steering DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1070 of 1200

weather temperature varies widely. Tire pressure will

decrease when the outdoor temperature drops.

Inflation pressures specified on the placard are

always the cold inflation pressure of the tire. Cold

inflation pressure is obtained after the vehicle has

not been operated for at least 3 hours, or the vehicle

is driven less than one mile after being inoperative

for 3 hours. Tire inflation pressures may increase

from 2 to 6 pounds per square inch (psi) during oper-

ation. Do not reduce this normal pressure build-up.

WARNING: OVER OR UNDER INFLATED TIRES

CAN AFFECT VEHICLE HANDLING. THE TIRE CAN

FAIL SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

TIRE PRESSURE FOR HIGH SPEED OPERATION

Chrysler Corporation advocates driving at safe

speeds within posted speed limits. Where speed lim-

its allow the vehicle to be driven at high speeds, cor-

rect tire inflation pressure is very important. For

speeds up to and including 120 km/h (75 mph), tires

must be inflated to the pressures shown on the tire

placard. For continuous speeds in excess of 120 km/h

(75 mph), tires must be inflated to the maximum

pressure specified on the tire sidewall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommend that tires equivalent to the origi-

nal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires not listed in the specifica-

tion charts may cause interference with vehicle com-

ponents. Under extremes of suspension and steering

travel, interference with vehicle components may

cause tire damage.WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DIAGNOSIS AND TESTING

