engine DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 812 of 1200

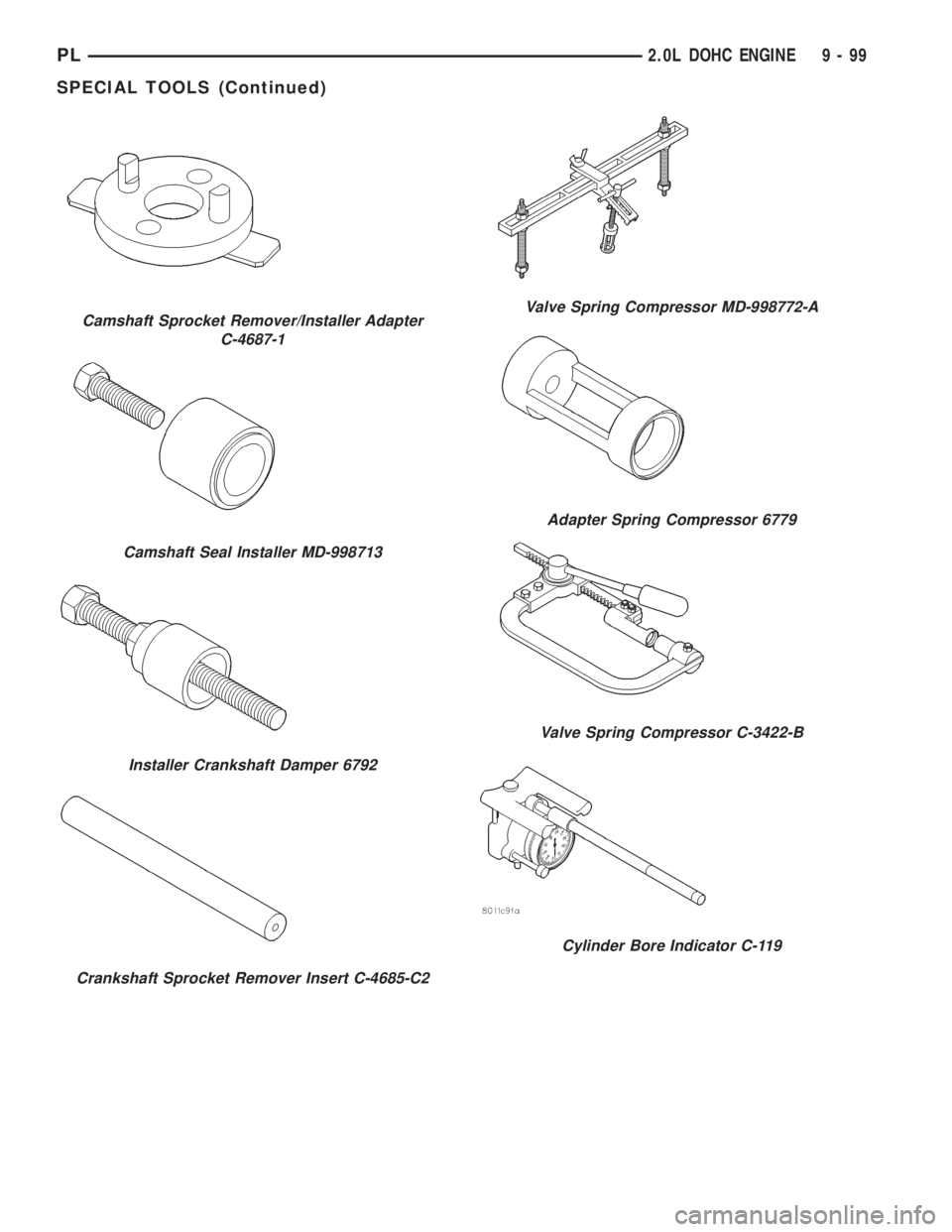

Camshaft Sprocket Remover/Installer Adapter

C-4687-1

Camshaft Seal Installer MD-998713

Installer Crankshaft Damper 6792

Crankshaft Sprocket Remover Insert C-4685-C2

Valve Spring Compressor MD-998772-A

Adapter Spring Compressor 6779

Valve Spring Compressor C-3422-B

Cylinder Bore Indicator C-119

PL2.0L DOHC ENGINE 9 - 99

SPECIAL TOOLS (Continued)

