change time DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 780 of 1200

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

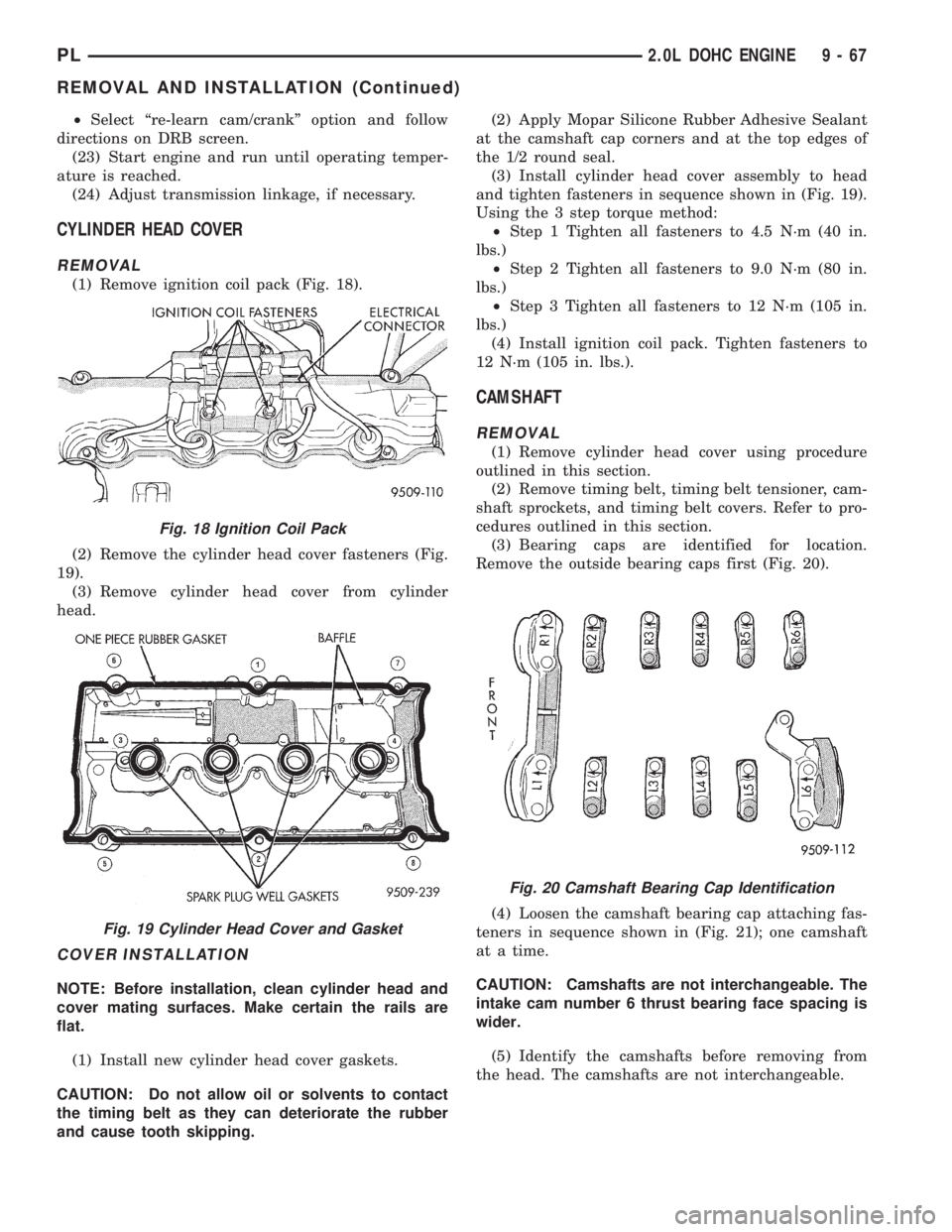

(1) Remove ignition coil pack (Fig. 18).

(2) Remove the cylinder head cover fasteners (Fig.

19).

(3) Remove cylinder head cover from cylinder

head.

COVER INSTALLATION

NOTE: Before installation, clean cylinder head and

cover mating surfaces. Make certain the rails are

flat.

(1) Install new cylinder head cover gaskets.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.(2) Apply Mopar Silicone Rubber Adhesive Sealant

at the camshaft cap corners and at the top edges of

the 1/2 round seal.

