maintenance DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 29 of 1200

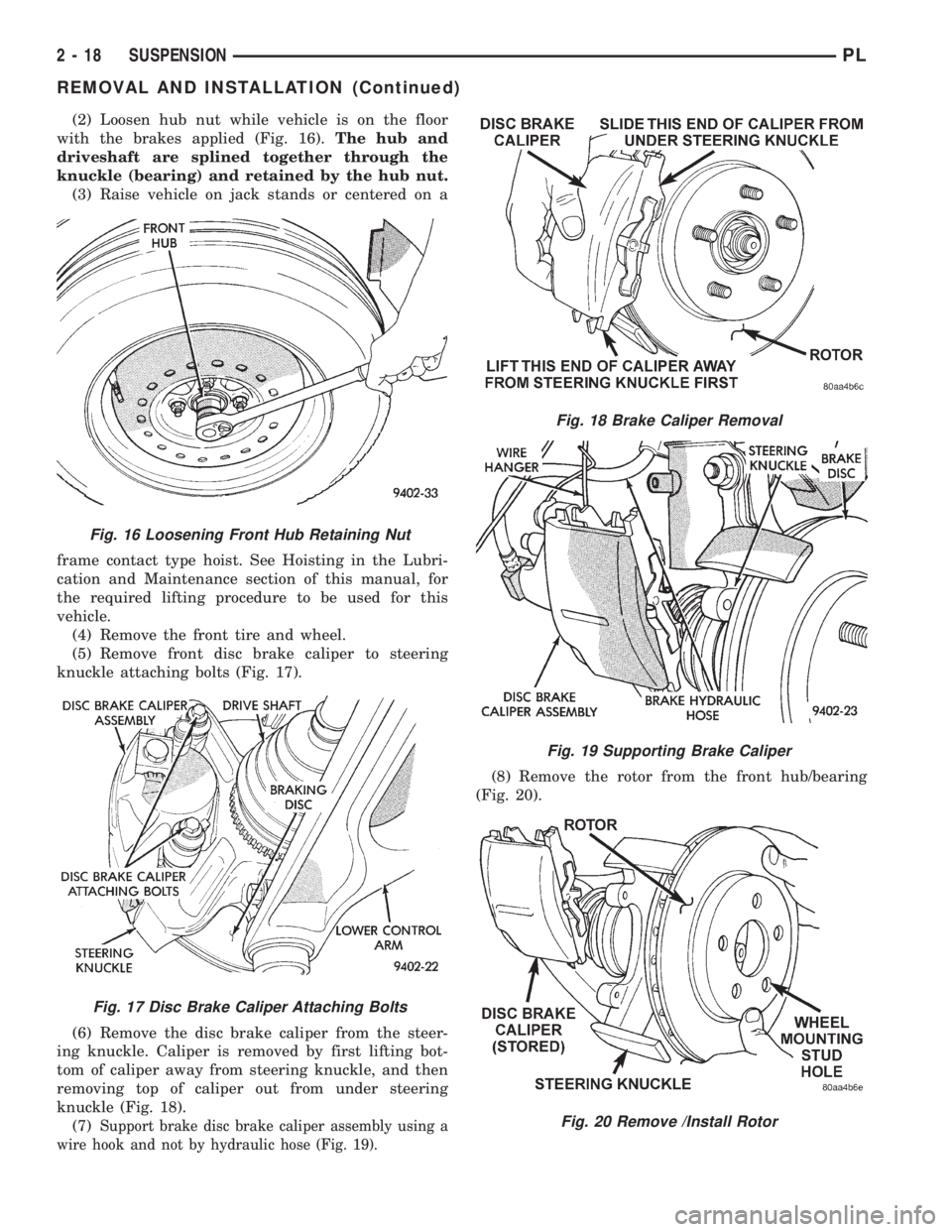

(2) Loosen hub nut while vehicle is on the floor

with the brakes applied (Fig. 16).The hub and

driveshaft are splined together through the

knuckle (bearing) and retained by the hub nut.

(3) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(4) Remove the front tire and wheel.

(5) Remove front disc brake caliper to steering

knuckle attaching bolts (Fig. 17).

(6) Remove the disc brake caliper from the steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle (Fig. 18).

(7)

Support brake disc brake caliper assembly using a

wire hook and not by hydraulic hose (Fig. 19).

(8) Remove the rotor from the front hub/bearing

(Fig. 20).

