lock DODGE JOURNEY 2020 Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: JOURNEY, Model: DODGE JOURNEY 2020Pages: 396, PDF Size: 25.53 MB

Page 194 of 396

192 IN CASE OF EMERGENCY

Front Fog Lamp

NOTE:

Turn the steering wheel to the right if replacing

t h

e left front fog lamp or to the left if replacing

the right front fog lamp to allow for easier

access to the front of the wheel well.

1. Remove the fasteners retaining the front l

ower wheel well access panel and remove

the access panel.

2. R emove the electrical connector from the

f

og lamp housing.

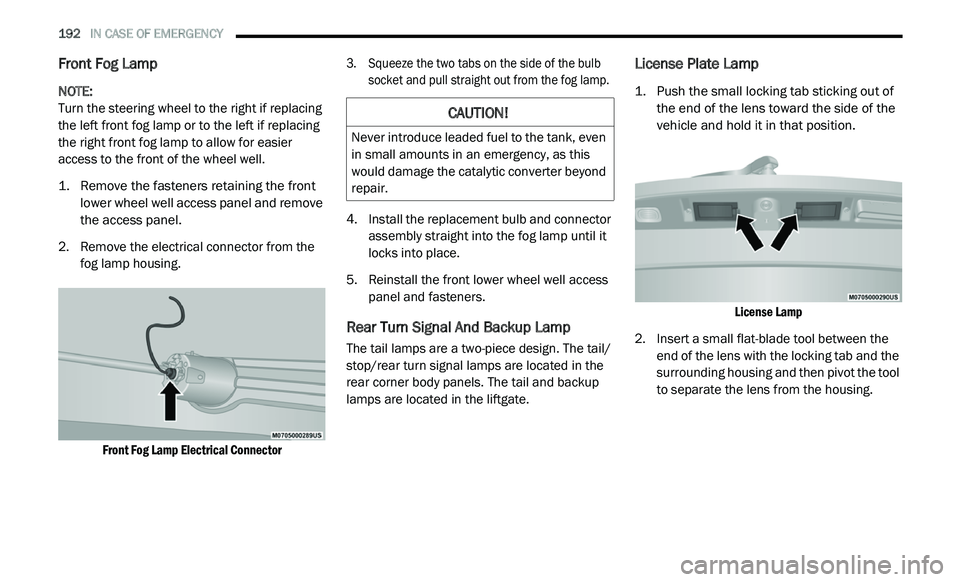

Front Fog Lamp Electrical Connector

3. S

queeze the two tabs on the side of the bulb

s

ocket and pull straight out from the fog lamp.

4. I nstall the replacement bulb and connector

a

ssembly straight into the fog lamp until it

locks into place.

5. R einstall the front lower wheel well access

p

anel and fasteners.

Rear Turn Signal And Backup Lamp

The tail lamps are a two-piece design. The tail/

stop/rear turn signal lamps are located in the

rear corner body panels. The tail and backup

lamps are located in the liftgate.

License Plate Lamp

1. Push the small locking tab sticking out of the end of the lens toward the side of the

vehicle and hold it in that position.

License Lamp

2. I nsert a small flat-blade tool between the

e

nd of the lens with the locking tab and the

surrounding housing and then pivot the tool

to separate the lens from the housing.

CAUTION!

Never introduce leaded fuel to the tank, even

in small amounts in an emergency, as this

would damage the catalytic converter beyond

repair.

Page 195 of 396

IN CASE OF EMERGENCY 193

3. Hold the lens with one hand and rotate the

bulb's electrical connector a quarter turn

counterclockwise, with the other hand

separate the bulb and connector assembly

from the lens.

4. R emove the bulb from the connector socket

a

nd install the replacement bulb.

5. I nstall the bulb and connector assembly

i

nto the lens and rotate the connector a

quarter turn clockwise to lock it in place.

6. I nsert the end of the lens without the

l

ocking tab into the housing on the liftgate

and then push the opposite end of the lens

into the housing, making sure it locks into

the housing.

