steering DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 940 of 1200

WARNING: WHEN HANDLING AN UNDEPLOYED

AIR BAG MODULE DURING SERVICING OF THE

STEERING COLUMN THE FOLLOWING PRECAU-

TIONS SHOULD BE OBSERVED. AT NO TIME

SHOULD ANY SOURCE OF ELECTRICITY BE PER-

MITTED NEAR THE INFLATOR ON THE BACK OF

THE AIR BAG MODULE. WHEN CARRYING A LIVE

MODULE, THE TRIM COVER SHOULD BE POINTED

AWAY FROM THE BODY TO MINIMIZE INJURY IF

MODULE ACCIDENTLY DEPLOYS. IF AIR BAG MOD-

ULE IS PLACED ON A BENCH OR OTHER SUR-

FACE, PLASTIC COVER SHOULD BE FACE UP TO

MINIMIZE MOVEMENT IN CASE OF ACCIDENTAL

DEPLOYMENT.

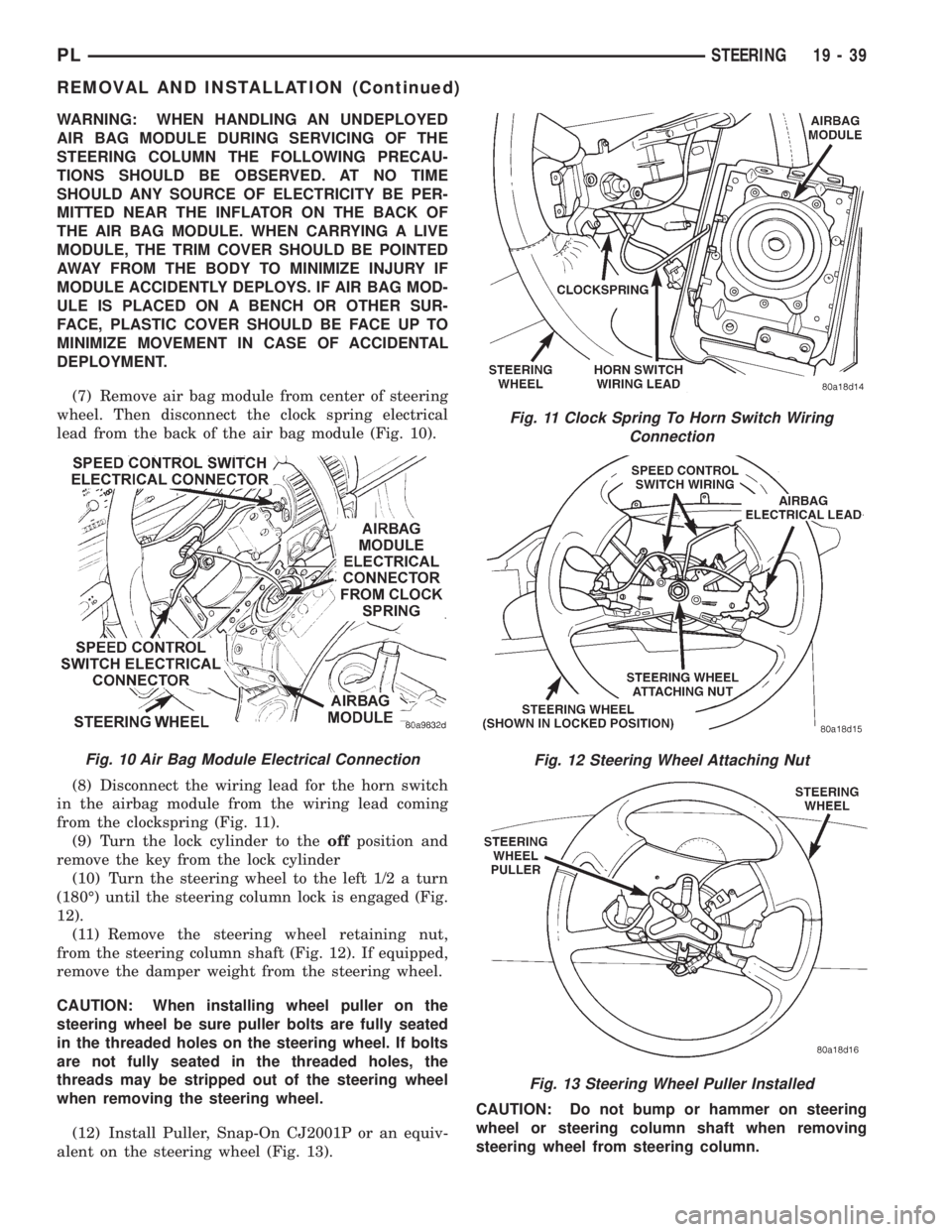

(7) Remove air bag module from center of steering

wheel. Then disconnect the clock spring electrical

lead from the back of the air bag module (Fig. 10).

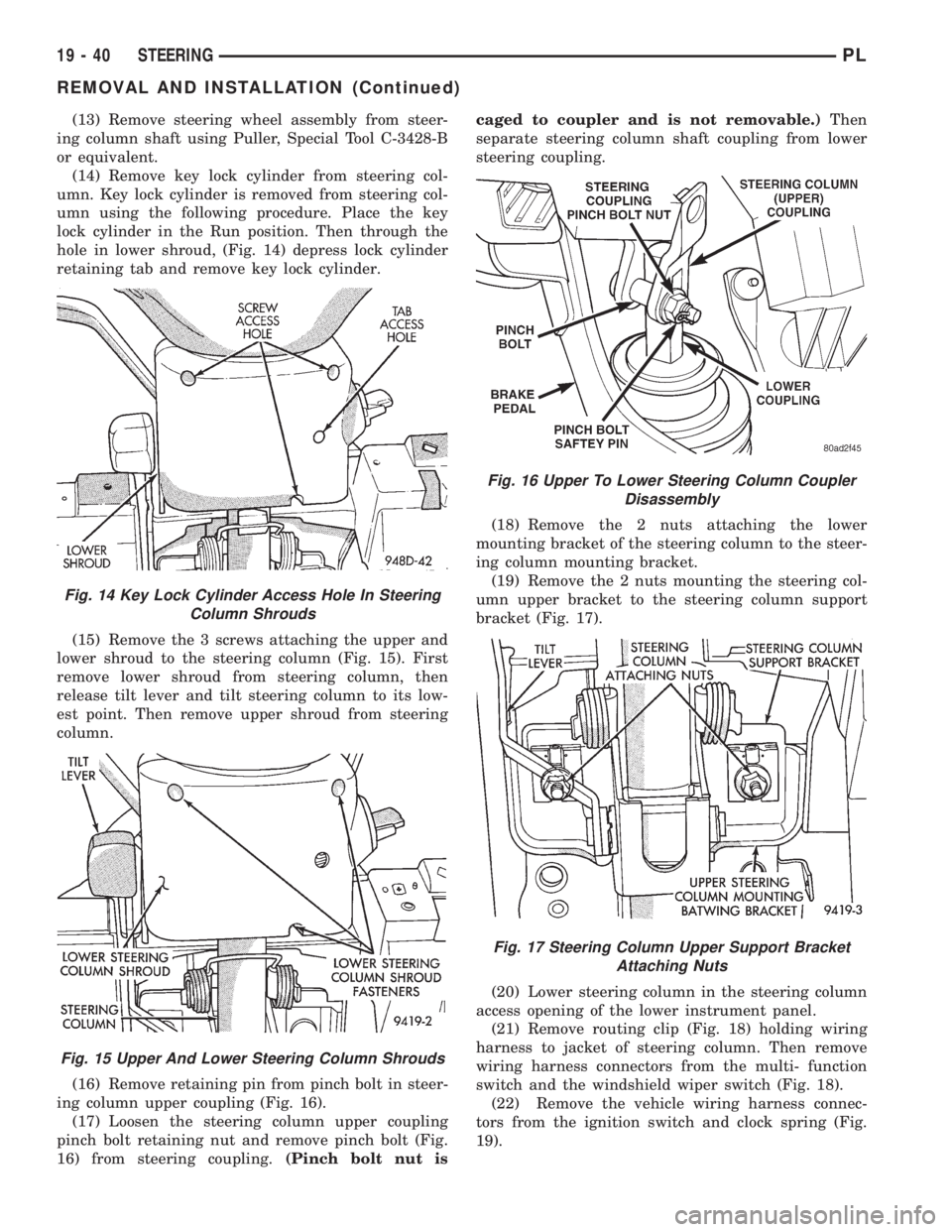

(8) Disconnect the wiring lead for the horn switch

in the airbag module from the wiring lead coming

from the clockspring (Fig. 11).

