oil temperature DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 194 of 1200

COOLING

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 2

AUTOMATIC TRANSMISSION OIL COOLER.... 3

COOLANT RECOVERY SYSTEM (CRS)....... 2

COOLANT.............................. 3

COOLING SYSTEM PRESSURE CAP......... 3

COOLING SYSTEM....................... 1

ENGINE BLOCK HEATER.................. 3

ENGINE THERMOSTAT.................... 3

RADIATOR............................. 3

WATER PUMP.......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 4

COOLING SYSTEM PRESSURE CAP......... 5

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 4

RADIATOR HOSES AND CLAMPS........... 5

WATER PUMP.......................... 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVEBELT DIAGNOSIS....... 13

COOLING SYSTEM DIAGNOSIS............. 7

COOLING SYSTEM FLOW CHECK.......... 14

DEAERATION.......................... 15

ELECTRIC FAN MOTOR TEST.............. 14

ENGINE THERMOSTAT TESTING........... 13

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP...................... 15

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14WATER PUMP DIAGNOSIS............... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVELÐSERVICING............ 16

COOLANTÐADDING ADDITIONAL......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 17

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTS............... 21

ENGINE BLOCK HEATER................. 21

ENGINE THERMOSTAT................... 18

RADIATOR DRAINCOCK.................. 20

RADIATOR FANS AND MOTOR............ 20

RADIATOR............................ 19

WATER PUMP INLET TUBE............... 18

WATER PUMP......................... 17

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT INSPECTION...... 22

CHEMICAL CLEANING................... 23

CLEANING COOLING SYSTEM............. 22

COOLING SYSTEM CAP.................. 22

RADIATOR FLUSHING................... 23

REVERSE FLUSHING.................... 23

WATER PUMP......................... 21

ADJUSTMENTS

BELT TENSION GAUGE METHOD........... 24

PROPER BELT TENSION................. 23

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 24

TORQUE.............................. 24

SPECIAL TOOLS

COOLING............................. 24

GENERAL INFORMATION

COOLING SYSTEM

The cooling system consists of an engine cooling

module, thermostat, coolant, and a water pump to

circulate the coolant. The engine cooling module may

consist of a radiator, electric fan motor, fan, shroud,

coolant reserve system, transmission oil cooler, hoses,

clamps, air condition condenser and transmission oil lines.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

Coolant flow circuit for the 2.0L engine is shown in

(Fig. 1).

