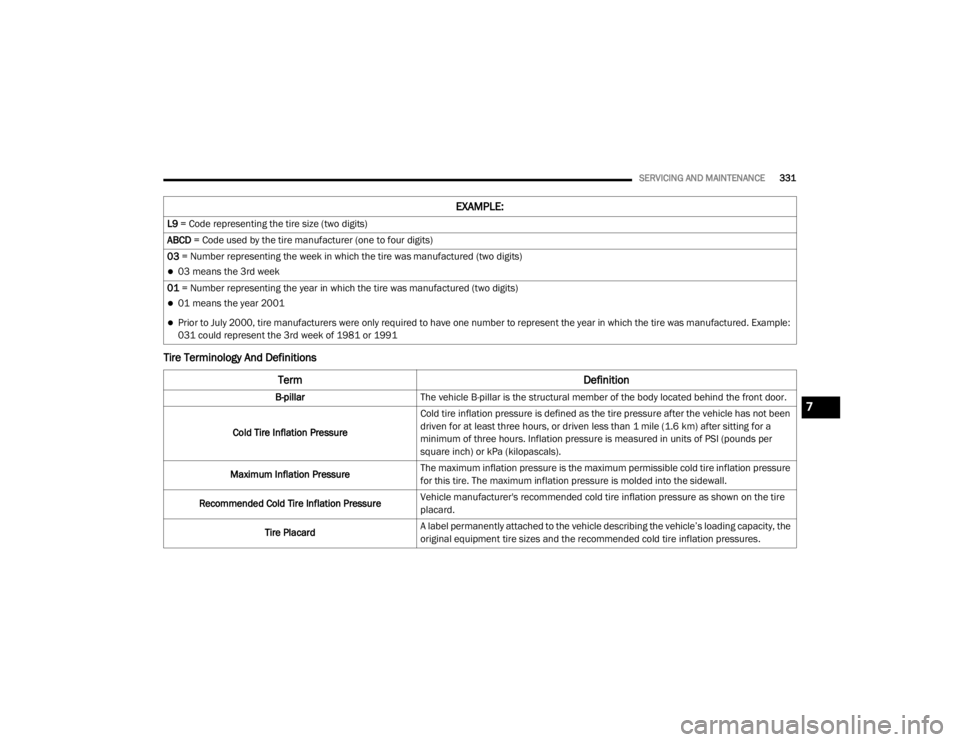

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

20_WD_OM_EN_USC_t.book Page 330

Page 333 of 464

SERVICING AND MAINTENANCE331

Tire Terminology And Definitions

L9 = Code representing the tire size (two digits)

ABCD = Code used by the tire manufacturer (one to four digits)

03 = Number representing the week in which the tire was manufactured (two digits)

03 means the 3rd week

01 = Number representing the year in which the tire was manufactured (two digits)

01 means the year 2001

Prior to July 2000, tire manufacturers were only required to have one number to represent the year in which the tire was manufactured. Example:

031 could represent the 3rd week of 1981 or 1991

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a

minimum of three hours. Inflation pressure is measured in units of PSI (pounds per

square inch) or kPa (kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure

for this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure Vehicle manufacturer's recommended cold tire inflation pressure as shown on the tire

placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

EXAMPLE:

7

20_WD_OM_EN_USC_t.book Page 331