(9) Turn the lock cylinder to theoffposition and

remove the key from the lock cylinder

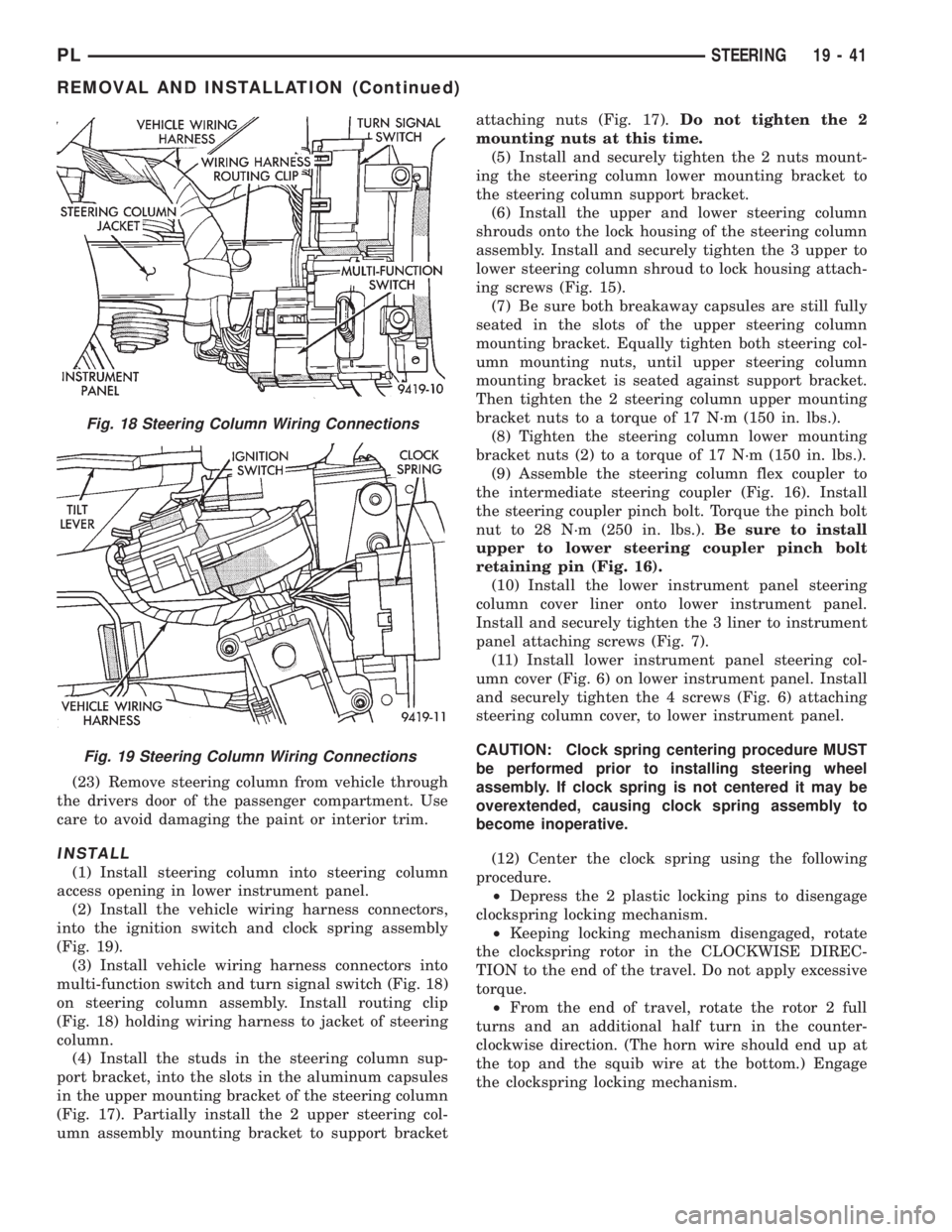

(10) Turn the steering wheel to the left 1/2 a turn

(180É) until the steering column lock is engaged (Fig.

12).

(11) Remove the steering wheel retaining nut,

from the steering column shaft (Fig. 12). If equipped,

remove the damper weight from the steering wheel.