PLCOOLING 7 - 1

Page 197 of 1200

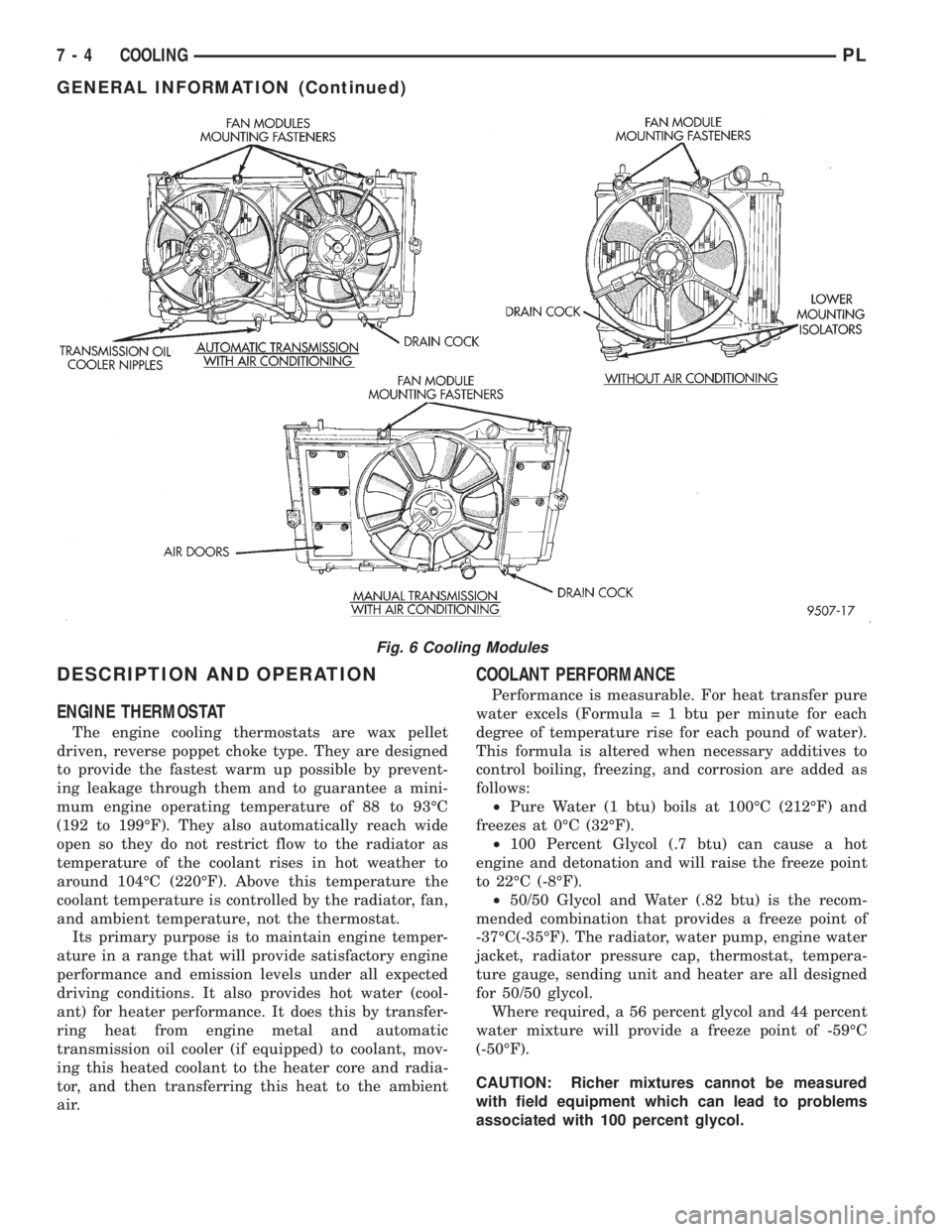

DESCRIPTION AND OPERATION

ENGINE THERMOSTAT

The engine cooling thermostats are wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the radiator, fan,

and ambient temperature, not the thermostat.

Its primary purpose is to maintain engine temper-

ature in a range that will provide satisfactory engine

performance and emission levels under all expected

driving conditions. It also provides hot water (cool-

ant) for heater performance. It does this by transfer-

ring heat from engine metal and automatic

transmission oil cooler (if equipped) to coolant, mov-

ing this heated coolant to the heater core and radia-

tor, and then transferring this heat to the ambient

air.

COOLANT PERFORMANCE

Performance is measurable. For heat transfer pure

water excels (Formula = 1 btu per minute for each

degree of temperature rise for each pound of water).

This formula is altered when necessary additives to

control boiling, freezing, and corrosion are added as

follows:

²Pure Water (1 btu) boils at 100ÉC (212ÉF) and

freezes at 0ÉC (32ÉF).

²100 Percent Glycol (.7 btu) can cause a hot

engine and detonation and will raise the freeze point

to 22ÉC (-8ÉF).

²50/50 Glycol and Water (.82 btu) is the recom-

mended combination that provides a freeze point of

-37ÉC(-35ÉF). The radiator, water pump, engine water

jacket, radiator pressure cap, thermostat, tempera-

ture gauge, sending unit and heater are all designed

for 50/50 glycol.

Where required, a 56 percent glycol and 44 percent

water mixture will provide a freeze point of -59ÉC

(-50ÉF).

CAUTION: Richer mixtures cannot be measured

with field equipment which can lead to problems

associated with 100 percent glycol.

Fig. 6 Cooling Modules

7 - 4 COOLINGPL

GENERAL INFORMATION (Continued)