Fig. 16 Loosening Front Hub Retaining Nut

Fig. 17 Disc Brake Caliper Attaching Bolts

Fig. 18 Brake Caliper Removal

Fig. 19 Supporting Brake Caliper

Fig. 20 Remove /Install Rotor

2 - 18 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 32 of 1200

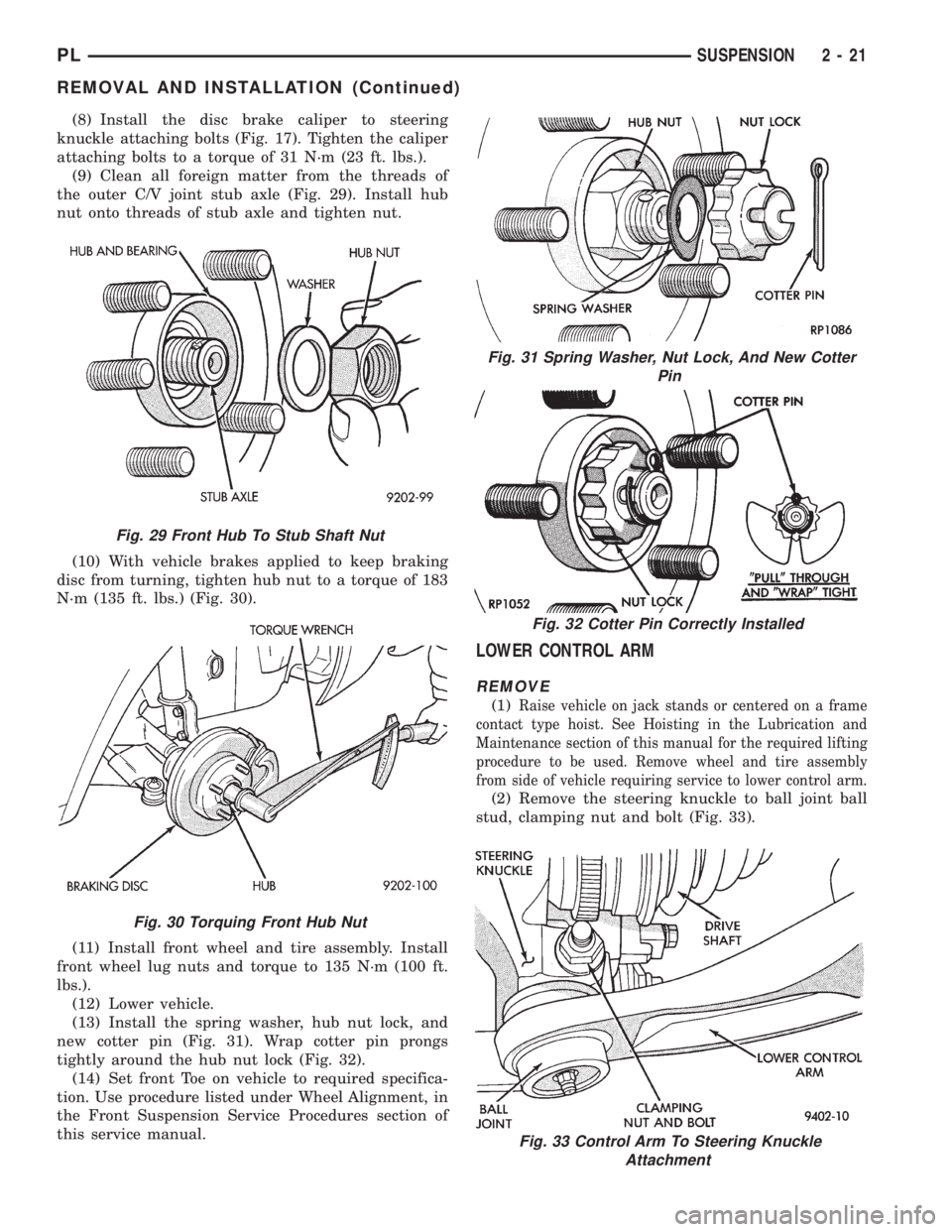

(8) Install the disc brake caliper to steering

knuckle attaching bolts (Fig. 17). Tighten the caliper

attaching bolts to a torque of 31 N´m (23 ft. lbs.).

(9) Clean all foreign matter from the threads of

the outer C/V joint stub axle (Fig. 29). Install hub

nut onto threads of stub axle and tighten nut.

(10) With vehicle brakes applied to keep braking

disc from turning, tighten hub nut to a torque of 183

N´m (135 ft. lbs.) (Fig. 30).

(11) Install front wheel and tire assembly. Install

front wheel lug nuts and torque to 135 N´m (100 ft.

lbs.).

(12) Lower vehicle.

(13) Install the spring washer, hub nut lock, and

new cotter pin (Fig. 31). Wrap cotter pin prongs

tightly around the hub nut lock (Fig. 32).

(14) Set front Toe on vehicle to required specifica-

tion. Use procedure listed under Wheel Alignment, in

the Front Suspension Service Procedures section of

this service manual.

LOWER CONTROL ARM

REMOVE

(1)Raise vehicle on jack stands or centered on a frame

contact type hoist. See Hoisting in the Lubrication and

Maintenance section of this manual for the required lifting

procedure to be used. Remove wheel and tire assembly

from side of vehicle requiring service to lower control arm.

(2) Remove the steering knuckle to ball joint ball

stud, clamping nut and bolt (Fig. 33).

Fig. 29 Front Hub To Stub Shaft Nut

Fig. 30 Torquing Front Hub Nut

Fig. 31 Spring Washer, Nut Lock, And New Cotter

Pin

Fig. 32 Cotter Pin Correctly Installed

Fig. 33 Control Arm To Steering Knuckle

Attachment

PLSUSPENSION 2 - 21

REMOVAL AND INSTALLATION (Continued)

Page 34 of 1200

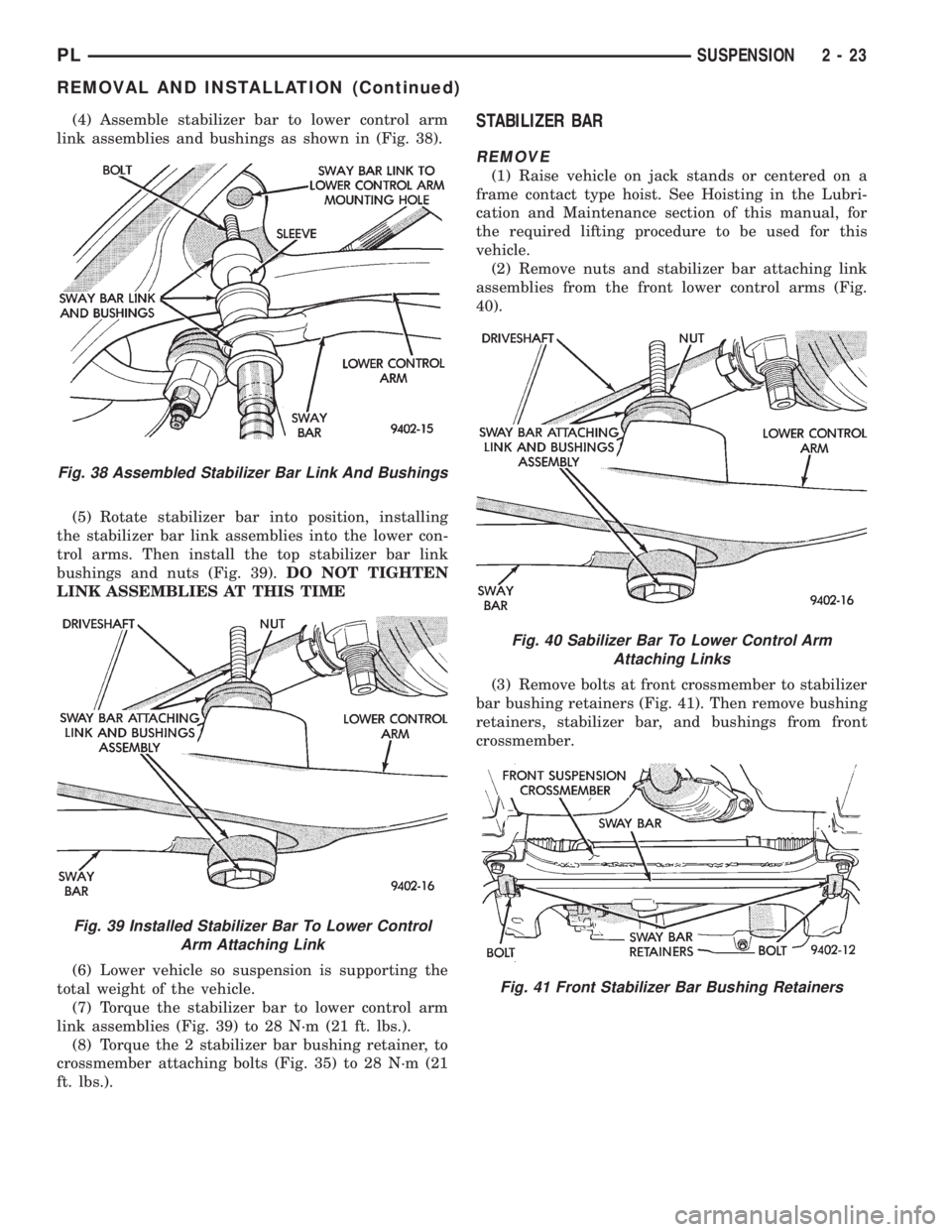

(4) Assemble stabilizer bar to lower control arm

link assemblies and bushings as shown in (Fig. 38).