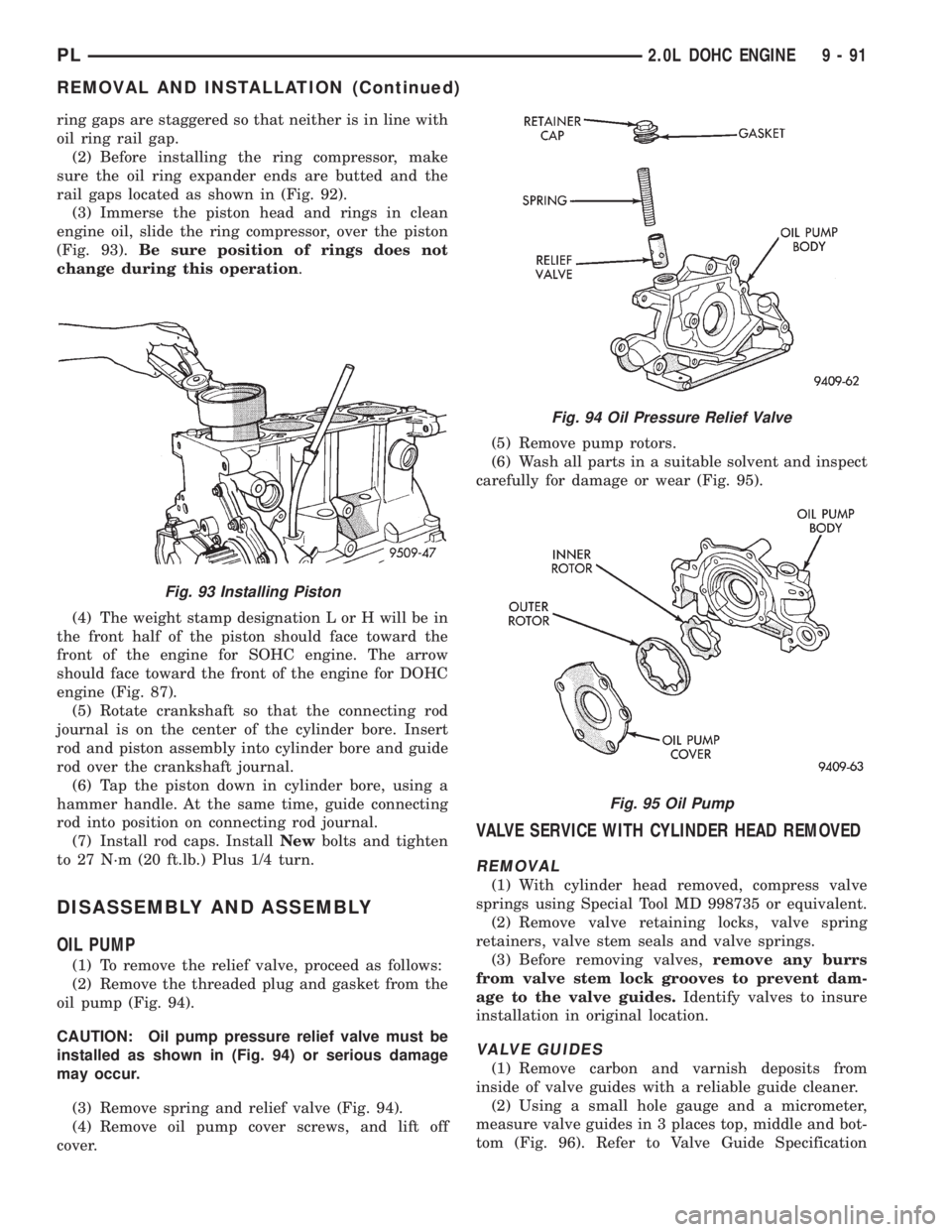

(3) Install cylinder head cover assembly to head

and tighten fasteners in sequence shown in (Fig. 19).

Using the 3 step torque method:

²Step 1 Tighten all fasteners to 4.5 N´m (40 in.

lbs.)

²Step 2 Tighten all fasteners to 9.0 N´m (80 in.

lbs.)

²Step 3 Tighten all fasteners to 12 N´m (105 in.

lbs.)

(4) Install ignition coil pack. Tighten fasteners to

12 N´m (105 in. lbs.).

CAMSHAFT

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Remove timing belt, timing belt tensioner, cam-

shaft sprockets, and timing belt covers. Refer to pro-

cedures outlined in this section.

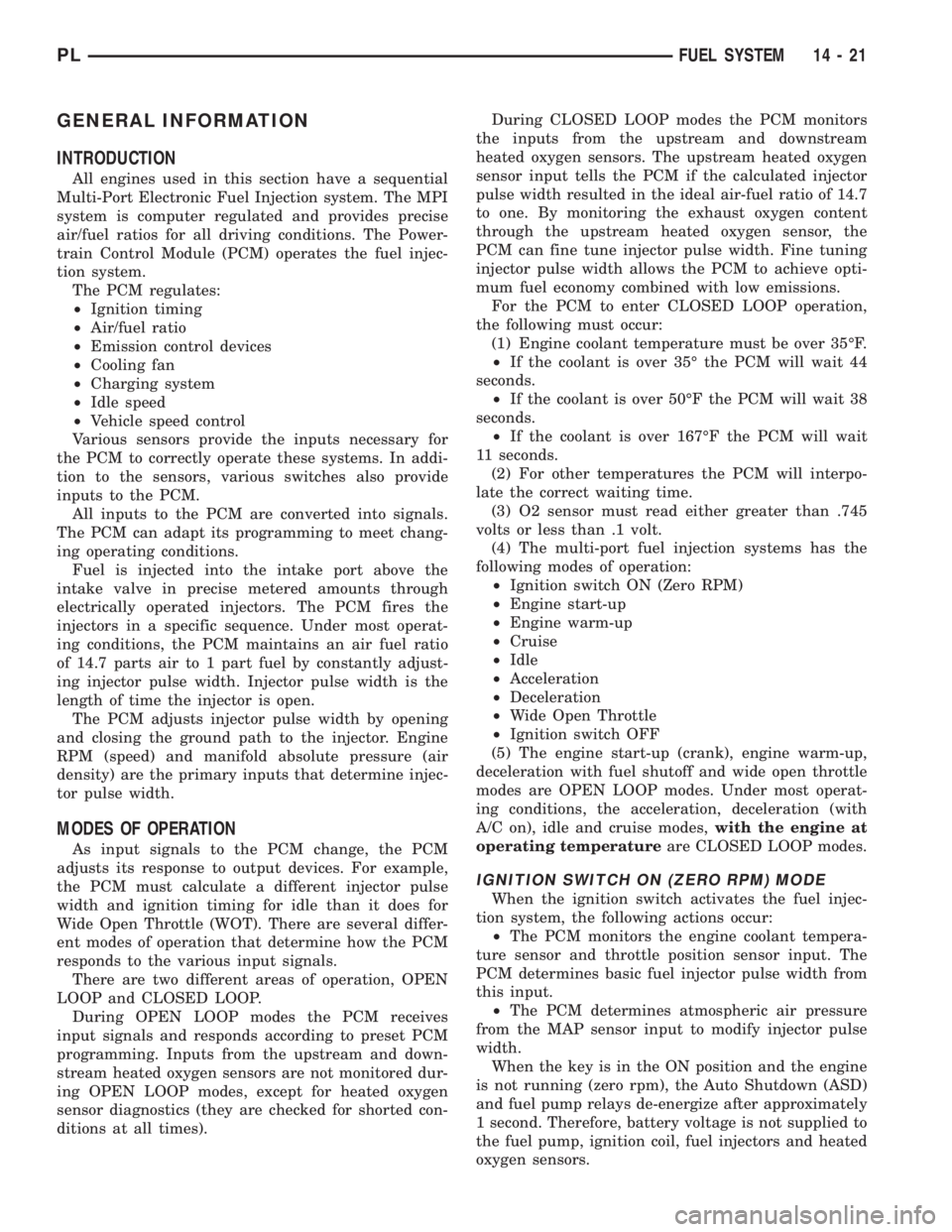

(3) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 20).

(4) Loosen the camshaft bearing cap attaching fas-

teners in sequence shown in (Fig. 21); one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

(5) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

Fig. 18 Ignition Coil Pack

Fig. 19 Cylinder Head Cover and Gasket

Fig. 20 Camshaft Bearing Cap Identification

PL2.0L DOHC ENGINE 9 - 67

REMOVAL AND INSTALLATION (Continued)

Page 804 of 1200

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 92).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 93).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine for SOHC engine. The arrow

should face toward the front of the engine for DOHC

engine (Fig. 87).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(7) Install rod caps. InstallNewbolts and tighten

to 27 N´m (20 ft.lb.) Plus 1/4 turn.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 94).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 94) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 94).

(4) Remove oil pump cover screws, and lift off

cover.(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 95).

VALVE SERVICE WITH CYLINDER HEAD REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool MD 998735 or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 96). Refer to Valve Guide Specification

Fig. 93 Installing Piston

Fig. 94 Oil Pressure Relief Valve

Fig. 95 Oil Pump

PL2.0L DOHC ENGINE 9 - 91

REMOVAL AND INSTALLATION (Continued)

Page 862 of 1200

GENERAL INFORMATION

INTRODUCTION

All engines used in this section have a sequential

Multi-Port Electronic Fuel Injection system. The MPI

system is computer regulated and provides precise

air/fuel ratios for all driving conditions. The Power-

train Control Module (PCM) operates the fuel injec-

tion system.

The PCM regulates:

²Ignition timing

²Air/fuel ratio

²Emission control devices

²Cooling fan

²Charging system

²Idle speed

²Vehicle speed control

Various sensors provide the inputs necessary for

the PCM to correctly operate these systems. In addi-

tion to the sensors, various switches also provide

inputs to the PCM.