Page 200 of 1200

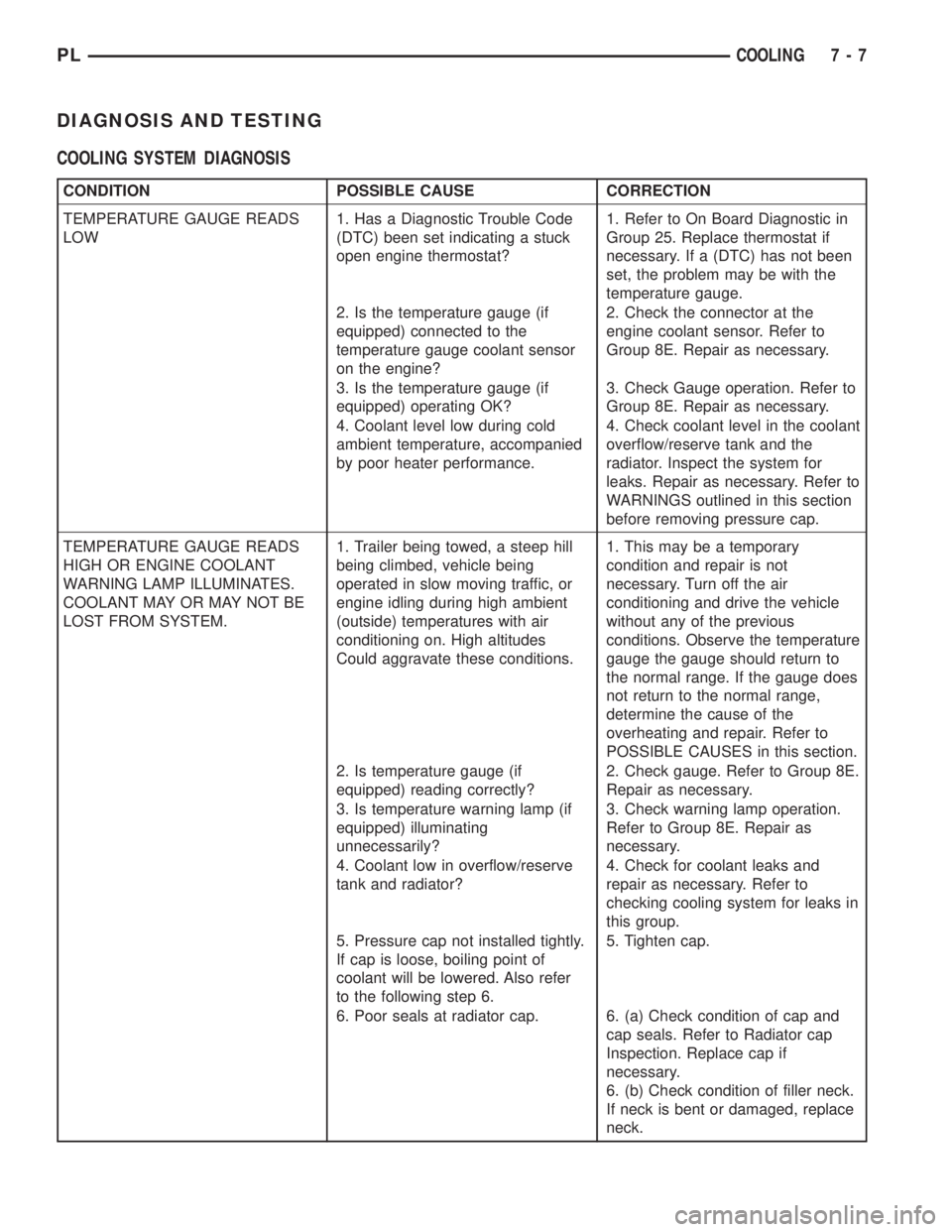

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open engine thermostat?1. Refer to On Board Diagnostic in

Group 25. Replace thermostat if

necessary. If a (DTC) has not been

set, the problem may be with the

temperature gauge.

2. Is the temperature gauge (if

equipped) connected to the

temperature gauge coolant sensor

on the engine?2. Check the connector at the

engine coolant sensor. Refer to

Group 8E. Repair as necessary.

3. Is the temperature gauge (if

equipped) operating OK?3. Check Gauge operation. Refer to

Group 8E. Repair as necessary.

4. Coolant level low during cold

ambient temperature, accompanied

by poor heater performance.4. Check coolant level in the coolant

overflow/reserve tank and the

radiator. Inspect the system for

leaks. Repair as necessary. Refer to

WARNINGS outlined in this section

before removing pressure cap.

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM.1. Trailer being towed, a steep hill

being climbed, vehicle being

operated in slow moving traffic, or

engine idling during high ambient

(outside) temperatures with air

conditioning on. High altitudes

Could aggravate these conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and drive the vehicle

without any of the previous

conditions. Observe the temperature

gauge the gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause of the

overheating and repair. Refer to

POSSIBLE CAUSES in this section.

2. Is temperature gauge (if

equipped) reading correctly?2. Check gauge. Refer to Group 8E.

Repair as necessary.

3. Is temperature warning lamp (if

equipped) illuminating

unnecessarily?3. Check warning lamp operation.

Refer to Group 8E. Repair as

necessary.

4. Coolant low in overflow/reserve

tank and radiator?4. Check for coolant leaks and

repair as necessary. Refer to

checking cooling system for leaks in

this group.

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following step 6.5. Tighten cap.

6. Poor seals at radiator cap. 6. (a) Check condition of cap and

cap seals. Refer to Radiator cap

Inspection. Replace cap if

necessary.

6. (b) Check condition of filler neck.

If neck is bent or damaged, replace

neck.

PLCOOLING 7 - 7

Page 208 of 1200

There may be internal leaks, which can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil, it indicates an inter-

nal leak in the engine. If there is an internal leak,

the engine must be disassembled for repair.

PRESSURE CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 10). Attach the

radiator pressure tester to thefiller neck nipple,

and pump air into the system. The pressure cap

upper gasket should relieve pressure at 69-124 kPa

(10-18 psi), and hold pressure at 55 kPa (8 psi) min-

imum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE PRESSURE CAP IS A SAFETY PRE-

CAUTION. WHEN HOT, THE COOLING SYSTEM

BUILDS UP PRESSURE. TO PREVENT SCALDING

OR OTHER INJURY, THE PRESSURE CAP SHOULD

NOT BE REMOVED WHILE THE SYSTEM IS HOT

AND/OR UNDER PRESSURE.

There is no need to remove the pressure cap at any

timeexceptfor the following purposes:

²Check and adjust coolant freeze point²Refill system with new coolant

²Conducting service procedures

²Checking for leaks

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE REMOVING

CAP. PLACE A SHOP TOWEL OVER THE CAP, AND

WITHOUT PUSHING DOWN, ROTATE IT COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE.

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS, PUSH DOWN ON THE CAP AND REMOVE

IT COMPLETELY. SQUEEZING THE RADIATOR

INLET HOSE WITH A SHOP TOWEL (TO CHECK

PRESSURE) BEFORE AND AFTER TURNING TO

THE FIRST STOP IS RECOMMENDED.

PRESSURE TESTING COOLING SYSTEM

PRESSURE CAP

Dip the pressure cap in water; clean off any depos-

its on the vent valve or its seat, and apply the cap to

end of radiator pressure tester (Fig. 11). Working the

plunger, increase the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the cap.

CAUTION: The radiator pressure tester is very sen-

sitive to small air leaks that will not cause cooling

system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn the tool

upside down, and recheck the pressure cap to con-

firm that the cap is faulty.

If the pressure cap tests properly while posi-

tioned the on radiator pressure tester, but will not

hold pressure or vacuum when positioned on the

filler neck, inspect the filler neck and cap top gas-

ket for irregularities that may prevent the cap from

sealing properly.

LOW COOLANT LEVEL AERATION

²Will cause corrosion in the system.

²High reading shown on the temperature gauge.

²Air in the coolant will also cause loss of flow

through the heater.

²Exhaust gas leaks into the coolant can also

cause the above problems.