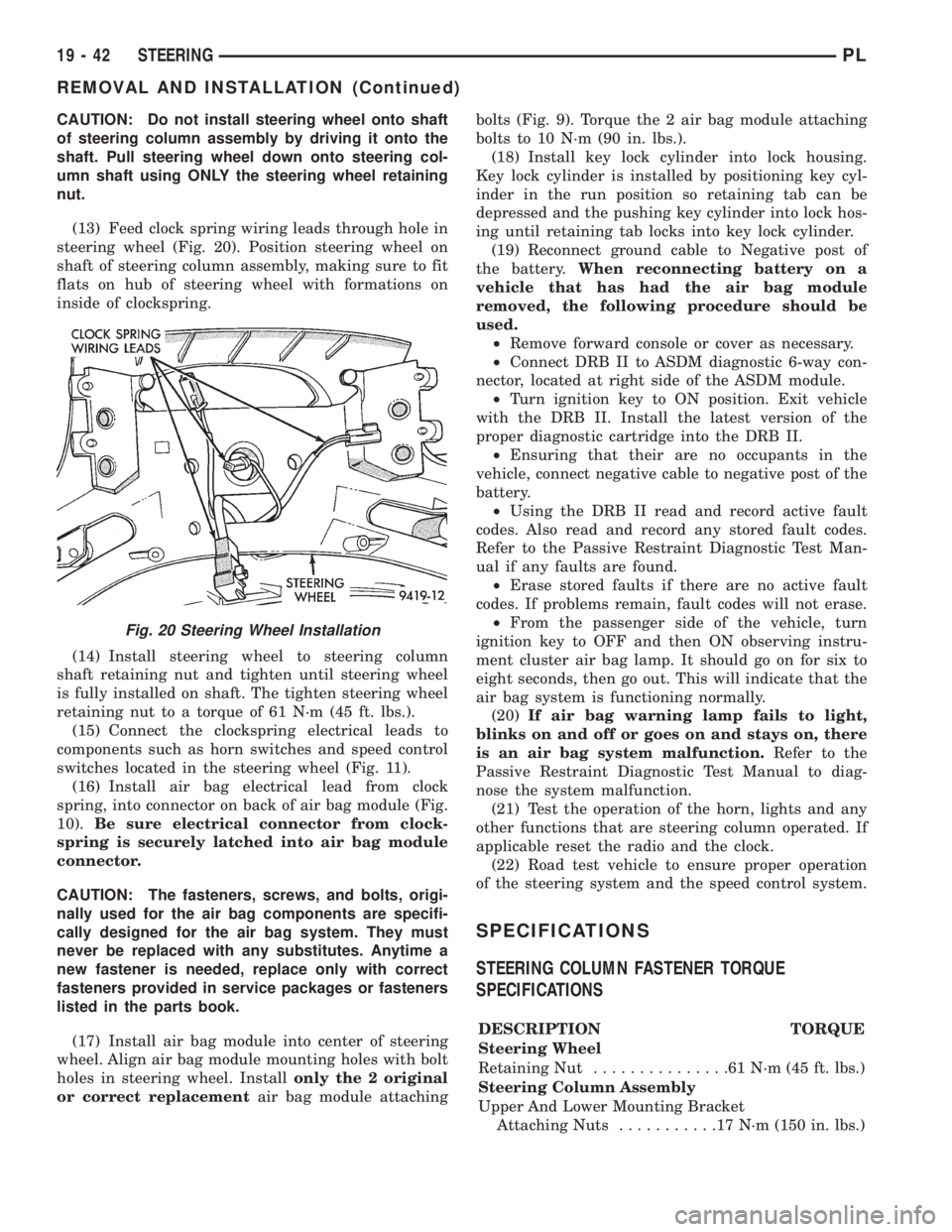

CAUTION: When installing wheel puller on the

steering wheel be sure puller bolts are fully seated

in the threaded holes on the steering wheel. If bolts

are not fully seated in the threaded holes, the

threads may be stripped out of the steering wheel

when removing the steering wheel.

(12) Install Puller, Snap-On CJ2001P or an equiv-

alent on the steering wheel (Fig. 13).CAUTION: Do not bump or hammer on steering

wheel or steering column shaft when removing

steering wheel from steering column.

Fig. 11 Clock Spring To Horn Switch Wiring

Connection

Fig. 12 Steering Wheel Attaching Nut

Fig. 13 Steering Wheel Puller Installed

Fig. 10 Air Bag Module Electrical Connection

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)

Page 941 of 1200

(13) Remove steering wheel assembly from steer-

ing column shaft using Puller, Special Tool C-3428-B

or equivalent.

(14) Remove key lock cylinder from steering col-

umn. Key lock cylinder is removed from steering col-

umn using the following procedure. Place the key

lock cylinder in the Run position. Then through the

hole in lower shroud, (Fig. 14) depress lock cylinder

retaining tab and remove key lock cylinder.

(15) Remove the 3 screws attaching the upper and

lower shroud to the steering column (Fig. 15). First

remove lower shroud from steering column, then

release tilt lever and tilt steering column to its low-

est point. Then remove upper shroud from steering

column.

(16) Remove retaining pin from pinch bolt in steer-

ing column upper coupling (Fig. 16).

(17) Loosen the steering column upper coupling

pinch bolt retaining nut and remove pinch bolt (Fig.

16) from steering coupling.(Pinch bolt nut iscaged to coupler and is not removable.)Then

separate steering column shaft coupling from lower

steering coupling.

(18) Remove the 2 nuts attaching the lower

mounting bracket of the steering column to the steer-

ing column mounting bracket.

(19) Remove the 2 nuts mounting the steering col-

umn upper bracket to the steering column support

bracket (Fig. 17).

(20) Lower steering column in the steering column

access opening of the lower instrument panel.

(21) Remove routing clip (Fig. 18) holding wiring

harness to jacket of steering column. Then remove

wiring harness connectors from the multi- function

switch and the windshield wiper switch (Fig. 18).

(22) Remove the vehicle wiring harness connec-

tors from the ignition switch and clock spring (Fig.

19).

Fig. 14 Key Lock Cylinder Access Hole In Steering

Column Shrouds

Fig. 15 Upper And Lower Steering Column Shrouds

Fig. 16 Upper To Lower Steering Column Coupler

Disassembly

Fig. 17 Steering Column Upper Support Bracket

Attaching Nuts

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 942 of 1200

(23) Remove steering column from vehicle through

the drivers door of the passenger compartment. Use

care to avoid damaging the paint or interior trim.

INSTALL

(1) Install steering column into steering column

access opening in lower instrument panel.

(2) Install the vehicle wiring harness connectors,

into the ignition switch and clock spring assembly

(Fig. 19).

(3) Install vehicle wiring harness connectors into

multi-function switch and turn signal switch (Fig. 18)

on steering column assembly. Install routing clip

(Fig. 18) holding wiring harness to jacket of steering

column.

(4) Install the studs in the steering column sup-

port bracket, into the slots in the aluminum capsules

in the upper mounting bracket of the steering column

(Fig. 17). Partially install the 2 upper steering col-

umn assembly mounting bracket to support bracketattaching nuts (Fig. 17).Do not tighten the 2

mounting nuts at this time.

(5) Install and securely tighten the 2 nuts mount-

ing the steering column lower mounting bracket to

the steering column support bracket.

(6) Install the upper and lower steering column

shrouds onto the lock housing of the steering column

assembly. Install and securely tighten the 3 upper to

lower steering column shroud to lock housing attach-

ing screws (Fig. 15).

(7) Be sure both breakaway capsules are still fully

seated in the slots of the upper steering column

mounting bracket. Equally tighten both steering col-

umn mounting nuts, until upper steering column

mounting bracket is seated against support bracket.

Then tighten the 2 steering column upper mounting

bracket nuts to a torque of 17 N´m (150 in. lbs.).

(8) Tighten the steering column lower mounting

bracket nuts (2) to a torque of 17 N´m (150 in. lbs.).

(9) Assemble the steering column flex coupler to

the intermediate steering coupler (Fig. 16). Install

the steering coupler pinch bolt. Torque the pinch bolt

nut to 28 N´m (250 in. lbs.).Be sure to install

upper to lower steering coupler pinch bolt

retaining pin (Fig. 16).

(10) Install the lower instrument panel steering

column cover liner onto lower instrument panel.

Install and securely tighten the 3 liner to instrument

panel attaching screws (Fig. 7).

(11) Install lower instrument panel steering col-

umn cover (Fig. 6) on lower instrument panel. Install

and securely tighten the 4 screws (Fig. 6) attaching

steering column cover, to lower instrument panel.

CAUTION: Clock spring centering procedure MUST

be performed prior to installing steering wheel

assembly. If clock spring is not centered it may be

overextended, causing clock spring assembly to

become inoperative.

(12) Center the clock spring using the following

procedure.

²Depress the 2 plastic locking pins to disengage

clockspring locking mechanism.

²Keeping locking mechanism disengaged, rotate

the clockspring rotor in the CLOCKWISE DIREC-

TION to the end of the travel. Do not apply excessive

torque.

²From the end of travel, rotate the rotor 2 full

turns and an additional half turn in the counter-

clockwise direction. (The horn wire should end up at

the top and the squib wire at the bottom.) Engage

the clockspring locking mechanism.

Fig. 18 Steering Column Wiring Connections

Fig. 19 Steering Column Wiring Connections

PLSTEERING 19 - 41

REMOVAL AND INSTALLATION (Continued)

Page 943 of 1200

CAUTION: Do not install steering wheel onto shaft

of steering column assembly by driving it onto the

shaft. Pull steering wheel down onto steering col-

umn shaft using ONLY the steering wheel retaining

nut.

(13) Feed clock spring wiring leads through hole in

steering wheel (Fig. 20). Position steering wheel on

shaft of steering column assembly, making sure to fit

flats on hub of steering wheel with formations on

inside of clockspring.