(5) Rotate stabilizer bar into position, installing

the stabilizer bar link assemblies into the lower con-

trol arms. Then install the top stabilizer bar link

bushings and nuts (Fig. 39).DO NOT TIGHTEN

LINK ASSEMBLIES AT THIS TIME

(6) Lower vehicle so suspension is supporting the

total weight of the vehicle.

(7) Torque the stabilizer bar to lower control arm

link assemblies (Fig. 39) to 28 N´m (21 ft. lbs.).

(8) Torque the 2 stabilizer bar bushing retainer, to

crossmember attaching bolts (Fig. 35) to 28 N´m (21

ft. lbs.).STABILIZER BAR

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove nuts and stabilizer bar attaching link

assemblies from the front lower control arms (Fig.

40).

(3) Remove bolts at front crossmember to stabilizer

bar bushing retainers (Fig. 41). Then remove bushing

retainers, stabilizer bar, and bushings from front

crossmember.

Fig. 38 Assembled Stabilizer Bar Link And Bushings

Fig. 39 Installed Stabilizer Bar To Lower Control

Arm Attaching Link

Fig. 40 Sabilizer Bar To Lower Control Arm

Attaching Links

Fig. 41 Front Stabilizer Bar Bushing Retainers

PLSUSPENSION 2 - 23

REMOVAL AND INSTALLATION (Continued)

Page 39 of 1200

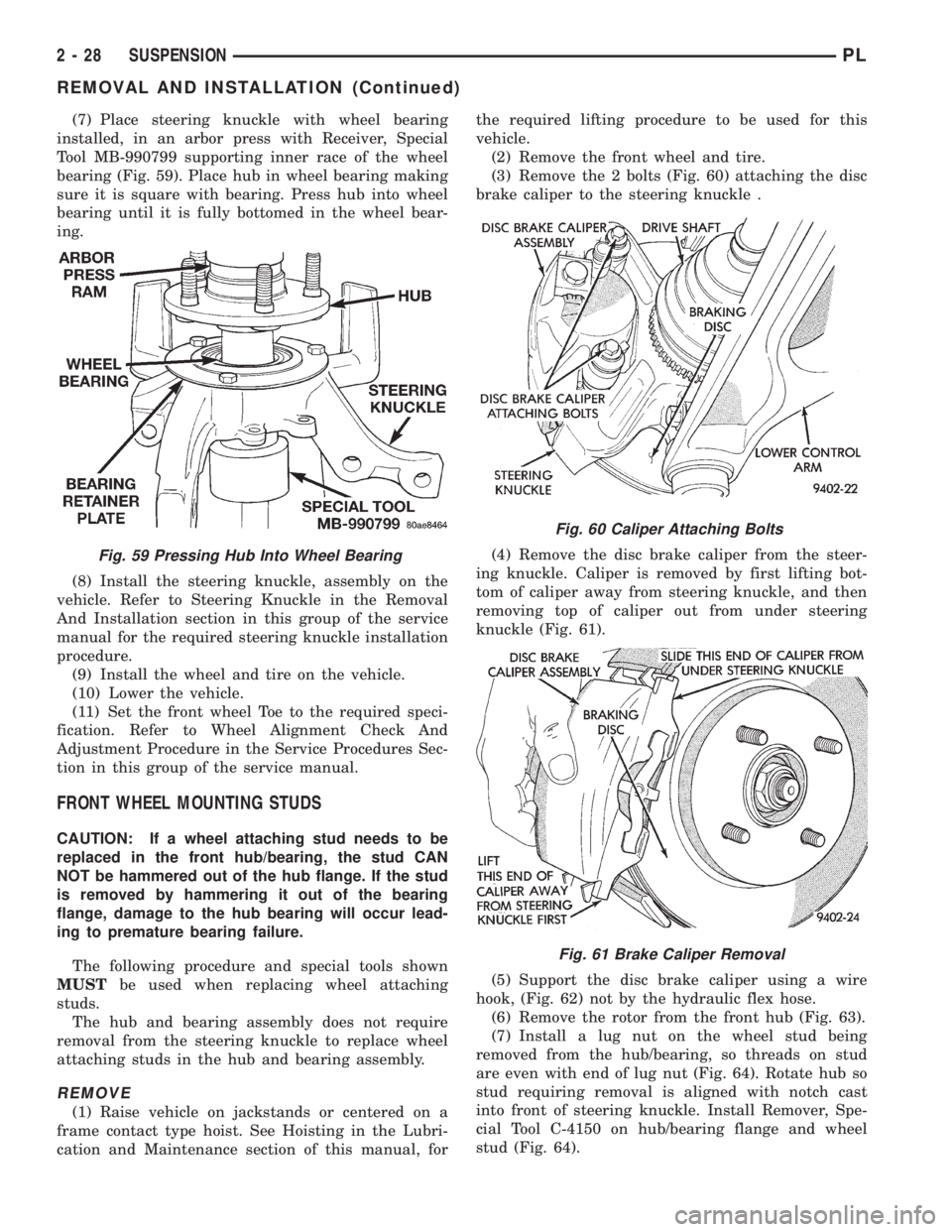

(7) Place steering knuckle with wheel bearing

installed, in an arbor press with Receiver, Special

Tool MB-990799 supporting inner race of the wheel

bearing (Fig. 59). Place hub in wheel bearing making

sure it is square with bearing. Press hub into wheel

bearing until it is fully bottomed in the wheel bear-

ing.

(8) Install the steering knuckle, assembly on the

vehicle. Refer to Steering Knuckle in the Removal

And Installation section in this group of the service

manual for the required steering knuckle installation

procedure.

(9) Install the wheel and tire on the vehicle.

(10) Lower the vehicle.

(11) Set the front wheel Toe to the required speci-

fication. Refer to Wheel Alignment Check And

Adjustment Procedure in the Service Procedures Sec-

tion in this group of the service manual.

FRONT WHEEL MOUNTING STUDS

CAUTION: If a wheel attaching stud needs to be

replaced in the front hub/bearing, the stud CAN

NOT be hammered out of the hub flange. If the stud

is removed by hammering it out of the bearing

flange, damage to the hub bearing will occur lead-

ing to premature bearing failure.

The following procedure and special tools shown

MUSTbe used when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, forthe required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire.

(3) Remove the 2 bolts (Fig. 60) attaching the disc

brake caliper to the steering knuckle .

(4) Remove the disc brake caliper from the steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle (Fig. 61).