DEAERATION

Air can only be removed from the system by gath-

ering under the pressure cap. On the next heat up it

will be pushed past the pressure cap into the CRS

tank by thermal expansion of the coolant. It thenFig. 10 Cooling System Pressure Cap

PLCOOLING 7 - 15

DIAGNOSIS AND TESTING (Continued)

Page 234 of 1200

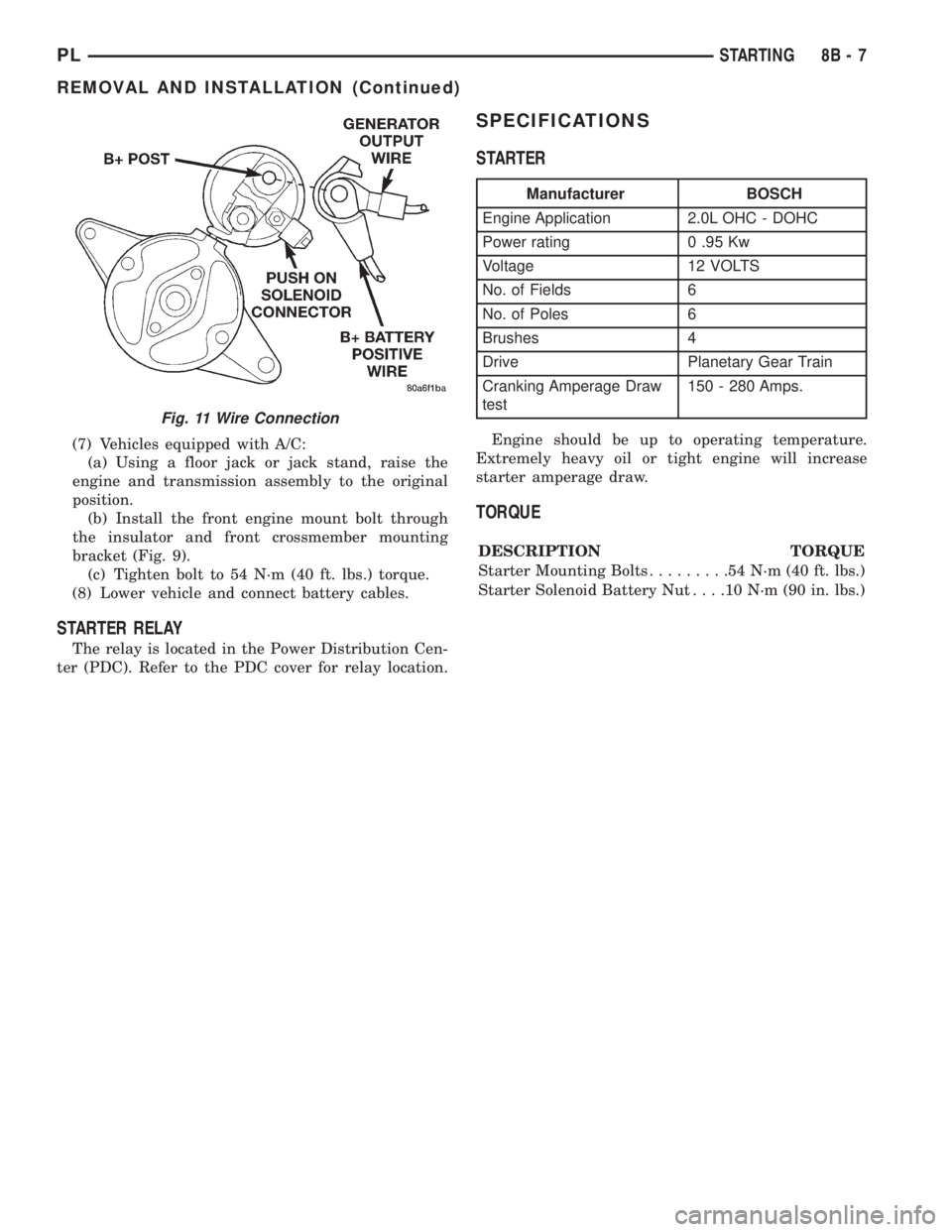

(7) Vehicles equipped with A/C:

(a) Using a floor jack or jack stand, raise the

engine and transmission assembly to the original

position.

(b) Install the front engine mount bolt through

the insulator and front crossmember mounting

bracket (Fig. 9).

(c) Tighten bolt to 54 N´m (40 ft. lbs.) torque.

(8) Lower vehicle and connect battery cables.

STARTER RELAY

The relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for relay location.

SPECIFICATIONS

STARTER

Engine should be up to operating temperature.

Extremely heavy oil or tight engine will increase

starter amperage draw.

TORQUE

DESCRIPTION TORQUE

Starter Mounting Bolts.........54N´m(40ft.lbs.)

Starter Solenoid Battery Nut. . . .10 N´m (90 in. lbs.)

Fig. 11 Wire Connection

Manufacturer BOSCH

Engine Application 2.0L OHC - DOHC

Power rating 0 .95 Kw

Voltage 12 VOLTS

No. of Fields 6

No. of Poles 6

Brushes 4

Drive Planetary Gear Train

Cranking Amperage Draw

test150 - 280 Amps.

PLSTARTING 8B - 7

REMOVAL AND INSTALLATION (Continued)

Page 237 of 1200

A battery temperature sensor located on the front

bumper beam is used to sense battery temperature.

This temperature data, along with data from moni-

tored line voltage, is used by the PCM to vary the

battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly and to maintain

the proper voltage depending on battery tempera-

ture.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

EVR (field control) circuitry, are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See On-

Board Diagnostic System Test in this group for more

information.