PRESSURE GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

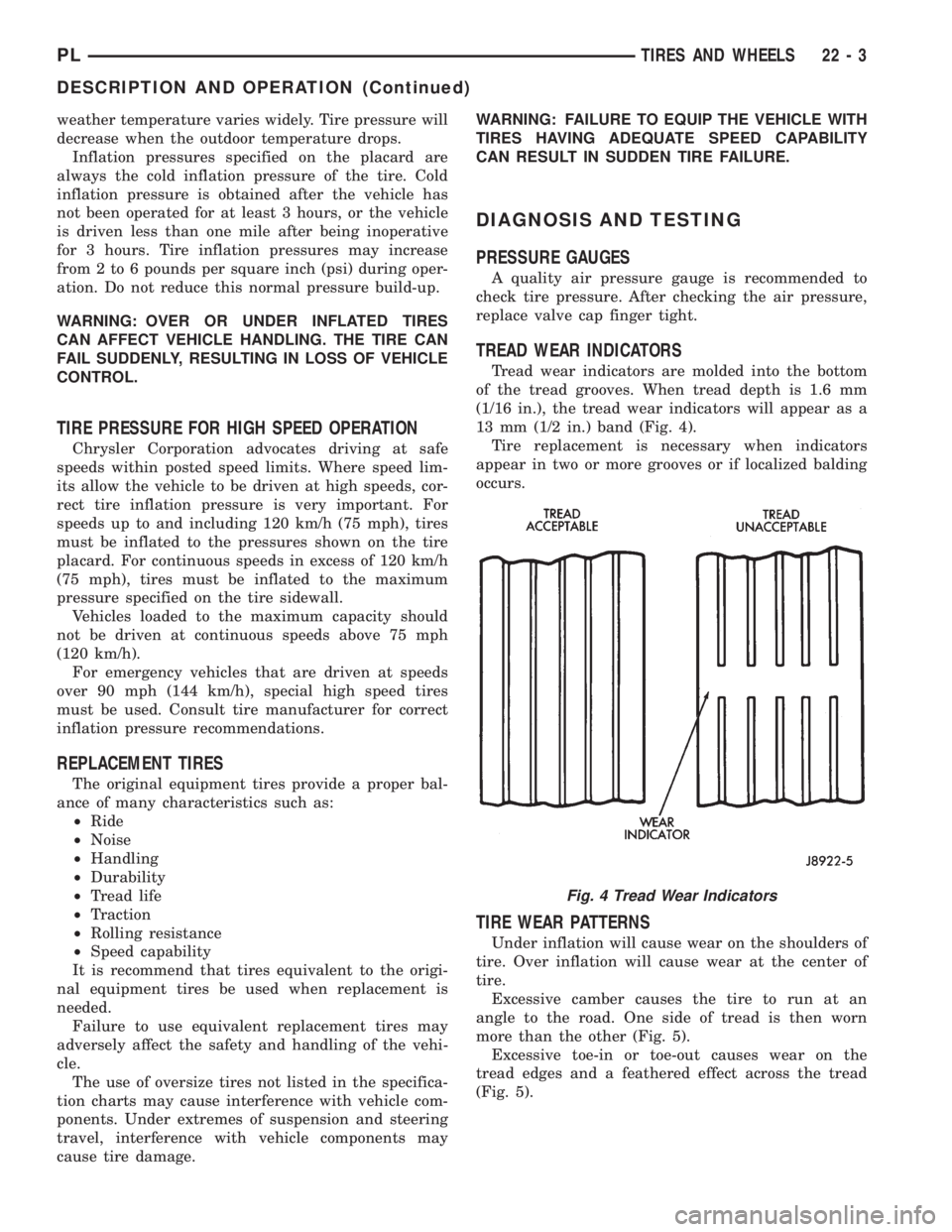

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 4).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

TIRE WEAR PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 5).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 5).

Fig. 4 Tread Wear Indicators

PLTIRES AND WHEELS 22 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1077 of 1200

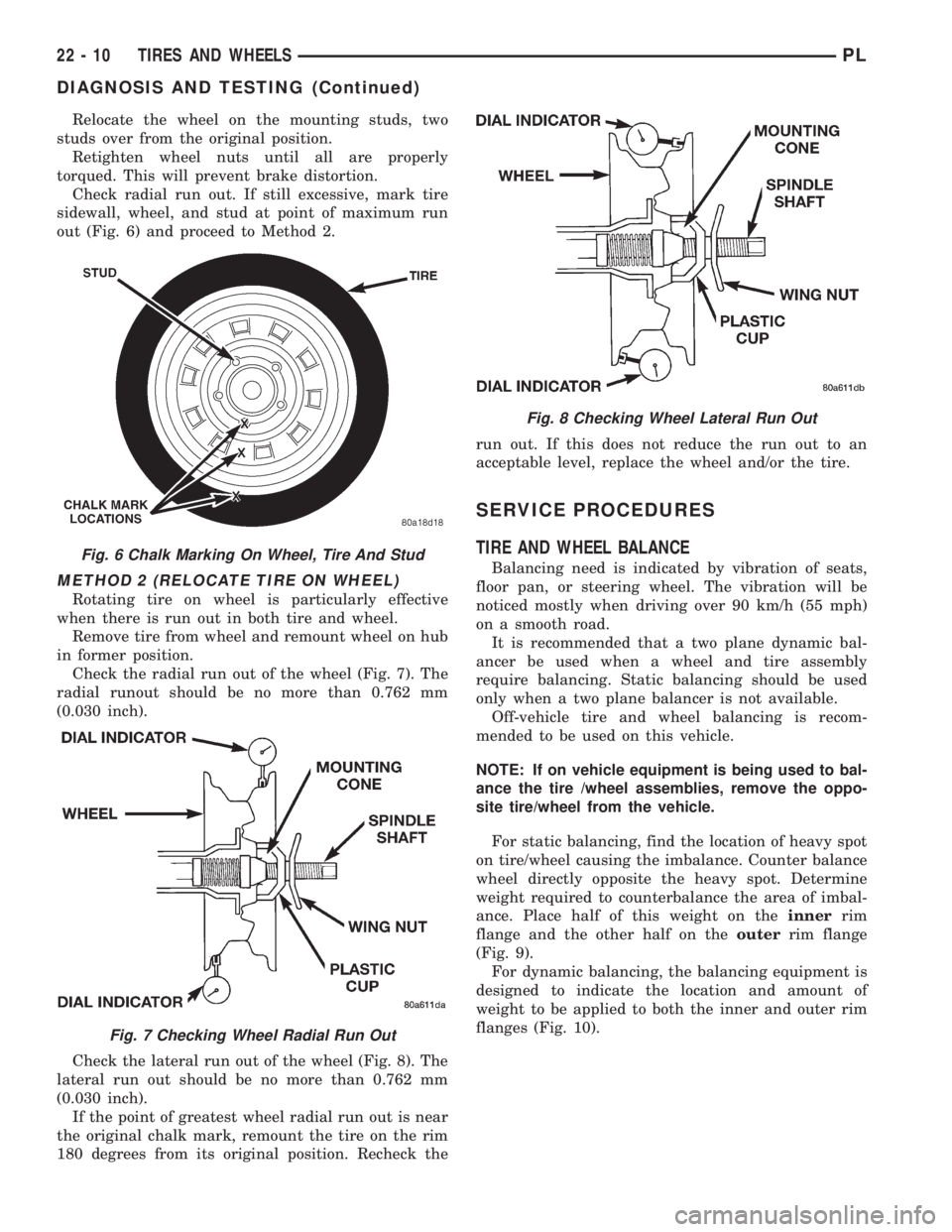

Relocate the wheel on the mounting studs, two

studs over from the original position.