Page 813 of 1200

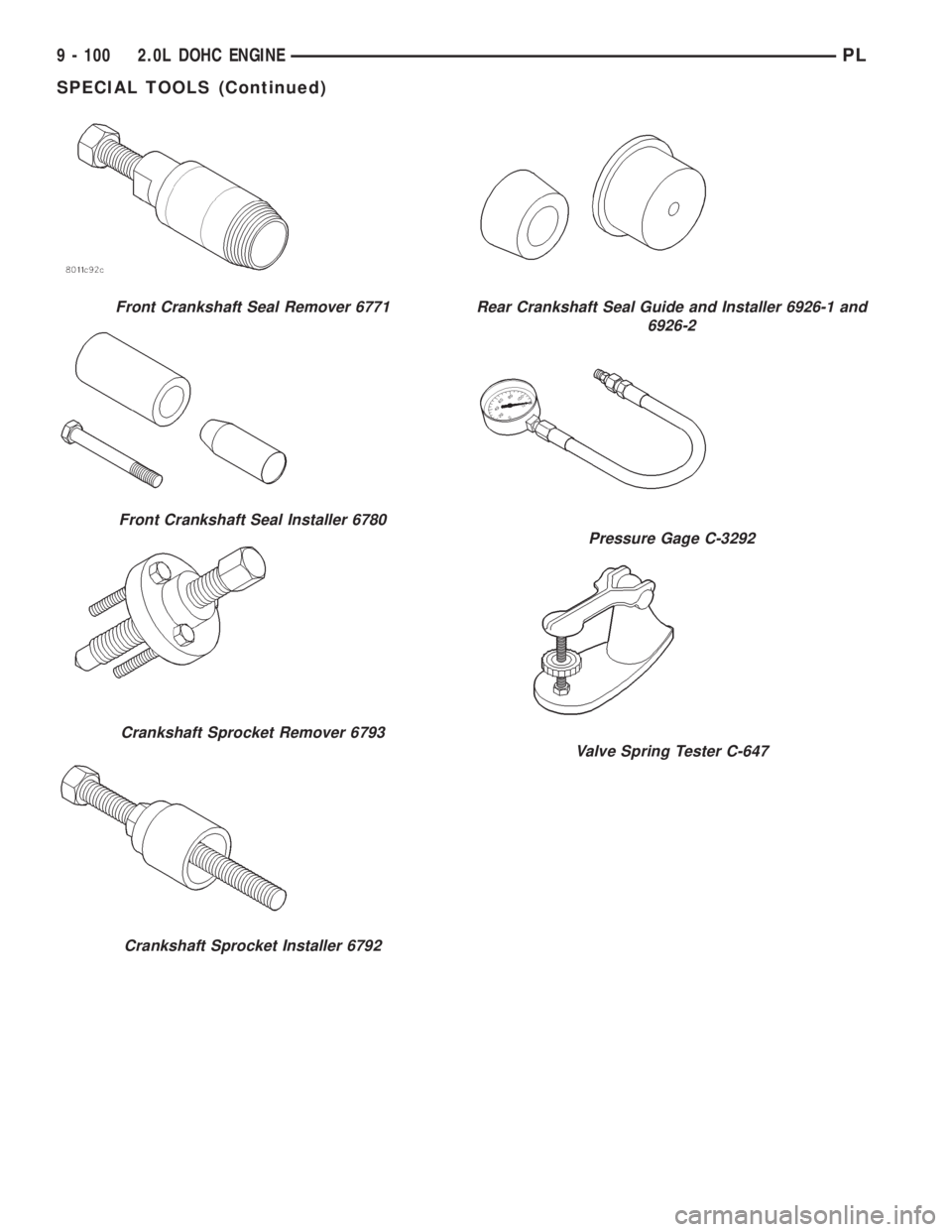

Front Crankshaft Seal Remover 6771

Front Crankshaft Seal Installer 6780

Crankshaft Sprocket Remover 6793

Crankshaft Sprocket Installer 6792

Rear Crankshaft Seal Guide and Installer 6926-1 and

6926-2

Pressure Gage C-3292

Valve Spring Tester C-647

9 - 100 2.0L DOHC ENGINEPL

SPECIAL TOOLS (Continued)

Page 814 of 1200

ENGINE

CONTENTS

page

1.8L SOHC ENGINE...................... 1

1.8L SOHC ENGINE

INDEX

page

GENERAL INFORMATION

1.8L SOHC ENGINE...................... 1

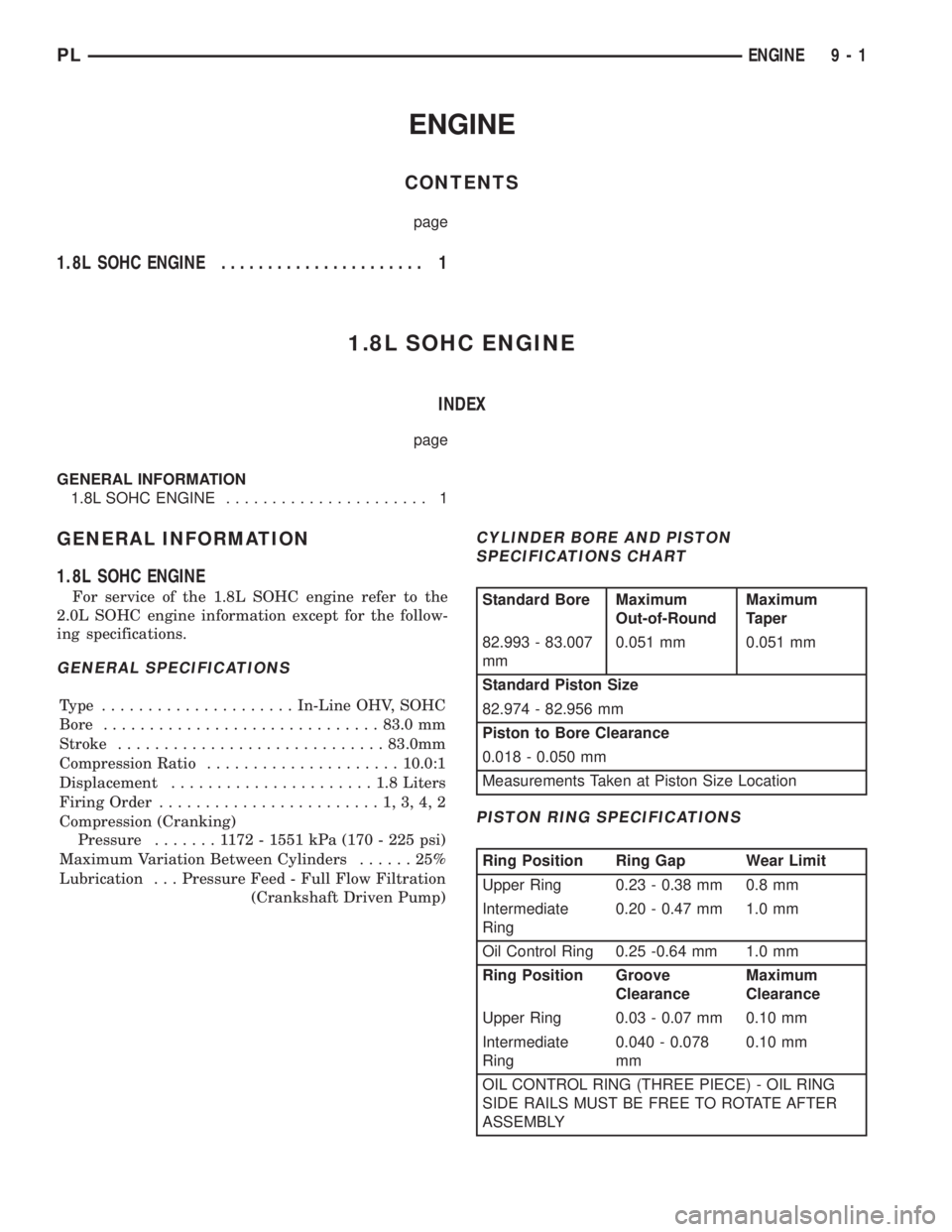

GENERAL INFORMATION

1.8L SOHC ENGINE

For service of the 1.8L SOHC engine refer to the

2.0L SOHC engine information except for the follow-

ing specifications.