All inputs to the PCM are converted into signals.

The PCM can adapt its programming to meet chang-

ing operating conditions.

Fuel is injected into the intake port above the

intake valve in precise metered amounts through

electrically operated injectors. The PCM fires the

injectors in a specific sequence. Under most operat-

ing conditions, the PCM maintains an air fuel ratio

of 14.7 parts air to 1 part fuel by constantly adjust-

ing injector pulse width. Injector pulse width is the

length of time the injector is open.

The PCM adjusts injector pulse width by opening

and closing the ground path to the injector. Engine

RPM (speed) and manifold absolute pressure (air

density) are the primary inputs that determine injec-

tor pulse width.

MODES OF OPERATION

As input signals to the PCM change, the PCM

adjusts its response to output devices. For example,

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygen

sensor diagnostics (they are checked for shorted con-

ditions at all times).During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than .745

volts or less than .1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.

IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

PLFUEL SYSTEM 14 - 21

Page 864 of 1200

below the minimum acceptable percentage, the PCM

stores a diagnostic trouble code in memory.

During certain idle conditions, the PCM may enter

a variable idle speed strategy. During variable idle

speed strategy the PCM adjusts engine speed based

on the following inputs.

²A/C sense

²Battery voltage

²Battery temperature

²Engine coolant temperature

²Engine run time

²Power steering pressure switch

²Vehicle mileage

ACCELERATION MODE

This is a CLOSED LOOP mode. The PCM recog-

nizes an abrupt increase in Throttle Position sensor

output voltage or MAP sensor output voltage as a

demand for increased engine output and vehicle

acceleration. The PCM increases injector pulse width

in response to increased fuel demand.

DECELERATION MODE

This is a CLOSED LOOP mode. During decelera-

tion the following inputs are received by the PCM:

²A/C pressure transducer

²A/C sense

²Battery voltage

²Intake air temperature

²Engine coolant temperature

²Crankshaft position (engine speed)

²Exhaust gas oxygen content (upstream heated

oxygen sensor)

²Knock sensor

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²IAC motor control changes in respones to MAP

sensor feedback

The PCM may receive a closed throttle input from

the Throttle Position Sensor (TPS) when it senses an

abrupt decrease in manifold pressure. This indicates

a hard deceleration. In response, the PCM may

momentarily turn off the injectors. This helps

improve fuel economy, emissions and engine braking.

If decel fuel shutoff is detected, downstream oxy-

gen sensor diagnostics is performed.

WIDE-OPEN-THROTTLE MODE

This is an OPEN LOOP mode. During wide-open-

throttle operation, the following inputs are received

by the PCM:

²Intake air temperature

²Engine coolant temperature

²Engine speed

²Knock sensor

²Manifold absolute pressure²Throttle position

When the PCM senses a wide-open-throttle condi-

tion through the Throttle Position Sensor (TPS) it de-

energizes the A/C compressor clutch relay. This

disables the air conditioning system.

The PCM does not monitor the heated oxygen sen-

sor inputs during wide-open-throttle operation except

for downstream heated oxygen sensor and both

shorted diagnostics. The PCM adjusts injector pulse

width to supply a predetermined amount of addi-

tional fuel.

IGNITION SWITCH OFF MODE

When the operator turns the ignition switch to the

OFF position, the following occurs:

²All outputs are turned off, unless 02 Heater

Monitor test is being run. Refer to Group 25,

On-Board Diagnostics.

²No inputs are monitored except for the heated

oxygen sensors. The PCM monitors the heating ele-

ments in the oxygen sensors and then shuts down.

DESCRIPTION AND OPERATION

SYSTEM DIAGNOSIS

The PCM can test many of its own input and out-

put circuits. If the PCM senses a fault in a major

system, the PCM stores a Diagnostic Trouble Code

(DTC) in memory.

For DTC information, refer to Group 25, Emission

Control Systems. See On-Board Diagnostics.

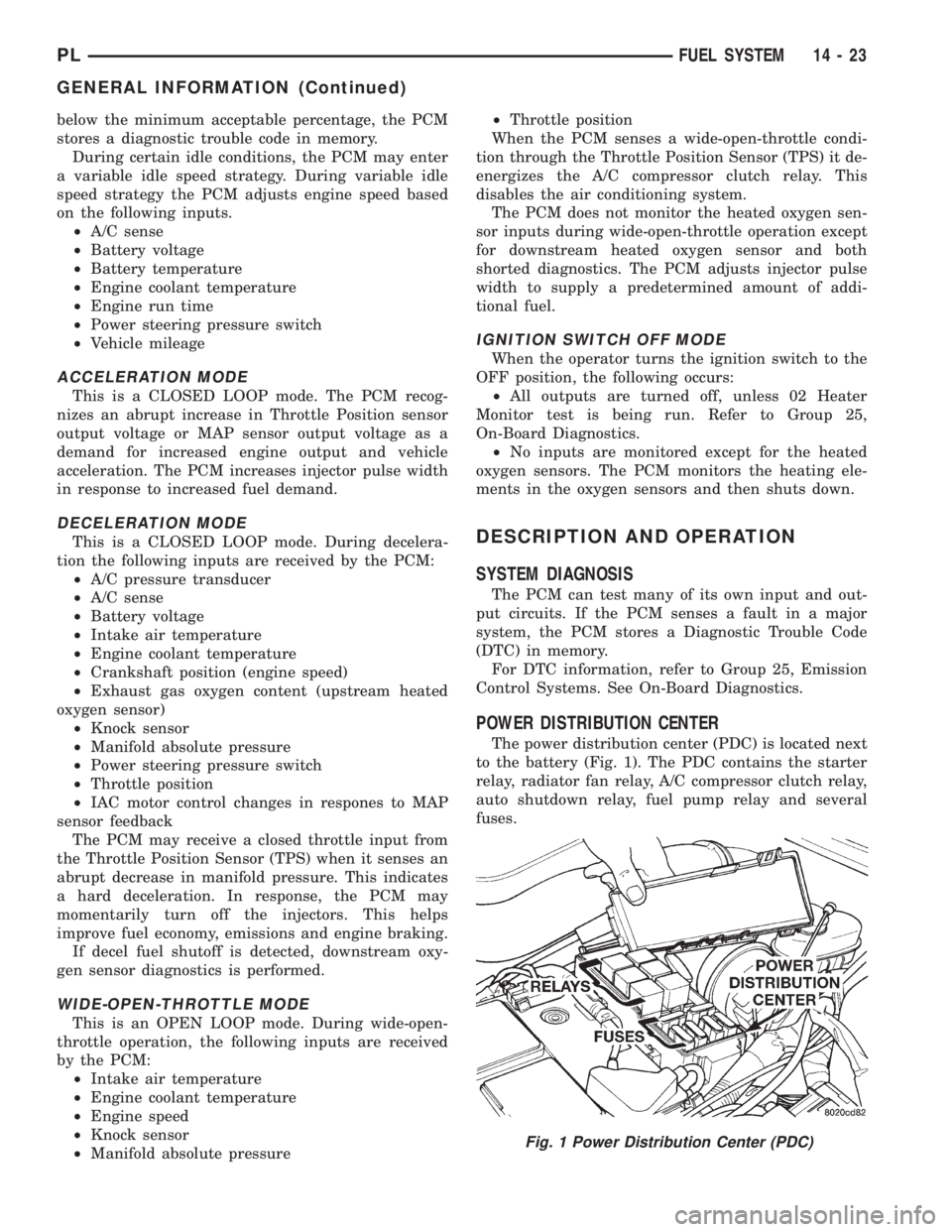

POWER DISTRIBUTION CENTER

The power distribution center (PDC) is located next

to the battery (Fig. 1). The PDC contains the starter

relay, radiator fan relay, A/C compressor clutch relay,

auto shutdown relay, fuel pump relay and several

fuses.

