jump start terminals DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 888 of 1200

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to group 8W, Wir-

ing Diagrams.

CAMSHAFT AND CRANKSHAFT POSITION SENSOR

Refer to Group 8D, Ignition for Diagnosis and Test-

ing of Camshaft and Crankshaft Sensors.

ENGINE COOLANT TEMPERATURE SENSOR

(1) With the key off, disconnect wire harness con-

nector from coolant temperature sensor (Fig. 79) or

(Fig. 80).(2) Connect a high input impedance (digital) volt-

ohmmeter to terminals A and B (Fig. 81). The ohm-

meter should read as follows:

²Engine/Sensor at normal operating temperature

around 200ÉF should read approximately 700 to

1,000 ohms.

²Engine/Sensor at room temperature around 70ÉF

ohmmeter should read approximately 7,000 to 13,000

ohms.

(3) T

est the resistance of the wire harness between

the PCM 60-way connector terminal 28 and the sensor

harness connector. Also check for continuity between

PCM 60-way connector terminal 51 and the sensor har-

ness connector. Refer to Group 8W, Wiring diagrams for

circuit information. If the resistance is greater than 1

ohm, repair the wire harness as necessary.

HEATED OXYGEN SENSOR

Use an ohmmeter to test the heating element of

the oxygen sensors. Disconnect the electrical connec-

tor from each oxygen sensor. The white wires in the

sensor connector are the power and ground circuits

for the heater. Connect the ohmmeter test leads to

terminals of the white wires in the heated oxygen

sensor connector. Replace the heated oxygen sensor if

the resistance is not between 4 and 7 ohms.

IDLE AIR CONTROL (IAC) MOTOR TEST

To preform a complete test of IAC motor and its

circuitry, refer to DRB scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

KNOCK SENSOR

The engine knock sensor is affected by a number of

factors. A few of these are: ignition timing, cylinder

pressure, fuel octane, etc. The knock sensor generates

an AC voltage whose amplitude increases with the

increase of engine knock. The knock sensor can be

tested with a digital voltmeter. The RMS voltage starts

Fig. 79 Engine Coolant Temperature Sensor

LocationÐSOHC

Fig. 80 Engine Coolant Temperature Sensor

LocationÐDOHC

Fig. 81 Engine Coolant Temperature Sensor

PLFUEL SYSTEM 14 - 47

DIAGNOSIS AND TESTING (Continued)

Page 1144 of 1200

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT-OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service±Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

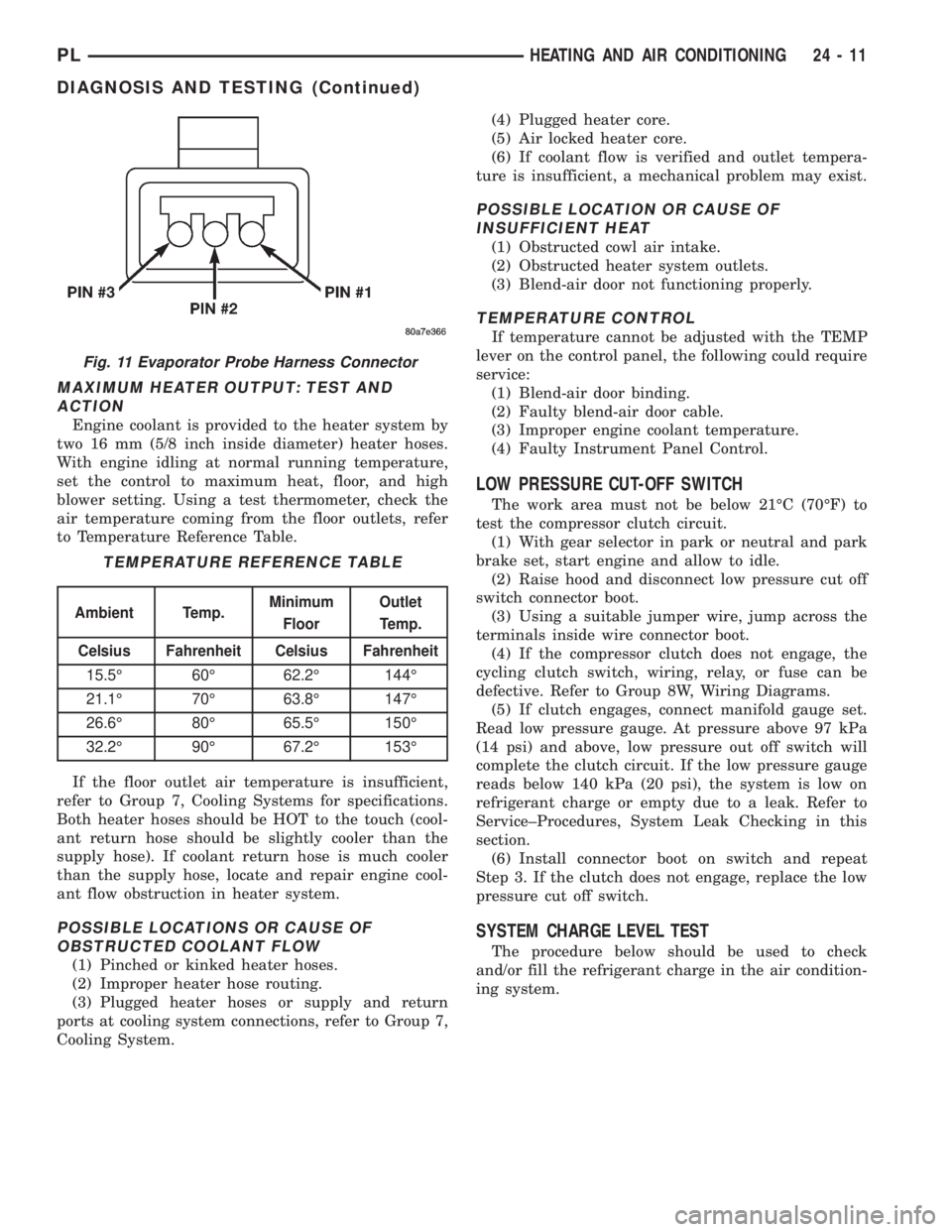

Fig. 11 Evaporator Probe Harness Connector

TEMPERATURE REFERENCE TABLE

Ambient Temp.Minimum

FloorOutlet

Temp.

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)