GENERAL SPECIFICATIONS

Type .....................In-Line OHV, SOHC

Bore..............................83.0 mm

Stroke.............................83.0mm

Compression Ratio.....................10.0:1

Displacement......................1.8Liters

Firing Order........................1,3,4,2

Compression (Cranking)

Pressure.......1172-1551 kPa (170 - 225 psi)

Maximum Variation Between Cylinders......25%

Lubrication . . . Pressure Feed - Full Flow Filtration

(Crankshaft Driven Pump)

CYLINDER BORE AND PISTON

SPECIFICATIONS CHART

Standard Bore Maximum

Out-of-RoundMaximum

Taper

82.993 - 83.007

mm0.051 mm 0.051 mm

Standard Piston Size

82.974 - 82.956 mm

Piston to Bore Clearance

0.018 - 0.050 mm

Measurements Taken at Piston Size Location

PISTON RING SPECIFICATIONS

Ring Position Ring Gap Wear Limit

Upper Ring 0.23 - 0.38 mm 0.8 mm

Intermediate

Ring0.20 - 0.47 mm 1.0 mm

Oil Control Ring 0.25 -0.64 mm 1.0 mm

Ring Position Groove

ClearanceMaximum

Clearance

Upper Ring 0.03 - 0.07 mm 0.10 mm

Intermediate

Ring0.040 - 0.078

mm0.10 mm

OIL CONTROL RING (THREE PIECE) - OIL RING

SIDE RAILS MUST BE FREE TO ROTATE AFTER

ASSEMBLY

PLENGINE 9 - 1

Page 815 of 1200

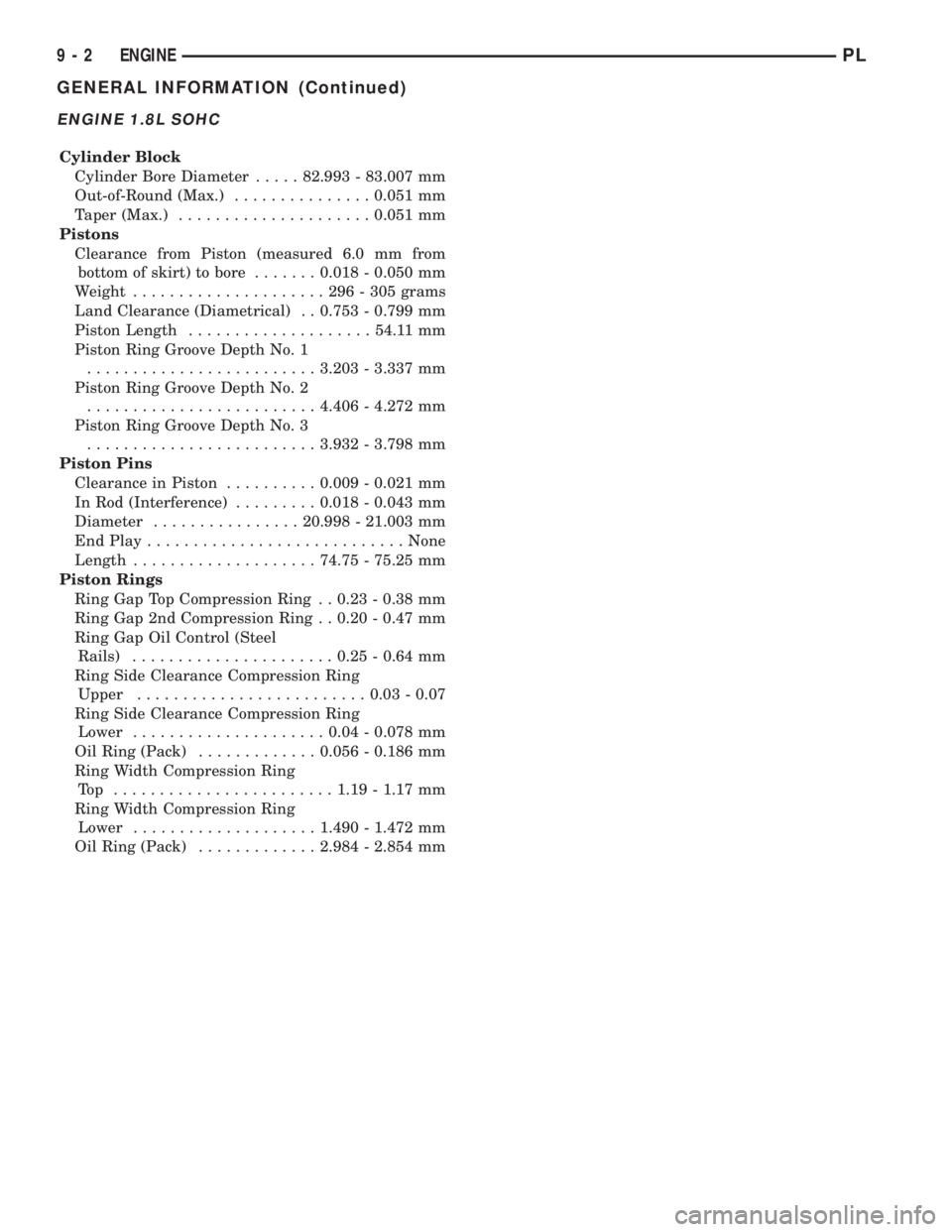

ENGINE 1.8L SOHC

Cylinder Block

Cylinder Bore Diameter.....82.993 - 83.007 mm

Out-of-Round (Max.)...............0.051 mm

Taper (Max.).....................0.051 mm

Pistons

Clearance from Piston (measured 6.0 mm from

bottom of skirt) to bore.......0.018 - 0.050 mm

Weight.....................296-305grams

Land Clearance (Diametrical) . . 0.753 - 0.799 mm

Piston Length....................54.11 mm

Piston Ring Groove Depth No. 1

.........................3.203 - 3.337 mm

Piston Ring Groove Depth No. 2

.........................4.406 - 4.272 mm

Piston Ring Groove Depth No. 3

.........................3.932 - 3.798 mm

Piston Pins

Clearance in Piston..........0.009 - 0.021 mm

In Rod (Interference).........0.018 - 0.043 mm

Diameter................20.998 - 21.003 mm

End Play............................None

Length....................74.75 - 75.25 mm

Piston Rings

Ring Gap Top Compression Ring . . 0.23 - 0.38 mm

Ring Gap 2nd Compression Ring . . 0.20 - 0.47 mm

Ring Gap Oil Control (Steel

Rails)......................0.25 - 0.64 mm

Ring Side Clearance Compression Ring

Upper.........................0.03 - 0.07

Ring Side Clearance Compression Ring

Lower.....................0.04 - 0.078 mm

Oil Ring (Pack).............0.056 - 0.186 mm

Ring Width Compression Ring

Top ........................1.19 - 1.17 mm

Ring Width Compression Ring

Lower....................1.490 - 1.472 mm

Oil Ring (Pack).............2.984 - 2.854 mm

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 816 of 1200

EXHAUST SYSTEM AND INTAKE MANIFOLD

CONTENTS

page page

GENERAL INFORMATION

CATALYTIC CONVERTER................... 4

EXHAUST BALL JOINT COUPLING.......... 1

EXHAUST FLEX-JOINT COUPLING (LEV)...... 2

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM.............................. 3