(5) Support the disc brake caliper using a wire

hook, (Fig. 62) not by the hydraulic flex hose.

(6) Remove the rotor from the front hub (Fig. 63).

(7) Install a lug nut on the wheel stud being

removed from the hub/bearing, so threads on stud

are even with end of lug nut (Fig. 64). Rotate hub so

stud requiring removal is aligned with notch cast

into front of steering knuckle. Install Remover, Spe-

cial Tool C-4150 on hub/bearing flange and wheel

stud (Fig. 64).

Fig. 59 Pressing Hub Into Wheel Bearing

Fig. 60 Caliper Attaching Bolts

Fig. 61 Brake Caliper Removal

2 - 28 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 54 of 1200

Inspect the tension strut for signs of contact with

the ground or road debris which has bent or caused

other damage to the tension strut. If the tension

strut is bent or damaged the tension strut will

require replacement.Do not attempt to repair or

straighten a tension strut.

STABILIZER BAR AND BUSHINGS

Inspect the stabilizer bar for damage or bending.

Inspect for broken or distorted stabilizer bar bush-

ings, bushing retainers, and worn or damaged stabi-

lizer bar to strut attaching links. If stabiizer bar to

rear frame rail bushing replacement is required,

bushings can be removed from sway bar by opening

slit and peeling bushing off sway bar.

STABILIZER BAR ATTACHING LINKS

Inspect the bushings and sleeves in the stabilizer

bar attaching links for damage or deterioration.

Inspect the stabilizer bar attaching link to ensure it

is not bent or broken. If any of these conditions are

present when inspecting the attaching links, replace-

ment of the attaching link is required.

SERVICE PROCEDURES

REAR WHEEL ALIGNMENT

Refer to Front And Rear Wheel Toe Setting Proce-

dures in the Wheel Alignment Check And Adjustment

section in this group of the service manual for the

required rear wheel Toe setting procedure.

REMOVAL AND INSTALLATION

STRUT ASSEMBLY

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly from

the vehicle.

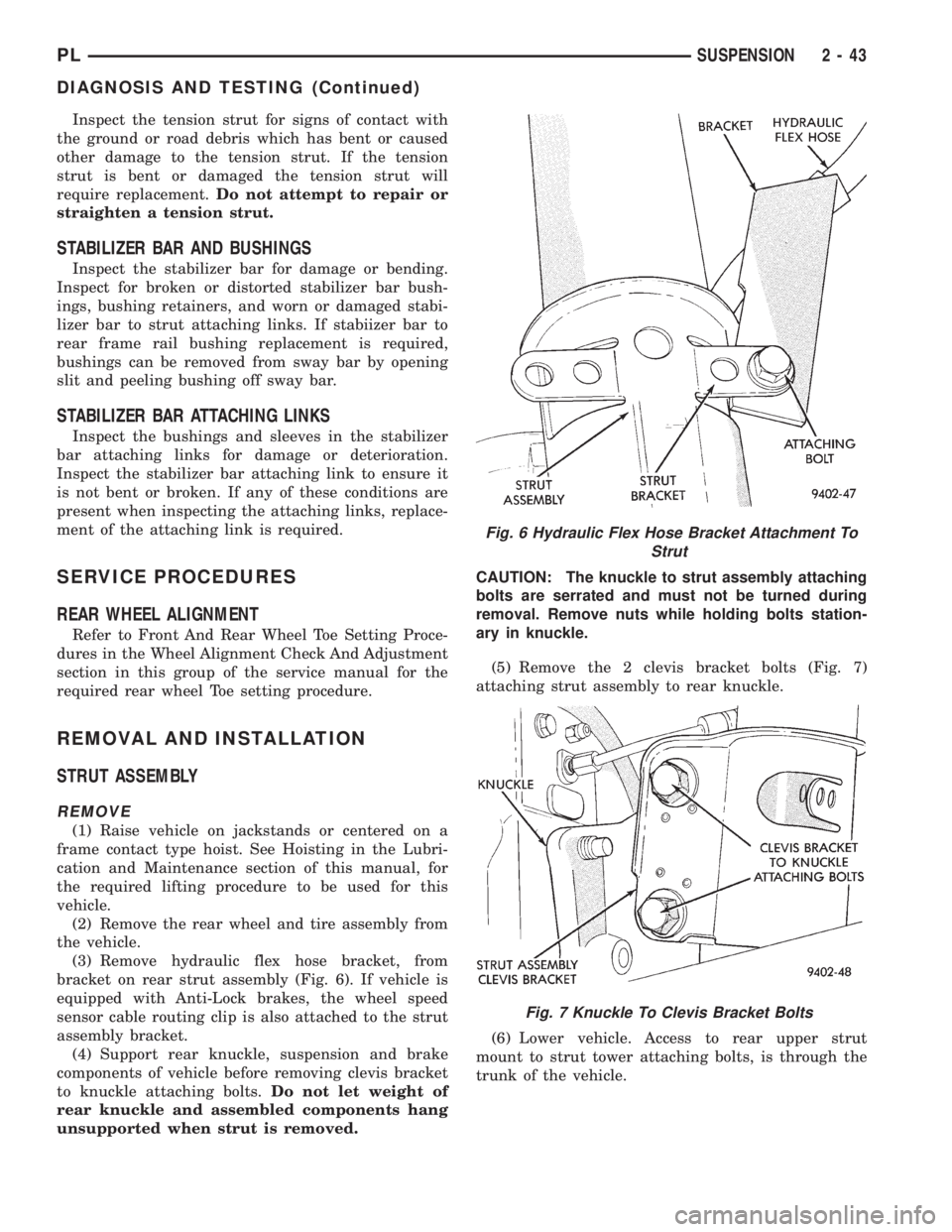

(3) Remove hydraulic flex hose bracket, from

bracket on rear strut assembly (Fig. 6). If vehicle is

equipped with Anti-Lock brakes, the wheel speed

sensor cable routing clip is also attached to the strut

assembly bracket.

(4) Support rear knuckle, suspension and brake

components of vehicle before removing clevis bracket

to knuckle attaching bolts.Do not let weight of

rear knuckle and assembled components hang

unsupported when strut is removed.CAUTION: The knuckle to strut assembly attaching

bolts are serrated and must not be turned during

removal. Remove nuts while holding bolts station-

ary in knuckle.

(5) Remove the 2 clevis bracket bolts (Fig. 7)

attaching strut assembly to rear knuckle.

(6) Lower vehicle. Access to rear upper strut

mount to strut tower attaching bolts, is through the

trunk of the vehicle.

Fig. 6 Hydraulic Flex Hose Bracket Attachment To

Strut

Fig. 7 Knuckle To Clevis Bracket Bolts

PLSUSPENSION 2 - 43

DIAGNOSIS AND TESTING (Continued)

Page 56 of 1200

strut assembly in the disassembly and assembly sec-

tion in this group of the service manual for the

required procedure to disassemble and assemble the

strut assembly for the removal of the coil spring.