Fig. 1 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 23

GENERAL INFORMATION (Continued)

Page 865 of 1200

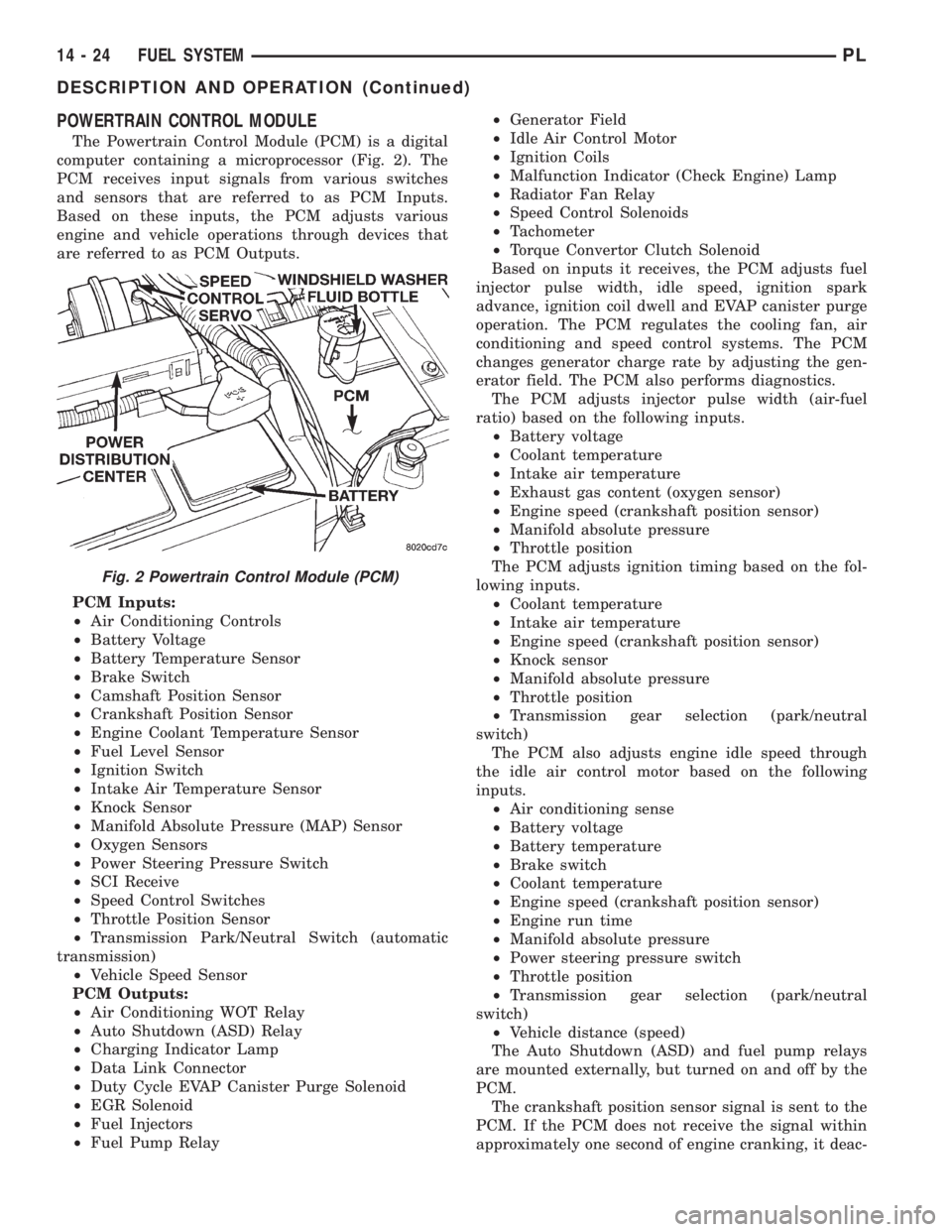

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) is a digital

computer containing a microprocessor (Fig. 2). The

PCM receives input signals from various switches

and sensors that are referred to as PCM Inputs.

Based on these inputs, the PCM adjusts various

engine and vehicle operations through devices that

are referred to as PCM Outputs.

PCM Inputs:

²Air Conditioning Controls

²Battery Voltage

²Battery Temperature Sensor

²Brake Switch

²Camshaft Position Sensor

²Crankshaft Position Sensor

²Engine Coolant Temperature Sensor

²Fuel Level Sensor

²Ignition Switch

²Intake Air Temperature Sensor

²Knock Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensors

²Power Steering Pressure Switch

²SCI Receive

²Speed Control Switches

²Throttle Position Sensor

²Transmission Park/Neutral Switch (automatic

transmission)

²Vehicle Speed Sensor

PCM Outputs:

²Air Conditioning WOT Relay

²Auto Shutdown (ASD) Relay

²Charging Indicator Lamp

²Data Link Connector

²Duty Cycle EVAP Canister Purge Solenoid

²EGR Solenoid

²Fuel Injectors

²Fuel Pump Relay²Generator Field

²Idle Air Control Motor

²Ignition Coils

²Malfunction Indicator (Check Engine) Lamp

²Radiator Fan Relay

²Speed Control Solenoids

²Tachometer

²Torque Convertor Clutch Solenoid

Based on inputs it receives, the PCM adjusts fuel

injector pulse width, idle speed, ignition spark

advance, ignition coil dwell and EVAP canister purge

operation. The PCM regulates the cooling fan, air

conditioning and speed control systems. The PCM

changes generator charge rate by adjusting the gen-

erator field. The PCM also performs diagnostics.

The PCM adjusts injector pulse width (air-fuel

ratio) based on the following inputs.

²Battery voltage

²Coolant temperature

²Intake air temperature

²Exhaust gas content (oxygen sensor)

²Engine speed (crankshaft position sensor)

²Manifold absolute pressure

²Throttle position

The PCM adjusts ignition timing based on the fol-

lowing inputs.

²Coolant temperature

²Intake air temperature

²Engine speed (crankshaft position sensor)

²Knock sensor

²Manifold absolute pressure

²Throttle position

²Transmission gear selection (park/neutral

switch)

The PCM also adjusts engine idle speed through

the idle air control motor based on the following

inputs.