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

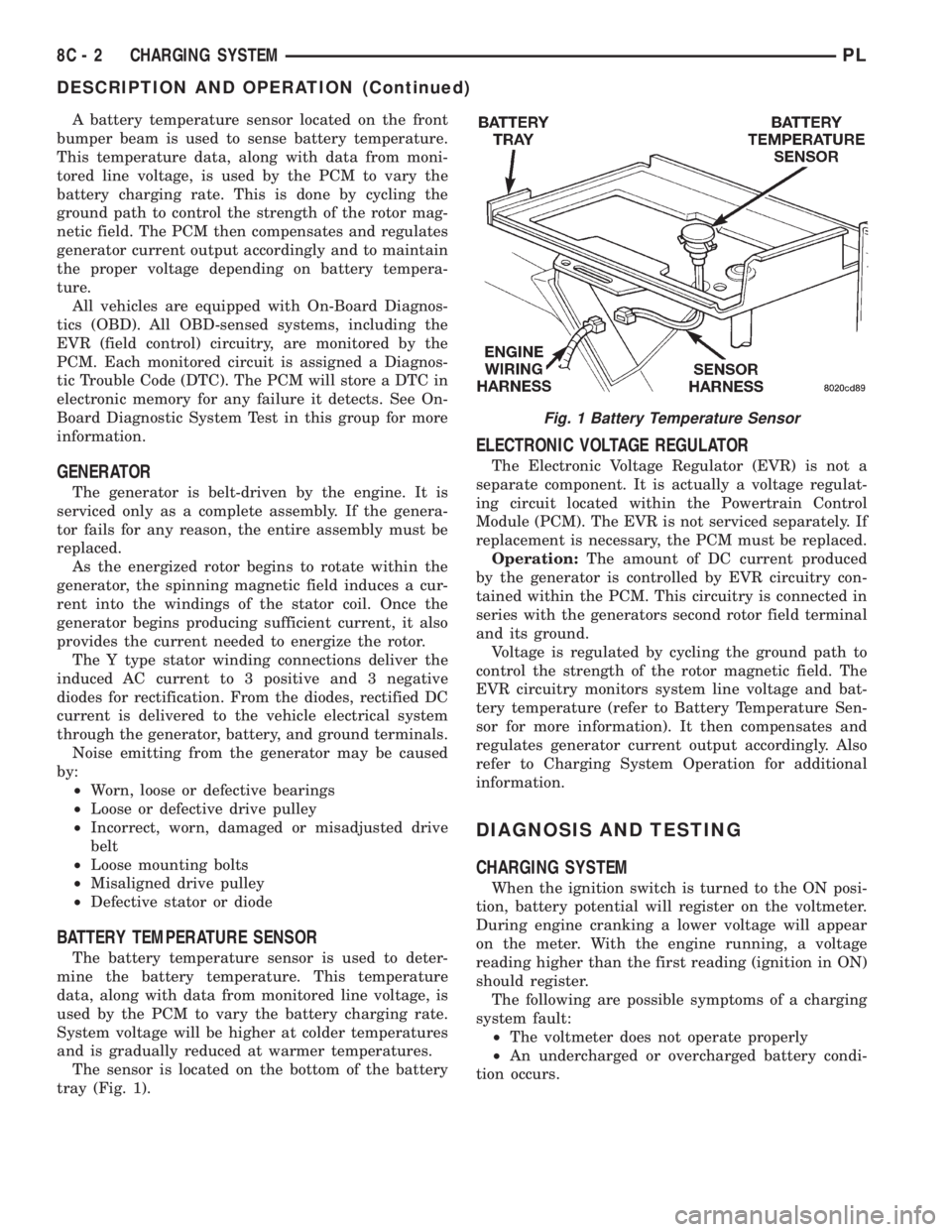

BATTERY TEMPERATURE SENSOR

The battery temperature sensor is used to deter-

mine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

The sensor is located on the bottom of the battery

tray (Fig. 1).

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Fig. 1 Battery Temperature Sensor

8C - 2 CHARGING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 250 of 1200

IGNITION SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

AUTOMATIC SHUTDOWN RELAY............ 3

CAMSHAFT POSITION SENSOR............. 4

COMBINATION ENGINE COOLANT

TEMPERATURE SENSOR................. 5

CRANKSHAFT POSITION SENSOR........... 4

ELECTRONIC IGNITION COILS.............. 3

IGNITION INTERLOCK.................... 7

IGNITION SWITCH....................... 7

IGNITION SYSTEM....................... 1

INTAKE AIR TEMPERATURE SENSOR........ 6

KNOCK SENSOR......................... 6

LOCK KEY CYLINDER..................... 7

MANIFOLD ABSOLUTE PRESSURE SENSOR

(MAP)............................... 6

POWERTRAIN CONTROL MODULE.......... 2

SPARK PLUG CABLES.................... 2

SPARK PLUGS.......................... 2

THROTTLE POSITION SENSOR (TPS)........ 6

DIAGNOSIS AND TESTING

CAMSHAFT POSITION SENSOR AND

CRANKSHAFT POSITION SENSOR......... 9

CHECK COIL TEST....................... 8

ENGINE COOLANT TEMPERATURE SENSOR . . . 9

FAILURE TO START TESTÐ2.0/2.4L......... 8

IGNITION TIMING PROCEDURE............. 9

INTAKE AIR TEMPERATURE SENSOR........ 9

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST......................... 9