STABILIZER BAR

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove both rear wheel and tire assemblies

from the vehicle.

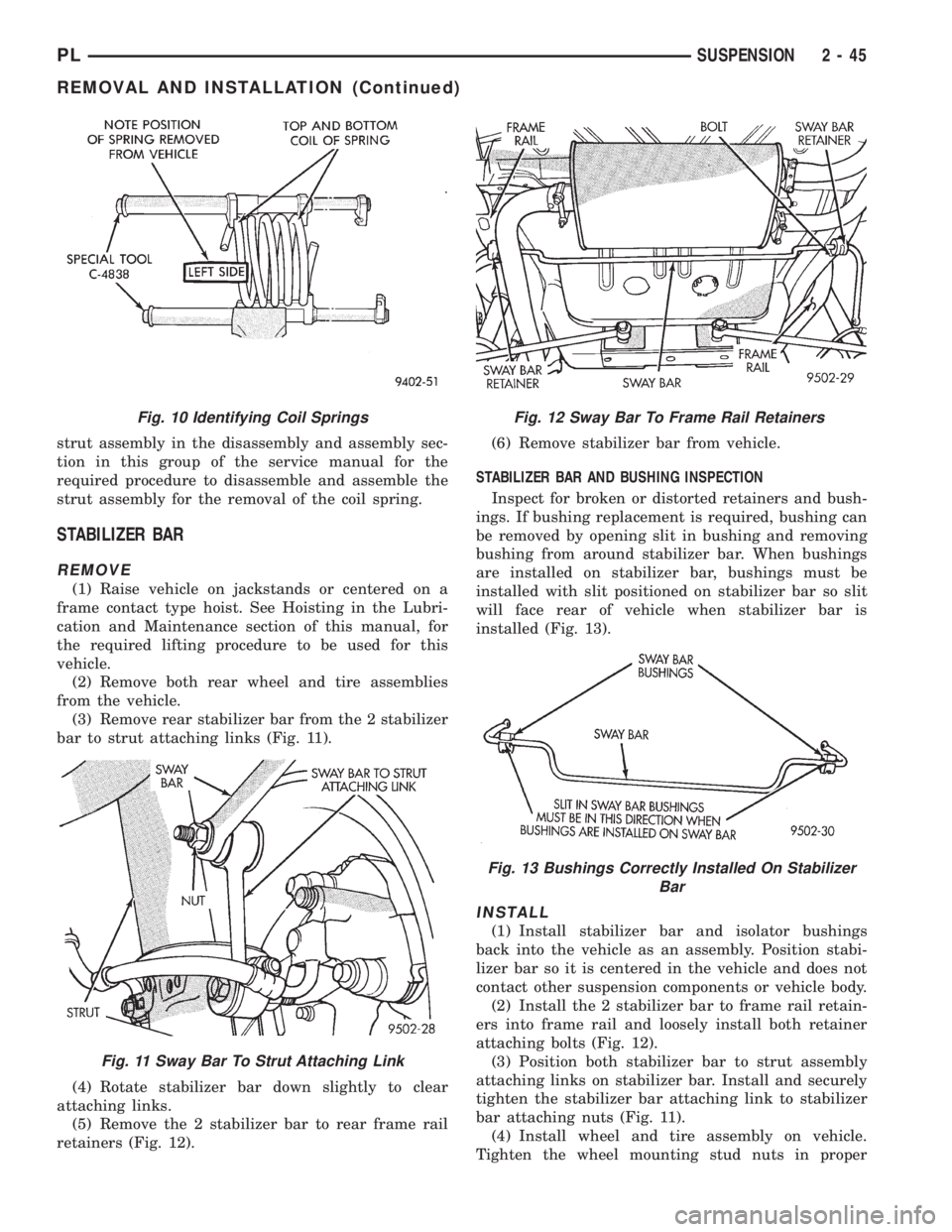

(3) Remove rear stabilizer bar from the 2 stabilizer

bar to strut attaching links (Fig. 11).

(4) Rotate stabilizer bar down slightly to clear

attaching links.

(5) Remove the 2 stabilizer bar to rear frame rail

retainers (Fig. 12).(6) Remove stabilizer bar from vehicle.

STABILIZER BAR AND BUSHING INSPECTION

Inspect for broken or distorted retainers and bush-

ings. If bushing replacement is required, bushing can

be removed by opening slit in bushing and removing

bushing from around stabilizer bar. When bushings

are installed on stabilizer bar, bushings must be

installed with slit positioned on stabilizer bar so slit

will face rear of vehicle when stabilizer bar is

installed (Fig. 13).

INSTALL

(1) Install stabilizer bar and isolator bushings

back into the vehicle as an assembly. Position stabi-

lizer bar so it is centered in the vehicle and does not

contact other suspension components or vehicle body.

(2) Install the 2 stabilizer bar to frame rail retain-

ers into frame rail and loosely install both retainer

attaching bolts (Fig. 12).

(3) Position both stabilizer bar to strut assembly

attaching links on stabilizer bar. Install and securely

tighten the stabilizer bar attaching link to stabilizer

bar attaching nuts (Fig. 11).

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

Fig. 10 Identifying Coil Springs

Fig. 11 Sway Bar To Strut Attaching Link

Fig. 12 Sway Bar To Frame Rail Retainers

Fig. 13 Bushings Correctly Installed On Stabilizer

Bar

PLSUSPENSION 2 - 45

REMOVAL AND INSTALLATION (Continued)

Page 57 of 1200

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(5) Lower the vehicle to the ground.

(6) With suspension supporting the full weight of

the vehicle, securely tighten the stabilizer bar

retainer to frame rail attaching bolts (Fig. 11).