²Air conditioning sense

²Battery voltage

²Battery temperature

²Brake switch

²Coolant temperature

²Engine speed (crankshaft position sensor)

²Engine run time

²Manifold absolute pressure

²Power steering pressure switch

²Throttle position

²Transmission gear selection (park/neutral

switch)

²Vehicle distance (speed)

The Auto Shutdown (ASD) and fuel pump relays

are mounted externally, but turned on and off by the

PCM.

The crankshaft position sensor signal is sent to the

PCM. If the PCM does not receive the signal within

approximately one second of engine cranking, it deac-

Fig. 2 Powertrain Control Module (PCM)

14 - 24 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 866 of 1200

tivates the ASD relay and fuel pump relay. When

these relays deactivate, power is shut off from the

fuel injectors, ignition coils, heating element in the

oxygen sensors and the fuel pump.

The PCM contains a voltage converter that

changes battery voltage to a regulated 9 volts direct

current to power the camshaft position sensor, crank-

shaft position sensor and vehicle speed sensor. The

PCM also provides a 5 volt direct current supply for

the manifold absolute pressure sensor and throttle

position sensor.

AIR CONDITIONING PRESSURE TRANSDUCERÐ

PCM INPUT

The Powertrain Control Module (PCM) monitors

the A/C compressor discharge (high side) pressure

through the air conditioning pressure transducer.

The transducer supplies an input to the PCM. The

PCM engages the A/C compressor clutch if pressure

is sufficient for A/C system operation.

AUTOMATIC SHUTDOWN (ASD) SENSEÐPCM

INPUT

The ASD sense circuit informs the PCM when the

ASD relay energizes. A 12 volt signal at this input

indicates to the PCM that the ASD has been acti-

vated. This input is used only to sense that the ASD

relay is energized.

When energized, the ASD relay supplies battery

voltage to the fuel injectors, ignition coils and the

heating element in each oxygen sensor. If the PCM

does not receive 12 volts from this input after

grounding the ASD relay, it sets a Diagnostic Trouble

Code (DTC).

BATTERY VOLTAGEÐPCM INPUT

The PCM monitors the battery voltage input to

determine fuel injector pulse width and generator

field control.

If battery voltage is low the PCM will increase

injector pulse width (period of time that the injector

is energized).

BATTERY TEMPERATURE SENSORÐPCM INPUT

The PCM uses the temperature of the battery area

to control the charge rate. The signal is used to reg-

ulate the system voltage. The system voltage is

higher at cold temperatures and is gradually reduced

as temperature is increased.

BRAKE SWITCHÐPCM INPUT

When the brake switch is activated, the PCM

receives an input indicating that the brakes are

being applied. The brake switch is mounted on the

brake pedal support bracket.

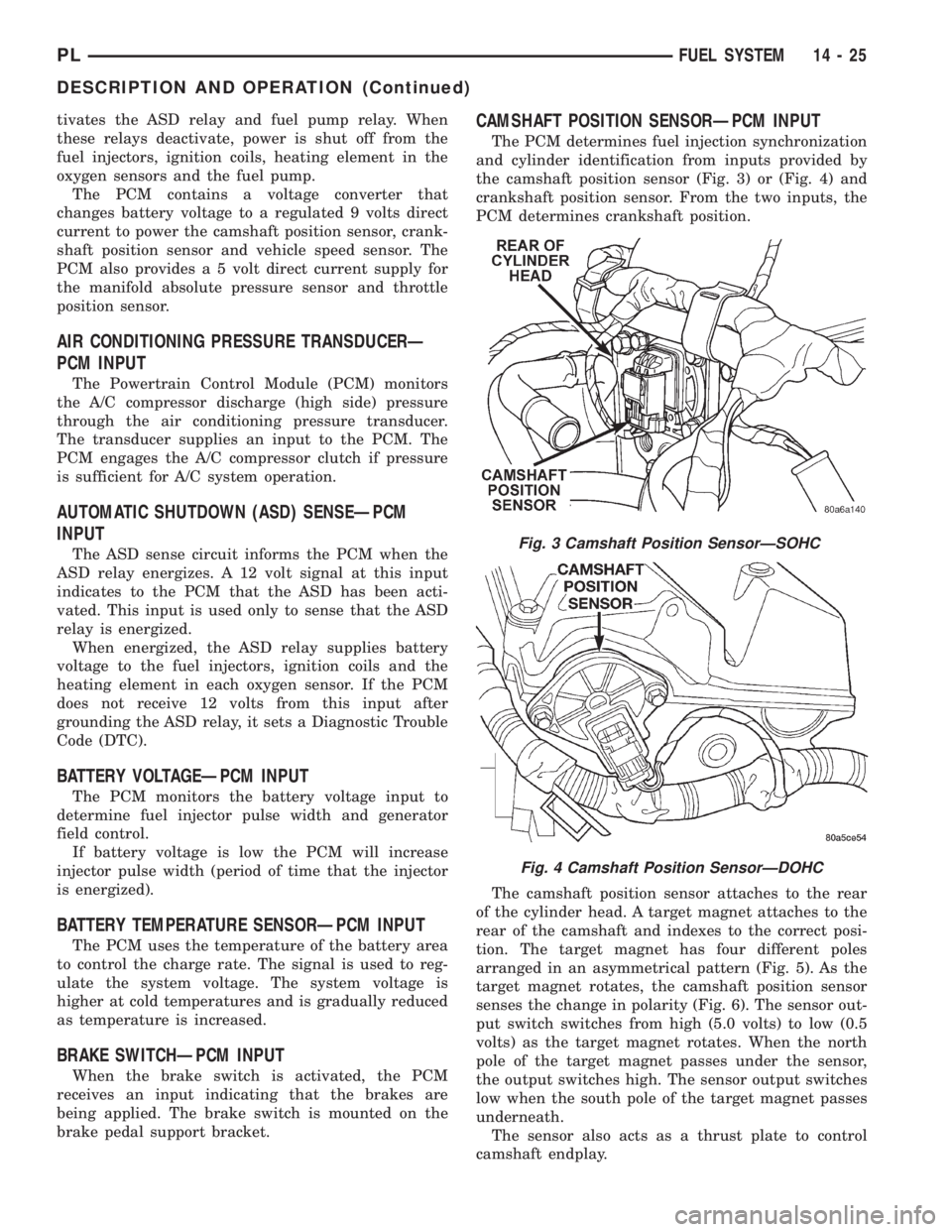

CAMSHAFT POSITION SENSORÐPCM INPUT

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

the camshaft position sensor (Fig. 3) or (Fig. 4) and

crankshaft position sensor. From the two inputs, the

PCM determines crankshaft position.

The camshaft position sensor attaches to the rear

of the cylinder head. A target magnet attaches to the

rear of the camshaft and indexes to the correct posi-

tion. The target magnet has four different poles

arranged in an asymmetrical pattern (Fig. 5). As the

target magnet rotates, the camshaft position sensor

senses the change in polarity (Fig. 6). The sensor out-

put switch switches from high (5.0 volts) to low (0.5

volts) as the target magnet rotates. When the north

pole of the target magnet passes under the sensor,

the output switches high. The sensor output switches

low when the south pole of the target magnet passes

underneath.