(14) Install steering wheel to steering column

shaft retaining nut and tighten until steering wheel

is fully installed on shaft. The tighten steering wheel

retaining nut to a torque of 61 N´m (45 ft. lbs.).

(15) Connect the clockspring electrical leads to

components such as horn switches and speed control

switches located in the steering wheel (Fig. 11).

(16) Install air bag electrical lead from clock

spring, into connector on back of air bag module (Fig.

10).Be sure electrical connector from clock-

spring is securely latched into air bag module

connector.

CAUTION: The fasteners, screws, and bolts, origi-

nally used for the air bag components are specifi-

cally designed for the air bag system. They must

never be replaced with any substitutes. Anytime a

new fastener is needed, replace only with correct

fasteners provided in service packages or fasteners

listed in the parts book.

(17) Install air bag module into center of steering

wheel. Align air bag module mounting holes with bolt

holes in steering wheel. Installonly the 2 original

or correct replacementair bag module attachingbolts (Fig. 9). Torque the 2 air bag module attaching

bolts to 10 N´m (90 in. lbs.).

(18) Install key lock cylinder into lock housing.

Key lock cylinder is installed by positioning key cyl-

inder in the run position so retaining tab can be

depressed and the pushing key cylinder into lock hos-

ing until retaining tab locks into key lock cylinder.

(19) Reconnect ground cable to Negative post of

the battery.When reconnecting battery on a

vehicle that has had the air bag module

removed, the following procedure should be

used.

²Remove forward console or cover as necessary.

²Connect DRB II to ASDM diagnostic 6-way con-

nector, located at right side of the ASDM module.

²Turn ignition key to ON position. Exit vehicle

with the DRB II. Install the latest version of the

proper diagnostic cartridge into the DRB II.

²Ensuring that their are no occupants in the

vehicle, connect negative cable to negative post of the

battery.

²Using the DRB II read and record active fault

codes. Also read and record any stored fault codes.

Refer to the Passive Restraint Diagnostic Test Man-

ual if any faults are found.

²Erase stored faults if there are no active fault

codes. If problems remain, fault codes will not erase.

²From the passenger side of the vehicle, turn

ignition key to OFF and then ON observing instru-

ment cluster air bag lamp. It should go on for six to

eight seconds, then go out. This will indicate that the

air bag system is functioning normally.

(20)If air bag warning lamp fails to light,

blinks on and off or goes on and stays on, there

is an air bag system malfunction.Refer to the

Passive Restraint Diagnostic Test Manual to diag-

nose the system malfunction.

(21) Test the operation of the horn, lights and any

other functions that are steering column operated. If

applicable reset the radio and the clock.

(22) Road test vehicle to ensure proper operation

of the steering system and the speed control system.

SPECIFICATIONS

STEERING COLUMN FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

Steering Wheel

Retaining Nut...............61N´m(45ft.lbs.)

Steering Column Assembly

Upper And Lower Mounting Bracket

Attaching Nuts...........17N´m(150 in. lbs.)

Fig. 20 Steering Wheel Installation

19 - 42 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 985 of 1200

the use of special dyes to aid in detecting fluid leaks.

The use of transmission sealers should be avoided,

since they may adversely affect seals.

DESCRIPTION AND OPERATION

TORQUE CONVERTER CLUTCH

A torque converter clutch is standard on all vehi-

cles. The torque converter clutch is activated only in

direct drive and is controlled by the engine electron-

ics. A solenoid on the valve body, is powered by the

powertrain control module to activate the torque con-

verter clutch.

HYDRAULIC CONTROL SYSTEM

The hydraulic control system makes the transaxle

fully automatic, and has four important functions to

perform. The components of any automatic control

system may be grouped into the following basic

groups:

²Pressure supply system

²Pressure regulating valves

²Flow control valves

²Clutches

²Band servos

Taking each of these basic groups or systems in

turn, the control system may be described as follows:

PRESSURE SUPPLY SYSTEM

The pressure supply system consists of an oil pump

driven by the engine through the torque converter.

The single pump furnishes pressure for all hydraulic

and lubrication requirements.Oil pump housing

assemblies are available with preselected pump

gears.

PRESSURE REGULATING VALVES

The pressure regulating valve controls line pres-

sure dependent on throttle opening. The governor

valve transmits regulated pressure to the valve body

(in conjunction with vehicle speed) to control upshift

and downshift.

The throttle valve transmits regulated pressure to

the transaxle (dependent on throttle position) to con-

trol upshift and downshift.

FLOW CONTROL VALVES

The manual valve provides the different transaxle

drive ranges selected by the vehicle operator.

The 1-2 shift valve automatically shifts the tran-

saxle from first to second or from second to first,

depending on the vehicle operation.

The 2-3 shift valve automatically shifts the tran-

saxle from second to third or from third to second

depending on the vehicle operation.The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done

by depressing the accelerator pedal past the detent

feel near wide open throttle.

The shuttle valve has two separate functions and

performs each independently of the other. The first is

providing fast release of the kickdown band, and

smooth front clutch engagement when a lift-foot

upshift from second to third is made. The second

function is to regulate the application of the kick-

down servo and band when making third±to±second

kickdown.

The bypass valve provides for smooth application

of the kickdown band on 1-2 upshifts.

The torque converter clutch solenoid allows for the

electronic control of the torque converter clutch. It

also disengages the torque converter at closed throt-

tle. This is done during engine warm-up and part-

throttle acceleration.

The switch valve directs oil to apply the torque

converter clutch in one position. The switch valve

releases the torque converter clutch in the other posi-

tion.

CLUTCHES, BAND SERVOS, AND ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons, are moved hydraulically to engage the

clutches and apply the bands. The pistons are

released by spring tension when hydraulic pressure

is released. On the 2-3 upshift, the kickdown servo

piston is released by spring tension and hydraulic

pressure.

The accumulator controls the hydraulic pressure

on the apply±side of the kickdown servo during the

1-2 upshift; thereby cushioning the kickdown band

application at any throttle position.

AUTOMATIC TRANSMISSION SHIFTER/IGNITION

INTERLOCK

The Shifter/Ignition Interlock, is a mechanical

cable operated system (Fig. 1). It interconnects the

automatic transmission floor±mounted shifter to the

steering column ignition switch. The interlock system

locks the floor±mounted shift lever into the PARK

position whenever the ignition switch is in the LOCK

or ACCESSORY position. When the key is in the

OFF or RUN position, the shifter is unlocked and

will move into any position. Also the interlock system

prevents the ignition switch from being turned to

LOCK or ACCESSORY position, unless shifter is in

the PARK position.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by alever typegear-

shift incorporated within the console. The control has

21 - 42 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 1005 of 1200

(7) Pull cable up and out of the gearshift mecha-

nism.

(8) Remove the three screws along the bottom of

the lower steering column cover and screw on the left

outward face of cover.

(9) Grasp the cover and pull rearward until the

clips disengage.

(10) Remove two screws at the upper area of the

column liner and lower left corner.

(11) Remove steering column cover and steering

column cover liner.

(12) Lift up the top cover and cluster bezel until

the clips disengage and separate to provide clear-

ance.

(13) Insert a screwdriver into access hole in the

lower shroud. Depress the cylinder button while

rotating the cylinder with the key inserted between

the ON and START positions. This will disengage the

cylinder from the column.

(14) Pull out the key cylinder.

(15) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud.

(16) Separate the upper and lower shrouds.