KNUCKLE

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

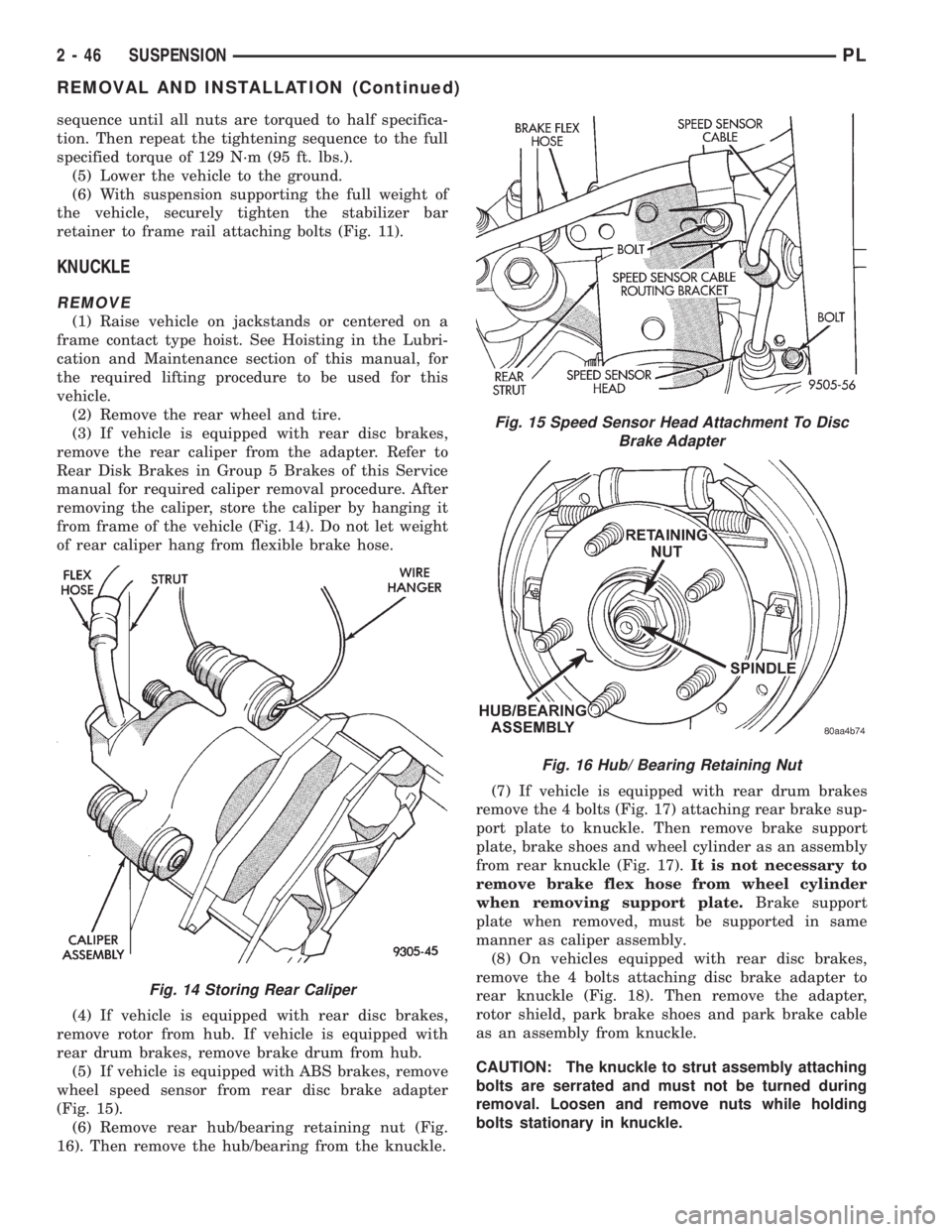

(2) Remove the rear wheel and tire.

(3) If vehicle is equipped with rear disc brakes,

remove the rear caliper from the adapter. Refer to

Rear Disk Brakes in Group 5 Brakes of this Service

manual for required caliper removal procedure. After

removing the caliper, store the caliper by hanging it

from frame of the vehicle (Fig. 14). Do not let weight

of rear caliper hang from flexible brake hose.

(4) If vehicle is equipped with rear disc brakes,

remove rotor from hub. If vehicle is equipped with

rear drum brakes, remove brake drum from hub.

(5) If vehicle is equipped with ABS brakes, remove

wheel speed sensor from rear disc brake adapter

(Fig. 15).

(6) Remove rear hub/bearing retaining nut (Fig.

16). Then remove the hub/bearing from the knuckle.(7) If vehicle is equipped with rear drum brakes

remove the 4 bolts (Fig. 17) attaching rear brake sup-

port plate to knuckle. Then remove brake support

plate, brake shoes and wheel cylinder as an assembly

from rear knuckle (Fig. 17).It is not necessary to

remove brake flex hose from wheel cylinder

when removing support plate.Brake support

plate when removed, must be supported in same

manner as caliper assembly.

(8) On vehicles equipped with rear disc brakes,

remove the 4 bolts attaching disc brake adapter to

rear knuckle (Fig. 18). Then remove the adapter,

rotor shield, park brake shoes and park brake cable

as an assembly from knuckle.

CAUTION: The knuckle to strut assembly attaching

bolts are serrated and must not be turned during

removal. Loosen and remove nuts while holding

bolts stationary in knuckle.