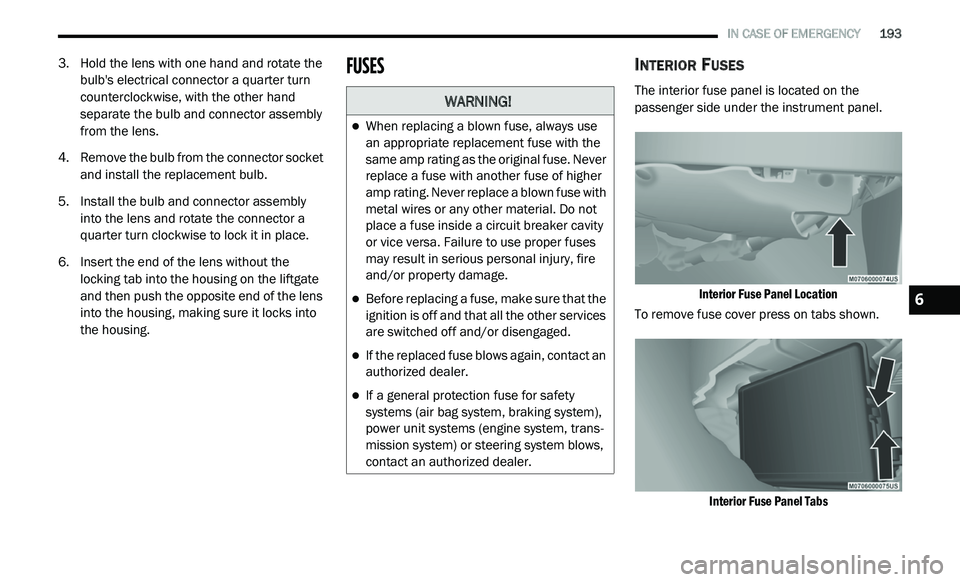

FUSESINTERIOR FUSES

The interior fuse panel is located on the

passenger side under the instrument panel.

Interior Fuse Panel Location

To remove fuse cover press on tabs shown.

Interior Fuse Panel Tabs

WARNING!

When replacing a blown fuse, always use

an appropriate replacement fuse with the

same amp rating as the original fuse. Never

replace a fuse with another fuse of higher

amp rating. Never replace a blown fuse with

metal wires or any other material. Do not

place a fuse inside a circuit breaker cavity

or vice versa. Failure to use proper fuses

may result in serious personal injury, fire

and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system, trans -

mission system) or steering system blows,

c o

ntact an authorized dealer.

6

Page 198 of 396

196 IN CASE OF EMERGENCY

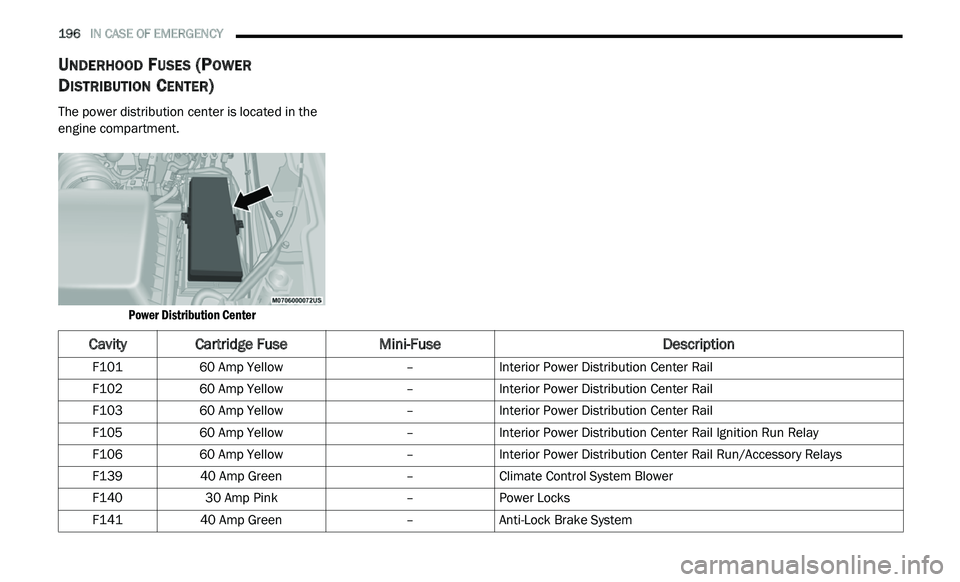

UNDERHOOD FUSES (POWER

D

ISTRIBUTION CENTER)

The power distribution center is located in the

engine compartment.