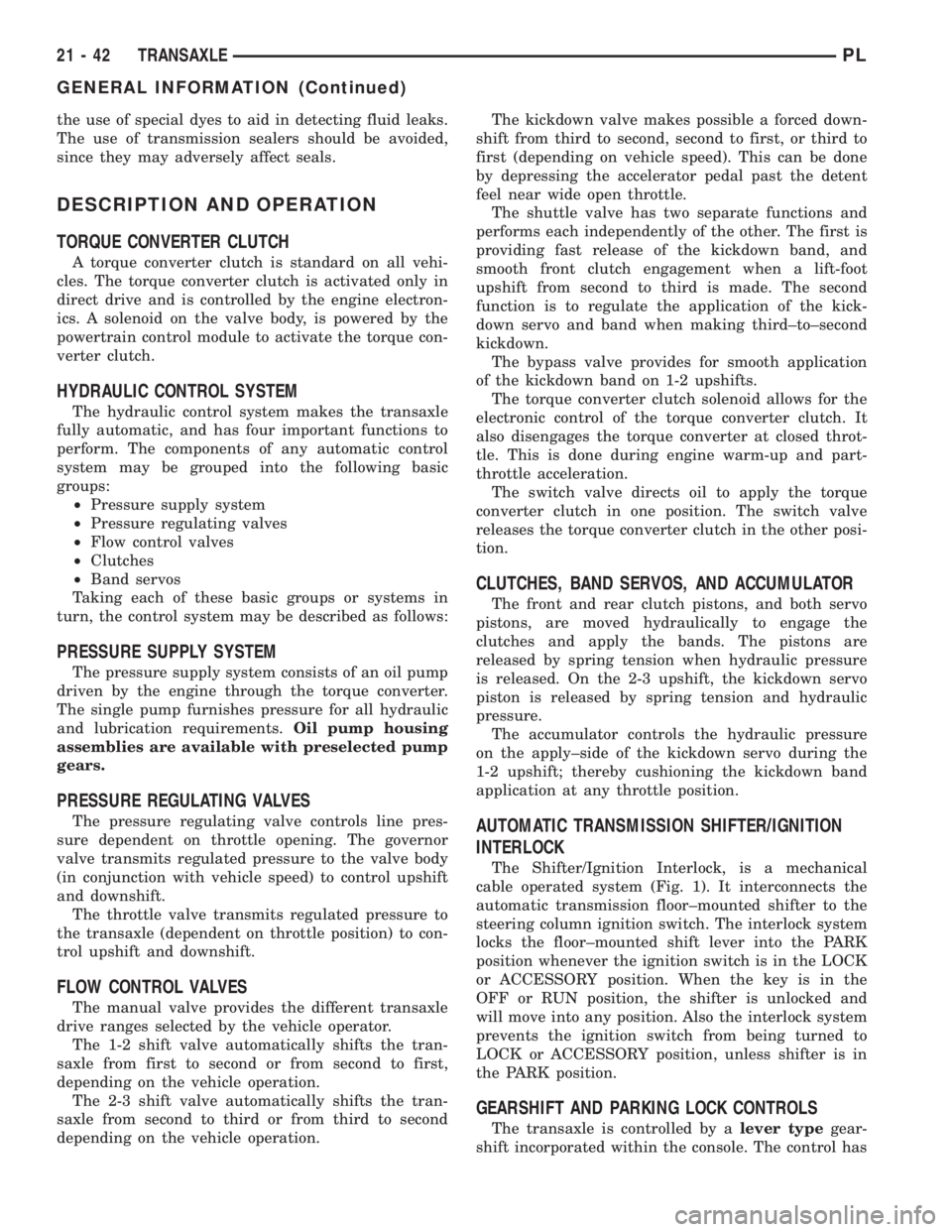

(17) Grasp the interlock cable clip and connector.

Remove the cable from the interlock housing (Fig.

17).

(18) Unclip the cable from the retaining clip

located within the wiring harness.

(19) Remove interlock cable from under center con-

sole mounting bracket and out front of dash panel.

INSTALLATION

CAUTION: When installing interlock cable assem-

bly, care must be taken not to bend exposed cable

wire and slug at shifter end of cable.

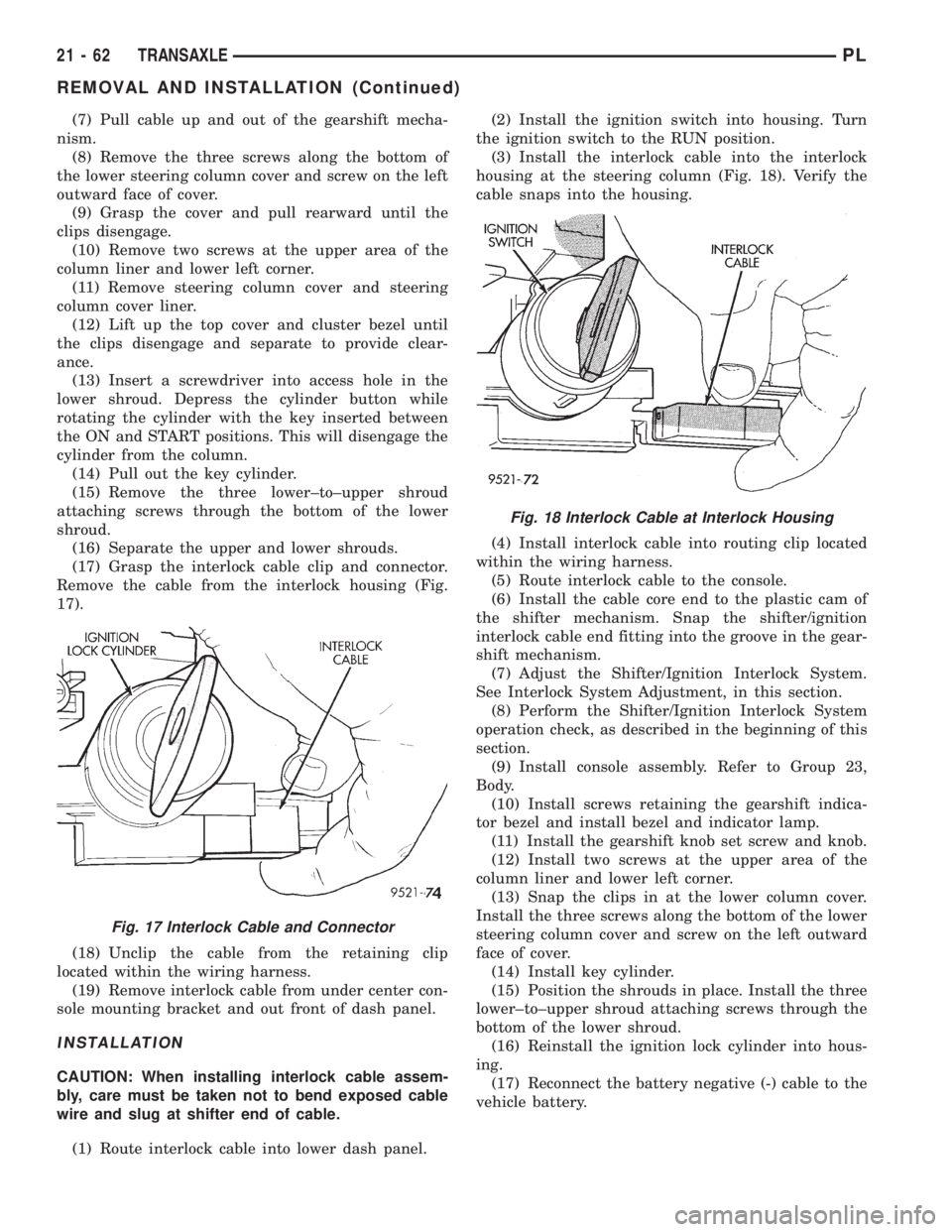

(1) Route interlock cable into lower dash panel.(2) Install the ignition switch into housing. Turn

the ignition switch to the RUN position.