Retighten wheel nuts until all are properly

torqued. This will prevent brake distortion.

Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 6) and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel.

Remove tire from wheel and remount wheel on hub

in former position.

Check the radial run out of the wheel (Fig. 7). The

radial runout should be no more than 0.762 mm

(0.030 inch).

Check the lateral run out of the wheel (Fig. 8). The

lateral run out should be no more than 0.762 mm

(0.030 inch).

If the point of greatest wheel radial run out is near

the original chalk mark, remount the tire on the rim

180 degrees from its original position. Recheck therun out. If this does not reduce the run out to an

acceptable level, replace the wheel and/or the tire.

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 90 km/h (55 mph)

on a smooth road.

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static balancing should be used

only when a two plane balancer is not available.

Off-vehicle tire and wheel balancing is recom-

mended to be used on this vehicle.

NOTE: If on vehicle equipment is being used to bal-

ance the tire /wheel assemblies, remove the oppo-

site tire/wheel from the vehicle.

For static balancing, find the location of heavy spot

on tire/wheel causing the imbalance. Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counterbalance the area of imbal-

ance. Place half of this weight on theinnerrim

flange and the other half on theouterrim flange

(Fig. 9).

For dynamic balancing, the balancing equipment is

designed to indicate the location and amount of

weight to be applied to both the inner and outer rim

flanges (Fig. 10).Fig. 6 Chalk Marking On Wheel, Tire And Stud

Fig. 7 Checking Wheel Radial Run Out

Fig. 8 Checking Wheel Lateral Run Out

22 - 10 TIRES AND WHEELSPL

DIAGNOSIS AND TESTING (Continued)

Page 1165 of 1200

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the CCD Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.

Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

²The preferred and most accurate method of

retrieving a DTC is by using the DRB scan tool. The

scan tool supplies detailed diagnostic information

which can be used to more accurately diagnose

causes for a DTC.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

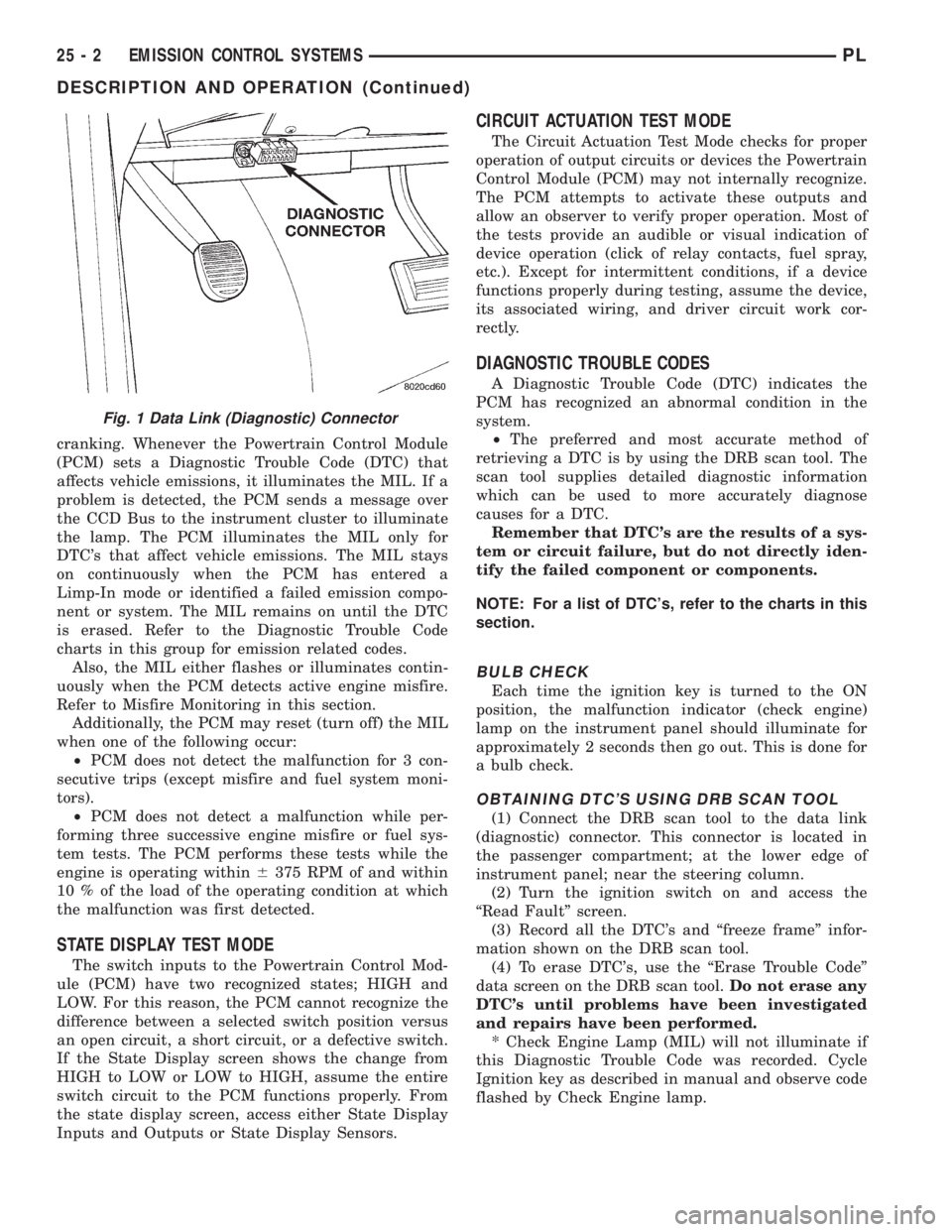

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

* Check Engine Lamp (MIL) will not illuminate if

this Diagnostic Trouble Code was recorded. Cycle

Ignition key as described in manual and observe code

flashed by Check Engine lamp.