The sensor also acts as a thrust plate to control

camshaft endplay.

Fig. 3 Camshaft Position SensorÐSOHC

Fig. 4 Camshaft Position SensorÐDOHC

PLFUEL SYSTEM 14 - 25

DESCRIPTION AND OPERATION (Continued)

Page 867 of 1200

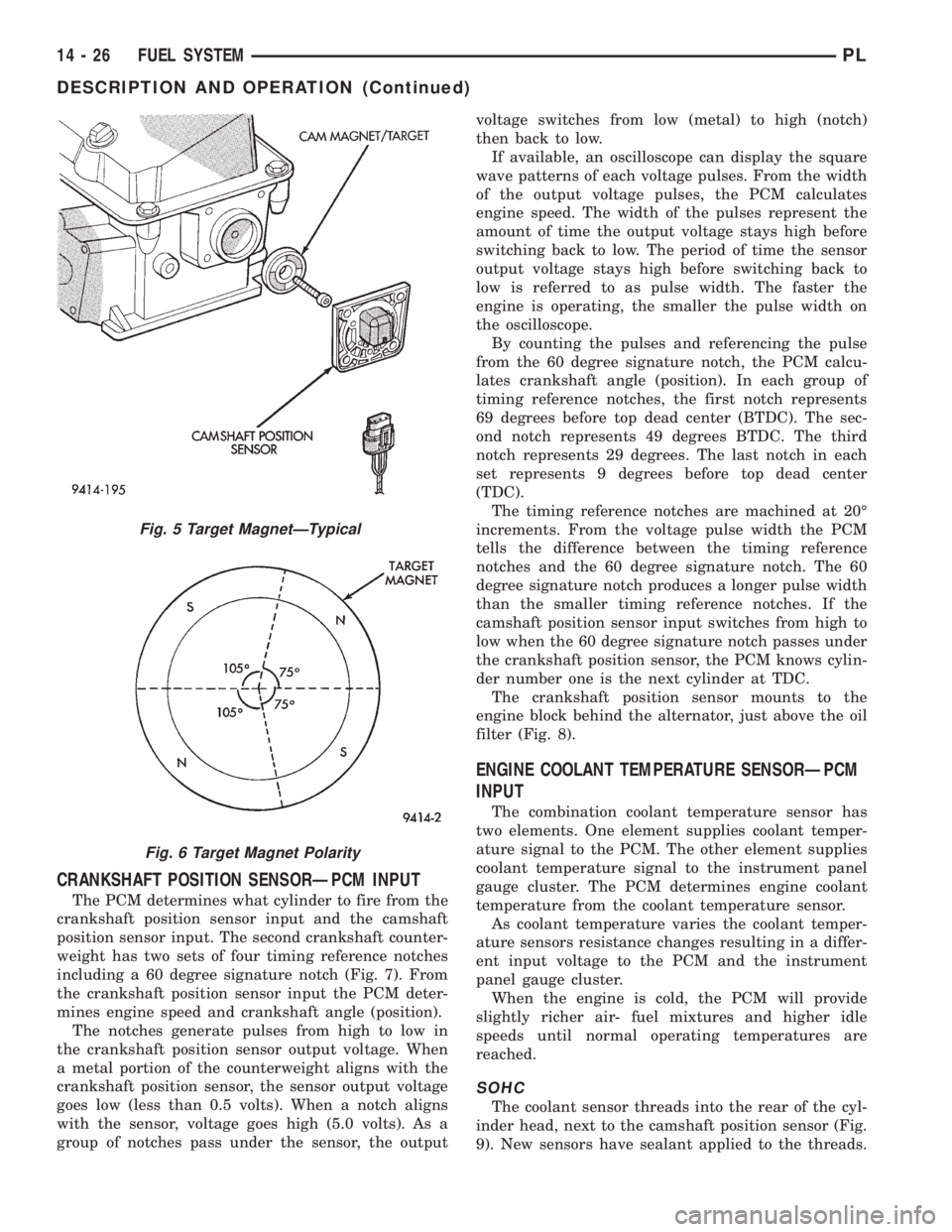

CRANKSHAFT POSITION SENSORÐPCM INPUT

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has two sets of four timing reference notches

including a 60 degree signature notch (Fig. 7). From

the crankshaft position sensor input the PCM deter-

mines engine speed and crankshaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the outputvoltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulses. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined at 20É

increments. From the voltage pulse width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The crankshaft position sensor mounts to the

engine block behind the alternator, just above the oil

filter (Fig. 8).

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The combination coolant temperature sensor has

two elements. One element supplies coolant temper-

ature signal to the PCM. The other element supplies

coolant temperature signal to the instrument panel

gauge cluster. The PCM determines engine coolant

temperature from the coolant temperature sensor.

As coolant temperature varies the coolant temper-

ature sensors resistance changes resulting in a differ-

ent input voltage to the PCM and the instrument

panel gauge cluster.

When the engine is cold, the PCM will provide

slightly richer air- fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

SOHC

The coolant sensor threads into the rear of the cyl-

inder head, next to the camshaft position sensor (Fig.

9). New sensors have sealant applied to the threads.