Power Distribution Center

CavityCartridge Fuse Mini-Fuse Description

F10160 Amp Yellow –Interior Power Distribution Center Rail

F102 60 Amp Yellow –Interior Power Distribution Center Rail

F103 60 Amp Yellow –Interior Power Distribution Center Rail

F105 60 Amp Yellow –Interior Power Distribution Center Rail Ignition Run Relay

F106 60 Amp Yellow –Interior Power Distribution Center Rail Run/Accessory Relays

F139 40 Amp Green –Climate Control System Blower

F140 30 Amp Pink –Power Locks

F141 40 Amp Green –Anti-Lock Brake System

Page 200 of 396

198 IN CASE OF EMERGENCY

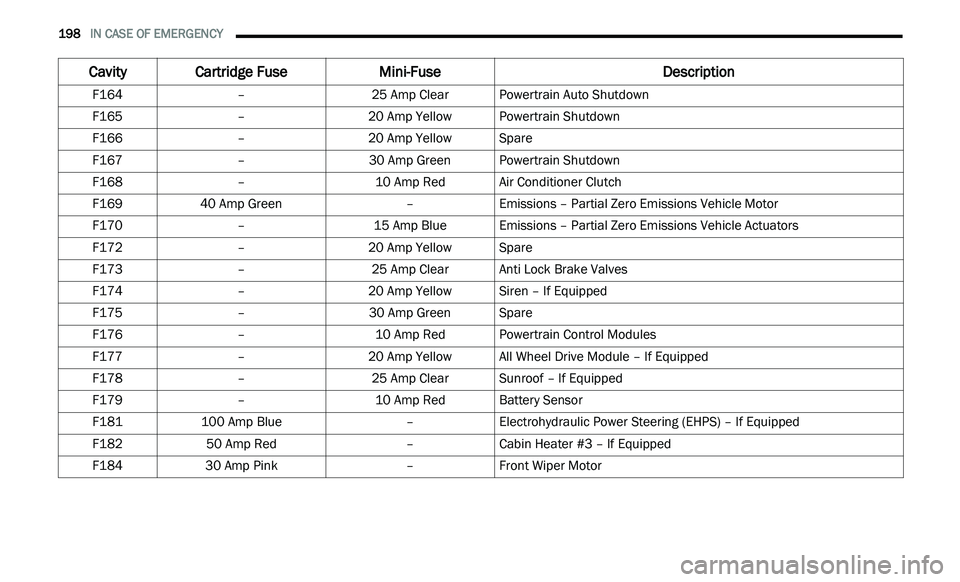

F164 –25 Amp ClearPowertrain Auto Shutdown

F165 –20 Amp Yellow Powertrain Shutdown

F166 –20 Amp Yellow Spare

F167 –30 Amp GreenPowertrain Shutdown

F168 –10 Amp RedAir Conditioner Clutch

F169 40 Amp Green –Emissions – Partial Zero Emissions Vehicle Motor

F170 –15 Amp BlueEmissions – Partial Zero Emissions Vehicle Actuators

F172 –20 Amp Yellow Spare

F173 –25 Amp ClearAnti Lock Brake Valves

F174 –20 Amp Yellow Siren – If Equipped

F175 –30 Amp GreenSpare

F176 –10 Amp RedPowertrain Control Modules

F177 –20 Amp Yellow All Wheel Drive Module – If Equipped

F178 –25 Amp ClearSunroof – If Equipped

F179 –10 Amp RedBattery Sensor

F181 100 Amp Blue –Electrohydraulic Power Steering (EHPS) – If Equipped

F182 50 Amp Red –Cabin Heater #3 – If Equipped

F184 30 Amp Pink –Front Wiper Motor

Cavity Cartridge Fuse Mini-FuseDescription

Page 202 of 396

200 IN CASE OF EMERGENCY