Fig. 1 Data Link (Diagnostic) Connector

25 - 2 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1168 of 1200

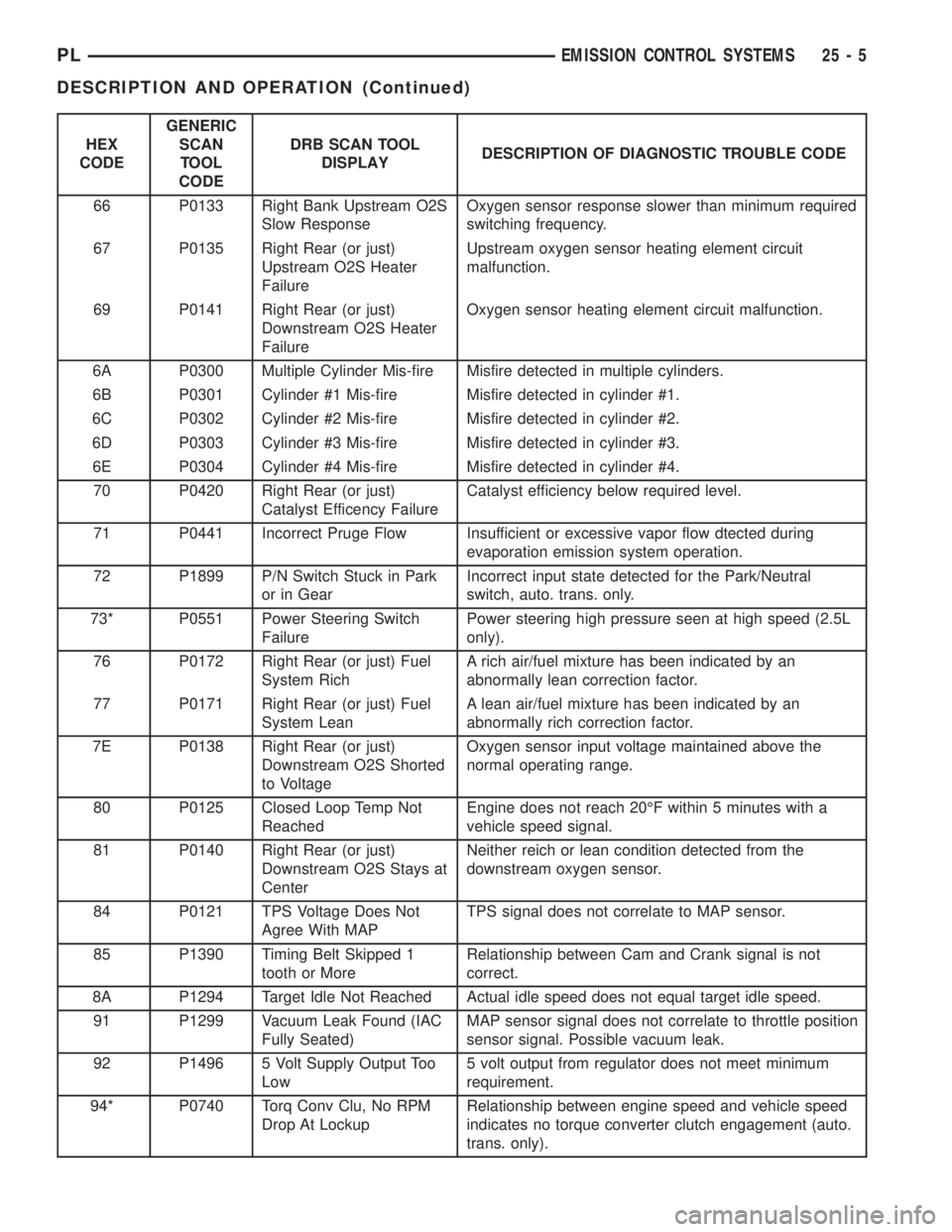

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC TROUBLE CODE

66 P0133 Right Bank Upstream O2S

Slow ResponseOxygen sensor response slower than minimum required

switching frequency.

67 P0135 Right Rear (or just)

Upstream O2S Heater

FailureUpstream oxygen sensor heating element circuit

malfunction.

69 P0141 Right Rear (or just)

Downstream O2S Heater

FailureOxygen sensor heating element circuit malfunction.

6A P0300 Multiple Cylinder Mis-fire Misfire detected in multiple cylinders.

6B P0301 Cylinder #1 Mis-fire Misfire detected in cylinder #1.

6C P0302 Cylinder #2 Mis-fire Misfire detected in cylinder #2.

6D P0303 Cylinder #3 Mis-fire Misfire detected in cylinder #3.

6E P0304 Cylinder #4 Mis-fire Misfire detected in cylinder #4.

70 P0420 Right Rear (or just)

Catalyst Efficency FailureCatalyst efficiency below required level.

71 P0441 Incorrect Pruge Flow Insufficient or excessive vapor flow dtected during

evaporation emission system operation.

72 P1899 P/N Switch Stuck in Park

or in GearIncorrect input state detected for the Park/Neutral

switch, auto. trans. only.

73* P0551 Power Steering Switch

FailurePower steering high pressure seen at high speed (2.5L

only).

76 P0172 Right Rear (or just) Fuel

System RichA rich air/fuel mixture has been indicated by an

abnormally lean correction factor.

77 P0171 Right Rear (or just) Fuel

System LeanA lean air/fuel mixture has been indicated by an

abnormally rich correction factor.

7E P0138 Right Rear (or just)

Downstream O2S Shorted

to VoltageOxygen sensor input voltage maintained above the

normal operating range.

80 P0125 Closed Loop Temp Not

ReachedEngine does not reach 20ÉF within 5 minutes with a

vehicle speed signal.

81 P0140 Right Rear (or just)

Downstream O2S Stays at

CenterNeither reich or lean condition detected from the

downstream oxygen sensor.

84 P0121 TPS Voltage Does Not

Agree With MAPTPS signal does not correlate to MAP sensor.

85 P1390 Timing Belt Skipped 1

tooth or MoreRelationship between Cam and Crank signal is not

correct.

8A P1294 Target Idle Not Reached Actual idle speed does not equal target idle speed.

91 P1299 Vacuum Leak Found (IAC

Fully Seated)MAP sensor signal does not correlate to throttle position

sensor signal. Possible vacuum leak.