SPARK PLUG CONDITION................ 10TESTING FOR SPARK AT COILÐ2.0/2.4L..... 7

THROTTLE POSITION SENSOR............. 9

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY........... 13

CAMSHAFT POSITION SENSORÐDOHC..... 14

CAMSHAFT POSITION SENSORÐSOHC..... 13

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐDOHC........ 15

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐSOHC......... 15

CRANKSHAFT POSITION SENSOR.......... 15

IGNITION COIL......................... 13

IGNITION INTERLOCK................... 18

IGNITION SWITCH...................... 16

LOCK CYLINDER HOUSING............... 18

LOCK KEY CYLINDER.................... 17

MAP/IAT SENSORÐDOHC................ 16

MAP/IAT SENSORÐSOHC................ 16

POWERTRAIN CONTROL MODULE (PCM) . . . 12

SPARK PLUG CABLE SERVICE............ 13

SPARK PLUG SERVICE.................. 12

SPARK PLUG TUBES.................... 13

THROTTLE POSITION SENSOR............ 16

SPECIFICATIONS

FIRING ORDERÐ2.0L................... 18

IGNITION COIL......................... 19

SPARK PLUG CABLE RESISTANCEÐDOHC . . 18

SPARK PLUG CABLE RESISTANCEÐSOHC . . . 18

SPARK PLUG.......................... 19

TORQUE SPECIFICATION................. 18

VECI LABEL........................... 18

GENERAL INFORMATION

INTRODUCTION

This section describes the electronic ignition sys-

tem for the 2.0L engines used in Neon vehicles.

The On-Board Diagnostics Section in Group 25

describes diagnostic trouble codes.

Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition relateditems. The Owner's Manual also contains mainte-

nance information.DESCRIPTION AND OPERATION

IGNITION SYSTEM

Ignition system operation and diagnostics, are

identical for 2.0L Single Overhead Cam (SOHC) and

2.0L Duel Overhead Cam (DOHC) engines.

PLIGNITION SYSTEM 8D - 1

Page 251 of 1200

The major difference between the two engines is

component location which affects the ignition system

service procedures. There are various sensors that

are in different locations due to a different cylinder

head and intake manifold.

The 2.0L engines use a fixed ignition timing sys-

tem. The distributorless electronic ignition system is

referred to as the Direct Ignition System (DIS).

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The system's three main components are

the coil pack, crankshaft position sensor, and cam-

shaft position sensor.

POWERTRAIN CONTROL MODULE

The Powertrain Control Module (PCM) controls the

ignition system (Fig. 1). The PCM supplies battery

voltage to the ignition coil through the Auto Shut-

down (ASD) Relay. The PCM also controls the ground

circuit for the ignition coil. By switching the ground

path for the coil on and off, the PCM adjusts ignition

timing to meet changing engine operating conditions.

During the crank-start period the PCM maintains

spark advance at 9É BTDC. During engine operation

the following inputs determine the amount of spark

advance provided by the PCM.