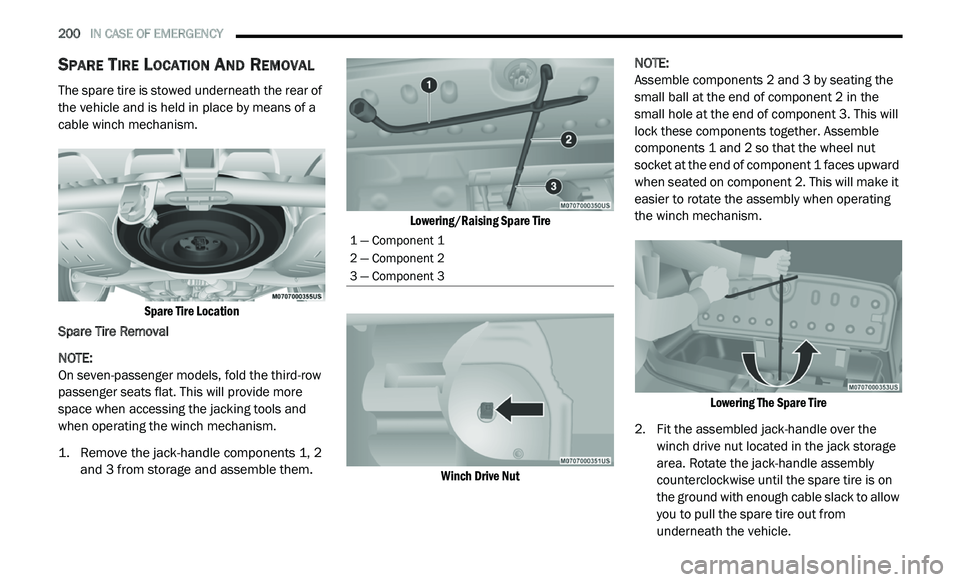

SPARE TIRE LOCATION AND REMOVAL

The spare tire is stowed underneath the rear of

the vehicle and is held in place by means of a

cable winch mechanism.

Spare Tire Location

Spare Tire Removal

NOTE:

On seven-passenger models, fold the third-row

p a

ssenger seats flat. This will provide more

space when accessing the jacking tools and

when operating the winch mechanism.

1. Remove the jack-handle components 1, 2 a

nd 3 from storage and assemble them.

Lowering/Raising Spare Tire

Winch Drive Nut

NOTE:

Assemble components 2 and 3 by seating the

s m

all ball at the end of component 2 in the

s m

all hole at the end of component 3. This will

lock these components together. Assemble

components 1 and 2 so that the wheel nut

socket at the end of component 1 faces upward

when seated on component 2. This will make it

easier to rotate the assembly when operating

the winch mechanism.

Lowering The Spare Tire

2. F it the assembled jack-handle over the

w

inch drive nut located in the jack storage

area. Rotate the jack-handle assembly

counterclockwise until the spare tire is on

the ground with enough cable slack to allow

you to pull the spare tire out from

underneath the vehicle.

1 — Component 1

2 — Component 2

3 — Component 3

Page 203 of 396

IN CASE OF EMERGENCY 201

(Continued)

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's

tread is on the ground.

4. T ilt the retainer at the end of the winch

c

able and remove it from the center of the

wheel.

