trunk release DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1115 of 1200

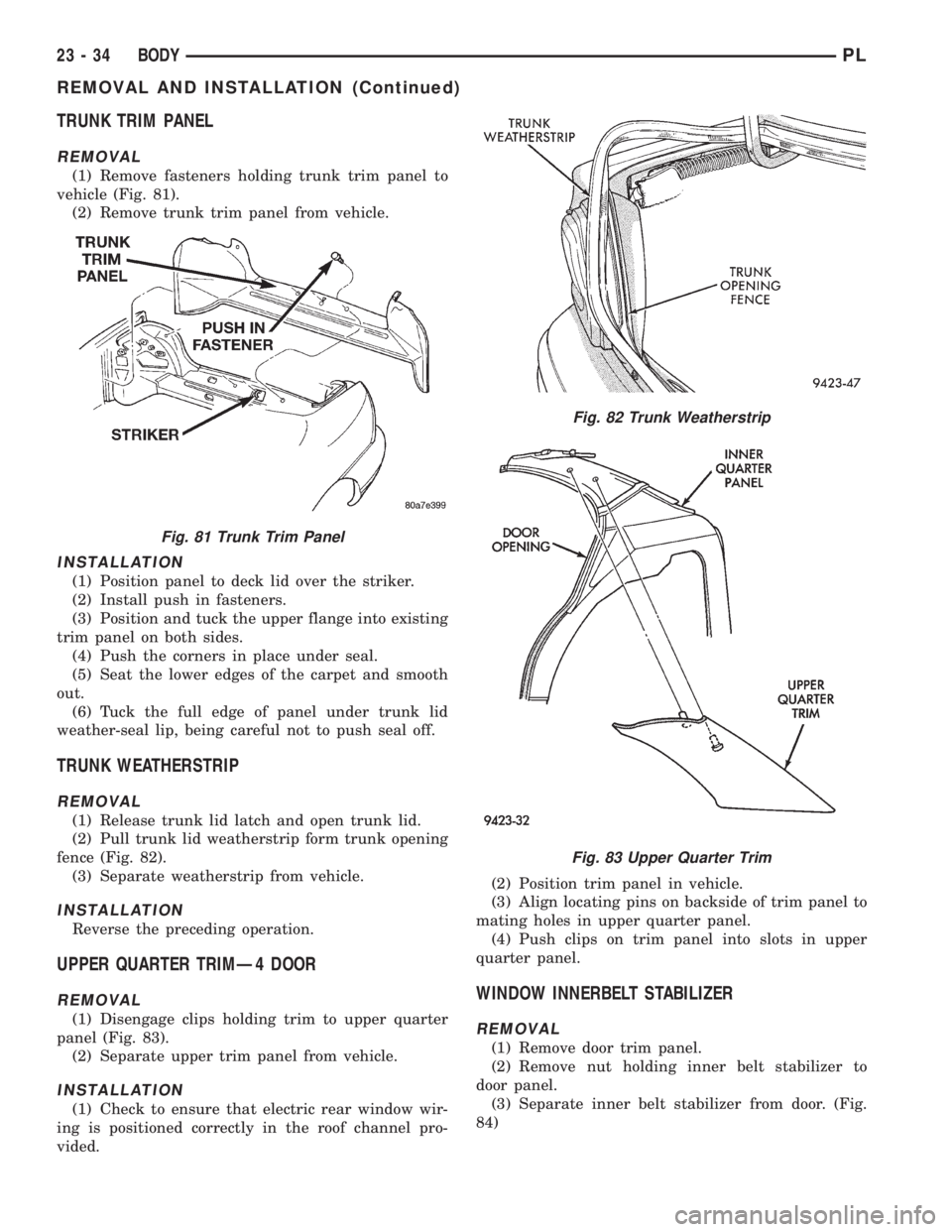

TRUNK TRIM PANEL

REMOVAL

(1) Remove fasteners holding trunk trim panel to

vehicle (Fig. 81).

(2) Remove trunk trim panel from vehicle.

INSTALLATION

(1) Position panel to deck lid over the striker.

(2) Install push in fasteners.

(3) Position and tuck the upper flange into existing

trim panel on both sides.

(4) Push the corners in place under seal.

(5) Seat the lower edges of the carpet and smooth

out.

(6) Tuck the full edge of panel under trunk lid

weather-seal lip, being careful not to push seal off.

TRUNK WEATHERSTRIP

REMOVAL

(1) Release trunk lid latch and open trunk lid.

(2) Pull trunk lid weatherstrip form trunk opening

fence (Fig. 82).

(3) Separate weatherstrip from vehicle.

INSTALLATION

Reverse the preceding operation.

UPPER QUARTER TRIMÐ4 DOOR

REMOVAL

(1) Disengage clips holding trim to upper quarter

panel (Fig. 83).

(2) Separate upper trim panel from vehicle.

INSTALLATION

(1) Check to ensure that electric rear window wir-

ing is positioned correctly in the roof channel pro-

vided.(2) Position trim panel in vehicle.

(3) Align locating pins on backside of trim panel to

mating holes in upper quarter panel.

(4) Push clips on trim panel into slots in upper

quarter panel.