EXHAUST SYSTEMS...................... 1

HEAT SHIELDS.......................... 3

DESCRIPTION AND OPERATION

EXHAUST MANIFOLD..................... 3

INTAKE MANIFOLD DOHC................. 3

INTAKE MANIFOLD SOHC................. 3

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART...... 4REMOVAL AND INSTALLATION

EXHAUST MANIFOLD.................... 11

EXHAUST PIPE AND MUFFLER............. 4

INTAKE MANIFOLDÐDOHC ENGINE......... 9

INTAKE MANIFOLDÐSOHC ENGINE......... 6

CLEANING AND INSPECTION

EXHAUST MANIFOLD.................... 12

INTAKE MANIFOLD DOHC................ 12

INTAKE MANIFOLD SOHC................ 12

SPECIFICATIONS

TORQUE CHART........................ 12

GENERAL INFORMATION

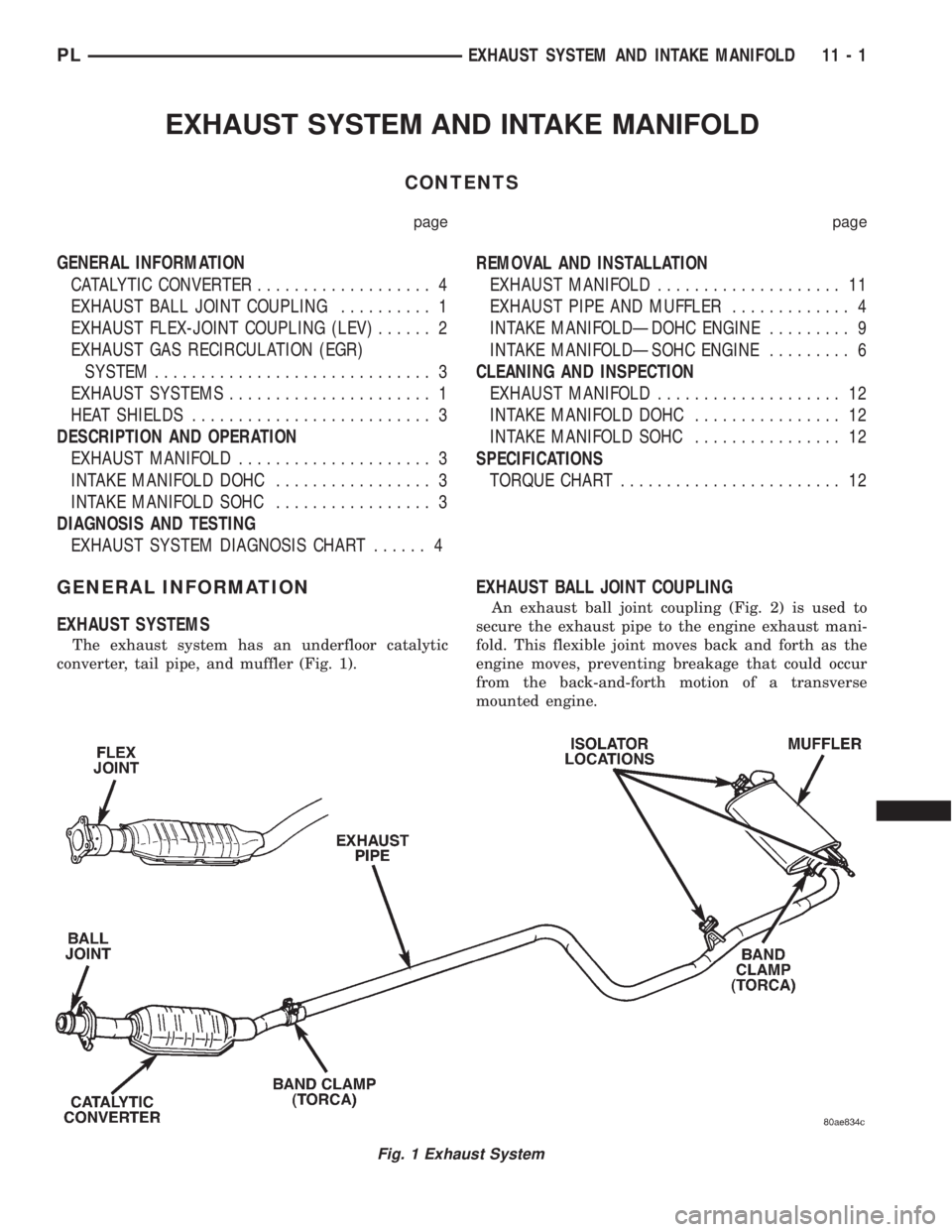

EXHAUST SYSTEMS

The exhaust system has an underfloor catalytic

converter, tail pipe, and muffler (Fig. 1).