Spare Tire Retainer

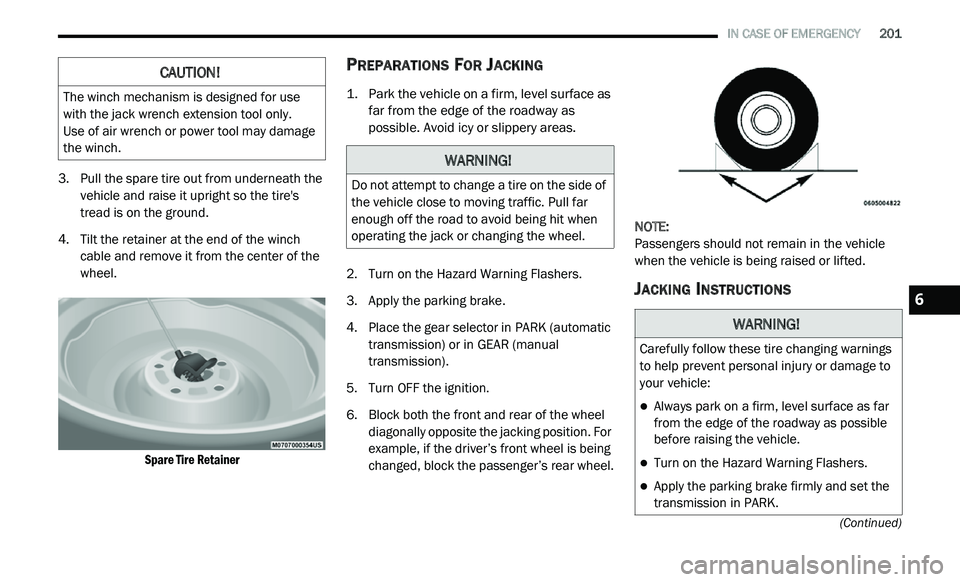

PREPARATIONS FOR JACKING

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as

possible. Avoid icy or slippery areas.

2. T urn on the Hazard Warning Flashers.

3

. A pply the parking brake.

4

. P lace the gear selector in PARK (automatic

t

ransmission) or in GEAR (manual

transmission).

5. T urn OFF the ignition.

6

. B lock both the front and rear of the wheel

d

iagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel. NOTE:

Passengers should not remain in the vehicle

w h

en the vehicle is being raised or lifted.

JACKING INSTRUCTIONS

CAUTION!

The winch mechanism is designed for use

with the jack wrench extension tool only.

Use of air wrench or power tool may damage

t h

e winch.

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

WARNING!

Carefully follow these tire changing warnings

to help prevent personal injury or damage to

your vehicle:

Always park on a firm, level surface as far

from the edge of the roadway as possible

before raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

6

Page 204 of 396

202 IN CASE OF EMERGENCY

Jack Warning Label

Jacking Locations

1. R

emove the spare tire, jack, and

j

ack-handle from stowage.

2. Lo osen, but do not remove, the wheel nuts

o

n the wheel with the flat tire. Turn the

wheel nuts counterclockwise one turn while

the wheel is still on the ground.

3. Place the jack in the notches underneath the l

ift area that is closest to the flat tire. Center

the jack saddle between the drain flute

formations on the sill flange. Turn the jack

screw clockwise to firmly engage the jack

saddle with the lift area of the sill flange.

Front Lifting Point

Block the wheel diagonally opposite the

wheel to be raised.

Never start or run the engine with the

vehicle on a jack.

Do not let anyone sit in the vehicle when it

is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised

vehicle, take it to a service center where it

can be raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire

change.

If working on or near a roadway, be

extremely careful of motor traffic.

To assure that spare tires, flat or inflated,

are securely stowed, spares must be

stowed with the valve stem facing the

ground.

WARNING! (Continued)

CAUTION!

Do not attempt to raise the vehicle by jacking

on locations other than those indicated in the

Jacking Instructions for this vehicle.