(3) Install the interlock cable into the interlock

housing at the steering column (Fig. 18). Verify the

cable snaps into the housing.

(4) Install interlock cable into routing clip located

within the wiring harness.

(5) Route interlock cable to the console.

(6) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the shifter/ignition

interlock cable end fitting into the groove in the gear-

shift mechanism.

(7) Adjust the Shifter/Ignition Interlock System.

See Interlock System Adjustment, in this section.

(8) Perform the Shifter/Ignition Interlock System

operation check, as described in the beginning of this

section.

(9) Install console assembly. Refer to Group 23,

Body.

(10) Install screws retaining the gearshift indica-

tor bezel and install bezel and indicator lamp.

(11) Install the gearshift knob set screw and knob.

(12) Install two screws at the upper area of the

column liner and lower left corner.

(13) Snap the clips in at the lower column cover.

Install the three screws along the bottom of the lower

steering column cover and screw on the left outward

face of cover.

(14) Install key cylinder.

(15) Position the shrouds in place. Install the three

lower±to±upper shroud attaching screws through the

bottom of the lower shroud.

(16) Reinstall the ignition lock cylinder into hous-

ing.

(17) Reconnect the battery negative (-) cable to the

vehicle battery.

Fig. 17 Interlock Cable and Connector

Fig. 18 Interlock Cable at Interlock Housing

21 - 62 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1006 of 1200

INTERLOCK SYSTEM ADJUSTMENT

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

with needle nose pliers and pull back on cable. This

will allow the ignition switch to be turned to the

LOCK or ACCESSORY position.

(8) Check that the interlock cable slug is com-

pletely seated into the shifter interlock lever.

(9) Check that the ignition switch is still in the

LOCK or ACCESSORY position.

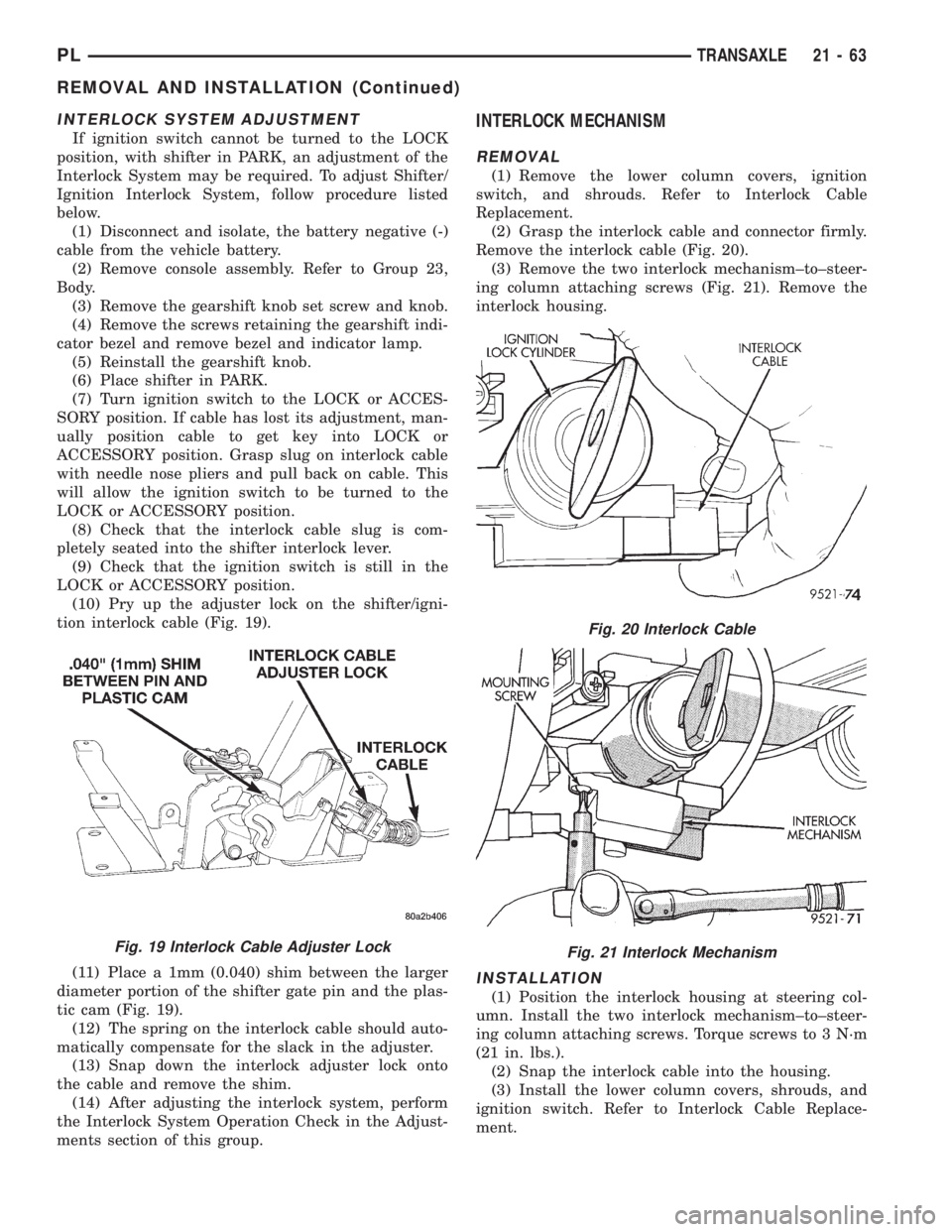

(10) Pry up the adjuster lock on the shifter/igni-

tion interlock cable (Fig. 19).

(11) Place a 1mm (0.040) shim between the larger

diameter portion of the shifter gate pin and the plas-

tic cam (Fig. 19).

(12) The spring on the interlock cable should auto-

matically compensate for the slack in the adjuster.

(13) Snap down the interlock adjuster lock onto

the cable and remove the shim.

(14) After adjusting the interlock system, perform

the Interlock System Operation Check in the Adjust-

ments section of this group.

INTERLOCK MECHANISM

REMOVAL

(1) Remove the lower column covers, ignition

switch, and shrouds. Refer to Interlock Cable

Replacement.

(2) Grasp the interlock cable and connector firmly.

Remove the interlock cable (Fig. 20).

(3) Remove the two interlock mechanism±to±steer-

ing column attaching screws (Fig. 21). Remove the

interlock housing.

INSTALLATION

(1) Position the interlock housing at steering col-

umn. Install the two interlock mechanism±to±steer-

ing column attaching screws. Torque screws to 3 N´m

(21 in. lbs.).

(2) Snap the interlock cable into the housing.

(3) Install the lower column covers, shrouds, and

ignition switch. Refer to Interlock Cable Replace-

ment.