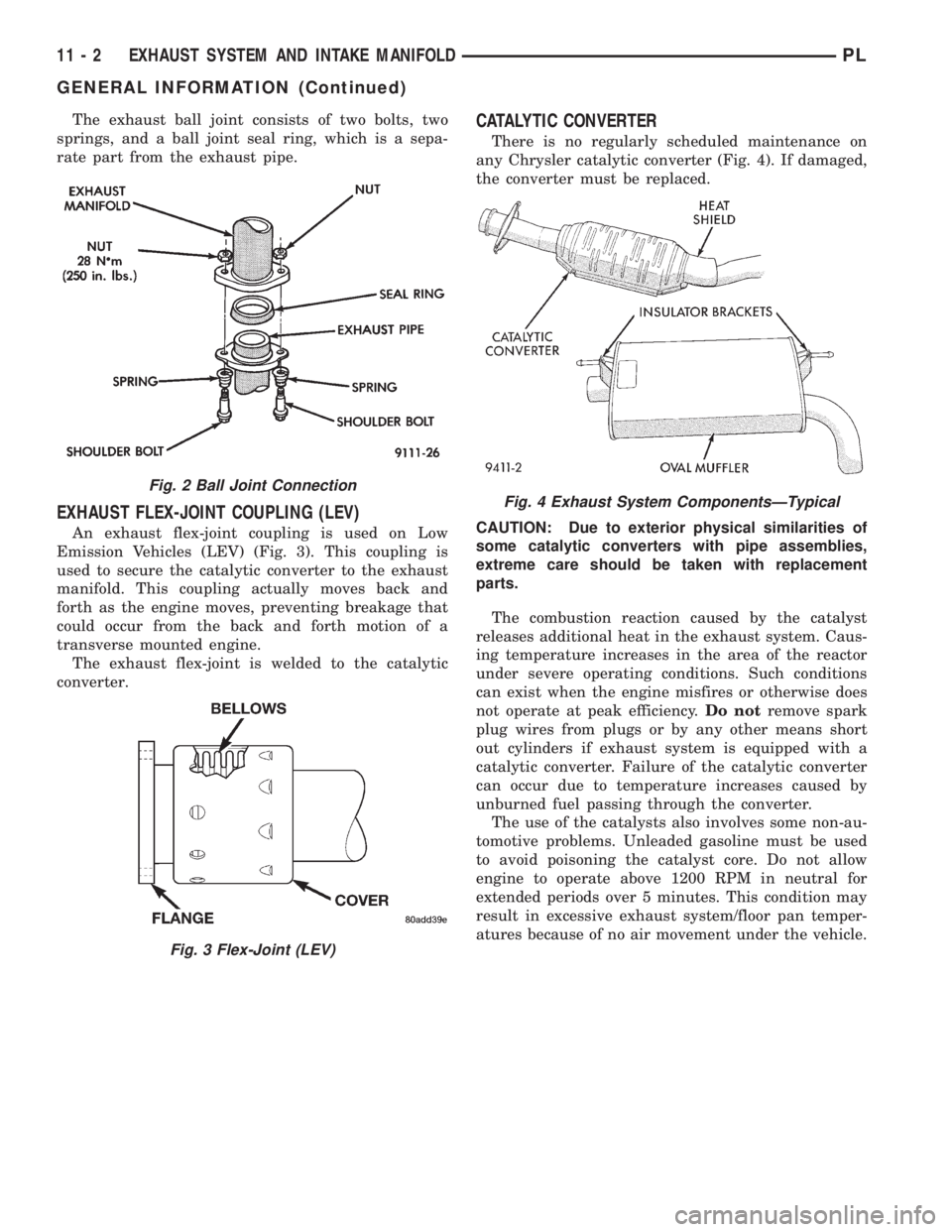

EXHAUST BALL JOINT COUPLING

An exhaust ball joint coupling (Fig. 2) is used to

secure the exhaust pipe to the engine exhaust mani-

fold. This flexible joint moves back and forth as the

engine moves, preventing breakage that could occur

from the back-and-forth motion of a transverse

mounted engine.

Fig. 1 Exhaust System

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 1

Page 817 of 1200

The exhaust ball joint consists of two bolts, two

springs, and a ball joint seal ring, which is a sepa-

rate part from the exhaust pipe.

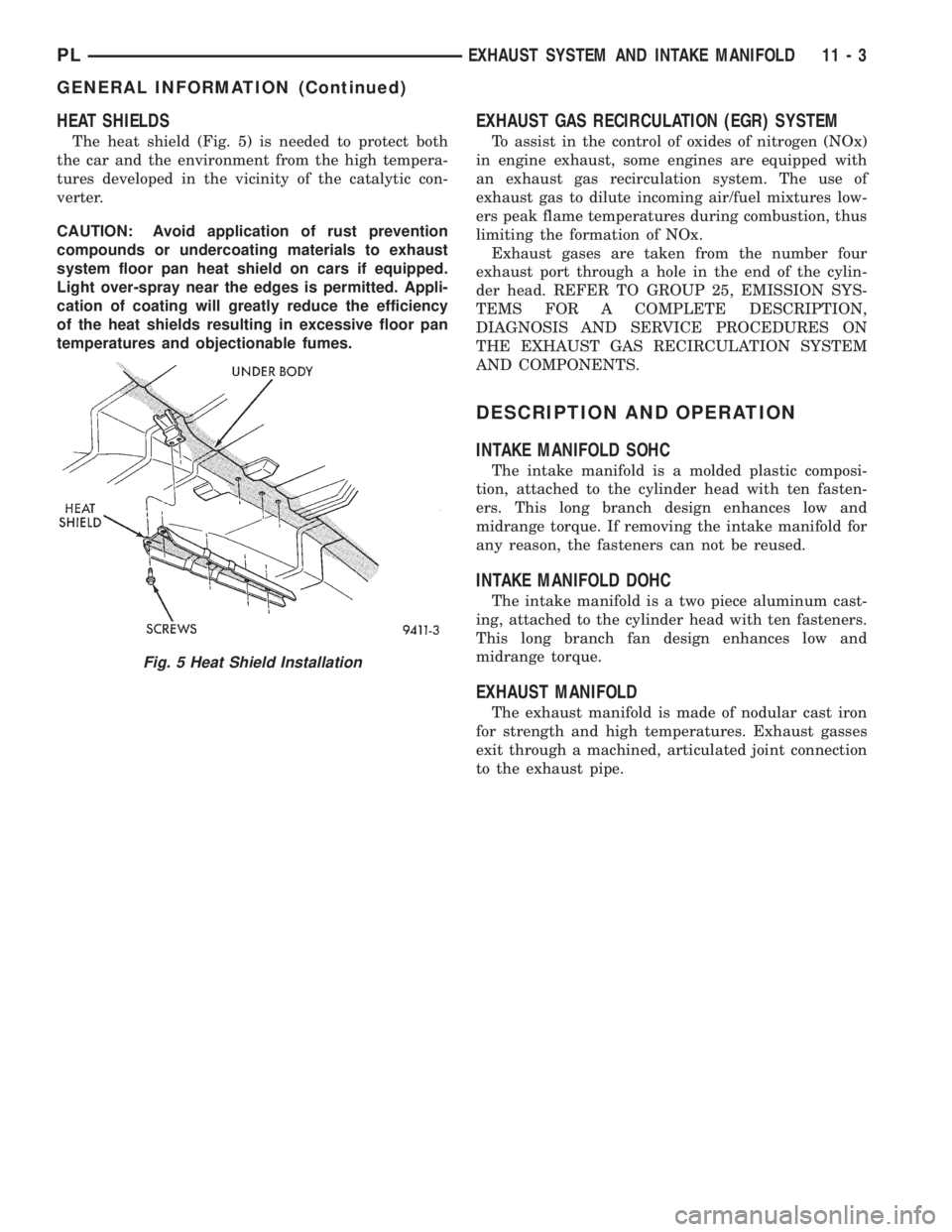

EXHAUST FLEX-JOINT COUPLING (LEV)