92 P1496 5 Volt Supply Output Too

Low5 volt output from regulator does not meet minimum

requirement.

94* P0740 Torq Conv Clu, No RPM

Drop At LockupRelationship between engine speed and vehicle speed

indicates no torque converter clutch engagement (auto.

trans. only).

PLEMISSION CONTROL SYSTEMS 25 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1182 of 1200

DIAGNOSIS AND TESTING

EGR SYSTEM ON-BOARD DIAGNOSTICS

The PCM performs an on-board diagnostic check of

the EGR system. The diagnostic system uses the

electronic EGR transducer for the system tests.

The diagnostic check activates only during selected

engine/driving conditions. When the conditions are

met, the PCM energizes the transducer solenoid to

disable the EGR. The PCM checks for a change in

the heated oxygen sensor signal. If the air-fuel mix-

ture goes lean, the PCM will attempt to enrichen the

mixture. The PCM registers a Diagnostic Trouble

Code (DTC) if the EGR system is not operating cor-

rectly. After registering a DTC, the PCM turns on the

malfunction indicator (Check Engine) lamp after 2

consecutive trips. There are 2 types of failures sensed

by the PCM. The first is a short or open in the elec-

trical solenoid circuit. the second is a mechhanical

failure or loss of vacuum. The Malfunction Indicator

Lamp (MIL) indicates the need for service.

If a problem is indicated by the MIL and a DTC for

the EGR system is set, check for proper operation of

the EGR system. Use the System Test, EGR Gas

Flow Test. If the EGR system tests properly, check

the system using the DRB scan tool. Refer to

On-Board Diagnosis sections in this Group. Also,

refer to the DRB scan tool and the appropriate Pow-

ertrain Diagnostics Procedure manual.

EGR SYSTEM TEST

WARNING: APPLY PARKING BRAKE AND/OR

BLOCK WHEELS BEFORE TESTING THE EGR SYS-

TEM.

(1) Check the condition of all EGR system hoses

and tubes for leaks, blockages, cracks, kinks and

hardening of rubber hoses. Repair and correct these

conditions before performing any tests.