Fig. 5 Target MagnetÐTypical

Fig. 6 Target Magnet Polarity

14 - 26 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 871 of 1200

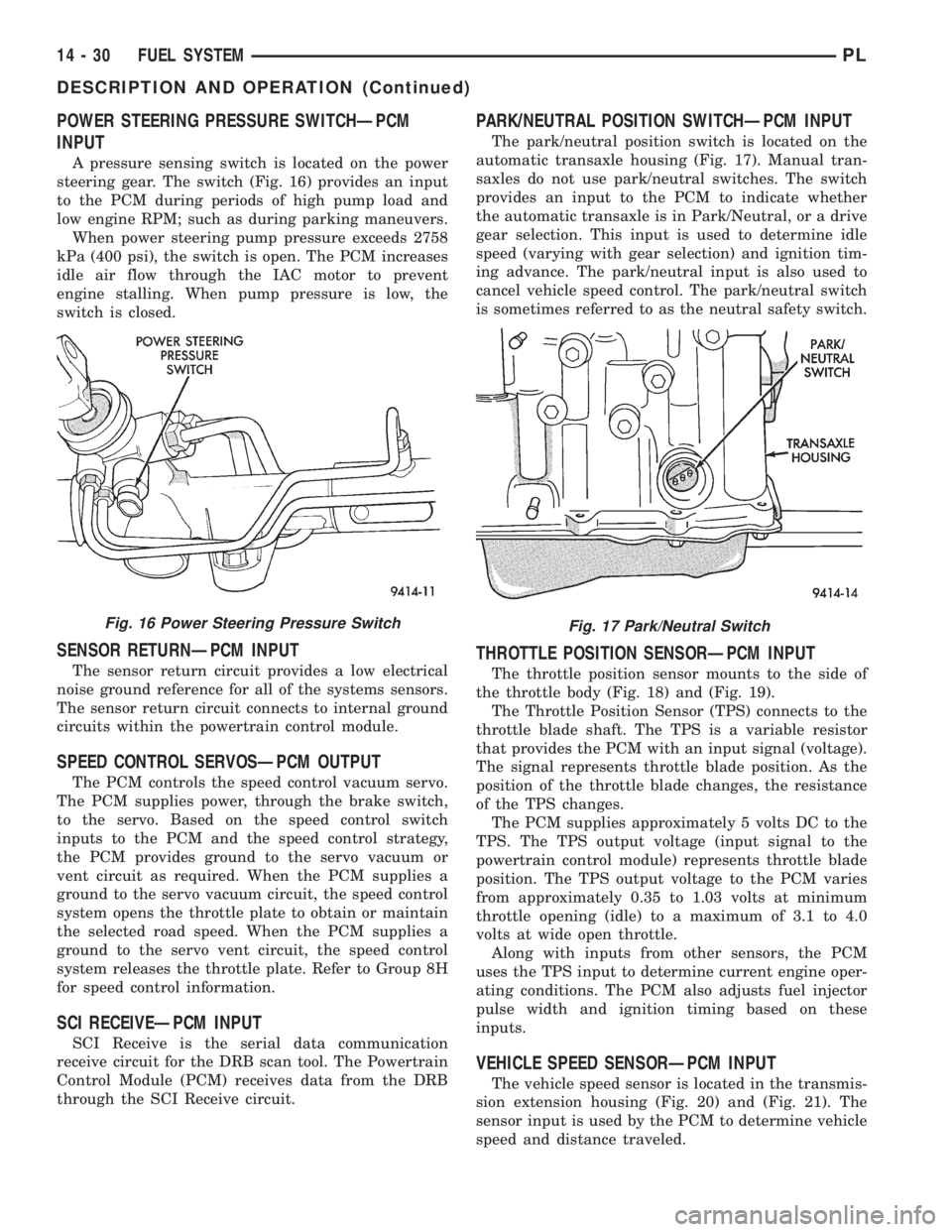

POWER STEERING PRESSURE SWITCHÐPCM

INPUT

A pressure sensing switch is located on the power

steering gear. The switch (Fig. 16) provides an input

to the PCM during periods of high pump load and

low engine RPM; such as during parking maneuvers.

When power steering pump pressure exceeds 2758

kPa (400 psi), the switch is open. The PCM increases

idle air flow through the IAC motor to prevent

engine stalling. When pump pressure is low, the

switch is closed.

SENSOR RETURNÐPCM INPUT

The sensor return circuit provides a low electrical

noise ground reference for all of the systems sensors.

The sensor return circuit connects to internal ground

circuits within the powertrain control module.

SPEED CONTROL SERVOSÐPCM OUTPUT

The PCM controls the speed control vacuum servo.

The PCM supplies power, through the brake switch,

to the servo. Based on the speed control switch

inputs to the PCM and the speed control strategy,

the PCM provides ground to the servo vacuum or

vent circuit as required. When the PCM supplies a

ground to the servo vacuum circuit, the speed control

system opens the throttle plate to obtain or maintain

the selected road speed. When the PCM supplies a

ground to the servo vent circuit, the speed control

system releases the throttle plate. Refer to Group 8H

for speed control information.

SCI RECEIVEÐPCM INPUT

SCI Receive is the serial data communication

receive circuit for the DRB scan tool. The Powertrain

Control Module (PCM) receives data from the DRB

through the SCI Receive circuit.

PARK/NEUTRAL POSITION SWITCHÐPCM INPUT

The park/neutral position switch is located on the

automatic transaxle housing (Fig. 17). Manual tran-

saxles do not use park/neutral switches. The switch

provides an input to the PCM to indicate whether

the automatic transaxle is in Park/Neutral, or a drive

gear selection. This input is used to determine idle

speed (varying with gear selection) and ignition tim-

ing advance. The park/neutral input is also used to

cancel vehicle speed control. The park/neutral switch

is sometimes referred to as the neutral safety switch.

THROTTLE POSITION SENSORÐPCM INPUT

The throttle position sensor mounts to the side of

the throttle body (Fig. 18) and (Fig. 19).

The Throttle Position Sensor (TPS) connects to the

throttle blade shaft. The TPS is a variable resistor

that provides the PCM with an input signal (voltage).

The signal represents throttle blade position. As the

position of the throttle blade changes, the resistance

of the TPS changes.

The PCM supplies approximately 5 volts DC to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.35 to 1.03 volts at minimum

throttle opening (idle) to a maximum of 3.1 to 4.0

volts at wide open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

VEHICLE SPEED SENSORÐPCM INPUT

The vehicle speed sensor is located in the transmis-

sion extension housing (Fig. 20) and (Fig. 21). The

sensor input is used by the PCM to determine vehicle

speed and distance traveled.