Page 205 of 396

IN CASE OF EMERGENCY 203

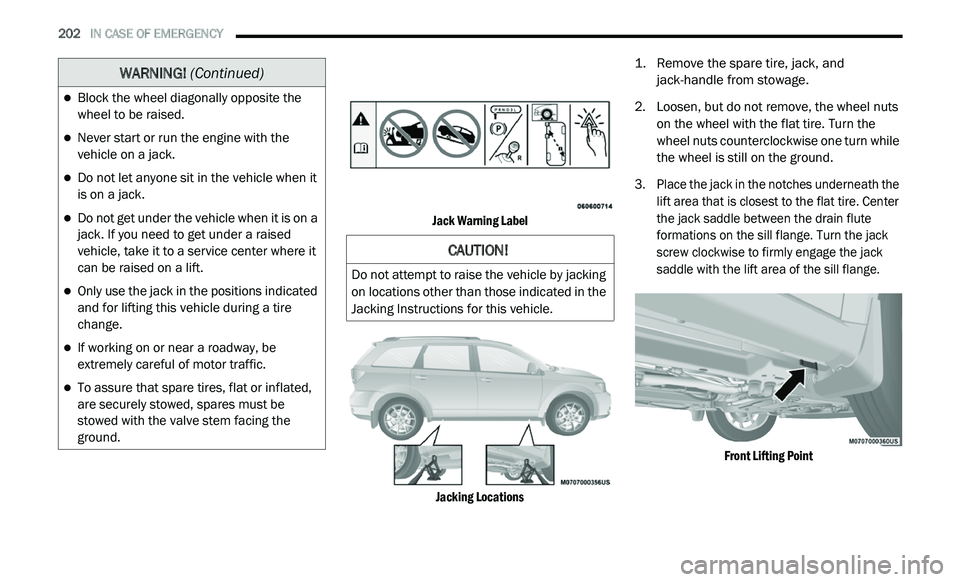

Front Jacking Location

Rear Lifting Point Rear Jacking Location

4. R aise the vehicle by turning the jack screw

c

lockwise with the jack handle. Raise the

vehicle until the tire just clears the road

surface and enough clearance is obtained

to install the spare tire. Minimum tire lift

provides maximum stability.

5. R emove the wheel nuts. If equipped with

w

heel covers, remove the wheel cover from

the wheel by hand. Do not pry the wheel

cover off. Then, pull the wheel off the hub. 6. M

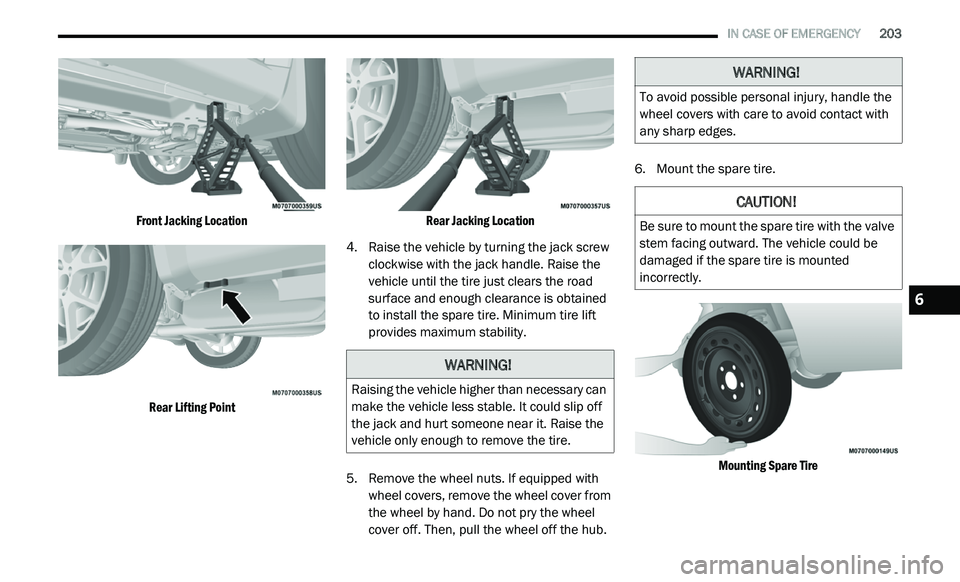

ount the spare tire.

M

ounting Spare Tire

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid possible personal injury, handle the

wheel covers with care to avoid contact with

any sharp edges.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

6

Page 206 of 396

204 IN CASE OF EMERGENCY

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited Use Spare” under “Tires” in

“Servicing And Maintenance” for additional

warnings, cautions, and information about

the spare tire, its use, and operation.

7. I nstall the wheel nuts with the cone-shaped

e

nd of the nut toward the wheel. Lightly

tighten the wheel nuts.