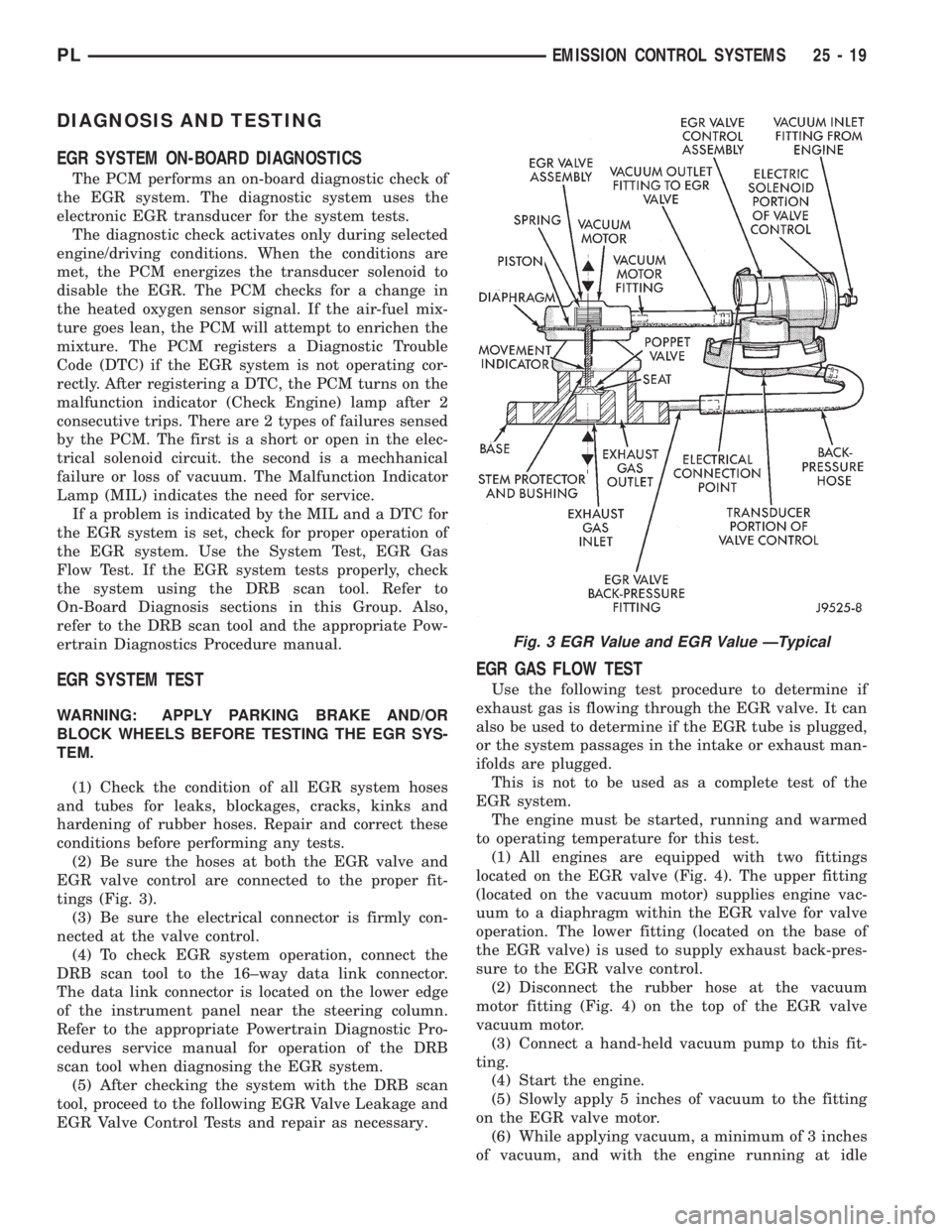

(2) Be sure the hoses at both the EGR valve and

EGR valve control are connected to the proper fit-

tings (Fig. 3).

(3) Be sure the electrical connector is firmly con-

nected at the valve control.

(4) To check EGR system operation, connect the

DRB scan tool to the 16±way data link connector.

The data link connector is located on the lower edge

of the instrument panel near the steering column.

Refer to the appropriate Powertrain Diagnostic Pro-

cedures service manual for operation of the DRB

scan tool when diagnosing the EGR system.

(5) After checking the system with the DRB scan

tool, proceed to the following EGR Valve Leakage and

EGR Valve Control Tests and repair as necessary.

EGR GAS FLOW TEST

Use the following test procedure to determine if

exhaust gas is flowing through the EGR valve. It can

also be used to determine if the EGR tube is plugged,

or the system passages in the intake or exhaust man-

ifolds are plugged.

This is not to be used as a complete test of the

EGR system.

The engine must be started, running and warmed

to operating temperature for this test.

(1) All engines are equipped with two fittings

located on the EGR valve (Fig. 4). The upper fitting

(located on the vacuum motor) supplies engine vac-

uum to a diaphragm within the EGR valve for valve

operation. The lower fitting (located on the base of

the EGR valve) is used to supply exhaust back-pres-

sure to the EGR valve control.

(2) Disconnect the rubber hose at the vacuum

motor fitting (Fig. 4) on the top of the EGR valve

vacuum motor.

(3) Connect a hand-held vacuum pump to this fit-

ting.

(4) Start the engine.

(5) Slowly apply 5 inches of vacuum to the fitting

on the EGR valve motor.