Fig. 19 Interlock Cable Adjuster Lock

Fig. 20 Interlock Cable

Fig. 21 Interlock Mechanism

PLTRANSAXLE 21 - 63

REMOVAL AND INSTALLATION (Continued)

Page 1064 of 1200

TRANSAXLE

CONTENTS

page page

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM........................ 1REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY................ 2

ADJUSTMENTS

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM ADJUSTMENT............ 4

DESCRIPTION AND OPERATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

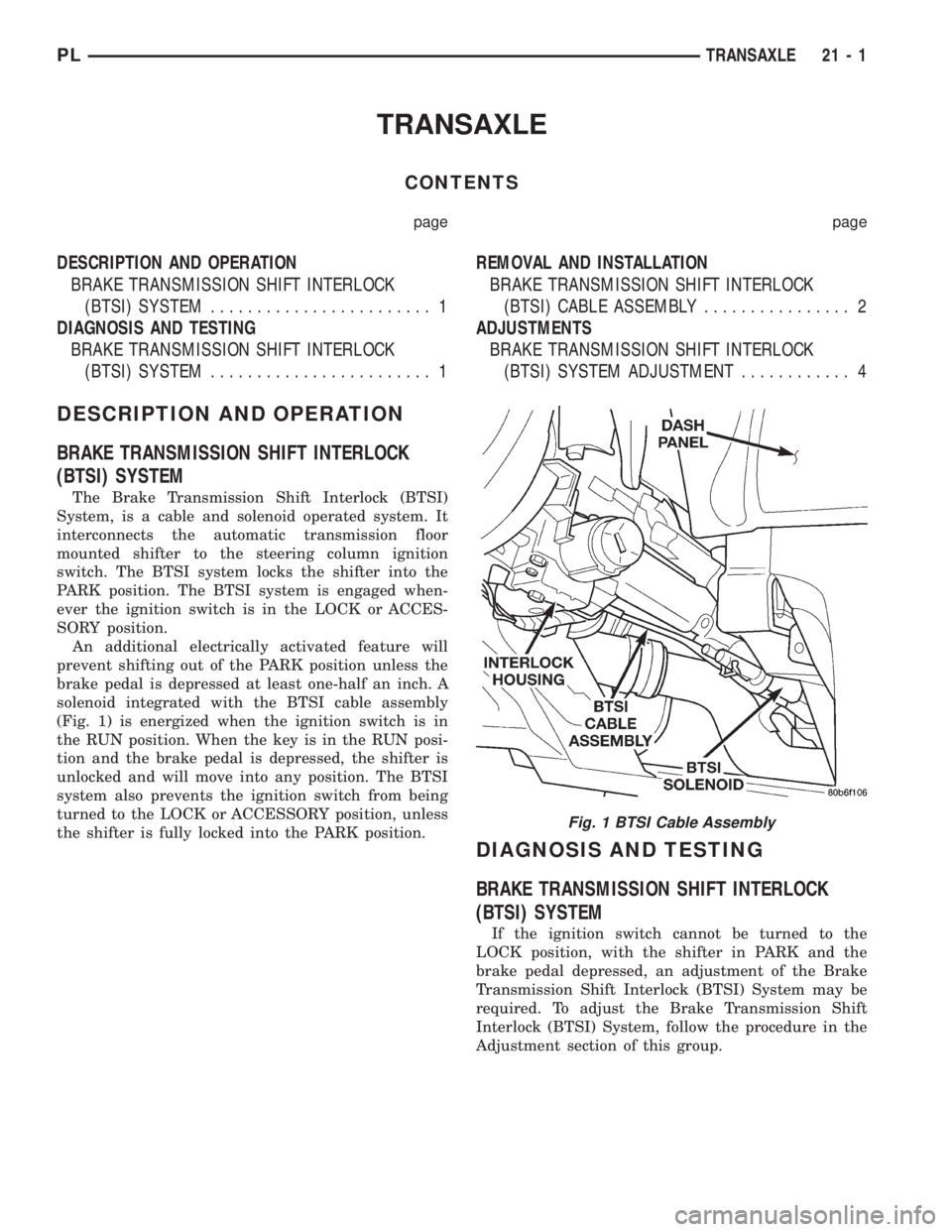

The Brake Transmission Shift Interlock (BTSI)

System, is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch. The BTSI system locks the shifter into the

PARK position. The BTSI system is engaged when-

ever the ignition switch is in the LOCK or ACCES-

SORY position.

An additional electrically activated feature will

prevent shifting out of the PARK position unless the

brake pedal is depressed at least one-half an inch. A

solenoid integrated with the BTSI cable assembly

(Fig. 1) is energized when the ignition switch is in

the RUN position. When the key is in the RUN posi-

tion and the brake pedal is depressed, the shifter is

unlocked and will move into any position. The BTSI

system also prevents the ignition switch from being

turned to the LOCK or ACCESSORY position, unless

the shifter is fully locked into the PARK position.

DIAGNOSIS AND TESTING

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) SYSTEM

If the ignition switch cannot be turned to the

LOCK position, with the shifter in PARK and the

brake pedal depressed, an adjustment of the Brake

Transmission Shift Interlock (BTSI) System may be

required. To adjust the Brake Transmission Shift

Interlock (BTSI) System, follow the procedure in the

Adjustment section of this group.