8. Lo wer the vehicle by turning the jack screw

c

ounterclockwise with the jack handle.

9. F

inish tightening the lug nuts. Push down on

t

he wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in

a star pattern until each nut has been

t i

ghtened twice. For the correct lug nut

torque, refer to “Wheel And Tire Torque

Specifications” in “Technical Specifications”.

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

10. Lo wer the jack to its fully closed position.

1

1. P lace the deflated (flat) tire in the cargo

a

rea. Do not stow the deflated tire in the

spare tire stowage location. Have the

deflated (flat) tire repaired or replaced as

soon as possible.

12. T o stow the winch cable and retainer, fit the

a

ssembled jack-handle over the winch drive

nut. Rotate the jack-handle assembly clockwise

until you hear the winch mechanism click three

times. It cannot be over tightened.

Stowing The Winch Cable And Retainer

13. S tow the jack-handle and jack. Remove the

w

heel blocks from the vehicle and release

the park brake.

14. C heck the tire pressure as soon as possible.

A

djust the tire pressure as required.WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to follow

this warning may result in serious injury.

Page 207 of 396

IN CASE OF EMERGENCY 205

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. T o ease the installation process for steel

w

heels with wheel covers, install two lug nuts

on the mounting studs which are on each

side of the valve stem. Install the lug nuts

with the cone shaped end of the nut toward

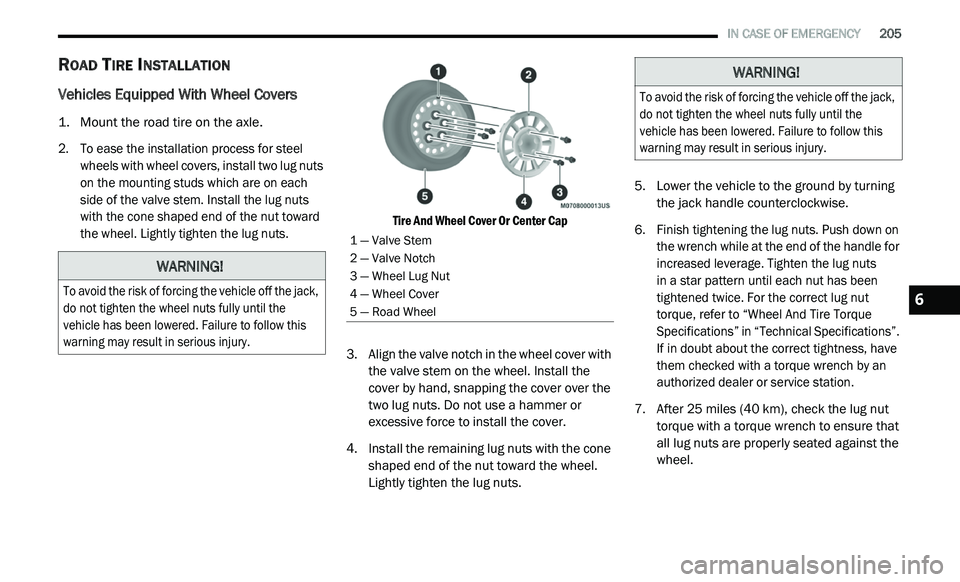

the wheel. Lightly tighten the lug nuts. Tire And Wheel Cover Or Center Cap

3. A lign the valve notch in the wheel cover with

t

he valve stem on the wheel. Install the

cover by hand, snapping the cover over the

two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. I nstall the remaining lug nuts with the cone

s

haped end of the nut toward the wheel.

Lightly tighten the lug nuts. 5. Lo

wer the vehicle to the ground by turning

t

he jack handle counterclockwise.

6. F inish tightening the lug nuts. Push down on

t

he wrench while at the end of the handle for

increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

t i

ghtened twice. For the correct lug nut

torque, refer to “Wheel And Tire Torque

Specifications” in “Technical Specifications”.

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

7. A fter 25

miles (40 km), check the lug nut

to

rque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Road Wheel

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

6