(6) While applying vacuum, a minimum of 3 inches

of vacuum, and with the engine running at idle

Fig. 3 EGR Value and EGR Value ÐTypical

PLEMISSION CONTROL SYSTEMS 25 - 19

Page 1200 of 1200

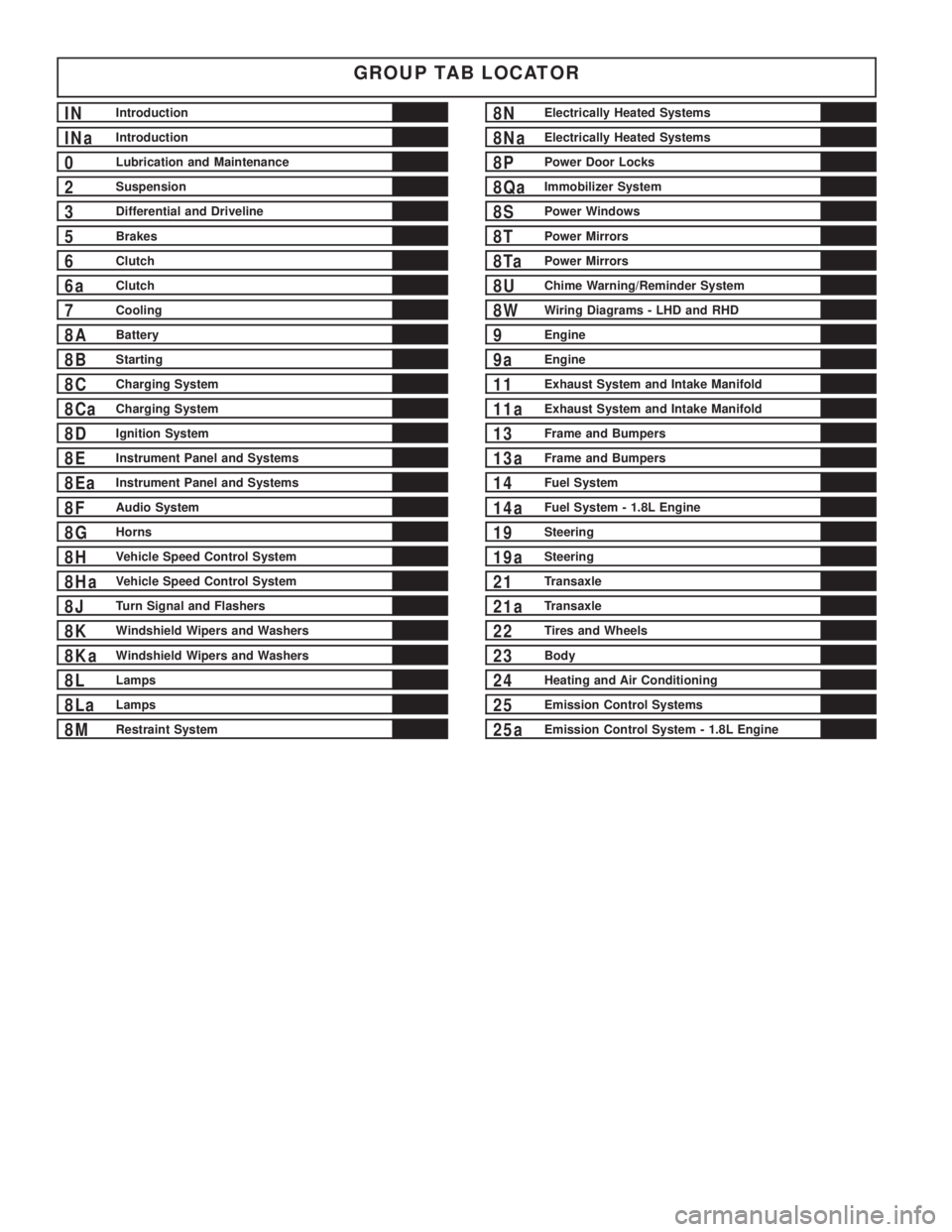

GROUP TAB LOCATOR

INIntroduction

INaIntroduction

0Lubrication and Maintenance

2Suspension

3Differential and Driveline

5Brakes

6Clutch

6aClutch

7Cooling

8ABattery

8BStarting

8CCharging System

8CaCharging System

8DIgnition System

8EInstrument Panel and Systems

8EaInstrument Panel and Systems

8FAudio System

8GHorns

8HVehicle Speed Control System

8HaVehicle Speed Control System

8JTurn Signal and Flashers

8KWindshield Wipers and Washers

8KaWindshield Wipers and Washers

8LLamps

8LaLamps

8MRestraint System

8NElectrically Heated Systems

8NaElectrically Heated Systems

8PPower Door Locks

8QaImmobilizer System

8SPower Windows

8TPower Mirrors

8TaPower Mirrors

8UChime Warning/Reminder System

8WWiring Diagrams - LHD and RHD

9Engine

9aEngine

11Exhaust System and Intake Manifold

11aExhaust System and Intake Manifold

13Frame and Bumpers

13aFrame and Bumpers

14Fuel System

14aFuel System - 1.8L Engine

19Steering

19aSteering

21Transaxle

21aTransaxle

22Tires and Wheels

23Body

24Heating and Air Conditioning

25Emission Control Systems

25aEmission Control System - 1.8L Engine