An exhaust flex-joint coupling is used on Low

Emission Vehicles (LEV) (Fig. 3). This coupling is

used to secure the catalytic converter to the exhaust

manifold. This coupling actually moves back and

forth as the engine moves, preventing breakage that

could occur from the back and forth motion of a

transverse mounted engine.

The exhaust flex-joint is welded to the catalytic

converter.

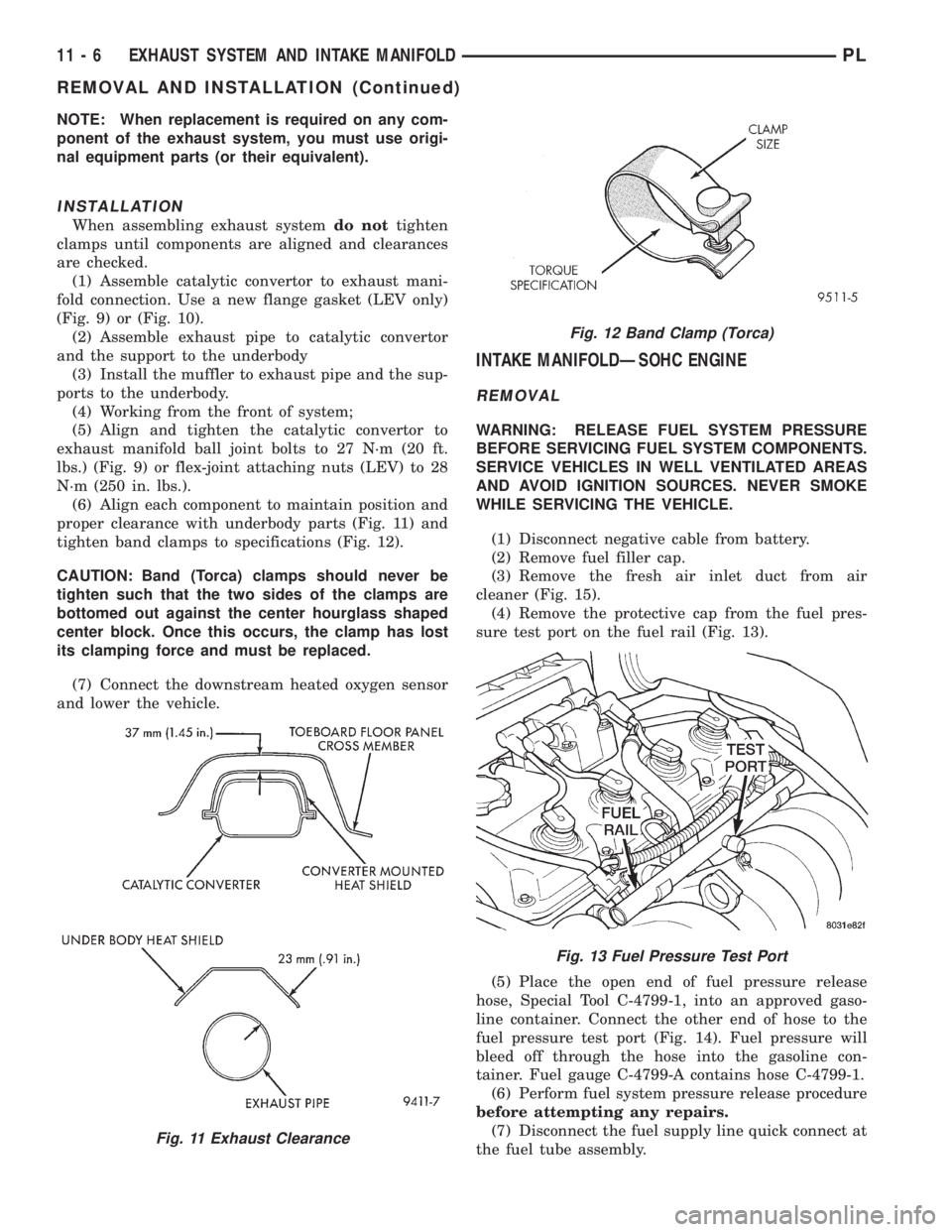

CATALYTIC CONVERTER

There is no regularly scheduled maintenance on

any Chrysler catalytic converter (Fig. 4). If damaged,

the converter must be replaced.

CAUTION: Due to exterior physical similarities of

some catalytic converters with pipe assemblies,

extreme care should be taken with replacement

parts.

The combustion reaction caused by the catalyst

releases additional heat in the exhaust system. Caus-

ing temperature increases in the area of the reactor

under severe operating conditions. Such conditions

can exist when the engine misfires or otherwise does

not operate at peak efficiency.Do notremove spark

plug wires from plugs or by any other means short

out cylinders if exhaust system is equipped with a

catalytic converter. Failure of the catalytic converter

can occur due to temperature increases caused by

unburned fuel passing through the converter.

The use of the catalysts also involves some non-au-

tomotive problems. Unleaded gasoline must be used

to avoid poisoning the catalyst core. Do not allow

engine to operate above 1200 RPM in neutral for

extended periods over 5 minutes. This condition may

result in excessive exhaust system/floor pan temper-

atures because of no air movement under the vehicle.

Fig. 2 Ball Joint Connection

Fig. 3 Flex-Joint (LEV)

Fig. 4 Exhaust System ComponentsÐTypical

11 - 2 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

GENERAL INFORMATION (Continued)

Page 818 of 1200

HEAT SHIELDS

The heat shield (Fig. 5) is needed to protect both

the car and the environment from the high tempera-

tures developed in the vicinity of the catalytic con-

verter.

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shield on cars if equipped.