²Intake air temperature

²Coolant temperature

²Engine RPM

²Intake manifold vacuum

²Knock sensor

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

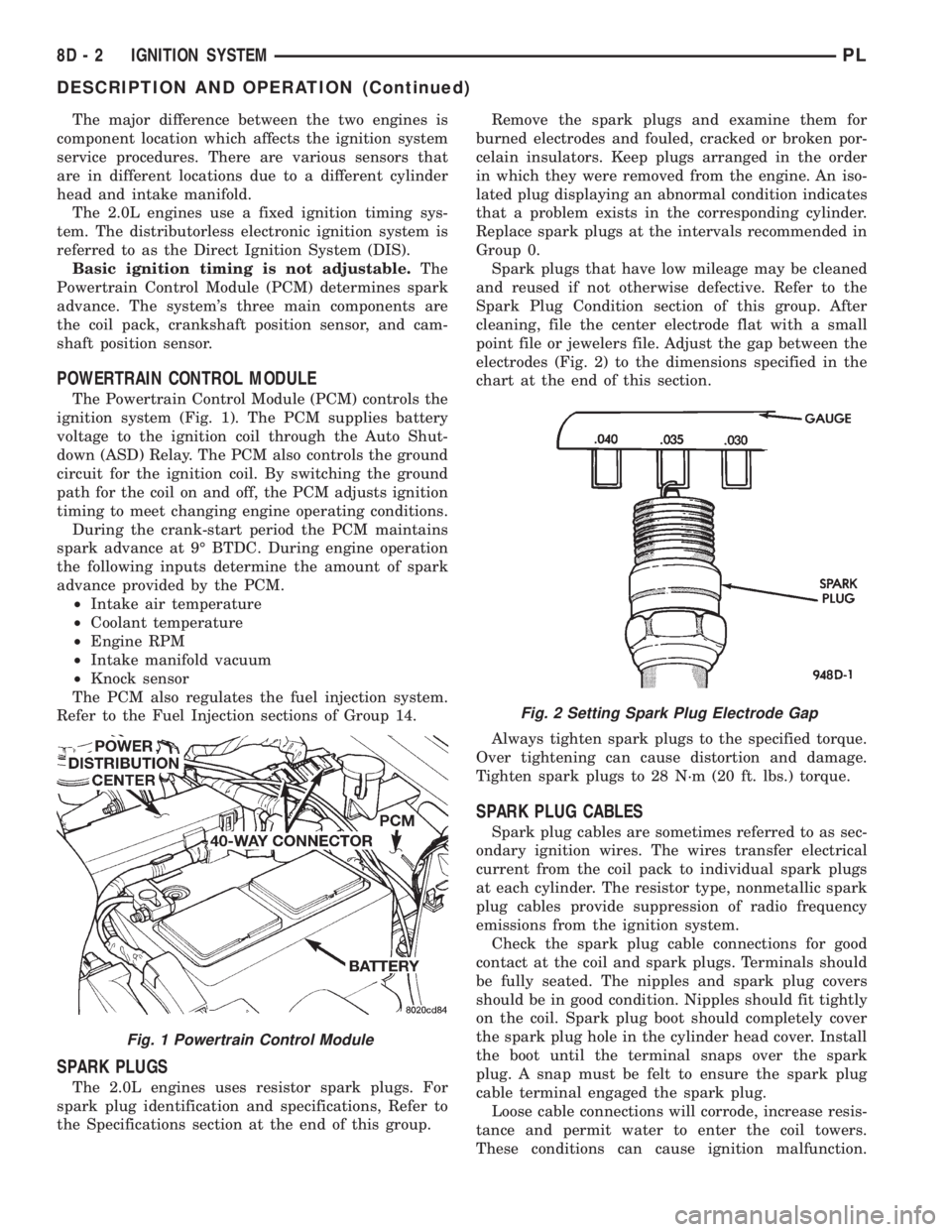

SPARK PLUGS

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group 0.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 2) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

Loose cable connections will corrode, increase resis-

tance and permit water to enter the coil towers.

These conditions can cause ignition malfunction.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 258 of 1200

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to

start test.

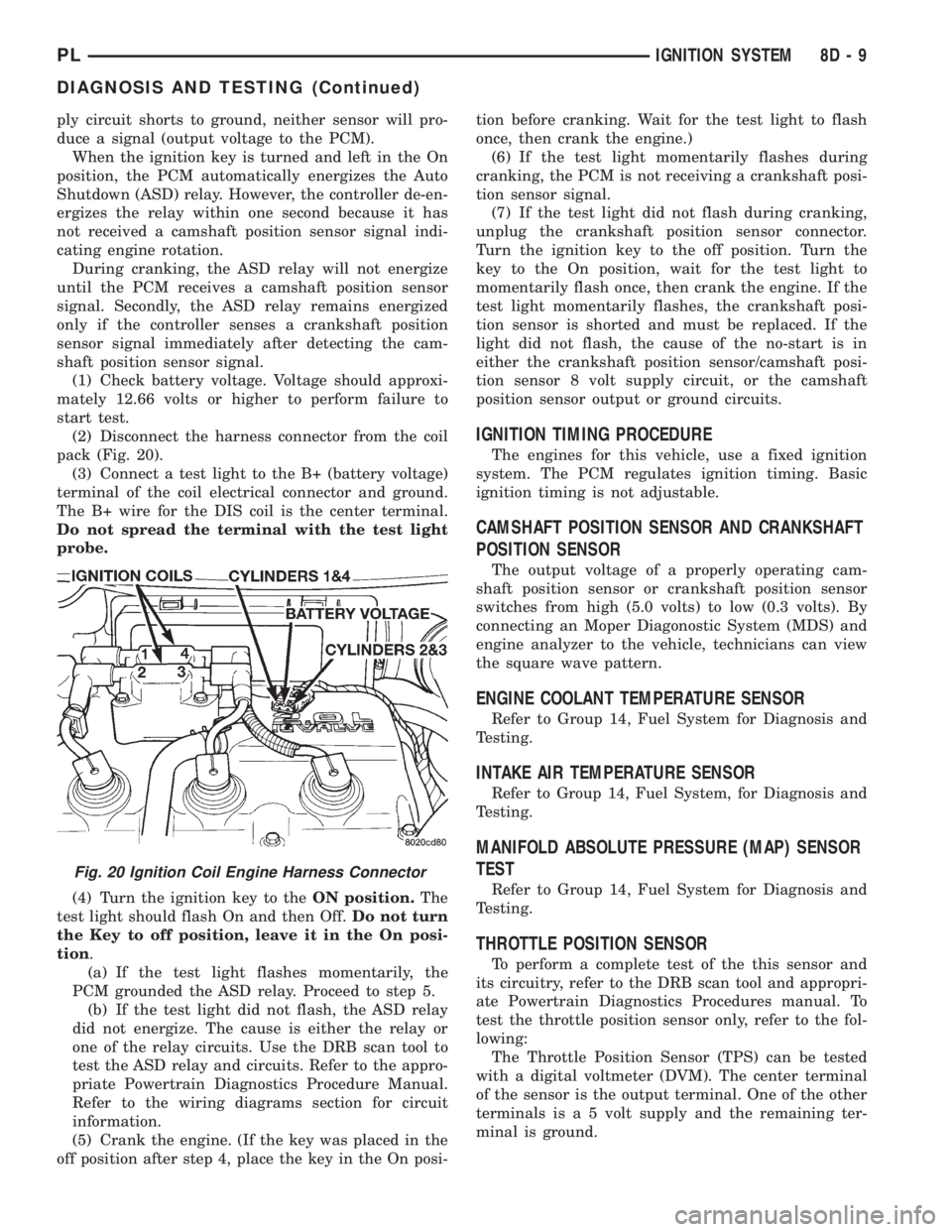

(2) Disconnect the harness connector from the coil

pack (Fig. 20).

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The B+ wire for the DIS coil is the center terminal.