WINDOW INNERBELT STABILIZER

REMOVAL

(1) Remove door trim panel.

(2) Remove nut holding inner belt stabilizer to

door panel.

(3) Separate inner belt stabilizer from door. (Fig.

84)

Fig. 81 Trunk Trim Panel

Fig. 82 Trunk Weatherstrip

Fig. 83 Upper Quarter Trim

23 - 34 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1120 of 1200

(5) Adjust glass so that a piece of paper can be

pulled between the glass and weatherstrip with some

tension.

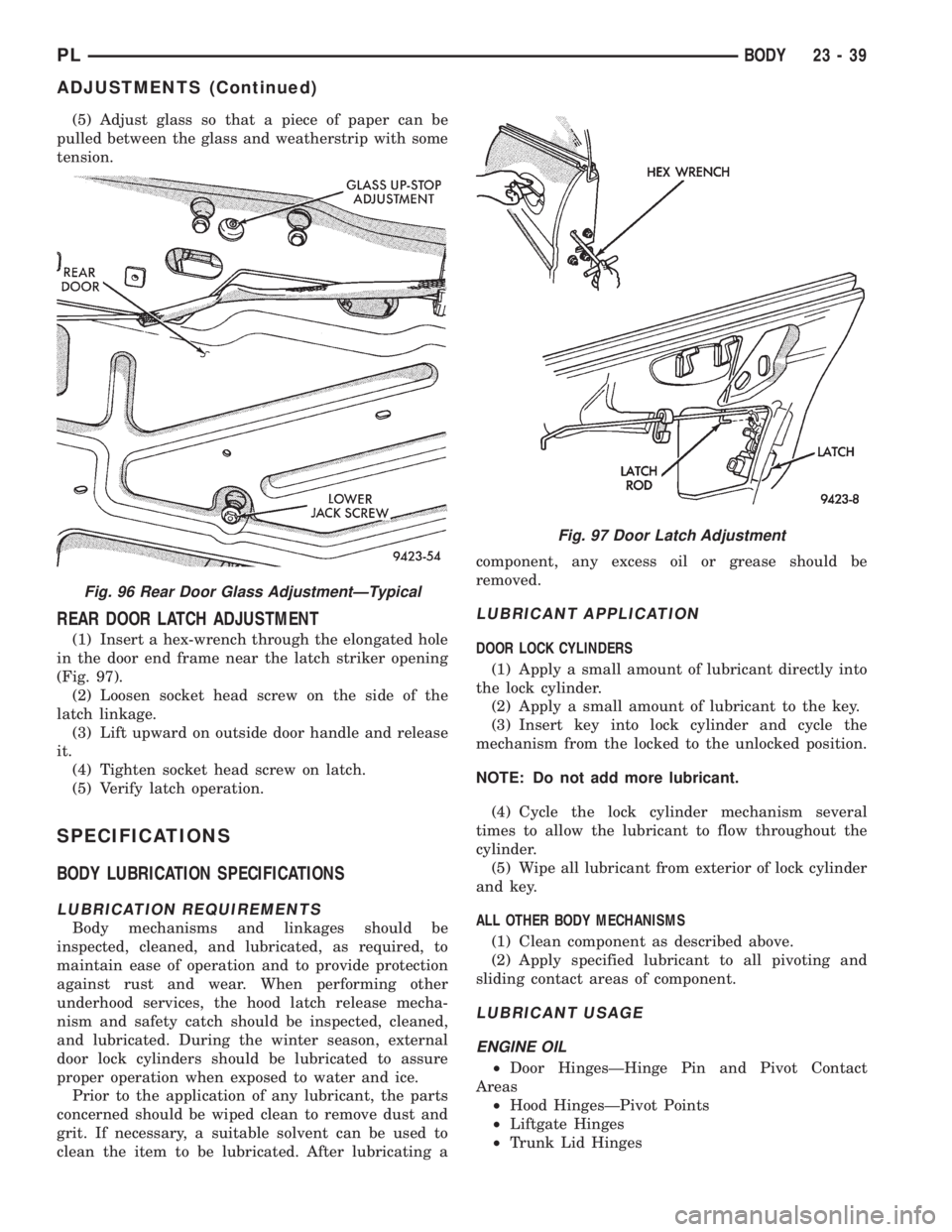

REAR DOOR LATCH ADJUSTMENT

(1) Insert a hex-wrench through the elongated hole

in the door end frame near the latch striker opening

(Fig. 97).

(2) Loosen socket head screw on the side of the

latch linkage.

(3) Lift upward on outside door handle and release

it.

(4) Tighten socket head screw on latch.

(5) Verify latch operation.

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other

underhood services, the hood latch release mecha-

nism and safety catch should be inspected, cleaned,

and lubricated. During the winter season, external

door lock cylinders should be lubricated to assure

proper operation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating acomponent, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door HingesÐHinge Pin and Pivot Contact

Areas

²Hood HingesÐPivot Points

²Liftgate Hinges

²Trunk Lid Hinges

Fig. 96 Rear Door Glass AdjustmentÐTypical

Fig. 97 Door Latch Adjustment

PLBODY 23 - 39

ADJUSTMENTS (Continued)