Fig. 1 BTSI Cable Assembly

PLTRANSAXLE 21 - 1

Page 1065 of 1200

REMOVAL AND INSTALLATION

BRAKE TRANSMISSION SHIFT INTERLOCK

(BTSI) CABLE ASSEMBLY

REMOVAL

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

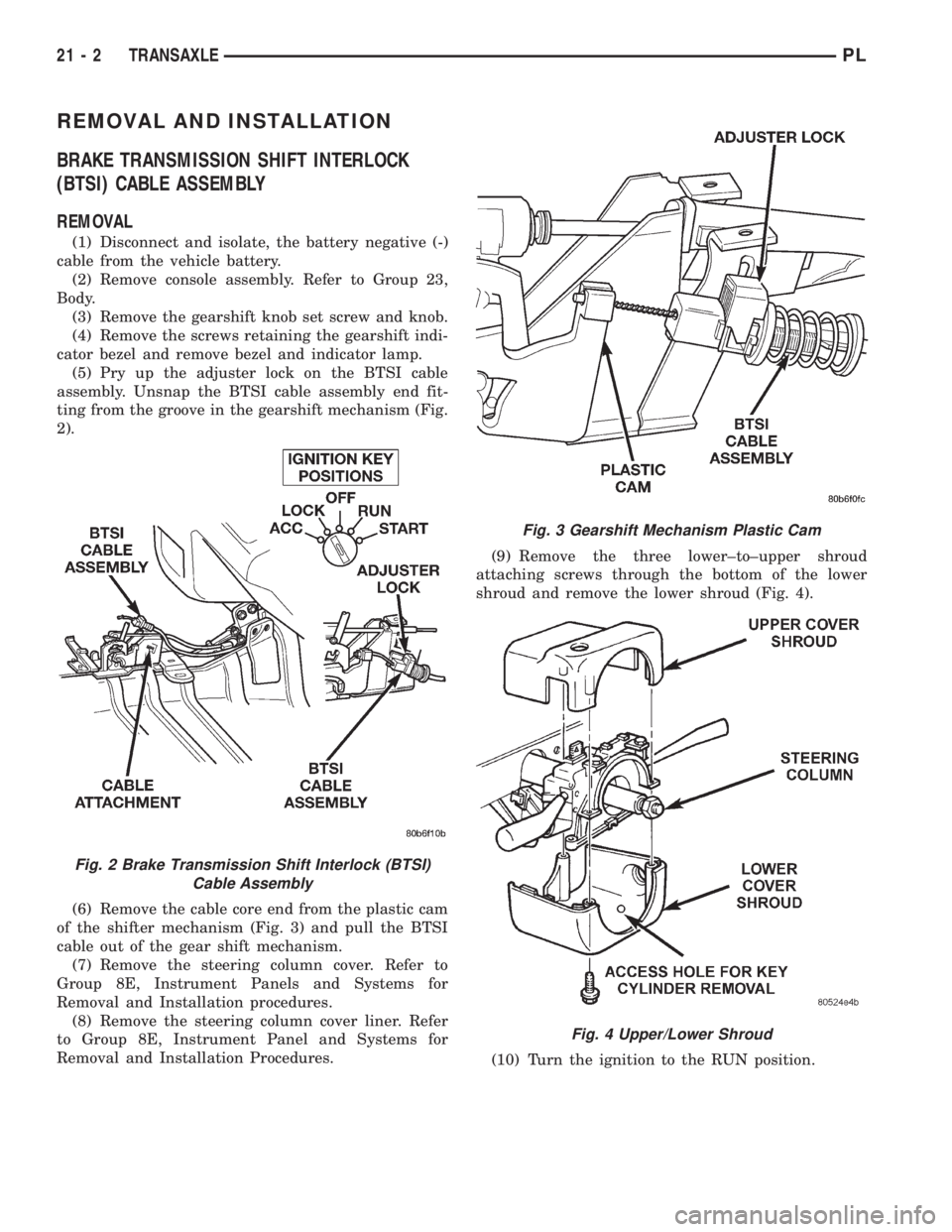

(5) Pry up the adjuster lock on the BTSI cable

assembly. Unsnap the BTSI cable assembly end fit-

ting from the groove in the gearshift mechanism (Fig.

2).

(6) Remove the cable core end from the plastic cam

of the shifter mechanism (Fig. 3) and pull the BTSI

cable out of the gear shift mechanism.

(7) Remove the steering column cover. Refer to

Group 8E, Instrument Panels and Systems for

Removal and Installation procedures.

(8) Remove the steering column cover liner. Refer

to Group 8E, Instrument Panel and Systems for

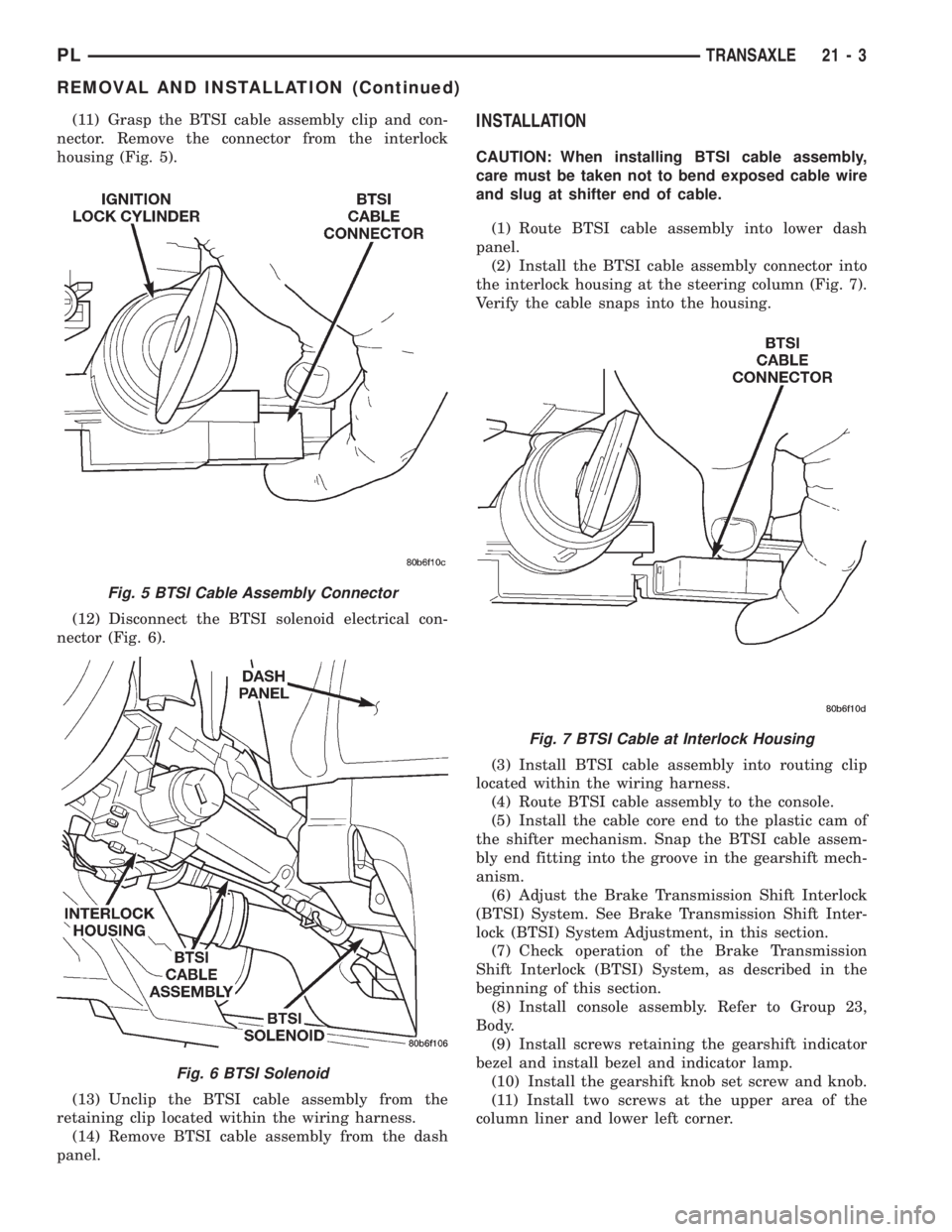

Removal and Installation Procedures.(9) Remove the three lower±to±upper shroud

attaching screws through the bottom of the lower

shroud and remove the lower shroud (Fig. 4).

(10) Turn the ignition to the RUN position.

Fig. 2 Brake Transmission Shift Interlock (BTSI)

Cable Assembly

Fig. 3 Gearshift Mechanism Plastic Cam

Fig. 4 Upper/Lower Shroud

21 - 2 TRANSAXLEPL

Page 1066 of 1200

(11) Grasp the BTSI cable assembly clip and con-

nector. Remove the connector from the interlock

housing (Fig. 5).

(12) Disconnect the BTSI solenoid electrical con-

nector (Fig. 6).

(13) Unclip the BTSI cable assembly from the

retaining clip located within the wiring harness.

(14) Remove BTSI cable assembly from the dash

panel.INSTALLATION

CAUTION: When installing BTSI cable assembly,

care must be taken not to bend exposed cable wire

and slug at shifter end of cable.

(1) Route BTSI cable assembly into lower dash

panel.

(2) Install the BTSI cable assembly connector into

the interlock housing at the steering column (Fig. 7).

Verify the cable snaps into the housing.

(3) Install BTSI cable assembly into routing clip

located within the wiring harness.

(4) Route BTSI cable assembly to the console.

(5) Install the cable core end to the plastic cam of

the shifter mechanism. Snap the BTSI cable assem-

bly end fitting into the groove in the gearshift mech-

anism.

(6) Adjust the Brake Transmission Shift Interlock

(BTSI) System. See Brake Transmission Shift Inter-

lock (BTSI) System Adjustment, in this section.

(7) Check operation of the Brake Transmission

Shift Interlock (BTSI) System, as described in the

beginning of this section.

(8) Install console assembly. Refer to Group 23,

Body.

(9) Install screws retaining the gearshift indicator

bezel and install bezel and indicator lamp.

(10) Install the gearshift knob set screw and knob.

(11) Install two screws at the upper area of the

column liner and lower left corner.

Fig. 5 BTSI Cable Assembly Connector

Fig. 6 BTSI Solenoid

Fig. 7 BTSI Cable at Interlock Housing

PLTRANSAXLE 21 - 3

REMOVAL AND INSTALLATION (Continued)