Fig. 14 Storing Rear Caliper

Fig. 15 Speed Sensor Head Attachment To Disc

Brake Adapter

Fig. 16 Hub/ Bearing Retaining Nut

2 - 46 SUSPENSIONPL

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1200

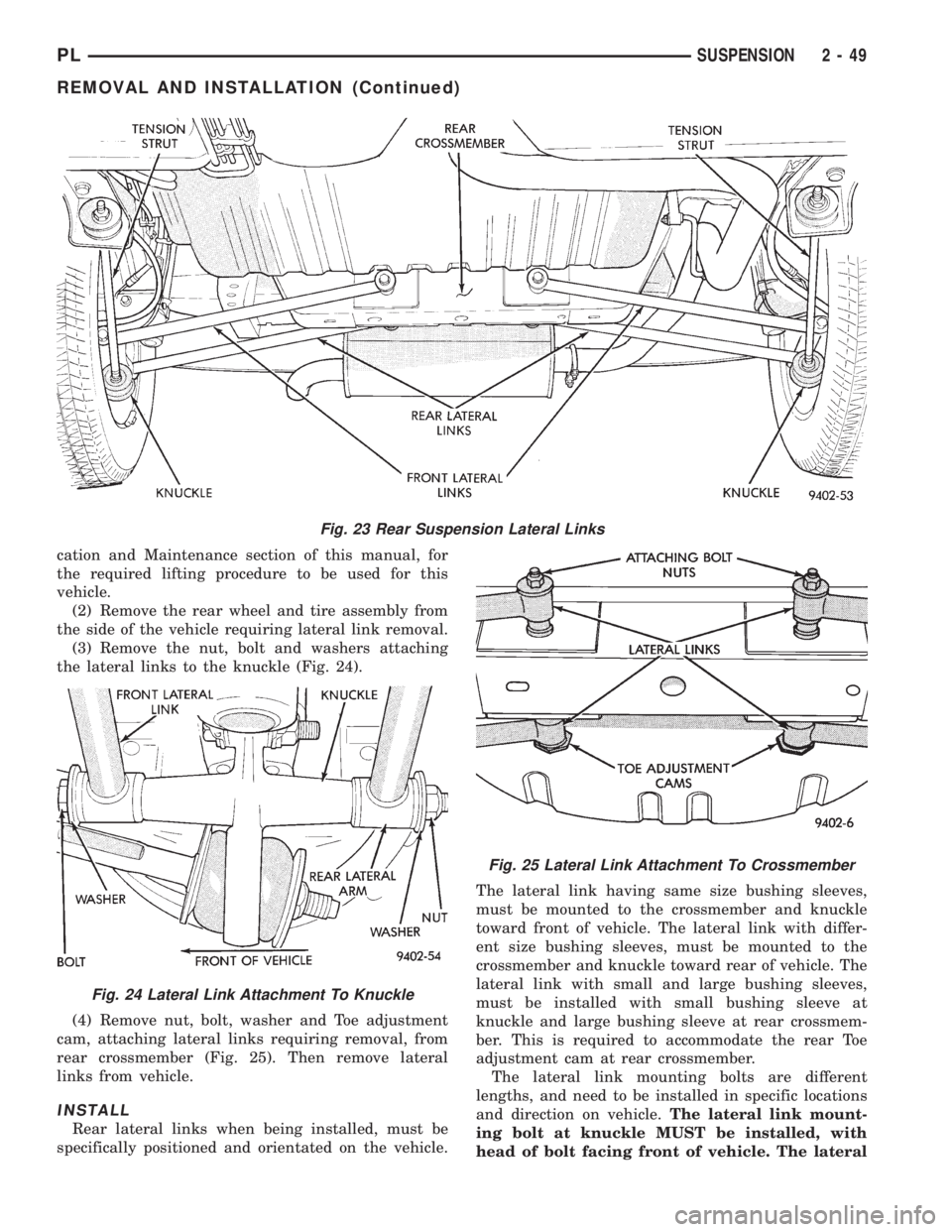

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly from

the side of the vehicle requiring lateral link removal.

(3) Remove the nut, bolt and washers attaching

the lateral links to the knuckle (Fig. 24).

(4) Remove nut, bolt, washer and Toe adjustment

cam, attaching lateral links requiring removal, from

rear crossmember (Fig. 25). Then remove lateral

links from vehicle.

INSTALL

Rear lateral links when being installed, must be

specifically positioned and orientated on the vehicle.The lateral link having same size bushing sleeves,

must be mounted to the crossmember and knuckle

toward front of vehicle. The lateral link with differ-

ent size bushing sleeves, must be mounted to the

crossmember and knuckle toward rear of vehicle. The

lateral link with small and large bushing sleeves,

must be installed with small bushing sleeve at

knuckle and large bushing sleeve at rear crossmem-

ber. This is required to accommodate the rear Toe

adjustment cam at rear crossmember.

The lateral link mounting bolts are different

lengths, and need to be installed in specific locations

and direction on vehicle.The lateral link mount-

ing bolt at knuckle MUST be installed, with

head of bolt facing front of vehicle. The lateral

Fig. 23 Rear Suspension Lateral Links

Fig. 24 Lateral Link Attachment To Knuckle

Fig. 25 Lateral Link Attachment To Crossmember

PLSUSPENSION 2 - 49

REMOVAL AND INSTALLATION (Continued)

Page 68 of 1200

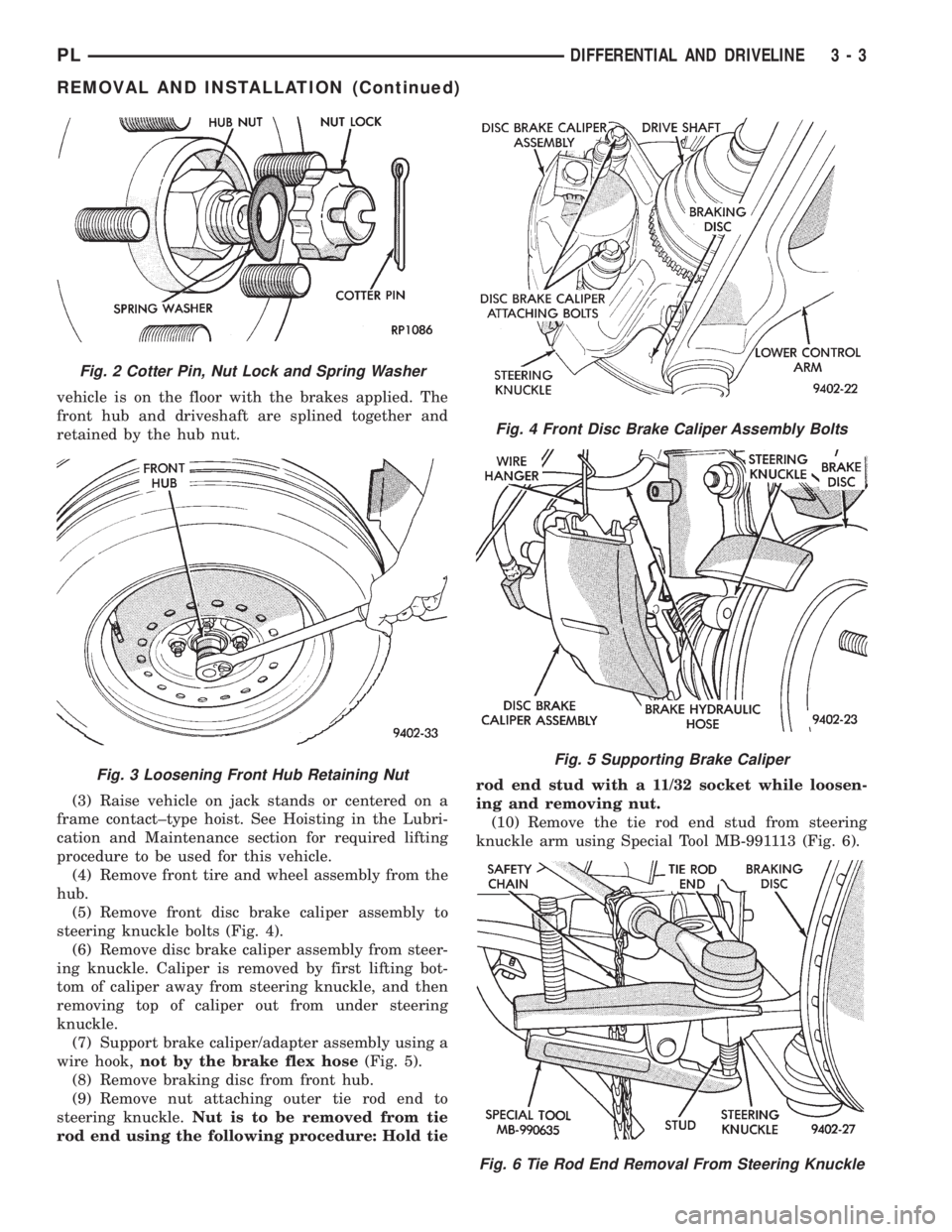

vehicle is on the floor with the brakes applied. The

front hub and driveshaft are splined together and

retained by the hub nut.

(3) Raise vehicle on jack stands or centered on a

frame contact±type hoist. See Hoisting in the Lubri-

cation and Maintenance section for required lifting

procedure to be used for this vehicle.