Do not spread the terminal with the test light

probe.

(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the ASD relay. Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

either the crankshaft position sensor/camshaft posi-

tion sensor 8 volt supply circuit, or the camshaft

position sensor output or ground circuits.

IGNITION TIMING PROCEDURE

The engines for this vehicle, use a fixed ignition

system. The PCM regulates ignition timing. Basic

ignition timing is not adjustable.

CAMSHAFT POSITION SENSOR AND CRANKSHAFT

POSITION SENSOR

The output voltage of a properly operating cam-

shaft position sensor or crankshaft position sensor

switches from high (5.0 volts) to low (0.3 volts). By

connecting an Moper Diagonostic System (MDS) and

engine analyzer to the vehicle, technicians can view

the square wave pattern.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to Group 14, Fuel System for Diagnosis and

Testing.

INTAKE AIR TEMPERATURE SENSOR

Refer to Group 14, Fuel System, for Diagnosis and

Testing.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to Group 14, Fuel System for Diagnosis and

Testing.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the throttle position sensor only, refer to the fol-

lowing:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Fig. 20 Ignition Coil Engine Harness Connector

PLIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 259 of 1200

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

SPARK PLUG CONDITION

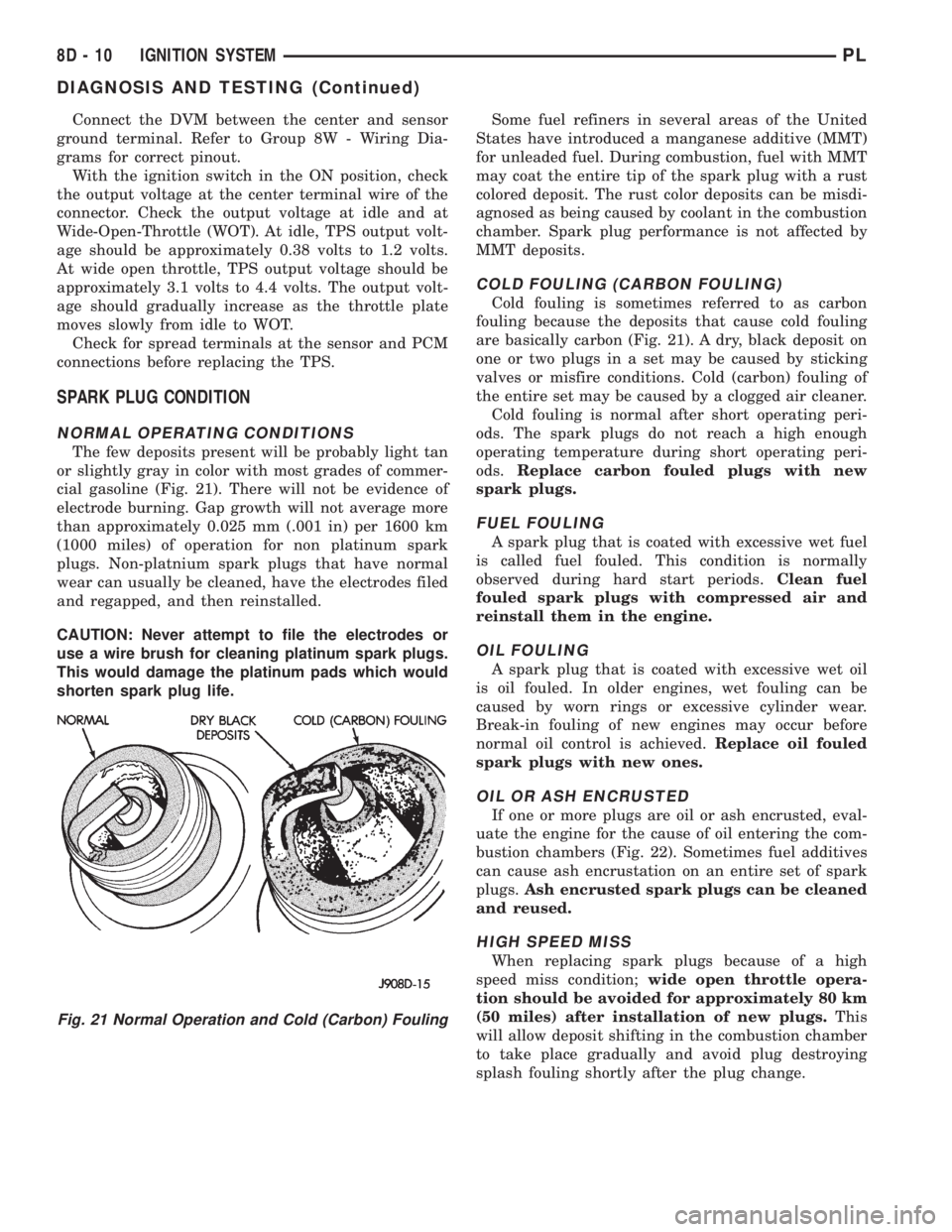

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 21). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 21). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 22). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

plugs.Ash encrusted spark plugs can be cleaned

and reused.

HIGH SPEED MISS

When replacing spark plugs because of a high

speed miss condition;wide open throttle opera-

tion should be avoided for approximately 80 km

(50 miles) after installation of new plugs.This

will allow deposit shifting in the combustion chamber

to take place gradually and avoid plug destroying

splash fouling shortly after the plug change.

Fig. 21 Normal Operation and Cold (Carbon) Fouling

8D - 10 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)