Light over-spray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

To assist in the control of oxides of nitrogen (NOx)

in engine exhaust, some engines are equipped with

an exhaust gas recirculation system. The use of

exhaust gas to dilute incoming air/fuel mixtures low-

ers peak flame temperatures during combustion, thus

limiting the formation of NOx.

Exhaust gases are taken from the number four

exhaust port through a hole in the end of the cylin-

der head. REFER TO GROUP 25, EMISSION SYS-

TEMS FOR A COMPLETE DESCRIPTION,

DIAGNOSIS AND SERVICE PROCEDURES ON

THE EXHAUST GAS RECIRCULATION SYSTEM

AND COMPONENTS.

DESCRIPTION AND OPERATION

INTAKE MANIFOLD SOHC

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with ten fasten-

ers. This long branch design enhances low and

midrange torque. If removing the intake manifold for

any reason, the fasteners can not be reused.

INTAKE MANIFOLD DOHC

The intake manifold is a two piece aluminum cast-

ing, attached to the cylinder head with ten fasteners.

This long branch fan design enhances low and

midrange torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit through a machined, articulated joint connection

to the exhaust pipe.

Fig. 5 Heat Shield Installation

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

GENERAL INFORMATION (Continued)

Page 821 of 1200

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble catalytic convertor to exhaust mani-

fold connection. Use a new flange gasket (LEV only)

(Fig. 9) or (Fig. 10).

(2) Assemble exhaust pipe to catalytic convertor

and the support to the underbody

(3) Install the muffler to exhaust pipe and the sup-

ports to the underbody.

(4) Working from the front of system;

(5) Align and tighten the catalytic convertor to

exhaust manifold ball joint bolts to 27 N´m (20 ft.

lbs.) (Fig. 9) or flex-joint attaching nuts (LEV) to 28

N´m (250 in. lbs.).

(6) Align each component to maintain position and

proper clearance with underbody parts (Fig. 11) and

tighten band clamps to specifications (Fig. 12).

CAUTION: Band (Torca) clamps should never be

tighten such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

its clamping force and must be replaced.

(7) Connect the downstream heated oxygen sensor

and lower the vehicle.

INTAKE MANIFOLDÐSOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the fresh air inlet duct from air

cleaner (Fig. 15).

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 13).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 14). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Perform fuel system pressure release procedure

before attempting any repairs.

(7) Disconnect the fuel supply line quick connect at

the fuel tube assembly.

Fig. 11 Exhaust Clearance

Fig. 12 Band Clamp (Torca)

Fig. 13 Fuel Pressure Test Port

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)

Page 822 of 1200

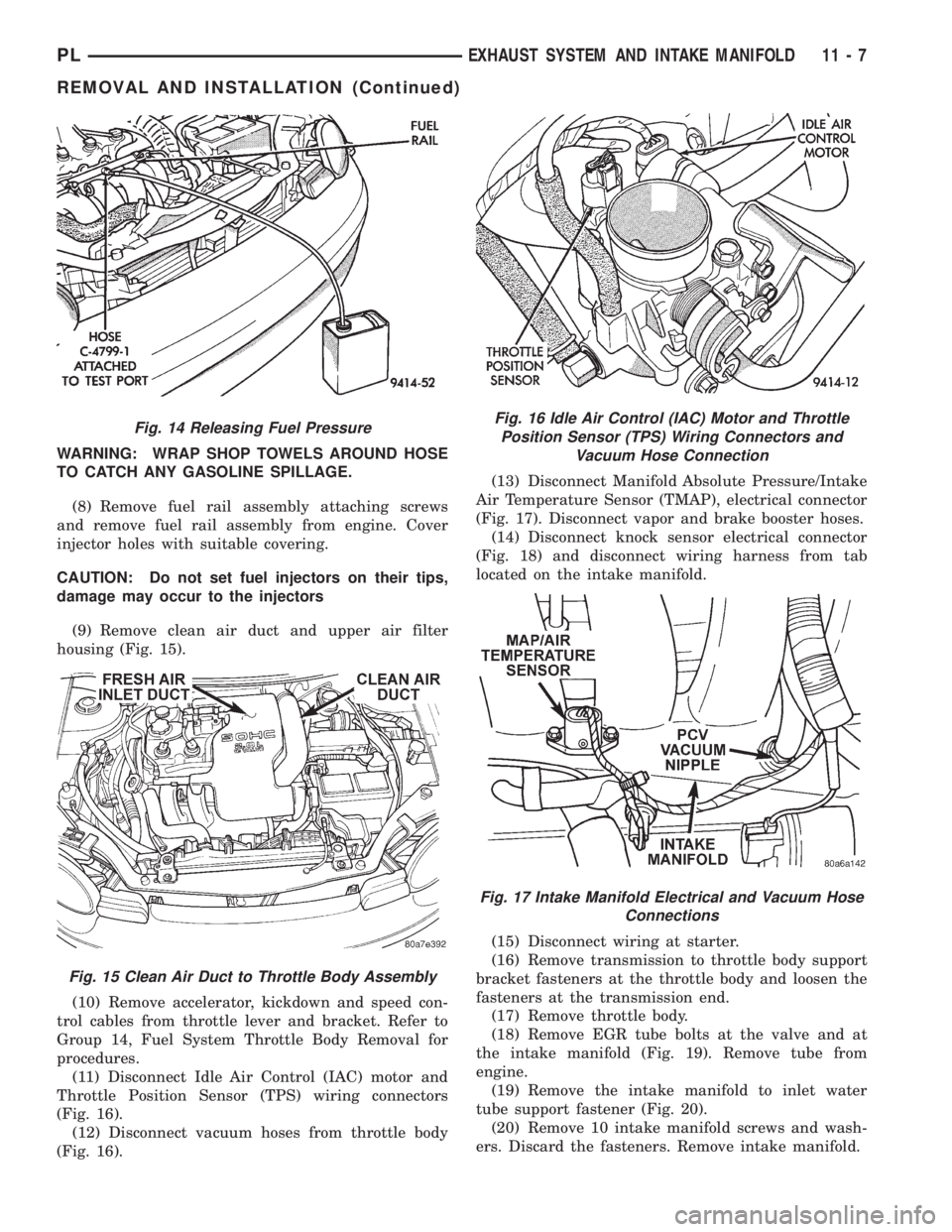

WARNING: WRAP SHOP TOWELS AROUND HOSE

TO CATCH ANY GASOLINE SPILLAGE.