Fig. 16 Power Steering Pressure SwitchFig. 17 Park/Neutral Switch

14 - 30 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 875 of 1200

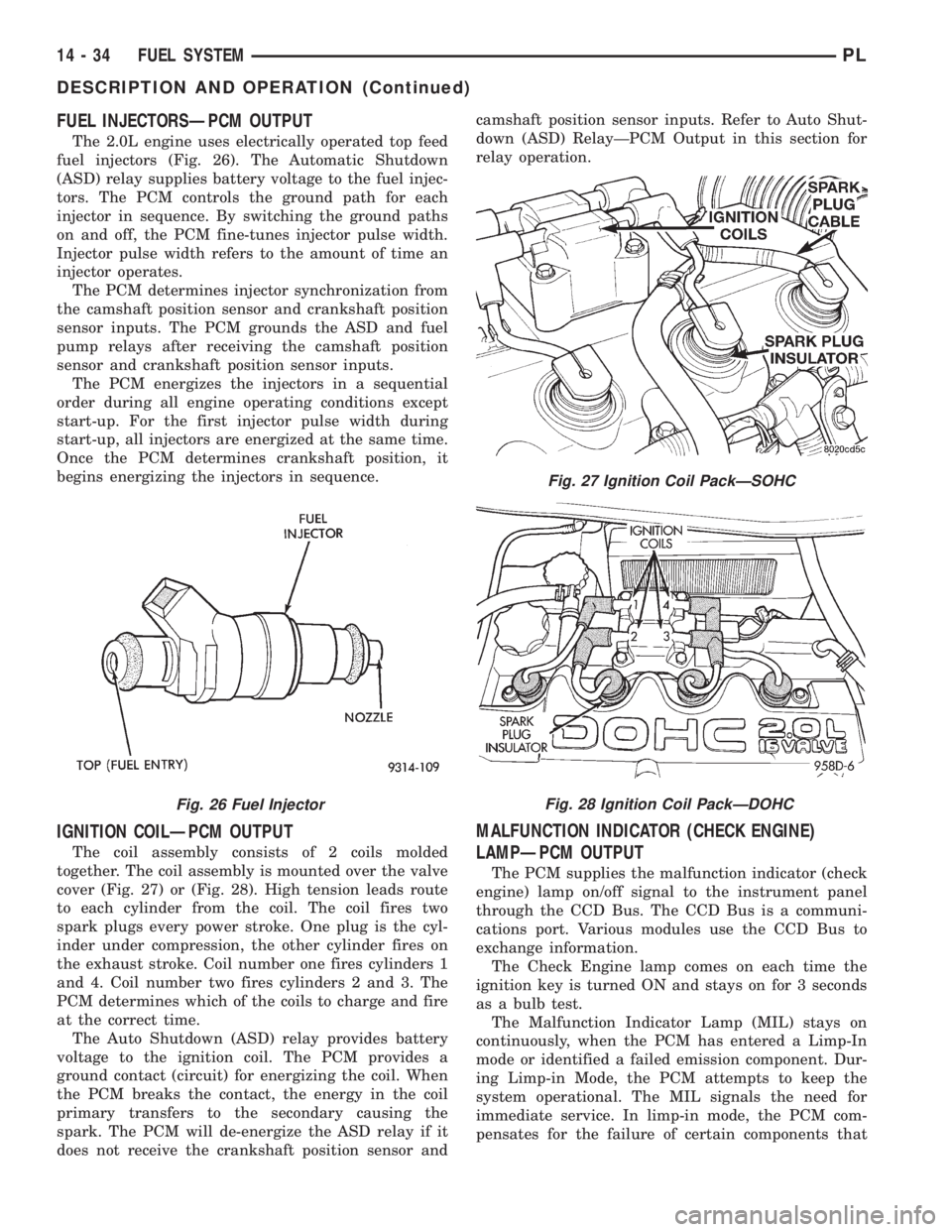

FUEL INJECTORSÐPCM OUTPUT

The 2.0L engine uses electrically operated top feed

fuel injectors (Fig. 26). The Automatic Shutdown

(ASD) relay supplies battery voltage to the fuel injec-

tors. The PCM controls the ground path for each

injector in sequence. By switching the ground paths

on and off, the PCM fine-tunes injector pulse width.

Injector pulse width refers to the amount of time an

injector operates.

The PCM determines injector synchronization from

the camshaft position sensor and crankshaft position

sensor inputs. The PCM grounds the ASD and fuel

pump relays after receiving the camshaft position

sensor and crankshaft position sensor inputs.

The PCM energizes the injectors in a sequential

order during all engine operating conditions except

start-up. For the first injector pulse width during

start-up, all injectors are energized at the same time.

Once the PCM determines crankshaft position, it

begins energizing the injectors in sequence.

IGNITION COILÐPCM OUTPUT

The coil assembly consists of 2 coils molded

together. The coil assembly is mounted over the valve

cover (Fig. 27) or (Fig. 28). High tension leads route

to each cylinder from the coil. The coil fires two

spark plugs every power stroke. One plug is the cyl-

inder under compression, the other cylinder fires on

the exhaust stroke. Coil number one fires cylinders 1

and 4. Coil number two fires cylinders 2 and 3. The

PCM determines which of the coils to charge and fire

at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor andcamshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output in this section for

relay operation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the CCD Bus. The CCD Bus is a communi-

cations port. Various modules use the CCD Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

Fig. 26 Fuel Injector

Fig. 27 Ignition Coil PackÐSOHC

Fig. 28 Ignition Coil PackÐDOHC

14 - 34 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 983 of 1200

31TH AUTOMATIC TRANSAXLE

INDEX

page page

GENERAL INFORMATION

FLUID LEVEL AND CONDITION............. 41

GENERAL INFORMATION................. 40

SELECTION OF LUBRICANT............... 41

SPECIAL ADDITIVES..................... 41

DESCRIPTION AND OPERATION

AUTOMATIC TRANSMISSION SHIFTER/

IGNITION INTERLOCK.................. 42

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR....................... 42

FLOW CONTROL VALVES................. 42

GEARSHIFT AND PARKING LOCK CONTROLS . 42

GOVERNOR............................ 43

HYDRAULIC CONTROL SYSTEM............ 42

PRESSURE REGULATING VALVES.......... 42

PRESSURE SUPPLY SYSTEM.............. 42

TORQUE CONVERTER CLUTCH SOLENOID

WIRING CONNECTOR.................. 43

TORQUE CONVERTER CLUTCH............ 42

DIAGNOSIS AND TESTING

CLUTCH AND SERVO AIR PRESSURE TESTS . 54

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA............ 55

HYDRAULIC PRESSURE TESTS............ 52

INTERLOCK SYSTEM OPERATION CHECK.... 55

ROAD TEST............................ 52

THREE SPEED TRANSAXLE DIAGNOSIS AND

TESTS.............................. 43

SERVICE PROCEDURES

ALUMINUM THREAD REPAIR.............. 58

FLUID AND FILTER CHANGE............... 56

FLUID DRAIN AND REFILL................. 57

FLUSHING COOLERS AND TUBES.......... 58

OIL PUMP VOLUME CHECK............... 58

REMOVAL AND INSTALLATION

GEARSHIFT CABLE...................... 59

GEARSHIFT MECHANISM................. 60

INTERLOCK MECHANISM................. 63

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH........................ 64

PUMP OIL SEAL......................... 67

SHIFTER IGNITION INTERLOCK CABLE...... 61THROTTLE PRESSURE CABLE............. 60

TRANSAXLE........................... 64

VEHICLE SPEED SENSOR PINION GEAR..... 64

DISASSEMBLY AND ASSEMBLY

ACCUMULATOR-RECONDITION............ 83

DIFFERENTIAL REPAIR................... 95

FRONT CLUTCH-RECONDITION............ 78

FRONT PLANETARY AND ANNULUS GEAR-

RECONDITION........................ 81

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION........................ 83

LOW/REVERSE (REAR)

SERVO-RECONDITION.................. 82

OIL PUMP-RECONDITION................. 78

OUTPUT SHAFT REPAIR.................. 89

PARKING PAWL......................... 89

REAR CLUTCH-RECONDITION............. 79

TRANSAXLE........................... 67

TRANSFER SHAFT REPAIR................ 83

VALVE BODY RECONDITION............... 74

CLEANING AND INSPECTION

VALVE BODY........................... 99

ADJUSTMENTS

BAND ADJUSTMENT.................... 101

BEARING ADJUSTMENT PROCEDURES..... 101

DIFFERENTIAL BEARING................. 102

GEARSHIFT CABLE...................... 99

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS....................... 101

OUTPUT SHAFT BEARING................ 102

SHIFTER/IGNITION INTERLOCK SYSTEM.... 100

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE........................ 100

TRANSFER SHAFT BEARING............. 103

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC . 105

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE............ 113

31TH TRANSAXLE TORQUE

SPECIFICATIONS..................... 113

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE............ 114

GENERAL INFORMATION

GENERAL INFORMATION

NOTE: Safety goggles should be worn at all times

when working on these transaxles.This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system. The identifica-

tion markings and usage of the transaxle are charted

in Diagnosis and Tests.

21 - 40 TRANSAXLEPL