(4) Remove front tire and wheel assembly from the

hub.

(5) Remove front disc brake caliper assembly to

steering knuckle bolts (Fig. 4).

(6) Remove disc brake caliper assembly from steer-

ing knuckle. Caliper is removed by first lifting bot-

tom of caliper away from steering knuckle, and then

removing top of caliper out from under steering

knuckle.

(7) Support brake caliper/adapter assembly using a

wire hook,not by the brake flex hose(Fig. 5).

(8) Remove braking disc from front hub.

(9) Remove nut attaching outer tie rod end to

steering knuckle.Nut is to be removed from tie

rod end using the following procedure: Hold tierod end stud with a 11/32 socket while loosen-

ing and removing nut.

(10) Remove the tie rod end stud from steering

knuckle arm using Special Tool MB-991113 (Fig. 6).

Fig. 2 Cotter Pin, Nut Lock and Spring Washer

Fig. 3 Loosening Front Hub Retaining Nut

Fig. 4 Front Disc Brake Caliper Assembly Bolts

Fig. 5 Supporting Brake Caliper

Fig. 6 Tie Rod End Removal From Steering Knuckle

PLDIFFERENTIAL AND DRIVELINE 3 - 3

REMOVAL AND INSTALLATION (Continued)

Page 89 of 1200

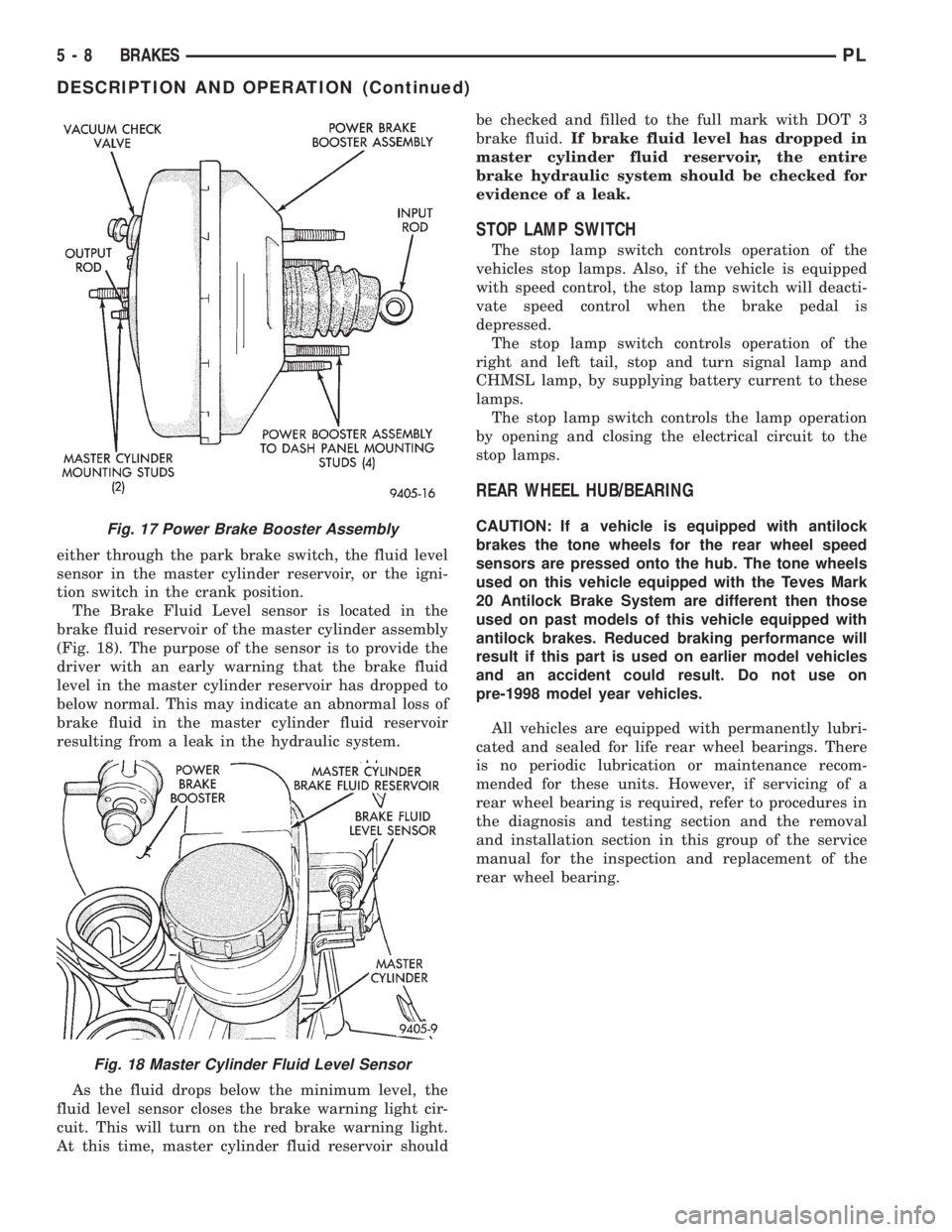

either through the park brake switch, the fluid level

sensor in the master cylinder reservoir, or the igni-

tion switch in the crank position.

The Brake Fluid Level sensor is located in the

brake fluid reservoir of the master cylinder assembly

(Fig. 18). The purpose of the sensor is to provide the

driver with an early warning that the brake fluid

level in the master cylinder reservoir has dropped to

below normal. This may indicate an abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.

As the fluid drops below the minimum level, the

fluid level sensor closes the brake warning light cir-

cuit. This will turn on the red brake warning light.

At this time, master cylinder fluid reservoir shouldbe checked and filled to the full mark with DOT 3

brake fluid.If brake fluid level has dropped in

master cylinder fluid reservoir, the entire

brake hydraulic system should be checked for

evidence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equipped

with speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

REAR WHEEL HUB/BEARING

CAUTION: If a vehicle is equipped with antilock

brakes the tone wheels for the rear wheel speed

sensors are pressed onto the hub. The tone wheels

used on this vehicle equipped with the Teves Mark

20 Antilock Brake System are different then those

used on past models of this vehicle equipped with

antilock brakes. Reduced braking performance will

result if this part is used on earlier model vehicles

and an accident could result. Do not use on

pre-1998 model year vehicles.

All vehicles are equipped with permanently lubri-

cated and sealed for life rear wheel bearings. There

is no periodic lubrication or maintenance recom-

mended for these units. However, if servicing of a

rear wheel bearing is required, refer to procedures in

the diagnosis and testing section and the removal

and installation section in this group of the service

manual for the inspection and replacement of the

rear wheel bearing.Fig. 17 Power Brake Booster Assembly

Fig. 18 Master Cylinder Fluid Level Sensor

5 - 8 BRAKESPL

DESCRIPTION AND OPERATION (Continued)