(8) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

(9) Remove clean air duct and upper air filter

housing (Fig. 15).

(10) Remove accelerator, kickdown and speed con-

trol cables from throttle lever and bracket. Refer to

Group 14, Fuel System Throttle Body Removal for

procedures.

(11) Disconnect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors

(Fig. 16).

(12) Disconnect vacuum hoses from throttle body

(Fig. 16).(13) Disconnect Manifold Absolute Pressure/Intake

Air Temperature Sensor (TMAP), electrical connector

(Fig. 17). Disconnect vapor and brake booster hoses.

(14) Disconnect knock sensor electrical connector

(Fig. 18) and disconnect wiring harness from tab

located on the intake manifold.

(15) Disconnect wiring at starter.

(16) Remove transmission to throttle body support

bracket fasteners at the throttle body and loosen the

fasteners at the transmission end.

(17) Remove throttle body.

(18) Remove EGR tube bolts at the valve and at

the intake manifold (Fig. 19). Remove tube from

engine.

(19) Remove the intake manifold to inlet water

tube support fastener (Fig. 20).

(20) Remove 10 intake manifold screws and wash-

ers. Discard the fasteners. Remove intake manifold.

Fig. 14 Releasing Fuel Pressure

Fig. 15 Clean Air Duct to Throttle Body Assembly

Fig. 16 Idle Air Control (IAC) Motor and Throttle

Position Sensor (TPS) Wiring Connectors and

Vacuum Hose Connection

Fig. 17 Intake Manifold Electrical and Vacuum Hose

Connections

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 823 of 1200

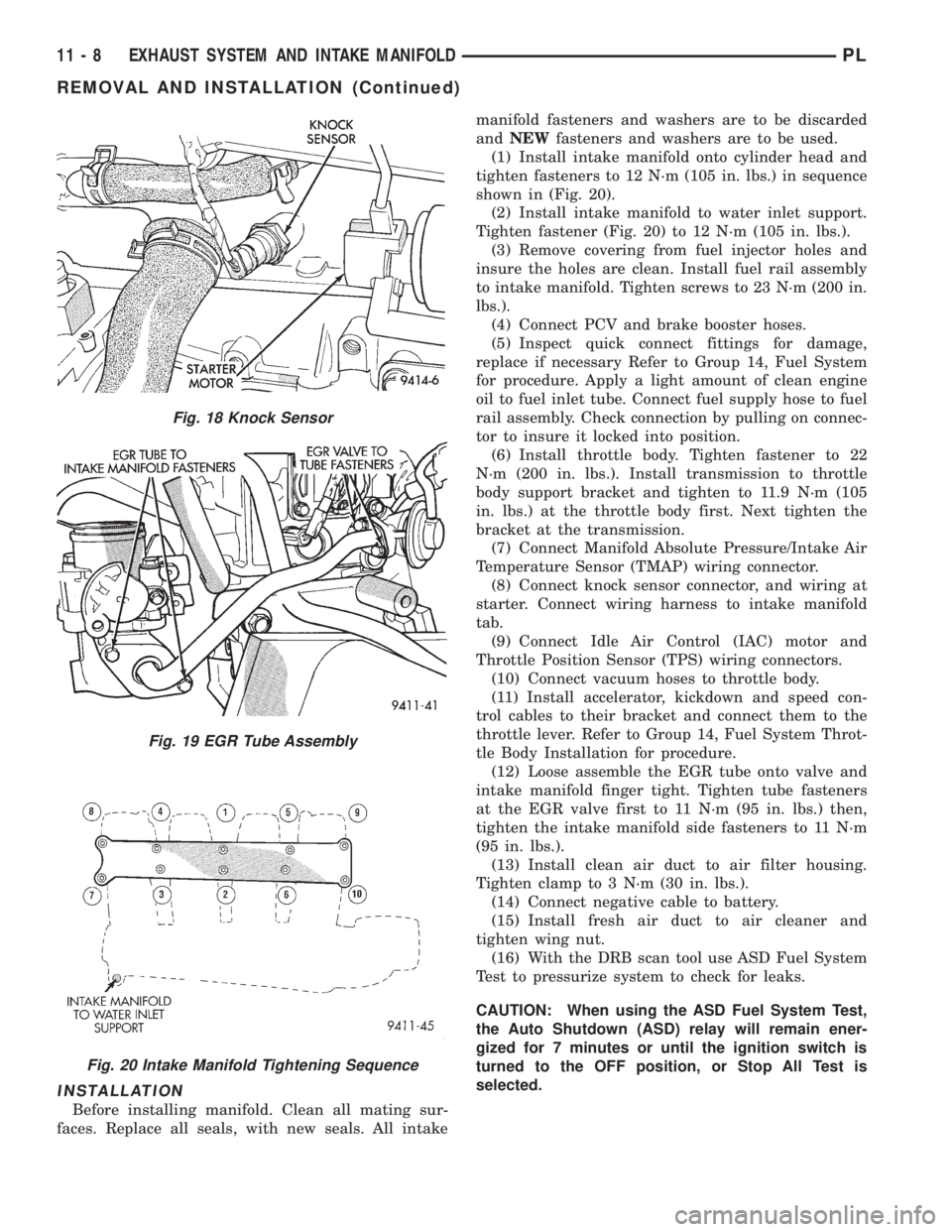

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all seals, with new seals. All intakemanifold fasteners and washers are to be discarded

andNEWfasteners and washers are to be used.

(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 20).

(2) Install intake manifold to water inlet support.

Tighten fastener (Fig. 20) to 12 N´m (105 in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.). Install transmission to throttle

body support bracket and tighten to 11.9 N´m (105

in. lbs.) at the throttle body first. Next tighten the

bracket at the transmission.

(7) Connect Manifold Absolute Pressure/Intake Air

Temperature Sensor (TMAP) wiring connector.

(8) Connect knock sensor connector, and wiring at

starter. Connect wiring harness to intake manifold

tab.

(9) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(10) Connect vacuum hoses to throttle body.

(11) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(12) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(13) Install clean air duct to air filter housing.

Tighten clamp to 3 N´m (30 in. lbs.).

(14) Connect negative cable to battery.

(15) Install fresh air duct to air cleaner and

tighten wing nut.

(16) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

Fig. 18 Knock Sensor

Fig. 19 EGR Tube Assembly

Fig. 20 Intake Manifold Tightening Sequence

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)